Page 1

®

ENGINEERING COMPANY INC.

51 Winthrop Road

Chester, Connecticut 06412-0684

Responder® LP Lightbar

Installation Guide:

Phone: (860) 526-9504

Fax: (860) 526-4078

Internet: www.whelen.com

Sales e-mail: autosale@whelen.com

Canadian Sales e-mail: canadiansales@whelen.com

Customer Service e-mail: custserv@whelen.com

Safety First

This document provides all the necessary information to allow your Whelen product to be properly and safely installed.

Before beginning the installation and/or operation of your new product, the installation technician and operator must

read this manual completely. Important information is contained herein that could prevent serious injury or damage.

• Proper installation of this product requires the installer to have a good understanding of automotive electronics,

systems and procedures.

• If mounting this product requires drilling holes, the installer MUST be sure that no vehicle components or other

vital parts could be damaged by the drilling process. Check both sides of the mounting surface before drilling

begins. Also de-burr any holes and remove any metal shards or remnants. Install grommets into all wire

passage holes.

• If this manual states that this product may be mounted with suction cups, magnets, tape or Velcro®, clean the

mounting surface with a 50/50 mix of isopropyl alcohol and water and dry thoroughly.

• Do not install this product or route any wires in the deployment area of your air bag. Equipment mounted or

located in the air bag deployment area will damage or reduce the effectiveness of the air bag, or become a

projectile that could cause serious personal injury or death. Refer to your vehicle owner’s manual for the air bag

deployment area. The User/Installer assumes full responsibility to determine proper mounting location, based

on providing ultimate safety to all passengers inside the vehicle.

• For this product to operate at optimum efficiency, a good electrical connection to chassis ground must be

made. The recommended procedure requires the product ground wire to be connected directly to the NEGATIVE

(-) battery post.

• If this product uses a remote device to activate or control this product, make sure that this control is located in

an area that allows both the vehicle and the control to be operated safely in any driving condition.

• Do not attempt to activate or control this device in a hazardous driving situation.

• This product contains either strobe light(s), halogen light(s), high-intensity LEDs or a combination of these

lights. Do not stare directly into these lights. Momentary blindness and/or eye damage could result.

• Use only soap and water to clean the outer lens. Use of other chemicals could result in premature lens cracking

(crazing) and discoloration. Lenses in this condition have significantly reduced effectiveness and should be

replaced immediately. Inspect and operate this product regularly to confirm its proper operation and mounting

condition. Do not use a pressure washer to clean this product.

• It is recommended that these instructions be stored in a safe place and referred to when performing

maintenance and/or reinstallation of this product.

• FAILURE TO FOLLOW THESE SAFETY PRECAUTIONS AND INSTRUCTIONS COULD RESULT IN DAMAGE TO

THE PRODUCT OR VEHICLE AND/OR SERIOUS INJURY TO YOU AND YOUR PASSENGERS!

Automotive: Lightbars

For warranty information regarding this product, visit www.whelen.com/warranty

©2007 Whelen Engineering Company Inc.

Form No.14106K (060711)

Page 1

Page 2

IMPORTANT! The lightbar

should be a minimum of 16"

from any radio antennas!

Permanent Mounting:

This mounting style requires removal of

the headliner. There may be a roof

support member that runs from the

drivers to the passengers side of the

vehicle. Do not drill through this

member.

Caution: Permanent mounting of this

product will require drilling. It is absolutely necessary to make sure that no

other vehicle components could be damaged by this process. Check both

sides of the mounting surface before starting. If damage is likely, select a

different mounting locati on.

