Page 1

ENGINEERING COMPANY INC.

51 Winthrop Road,

Chester, Connecticut 06412-0684

Phone: (860) 526-9504

Fax: (860) 526-4078

Mounting:

IMPORTANT! When selecting a mounting location, keep in

mind that there must be a minimum of 2” clearance around

the perimeter of the lighthead and any vehicle components

(insulation, etc.). The rear of the lighthead must have a

minimum 1/8" clearance. This increases airflow over the

heatsink and helps maintain proper operating temperature.

Caution: Permanent mounting of this product will require

drilling. It is absolutely necessary to make sure that no other

vehicle components could be damaged by this process.

Check both sides of the mounting surface before starting. If

damage is likely, select a different mounting location.

1. Mark off the 4 mounting holes and the “cut-out” area as shown in the

mounting diagram.

2. Using a 1/4” drill bit, drill the 4 mounting holes then carefully cut and

remove the area of the mounting surface indicated. Do not remove

the mounting surface where the mounting holes are drilled.

3. Insert the screw grommet flange into the 4 holes drilled in step 2.

Automotive: Lightheads

©2008 Whelen Engineering Company Inc.

Form No.14173B (051911)

For warranty information regarding this product, visit www.whelen.com/warranty

®

Installation Guide:

600 Series LED Scenelight

Internet: www.whelen.com

Sales e-mail: autosale@whelen.com

Canadian Sales e-mail: autocan@whelen.com

Customer Service e-mail: custserv@whelen.com

4. Route the cable to your power source and refer to “wiring

information” for connections and fusing. After testing the lighthead,

position it onto the mounting surface and secure it to the vehicle

using the four #6 x 1-3/4” sheet metal screws provided.

WARNING! All customer supplied wires that connect to the

positive (+) terminal of the battery must be sized to supply at

least 125% of the maximum operating current and FUSED “at

the battery” to carry that load. DO NOT USE CIRCUIT

BREAKERS WITH THIS PRODUCT!

IMPORTANT! It is the responsibility of the installation

technician to make sure that the installation and operation of

this product will not interfere with or compromise the

operation or efficiency of any vehicle equipment!

IMPORTANT! Before returning the vehicle to active service,

visually confirm the proper operation of this product, as well

as all vehicle components/equipment.

CAUTION! DO NOT LOOK DIRECTLY AT THESE LEDS WHILE THEY ARE ON.

MOMENTARY BLINDNESS AND/OR EYE DAMAGE COULD RESULT!

IMPORTANT WARNING!

ENGINEERING COMPANY INC.

51 Winthrop Road,

Chester, Connecticut 06412-0684

Phone: (860) 526-9504

Fax: (860) 526-4078

Mounting:

IMPORTANT! When selecting a mounting location, keep in

mind that there must be a minimum of 2” clearance around

the perimeter of the lighthead and any vehicle components

(insulation, etc.). The rear of the lighthead must have a

minimum 1/8" clearance. This increases airflow over the

heatsink and helps maintain proper operating temperature.

Caution: Permanent mounting of this product will require

drilling. It is absolutely necessary to make sure that no other

vehicle components could be damaged by this process.

Check both sides of the mounting surface before starting. If

damage is likely, select a different mounting location.

1. Mark off the 4 mounting holes and the “cut-out” area as shown in the

mounting diagram.

2. Using a 1/4” drill bit, drill the 4 mounting holes then carefully cut and

remove the area of the mounting surface indicated. Do not remove

the mounting surface where the mounting holes are drilled.

3. Insert the screw grommet flange into the 4 holes drilled in step 2.

Automotive: Lightheads

©2008 Whelen Engineering Company Inc.

Form No.14173B (051911)

For warranty information regarding this product, visit www.whelen.com/warranty

®

Installation Guide:

600 Series LED Scenelight

Internet: www.whelen.com

Sales e-mail: autosale@whelen.com

Canadian Sales e-mail: autocan@whelen.com

Customer Service e-mail: custserv@whelen.com

4. Route the cable to your power source and refer to “wiring

information” for connections and fusing. After testing the lighthead,

position it onto the mounting surface and secure it to the vehicle

using the four #6 x 1-3/4” sheet metal screws provided.

WARNING! All customer supplied wires that connect to the

positive (+) terminal of the battery must be sized to supply at

least 125% of the maximum operating current and FUSED “at

the battery” to carry that load. DO NOT USE CIRCUIT

BREAKERS WITH THIS PRODUCT!

IMPORTANT! It is the responsibility of the installation

technician to make sure that the installation and operation of

this product will not interfere with or compromise the

operation or efficiency of any vehicle equipment!

