Page 1

®

ENGINEERING COMPANY INC.

51 Winthrop Road

Chester, Connecticut 06412-0684

Phone: (860) 526-9504

Installation Guide:

8-Outlet Relay Box

Model PCC8R

Fax: (860) 526-4078

Internet: www.whelen.com

Sales e-mail: autosale@whelen.com

Canadian Sales e-mail: autocan@whelen.com

Customer Service e-mail: custserv@whelen.com

Safety First

This document provides all the necessary information to allow your Whelen product to be properly and safely installed.

Before beginning the installation and/or operation of your new product, the installation technician and operator must

read this manual completely. Important information is contained herein that could prevent serious injury or damage.

• Proper installation of this product requires the installer to have a good understanding of automotive electronics,

systems and procedures.

• If mounting this product requires drilling holes, the installer MUST be sure that no vehicle components or other

vital parts could be damaged by the drilling process. Check both sides of the mounting surface before drilling

begins. Also de-burr the holes and remove any metal shards or remnants. Install grommets into all wire passage

holes.

• If this manual states that this product may be mounted with suction cups, magnets, tape or Velcro®, clean the

mounting surface with a 50/50 mix of isopropyl alcohol and water and dry thoroughly.

• Do not install this product or route any wires in the deployment area of your air bag. Equipment mounted or

located in the air bag deployment area will damage or reduce the effectiveness of the air bag, or become a

projectile that could cause serious personal injury or death. Refer to your vehicle owner’s manual for the air bag

deployment area. The User/Installer assumes full responsibility to determine proper mounting location, based on

providing ultimate safety to all passengers inside the vehicle.

• For this product to operate at optimum efficiency, a good electrical connection to chassis ground must be made.

The recommended procedure requires the product ground wire to be connected directly to the NEGATIVE (-)

battery post.

• If this product uses a remote device to activate or control this product, make sure that this control is located in an

area that allows both the vehicle and the control to be operated safely in any driving condition.

• Do not attempt to activate or control this device in a hazardous driving situation.

• If this product contains strobe light(s), halogen light(s) or high-intensity LEDs, do not stare directly into these

lights at a close distance. Momentary blindness and/or eye damage could result.

• If this product contains strobe light(s), halogen light(s) or high-intensity LEDs, use only soap and water to clean

the lamp lens. Use of other chemicals could result in premature lens cracking (crazing) and discoloration. Lenses

in this condition have significantly reduced effectiveness and should be replaced immediately. Inspect and

operate this product regularly to confirm its proper operation and mounting condition. Do not use a pressure

washer to clean this product.

• It is recommended that these instructions be stored in a safe place and referred to when performing maintenance

and/or reinstallation of this product.

• FAILURE TO FOLLOW THESE SAFETY PRECAUTIONS AND INSTRUCTIONS COULD RESULT IN DAMAGE TO

THE PRODUCT OR VEHICLE AND/OR SERIOUS INJURY TO YOU AND YOUR PASSENGERS!

Automotive: Other

For warranty information regarding this product, visit www.whelen.com/warranty

©2009 Whelen Engineering Company Inc.

Form No.14326 (071309)

Page 1

Page 2

Selecting a mounting location...

The logical choice for a mounting area would be a trunk or similar

compartment. However, due to the wide variety of vehicles onto which the

relay box could be installed, this is not always possible. The following

guidelines will help the installer select an acceptable alternative:

• Do not select a location where the relay box will be exposed to

potential damage from any unsecured or loose equipment in the

vehicle.

• Be sure the area selected will not allow the relay box to be

exposed to water!

• When routing the relay box’s wires, it is important to choose a

path that will keep these wires away from excessive heat and

from any vehicle equipment that could compromise the integrity

of the wires (ex. trunk lids, door jams, etc.)

When the best mounting location has been determined, securely fasten

the relay box to it’s mounting surface using the supplied hardware.

Pin 1 - to an ignition controlled electrical circuit.

Pin 2 - to Chassis Ground.

Pin 3 - to vehicle parking light circuit (backlight connection).

Relay Connections - Each relay can function as either a Dry Contact

Relay or as a Standard Outlet. The function is determined by the position

of that relay’s fuse. Refer to the illustration below for wiring information.

Dip Switches...

The relay box has two dip switch banks that are accessible from the rear

of the unit. Each bank consists of 8 dip switches; one for each relay. For

example, the position of dip switch #6 will effect relay #6.

Bank #1 is used to disable diagnostic feedback for a given relay

configured to operate as a Dry Contact Relay. In the UP (default) position,

the outlet will return diagnostic feedback to the control head. In the DOWN

position, no diagnostic information for that outlet is sent to the control

head.

