30" EYE-LEVEL&ROWAVE RANGE

30" EYE-LEVEL RANGE

ve Ovens, Compactors, Room Air Conditioners, Dehumidifiers, Automatic

Washers,

Clothes Dryers, Freezers, Refrigerator-Freezers, Ice Makers,Dishwasl

Before you begin

II

Read these instructions completely and carefully.

If followed, they will simplify the installation job.

If your range does not have a microwave upper

oven, disregard the following microwave information.

IMPORTANT:

Observe all governing codes and ordinances.

Failure to follow these instructions could lead

to fire or electrical shock hazard.

A. Space requirements

PRECAUTIONS TO AVOID POSSIBLE EXPOSURE TO EXCESSIVE MICROWAVE ENERGY

Do not attempt to operate this oven with the door open

since open-door operation can result in harmful exposure to

microwave energy. It is important not to defeat or tamper

with the safety interlocks.

Do

not place any object between the oven front face and

the door or allow soil or cleaner residue to accumulate on

sealing surfaces.

Do not operate the oven if it is damaged. It is particularly

important that the oven door close properly and that

there is no damage to the:

1. Door (bent)

2. Hinges and latches (broken or loosened)

3. Door seals and sealing surfaces.

The oven should not be adjusted or repaired by anyone

except properly qualified service personnel.

The oven should be checked for microwave leakage by

qualified service personnel after a repair is made.

Do not operate the oven if the door glass is broken.

/

==lrll_i-i==

--

/’

-

I]

A

L

B

d

1 -a

!

III

L

P

/ t

WALL

RECEPTACLE

go0

t-F-

I

7”

MAX.

\

I

A=

Height for range with eye-level oven plus vent hood:

7l-7/8” min.

Height for range with eye-level oven alone: 66-l/8” min.

B=

C= Width between counters: 30-318” to 30-l/2”.

D= Height of countertop: 35.5/8” to 36.13/16”.

E=

Depth: 22-112”.

F=

Pigtail receptacle location: 8” to 22” from either cabinet,

7” max. from floor.

To prevent discoloration of base cabinet, front of oven frame

must extend at least l/2” beyond front surface of cabinets.

Do not seal range to cabinets.

\

The copper power cord (pigtail) must run downward, left or right

to the wall receptacle to avoid pinching the cord between rear

portion of the range and wall.

Top of eye-level oven may be installed against bottom of overhead cabinet. However, for easy installation and removal, allow

1” clearance between oven top and cabinet. or 1” clearance

between hood top and cabinet. When hood is attached to cabinet, allow 1” clearance between hood bottom and oven top.

The back of a free-standing range may be installed against a

vertical wall. Sides may be installed against base cabinets or

against vertical walls extending above upper edge of the cook

top.

CAUTION:

Reaching over heated surface elements causes risk _.

being burned. To eliminate hazard, cabinets should NOT

be installed above range.

If cabinets are already provided, reduce hazard by instal-

ling a range hood. Hood should project horizontally beyond

bottom of cabinets by a minimum of 5 inches.

I-If

B.Check microwave for damage

Remove all packing material from the oven cavity. When

unpacking the unit, check for damage such as misaligned

door, damaged gaskets around the door, or dents inside the

oven or on the exterior. If there is any damage, please do

not operate the unit until it has been checked by an authorized Whirlpool trained service technician.

C. Electrical requirements

Wire size and connectors must conform to

the ampere rating of the range as stated in

paragraph C-l.

IMPORTANT:

SAVE THESE INSTRUCTIONS FOR THE

LOCAL ELECTRICAL INSPECTOR’S USE

WARNING: DO NOT PLUG THE “PIGTAIL”

POWER CORD INTO A LIVE WALL

RECEPTACLE

PERMANENTLY CONNECTED TO THE

TERMINAL BLOCK.

