Page 1

®

ENGINEERING COMPANY INC.

51 Winthrop Road

Chester, Connecticut 06412-0684

Phone: (860) 526-9504

Installation Guide:

Raider™ LED Lightbar

(Single Lighthead)

Fax: (860) 526-4078

Internet: www.whelen.com

Sales e-mail: autosale@whelen.com

Canadian Sales e-mail: autocan@whelen.com

Customer Service e-mail: custserv@whelen.com

Safety First

This document provides all the necessary information to allow your Whelen product to be properly and safely installed.

Before beginning the installation and/or operation of your new product, the installation technician and operator must

read this manual completely. Important information is contained herein that could prevent serious injury or damage.

• Proper installation of this product requires the installer to have a good understanding of automotive electronics,

systems and procedures.

• If mounting this product requires drilling holes, the installer MUST be sure that no vehicle components or other

vital parts could be damaged by the drilling process. Check both sides of the mounting surface before drilling

begins. Also de-burr any holes and remove any metal shards or remnants. Install grommets into all wire

passage holes.

• If this manual states that this product may be mounted with suction cups, magnets, tape or Velcro®, clean the

mounting surface with a 50/50 mix of isopropyl alcohol and water and dry thoroughly.

• Do not install this product or route any wires in the deployment area of your air bag. Equipment mounted or

located in the air bag deployment area will damage or reduce the effectiveness of the air bag, or become a

projectile that could cause serious personal injury or death. Refer to your vehicle owner’s manual for the air bag

deployment area. The User/Installer assumes full responsibility to determine proper mounting location, based

on providing ultimate safety to all passengers inside the vehicle.

• For this product to operate at optimum efficiency, a good electrical connection to chassis ground must be

made. The recommended procedure requires the product ground wire to be connected directly to the NEGATIVE

(-) battery post.

• If this product uses a remote device to activate or control this product, make sure that this control is located in

an area that allows both the vehicle and the control to be operated safely in any driving condition.

• Do not attempt to activate or control this device in a hazardous driving situation.

• This product contains either strobe light(s), halogen light(s), high-intensity LEDs or a combination of these

lights. Do not stare directly into these lights. Momentary blindness and/or eye damage could result.

• Use only soap and water to clean the outer lens. Use of other chemicals could result in premature lens cracking

(crazing) and discoloration. Lenses in this condition have significantly reduced effectiveness and should be

replaced immediately. Inspect and operate this product regularly to confirm its proper operation and mounting

condition. Do not use a pressure washer to clean this product.

• It is recommended that these instructions be stored in a safe place and referred to when performing

maintenance and/or reinstallation of this product.

• FAILURE TO FOLLOW THESE SAFETY PRECAUTIONS AND INSTRUCTIONS COULD RESULT IN DAMAGE TO

THE PRODUCT OR VEHICLE AND/OR SERIOUS INJURY TO YOU AND YOUR PASSENGERS!

Automotive: Lightbars

For warranty information regarding this product, visit www.whelen.com/warranty

©2007 Whelen Engineering Company Inc.

Form No.14089D (050510)

Page 1

Page 2

Specifications:

Input Voltage: 12.8 VDC +/- 20%

Input Current: Peak - 400ma / Avg - 160ma

Sync Phase: Phase I & II @ 400ms

Input Scan-Lock™: +12 VDC

Installation:

IMPORTANT! The lightbar should be located a minimum of

16" from any radio antennas!

Note: When routing wires, it is

important that you choose a

path that will keep the wires

away from any excessive heat

or any vehicle equipment that

could compromise the integrity

of the wires (ex. trunk lids, door

jams, etc.).

Caution: Permanent mounting

of this product will require

drilling. It is absolutely

necessary to make sure that no

other vehicle components

could be damaged by this

process. Check both sides of

the mounting surface before starting. If damage is likely, select a

different mounting location.