IMPORTANT! Before returning the vehicle to active service,

visually confirm the proper operation of this product, as well

as all vehicle components/equipment.

IMPORTANT WARNING!

Page 1

CAUTION! DO NOT LOOK DIRECTLY AT THESE LEDS WHILE THEY ARE ON.

MOMENTARY BLINDNESS AND/OR EYE DAMAGE COULD RESULT!

Page 2

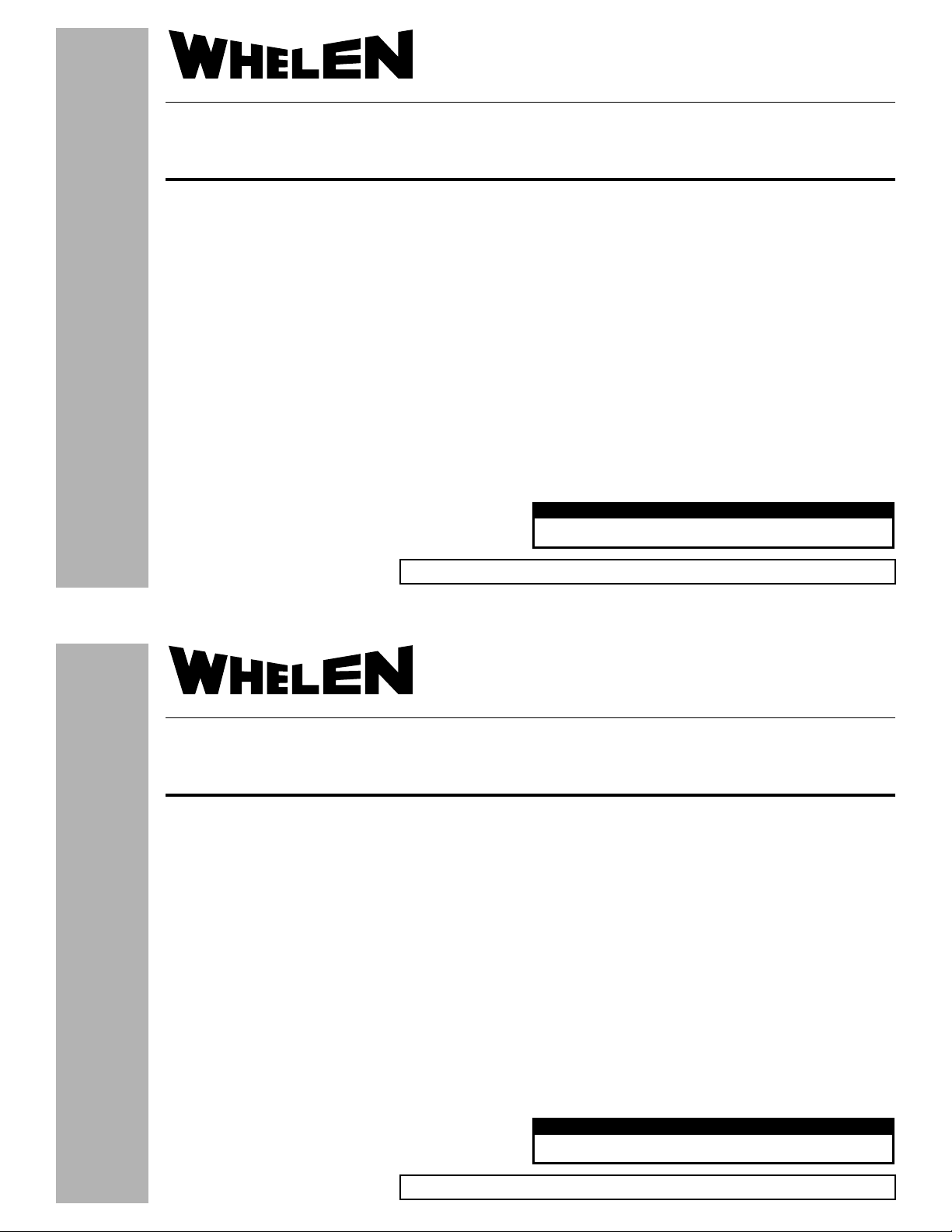

QTY QTY QTY

111

A/R

11

111

ITEM

444

A/R

A/R

1

111

PART NUMBER

01-066A669-_0

01-066A669-_1

01-066A669-_2

15-061416-280

1

68-1984963-30

2

01-026A533-_0

3

01-026A533-_1

4

5

01-026A533-_2

38-0464253-00

6

7

11-76D258-000

11-26A668-000

8

LED N C600 SERIES SCENELIGHT ( O ONNECTOR)