1. This appliance must be connected to the proper

electrical voltage and frequency as specified on

nameplate. Models rated at 15 KW on 240 volts

(11.25 KW on 208 V) or more require a separate 50

ampere circuit. Models rated less than 15 KW on 240

volts (11.25 KW on 208 V) require a separate 40

ampere circuit. Fuse both sides of the line. DO NOT

fuse the neutral. A time-delay fuse or circuit breaker

is recommended. Wire sizes must conform to the

requirements of the National Electrical Code and/or

local codes and ordinances for the kilowatt rating of

the range. The nameplate is located on the front

frame of the main oven behind the main door. For

the Eye-level Microwave, it is on the front frame

behind microwave oven door.

2. All wires ending at the appliance must terminate in

ring type terminals.

3. All power cords and cables to appliance must be

fitted with a UL approved strain relief.

4. The range should be connected with copper wire

only. Aluminum wire requires special connectors.

Improper use may create a fire hazard.

5. Appliance may be connected directly to the fused

disconnect (or circuit breaker) box through flexible

armored or non-metallic sheathed copper cable. Do

not use an extension cord. Allow 4 feet (min.) slack

so appliance can be moved for servicing. Wire sizes

must conform to the ampere rating of the range. See

paragraph C-l above.

6. WARNING: THE TERMINAL BLOCK ON THE

APPLIANCE ACCEPTS COPPER WIRE ONLY,

NOT ALUMINUM. IF ALUMINUM HOUSE WIRING

MUST BE CONNECTED, USE ONE OF THE

FOLLOWING PROCEDURES:

BEFORE

CORD IS

Attach special ring connectors to the aluminum

house wiring that are UL listed and designed

for joining copper to aluminum. These special

ring connectors (available at electrical supply

houses) can be attached directly to the range

terminal block.

The connectors must conform to the ampere

rating of the range as stated in paragraph C-l.

