Page 1

®

ENGINEERING COMPANY INC.

Route 145, Winthrop Road,

Chester, Connecticut 06412

Phone: (860) 526-9504

Fax: (860) 526-2009

Internet: www.whelen.com

Sales/Service e-mail: aviation@whelen.com

90101 Series Strobe Light Power Supply

Installation . . .

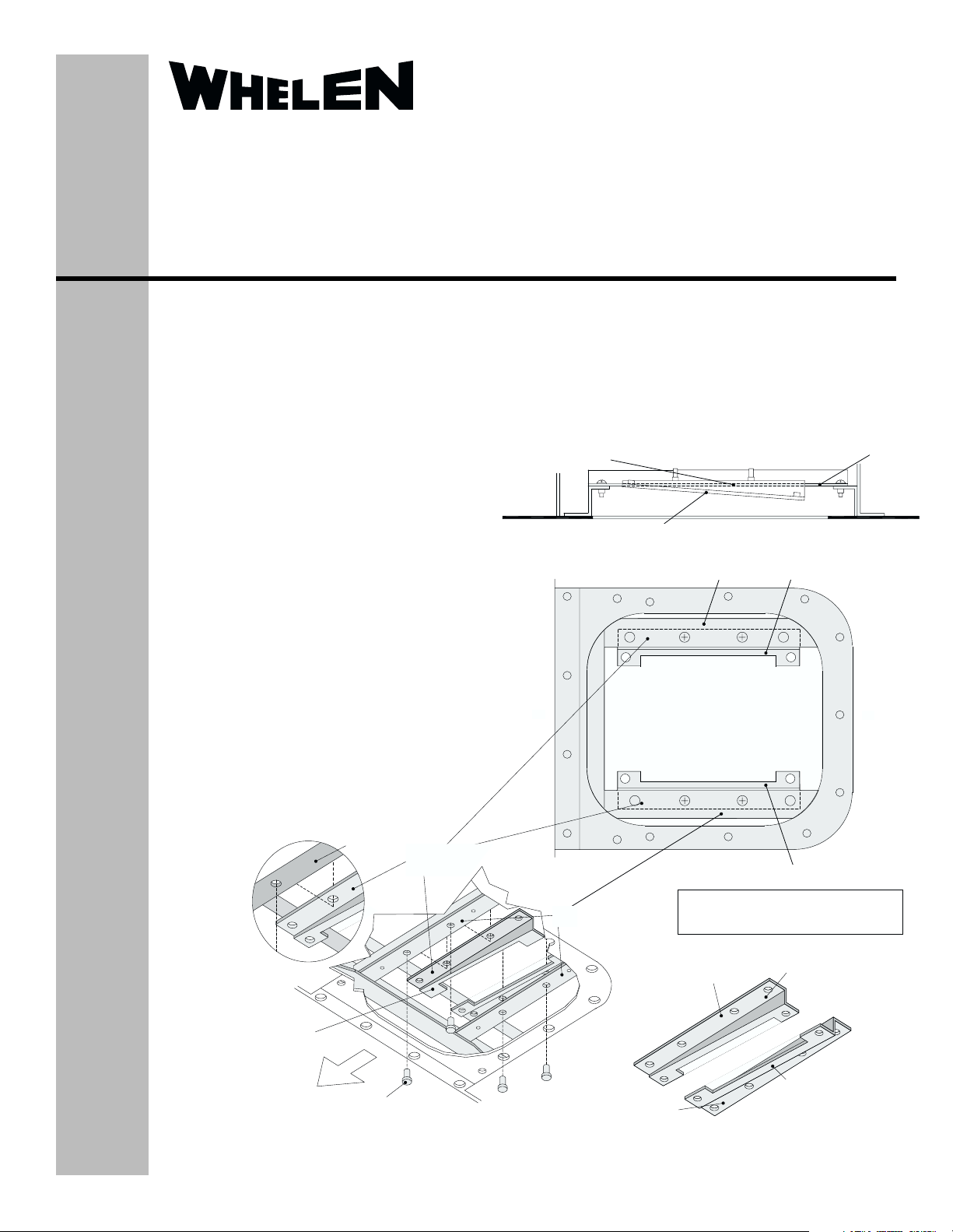

1. On both wings of the aircraft, remove the

wingtip access panel by unscrewing the

mounting screws.

2. Remove existing strobe light power supply

from the wing -t ip acc ess cut -out by re movi ng

the four mounting screws. Disconnect cables

from power supply.

3. Install the two supplied mounting brackets

(“A” and “B”) with lips on top of existing

brackets, located inside wing-tip access cutout, and secure with the four mounting

screws.

IMPORTANT NOTE: When brackets are

installed, insure that the upward slope is

facing outboard of the wing.