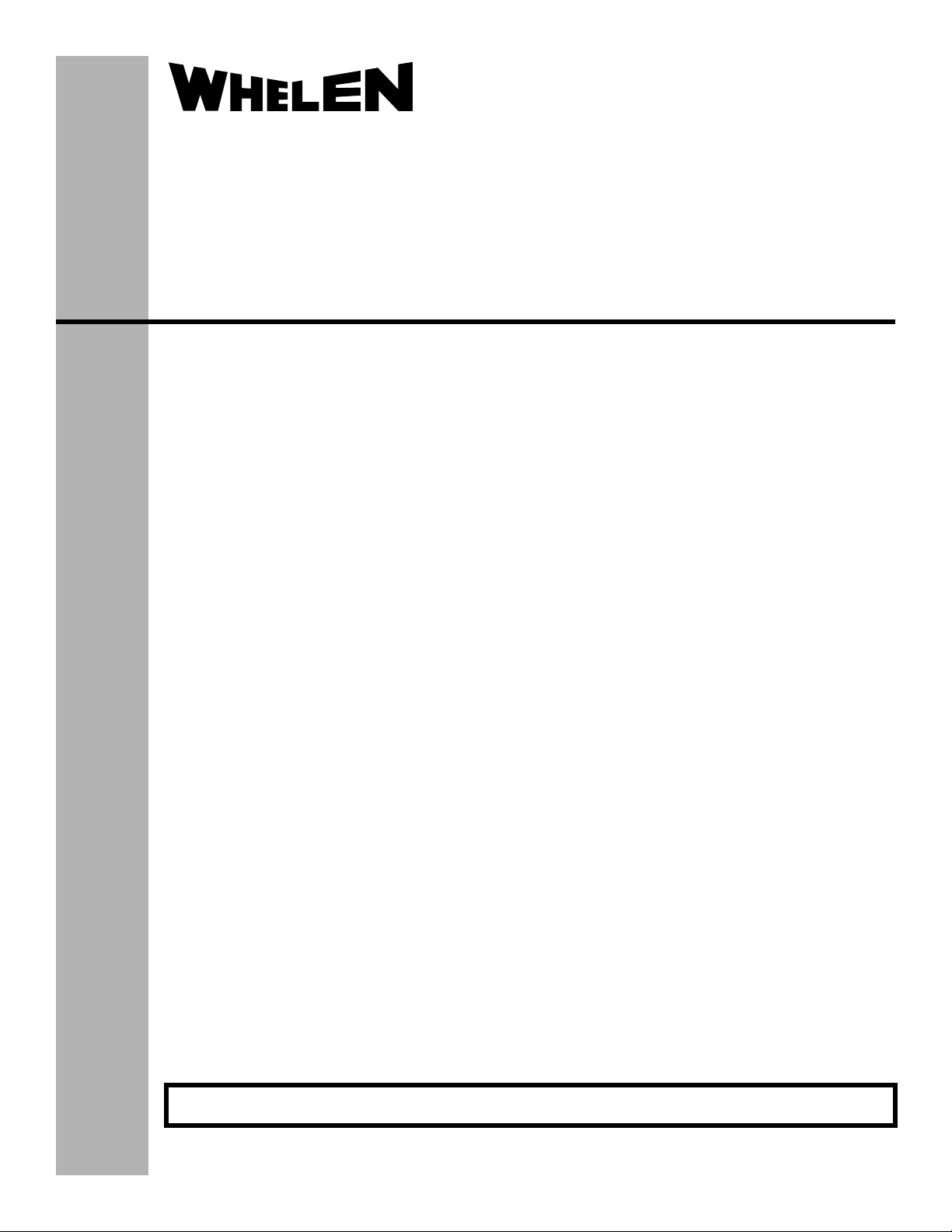

1. When the mounting location has been determined, slide the 2 mounting bolts

into the lightbar extrusion, one bolt in each track. Position these bolts so that

they are at opposite ends of the extrusion and as far appart as possible.

2. Place the lightbar on the vehicle in its proposed mounting location. Mark the

location of the 2 mounting bolts onto the mounting surface. Also, mark the area

for the wire passage hole. This hole should be located directly below where the

wires exit the extrusion.

3. Remove the lightbar and drill two, 5/16” dia. mounting holes and a 5/16” dia.

wire passage hole. De-burr all three holes and install a rubber grommet

(customer supplied) into the wire passage hole.

4. Route the wires through the grommet and to the necessary switches and

power source as shown in the diagram below.

5. Secure the Responder® to the vehicle using the hardware provided. From the

underside of the mounting surface, apply RTV around each mounting hole and

the grommeted wire passage hole to prevent water from entering these

openings.

Remove

screw

Lift lighthead

out to access

mounting

screws.

Permanent Mounting / Plastic Base

1.

1.

1.

2.

.

2

3.

.

3

.

3

.

3

4.

.

4

5

.

Remove

one end

cap

3/8-16 X 1-1/4"

STEP BOLT

3/8" FLAT

WASHER

3/8-16

HEX NUT

Remove the outer dome and the screws that hold

down the endcap lightheads

and lift the (2)

Install the #10 screws into the 4 mounting holes

to open up the holes.

Remove the screws, position the base on the

proposed mounting location then scribe the

mounting surface where the mounting holes are

to be drilled.

Remove the base and drill the 4 mounting holes

using a # drill .

Install the lightbar. Replace the lightheads & dome.

lightheads out.

16 bit

3/8" SPLIT

LOCK WASHER

(use a T-10 TORX bit)

Temporary Mount (Magnetic, Suction Cup, etc.):

WARNING: The use of any

magnetically mounted warning

device on the outside of a vehicle in

motion is not recommended and is at

the sole risk and responsibility of the

user.

Magnetic/suction: Thoroughly clean

the proposed mounting surface prior to

mounting. For suction cup mounting, wipe the suction cup clean, place the beacon

onto its mounting surface and apply gentle pressure to ensure a good seal has been

achieved. The Magnetic/Suction Cups mount the same way as standard suction

cups but are best suited to a flat, steel surface. Magnetic: Place lightbar onto the

mounting surface and plug it into the vehicle cigar lighter.

