Whirlpool 675474 Instruction Sheet

INSTRUCTION SHEET

for 675474 Impeller Kit

wWARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all panels before operating.

Failure to do so can result in death or electrical shock.

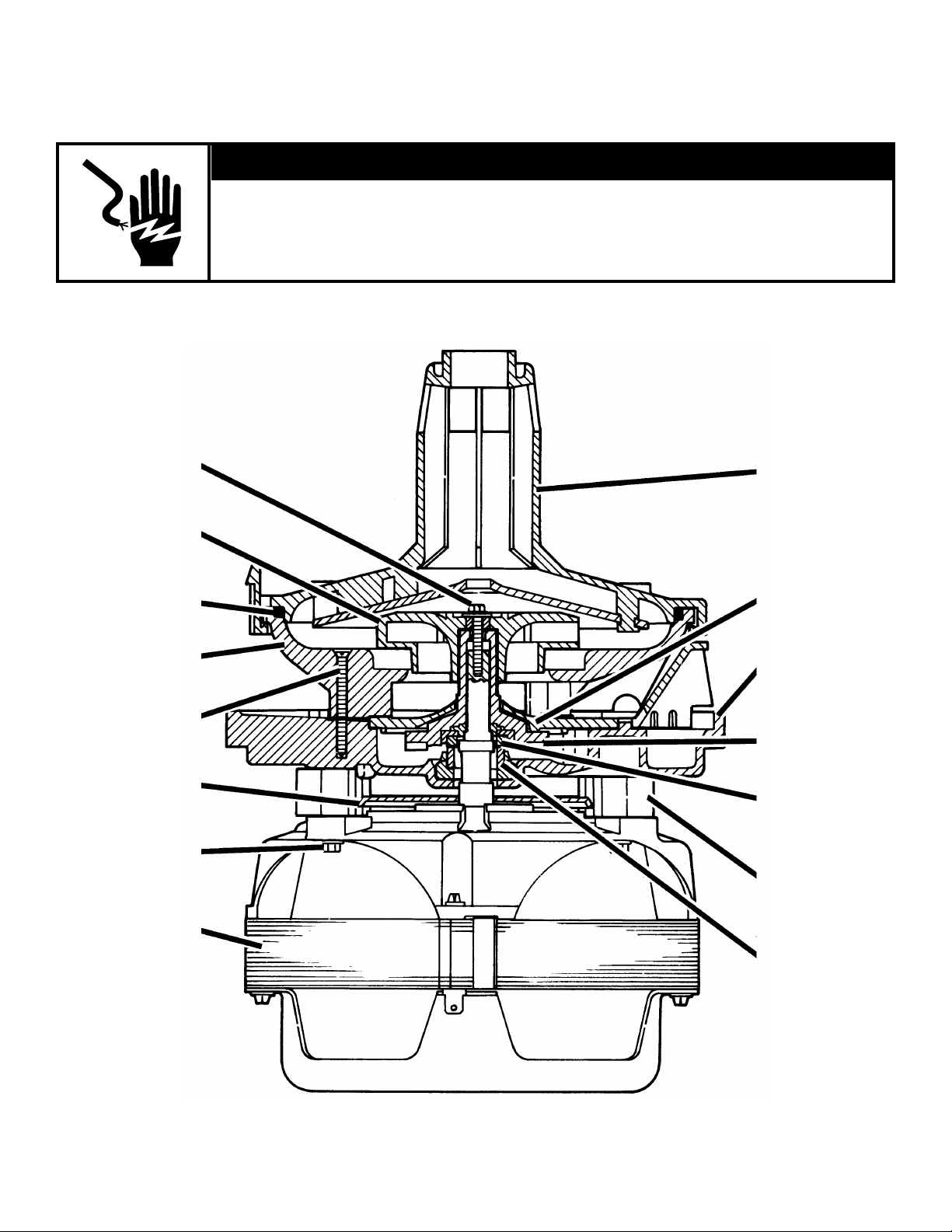

Impeller mounting

screw

Wash impeller

Pump seal

Lower pump housing

Lower pump

housing screw (3)

Slinger

Pump mounting

plate screw (4)

pump housing

Upper

Drain cover

Pump

mounting

plate

Drain impeller

Ceramic seal

Pump

mounting

extensions (4)

Motor

© Whirlpool Corporation 1997

(All Rights Reserved)