4. Connect the Whelen Strobe Light Power

Supply to the connectors of the existing

cables and install the power supply onto “A”

and “B” mounting brackets with the

connectors facing outboard. Secure the

power supply with the four #8-32 MS5195746mounting screws (supplied) to the “A” and

“B” mounting brackets.

5. Replace the wingtip access panel over the

wingtip cut-out, and secure w it h the m oun tin g

screws.

EXISTING

BRACKET

MOUNTING BRACKET

LIPS ON TOP OF EXISTING

BRACKETS

Wingtip Power Supply Replacement for

Cessna Citation 550, Ser ial #128 and above,

S550 and 560 serial #0001-0256 w ithout

SB560-3308 applied, with 90159 Series

Wingtip Strobe Light Assembly.

MOUNTING BRACKET LIPS

ON TOP OF EXISTING

BRACKETS

MOUNT. BRACKETS “A” & “B” TO SLOPE UPWARD FACING OUTBOARD OF AIRCRAFT WING

EXISTING BRACKET

OUTBOARD

MOUNTING BRACKET “B”

MOUNTING BRACKET “A”

EXISTING

BRACKET

VIEW A-A

INBOARD

MOUNTING BRACKETS “A”

AND “B” ARE TO SLOPE

UPWARD FACING OUTBOARD

OF AIRCRAFT WING

EXISTING MOUNTING SCREWS (QTY. 4) TO SECURE

Aviation

MOUNTING BRACKETS TO EXISTING BRACKETS

©1997 Whelen Engineering Company Inc.

Form No.13048C (052102)

EXISTING

BRACKET

D

AR

O

TB

U

O

BRACKET LIP

NOTE: ACCESS CUT-OUT SHOWN IN

ISOMETRIC DRAWINGS AS SEEN FROM

BELOW THE AIRCRAFT’S WING

MOUNTING BRACKET “B”

BRACKET LIP

PN / 11-170576-000

MOUNTING BRACKET “A”