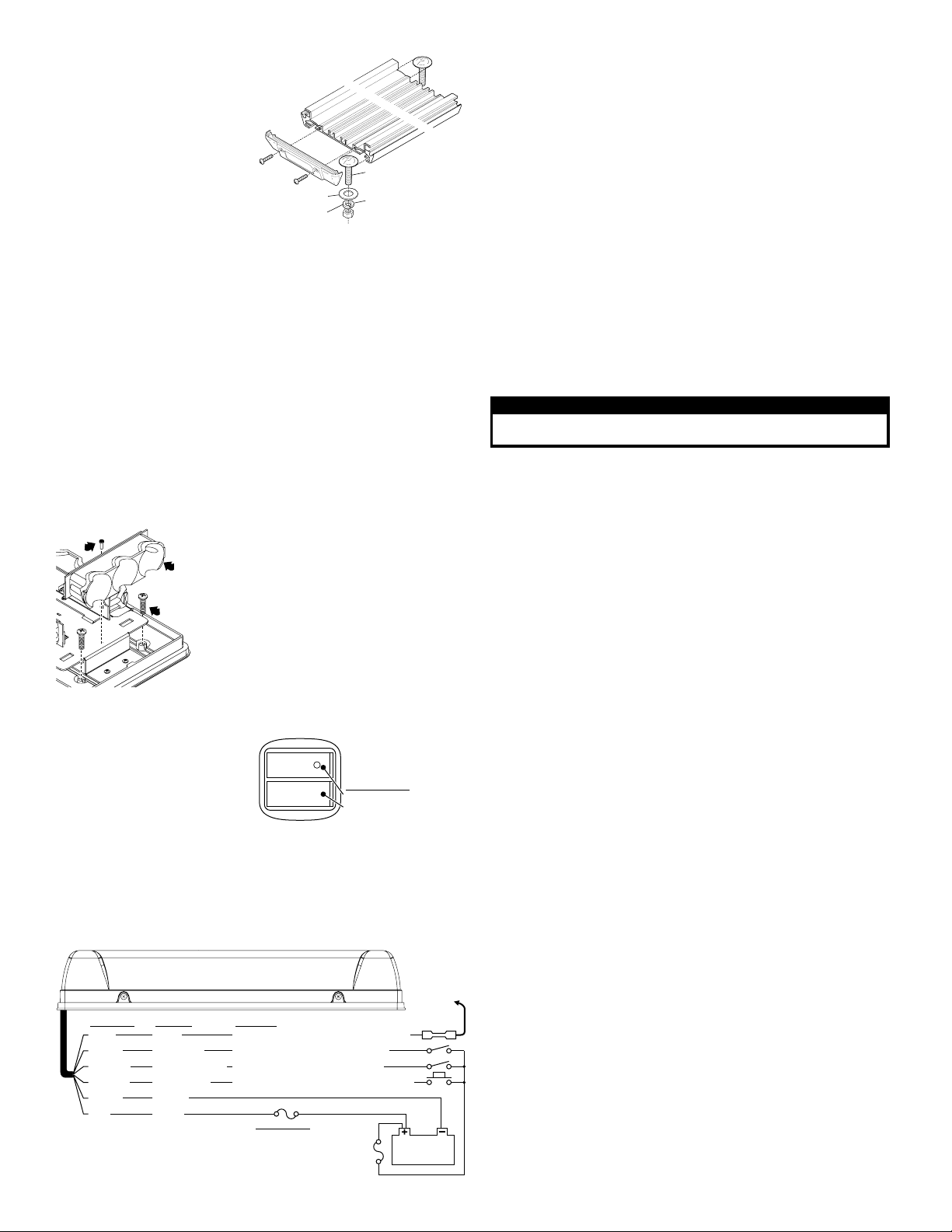

Wiring Diagram:

All models except R2LPQH (See page 3)

Responder® LP

Wire Color

GREY SYNC Networks with other SYNC-capable lights

VIOLET

ORANGE

WHT/VIO

BLACK

RED

NOTE:

All fuses and switches

are customer supplied

Function Operation

Low Power

Pattern Override

Scan-Lock™

Apply +VBATT for Low Power mode

Apply +VBATT for Pattern Override

Flash Pattern Selection (see pattern list)

Ground

Power

Fuse Values

24 Volt Models

R1LP***

R2LPH***

-5A

-5A

- 7.5A

NOTE: The cigar cord adaptor

is equipped with an 8 Amp fuse.

Use a replacement fuse with an

identical value.

Switch Functions:

SW1 = ON/OFF

SW2 = Scan-Lock™ / Momentary

(

12 volt model only

1A

Fuse

)

Connect to

GREY SYNC

wire from

another

SYNC light

BUTT SPLICE

12 24V/ V

Battery

Wiring:

WARNING! All customer supplied wires that connect to the positive terminal of

the battery must be sized to supply at least 125% of the maximum operating

current and FUSED at the battery to carry the load. DO NOT USE CIRCUIT

BREAKERS WITH THIS PRODUCT!

Scan-Lock™:

To operate Scan-Lock, switch the lightbar on. The Scan-Lock wire will be either

WHT/VIO or WHT (See wiring) Magnetic and Suction mount models use a

momentary switch on the cigar plug instead of a wire (12 volt only).

TO CHANGE PATTERNS: To cycle forward to the next pattern apply +VBAT to the

Scan-Lock wire (or switch) for less than 1 second and release. To cycle back to the

previous pattern apply +VBAT to Scan-Lock™ wire for over 1 second and release.

TO CHANGE THE DEFAULT PATTERN: When the desired pattern is displayed,

allow it to run for more than 5 seconds. The lighthead will now display this pattern

when initially activated.

TO RESTORE THE FACTORY DEFAULT PATTERN: With power off, apply +VBAT

to the Scan-Lock™ wire (or switch). While continuing to apply power to Scan-Lock

turn lighthead(s) on. The factory default pattern will be displayed.

A Normally Open momentary switch can be used to control Scan-Lock. See

below for available flash patterns.

IMPORTANT WARNING!

CAUTION! DO NOT LOOK DIRECTLY AT THESE LEDS WHILE THEY ARE ON.

MOMENTARY BLINDNESS AND/OR EYE DAMAGE COULD RESULT!

Available Flash Patterns:

1. ActionScan™

2. SignalAlert™ ALT

3. SignalAlert Sim)

4. SignalAlert (Alt/Sim)

5. CometFlash® (Alt)

6. CometFlash (Sim)

7. CometFlash (Alt-Sim)

8. DoubleFlash 75 (Alt)

9. DoubleFlash 75 (Sim)

10.DoubleFlash 75 (Alt-Sim)

11.SingleFlash 75 (Alt)

12.SingleFlash 75 (Sim)

13.SingleFlash 75 (Alt-Sim)

14.LongBurst™ (Alt)

15.LongBurst (Sim)

16.LongBurst (Alt-Sim)

17.SingleFlash 60 (Alt) CA

18.SingleFlash. 60 (Sim) CA

CA = Calif. Title XIII Com pliant Alt = Alternating Sim = Simultaneo us Alt-Sim = Alternating-Simultaneous

= SYNC

*

19.SingleFl. 60 (Alt-Sim) CA

20.SingleFlash 90 (Alt) CA

21.SingleFlash 90 (Sim) CA

22.SingleFl. 90 (Alt-Sim) CA

23.SingleFlash 120 (Alt) CA

*

24.SingleFlash 120 (Sim) CA

*

25.SingleFl. 120(Alt-Sim) CA

26.SingleFlash 240 (Alt)

*

27.SingleFlash 240 (Sim)

*

28.SingleFlash 240 (Alt-Sim)

29.MicroBurst™ (Alt)

*

30.MicroBurst (Sim)

*

31.MicroBurst (Alt-Sim)

32.ActionFlash™ (Alt)

*

33.ActionFlash (Sim)

*

34.ActionFlash (Alt-Sim)

35.PingPong™

36.FlimFlam (Alt.)

37.ModuFlash™ (Alt)

38.ModuFlash (Sim)

39.Steady 2.5%

40. Steady 4%

41.Steady 6%

42.Steady 8%

43.Steady 12%

44.Steady 40%

45.InOut

46.Sweep

47.LongBurst Sweep

48.InOut Blast

49.Sequence On/Off

50.ZigZag

51.Rotator 90

52.Rotator 120

53.Rotator 150

54.Rotator 250

Sync:

To SYNC two lightbars, configure both lightbars to display the same flash pattern.

With the power off, connect the GREY wire from each lightbar together. When the

lightbars are activated, their patterns will be synchronized. Only the flash patterns

designated for SYNC in the flash pattern list may be used.

Hi/Low Power:

Allows user to step the unit down to low power for nighttime use.

Latching Mode: By applying +VBAT to the VIOLET wire for less than 1 second, the

lightbar is “latched” into low power. The unit must be turned off and then back on to

restore normal high power operation (Momentary switch).