Caution: As it will be necessary to drill holes into the mounting

surface, the installer MUST be sure that no vehicle components or

other vital parts could be damaged by the drilling process. Check

both sides of the mounting surface before drilling!

Wiring...

Relay Power - Using appropriately sized wires (see chart on Page 3),

extend the two Main Power wires to the vehicle battery. Install a Fuse

Block equipped with a 40 Amp fuse onto the end of each wire. Connect

each fuse block to the POS (+) battery terminal. NOTE: Do not place the

fuses in their holders until all electrical connections have been completed.

WARNING! Combined relay current can not exceed 70 Amps at any

time!

WARNING! All customer supplied wires, that connect to the positive

(+) terminal of the battery, must be sized to supply at least 125% of

the maximum operating current, and fused “at the battery” to carry

the load! DO NOT USE CIRCUIT BREAKERS WITH THIS PRODUCT!

System Wiring - Using appropriately sized wire, extend the wires from the

‘System’ port as follows:

Dip Switch

Bank #2

Dip Switch

Bank #1

Bank #2 determines the operational style of the control head buttons. In

the UP (default) position, the buttons operate with a “Push ON / Push

OFF” style. In the DOWN position, the buttons function in a “Momentary”

style, with the relay being active only while its corresponding button is

pressed.

Diagnostics...

The RELAY BOX provides diagnostic feedback to the control head.

NOTE: The diagnostic operation for that relay should be disabled as

outlined in the “Dip Switch” section.

The diagnostic LED for each relay is located adjacent to the control head

button for a given relay and operates as follows:

LED On Steady - Relay is operating properly

LED Single Flash - Relay has failed to close

LED Double Flash - Relay is stuck closed.

WARNING! If a diagnostic LED indicates a problem, do not operate

that relay until the cause has been identified and repaired.

Fuse Position #1:

Dry Contact Relay

1

1-

Normally Closed

2

2 - Normally Open

3-

Common

3

Fuse Position #2:

Standard Outlet

Relay On

1

1 - Open

2

2 - +VBAT

3 - Open

3

Relay Off

1-

23 - Open

+VBAT

Open

Relay 1

(20A Max)

Relay 2

(20A Max)

Relay 3

(20A Max)

Relay 4

1( 0A Max)

Relay

Power

40 Amp

Fuse

40 Amp

Fuse

Relay 5

Relay 6

(10A Max)

To POS (+)

Battery Terminal

(10A Max)

Relay 7

(10A Max)

Relay 8

System

(10A Max)