PN / 11-170575-000

Page 1

Page 2

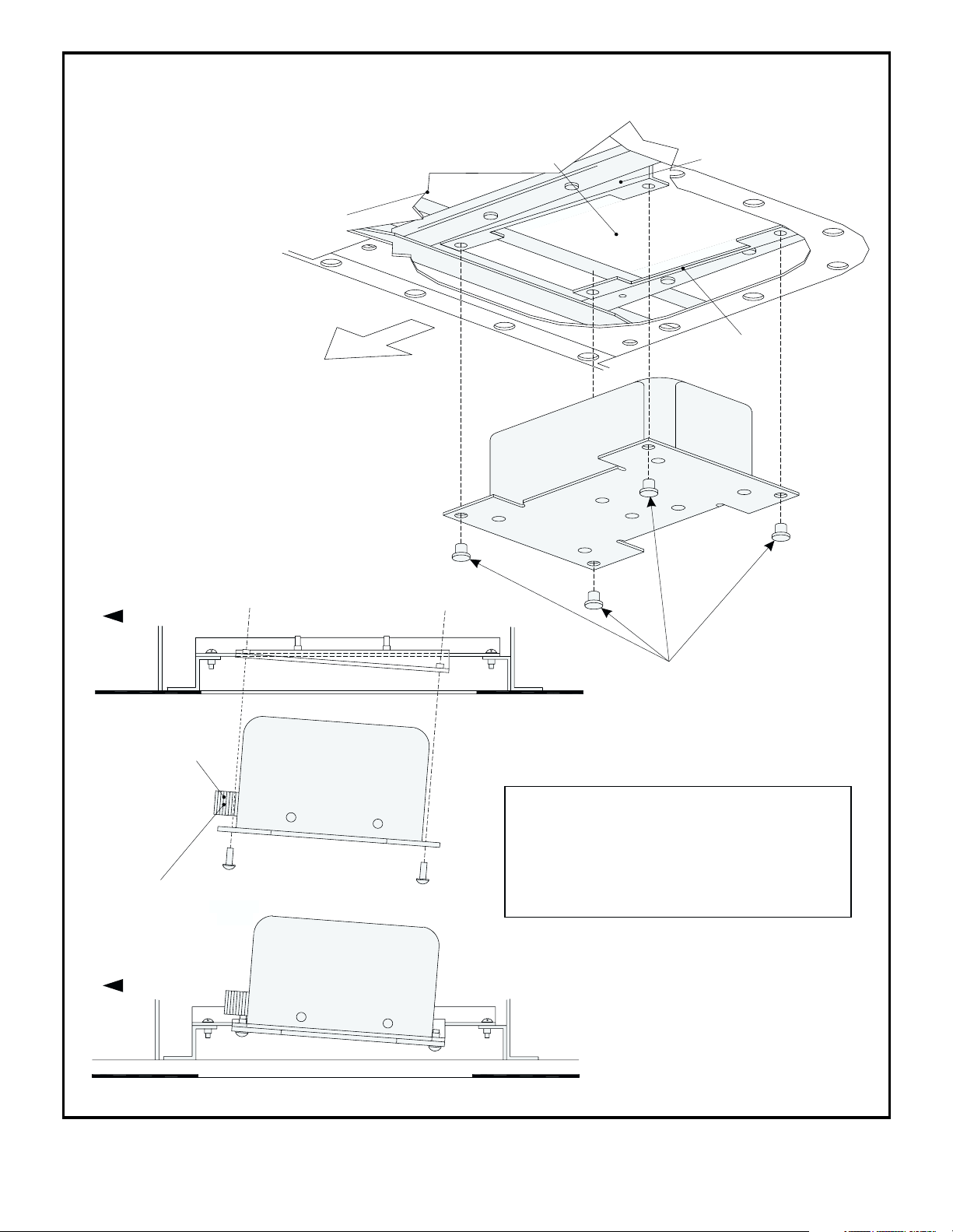

Strobe Light Power Supply Installation Instructions (Whelen 90101 Series)

AIRCRAFT

SKIN

UTBO

O

ARD

ACCESS

CUT-OUT

H

W

T

H

IG

L

MOUNTING

BRACKET “B”

MOUNTING

BRACKET “A”

E

B

O

Y

R

L

T

P

S

P

U

N

S

E

L

R

E

E

W

O

P

OUTBOARD

CONNECTORS ON STROBE

LIGHT POWER SUPPLY

MUST FACE OUTWARD

IMPORTANT NOTE: CONNECT

CABLES TO STROBE LIGHT

POWER SUPPLY BEFORE

INSERTING INSIDE ACCESS

CUT-OUT AND SECURE TO

MOUNTING BRACKETS.

OUTBOARD

WHELEN STROBE

LIGHT POWER SUPPLY

WHELEN STROBE

LIGHT POWER SUPPLY

Four, #8-32 (MS51957-46)

mounting screws to secure

strobe light power supply

to mounting brackets “A” & “B”

WARNING! THE STROBE LIGHT POWER SUPPLY

IS A HIGH VOLTAGE DEVICE. DO NOT REMOVE

STROBE TUBES OR DISMANTLE THE STROBE

LIGHT HEAD ASSEMBLIES WHILE IN OPERATION.

WAIT 10 MINUTES AFTER TURNING POWER

OFF

BEFORE STARTING WORK ON ANY TROUBLE

SHOOTING.

Form No.13048C

Page 2

Page 3

WHELEN 90159 SERIES WINGTIP

STROBE LIGHT ASSEMBLY

WARNING! THE STROBE LIGHT POWER SUPPLY IS A HIGH VOLTAGE

DEVICE DO NOT REMOVE STROBE TUBES OR DISMANTLE THE

WINGTIP SECTION

STROBE LIGHT HEAD ASSEMBLIES WHILE IN OPERATION.

OFF

WAIT 10 MINUTES AFTER TURNING POWER BEFORE STARTING

WORK ON ANY TROUBLE SHOOTING.

(MS51958-65)

BASE PLATE MOUNTING SCREWS (4)

#10-32 X ¾ INCH, PHILLIPS PAN HEAD

LENS GASKET

LENS

(MS51960-70)

PHILLIPS FLAT HEAD

LENS RETAINER MOUNTING

SCREWS (2), #10-32X1INCH,

NOTE: AT INSTALLATION,

MOUNTING SCREWS SHOULD BE

EVENLY

TIGHTENED TO A

MAXIMUM OF 13 IN./LBS. OF

LENS RETAINER

TORQUE.

IMPORTANT! SCREWS SHOULD

BE ALTERNATELY TIGHTENED

UNTIL THE FINAL TORQUE VALUE

HAS BEEN ACHIEVED.

TO POWER SUPPLY

Form No.13048C

(+ 28 VDC)

(-) GROUND

WHITE WIRE POSITIVE,

BLACK WIRE NEGATIVE,

BASE PLATE

Wingtip Anti-collision/

ASSEMBLY

Position Strobe Light Replacement

for Cessna 550 and 560 Series . . .

Page 3

the Whelen light assembly, using DME-20 or equivilant.

NOTE: CONNECTION METHOD TO BE CERTIFIED FAA TYPE.

1. Remove existing wingtip assembly.

2. Clean all excess adhesive from opening and mounting surface.

3. Fill lower hole, if any, with hardware included seperately.

4. Position doubler plate inside wing behind opening.

5. The position light wires should be fed through doubler plate.

6. Observe polarity of existing position light wires, and connect to the wires of

assembly to the doubler plate to align into position for step 9.

four base plate mounting screws.

7. Remove lens retainer, lens and gasket from base plate assembly.

8. Using the two lens retainer mounting screws, temporarily attach the base

9. Permanently align and attach base plate assembly to doubler plate using the

gasket, lens and lens retainer to base plate assembly, using the two lens

retainer screws. NOTE: Gasket should be aligned properly.