Level Mode: Applying +VBAT to the VIOLET wire for more than 1 second holds the

lightbar in low power mode until voltage is removed (Toggle switch).

Pattern Override:

Applying +VBAT to the ORANGE wire while lightheads are activated, will change the

flash pattern to whatever pattern override is programmed for. To program the flash

pattern activate the lightbar then activate pattern override by applying +VBAT to the

ORANGE wire and select a flash pattern using Scan-Lock.

IMPORTANT! It is the responsibility of the installation technician to make sure

that the installation and operation of this product will not interfere with or

compromise the operation or efficiency of any vehicle equipment! Before

returning the vehicle to active service, visually confirm the proper operation of

this product, as well as all vehicle components/equipment.

Page 2

Page 3

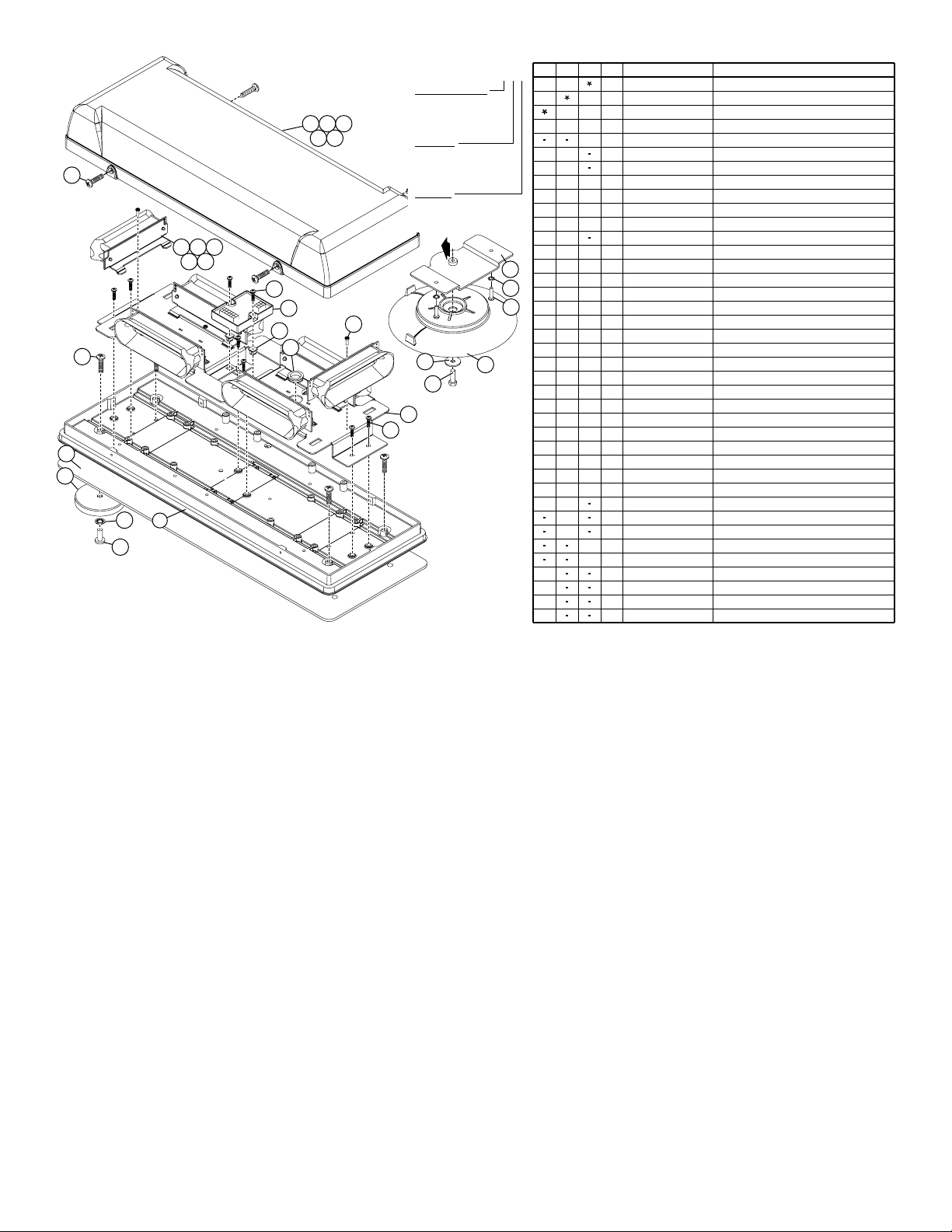

ITEM PART NUMBER DESCRIPTION

1

1

22

717

212

11

11

A/R

A/R

A/R

A/R

A/R

A/R

A/R

A/R

66

121

1

A/R

A/R

A/R

A/R

A/R

A/R

A/R

A/R

A/R

A/R

44

4

4

4

1

2

1

3

4

5

6

1

7

8

9

10

11

12

13

14

15

16

17

18

19

2

20

1

21

22

23

24

25

26

27

28

29

30

31

4

32

1

33

34

35

36

01-0684791__P

01-0684791__M

01-0684791__V

11-381890-000

46-076A219-00

02-0243725-00

46-0743503-00

13-062C40-16J

26-0115037-04

15-081416-060

26-0215001-06

39-0403023-04

11-386602-000

21-11263204-0

01-026A518-11

01-026A518-21

01-026A518-31

01-026A518-41

01-026A518-51

14-040285-063

01-026A213-00

15-081416-080

46-076A239-00

26-0215001-03

68-2986619-10

68-2986619-20

68-2986619-30

68-2986619-40

68-2986619-50

15-061416-080

15-101416-100

16-1021220-45

65-0010191-00

15-101416-160

38-026A402-00

14-130436-120

16-1302820-06

08-1583927-05

07-76A350-023

RESPONDER LP, PERMANENT MT

RESPONDER LP, MAGNET MT

RESPONDER LP, SUCTION MT

BASE, HOUSING RESPONDER 2

HARNESS INPUT RESPONDER LP

CORD, CIGAR PLUG DUAL SWITCH

HARNESS INPUT POW CORD DUAL SW LP. RSPNDR

SCREW GROMMET, #6/#8 FASTEX FASTEX

CABLE CLAMP, 1/4"D, 3/8"W .203" MTG HOLE, BLK

SCREW, 8 X 3/8 PPHSMS 410 SS TYPE A

TY WRAP, 6" BLACK

HOUSING, 3 POS SOCKET COMM MATE-N-LOK

BASE, MTG LIGHTHEADS LPRSPNDR

GROMMET, 1" SLIM LINE

LIN6 LED 12V AMB JUSTICE CREE

LIN6 LED 12V BLU JUSTICE CREE

LIN6 LED 12V WHT JUSTICE CREE

LIN6 LED 12V GRN JUSTICE CREE

LIN6 LED 12V RED JUSTICE CREE

SCREW, 4-40 X 3/8 TORX PH TRLBLR 410 SS, BLK OX.

