Page 1

®

ENGINEERING COMPANY INC.

51 Winthrop Road

Chester, Connecticut 06412-0684

600 Series Strobe Lighthead

Installation Guide:

Phone: (860) 526-9504

Fax: (860) 526-4078

Internet: www.whelen.com

Sales e-mail: autosale@whelen.com

Canadian Sales e-mail: autocan@whelen.com

Customer Service e-mail: custserv@whelen.com

Safety First

This document provides all the necessary information to allow your Whelen product to be properly and safely installed.

Before beginning the installation and/or operation of your new product, the installation technician and operator must

read this manual completely. Important information is contained herein that could prevent serious injury or damage.

• Proper installation of this product requires the installer to have a good understanding of automotive electronics,

systems and procedures.

• If mounting this product requires drilling holes, the installer MUST be sure that no vehicle components or other

vital parts could be damaged by the drilling process. Check both sides of the mounting surface before drilling

begins. Also de-burr any holes and remove any metal shards or remnants. Install grommets into all wire

passage holes.

• If this manual states that this product may be mounted with suction cups, magnets, tape or Velcro®, clean the

mounting surface with a 50/50 mix of isopropyl alcohol and water and dry thoroughly.

• Do not install this product or route any wires in the deployment area of your air bag. Equipment mounted or

located in the air bag deployment area will damage or reduce the effectiveness of the air bag, or become a

projectile that could cause serious personal injury or death. Refer to your vehicle owner’s manual for the air bag

deployment area. The User/Installer assumes full responsibility to determine proper mounting location, based

on providing ultimate safety to all passengers inside the vehicle.

• For this product to operate at optimum efficiency, a good electrical connection to chassis ground must be

made. The recommended procedure requires the product ground wire to be connected directly to the NEGATIVE

(-) battery post.

• If this product uses a remote device to activate or control this product, make sure that this control is located in

an area that allows both the vehicle and the control to be operated safely in any driving condition.

• Do not attempt to activate or control this device in a hazardous driving situation.

• This product contains either strobe light(s), halogen light(s), high-intensity LEDs or a combination of these

lights. Do not stare directly into these lights. Momentary blindness and/or eye damage could result.

• Use only soap and water to clean the outer lens. Use of other chemicals could result in premature lens cracking

(crazing) and discoloration. Lenses in this condition have significantly reduced effectiveness and should be

replaced immediately. Inspect and operate this product regularly to confirm its proper operation and mounting

condition. Do not use a pressure washer to clean this product.

• It is recommended that these instructions be stored in a safe place and referred to when performing

maintenance and/or reinstallation of this product.

• FAILURE TO FOLLOW THESE SAFETY PRECAUTIONS AND INSTRUCTIONS COULD RESULT IN DAMAGE TO

THE PRODUCT OR VEHICLE AND/OR SERIOUS INJURY TO YOU AND YOUR PASSENGERS!

Automotive: Lightheads

For warranty information regarding this product, visit www.whelen.com/warranty

©2001 Whelen Engineering Company Inc.

Form No. 13643C (052311)

