Page 1

®

ENGINEERING COMPANY INC.

Route 145, Winthrop Road,

Chester, Connecticut 06412

Phone: (860) 526-9504

Fax: (860) 526-2009

Internet: www.whelen.com

Sales/Service e-mail: aviation@whelen.com

Installation Guide :

70946( )-series

Models 7094601, 7094602, 7094603, 7094604

P/N: 01-0770946-01, 01-0770946-02

01-0770946-03, 01-0770946-04

LED Position/Anti-Collision Light Assembly

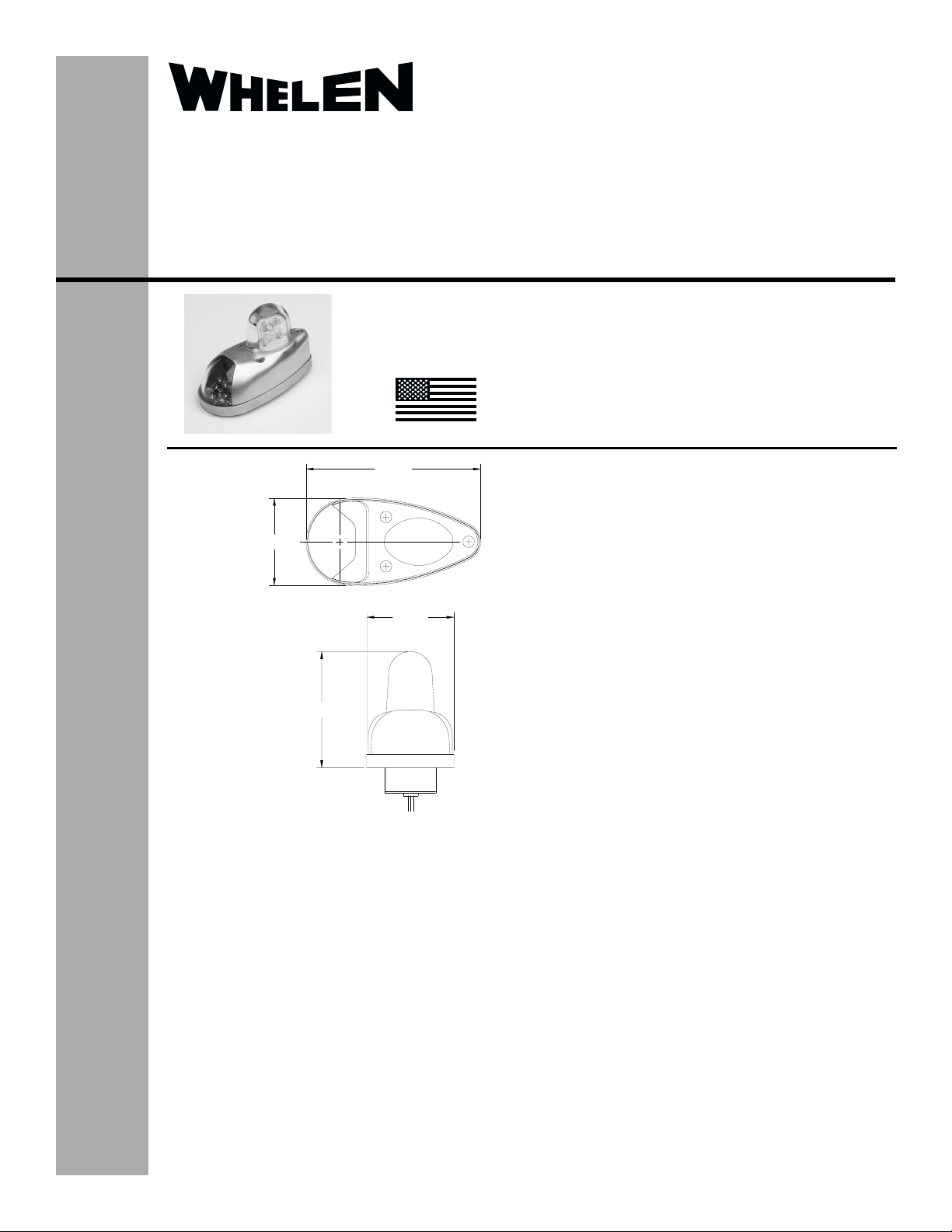

OVERALL

DIMENSIONS

2.12

2.85

OPERATING INSTRUCTIONS:

Operational Voltage:. . . . . . 28 VDC Nominal

Position Light Input Current:0.3 Amps

EQUIPMENT LIMITATIONS: The model 70946

Series must be properly mounted to comply with

FAR Part 91.205(c-2) & (c-3). The light assembly

should be mounted so that the light distribution

pattern is not obstructed by any parts of the aircraft.