10. Remove the two lens retainer screws.

11. Following the proc edu re p r ov ide d f or th e m ou nti ng hard w are, se cu rely attach

13. Connect strobe power cable to strobe light power supply.

Page 4

DATE

11/17/92

11/2/92

DESCRIPTION

DELETED RIVETS

ADDED -02 & -03 UNITS

8386

8339

G

F

REV ECN

12/10/92

ADDED NOTES

8464

H

6/15/93

ADDED SHEET #4

9254

J

1/25/94

CHGD SPECS

10100

K

2/17/94

REV'D DWG & SPECS

10210

L

6/6/94

ROTATEMS CONNECTORS

10714

M

10/28/94

ADDED -05 ASSEMBLY

11300

N

2/2/95

ADDED -06 ASSEMBLY

11776

P

5/22/96

REVISEDRADIATED SUSCEPT. NOTE

14469

R

10/24/96

ADDED -07 ASSEMBLY

REV'DRADIATED SUSCEPT. NOTE

15283

T

3/4/97

REV'DRADIATED EMISSIONS NOTE

16256

U

7/8/97

ADDED-01 ASSEMBLY

17398

W

GENERAL NOTES:

(AVG)

JOULES......................16,6,6,6

FLASHRATE................45±5 BURSTS PER MIN.

INPUT CURRENT........4 AMPS or 2 AMPS

INPUT VOLTAGE.........14 VDC or 28 VDC (TYP)

1. SPECIFICATIONS:

WEIGHT......................1.7 lbs.

34 JOULES WITHIN 405ms.

ENERGY.....................22 JOULES WITHIN 200ms.

1.36 TYP.

PART NUMBERS 01-0790159-( ) MEETS THE MINIMUM REQUIREMENTS

STATED IN FAR PART 23 & PART 25 FOR ANTI-COLLISION LIGHT SYSTEMS.

2. THIS POWER SUPPLY (P/N 01-0790101-04) USED WITH STROBE LIGHT

TEMPERATURE/ALTITUDE - SECT. 4, CAT. D2

ENVIRONMENTAL TEST REQUIREMENTS IN ACCORDANCE WITH RTCA/DO-160C:

3. THE 01-0790101-04 POWER SUPPLY COMPLIES WITH THE FOLLOWING

VIBRATION - SECT. 8, ROBUST (8.6)

4

OFSHEET

25

2/18/94

REV

ROUTE145

CHESTER,CT 06412-0684

TELEPHONE(203) 526-9504

REL.DATE

POWER SUPPLY, STROBE LIGHT (HTS-CF-MS)

INPUT OUTPUT LABEL

01-0790101-04

10-0330445-00

1

1

ITEMQTY. DESCRIPTIONPARTNUMBER

R

PIONEERSIN SAFETY SIGNALS

DRAWINGWITHOUT WRITTEN AUTHORIZATION FROM WHELEN

COMPANYANY REPRODUCTION, DISCLOSURE OR USE OF THIS

THISDRAWING IS PROPRIETARY TO THE WHELEN ENGINEERING

WHELENENG. CO.

1994

C

ENGINEERINGCOMPANY

ENGINEERINGCOMPANY IS PROHIBITED.

UNLESSOTHERWISE SPECIFIED

TOLERANCE:

HTS - 90101 SERIES

1.7 lbs.

CALC.WT.

CONTRACTNO.

CUSTOMER

.XX = ±.03

ANGLES±1/2ANGLES °

90101 W

DWGNO.

NONE

POWER SUPPLY ASSY.

10402

SCALE

CAGECODE

2/21/94

2/18/94

10/28/94

10/28/94

DATE

DATE

DATE

DATE

JPA

VGC

VGC

GPS

APP.

ENG.

CH.

DR.

.XXX = ±.020

FINISH

MATERIAL

#

CAP PLUG

MFG. LABEL

POWER SUPPLY, HTS-CF-MS - MOD YAL14/28Q4516-1VA

22-0430469-00

01-0267530-00

10-0530592-02

2

41

13

2

POWER INPUT - SECT. 16, CAT B

SALT SPRAY - SECT. 14, CAT. S

SAND & DUST - SECT. 12, CAT. D

FLUIDS SUSCEPTABILITY - SECT. 11, SPRAY TEST (11.4.1)

WATERPROOFNESS - SECT. 10, CAT. S

VOLTAGE SPIKE - SECT. 17, CAT. B, PAR. 17.4

AUDIO FREQUENCY CONDUCTED SUSPECT. - SECT. 18, CAT. B, PAR. 18.3.1

MAGNETIC FIELDS INDUCED INTO EQ. - SECT. 19, CAT. B, PAR. 19.3.1

SPIKES INDUCED INTO INTERCONN. CABLES - SECT. 19, CAT. B, PAR 19.3.4

RADIATED AND CONDUCTED SUSCEPTABILITY - SECT. 20, CAT. U, PAR 20.4, 20.5

U

RADIATED AND CONDUCTED EMISSIONS - SECT. 21, CAT. B, PAR. 21.3, 21.4

R

4. FAA - STC, TSO - C96a APPROVED

5.60

.187 DIA.

