Page 1

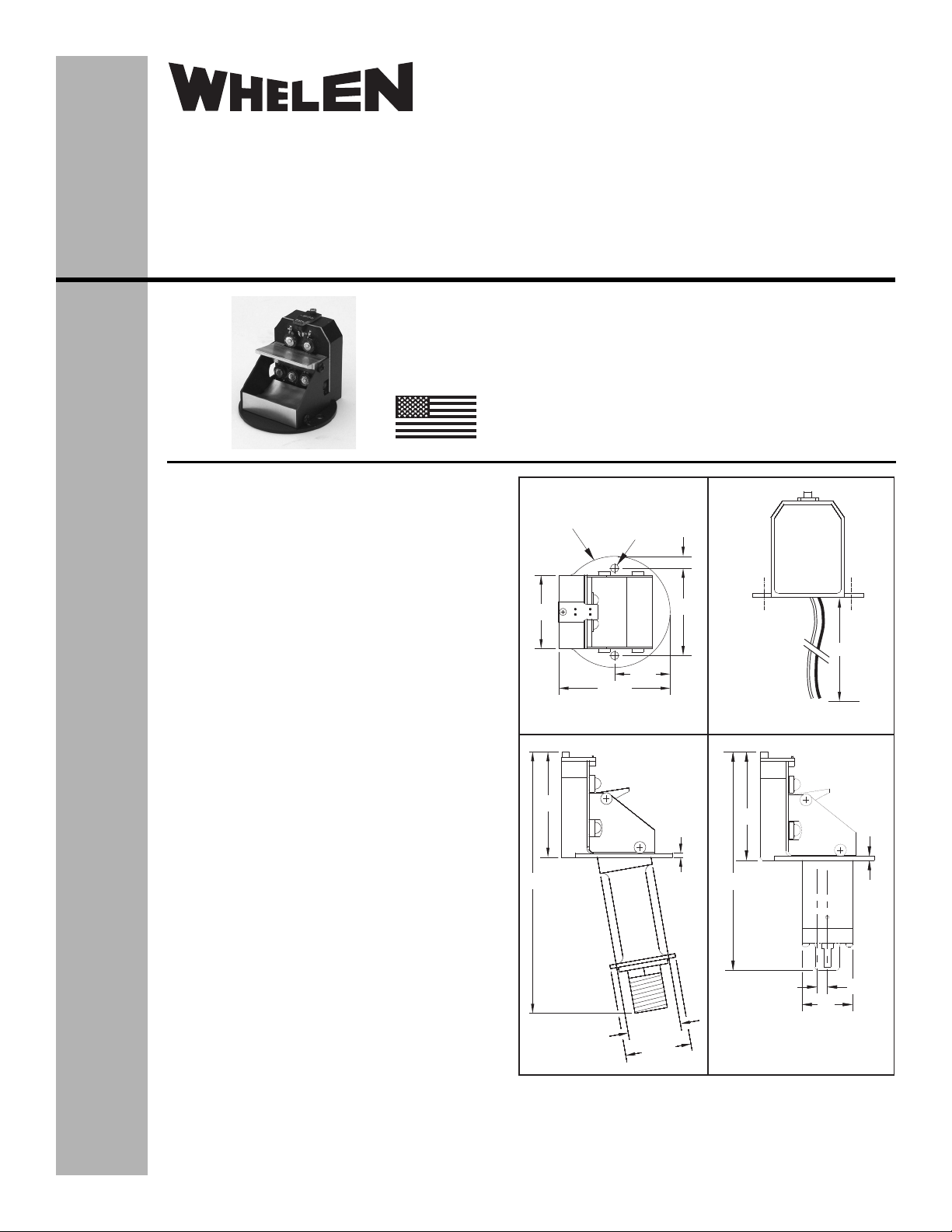

12.0” ±1.0”

MODELS 7096303

& 7096304 SHOWN

FOR REFERENCE.