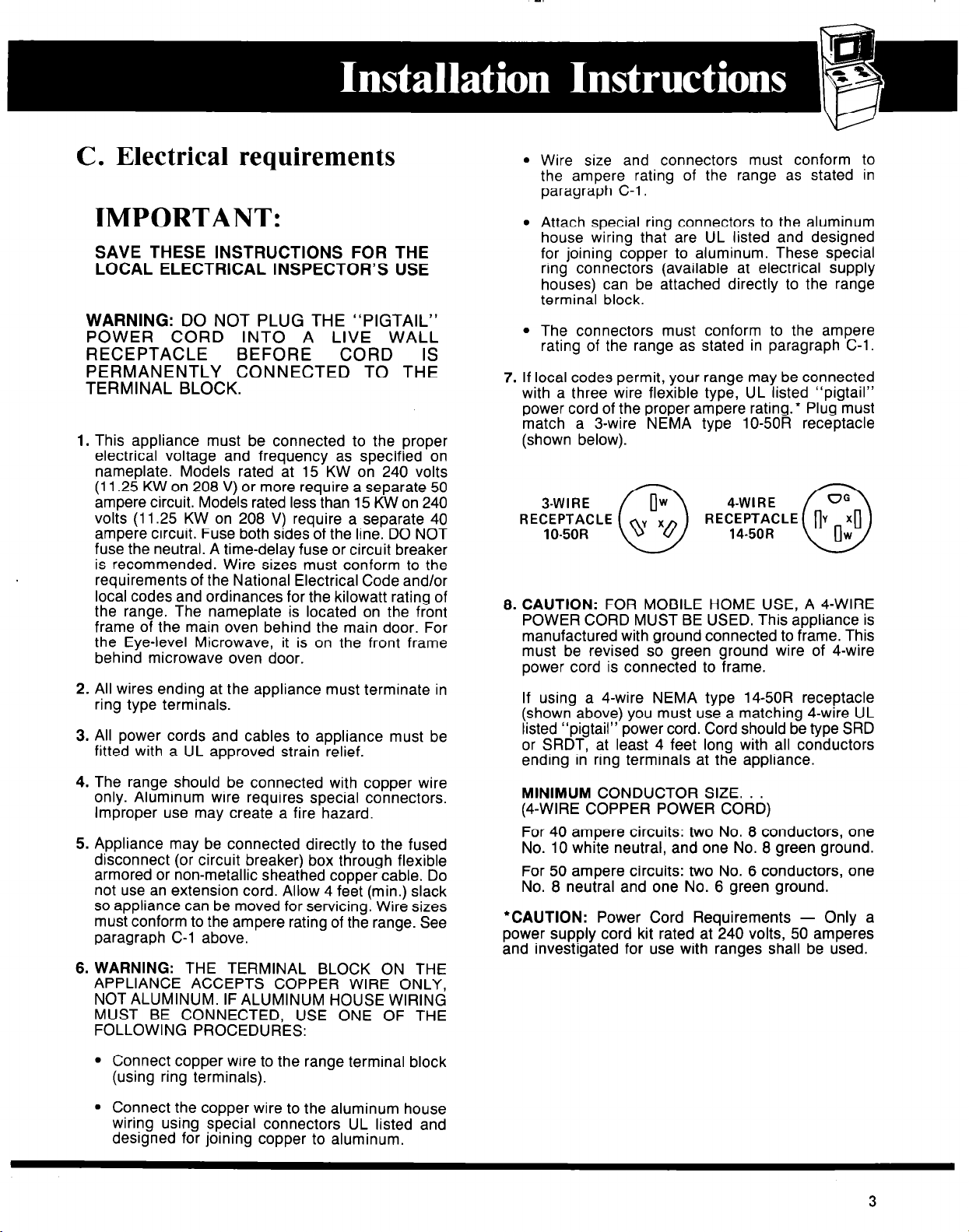

7. If local codes permit, your range may be connected

with a three wire flexible type, UL listed “pigtail”

power cord of the proper ampere rating.* Plug must

match a 3-wire NEMA type lo-50R receptacle

(shown below).

8. CAUTION: FOR MOBILE HOME USE, A 4-WIRE

POWER CORD MUST BE USED. This appliance is

manufactured with ground connected to frame. This

must be revised so green ground wire of 4-wire

power cord is connected to frame.

If using a 4-wire NEMA type 14-50R receptacle

(shown above) you must use a matching 4-wire UL

listed “pigtail” power cord. Cord should be type SRD

or SRDT, at least 4 feet long with all conductors

ending in ring terminals at the appliance.

MINIMUM CONDUCTOR SIZE. . .

(4-WIRE COPPER POWER CORD)

For 40 ampere circuits: two No. 8 conductors, one

No. 10 white neutral, and one No. 8 green ground.

For 50 ampere circuits: two No. 6 conductors, one

No. 8 neutral and one No. 6 green ground.

*CAUTION: Power Cord Requirements - Only a

power supply cord kit rated at 240 volts, 50 amperes

and investigated for use with ranges shall be used.

l Connect copper wire to the range terminal block

(using ring terminals).

l Connect the copper wire to the aluminum house

wiring using special connectors UL listed and

designed for joining copper to aluminum.

3

Begin the installation

Remove racks and all other contents from oven

before moving appliance. Be sure to remove all

packaging material (cardboard, protective film,

etc.) from range before use.

A. Remove shipping skid

.m..CARDBOARDPADS

UNDER APPLIANCE

Begin electrical connection

Grounding Instructions

WARNING:

THIS APPLIANCE MUST BE CONNECTED TO A

GROUNDED, METALLIC, PERMANENT WIRING

SYSTEM, OR AN EQUIPMENT GROUNDING CONDUCTOR SHOULD BE RUN WITH THE CIRCUIT

CONDUCTORS AND CONNECTED TO THE EQUIP-

MENT GROUNDING TERMINAL OR LEAD ON THE

APPLIANCE.

SHIPPING iKID

Remove the 4 cardboard pads from shipping box. Place

them on floor as shown to protect appliance’s finish.

Rest appliance (on its back) on pads.

Remove the two 318” shipping bolts from wooden skid.

Discard the skid.

\

,.

B. Extend leveling legs

ADJUSTABLE WRENCH

BOTTOM OF

LEVELING LEG

Once skid is removed, 4 leveling legs are exposed at

bottom of frame.