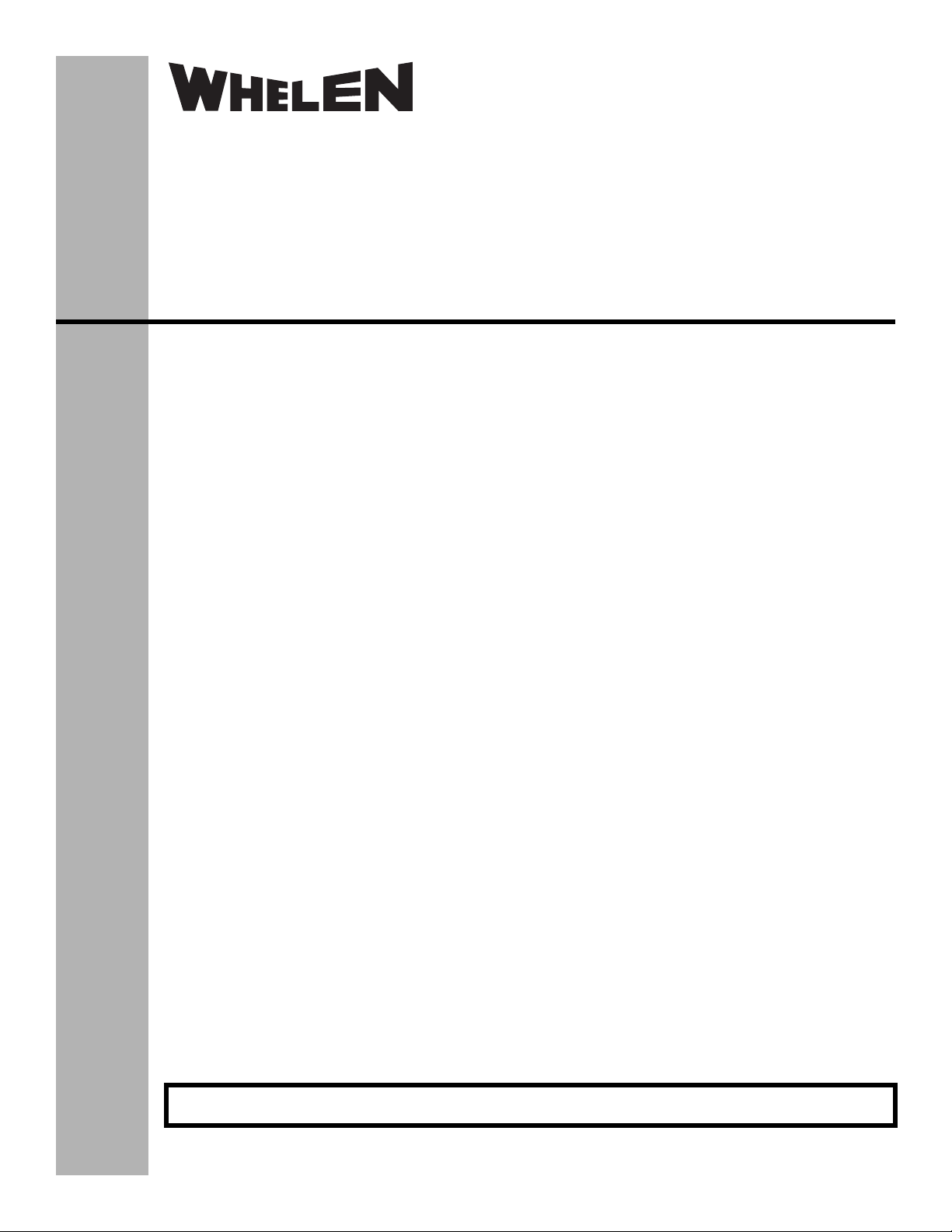

1. Position the unit in its proposed mounting location. Draw a pencil

line onto the mounting surface along the top and bottom of the

extrusion and a “centerline” centered between the two.

2. Two 1/4” holes are required to mount this unit. These holes may

be located anywhere along the horizontal centerline that you drew

in step one. It’s best to locate the holes as far apart as possible.

Mark the hole location onto the mounting surface.

3. Using a 1/4” drill bit, drill a hole in the areas scribed in step 2.

4. Insert the two hex-head mounting bolts (included) into one of the 3

channels in the housing. There is a hole in each channel.

5. Align these bolts with the 2 mounting holes and insert them into

the mounting holes.

6. Install an elastic stop nut onto each bolt and tighten firmly.

Extrusion end view (without end cap)

MOUNTING

SURFACE

Mount to any 1

of 3 channels

in the extrusion

MOUNTING

SURFACE

#10-24

X3/4"

HEX

HEAD

(

)

QTY 2

Wiring: Refer to the wiring diagram on the next page.

WARNING: All customer supplied wires that connect to the positive

terminal of the battery must be sized to supply at least 125% of the

maximum operating current and FUSED

at the battery to carry that

load. DO NOT USE CIRCUIT BREAKERS WITH THIS PRODUCT!