.156 DIA. MTG HOLE

(2 PLACES)

.225

1.625*

*1.65 for models:

709630

709630

0

1

2

1.390

1.050

2.10

2.10 DIA.

1.98

4.939

1.000

1.275

CONNECTOR SHOWN

FOR MODELS 7096301

& 7096302

MODELS 7096305,

7096306 & 7096307

SHOWN

.075

1.98

4.017

.075

.19

.93

®

ENGINEERING COMPANY INC.

MADE IN THE U.S.A.

Route 145, Winthrop Road,

Chester, Connecticut 06412

Phone: (860) 526-9504

Fax: (860) 526-2009

Internet: www.whelen.com

Sales/Service e-mail: aviation@whelen.com

Installation Guide:

Model 70963( )-series

Models 7096301, 7096302, 7096303,

7096304, 7096305, 7096306, 7096307

P/N: 01-0770963-01, 01-0770963-02

01-0770963-03, 01-0770963-04

01-0770963-05, 01-0770963-06

01-0770963-07

LED Forward Position Light Assembly

OPERATING INSTRUCTIONS:

Operational Voltage: . . . . . 22-30 VDC (28 VDC nom)

Nominal Input Current: . . .0.3 Amps

EQUIPMENT LIMITATIONS: An approved forward position

lighting system consists of two lights, one located on each

wingtip. The lights must be installed under a protective lens.

Additional testing may be required.

CONTINUED AIRWORTHINESS: The 70963 series LED

wingtip position light assembly is designed with 6 LED’s. If

any one LED fails, the unit must be repaired or replaced.

Aviation

Note: To reduce eyestrain, use an optical filter such as dark

glasses or a blue covering dome during LED inspection.

INSTALLATION PROCEDURES: The following information

is to assist in the installation of a Whelen LED Forward

Position Light System.

1. Choose the appropriate 70963( ) series replacement

light assembly.

2. The installation procedure described in the following

text will be confined to a single light installation, but is

identical for multiple light installations.

3. Remove the old light, locate and save the existing

+28VDC lead and (-) ground lead. Clean and prep

ends as required.

4. Connect the existing +28VDC and existing ground

leads. Both leads must be connected by an approved

FAA connection. Insure that wire leads are clear of any

obstacles and ty-wrap as required. CAUTION! Do not

touch the LED with either fingers or sharp objects. This

could soil and/or damage the LED and effect its optical

performance.

5. Position the base of the new light assembly onto the

mounting surface. Install using the existing hardware.

6. Check all avionics systems for interference from the

installation.

7. A flight check should be performed by a properly

certified pilot.

8. Update aircraft records, complete Form 337 and obtain

FAA field approval for installation, if necessary.

©2004 Whelen Engineering Company Inc.

Form No.13911D (052214)

TSO-C30c

TYPES I & II

APPROVED

Page 1

The conditions and tests required for TSO approval of this

article are minimum performance standards. It is the

responsibility of those installing this article either on or

within a specific type or class of aircraft to determine that

the aircraft installation conditions are within the TSO

standards. TSO articles must have separate approval for

installation in aircraft. The article may be installed only if

performed under 14 CFR part 43 or the applicable

airworthiness requirements.

