Page 1

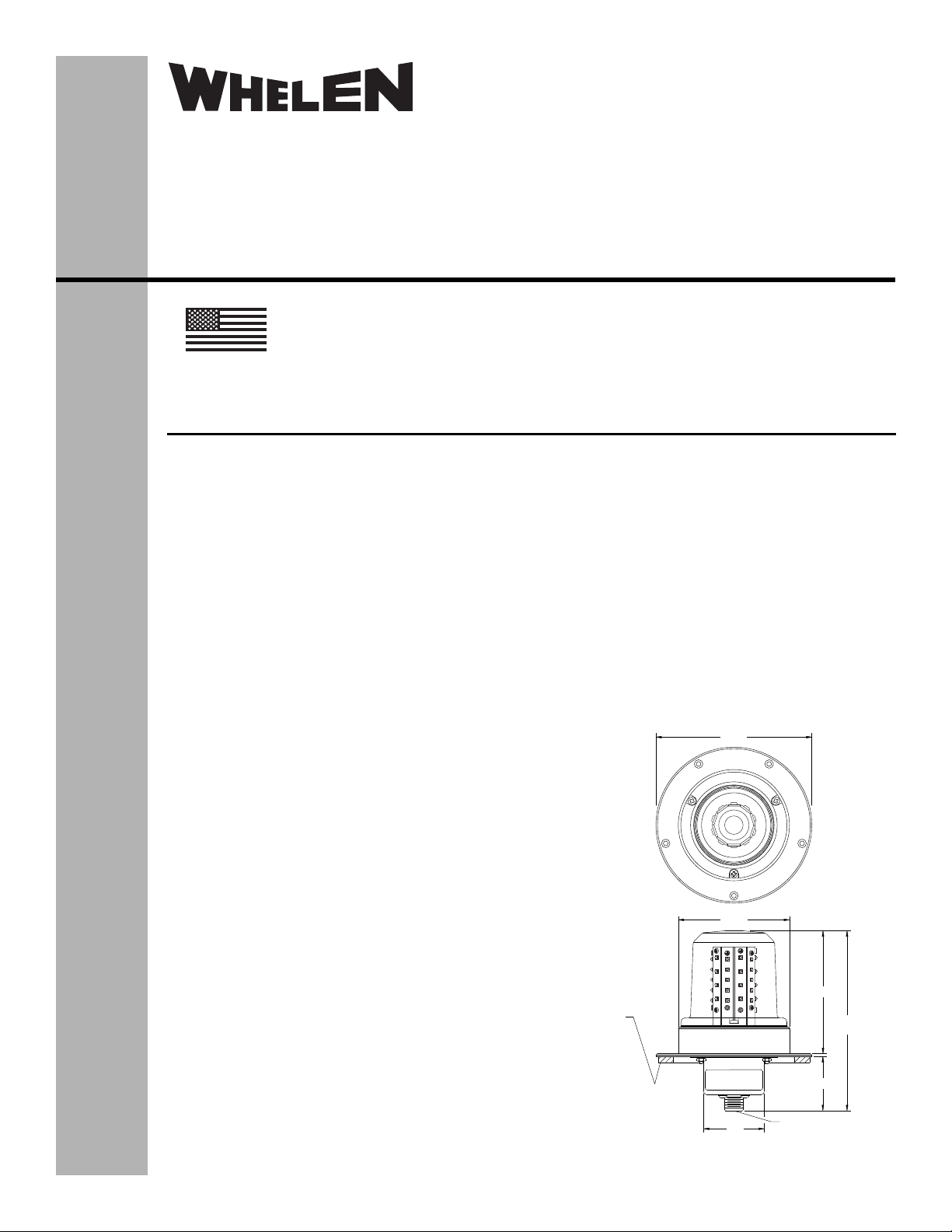

5.94

5.84

4.04 ± .06

1.75

5.14

2.00

3.66

CONNECTOR

MS3102R10SL-3P

MTG GASKET

(REF)

®

ENGINEERING COMPANY INC.

MADE IN THE U.S.A.

