Whelen SAK46 User Manual

®

ENGINEERING COMPANY INC.

CAUTION

Loud siren noise can cause

hearing damage and/or loss.

Refer to OSHA Section 1910.95 prior

to putting ANY siren into service!

Wear

Protection!

ACTIVATION OF THIS

SIREN MAY DAMAGE

UNPROTECTED EARS!

51 Winthrop Road

Chester, Connecticut 06412-0684

Phone: (860) 526-9504

Fax: (860) 526-4078

Model SAK46 for Projector™ Series SA315

Model HWLCI12 for Howler™ Siren Speaker

Mounting to the 2012 Chevy Impala

Installation Guide:

Internet: www.whelen.com

Sales e-mail: autosale@whelen.com

Canadian Sales e-mail: canadiansales@whelen.com

Customer Service e-mail: custserv@whelen.com

DANGER! Sirens produce extremely loud emergency warning tones! Exposure to these tones without

proper and adequate hearing protection, could cause ear damage and/or hearing loss! The Occupational Safety &

Health Administration (www.osha.gov) provides information necessary to determine safe exposure times in

Occupational Noise Exposure Section 1910.95. Until you have determined the safe exposure times for your

specific application, operators and anyone else in the immediate vicinity should be required to wear an approved

hearing protection device. FAILURE TO FOLLOW THIS RECOMMENDATION COULD CAUSE HEARING LOSS!

Safety First

This document provides all the necessary information to allow your Whelen product to be properly and safely installed.

Before beginning the installation and/or operation of your new product, the installation technician and operator must

read this manual completely. Important information is contained herein that could prevent serious injury or damage.

• Proper installation of this product requires the installer to have a good understanding of automotive electronics,

systems and procedures.

• Failure to use specified installation parts and/or hardware will void the product warranty!

• If mounting this product requires drilling holes, the installer MUST be sure that no vehicle components or other

vital parts could be damaged by the drilling process. Check both sides of the mounting surface before drilling

begins. Also de-burr any holes and remove any metal shards or remnants. Install grommets into all wire

passage holes.

• If this manual states that this product may be mounted with suction cups, magnets, tape or Velcro®, clean the

mounting surface with a 50/50 mix of isopropyl alcohol and water and dry thoroughly.

• Do not install this product or route any wires in the deployment area of your air bag. Equipment mounted or

located in the air bag deployment area will damage or reduce the effectiveness of the air bag, or become a

projectile that could cause serious personal injury or death. Refer to your vehicle owner’s manual for the air bag

deployment area. The User/Installer assumes full responsibility to determine proper mounting location, based

on providing ultimate safety to all passengers inside the vehicle.

• For this product to operate at optimum efficiency, a good electrical connection to chassis ground must be

made. The recommended procedure requires the product ground wire to be connected directly to the NEGATIVE

(-) battery post.

• If this product uses a remote device to activate or control this product, make sure this control is located in an

area that allows both the vehicle and the control to be operated safely in any driving condition. DO NOT

ATTEMPT TO ACTIVATE OR CONTROL THIS DEVICE IN A HAZARDOUS DRIVING SITUATION.

• It is recommended that these instructions be stored in a safe place and

referred to when performing maintenance and/or reinstallation of this

product.

• FAILURE TO FOLLOW THESE SAFETY PRECAUTIONS AND

INSTRUCTIONS COULD RESULT IN DAMAGE TO THE PRODUCT OR

VEHICLE AND/OR SERIOUS INJURY TO YOU AND YOUR PASSENGERS!

Automotive: Sirens/Switches

For warranty information regarding this product, visit www.whelen.com/warranty

©2012 Whelen Engineering Company Inc.

