Page 1

®

ENGINEERING COMPANY INC.

51 Winthrop Road

Chester, Connecticut 06412-0684

500 Series Linear Super-LED® Lighthead

Installation Guide:

Phone: (860) 526-9504

Fax: (860) 526-4078

Internet: www.whelen.com

Sales e-mail: autosale@whelen.com

Canadian Sales e-mail: autocan@whelen.com

Customer Service e-mail: custserv@whelen.com

Safety First

This document provides all the necessary information to allow your Whelen product to be properly and safely installed.

Before beginning the installation and/or operation of your new product, the installation technician and operator must

read this manual completely. Important information is contained herein that could prevent serious injury or damage.

• Proper installation of this product requires the installer to have a good understanding of automotive electronics,

systems and procedures.

• If mounting this product requires drilling holes, the installer MUST be sure that no vehicle components or other

vital parts could be damaged by the drilling process. Check both sides of the mounting surface before drilling

begins. Also de-burr any holes and remove any metal shards or remnants. Install grommets into all wire

passage holes.

• If this manual states that this product may be mounted with suction cups, magnets, tape or Velcro®, clean the

mounting surface with a 50/50 mix of isopropyl alcohol and water and dry thoroughly.

• Do not install this product or route any wires in the deployment area of your air bag. Equipment mounted or

located in the air bag deployment area will damage or reduce the effectiveness of the air bag, or become a

projectile that could cause serious personal injury or death. Refer to your vehicle owner’s manual for the air bag

deployment area. The User/Installer assumes full responsibility to determine proper mounting location, based

on providing ultimate safety to all passengers inside the vehicle.

• For this product to operate at optimum efficiency, a good electrical connection to chassis ground must be

made. The recommended procedure requires the product ground wire to be connected directly to the NEGATIVE

(-) battery post.

• If this product uses a remote device to activate or control this product, make sure that this control is located in

an area that allows both the vehicle and the control to be operated safely in any driving condition.

• Do not attempt to activate or control this device in a hazardous driving situation.

• This product contains either strobe light(s), halogen light(s), high-intensity LEDs or a combination of these

lights. Do not stare directly into these lights. Momentary blindness and/or eye damage could result.

• Use only soap and water to clean the outer lens. Use of other chemicals could result in premature lens cracking

(crazing) and discoloration. Lenses in this condition have significantly reduced effectiveness and should be

replaced immediately. Inspect and operate this product regularly to confirm its proper operation and mounting

condition. Do not use a pressure washer to clean this product.

• It is recommended that these instructions be stored in a safe place and referred to when performing

maintenance and/or reinstallation of this product.

• FAILURE TO FOLLOW THESE SAFETY PRECAUTIONS AND INSTRUCTIONS COULD RESULT IN DAMAGE TO

THE PRODUCT OR VEHICLE AND/OR SERIOUS INJURY TO YOU AND YOUR PASSENGERS!

Automotive: Lightheads

For warranty information regarding this product, visit www.whelen.com/warranty

©2004 Whelen Engineering Company Inc.

Form No.13949G (032008)

Page 1

Page 2

NOTICE! Prior to installing on any vehicle, check your state motor

vehicle codes to confirm that this product complies with any and all

state statutes.