Loosen legs by applying an adjustable wrench to the

1%” base of the leveling legs. Back each of them out

about 4 complete turns.

CAUTION: Before connecting flexible armored cable

for permanent wiring, disconnect power at fuse box or

circuit breaker.

A. Remove terminal block cover

3/8” BRASS NUTS 3

TERMINAL

BLOCK ,

COVER

Terminal block cover is located on back of the ap-

pliance near the bottom.

Remove retaining screws to expose electrical terminal

block.

USE ONLY the supplied 3/8” brass nuts when connec-

ting cord.

USE ONLY ring type terminals to connect cord.

Stand appliance on its base.

B. Strain relief required

LOCKING , II

INSERT FROM

UNDER FRAME

Use this wiring method ONLY if local codes permit

connecting frame grounding conductor to neutral

wire of power cord.

THIS APPLIANCE IS MANUFACTURED WITH

NEUTRAL TERMINAL CONNECTED TO THE

FRAME.

If local codes do not permit grounding through the

neutral. The 3-conductor cord or cable assembly

must be replaced by a 4-conductor cord. The

replacement cord must be rated 240 volts, 50

amperes and investigated for use with ranges.

1.

Connect neutral wire to the center silver-colored

terminal.

2.

Connect remaining 2 wires to the terminals on either

side of the silver colored terminal.

Disconnect clamping ring from strain relief. Push relief

(from bottom) through hole beneath terminal block.

Tighten clamping ring (from above) onto strain relief

threads.

W-m _--,.- is* ~l--T-i+..4

Run cord or cable through strain relief.

Leave enough slack to attach ring-type terminals to

terminal block. Tighten clamping screws.

,_.~.,,. --L-n-U -I--Y.-w-

RUN CORD THROUGH

STRAIN RELIEF

C. If frame grounding is allowed

3.

Use ring type terminals only. Connect with the brass

nuts that are taped to the frame. Do not loosen factory installed nuts already on the terminal.

4.

Replace terminal block cover.

D. 4-wire electrical connections

SILVER COLORED.

TERMINAL

i

y I”’

RELIEF :

SILVER COLORED

NEUTliAIv

1 ’ ’

Use this wiring method for mobile homes and

whenever a 4-wire installation is required.

1. Remove the grounding strap screw from the range

frame. Keep this ground screw. Bend up the grounding strap so that it does not contact the range frame.

2. Connect the green ground wire to the frame of the

appliance with the ground screw, using the hole in

the frame where the ground strap was removed.

3. Connect the white neutral wire of the power cord to

the silver colored terminal of the terminal block. Connect the remaining wires to the outer terminals.

4. Replace the terminal block cover.

5

/A 1 Level and position

” the range

Gl

NOTE:

If installing the option vent hood, go to that step now.

Instructions are on page 7. Level and position the

range after the vent hood is attached.

Check operation

5

CAUTION:

Do not touch any heating elements. They may be hot

and you may be burned.

I

SPIRIT

LEVEL -\

‘-

A. Leveling

Move range into fiGI operating position. Use caution

when moving this appliance to prevent damage to floor

coverings. The weight of the appliance may cause rip-

ping, scratching or other damage to the floor. For best

results, slide appliance onto cardboard or hardboard

before moving to prevent damage.

Place rack in oven. Put spirit level on rack. If range

needs leveling, remove oven drawer. The tops of level-

ing legs will be exposed as shown.

Use a 3/” allen wrench to raise or lower legs as needed.

IMPORTANT: Oven must be properly leveled for

satisfactory baking conditions.

B. Remove shipping clips

Each of the 4 elements is

secured by a shipping clip.

Using screwdriver or pliers,

bend upper part of the clip

to vertical position. Slide

clip out and discard

it.

A. Surface elements

Turn on each of the 4 surface elements. Check to be certain they heat and check for proper operation of surface

indicator light(s).

B. Oven elements

BAKE - Set selector switch on BAKE. Turn thermostat to

350° BAKE. The bottom element should glow red and in-

dicator light should be on. The upper element should

become hot but NOT glow red.