ASS'Y, PCB RESPONDER FLASHER 6 CHANNEL

SCREW, 8 X 1/2 PPHSMS 410 SS

ASS'Y, HARNESS 6 OUTPUT RESPONDER LP

TY WRAP, 3" BLACK

DOME, AMB NO OPTIC LP no MTG DETAILRSPNDR

DOME, BLU NO OPTIC LP MTG DETAILRSPNDR no

DOME, CLR NO OPTIC LP MTG DETAILRSPNDR no

DOME, GRN NO OPTIC LP MTG DETAILRSPNDR no

DOME, RED NO OPTIC LP MTG DETAILRSPNDR no

SCREW, 6 X 3/8 PPH PLASTI LOK

SCREW, 10 X 5/8 PPHSMS 410 SS

WASHER, #10 INT TOOTH LOCK SS

MAGNET, X-50 (RB-50) NICKLE PLATEDRSPNDR

SCREW, 10 X 1 PPHSMS TYPE A

GASKET, MOUNTING RESPONDER 2

SCREW, 1/4-20 X 3/4" HEX HD MS SS

WASHER, FLAT 1/4" 7/8 OD SS 17/64 ID .056-.070" THK

SUCTION CUP, MAGNET MOUNT

PLATE, ADAPTR MAG/SUC. MT BLACK RSPNDR LP

36

29

28

QTY QTY QTY

1 1 1

1

1

2

1

7

2

1

1

1

A/R A/RA/R

A/R

A/R

A/R

A/R

6

1

2

1

A/R

A/R A/RA/R

A/R

A/R

A/R

A/R

RESPONDER LP

LINEAR 6 LED

22

23

24

25

26

27

12

13

14

15

16

01-0684791___

OUTER DOME COLOR

A=

AMBER

B=

BLUE

C=

CLEAR

G=

GREEN

R=

RED

LED COLOR

1=

AMBER

2=

BLUE

3=

WHITE

4=

GREEN

5=

RED

MOUNTING

P=

PERMANENT

M=

MAGNET

V=

MAGNET/SUCTION

CUP MOUNTV=

TOWARD

CENTER

19

18

5

31

11

17

34

35

33

10

7

32

30

4

4

1

29

28

2

2

2

2

Page 3

Page 4

44

32 30

26

25

24

QTY QTY QTY

29

3133

46

27

34

46

18

16

14

15

17

21

13

20

19

12

9

21

7

28

1

1

1

1

9

1

7

2

1

1

1

A/R

A/R

A/R

A/R

6

2

1111

A/R

4

2

4

2

A/R

A/R

A/R

A/R A/RA/R

A/R

4

3

45

2

2

2

4

2

2

11

RESPONDER LP

HEAVY DUTY

3 CONICAL LED

01-0684742___

41

42

43

37

39

38

36

35

ITEM PART NUMBER DESCRIPTION

1

1

1

1

9

1

7

2

1

1

1

A/R

A/R

A/R

A/R

6

1

2

A/R

4

2

4

2

A/R

A/R

A/R

A/R

4

4

4

4

4

A/R

2 2

1

1

1

9

1

7

2

1

1

A/R

A/R

A/R

A/RA/RA/R

A/R

6

1

2

A/R

4

2

4

2.662.662.66

2

A/R

A/R

A/R

A/R

4

1

01-0684742__P

01-0684742__M

01-0684742__V

11-36D115-002

1

11-36D115-001

2

21-11101610-0

3

46-076A219-00

4

5

02-0243725-00

46-0743503-00

6

7

13-062C40-16J

26-0115037-04

8

15-081416-060

9

26-0215001-06

10

39-0403023-04

11

11-386602-000

12

21-11263204-0

13

01-026B568-10

14

01-026B568-20

15

01-026B568-30

16

01-026B568-40

17

01-026B568-50

18

14-040285-063

19

01-026A213-00

20

15-081416-080

21

46-076A239-00

22

26-0215001-03

23

21-1706090300

24

25

11-282151-000

14-0023347-00

26

27

38-0541780-00

28

38-0143763-00

29

68-2986618-10

68-2986618-20

30

68-2986618-30

31

68-2986618-40

32

68-2986618-50

33

15-061416-080

34

01-0441771-02

35

14-130216-100

36

16-1321560-02

37

65-0010192-00

38

08-0640834-01

39

66-0715403-00

40

14-130436-120

41

16-1302820-06

42

08-1583927-05

43

14-130536-12K

44

45

07-764726-023

10-0523326-00

46

10-0322783-02

47

RESPONDER LP, HEAVY DUTY, PERM. MT

RESPONDER LP, HEAVY DUTY, MAG MT

RESPONDER LP, HEAVY DUTY, SUC MT

BASE 15.88" MACH. no RIVNUTS LP RSPNDR

BASE 15.88" MACH. RIVNUTS LP RSPNDR

GROMMET, 5/16 ID X 1/2 HOLE

ASS'Y, HARNESS INPUT RESPONDER LP

CORD, CIGAR PLUG DUAL SWITCH

HARNESS INPUT PWR CRD DUAL SW LPRSPND

SCREW GROMMET, #6/#8 FASTEX FASTEX

CAB. CLAMP, 1/4"D, 3/8"W .203" MT. HOLE, BLK

SCREW, 8 X 3/8 PPHSMS 410 SS TYPE A

TY WRAP, 6" BLACK

HOUSING, 3 POS SOCKET COMM MATE-N-LOK

BASE, MTG LIGHTHEADS RESPONDER LP

GROMMET, 1" SLIM LINE

SUB ASSY, CON3 HINGE AMB AMP JUSTICE

SUB ASSY, CON3 HINGE BLU AMP JUSTICE

SUB ASSY, CON3 HINGE WHT AMP JUSTICE

SUB ASSY, CON3 HINGE GRN AMP JUSTICE

SUB ASSY, CON3 HINGE RED AMP JUSTICE

SCREW, 4-40 X 3/8 TORX PH TRLBLR 410 SS, BLK OX.