Form No.14569 (022912)

Page 1

1/4" SPLIT LOCKWASHER

(QTY 1)

1/4 - 20 X 1-1/4"

HEX HD SS (QTY 1)

TO HOWLER

BRACKET

1/4 - 20 X 1-1/4"

PFHMS (QTY 3)

TO SA315

BRACKET

5/16 X 1" HEX HD

SHEET METAL

SCREW (QTY 4)

3/8" FLAT

WASHER (QTY 2)

3/8 - 16 ELASTIC

STOP NUT (QTY 2)

5/16 ELASTIC

STOP NUT

(QTY 2)

5/16 - 18 X 1 HEX HD BOLT (QTY 2)

HEADLIGHT SUPPORT

5/16 FLAT WASHER (QTY 2)

DRAIN

HOLES

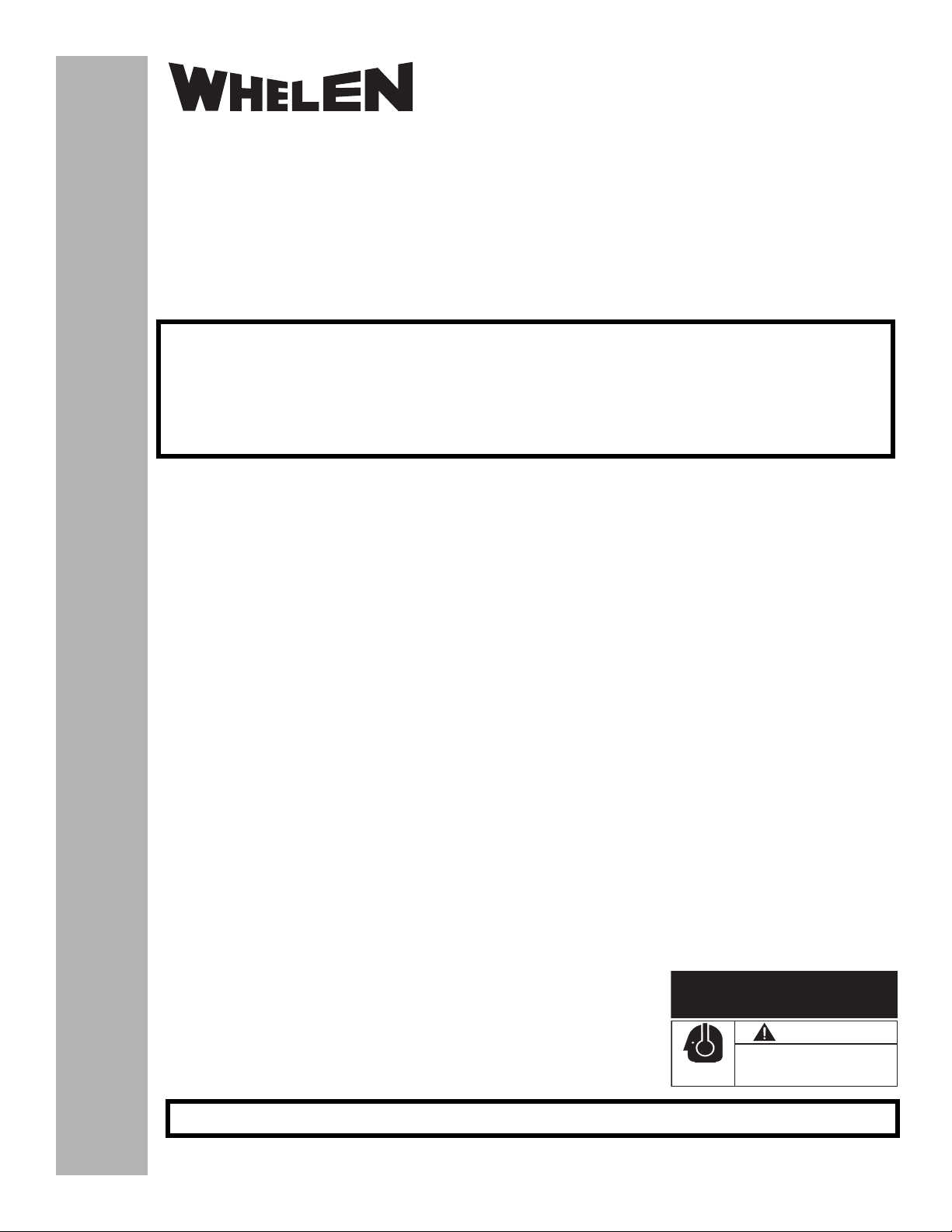

Model SAK46 / Mounting the SA315 siren speaker to the bracket:

A

A

wire

exit &

drain

hole

SA315 Rear View

Remove 4 screws and remove brackets.