BROIL - Set selector switch on BROIL. Turn thermostat

to high. The top element should glow red and indicator

light should be on.

C. Rotisserie

Place straight oven rack on bottom ledge position

Place broiler pan on oven rack

Place special rotisserie rack on broiler pan. Position the spit

bar on this special rack.

Rotation should start when spit bar is inserted into recep-

tacle in back of oven.

D. Clock

Refer to operating instructions in the Use and Care Guide

(packed in the oven).

(if optional rotisserie kit is installed)

(if so equipped)

E. Cleaning

See the

care and cleaning instructions.

Use

and Care Guide (packed in the oven) for proper

Before you call

for service. . .

C. Complete elec

Back appliance away from

wall, leaving room to make

connection.

Plug flexible pigtail into ap-

proved receptacle (if allow-

ed by local codes). OR

Connect flexible armored or

non-metallic shielded cable

directly to fused disconnect

box.

6

t.rical connection

See the Use and Care Guide for trouble-shooting checklist.

Be sure pigtail power cord is plugged in.

Check for blown fuses or tripped circuit breaker.

If you must call for service. . .

You will need the appliance model and serial number.

Find the serial plate on the front frame of the main oven

behind the main door. For the Eye-level Microwave, it is

on the front frame behind the microwave oven door.

7 Installing optional

C. Connect vent hood

Ll

CAUTION:

Disconnect from electrical supply before installing

vent hood.

vent hood

A. Space required

EYE-LEVEL RANGE

Install vent hood BEFORE making final electrical connection.

When measuring, remember that leveling legs will be adjusted. Total height needed for vent hood is 71-7/e” with

legs extended about half way.

The top of the vent hood may be installed against bottom

of over head cabinets.

B. Remove knockout plug

Reach through hole in bottom of vent hood, pull out power

cord until all slack is removed.

Place vent hood on the top of the oven. Lift front of vent

hood and connect vent hood power cord to the receptacle

in the top of the oven.

Rest vent hood on the top of the oven.

VENT HOOD

BACK

\

ORIGINAL

,/POSITION \

REMOVE

IT

Position appliance so that front and back are accessible.

Knockout plug is at right rear of oven top panel.

Use hammer and screwdriver as shown to remove knockout plug.

CAUTION: Avoid damage to power supply receptacle

located below knockout plug.

I

THIS POSITION

OVEN

BACK

Loosen screws holding the 2 mounting plates on the back

of the vent hood. Rotate these plates (as shown) until

the lower holes line up with matching screwholes in the

Fasten plates to the oven back using the 2 screws supplied

with the vent kit. Retighten the screws that were loosened

in the vent hood.

To connect ducting

stallation, see instructions packed with the vent hood.

See instructions packed with the vent hood for details on

proper use and care.

When vent hood installation is finished, go to Step 4,

“Level and position range” on page 6.

or to use vent hood in a ductless in-

i

HOME 5% APPLIANCES

Making your world a little easier.

Part No. 313480

Rev.

6

In the event your WHIRLPOOL appliance should need service, call the dealer from whom you purchased the

appliance or a WHIRLPOOL franchised TECH-CARE@

directory listed under “Appliances-Household-Major-Service and Repair.” You can also obtain his name and number

by dialing, free. the Whirlpool COOL-LINE” service (SW) 2551301. Dial just as

special operator will tell you the name and number of your nearest Whirlpool TE

normal working hours,, Whirlpool consultants at this same number will also answer any questions about operating or

maintaining your appltance not covered in your Use and Care Guide.

Learn the benefits of using TECH-CARE service for maintaining the quality originally built into your

WHIRLPOOL appliance.

service company. He is in the Yellow Pages of your telephone

ou normally dial long distance. A

H-CARE@ service outlet. During

8

Printed in U.S.A.

idifiers, Automatic Washers, Clothes Dryers, Freezers, Refrigerator-Freezers, Ice Makers, Dishwashers, Built-In Ovens and Surface Units, Ranges, Microv

Loading...

Loading...