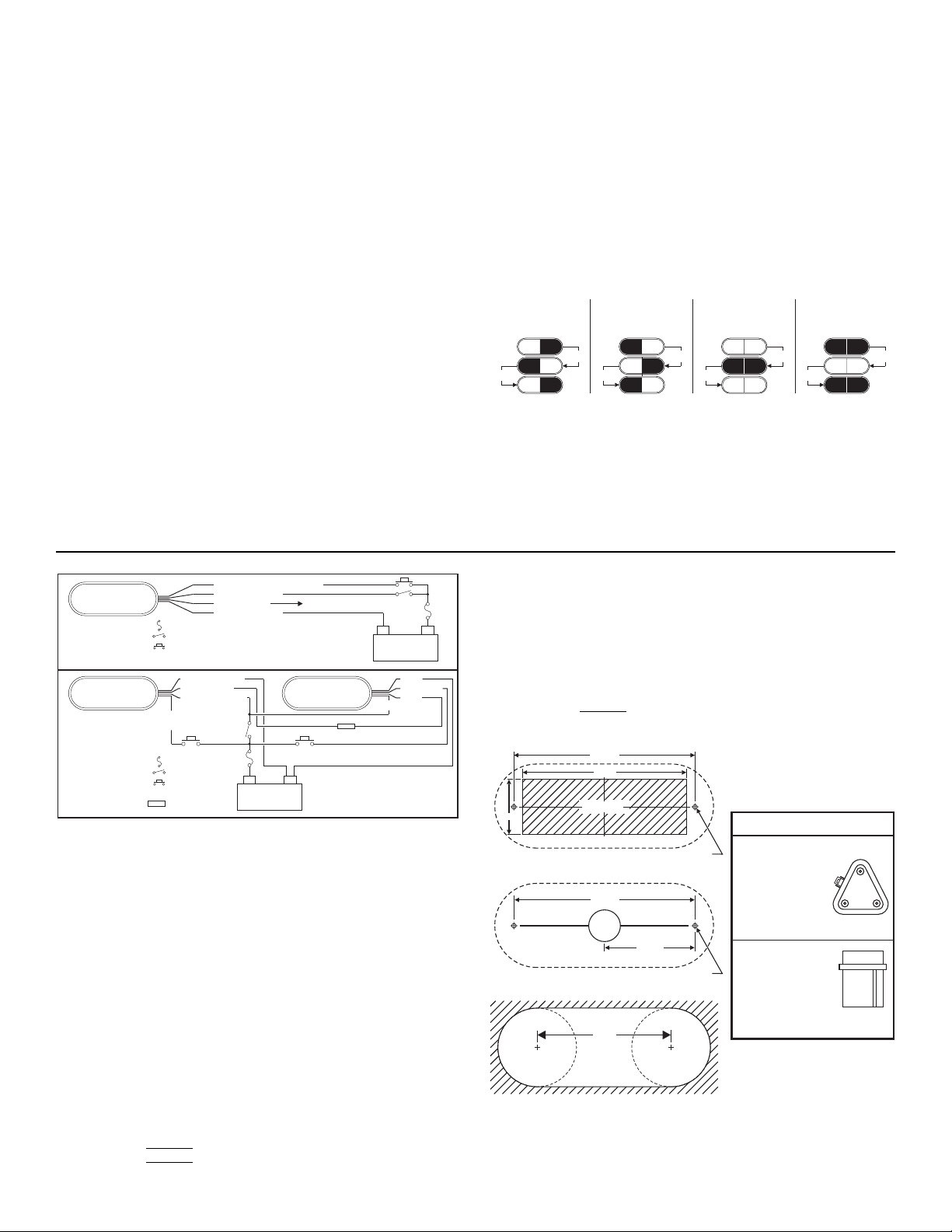

Installation: Refer to the diagrams shown for mounting measurements

specific to your model.

IMPORTANT: Customer supplied wire must be a minimum of 18 gauge.

5FLANGE* Notes: Mark the mounting and cut out holes onto the

mounting surface. Drill the 2 mounting holes to the sizes noted and

remove the area that the lighthead fits into. Thread the wires through the

rubber gasket and extend to your power source. Attach the housing to

vehicle using the flange and supplied mounting hardware. Extend the

wires to your power source.

5TSMA* and 5LSMA* Notes: Mark off the measurements and drill the

wire access and mounting holes. Thread the wires through the rubber

gasket, through the wire access hole and to your power source. Attach

housing to vehicle using supplied mounting hardware and flange. Extend

the wires to your power source.

5GROMMET Notes: Mark off the measurements, drill the two 1.25” holes

and cut out the center area. Install the rubber grommet. Assemble the

flange, lighthead and adapter then snap this assembly into the grommet.

Extend the wires to your power source.

Scan-Lock™: To advance pattern: With the lighthead active, apply

+VBAT to the WHT/VIO wire for less than 1 second. To cycle to previous

patterns: Apply +VBAT for more than 1 second. To restore factory

default pattern: Turn off power to the lighthead. Apply +VBAT to the

WHT/VIO wire while turning the lighthead on. Continue to apply voltage to

the WHT/VIO wire for 5 seconds.

SYNC Operation: Some of the patterns available for the standard SYNC

lighthead are described as being either Phase 1 (PH.1) or Phase 2 (PH.2).

These terms define how patterns on lightheads with their SYNC wires

connected relate to each other. Lightheads configured to display the same

Phase of a given pattern (Phase 1 or Phase 2) will flash simultaneously.

Lightheads configured to Phase 2 of a given pattern will alternate with

Phase 1 lightheads.

Split lightheads have 2 additional phases. Their operation is more easily

understood using the following illustration:

Split Lighthead Operation

PHASE 1

LEFT

side lights up and

ON OFF

then

ON OFF

RIGHT

with side.alternates

then

ONOFF

RIGHT

then

PHASE 2

side lights up and

LEFT

with side.alternates

ONOFF

then

ON OFF

ONOFF

PHASE 3

BOTH sides flash together

(ON-OFF-ON).

ON ON

then

then

Note: Phases 3 & 4 are visually indistinguishable.

OFFOFF

ON ON

PHASE 4

BOTH sides flash together

(OFF-ON-OFF).

OFFOFF

then

ON ON

then

OFFOFF

NOTE: The SYNC wire can be connected to other SYNC-capable power

supplies to synchronize their output.

Be sure to cap the SYNC wire if it is not used.

IMPORTANT! Before returning the vehicle to active service, visually

confirm the proper operation of this product, as well as all vehicle

components/equipment.