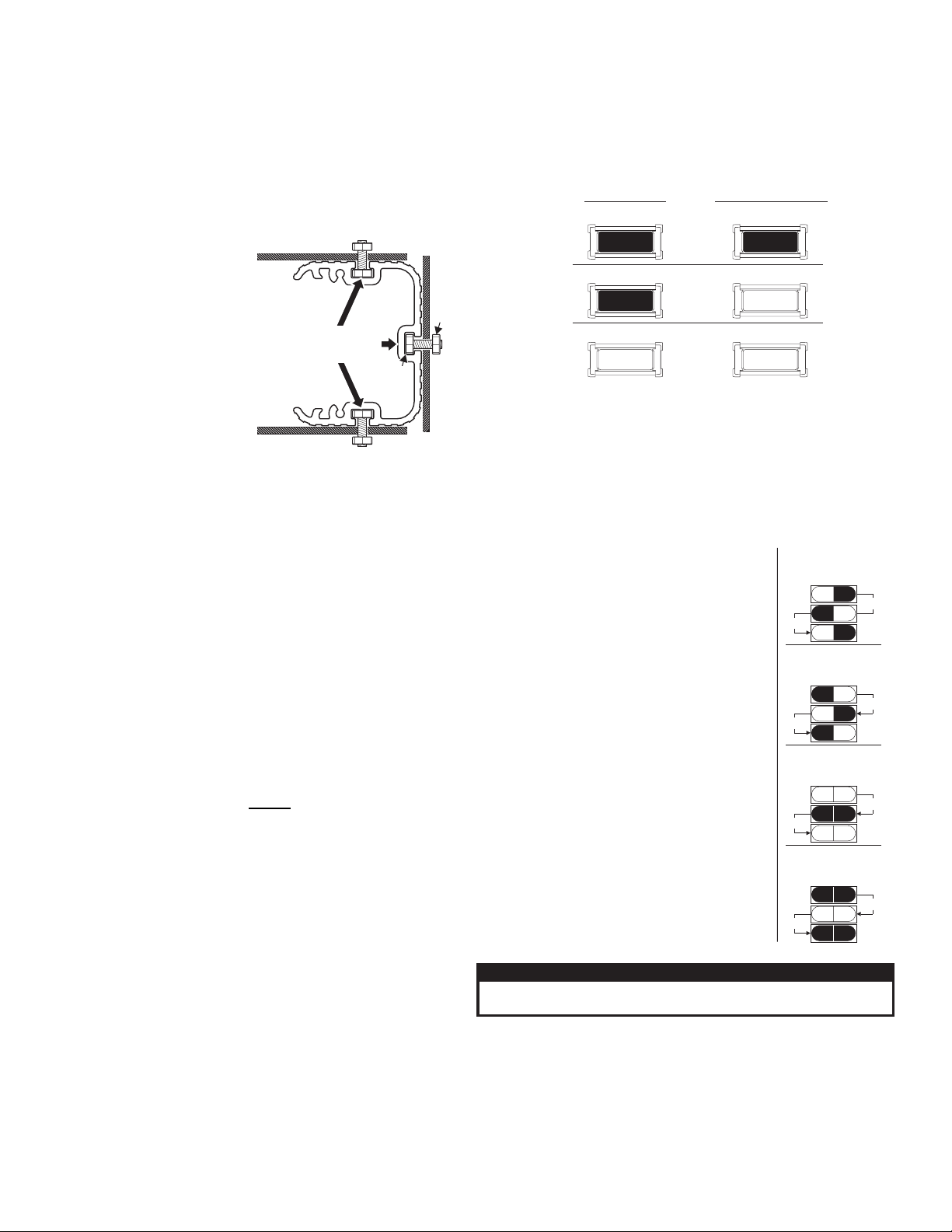

Scan-Lock™ (Blue)

This lighthead has 25 flash patterns (69 patterns for Split-LED) some of

which are available in 2 or 4 modes; Phases 1, 2, 3 or 4 (See SYNC).

The patterns are changed with the BLUE wire. With the lighthead on:

To advance to the next pattern, apply +12 VDC to the BLUE wire for

less than 1 second. To cycle backwards to previous patterns, apply +12

VDC for more than 1 second.

To reset to the factory default pattern, turn off power to the lighthead.

While applying +12 VDC to the BLUE wire, turn the lighthead back on.

Continue to apply voltage to the BLUE wire for 5 seconds.

With SYNC, all lightheads configured to display the Phase 1 mode of a

given pattern will flash simultaneously. Any lightheads configured to

display the Phase 2 mode of a pattern, will alternate with any Phase 1

lightheads with the same pattern.

