Page 1

®

ENGINEERING COMPANY INC.

51 Winthrop Road

Chester, Connecticut 06412-0684

Phone: (860) 526-9504

Universal Mounting Bracket

SA314 / SA315 Siren Speaker

Installation Guide:

Fax: (860) 526-4078

Internet: www.whelen.com

Sales e-mail: autosale@whelen.com

Canadian Sales e-mail: autocan@whelen.com

Customer Service e-mail: custserv@whelen.com

DANGER! Sirens produces extremely loud emergency warning tones! Exposure to these

tones without proper and adequate hearing protection, could cause ear damage and/or hearing

loss! The Occupational Safety & Health Administration (www.osha.gov) provides information

necessary to determine safe exposure times in Occupational Noise Exposure Section 1910.95.

Until you have determined the safe exposure times for your specific application, operators and

anyone else in the immediate vicinity should be required to wear an approved hearing protection

device. FAILURE TO FOLLOW THIS RECOMMENDATION COULD CAUSE HEARING LOSS!

Safety First

This document provides all the necessary information to allow your Whelen product to be properly and safely installed.

Before beginning the installation and/or operation of your new product, the installation technician and operator must

read this manual completely. Important information is contained herein that could prevent serious injury or damage.

• Proper installation of this product requires the installer to have a good understanding of automotive electronics,

systems and procedures.

• If mounting this product requires drilling holes, the installer MUST be sure that no vehicle components or other

vital parts could be damaged by the drilling process. Check both sides of the mounting surface before drilling

begins. Also de-burr any holes and remove any metal shards or remnants. Install grommets into all wire

passage holes.

• If this manual states that this product may be mounted with suction cups, magnets, tape or Velcro™, clean the

mounting surface with a 50/50 mix of isopropyl alcohol and water and dry thoroughly.

• Do not install this product or route any wires in the deployment area of your air bag. Equipment mounted or

located in the air bag deployment area will damage or reduce the effectiveness of the air bag, or become a

projectile that could cause serious personal injury or death. Refer to your vehicle owners manual for the air bag

deployment area. The User/Installer assumes full responsibility to determine proper mounting location, based

on providing ultimate safety to all passengers inside the vehicle.

• For this product to operate at optimum efficiency, a good electrical connection to chassis ground must be

made. The recommended procedure requires the product ground wire to be connected directly to the NEGATIVE

(-) battery post.

• If this product uses a remote device to activate or control this product, make sure this control is located in an

area that allows both the vehicle and the control to be operated safely in any driving condition. DO NOT

ATTEMPT TO ACTIVATE OR CONTROL THIS DEVICE IN A HAZARDOUS DRIVING SITUATION.

• It is recommended that these instructions be stored in a safe place and

referred to when performing maintenance and/or reinstallation of this

product.

• FAILURE TO FOLLOW THESE SAFETY PRECAUTIONS AND

INSTRUCTIONS COULD RESULT IN DAMAGE TO THE PRODUCT OR

VEHICLE AND/OR SERIOUS INJURY TO YOU AND YOUR PASSENGERS!

ACTIVATION OF THIS

SIREN MAY DAMAGE

UNPROTECTED EARS!

CAUTION

Loud siren noise can cause

hearing damage and/or loss.

Wear

Refer to OSHA Section 1910.95 prior

Protection!

to putting ANY siren into service!

Automotive: Sirens/Switches

For warranty information regarding this product, visit www.whelen.com/warranty

©1999 Whelen Engineering Company Inc.

Form No.13497J (050208)

Page 1

Page 2

wire

exit

&

drain

hole

Selecting a Mounting Location: The mounting location should not only be as

flat as possible but also allow the speaker to project its tone parallel with the road.

For specific applications for the universal bracket, refer to the following pages.

Installation:

1. Position the bracket onto the desired mounting area and mark off the

mounting holes using the bracket as a template.

2. In the center of the 4 holes you marked off, drill a 1/8 inch pilot hole into the

mounting surface for each of the mounting screws then enlarge the pilot

holes with a 9/32 inch drill. If you can get access to the other side of the

mounting area, and it is not too thick, you may want to substitute the

mounting screws with nuts, bolts and washers (customer supplied) of

comparable strength and thickness.

3. Secure the bracket onto the mounting surface with the supplied mounting

hardware. NOTE: You may need a socket and drill to drive the screws.

4. Attach speaker to bracket with the supplied mounting hardware then extend

the WHITE (Positive) and BLACK (Negative) speaker wires to your amplifier

and connect as shown in the amplifiers instructions.