Carbon

face seal

Cutaway view – Whirlpool pump and motor assembly

Instruction Sheet 675475 Rev. A 8/97

1

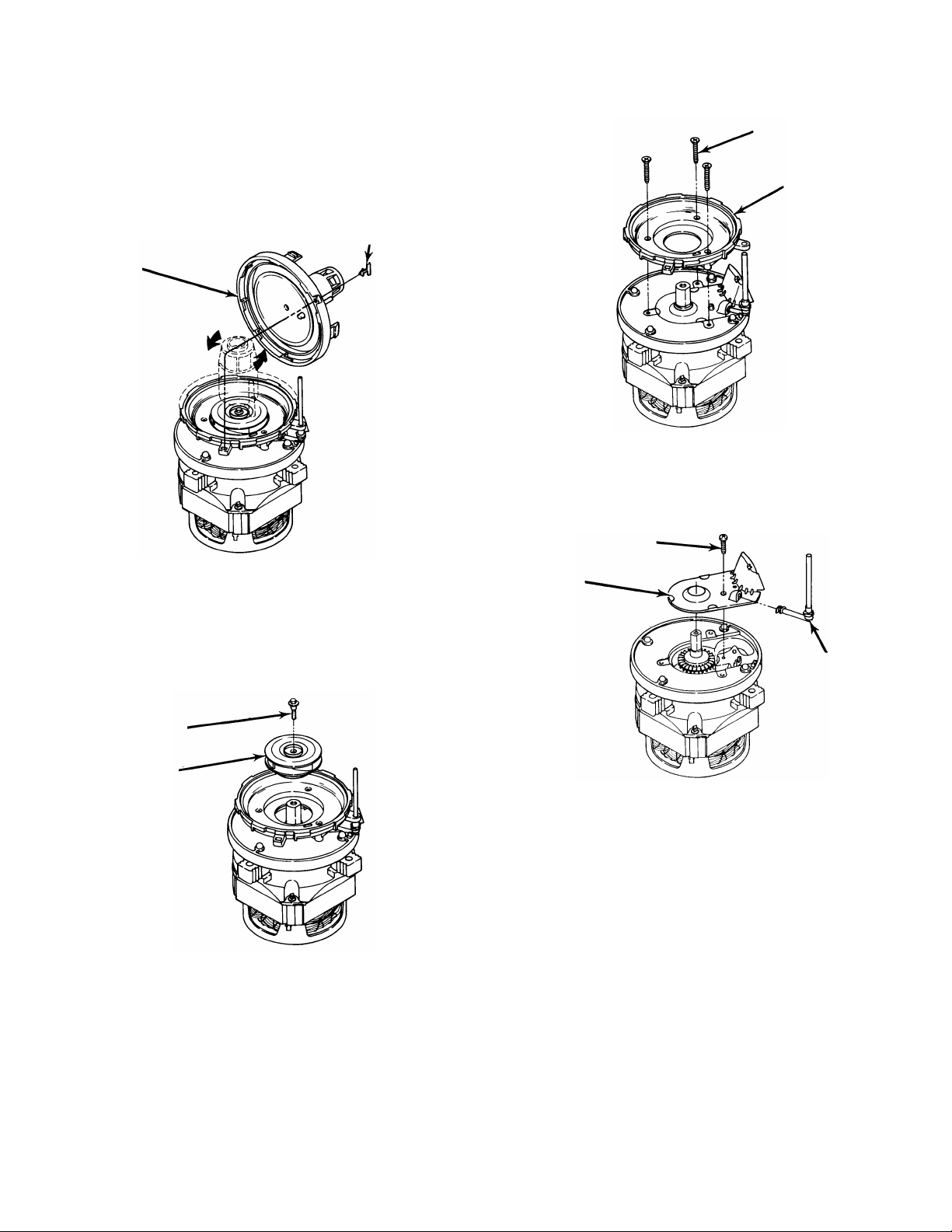

Disassembly:

1. Disconnect power or unplug dishwasher.

2. Remove blue locking tab, then rotate upper pump

housing counterclockwise and lift out of locating slots.

See Figure 1.

NOTE: Some early production pumps utilized a plastic tie to prevent rotation of upper pump housing. Tie

must be cut before upper housing can be removed.

Blue

Upper

pump

housing

Figure 1

locking tab

4. Using a Phillips head screwdriver, remove three

(3) screws which secure lower pump housing to

pump mounting plate. Lower pump housing can

now be removed. See Figure 3.

(3) Pump housing

screws

Lower pump

housing

Figure 3

5. Remove screw which secures drain pump cover to

pump mounting plate, and remove drain pump cover

and air bleed standpipe assembly. See Figure 4.

Phillips head screw

Drain pump

cover

3. To remove the impeller mounting screw, use 5⁄16"

nutdriver. Impeller mounting screw has right-hand

thread. If mounting screw is hard to back out, redrive

to tighten, then back out. Lift wash impeller off shaft.

See Figure 2.

Impeller

mounting

screw

Wash impeller

Figure 2

Drain air

bleed

standpipe

Figure 4

(continued)