Page 2

Port

3

3 - To Backlight Control

2

2 - To Chassis Ground

1

1 - To Ignition Controlled +12V

Fuse

Fuse

RELAY

RELAY5RELAY6RELAY7RELAY

RELAY2RELAY3RELAY

1

4

8

Page 3

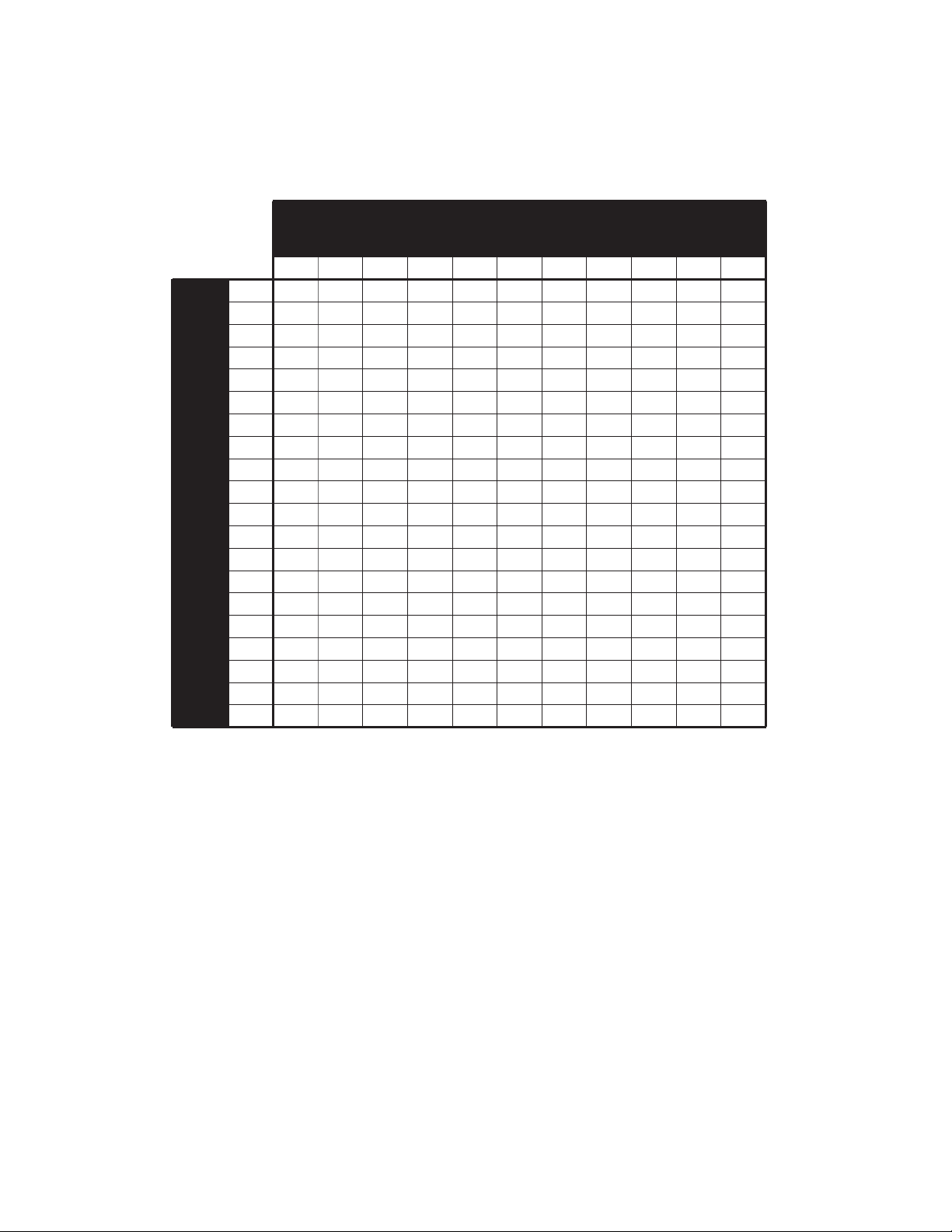

Wire Gauge

Calculation Chart

Wire Gage (AWG)

22

20

5

10

15

20

25

30

35

40

45

50

55

60

65

70

75

80

85

90

95

Current Draw (AMPS)

100

6

9.5

3

5

INS.

INS. INS.

INS.

INS.

INS.

INS.

INS.

INS.

INS.

INS.

INS.

INS.

INS.

INS.

INS.

INS.

INS.

INS.

3

INS.

INS. INS.

INS.

INS.

INS.

INS.

INS.

INS.

INS.

INS.

INS.

INS.

INS.

INS.

INS.

INS.

18

16

14

15

24.5

7.5

5

4

3

INS.

INS.

INS. INS.

INS. INS.

INS. INS.

INS. INS.

INS. INS.

INS. INS.

INS. INS. INS.

INS. INS. INS.

INS. INS. INS.

INS. INS. INS.

INS. INS. INS.

INS. INS. INS.

3.5

12

8

6

5

4

3

39

19.5

13

9.5

8

6.5

5.5

5

4.5

4

3.5

3

3

3

12

62

31

20.5

15.5

12.5

10.5

9

7.5

7

6

5.5

5

5

4.5

4

4

3.5

3.5

3.5

3

10

98

49

32.5

24.5

19.5

16.5

14

12.5

11

10

9

8

7.5

7

6.5

6

6

5.5

5

5

8

156

78

52

39

31

26

22.5

19.5

17.5

15.5

14

13

12

11

10.5

10

9

8.5

8

8

6

248

124

82.5

62

49.5

41.5

35.5

31

27.5

25

22.5

20.5

19

17.5

16.5

15.5

14.5

14

13

12.5

4

395

197

131

98.5

79

66

56.5

49.5

44

39.5

36

33

30.5

28

26.5

24.5

23

22

21

19.5

2

629

314

209

157

125

104

89.5

78.5

69.5

63

57

52.5

48.5

45

42

39

37

35

33

31.5

All Distances Shown Are In FeetINS. = Insufficient

To use this chart...

1. Determine the amount of current being drawn through the wire. Locate this number in the vertical left-hand

column. If the current value is between adjacent values, use the higher number.

2. Follow this row until the length of the installed wire is shown. If the exact length is between adjacent values, use

the higher number. Follow this column upwards to find the recommended size (gage) for this wire.

In the example shown below, the size for a wire with an installed length of 36 feet, through which 22 amps of current

will be drawn, must be determined.

A row for 22 amps is not shown, so the row for 25 amps will be used. Follow this row to the right. A column for 36 feet

is not show, so the column for 49.5 feet will be used. Following this column to the top will show that the size of this

wire must be at least 6 gage.

Page 3

Loading...

Loading...