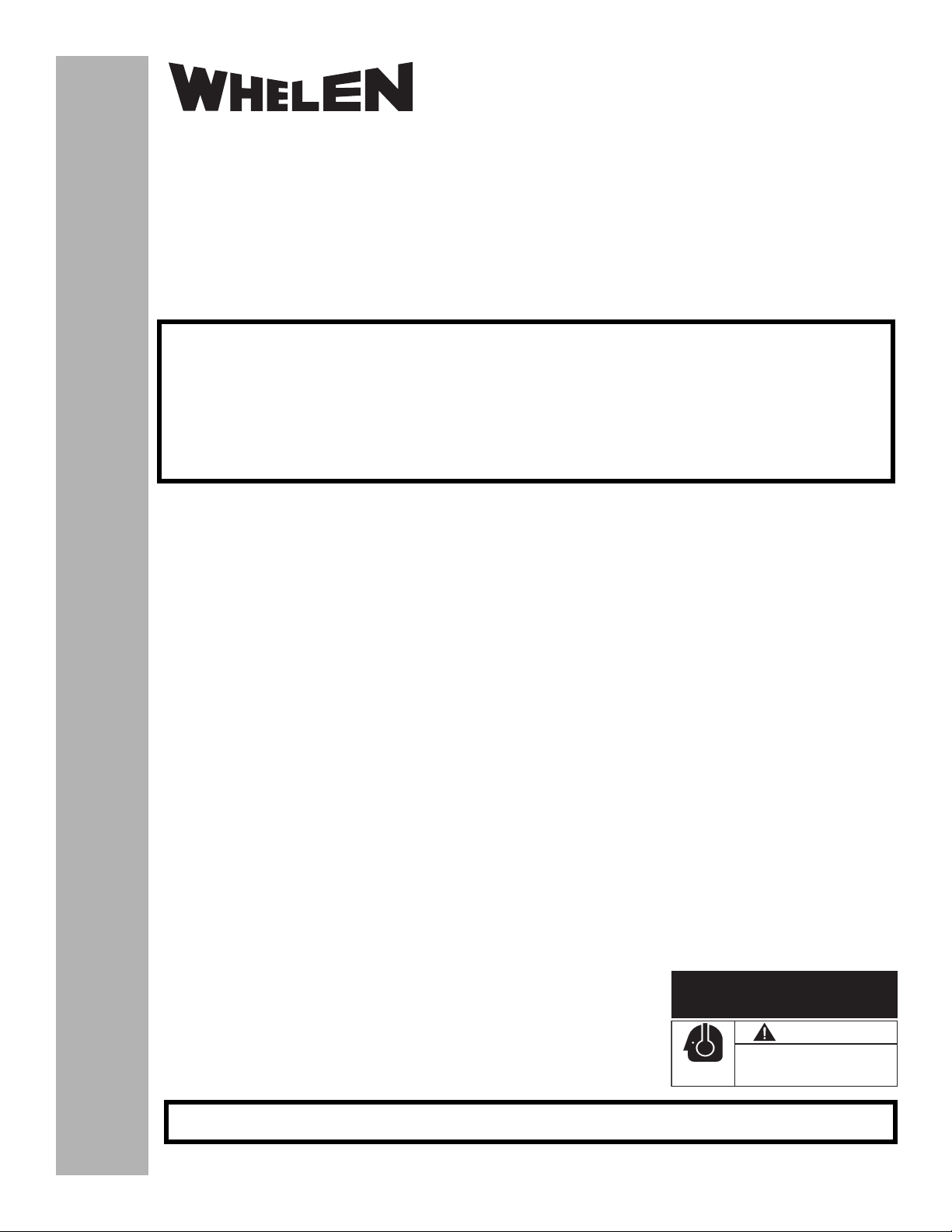

Mounting

the Speaker

1/4 - 20 X 1-1/2"

HEX HEAD SS

1/4" SPLIT

LOCK WASHER

SA315

1/4 X 20 X 1-1/4

HEX HEAD

1/4" SPLIT

LOCK WASHER

SA314

IMPORTANT: It is the responsibility of the installation technician

to make sure that the installation and operation of this product

will not interfere with or compromise the operation or efficiency

of any vehicle equipment!

to Bracket

#14 X 1" PPHSMS

1/4" INTERNAL TOOTH

LOCKWASHER

APPLICATION HARDWARE QTY

2004-05 DURANGO . . . . . . . . . . . . . . . . . . . . NUT: 5/16-18 Hex SS 1/2" Diameter . . . . . . . . . . . . . . . . . . . . . . . . 2