Page 1

Page 2

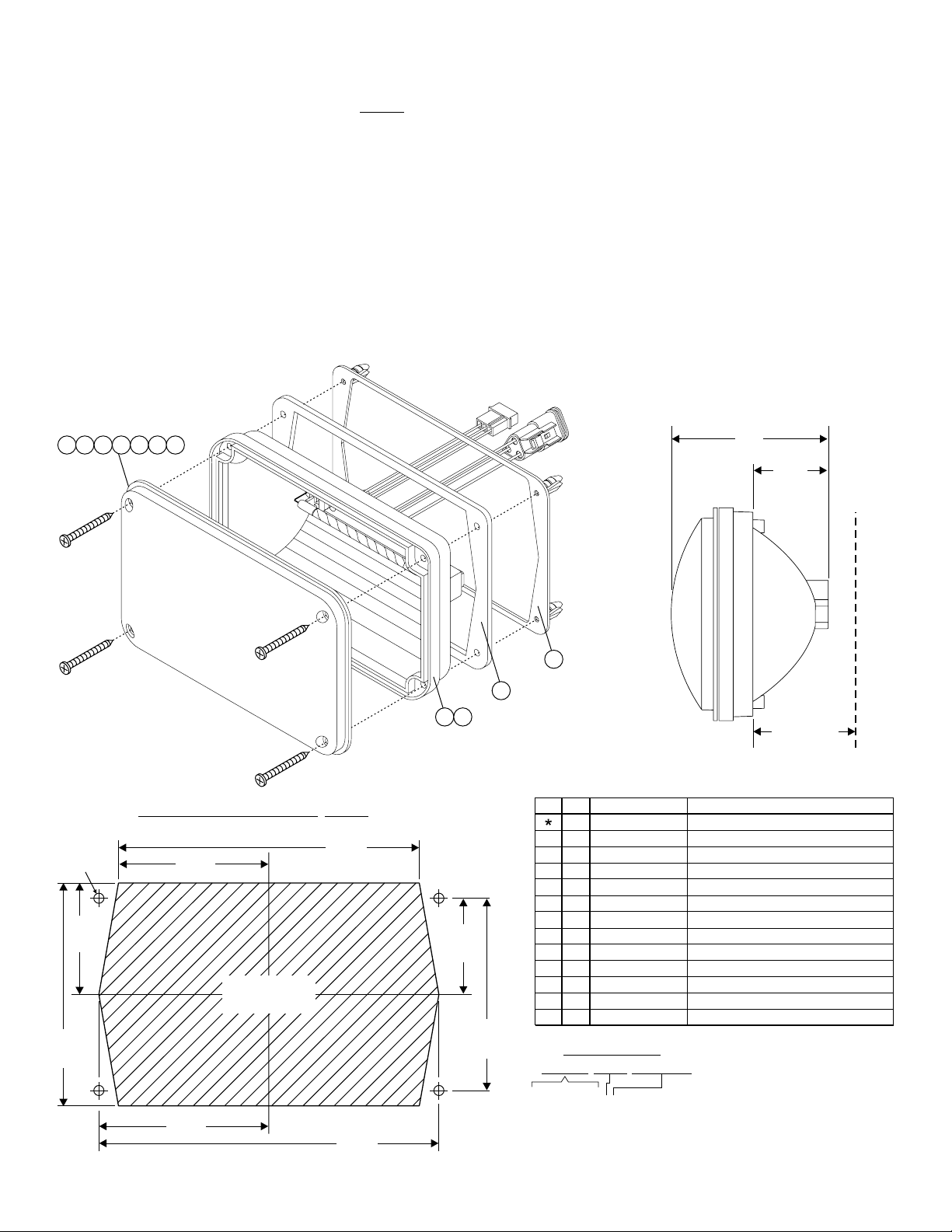

Installation:

WARNING! All customer supplied wires that connect to the positive terminal of the battery must be sized to supply at least 125% of

the maximum operating current and FUSED

PRODUCT!

WARNING! The strobe light power supply is a high voltage device. Do not touch or remove the strobe tube assembly while in

operation. Wait 10 minutes after disconnecting the unit from its power source before starting any work or trouble

shooting.

1. First check behind the proposed mounting area. Note that the mounting surface must be flat. There must be at least 2” clearance behind the

lighthead.

2. Using the measurements supplied, mark the locations for the mounting holes and lighthead cut-out hole onto the mounting surface. Be sure

to double-check all your measurements before cutting or drilling.

3. Drill the four .250” mounting holes for the screw grommet flange then cut the lighthead cut-out hole as indicated.

4. Connect the wires to your Strobe Power Supply (refer to your power supply manual for wiring information. Be sure to test for proper

operation of your lighthead prior to use.

at the battery to carry that load. DO NOT USE CIRCUIT BREAKERS WITH THIS

Pos. 1 - Annode

Cathode

Pos. 2 -

Trigger

Pos. 3 -

REQUIRED MOUNTING DEPTH

45678910

600 Series Linear Strobe Lighthead

MOUNTING DIMENSIONS

.250" hole

(4 places)

1.885"

2.545"

AREA TO BE

REMOVED

5.090"

12

1.625"

A

Pos. - Annode

Pos. B -

Cathode

Pos. C -

Trigger

12

11

600 SERIES LINEAR STROBE / PARTS LIST

QTY

A/R

A/R

4

A/R 4

A/R

A/R

A/R

A/R

A/R

A/R

1

1

PART NUMBER

ITEM

01-0663415-( )

02-0363173-00

1

02-0363173-01

2

3

15-061416-280

68-3183587-10

5

68-3183587-20

68-3183587-30

6

68-3183587-40

7

68-3183587-50

8

68-3183587E50

9

10

02-0363416-( )

38-0242717-00

11

11-76D258-000

12

REFLECTOR ASSEMBLY

600 LINEAR STROBE AMP CONN/

600 LINEAR STROBE DEUTSCH CONN/

SCREW #6 X 1-3/4" PPHSMS/

LENS MODEL 600 AMBER//

LENS MODEL 600 BLUE//

LENS MODEL 600 CLEAR//

LENS MODEL 600 GREEN//

LENS MODEL 600 RED//

LENS MODEL 600 KKKE-SPEC RED//

LENS / SPLIT 600/

GASKET

SCREW GROMMET FLANGE

3.10"

1.452"

2" MINIMUM

DESCRIPTION

3.770"

2.875"

5.750"

Page 2

3.250"

PART NUMBER KEY:

BASIC P/N

01-0663415-__

COLOR

CONNECTOR

COLOR:

R=RED

B=

COLOR:

COLOR:

COLOR:

COLOR:

COLOR:

COLOR:

CONNECTOR: 0 =1=AMP CONNECTOR

BLUE

G=

GREEN

A=

AMBER

C=

CLEAR

*=

SPLIT

5=

KKKE-SPEC RED

DEUTSCH CONNECTORCONNECTOR:

Loading...

Loading...