NOTE: If strap retainer brackets are

present on your Howler speaker, they

must be removed for this installation.

Howler Front View

Mount the SA315 siren speaker to its bracket (Fig. 1). The SA315 mounting kit comes with 3 long screws (1/4-20 X 1-1/4”

PHILLIPS FLAT HEAD METAL SCREWS) Longer screws are necessary to go through the mounting bracket, the siren

housing and into the siren driver. They will replace 1 of the 2 short screws (“A”) that now secure the driver to the speaker

housing when your speaker is shipped. A short screw must be used in the hole

that does not go through the bracket to properly secure the driver to the

housing. If you remove all 4

screws at once be sure to hold

the driver in place.

IMPORTANT: The SA315

speaker must be oriented so

the wire passage hole is in the

“6 o’clock” position (closest to

the road). This is also the drain

hole. Improper mounting will

result in premature driver

failure and void the warranty.

Mounting the SA315 bracket to the vehicle:

1. Unplug and remove the driver side headlight assembly from the vehicle

following manufacturers instructions.

2. Remove the 2 bolts which help secure the bumper (Fig. 2) and secure the

bracket to the vehicle where the bumper mounts using these 2 bolts.

3. Extend the WHITE (Positive) and Black (Negative) wires to your siren

amplifier and connect as instructed in the amplifier manual. Reinstall the

headlight assembly.

Fig. 1

Howler siren has been designed with a built-in timing circuit. The Occupational Safety &

Health Administration (OSHA) (www.osha.gov) provides information necessary to

determine safe exposure times in Noise and Hearing Conservation, Section 1910.95

(Occupational Noise Exposure). Until you have determined the safe exposure times for your

specific application, this siren should be configured for the minimum operating time and

operators should be required to use an approved hearing protection device. FAILURE

TO FOLLOW THIS RECOMMENDATION COULD CAUSE HEARING LOSS!

1. Mount the Howler to the bracket using the supplied 5/16 X 1” HEX HD

SHEET METAL SCREWS. The Howler must be mounted with the

drainage holes on the bottom.

2. Mount the Howler bracket to the back of the SA315 bracket with the

supplied 5/16 HEX HEAD BOLTS, 5/16 FLAT WASHERS AND 5/16

ELASTIC STOP NUTS (Figs. 2 & 3).

3. Secure the Howler bracket to the vehicle headlight support using

the supplied 5/16 - 18 X 1” HEX HEAD BOLTS, 5/16 FLAT

WASHERS AND 5/16 ELASTIC STOP NUTS (Figs. 2 & 3).

4. Extend the WHITE (Positive) and Black (Negative) wires to your siren

amplifier and connect as instructed in the siren manual.

Model HWLCI12 (requires SAK46)

Mounting the Howler speaker

and bracket:

IMPORTANT! READ THESE WARNINGS

BEFORE CONTINUING!

The Howler™ Supplemental Siren was

designed for use in high-risk areas such as an

intersection. It is not intended to be, nor should

be operated as a replacement or alternative to

the vehicle's primary siren. The low-frequency

tones of the Howler demonstrate significantly

different audio characteristics as compared to

those of a traditional higher-frequency siren.

While the low-frequency tones are better able to penetrate other vehicles, thus

alerting drivers to the presence of the responding emergency vehicle, these tones

may also penetrate into the

responding vehicle itself.

This could potentially

expose the operator to

increased noise levels.

To help eliminate

overexposure, the

Page 2

Fig. 3

Loading...

Loading...