(4) MOUNTING HOLES

5.100 MTG.

.25

321

5.00

TEST

AFTER FINAL

INSTALL CAP

.95

.25

3.625 MTG.

4.13

3.21

.080

CONN.(REF)

WIRING

C=SYNC.

B=GROUND(-)

A=POWER(+)

OR EQUIVALENT

MS3102R10SL-3P

INPUT

C=SYNC.

B=GROUND-

3.12

A=POWER

OUTPUT

A=ANODE

C=CATHODE

B=TRIGGER

Form No.13048C

Page 4

WIRING

OR EQUIVALENT

MS3102R10SL-3S CONN.(REF)

C=CATHODE

B=TRIGGER

A=ANODE

Page 5

1/19/9381/19/93

CHG 70603 TITLE

UPDATEDWG

ADD SHEET 2

ADD SHIELD GRD9213

REMOVE GASKET

CHG P/N OF IT 5

REV STROBE ASSY

REV'D SCREWS TO #6

9526

9149

9881

9019

8615

8902

B

A

REV ECN DESCRIPTION DATEREV ECN DESCRIPTION DATE

5/20/02

11/12/98

ADD "STC", DELETED "PMA"

ADDED TORQUESPEC TO LENS

RETAINERMTG SCREWS

20986

25628

U

V

10025

F

D

E

G

H

C

.62 R.

4/24/96

5/22/96

3/13/97

10/16/95

11/21/95

ROUTE 145

CHESTER, CT06412-0684

RIGHT LIGHTASSY. POS./ANTI-COLL. (PLASTIC LENS)01-0790159-02

01-0790159-05 LEFTLIGHT ASSY.POS./ANTI-COLL. (GLASS LENS)

*

*

R

LEFT LIGHTASSY. POS./ANTI-COLL. (PLASTIC LENS)

PART NUMBER DESCRIPTION

01-0790159-01

*

THISDRAWING IS PROPRIETARY TO THE WHELEN ENG.CO. INC., ANY

QUANTITY ITEM

REPRODUCTION,DISCLOSURE OR USE OF THIS DRAWING WITHOUT

TELEPHONE (860) 526-9504

ENGINEERING COMPANYINC.

MATERIAL

WRITTENAUTHORIZATION FROM WHELEN ENG. CO. INC. IS PROHIBITED

USEITEM 7 GASKET

ADDEDWEIGHTS

-05THRU -08

ADDEDFAA NOTE

CHANGEDP/N ITEM 5

ADDEDNEW ASSEMBLYS

CH.HDWARE, ADDED GASKET

DELETEDGASKET FOR GLASS LENS

REVISEDRADIATED SUSCEPT. NOTE

REV'DRADIATED SUSCEPT. NOTE

REV'DRADIATED EMISSIONS NOTE

ADDEDASSY'S -09 & -10

13401

M

13609

14305

N

P

REQUIRED IN WINGTIP

MIN. OPENING

14470

R

ADDEDITEM # 22

16349

T

NOTES:

1. SPECIFICATIONS:

POSITION LIGHT VOLTAGE......27.5V+/-0.5V

AVIATIONRED, GREEN, AND WHITE.

2. UNIT COMPLIES WITH COLOR REQUIREMENTS OF FARPART 25.1397(a).

POWER SUPPLYOF 22 JOULES MINIMUM, 30 JOULES MAXIMUM.

3. UNIT COMPLIES WITH FARPART 25.1401 REQUIREMENTS USING AN APPROVED

IN ACCORDANCE WITH RTCA/DO-160C:

4. UNIT COMPLIES WITH THE FOLLOWING ENVIRONMENTALTEST REQUIREMENTS

FLASHTUBE.............................XENON

VIBRATION:SECT. 8, ROBUST (8.6)

HUMIDITY: SECT.6, CATEGORY C

TEMPERATURE/ALTITUDE:SECT. 4, CATEGORYD2

LABEL, MFG.

RETAINER,LENS - POSITION LIGHT

LENS, GLASS

#10-32 X 1" PHILLIPS FHMS14-0050619-69

LENS, POSITION LIGHT - RED

1/8 x 1/2 FOAM PAD38-0125020-00

10-0530693-02

68-4230020-50

11-270587-001

68-4170665-30

68-4170665-34 LENS,GLASS EMI COATED

17

18

16

21--11

20

19

1

-

1

11

22

1

-

1111

--

11

-

111--1111111

22

1122

-1

1

1

-01 & -02 W/PLASTIC LENS - 1.3 lbs.