PCB RESPONDER FLASHER 6 CHANNEL

SCREW, 8 X 1/2 PPHSMS 410 SS

ASS'Y, HARNESS 6 OUTPUT LPRSPNDR

TY WRAP, 3" BLACK

GROMMET, #6/#8 .265-.286 HOLE, .030 HD HT

ENDCAP, CVR EXTRUSION ECONO LTBAR

SCREW, 10-24 X 1.25" TX PHD SWEDGE FM

GASK, .25 CORD EPDM SPONGE ECONO BAR

GASKET, DOME ENDCAP RESPONDER LP

DOME, AMB OPTIC LP no MTG DETAILRSPNDR

DOME, BLU OPTIC LP no MTG DETAILRSPNDR

DOME, CLR OPTIC LP no MTG DETAILRSPNDR

DOME, GRN OPTIC LP no MTG DETAILRSPNDR

DOME, RED OPTIC LP no MTG DETAILRSPNDR

SCREW, 6 X 1/2 PPHSMS SS TYPE A

KIT, EXTR STEP BOLT MT 1-1/4" AUTOBWL FEED.

SCREW, 1/4-20 X 5/8 PPHMS

WASHER, 1/4 INTRNAL TOOTH LOCK

MAG., X-80 NEW DMS RB80) NICKLE PLATE

PAD, MTG, MAG MT W/.406 DIATHRU HOLE

THREADLOCKER, 242 LOCTITE

SCREW, 1/4-20 X 3/4" HEX HD MS SS

WSHR, FLT 1/4" 7/8 OD SS 17/64 ID .056-.070" THK

SUCTION CUP, MAGNET MOUNT

SCREW, 1/4-20 X 3/4 SKT HD SET NECK POINT SS

PLATE, ADAPT MAG/SUC CUP MINI LTBAR

LABEL, M/N RESPONDER LP SERIES

LABEL, AIRBAG & MAG MT WARNING

OUTER DOME COLOR

A=

AMBER

B=

BLUE

C=

CLEAR

G=

GREEN

R=

RED

LED COLOR

1=

AMBER

2=

BLUE

3=

WHITE

4=

GREEN

5=

RED

MOUNTING

P=

PERMANENT

M=

MAGNET

V=

MAGNET/SUCTION

CUP MOUNTV=

Page 4

Page 5

QTY QTY QTY

11

1

1

1

1

2

22

1

717

7

2 2

2

1

1

11

1

11

1

A/R A/R A/R

A/R

A/R

A/R

A/R

A/R

A/R

A/R

A/R

A/R

A/R

A/R

A/R

66

6

121

1

2

1

11

A/R

A/R

A/R

A/R A/R A/R

A/R

A/R

A/R

A/R

A/R

A/R

A/R

A/R

A/R

A/R

A/R

A/R

4

4

4

4

4

2

2

2

2

2

2

1

1

11

1

ITEM PART NUMBER DESCRIPTION

1

1

1

2

3

4

5

6

1

7

8

9

10

11

12

13

14

15

16

17

18

19

2

20

21

22

23

24

25

26

44

27

28

29

30

31

4

32

1

33

34

35

36

37

2

38

39

01-0684730__P

01-0684730__M

01-0684730__V

11-381890-000

46-076A219-00

02-0243725-00

46-0743503-00

13-062C40-16J

26-0115037-04

15-081416-060

26-0215001-06

39-0403023-04

11-386602-000

21-11263204-0

01-026B568-10

01-026B568-20

01-026B568-30

01-026B568-40

01-026B568-50

14-040285-063

01-026A213-00

15-081416-080

46-076A239-00

26-0215001-03

68-2986618-10

68-2986618-20

68-2986618-30

68-2986618-40

68-2986618-50

15-061416-080

15-101416-100

16-1021220-45

65-0010191-00

15-101416-160

38-026A402-00

14-130436-120

16-1302820-06

08-1583927-05

07-76A350-023

10-0523326-00

10-0322783-02

10-0523370-__

RESPONDER LP, PERMANENT MT

RESPONDER LP, MAGNET MT

RESPONDER LP, SUCTION MT

BASE, HOUSING RESPONDER 2

HARNESS INPUT LPRSPNDR

CORD, CIGAR PLUG DUAL SWITCH

HARNESS INPUT POW. CORD DUAL SW RSPNDR LP

SCREW GROMMET, #6/#8 FASTEX

CABLE CLAMP, 1/4"D, 3/8"W .203" MTG HOLE, BLACK

SCREW, 8 X 3/8 PPHSMS 410 SS TYPE A

TY WRAP, 6" BLACK

HOUSING, 3 POS SOCKET COMM MATE-N-LOK

BASE, MTG LIGHTHEADS RESPONDER LP

GROMMET, 1" SLIM LINE

SUB ASSY, CON3 HINGE AMB AMP JUSTICE

SUB ASSY, CON3 HINGE BLUE AMP JUSTICE

SUB ASSY, CON3 HINGE WHITE AMP JUSTICE

SUB ASSY, CON3 HINGE GREEN AMP JUSTICE

SUB ASSY, CON3 HINGE RED AMP JUSTICE

SCREW, 4-40 X 3/8 TORX PH TRLBLR 410 SS, BLK OX.