Page 2

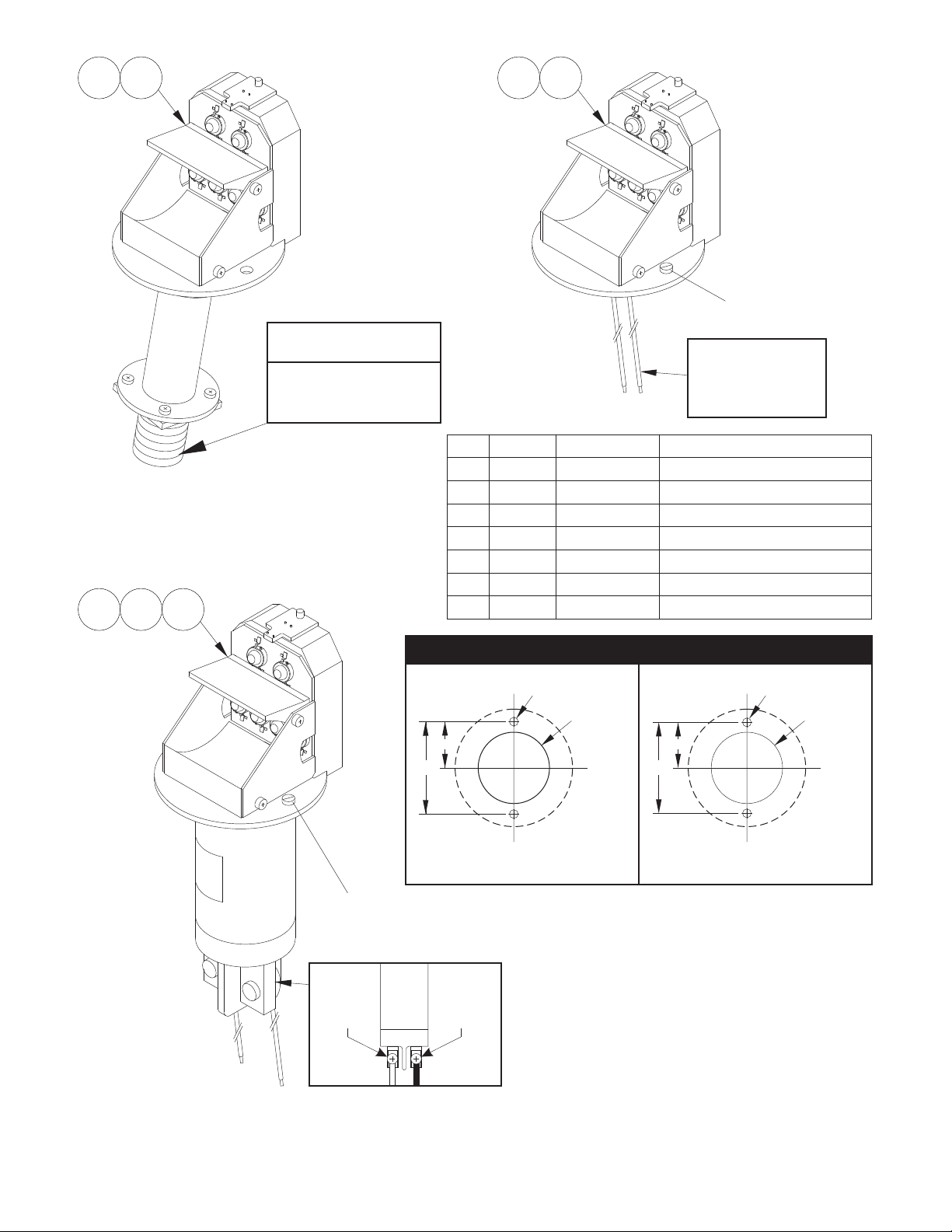

12 34

567

Fillister Head Screw (2)

MS35275-228

ModelITEM

7096301

1

7096303

3

7096302

2

7096304

7096305

7096306

7096307

4

5

6

7

Part Number

01-0770963-01

01-0770963-03

01-0770963-02

01-0770963-04

01-0770963-05

01-0770963-06

01-0770963-07

Description

Forward Position Light (Green)

Forward Position Light (Green)

Forward Position Light (Red)

Forward Position Light (Red)

Forward Position Light (Green) 680

Forward Position Light (Red)

Forward Position Light (Green)

Connector Wiring

JD38999 / 20FA98PN

Pos. A

Pos. B

Pos. C

(+) 28VDC

(-) Ground

No Connection

20 AWG Wire

M22759/43

White

Black

(+) 28VDC

(-) Ground

WHT

(-)

Ground

BLK

(+)

28VDC

GND

+28

VDC

#6 - 32 MTG THREAD

(2 PLACES)

#6 - 32 MTG THREAD

(2 PLACES)

1.275 DIA. 1.275 DIA.

1.650 1.625

.825 .8125

Models 7096301, 7096302 Models

7096305, 7096306 & 7096307

7096303, 7096304,

SUGGESTED MTG PATTERNS

Fillister Head Screw (2)

MS35275-228

Page 2

Loading...

Loading...