Sync (Grey)

To sync two lightheads, configure both lightheads to display the same Phase

1 pattern. With the power off, connect the GREY wire from each lighthead

together. When the lightheads are activated, their patterns will be

synchronized. To configure the two lightheads to alternate their patterns,

advance the pattern of either lighthead to Phase 2 of the current pattern.

EXAMPLE:

DRIVER SIDE

Phase 1

)

QTY 2

(

#10-24 ELASTIC

STOP NUT

Phase 1

Phase 2

Standard Lighthead Patterns:

1. SignalAlert™75 ....PH.1

2. SignalAlert™ PH.2

MOUNTING

SURFACE

. CometFlash® ....PH.1

375

. CometFlash® PH.2

4 75....

. DoubleFlash PH.1

5 75....

. DoubleFlash PH.2

6 75....

. SingleFlash PH.1

7 75.....

. SingleFlash PH.2

8 75.....

9. ComAlert™75 .....PH.1

NOTE: BOLD = CA Title XIII Compliant Pattern = SYNC PatternItalic

1 . ComAlert™ PH.2

0 75 .....

. LongBurst™ .....PH.1

11 75

2. LongBurst™ PH.2

1 75.....

. PingPong™ PH.1

13 75.....

. PingPong™ PH.2

14 75.....

16. SingleFlash 90

17. SingleFlash 120

18. SingleFlash 300

Split Lighthead Patterns:

1. SignalAlert™75 ....PH.1

2. SignalAlert™ PH.2

3. SignalAlert™ PH.3

4. SignalAlert™ PH.4

5. CometFlash® ....PH.1

6. CometFlash® PH.2

7. CometFlash® PH.3

8. CometFlash® PH.4

9. DoubleFlash PH.1

10. DoubleFlash PH.2

11. DoubleFlash PH.3

12. DoubleFlash PH.4

13. SingleFlash PH.1

14. SingleFlash PH.2

15. SingleFlash PH.3

16. SingleFlash PH.4

17. ComAlert™75 .....PH.1

18. ComAlert™ PH.2

19. ComAlert™ PH.3

20. ComAlert™ PH.4

21. LongBurst™ .....PH.1

22. LongBurst™ PH.2

23. LongBurst™ PH.3

24. LongBurst™ .....PH.4

25. PingPong™ PH.1

26. PingPong™ PH.2

27. PingPong™ PH.3

28. PingPong™ PH.4

29. SSNF PH.1

30. SSNF PH.2

31. SingleFlash60.....ALT

32. SingleFlash60.....SIM

33. SingleFlash90.....ALT

34. SingleFlash90.....SIM

35. SingleFlash120....ALT

75 ....

75 ....

75 ....

75

75....

75....

75....

75 ...

75 ...

75 ...

75 ...

75....

75....

75....

75....

75 .....

75 .....

75 .....

75

75.....

75.....

75

75 ....

75 ....

75 ....

75 ....

75 .........

75 .........

36. SingleFlash120....SIM

37. SingleFlash300.....ALT

38. SingleFlash300.....SIM

9 DoubleFlash 150 ....ALT

3.

40 DoubleFlash 150 SIM

. ....

41 ComAlert™150 ALT

. .....

42 ComAlert™150 SIM

. .....

43 ActionFlash™ 50 ....ALT

.

44. ActionFlash™ 50 ....SIM

45. ActionFlash™ 150 ...ALT

46. ActionFlash™ 150 ...SIM

47. ModuFlash™ .......ALT

48. ModuFlash™ .......SIM

49. DoubleFlash 120 ...ALT

50. DoubleFlash 120 ...SIM

51. PingPong™ 120....ALT

52. PingPong™ 120 ....SIM

53. TripleFlash™75 ...ALT

54. TripleFlash 75....SIM

55. TripleFlash 120 . . ALT

56. TripleFlash 120...SIM

57. SigAlertCal.™.....ALT

58. SigAlertCal.™.....SIM

59. Action1..........ALT

60. Action1 ..........SIM

61. Action2..........ALT

62. Action2 ..........SIM

63. CalScan™......Alt/Sim

64. ActionScan™ ....Alt/Sim

65. SteadyFlash 60

66. SteadyFlash 75

67. SteadyFlash 90

68. SteadyFlash 120

69. Steady & Steady

NOTE: BOLD = CA Title XIII Compliant Pattern

= SYNC PatternItalic

IMPORTANT WARNING!