RADIATEDAND CONDUCTED EMISSIONS: SECTION 21, CATEGORY B, PAR. 21.3, 21.4

RADIATEDAND CONDUCTED SUSCEPTABILITY: SECTION 20, CATEGORYU, PAR. 20.4, 20.5

SPIKES INDUCED INTO INTERCONN. CABLES: SECT.19, CAT. B, PAR.19.3.4

VOLTAGESPIKE: SECT. 17, CATEGORYB, PAR. 17.4

WATERPROOFNESS:SECT. 10, CATEGORY S

FLUIDS SUSCEPTABILITY:SECT. 11, SPRAYTEST (11.4.1)

SALTSPRAY: SECT. 14, CATEGORYS

EXPLOSION: SECT.9, CATEGORY A

MAGNETIC FIELDS INDUCED INTO EQ.: SECTION 19, CAT.B, PAR. 19.3.1

POWER INPUT:SECTION 16, CATEGORY B

SAND AND DUST:SECTION 12, CATEGORY D

AUDIO FREQENCY CONDUCTED SUSCEPTABILITY:SECT. 18, CAT.B, PAR. 18.3.1

R

6. WEIGHTS: -05 & -06 W/GLASS LENS - 1.9 lbs.

5. FAA- STC, TSO-C30c AND TSO-C96a APPROVED.

T

11-- - - 22

GASKET,LENS - POSITION LIGHT

LAMP - W1290-28

LENS, POSITION LIGHT - GREEN

38-0230021-00

34A0428020-65

68-4230020-40

15

-

114

113

1

11

11

1-

RETAINER,PLASTIC LENS

LENS, PLASTIC

LABEL, MADE IN USA

LABEL, MFG.-01 & -02 ASSYS.

SCREW, 6-32 X 1/2 PPHMS (MS51957-30)

14-0050503-30

19-190154-001

68-4170581-3A

10-0320776-00

10-0530572-02

84716

112

1111019

11

11111

--

-

44111111441111

-

--

-

--

-

--

11

GASKET,LENS

STROBE ASSY- WINGTIP LIGHT

SCREW, 6-32 X 3/4 PPHSS (MS51957-32)

14-0050503-32

38-0270590-00

02-0270603-00

1

15441321

RETAINER,GLASS LENS

BASEPLATEASSY, WINGTIP LIGHT

#10-32 X 3/4" PPHMS

14-0050620-65

19-190187-001

06-170600-000

--

11

11

DOUBLER PLATE

01-0790159-10 RIGHTLIGHT ASSY.POS./ANTI-COLL. (EMI GLASS)

07-790157-001

1

1141141

11114411111144

*

RIGHT LIGHTASSY. POS./ANTI-COLL. (GLASS LENS)

LEFT LIGHTASSY. POS./ANTI-COLL. (EMI GLASS)

01-0790159-09

01-0790159-06

*

*

SEE SHEET 211057

13203

11312

J

L

K

12

11/1/94

RELEASEDATEDATESCALEDR.TOLERANCE: UNLESS OTHERWISE SPECIFIED

ISSUE SHEET OF

11/30/92

WINGTIP LIGHT

NONE

POSITION/ANTI-COLLISION

90159 V

DWGNO. REV

JAN

JAN

VGC

GPS

CH.

ENG.

APP.

10402

CAGECODEWHELENENG. CO. INC.

.XX=±.02

.XXX=±.002

1994

C

ANGLES ± 1/2°

FINISH

2/5/96CHANGEDMOUNTING HARDWARE

11/1/94

9/7/94

1/13/94

12/2/93

8/27/93

6/3/93

5/17/93

4/6/93

9.375

CLEARANCE HOLES FOR #10

8.12

3.45

.49

(2)PLACES

(2) PLACES

LENS RETAINER MOUNTING SCREW

2.38

A - ANODE

B - TRIGGER

3 PIN CONNECTOR

MS 3106F-10SL-3P

1.6

C - CATHODE

19.11 R.

7.65 R.

MOUNTING CONFIGURATION

.85 R.

2

10

22

20

NOTE:

MOUNTING SCREWS TO

BE TIGHTENED EVENLY

TO A MAXIMUM OF

13 IN./LBS. OF TORQUE.

IMPORTANT...

SCREWS SHOULD BE

ALTERNATELY TIGHTENED

UNTIL THE FINAL TORQUE

VALUE HAS BEEN

9765431

ACHIEVED.

19

8

1815

BY MOUNTING SCREW (ITEM 4)

SHIELD GROUND: TO BE SECURED

WHITE (POSITIVE)

BLACK (GROUND)

17

16

14

Form No.13048C

13

4

11.03

9.375

26"

APPROX.