A limited amount of obstruction is permitted (Ref.

FAR Part 23.1401 for anti-collision lights, and FAR

23.187 for position lights).

A minimum 20 joule power supply is n eeded to meet

Class II intensity requirements.

The base plate must be mounted parallel to the

Aviation

vertical and horizontal centerlines of the aircraft to

project patterns properly.

TSO-C30c

TYPES I & II AP PRO VED

TSO-C96a

CLASS II APPROVED

MADE IN THE U.S.A.

4.25

2.12

The conditions and tests required for TSO approval of this

article are minimum performance standards. It is the

responsibility of those installing this article either on or

within a specific type or class of aircraft to determine that

the aircraft installation conditions are within the TSO

standards. TSO articles must have separate approval for

installation in aircraft. The article may be installed only if

performed under 14 CFR part 43 or the applicable

airworthiness requirements.

CONTINUED AIRWORTHINESS: The model 70946 Series

LED Forward Position/Strobe light assembly is designed with

(6) LED’s. If any one LED fails, the uni t must be r epaired or

replaced. Inspect the lenses for excessive scratches or

pitting. Replace if necessary

INSTALLATION PROCEDURES: The following information

is to assist in the installation of a Whelen LED Forward

Position Light System.

1. Choose the appropriate 70946( ) series replacement

light assembly.

2. The installation procedure described in the following

text will be confined to a single light installation, but is

identical for multiple light installations.

3. If necessary, fabricate the mounting pattern using

dimensions found in Fig.1.

4. Make the necessary wiring connections using 20 AWG

minimum wire for the position lights, and Whelen 16

AWG 3/c ca bl e for t he s trob e li ghts. All connectio ns m us t

use FAA approved techniques.

5. Remove the (3) #6-32 x 5/16 retainer mounting screws

and retainer.

6. Attach the base assembly to the wingtip using (3) #6-32

pan head screws.

7. Re-attach lens retainer.

8. Check all avionics systems for interference from

installation.

9. A flight check shoul d be perfo rmed by a pro per ly certi fied

pilot.

10. When necessary, waterproof the assembly to aircraft.

Apply aviation approved single part silicone (RTV) or

equivalent around any open area where water could get

in.

11. Update aircraft records, complete Form 337 and obtain

FAA field app rov al for installation.

©2005 Whelen Engineering Company Inc.

Form No.14013C (071306)