CAUTION! DO NOT LOOK DIRECTLY AT THESE LEDS WHILE THEY ARE ON.

MOMENTARY BLINDNESS AND/OR EYE DAMAGE COULD RESULT!

IMPORTANT! It is the responsibility of the installation technician to

make sure that the installation and operation of this product will not

interfere with or compromise the operation or efficiency of any vehicle

equipment!

PASSENGER SIDE

Phase 1

Phase 2

Phase 2

19

DoubleFlash 150

.

ComAlert™15075 ....

20.

. ActionFlash™

21 1

22. ActionFlash™ 2

23. ModuFlash™

24. ActionScan™15. SingleFlash 60

25. Steady

LEFT

then

RIGHT

then

™

™

™

BOTH sides flash together

(ON-OFF-ON).

then

BOTH sides flash together

(OFF-ON-OFF).

then

PHASE 1

side lights up and

ON OFF

ON OFF

PHASE 2

side lights up and

ON OFF

PHASE 3

ON ON

ON ON

PHASE 4

ON ON

RIGHT

with side.alternates

then

ONOFF

LEFT

with side.alternates

ONOFF

then

ONOFF

then

OFFOFF

OFFOFF

then

OFFOFF

IMPORTANT! Before returning the vehicle to active service, visually

confirm the proper operation of this product, as well as all vehicle

components/equipment.