PCB RESPONDER FLASHER 6 CHANNEL

SCREW, 8 X 1/2 PPHSMS 410 SS

HARNESS 6 OUTPUT RESPONDER LP

TY WRAP, 3" BLACK

DOME, AMB OPTIC LP W/O MTG DETAILSRSPNDR

DOME, BLU OPTIC LP W/O MTG DETAILSRSPNDR

DOME, CLR OPTIC LP W/O MTG DETAILSRSPNDR

DOME, GRN OPTIC LP W/O MTG DETAILSRSPNDR

DOME, RED OPTIC LP W/O MTG DETAILSRSPNDR

SCREW, 6 X 3/8 PPH PLASTI LOK

SCREW, 10 X 5/8 PPHSMS 410 SS

WASHER, #10 INT TOOTH LOCK STAINLESS STEEL

MAGNET, X-50 (RB-50) NICKLE PLATEDRSPNDR

SCREW, 10 X 1 PPHSMS TYPE A

GASKET, MOUNTING RESPONDER 2

SCREW, 1/4-20 X 3/4" HEX HD MS SS

WASHER, FLAT 1/4" 7/8 OD SS 17/64 ID .056-.070" THK

SUCTION CUP, MAGNET MOUNT

PLATE, ADAPTER MAG/SUC MT BLK LP. RSPNDR

LABEL, M/N RESPONDER LP SERIES

LABEL, AIRBAG & MAG MT WARNING

LABEL, MODEL / SERIAL NUMBER

36

29

28

35

34

33

RESPONDER LP

CONICAL 3 LED

01-0684730___

OUTER DOME COLOR

A=

AMBER

B=

BLUE

C=

CLEAR

G=

GREEN

R=

RED

LED COLOR

1=

AMBER

2=

BLUE

3=

WHITE

4=

GREEN

5=

RED

MOUNTING

P=

PERMANENT

M=

MAGNET

V=

MAGNET/SUCTION

CUP MOUNTV=

23 26

25

2422

37

27

37

17

13

12

161415

19

18

5

31

11

10

7

32

30

1

29

28

Page 5

Page 6

QTY QTY QTY

1

1

1

1

9

1

7

2

1

1

1

A/R

A/R

A/R

A/R

6

1

2

11 1

A/R

4

2

4

2

A/R

A/R

A/R

A/R A/RA/R

A/R

4

2

2

2

4

2

2

11

HEAVY DUTY LINEAR 6

ITEM PART NUMBER DESCRIPTION

1

1

2

1

3

1

1

4

1

5

1

6

1

7

9

9

8

1

1

9

7

7

10

2

2

11

1

1

12

1

13

1

1

A/R

A/R

A/R

A/R

A/R

14

15

A/R

16

A/R

A/RA/RA/R

17

18

A/R

19

6

6

20

1

1

21

2

2

22

23

A/R

A/R

4

4

24

25

2

2

26

4

4

2.662.662.66

27

28

2

2

A/R

A/R

A/R

29

30

31

A/R

A/R

A/R

32

A/R

A/R

34

4

4

35

1

36

4

37

4

38

4

39

4

40

33

A/R

41

42

43

44

45

46

2

2

47

RESPONDER LP

01-0684792___

01-0684792__P

01-0684792__M

01-0684792__V

11-36D115-002

11-36D115-001

21-11101610-0

46-076A219-00

02-0243725-00

46-0743503-00

13-062C40-16J

26-0115037-04

15-081416-060

26-0215001-06

39-0403023-04

11-386602-000

21-11263204-0

01-026A518-11

01-026A518-21

01-026A518-31

01-026A518-41

01-026A518-51

14-040285-063

01-026A213-00

15-081416-080

46-076A239-00

26-0215001-03

21-1706090300

11-282151-000

14-0023347-00

38-0541780-00

38-0143763-00

68-4986619-10

68-4986619-20

68-4986619-30

68-4986619-40

68-4986619-50

15-061416-080

01-0441771-02

14-130216-100

16-1321560-02

65-0010192-00

08-0640834-01

66-0715403-00

14-130436-120

16-1302820-06

08-1583927-05

14-130536-12K

07-764726-023

10-0523326-00

10-0322783-02

OUTER DOME COLOR

A=

B=

C=

G=

R=

RESPONDER LP, HEAVY DUTY, PERMANENT MT

RESPONDER LP, HEAVY DUTY, MAGNET MT

RESPONDER LP, HEAVY DUTY, SUCTION MT

BASE, 15.88" MACHINED no RIVNUTS LP RESP.

BASE, 15.88" MACHINED RIVNUTS LP RESP.

GROMMET, 5/16 ID X 1/2 HOLE

ASS'Y, HARNESS INPUT RESPONDER LP

CORD, CIGAR PLUG DUAL SWITCH

HARNESS INPUT POWER / DUAL SW RSPNDR LP

SCREW GROMMET, #6/#8 FASTEX FASTEX

CABLE CLAMP, 1/4"D, 3/8"W .203" MTG HOLE, BLK

SCREW, 8 X 3/8 PPHSMS 410 SS TYPE A

TY WRAP, 6" BLACK

HOUSING, 3 POS SOCKET COMM MATE-N-LOK

BASE, MTG LIGHTHEADS RESPONDER LP

GROMMET, 1" SLIM LINE

LIN6 LED 12V AMBER JUSTICE CREE

LIN6 LED 12V BLUE JUSTICE CREE

LIN6 LED 12V WHITE JUSTICE CREE

LIN6 LED 12V GREEN JUSTICE CREE

LIN6 LED 12V RED JUSTICE CREE

SCREW, 4-40 X 3/8 TORX PH TRLBLR 410 SS, BLK OX.