2004-05 DURANGO . . . . . . . . . . . . . . . . . . . BOLT: 5/16-18 X 1 Hex Head SS . . . . . . . . . . . . . . . . . . . . . . . . . .2

2004-05 DURANGO . . . . . . . . . . . . . . . . . . . . WASHER: 5/16 Split Lock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

2001 TAURUS . . . . . . . . . . . . . . . . . . . . . . . . SCREW: 1/4 X 1" Hex Washer Head Self Drilling . . . . . . . . . . . . . 4

For Any Application / Bracket to vehicle . . SCREW: 5/16 X 1" Hex Head SMS SS . . . . . . . . . . . . . . . . . . . . . 4

For Any Application / Bracket to vehicle . . WASHER: 5/16" Flat SS 3/4" Outer Diameter . . . . . . . . . . . . . . . .2

Mounting SA314 Speaker To Bracket . . . . . SCREW: 14 X 1 PPHSMS A Point . . . . . . . . . . . . . . . . . . . . . . . . . 4

Mounting SA314 Speaker To Bracket . . . . . WASHER: 1/4 Internal Tooth Lock . . . . . . . . . . . . . . . . . . . . . . . . .4

Mounting SA315 Speaker to Bracket . . . . . SCREW: 1/4-20 X 1-1/2 Hex Head SS. . . . . . . . . . . . . . . . . . . . . . 3

Mounting SA315 Siren Driver to Housing. . BOLT: 1/4 X 20 X 1-1/4 Hex Head . . . . . . . . . . . . . . . . . . . . . . . . . 1

Mounting SA315 Speaker to Bracket . . . . . WASHER: 1/4 Split Lock Washer . . . . . . . . . . . . . . . . . . . . . . . . . .4