DESCRIPTION

LED AMP600 SERIES SCENELIGHT ( ™ CONNECTOR)

LED Deutsch600 SERIES SCENELIGHT ( ® CONNECTOR)

#6 X 1-3/4" PHILLIPS PAN HEAD SMS

LENS / CLEAR OPTIC SCENE LIGHT 600 SERIES

SUB-ASS'Y LED SCENE LT 600 NO CONNECTOR//

SUB-ASS'Y LED SCENE LT 600 AMP CONNECTOR//

SUB-ASS'Y LED SCENE LT 600 DEUTSCH CONN.//

GASKET 600 SERIES without FLANGE/

SCREW GROMMET FLANGE

COVER / HEATSINK 6/700 SCENE LT

This border represents the 2" clearance required around the perimeter of the heatsink.

NO VEHICLE COMPONENTS ARE ALLOWED WITHIN THIS AREA!

Following measurements shown,

2"

cut along this line.

Polycarbonate

3.770"

3.250"

Heatsink

Cover

2"

Lighthead

()Rear View

5.090"

5.750"

.250" Dia,

Mounting

Holes

(4) Places

PART NO. KEY:

01-066A669-__

VOLTAGE

1=2=12V

24V

CONNECTOR

0=

1=

2=

1

NOTE: Proper lens orientation

requires the word "TOP"

to be at the top of the lens.

WHELEN ENG. CO 600

SAE-WW5-00

600 Series

LED Scenelight

TOP

WHELEN ENG. CO 600

WIRING DIAGRAM

Switch

(SP/ST)

NONE

AMP

DEUTSCH

SAE-STIR-00 DOT

Fuse 5A (for V)

3A (for V)

+VBAT

8

7

6

5

3

4

2

PIN HOUSING

Position 1

Position 2

Position 3

or BLK/WHT / Ground(24V

SOCKET HOUSING (DEUTSCH)

Position A

Position B

Position C

or BLK/WHT / Ground(24V

(AMP)

/ White (+) VDC

/ No Connection

/ Black / Ground

/ White (+)DCV

/ Sealing Plug

/ Black / Ground

)

)

123

A

C

B

600 Series 12 volt Specifications/

12

24

Input Voltage:

Input Current:

12.8 VDC +/- 20%

2 AMPS

600 Series 24 volt Specifications/

Input Voltage:

Input Current:

25.6 VDC +/- 20%

1 AMP

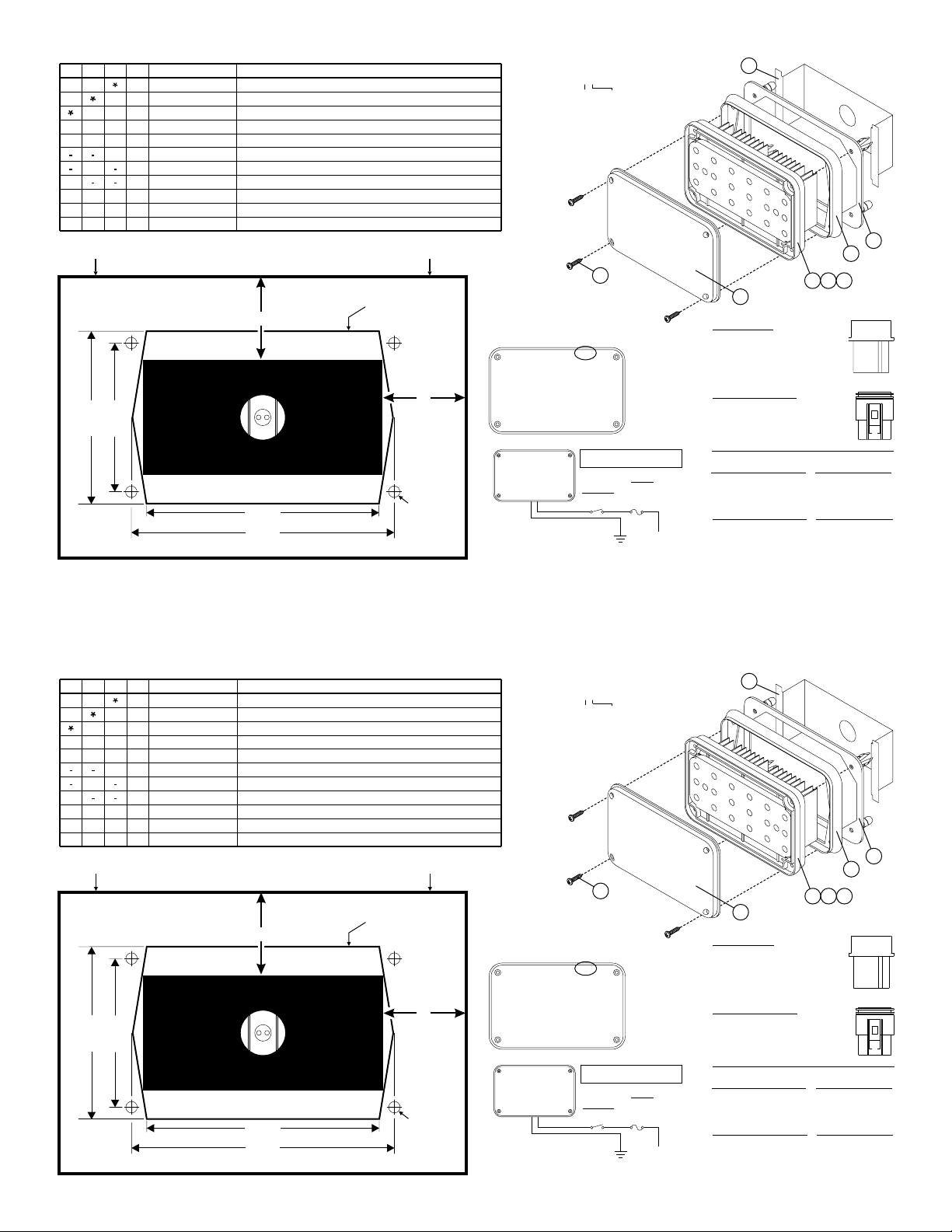

QTY QTY QTY

111

A/R

11

111

ITEM

444

A/R

A/R

1

111

PART NUMBER

01-066A669-_0

01-066A669-_1

01-066A669-_2

15-061416-280

1

68-1984963-30

2

01-026A533-_0

3

01-026A533-_1

4

5

01-026A533-_2

38-0464253-00

6

7

11-76D258-000

11-26A668-000

8

LED N C600 SERIES SCENELIGHT ( O ONNECTOR)

DESCRIPTION

LED AMP600 SERIES SCENELIGHT ( ™ CONNECTOR)

LED Deutsch600 SERIES SCENELIGHT ( ® CONNECTOR)

#6 X 1-3/4" PHILLIPS PAN HEAD SMS

LENS / CLEAR OPTIC SCENE LIGHT 600 SERIES

SUB-ASS'Y LED SCENE LT 600 NO CONNECTOR//

SUB-ASS'Y LED SCENE LT 600 AMP CONNECTOR//

SUB-ASS'Y LED SCENE LT 600 DEUTSCH CONN.//

GASKET 600 SERIES without FLANGE/

SCREW GROMMET FLANGE

COVER / HEATSINK 6/700 SCENE LT

This border represents the 2" clearance required around the perimeter of the heatsink.

NO VEHICLE COMPONENTS ARE ALLOWED WITHIN THIS AREA!

Following measurements shown,

2"

cut along this line.

Polycarbonate

3.770"

3.250"

Heatsink

Cover

2"

Lighthead

()Rear View

5.090"

5.750"

.250" Dia,

Mounting

Holes

(4) Places

Page 2

PART NO. KEY:

01-066A669-__

VOLTAGE

1=2=12V

24V

CONNECTOR

0=

1=

2=

1

NOTE: Proper lens orientation

requires the word "TOP"

to be at the top of the lens.

WHELEN ENG. CO 600

SAE-WW5-00

600 Series

LED Scenelight

TOP

WHELEN ENG. CO 600

WIRING DIAGRAM

Switch

(SP/ST)

NONE

AMP

DEUTSCH

SAE-STIR-00 DOT

Fuse 5A (for V)

3A (for V)

+VBAT

8

7

6

5

3

4

2

PIN HOUSING

Position 1

Position 2

Position 3

or BLK/WHT / Ground(24V

SOCKET HOUSING (DEUTSCH)

Position A

Position B

Position C

or BLK/WHT / Ground(24V

(AMP)

/ White (+) VDC

/ No Connection

/ Black / Ground

/ White (+)DCV

/ Sealing Plug

/ Black / Ground

)

)

123

A

C

B

600 Series 12 volt Specifications/

12

24

Input Voltage:

Input Current:

12.8 VDC +/- 20%

2 AMPS

600 Series 24 volt Specifications/

Input Voltage:

Input Current:

25.6 VDC +/- 20%

1 AMP

Loading...

Loading...