PCB RESPONDER FLASHER 6 CHANNEL

SCREW, 8 X 1/2 PPHSMS 410 SS

ASS'Y, HARNESS 6 OUTPUT RESPONDER LP

TY WRAP, 3" BLACK

GROMMET, #6/#8 .265-.286 HOLE, .030 HD HT

ENDCAP, COVER EXTRUSION ECONOMY LTBAR

SCREW, 10-24 X 1.25" TX PHD SWEDGE FORM

GASKET, .25 CORD EPDM SPONGE ECONO BAR

GASKET, DOME ENDCAP RESPONDER LP

DOME, AMB NON OPTIC RSPNDR LP no MTG DETAIL

DOME, BLU NON OPTIC MTG DETAILRSPNDR LP no

DOME, CLR NON OPTIC MTG DETAILRSPNDR LP no

DOME, GRN NON OPTIC MTG DETAILRSPNDR LP no

DOME, RED NON OPTIC MTG DETAILRSPNDR LP no

SCREW, 6 X 1/2 PPHSMS SS TYPE A

KIT, EXTR STEP BOLT MT 1-1/4" AUTOBOWL FEEDER

SCREW, 1/4-20 X 5/8 PPHMS

WASHER, 1/4 INTRNAL TOOTH LOCK

MAGNET, X-80 NEW DMS (RB80) NICKLE PLATED

PAD, MTG, MAG MOUNT W/.406 DIATHRU HOLE

THREADLOCKER, 242 LOCTITE

SCREW, 1/4-20 X 3/4" HEX HD MS SS

WASHER, FLAT 1/4" 7/8 OD SS 17/64 ID .056-.070" THK

SUCTION CUP, MAGNET MOUNT

SCREW, 1/4-20 X 3/4 SKT HD SET NECK W/POINT SS

PLATE, ADAPTER MAG/SUCTION CUP MINI LTBAR

LABEL, M/N RESPONDER LP SERIES

LABEL, AIRBAG & MAG MT WARNING

AMBER

BLUE

CLEAR

GREEN

RED

LED COLOR

1=

2=

3=

4=

5=

AMBER

BLUE

WHITE

GREEN

RED

MOUNTING

P=

PERMANENT

M=

MAGNET

V=

MAGNET/SUCTION

CUP MOUNTV=

46

34

46

18

16

14

17

15

3133

21

13

20

27

29

32 30

19

26

12

6

25

24

1

2

45

3

7

28

44

39

35

43

41

42

37

38

36

Page 6

Page 7

QTY QTY QTY

ITEM PART NUMBER DESCRIPTION

01-0686095__P

01-0686095__M

01-0686095__V

1

1

A/R

A/R

A/R

A/R

2

1

A/R

A/R

A/R

A/R

A/R

4

1

11-381890-000

1

46-076A219-00

2

02-0243725-00

3

46-0743503-00

4

5

13-062C40-16J

26-0115037-04

6

15-081416-060

7

26-0215001-06

8

39-0402023-04

9

11-386602-000

10

21-11263204-0

11

01-026A518-12

12

01-026A518-22

13

01-026A518-32

14

01-026A518-42

15

01-026A518-52

16

14-040285-063

17

01-026A899-00

18

15-081416-080

19

46-076A239-00

20

26-0215001-03

21

68-2986619-10

22

68-2986619-20

23

68-2986619-30

24

25

68-2986619-40

68-2986619-50

26

27

15-061416-080

28

15-101416-100

29

16-1021220-45

65-0010191-00

30

15-101416-160

31

38-026A402-00

32

14-130436-120

33

16-1302820-06

34

08-1583927-05

35

07-76A350-023

36

1 1 1

1

1

1

1

2

22

1

7

717

2

212

1

1

11

1

11

A/R A/RA/R

A/R

A/R

A/R

A/R

A/R

A/R

A/R

A/R

66

6

121

1

2

1

1

A/R

A/R

A/R A/RA/R

A/R

A/R

A/R

A/R

A/R

A/R

A/R

A/R

4

44

4

4

4

4

2

2

2

2

RESPONDER LP

HEAVY DUTY LINEAR 6

01-0686095___

OUTER DOME COLOR

A=

AMBER

B=

BLUE

C=

CLEAR

G=

GREEN

R=

RED

LED COLOR

1=

AMBER

2=

BLUE

3=

WHITE

4=

GREEN

5=

RED

MOUNTING

P=

PERMANENT

M=

MAGNET

V=

MAGNET/SUCTION

CUP MOUNTV=

RESPONDER LP, PERMANENT MT

RESPONDER LP, MAGNET MT

RESPONDER LP, SUCTION MT

BASE, HOUSING RESPONDER 2

HARNESS INPUT RESPONDER LP

CORD, CIGAR PLUG DUAL SWITCH

HARNESS INPUT POW. CORD DUAL SW RSPNDR LP

SCREW GROMMET, #6/#8 FASTEX

CABLE CLAMP, 1/4"D, 3/8"W .203" MTG HOLE, BLK

SCREW, 8 X 3/8 PPHSMS 410 SS TYPE A

TY WRAP, 6" BLACK

HOUSING, 2 POS SOCKET COMM MATE-N-LOK

BASE, MTG LIGHTHEADS RESPONDER LP

GROMMET, 1" SLIM LINE

LIN6 LED 24V AMB JUSTICE CREE

LIN6 LED 24V BLU JUSTICE CREE

LIN6 LED 24V WHT JUSTICE CREE

LIN6 LED 24V GRN JUSTICE CREE

LIN6 LED 24V RED JUSTICE CREE

SCREW, 4-40 X 3/8 TORX PH TRLBLR 410 SS, BLK OX.

PCB FLASHER 6 CHANNELRSPNDR

SCREW, 8 X 1/2 PPHSMS 410 SS

HARNESS 6 OUTPUT RESPONDER LP

TY WRAP, 3" BLACK

DOME, AMB NO-OPTIC LP no MTG DETAILSRSPNDR

DOME, BLU NO-OPTIC LP MTG DETAILSRSPNDR no

DOME, CLR NO-OPTIC LP MTG DETAILSRSPNDR no

DOME, GRN NO-OPTIC LP MTG DETAILSRSPNDR no

DOME, RED NO-OPTIC LP MTG DETAILSRSPNDR no

SCREW, 6 X 3/8 PPH PLASTI LOK

SCREW, 10 X 5/8 PPHSMS 410 SS

WASHER, #10 INT TOOTH LOCK STAINLESS STEEL

MAGNET, X-50 (RB-50) NICKLE PLATEDRSPNDR

SCREW, 10 X 1 PPHSMS TYPE A

GASKET, MOUNTING RESPONDER 2

SCREW, 1/4-20 X 3/4" HEX HD MS SS

WASHER, FLAT 1/4" 7/8 OD SS 17/64 ID .056-.070" THK

SUCTION CUP, MAGNET MOUNT

PLATE, ADAPT MAG/SUC MT BLK LP. RSPNDR

TOWARD

CENTER

36

29

28

38

34

33

23

24

22

25

26

27

13

14

12

15

16

19

18

5

17

11

31

10

7

1

30

29

28

32

40

39

36

37

Page 7

Loading...

Loading...