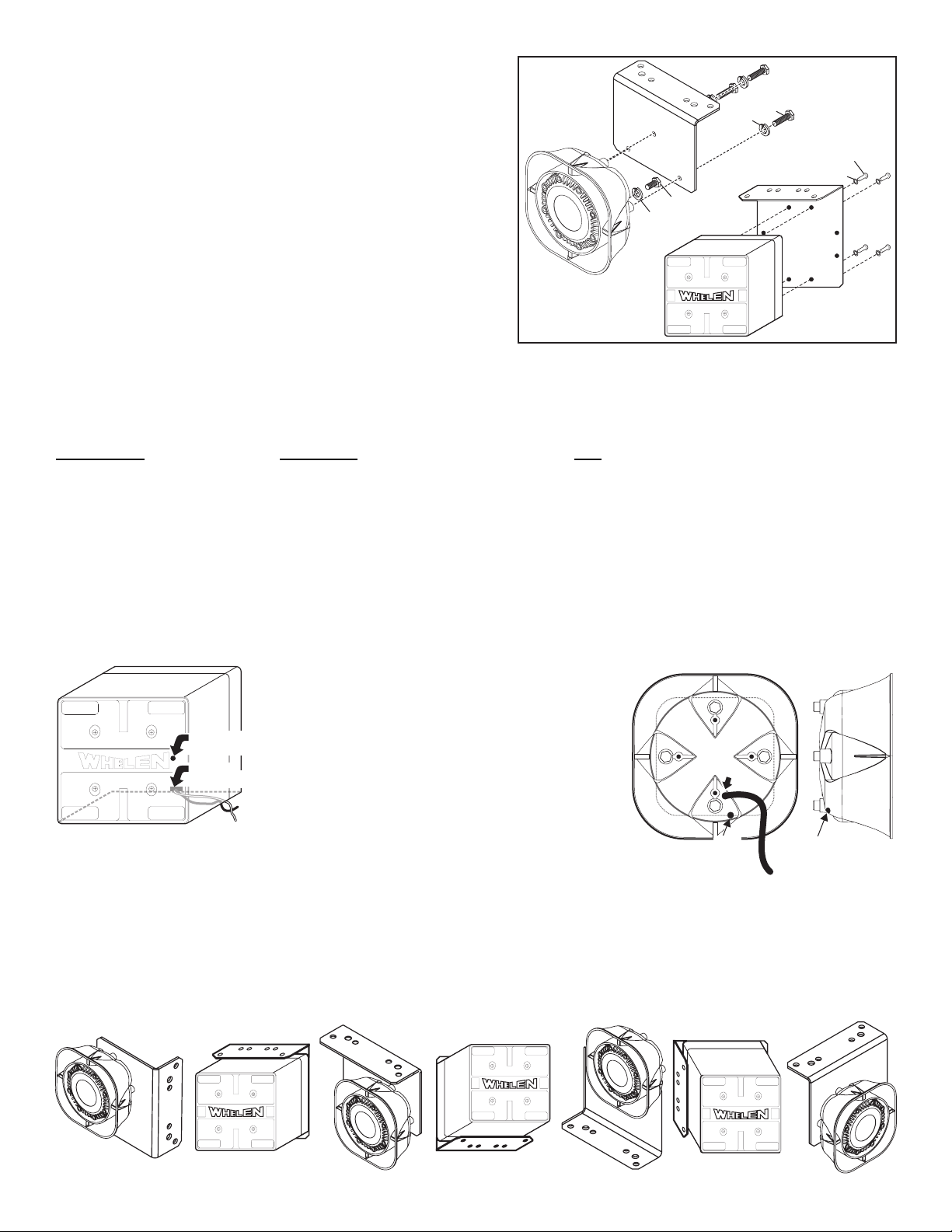

SA314

WARNING: Speaker wires must exit the bottom of the speaker.

The wire hole also serves as a drainage hole. Improper mount-

The SA315 siren speaker mounting kit comes with

3 long bolts (1/4-20 X 1-1/2” Hex Head SS). The

longer bolts are necessary to go through the

mounting bracket, through the siren housing and

into the siren driver. They will replace 3 of the 4

shorter bolts (“A”) that now secure the siren driver

to the speaker housing. Your speaker is shipped

with 2 or more of the shorter bolts installed. A short

bolt must be used in the hole that does not go

through the bracket so it will properly secure the

driver to the housing. If you need to remove all 4

bolts at once be sure to hold the driver in place.

SA315 / Rear View

Side View

ing will result in siren driver failure and void the siren warranty.

IMPORTANT NOTE: In most applications the existing drain hole

will work fine. However, since this mounting bracket can mount

NEW DRAIN

HOLE HERE

EXISTING

DRAIN HOLE

in a variety of positions the drain hole in the bottom of the

speaker can be ineffective if the speaker is mounted with the

drain hole facing to the side. If your application does not allow

this an alternate drain hole may be drilled.

wire

wire

exit &

exit &

drain

drain

hole

hole

Drilling a drain hole / SA314: Drill a small drainage hole in the

area indicated, using a 1/8” (.125) drill bit. There is a second wall

behind the outer surface that you must not drill through. Use a drill

stop set to a 1/4” depth. This will insure that you don’t hit any internal speaker parts while drilling the hole.

New

drain

hole

New

drain

hole

Drilling a drain hole / SA315: Remove the bolts that hold the driver to the speaker body and slide

the driver out. Drill a small drainage hole in the rear of the speaker as shown. The hole should be drilled in the rear, on the curved part of the speaker body

(See side view) using a 1/8” drill bit. Make sure the hole is located on the bottom (depending on the position the speaker will be in after mounting). Be sure

you drill through both the outer and inner walls of the siren housing so the drain hole will reach the driver compartment. Reassemble the speaker, reinstalling

the driver into the speaker body and securing the driver with the bolts you removed. WARNING: When you are reassembling the speaker, be very

careful not to pinch the wires between the siren driver and the housing. Feed the wires through the wire hole first.

Possible Mounting Positions: The SA314 or SA315 can mount to the universal bracket in a variety of positions depending on what your mounting

requirements are. The only necessity is that the speaker wires exit the bottom, (toward the ground) since this hole also serves as the drainage

hole for the speaker.

Page 2

Page 3

Installation / 2001 Ford Taurus:

READ BEFORE INSTALLING: The speaker will mount in the area

usually occupied by the air bag system. If your vehicle is equipped

with A.B.S. you can not mount the speaker in this location.

For this appication, the speaker will mount under the battery tray. First you

will need to remove the battery and tray, and the air filter and housing (Fig.

2). The speaker bracket will mount to the drivers side of the engine

compartment, on the side wall.

1. Disconnect the ground on the battery, remove the battery and tray

and then remove the air filter and housing.

2. Attach the speaker to the bracket (Fig. 1). An SA314 is shown. See

page 2 for an SA315.

3. Position the bracket (with speaker) onto the mounting area. Do not

position it so far forward that the speaker is muffled. Be sure the

bracket doesn’t interfere with any existing vehicle components. Using

the bracket as a template, mark the mounting surface where the

mounting screws will be located.