Page 2

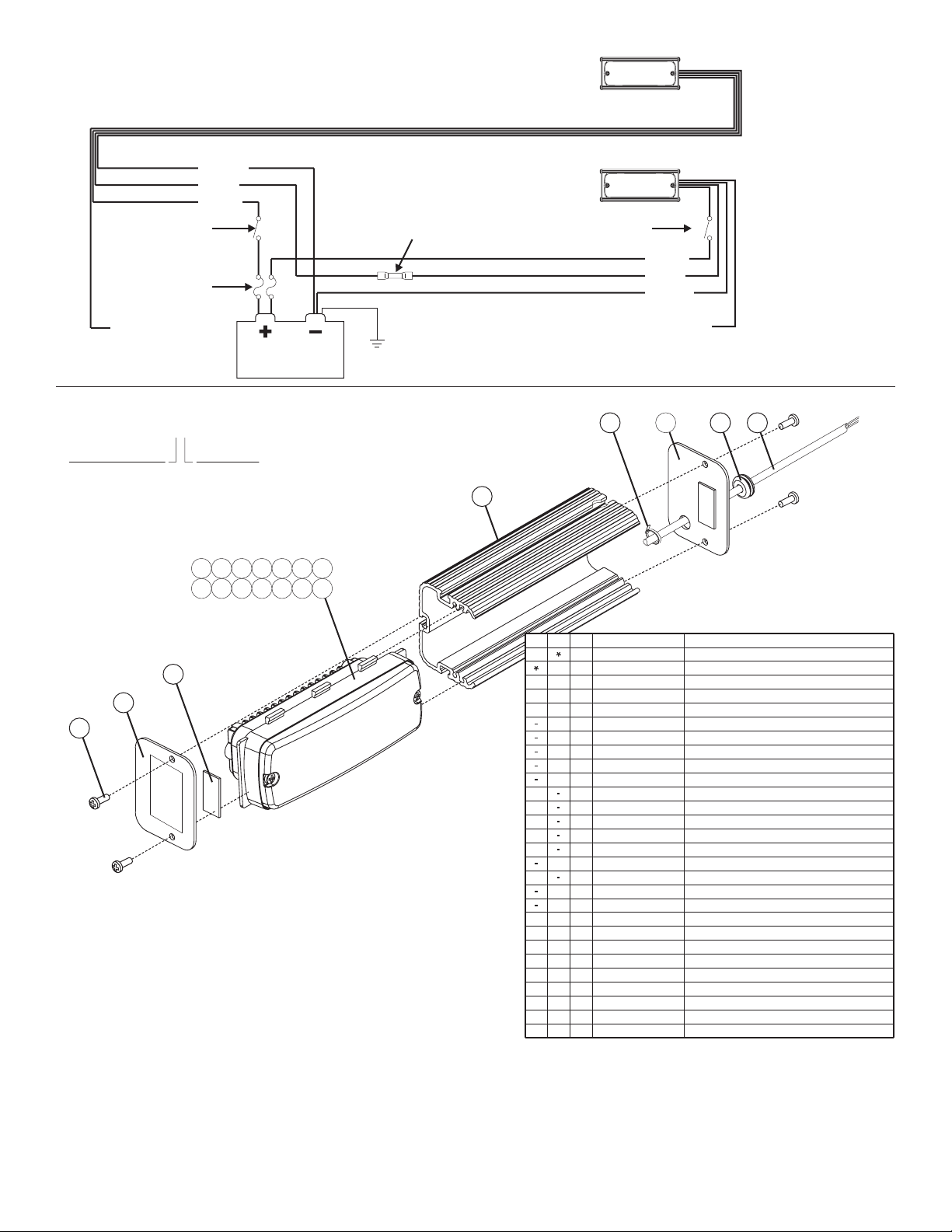

Page 3

BLACK

GREY

WHITE

SPST switch

(customer supplied)

Fuses - 3A each

(customer supplied)

BLUE

(See Scan-Lock™)

BATTERY

Butt Splice*

(customer supplied)

This connection is not

*

necessary unless the

lightbars are to be SYNC’d

SPST switch

(customer supplied)

(See Scan-Lock™)

WHITE

GREY

BLACK

BLUE

WHITE

: +12VDC

Y

GRE : SYNC

BLACK: Ground

BLUE: Scan-Lock™

: +12VDC

WHITE

GRE : SYNC

Y

BLACK: Ground

BLUE: Scan-Lock™

PART NO. KEY

01-0684684-__

LED/LENS COLOR

1=AMBER/CLEAR

2=

BLUE/CLEAR

3=

WHITE/CLEAR

4=

GREEN/CLEAR

5=

RED/CLEAR

A=

AMBER/AMBER

D=

RED-WHITE/CLEAR

J=

RED-BLUE/CLEAR

2

1

ORIENTATION

0=HORIZONTAL

1=VERTICAL

12

11

561387

4 9

3

15 16 17

14

10

18

QTY QTY

4114

2

AR

AR

AR

AR

AR

AR

AR

AR

AR

AR

AR

AR

AR

AR

11

11

111

11

11

2

ITEM

1

2

3

2

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

1

21

22

23*

24*

11

25*

2

26*

22

*NOT SHOWN

20 21 2219

PART NUMBER

01-0684684-_0

01-0684684-_1

14-062219-06D

11-243354-007

38-0143142-01

01-066C289153

01-066C289143

01-066C289133

01-066C289123

01-066C289113

01-066C291153

01-066C291143

01-066C291133

01-066C291123

01-066C291113

01-066C2891A3

01-066C2911A3

01-066C290-J3

01-066C290-D3

11-46A704-005

26-0215001-06

11-243355-007

21-11071006-0

46-9441898025

46-0743437-01

46-0743437-00

13-104120-062

14-104436-120

LIGHT ASSY / SINGLE LINEAR-LED®

LIGHT ASSY SINGLE VERTICAL/ LINEAR-LED®

SCREW 6-32 X 3/8 PPH ROLOX/

ENDCAP EXTRUSION without HOLE 500 SERIES

GASKET ENDCAP

500 SYNC REDLINEAR-LED

500 SYNC GREENLINEAR-LED

500 SYNC WHITELINEAR-LED

500 SYNC BLUELINEAR-LED

500 SYNCLINEAR-LED AMBER

500 SYNC RED VERTLINEAR-LED

500 SYNC GREEN VERTLINEAR-LED

500 SYNC WHITE VERTLINEAR-LED

500 SYNC BLUE VERTLINEAR-LED

500 SYNC AMBER VERTLINEAR-LED

500 SYNC AMBER/AMBERLINEAR-LED

500 SYNC AMBER/AMBER VERTLINEAR-LED

500 SYNC RED/BLULINEAR-LED

500 SYNC RED/LINEAR-LED WHT

HOUSING 500 SERIES 5.406" BLACK/

TY-WRAP 6" BLACK,

ENDCAP EXTRU CABLE HOLE 500 SERGROMMET / . with .

GROMMET, IC7/32 ID 7/16 OD 3/16 TH K

CABLE -4vvv 4/C 22 GA 2.5' STRIP 2"/STRIP 1 1/4"/

HARNESS ASSY SYNC SCAN LOCK SINGLE 500 LED

HARNESS ASSY INPUT POWER SINGLE 500 LED//

NUT 10-24 ELASTIC STOP/

SCREW / 10-24 X 3/4 HEX HD MS

DESCRIPTION

/--/

Page 3

Loading...

Loading...