1.89

22"

APPROX.

12

21

11

.62

3.06

3.50

(PLASTIC LENS)

3.65

REF.

WINGTIP SECTION

(GLASS LENS)

Page 5

Page 6

DATEREV ECN

12/2/93

8/27/93

DESCRIPTION

UPDATEDWG

ADDSHEET 2 (W\TAILIGHT)

9881

9526

G

F

REV ECN

DATE

5/20/02

11/12/98

DESCRIPTION

ADDEDTORQUE SPEC TO LENS

RETAINERMTG SCREWS

ADD"STC", DELETED "PMA"

25628

20986

V

U

9.375

3.45

1/13/94

ADDTAIL LIGHT SHIELD

10025

H

11/1/94

9/7/94

10/16/95

11/21/95

2/5/96

4/24/96

5/22/96

3/13/97

ADDEDWEIGHTS

ADDEDFAANOTE

ADDEDNEW ASSEMBLYS

CHANGEDP/N ITEM 3

-05THRU -08

CHANGEDMOUNTING HARDWARE

DELGASKET FOR GLASS LENS

USEITEM 10 GASKET

CHANGEDHARDWARE, ADDED GASKET

CHGTAIL LIGHT SHIELD

REVISEDRADIATED SUSCEPT. NOTE

REVISEDRADIATED SUSCEPT. NOTE

REVISEDRADIATED EMISSIONS NOTE30ADDEDITEM #30

ADDEDASSY'S -11 AND -12

11057

11312

13401

14302

13203

13609

14470

J

16349

K

M

P

L

N

R

T

#10-32 X 1" PHILLIPS FHMS

#10-32 X 3/4" PPHMS

GASKET,LENS

SCREW, 6-32 X 1/2 PPHSS (MS51957-30)

14-0050620-65

38-0270590-00

14-0050503-30

819110

44

11

11

441111

LAMPHOLDER ASSY,TAIL LIGHT (WINGTIP)

LAMP,ESG HALOGEN 28V

SCREW, 2-56 X 5/8 PPHM (MS51957-08)

14-0050531-08

34-0428070-64

11

11

11

11

11

11

11

11

BASEPLATEASSY, WINGTIP LIGHT

STROBE ASSY,WINGTIP LIGHT

NUT,2-56 SELF-LOCKING (MS21042-02)

13-0050517-02

06-170600-001

02-0270603-00

2

314451617

11

1

141

11441

141

141

141

DOUBLER PLATE

RIGHT LIGHTASSY. POS./ANTI-COLL/TAIL(EMI GLASS)

07-790177-001

01-0790159-12

1

1

1

1

1

1

*

LEFT LIGHTASSY. POS./ANTI-COLL/TAIL(EMI GLASS)

01-0790159-11

*

NOTES:

FLASHTUBE.............................XENON

POSITION LIGHT VOLTAGE......27.5V0.5V

1. SPECIFICATIONS:

.62 R.

AVIATIONRED, GREEN, AND WHITE.

2. UNIT COMPLIES WITH COLOR REQUIREMENTS OF FARPART 25.1397(a).

POWER SUPPLYOF 22 JOULES MINIMUM, 30 JOULES MAXIMUM.

3. UNIT COMPLIES WITH FARPART 25.1401 REQUIREMENTS USING AN APPROVED

VIBRATION:SECT. 8, ROBUST (8.6)

HUMIDITY: SECT.6, CATEGORY C

TEMPERATURE/ALTITUDE: SECT. 4, CATEGORYD2

IN ACCORDANCE WITH RTCA/DO-160C:

4. UNIT COMPLIES WITH THE FOLLOWING ENVIRONMENTALTEST REQUIREMENTS

RETAINER, PLASTIC LENS

LENS, PLASTIC

LABEL, MADE IN USA

LENS, POSITION LIGHT - RED

RETAINER, LENS - POSITION LIGHT

LENS, POSITION LIGHT - GREEN

LAMP - W1290-28

GASKET,LENS - POSITION LIGHT

68-4230020-50

68-4230020-40

34A0428020-65

38-0230021-00

16

17

18

19

1

1

1

-

11111

-

1111-

-

-

-

-

1111-

LABEL, MFG.

19-190154-0011102-0250546-00

68-4170581-3A

10-0320776-00

14-0050619-69

10-0530692-02

15

11112113

14

22

11114

-

-

--

22

-1111

-1111

-

--

-

1/8 x 1/2 FOAM PAD

FLATWASHER,#4 BRASS

SCREW, 6-32 X 3/4 PPHSS (MS51957-32)

SHIELD, TAILLIGHT - WINGTIP

GROMMET

SCREW, 6-32 X 5/16 PPHSS

RETAINER, GLASS LENS

LENS, GLASS

LABEL, MFG.