Page 1

Page 2

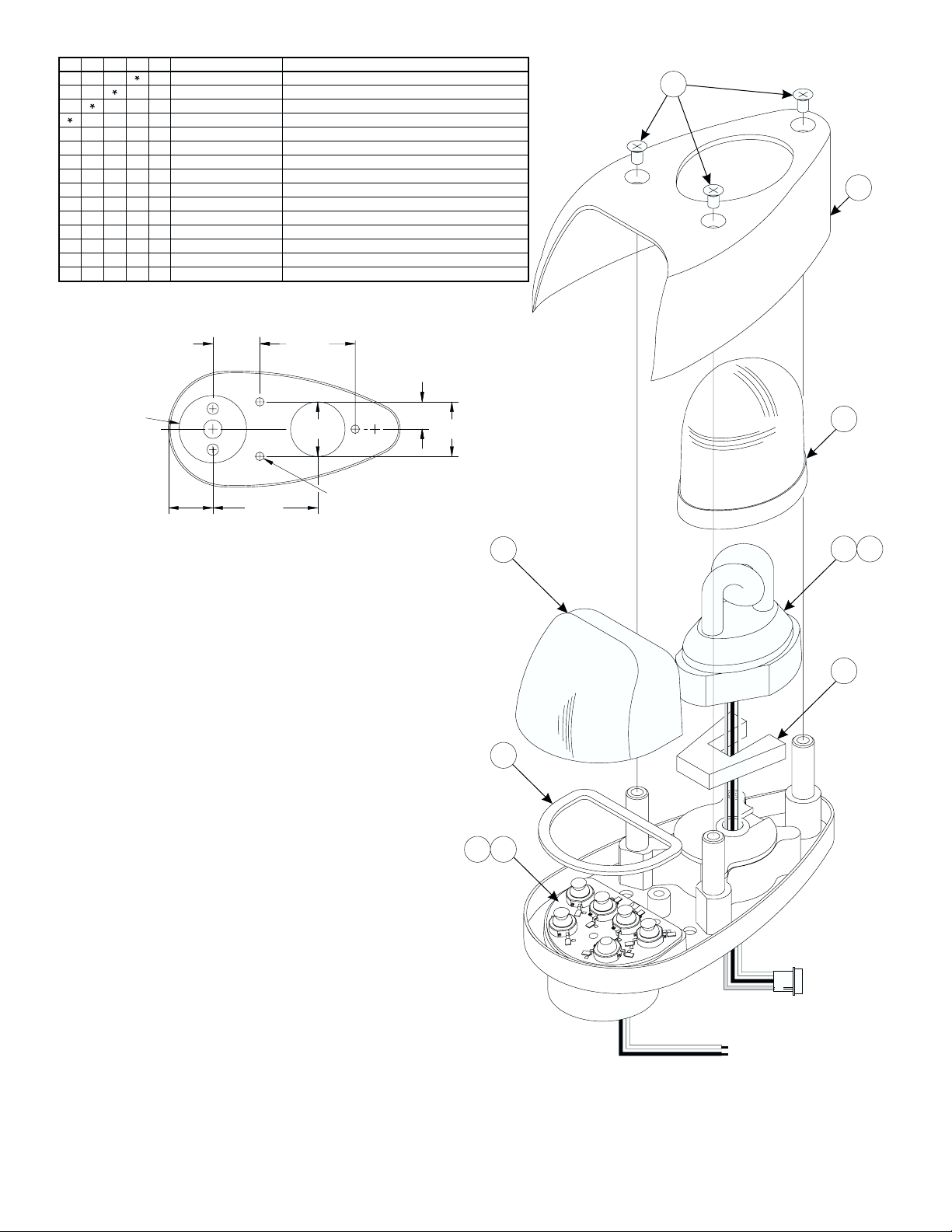

ITEM PART NUMBER DESCRIPTION

QTYQTYQTY QTY

01-0770971-40

01-0770971-50

01-0770971-03

01-0770971-04

70946 FORWARD POSITION LIGHT (GREEN LED)

70946 FORWARD POSITION LIGHT (RED LED)

70946 FORWARD POSITION LIGHT (GREEN LED)

70946 FORWARD POSITION LIGHT (RED LED)

1

14-0050563-24

13333

1111

11111

---

1

-

-

11

1

111

1

-

1

-

-

1

1

1

111

1111

19-170927-009

2

68-2290005-34

3

36-0050628-00

4

5

36-0050626-01

38-0130107-00

6

01-0270972-01

7

01-0270972-02

8

38-0250883-00

9

68-2270911-31

10

SCREW, #6-32 x 1/4 P100FH/CSK

WINGTIP STROBE LENS RETAINER

STROBE LENS (CLEAR)

FLASHTUBE ASSEMBLY

FLASHTUBE ASSEMBLY (w/Connector)

GASKET

LED ASSEMBLY, 6 LED (GREEN)

LED ASSEMBLY, 6 LED (RED)

LENS GASKET

LENS (CLEAR)

Fig. 1

Mounting

.86

1.750

Information

1.25 DIA.

Mounting Hole

for #6-32 Hardware

.813

1.925

WIRING (Strobe):

The strobe connections are as follows. Observe the following

strobe color coding:

(3 places)

.50

2

1.001.00

10

3

5

4

RED Pin 1 (Anode)

BLACK Pin 2 (Cathode)

WHITE Pin 3 (Trigger)

CAUTION! If pins 1 & 2 or pins 2 & 3 are reversed, the system will

appear to operate normally, however this condition will cause

premature flash tube failure.

WIRING (LED):

Connect the forward position light wires as follows, using 20 awg

minimum, approved aviation wire or cable. Observe the following

color coding:

WHITE To (+) 28 Volts DC

BLACK To (-) Ground

6

9

87

Strobe

Wires

3- I E

WH T (Trigger)

2- AC

BL K (Cathode)

123

1- ( )

RED Anode

LED

Wires

7094603, 7094604 connector

shown for reference only.

BL K (-) GroundAC

WHITE (+)28 Volts

Page 2

Loading...

Loading...