675475-A

2

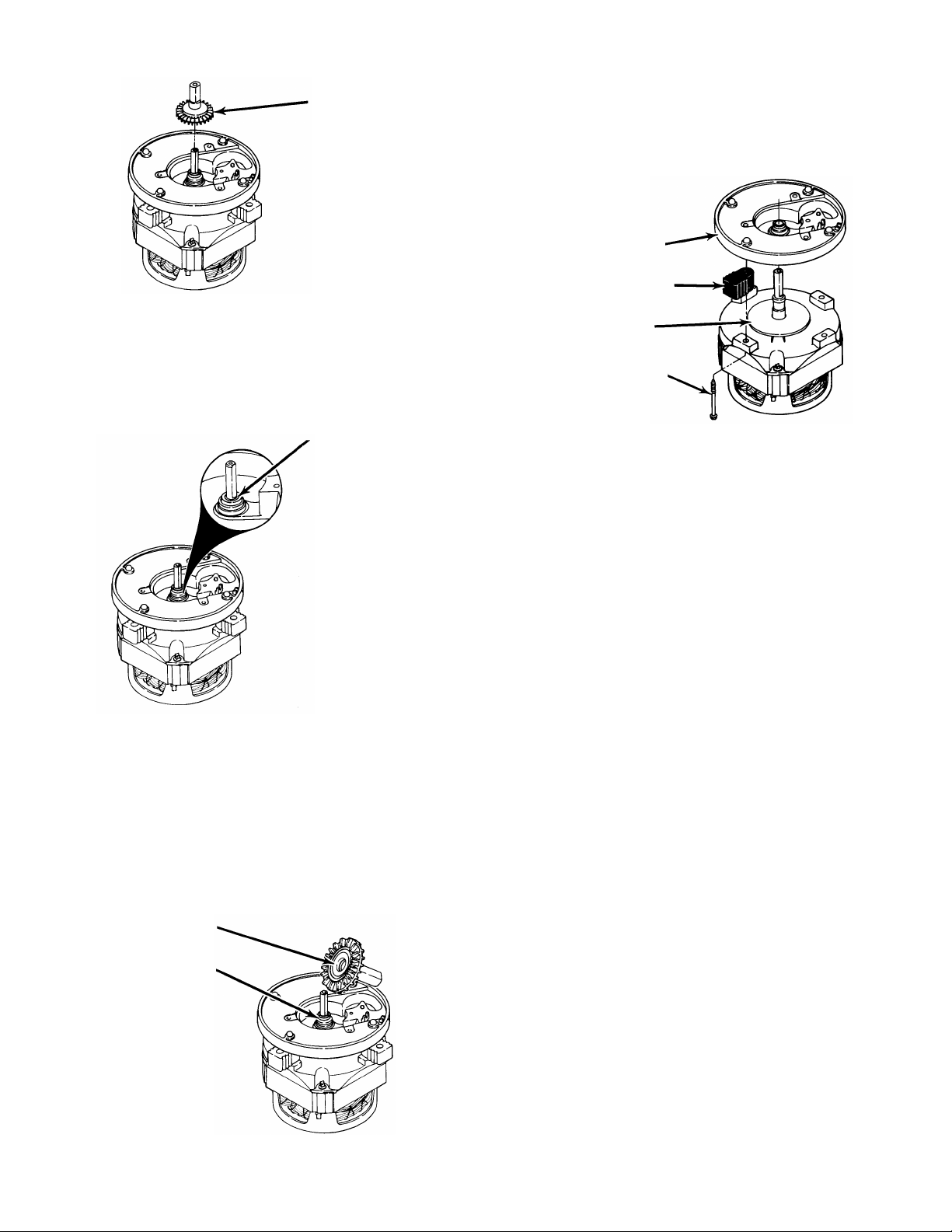

6. Remove drain impeller by pulling it straight up off the

shaft. See Figure 5.

Drain

impeller

Figure 5

7. There may or may not be drain impeller shim(s)

on motor shaft. See Figure 6. Shim washer(s) are

designed to compensate for variations in tolerance

and do not appear in parts lists. Do not remove

shims. If motor is replaced, shims will be on new

replacement motor if required.

Motor shim(s)

Figure 6

8. Both halves of seal assembly are now visible. This

assembly consists of a stationary half and a half

that revolves. The stationary half has a carbon

face attached to a rubber, spring-loaded body. See

Figure 7. The movable half is a ceramic ring seated in

a rubber bushing. Both can be easily pried out of

location with a small screwdriver.

IMPORTANT: When rebuilding pump, always replace

both seal halves and drain impeller.

Ceramic seal half

9. Using the 1⁄4" nutdriver, remove four (4) screws which

secure pump mounting plate to motor, and lift pump

mounting plate off motor. See Figure 8.

10. Rubber pump mounting extensions can be removed

from pump mounting plate. See Figure 8.

11. If motor is to be replaced, slinger can now be

removed. See Figure 8.

Pump mounting plate

Mounting extension

Large slinger

(4) Screws

Figure 8

Reassembly:

1. Before you begin, check motor for the following:

a. Rotor shaft end play – Maximum is .010".

b. Rotor rotation – Should rotate freely.

c. Top mount bearing – If there is evidence of water

having entered area, add a few drops of SAE

No. 20 non-detergent motor oil to reservoir.

d. Electrical open, shorted or grounded winding

(See check procedure page 3-50 of Dishwasher

Service Manual 828837).

2. Install slinger by pressing it onto motor shaft so that it

bottoms out.

3. With trichloroethane (or equivalent), clean out carbon

face seal seat area of pump mounting plate.

4. Slip four (4) rubber mounting extensions onto pump

mounting plate.

5. With motor positioned so electrical connector is facing

front, position pump mounting plate on motor so drain

outlet is facing right side. Drive four (4) screws which

secure pump mounting plate to motor, but do not

completely tighten.

Carbon face seal

675475-A

Figure 7

(continued)

3

Loading...

Loading...