LENS, GLASS EMI COATED

11-270587-001

16-0400910-03

14-0050503-32

21-11091202-0

14-0050503-27

23

25

24

22

11

11

11

11

38-0125020-00

222120

1

1

11

11

12211

1

11

1

11

12211

70-0350567-00

19-190187-001

68-4170665-30

10-0530694-02

68-4170665-34

26

28

27

11

--

-03 & -04 W/PLASTIC LENS - 1.4 lbs.

--

--2911

EXPLOSION: SECT.9, CATEGORY A

MAGNETIC FIELDS INDUCED INTO EQ.: SECTION 19, CAT. B, PAR.19.3.1

POWER INPUT:SECTION 16, CATEGORY B

SAND AND DUST:SECTION 12, CATEGORY D

SPIKES INDUCED INTO INTERCONN. CABLES: SECT.19, CAT. B, PAR.19.3.4

AUDIO FREQENCY CONDUCTED SUSCEPTABILITY:SECT. 18, CAT.B, PAR. 18.3.1

R

5. FAA- STC, TSO-C30c AND TSO-C96a APPROVED.

T

RADIATEDAND CONDUCTED EMISSIONS: SECTION 21, CATEGORY B, PAR. 21.3, 21.4

RADIATEDAND CONDUCTED SUSCEPTABILITY: SECTION 20, CATEGORYU, PAR. 20.4, 20.5

VOLTAGESPIKE: SECT. 17, CATEGORYB, PAR. 17.4

WATERPROOFNESS:SECT. 10, CATEGORYS

FLUIDS SUSCEPTABILITY:SECT. 11, SPRAYTEST (11.4.1)

SALTSPRAY: SECT. 14,CATEGORY S

11

11

11----30

11

11

11

111122

--

6. WEIGHTS: -07 & -08 W/GLASS LENS - 2.0 lbs.

28

12

8.12

19.11 R.

8

7

24

26

7.65 R.

NOTE:

PLACE BETWEEN LAMPHOLDER

AND MOUNTING SURFACE

23

6

.49

2.38

.85 R.

MIN. OPENING

REQUIRED IN WINGTIP

MOUNTING CONFIGURATION

9

27

11

10

LEFT LIGHTASSY. POS./ANTI-COLL/TAIL(GLASS LENS)

RIGHT LIGHTASSY. POS./ANTI-COLL/TAIL(GLASS LENS)

RIGHT LIGHTASSY. POS./ANTI-COLL/TAIL(PLASTIC LENS)

01-0790159-04

01-0790159-08

01-0790159-07

*

*

*

13

ROUTE 145

LEFT LIGHTASSY. POS./ANTI-COLL/TAIL(PLASTIC LENS)

PART NUMBER DESCRIPTION

01-0790159-03

*

THISDRAWING IS PROPRIETARY TO THE WHELEN ENG.CO. INC., ANY

QUANTITY ITEM

NOTE:

MOUNTING SCREWS TO

BE TIGHTENED EVENLY

CHESTER, CT06412-0684

R

REPRODUCTION,DISCLOSURE OR USE OF THIS DRAWING WITHOUT

TO A MAXIMUM OF

TELEPHONE (860) 526-9504

ENGINEERINGCOMPANY INC.

MATERIAL

WRITTENAUTHORIZATION FROM WHELEN ENG. CO. INC. IS PROHIBITED

13 IN./LBS. OF TORQUE.

22

11/1/94

RELEASEDATEDATESCALEDR.TOLERANCE: UNLESS OTHERWISE SPECIFIED

ISSUE SHEET OF

7/29/93

WINGTIP LIGHT

NONE

90159 V

POSITION/ANTI-COLLISION

DWGNO. REV

VGC

GPS

JNELSON

JNELSON

CH.

ENG.

APP.

10402

CAGECODE

.XX=±.02

.XXX=±.002

WHELENENG. CO. INC.

1993

C

ANGLES ± 1/2°

FINISH

IMPORTANT...

SCREWS SHOULD BE

ALTERNATELY TIGHTENED

UNTIL THE FINAL TORQUE

VALUE HAS BEEN

ACHIEVED.

22

CLEARANCE HOLES FOR #10

(2)PLACES

(2) PLACES

LENS RETAINER MOUNTING SCREW

MS 3106F-10SL-3P

3 PIN CONNECTOR

1.6

11.03

9.375

A -ANODE

.62

C - CATHODE

B - TRIGGER

9

BLACK (GROUND)

WHITE (POSITIVE)

SHIELD GROUND: TO BE SECURED

BY MOUNTING SCREW (ITEM 8)

345

2

201716

19

18 21

25

1

22"

APPROX.

26"

APPROX.

1.89

3.06

3.50

(PLASTIC LENS)

22"

APPROX.

REF.

WINGTIP SECTION

8

15

29

14

Form No.13048C

3.65

(GLASS LENS)

Page 6

Loading...

Loading...