Note: Do not allow the new mounting hole locations to be directly

adjacent to any existing holes.

4. Remove the speaker from the bracket. Using the self-tapping screws

and washers supplied, mount the bracket onto the vehicle.

Note: You will need to drive the self tapping screws in with a socket

attached to a drill.

5. Remount the speaker to the bracket making sure that the speaker

wires exit the bottom for proper drainage .

6. Extend the WHITE (Positive) and BLACK (Negative) speaker wires to

your siren amplifier and connect as shown in the amplifiers

instructions.

Fig. 1

Fig. 2 Mounting area shown with

Battery and tray plus air filter and

filter housing removed. The siren

will mount in this area.

Installation / 2004-05 Dodge Durango:

1. First you will have to remove the grill. To remove the grill, you first

have to remove both headlight assemblies. Refer to your vehicle

owners manual for the proper procedure for both.

2. The speaker bracket will mount to the side of the support brace (on

the passenger side) that is indicated in Figure 1 below.

3. Place the bracket onto the mounting area in the exact position it will

be mounted, then using the bracket as a template mark the 2

mounting holes off onto the mounting surface.

DRIVERS SIDE

Fig. 3

Mark location of

the top edge of

the bracket.

The top view of the bracket

shows which holes to use

FRONT OF VEHICLE

4. Secure the speaker to the mounting bracket. . An SA314 is shown.

See page 2 for an SA315.

5. Drill the 2 mounting holes using a drill bit sized for a 5/16 - 18 hex

head bolt and secure the bracket (with speaker) onto the mounting

area with the supplied mounting hardware.

6. Extend the WHITE (Positive) and BLACK (Negative) speaker wires to

your siren amplifier and connect as shown in the amplifiers

instructions.

FIG. 2

for this application

MOUNTING

AREA

FIG. 1

Page 3

5/16 - 18

1/2" DIA.

HEX NUT

5/16 SPLIT

LOCK

WASHER

Use these

holes for this

application.

5/16 - 18 X 1

HEX HEAD BOLT

Page 4

Air

Conditioner

Condensor

Mounting

screws

Mounting: / 2002 - 2003 Ford Explorer: The speaker will be located in front of the driver side front tire, behind the bumper. You will use two existing

nuts and their bolts that are already on the vehicle. Always be sure that the speaker wires exit the bottom after mounting for proper drainage.

1. Secure the bracket to the speaker using the supplied mounting hardware (See hardware applications on page 2). An SA314 is shown in Fig. 1.

Refer to page 2 for the SA315. Be sure you mount the SA315 onto the bracket in the same position the SA314 is shown here.

2. Looking in through the drivers side wheel well, find the 2 existing bolts on the vehicle that match up to the brackets mounting holes.

3. Remove the 2 nuts from their bolts and mount the bracket (with speaker) securing it with the 2 nuts you removed (Figs. 2A & 2B).

4. Extend the WHITE (+) and BLACK (-) speaker wires to your siren amplifier and connect as shown in the amplifier instructions.

Fig. 1 Mount Siren to Bracket

L

L

FRONT OF VEHICLE

E

W

L

E

E

H

W

Top view of bracket

shows which holes

fit this application

FRONT OF VEHICLE

SA314

SIREN

SA314

SIREN

Fig. 2A

Fig. 2B

Mounting: 2003 Suburban / Tahoe: The siren will mount in front of the vehicles gravel shield, just forward of (and below) the air

conditioner condenser as shown (Figs. 2 & 3). Always be sure that the sirens wires exit the bottom of the siren after mounting for proper

drainage of the siren.

1. Place the bracket onto the mounting surface and mark off the location of the mounting holes.

2. Remove the bracket and drill the mounting holes an appropriate size for the supplied mounting hardware (See hardware applications on page 2).

3. Secure the bracket to the speaker using the mounting hardware provided for your model speaker. An SA314 is shown. See page 2 for an SA315.

4. Secure the bracket (with speaker) to the mounting location with the supplied mounting hardware.

5. Extend the WHITE (+) and BLACK (-) speaker wires to your siren amplifier and connect as shown in the amplifiers instructions.

Top view of bracket

shows which holes

fit this application

Siren attaches to

bracket as shown

Mounting

Mounting

screws

Screws

FIG. 2FIG. 1

Air Conditioner

Air Conditioner

Condensor

Condenser

b

b

e

u

R

r

C

o

v

e

FIG. 3

Gravel

Shield

Gravel Shield

Front Bumper

r

Page 4

Loading...

Loading...