51 Winthrop Road

Chester, Connecticut 06412-0684

Phone: (860) 526-9504

Fax: (860) 526-2009

Internet: www.whelen.com

Sales/Service e-mail: aviation@whelen.com

Installation Guide:

Model 70905( )-series

Model 7090501

P/N:01-0770905-01

LED Flashing Anti-Collision

Light Assembly

OPERATING INSTRUCTIONS:

Operational Voltage: . . . . .24 - 32 VDC

Average Input Current: . . .0.45 Amps

Peak Input Current: . . . . . .2.5 Amps @ .25 Seconds

EQUIPMENT LIMITATIONS:

Rotorcraft for which type certificate was applied for after

April 1, 1957 to August 11,1971:

The anti-collision system must produce a minimum of 100

effective candelas in Aviation Red or White, 360° around the

vertical axis, 30° above and below the horizontal plane. A single

beacon will meet this requirement.

Rotorcraft for which type certificate was applied for after

August 11, 1971 to February 5, 1976:

The anti-collision system must produce a minimum of 400

effective candelas in Aviation Red or White, 360° around the

vertical axis, 30° above and below t he horizontal plane. This

beacon does not meet this requirement.

Rotorcraft for which type certificate was applied for after

February 5, 1976:

The anti-collision system must produce a minimum of 150

effective candelas in Aviation Red, 360° around the vertical

axis, 30° above and below the horizontal plane. A single

beacon will meet this requirement.

Certain types of installations may require additional testing.

CONTINUED AIRWORTHINESS: The 70905 series LED anti-

collision light assembly is designed with 5 columns consisting of

5 LEDs each, and 5 columns consisting of 4 LEDs each. Should

any one LED or any vertical column fail, the unit must be

repaired or replaced.

NOTE: To reduce eye strain, use an optical filter s uch as dark

glasses or a blue covering dome during LED inspection. Inspect

the lens. Replace if there is any excessiv e scratching, pitting,

discoloration or cracking.

INSTALLATION PROCEDURES: The following information is

to assist in the installation of a Whelen LED Flashing Anticollision Light System.

1. The installation procedure described in the following text

Aviation

will be confined to a single li ght in stallation, but is identical

for multiple light installations.

2. Prepare the aircraft for means to secure the LED Flashing

Anti-collision Light assembly (see reference AC 43.13-2A

Chapter 4)

3. 28 VDC (+) and (-) ground leads equipped with an

appropriate sized breaker to be supplied to the LED

Flashing Anti-collisio n Light Assembly System. Both leads

must be connected by an approved FAA connection.

TSO-C96a CLASS I

APPROVED

The conditions and tests required for TSO approval of this

article are minimum performance standards. It is the

responsibility of those installing this a rticle either on or w ithin

a specific type or class of aircr aft to determi ne that the ai rcraft

installation conditions are within the TSO standards. TSO

articles must have separate approval for inst allatio n in aircraf t.

The article may be installed only if perform ed under 14 CFR

part 43 or the applicable airworthiness requirements.

Insure that the wire leads are all clear of any obstructions and

ty-wrap as required.

4. Install the light assembly by securing to aircraft using the

appropriate, approved hardware. Note: Lens mounting screws

installed with 5-7 in./lbs. of torque.

5. Check all avionics systems for interference from this

installation.

6. A flight check should be performed by a properly certified pilot.

7. All inverted (bottom) mounted units shall require waterproofing

of the mounting hardware. An applicati on of si ngle-part silic one

(RTV) or equivalent applied over top of the mounting hardware,

after installation, is recommended. Reference page 2 for an

illustration. Inverted and/or standard mounted units, when

necessary, may require waterproofing around any open area

where water could get in. Specifically, the lens to the flasher

base assembly, and the flasher base assembly to the aircraft.

Note: It is permissable to drill a 1/8” drain hole in the center of

the lens for bottom mount units.

8. Update aircraft records, complete Form 337 and obtain FAA

field approval for installation, as necessary.

©2003 Whelen Engineering Company Inc.

Form No.13795G (020513)

Page 1

Page 2

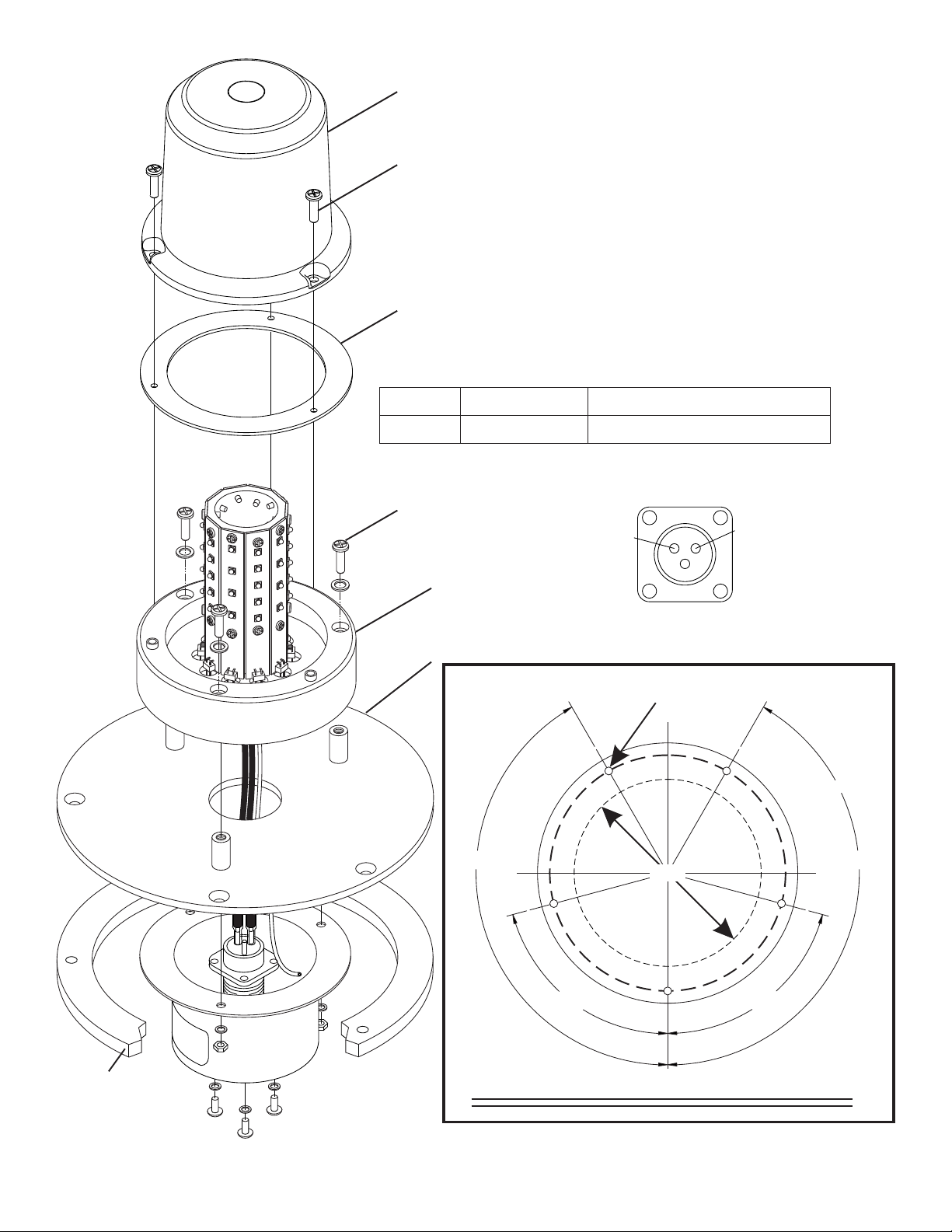

75°

150°

75°

150°

Model

7090501

Part Number

01-0770905-01

Description

28VDC, MS Connector

Lens

P/N: 68-4990257-30

Screw

P/N: 14-062216-05M

Gasket

P/N: 38-0250843-00

Mounting Adaptor Plate

P/N: 07-770907-110

Gasket

P/N: 38-0250225-00

LED Module (10 sided)

P/N: 01-0271777-01

TYPICAL MOUNTING HOLE PATTERN(S)

BLACK

MS CONNECTOR WIRING

(REAR VIEW)

WHITE

A

C

B

3.750

(5) Mounting Holes (for #6-32

hardware) on 4.656 bolt circle

“RTV” required after hardware installation

for inverted (bottom) mounted units

Page 2

Loading...

Loading...