Wiring

500 Series

Lighthead

500 Series

Lighthead

= 3A Fuse

= SP/ST Switch

= Momentary

WHT/VIO

(Scan-Lock™)

= 3A Fuse

= SP/ST Switch

= Momentary

= Butt Splice

WHT/VIO (Scan-Lock™)

RED (+12VDC)

GRY (Sync)

BLK (Ground)

Switch (N.O.)

BLK (Ground)

GRY (Sync)

RED (+12VDC)

Switch (N.O.)

Cut & cap GRY wire

All switches and fuses

are customer supplied

500 Series

Lighthead

(-)

(+)

Battery

(-)

Battery

BLK

WHT/VIO

GRY

RED

All switches and fuses

are customer supplied

(+)

Split Lighthead Patterns

1. SignalAlert™ 75 ...... PH.1

2. SignalAlert 75 .......... PH.2

3. SignalAlert 75 .......... PH.3

4. SignalAlert 75 .......... PH.4

5. CometFlash® 75 ..... PH.1

6. CometFlash 75 ........ PH.2

7. CometFlash 75 ........ PH.3

8. CometFlash 75 ........ PH.4

9. DoubleFlash 75...... PH.1

10. DoubleFlash 75...... PH.2

11. DoubleFlash 75...... PH.3

12. DoubleFlash 75...... PH.4

13. SingleFlash 75 ....... PH.1

14. SingleFlash 75 ....... PH.2

15. SingleFlash 75 ....... PH.3

16. SingleFlash 75 ....... PH.4

17. ComAlert™ 75......... PH.1

18. ComAlert 75 ............ PH.2

19. ComAlert 75 ............ PH.3

20. ComAlert 75 ............ PH.4

21. LongBurst™ 75 ....... PH.1

22. LongBurst 75 ........... PH.2

23. LongBurst 75 ........... PH.3

24. LongBurst 75 ........... PH.4

25. PingPong™ 75 ....... PH.1

26. PingPong 75 ........... PH.2

27. PingPong 75 ........... PH.3

28. PingPong 75 ........... PH.4

29. SSNF 75 ..................PH.1

30. SSNF 75 ..................PH.2

31. SingleFlash 60......... ALT

32. SingleFlash 60..........SIM

33. SingleFlash 90......... ALT

34. SingleFlash 90..........SIM

35. SingleFlash 120....... ALT

36. SingleFlash 120........SIM

37. SingleFlash 300 .........ALT

38. SingleFlash 300 .........SIM

39. DoubleFlash 150........ALT

40. DoubleFlash 150........SIM

41. ComAlert™150 ..........ALT

42. ComAlert150.............. SIM

43. ActionFlash™50 ........ALT

44. ActionFlash50 ............SIM

45. ActionFlash150 ..........ALT

46. ActionFlash150 ..........SIM

47. ModuFlash™ .............ALT

48. ModuFlash .................SIM

49. DoubleFlash 120...... ALT

50. DoubleFlash 120...... SIM

51. PingPong 120 ..........ALT

52. PingPong 120 .......... SIM

53. TripleFlash™ 75.......ALT

54. TripleFlash 75 .......... SIM

55. TripleFlash 120 ........ ALT

56. TripleFlash 120 ........ SIM

57. SigAlert Cal.............. ALT

58. SigAlert Cal.............. SIM

59. Action 1 .................... ALT

60. Action 1 .................... SIM

61. Action 2 .................... ALT

62. Action 2 .................... SIM

63. CalScan™ .........ALT/SIM

64. ActionScan™ .....ALT/SIM

65. SteadyFlash 60

66. SteadyFlash 75

67. SteadyFlash 90

68. SteadyFlash 120

69. Steady & Steady

NOTE: BOLD = California Title XIII Compliant Pattern Italic = SYNC Patterns

NOTE: PHASE 1 ALWAYS ALTERNATES WITH PHASE 2

PHASE 3 ALWAYS

ALTERNATES WITH PHASE 4

Standard Lighthead Patterns

1. SignalAlert™ 75 .......PH.1

2. SignalAlert™ 75 .......PH.2

3. CometFlash® 75 ...... PH.1

4. CometFlash® 75 ...... PH.2

5. DoubleFlash 75........ PH.1

6. DoubleFlash 75........ PH.2

7. SingleFlash 75 .........PH.1

8. SingleFlash 75 .........PH.2

9. ComAlert™ 75 .........PH.1

10. ComAlert™ 75 ......... PH.2

11. LongBurst™ 75 ....... PH.1

12. LongBurst™ 75 ....... PH.2

13. PingPong™ 75 ........ PH.1

14. PingPong™ 75 ........ PH.2

15. SingleFlash 60

16. SingleFlash 90

17. SingleFlash 120

18. SingleFlash 300

19. DoubleFlash 150

20. ComAlert™150

21. ActionFlash™1

22. ActionFlash™2

23. ModuFlash™

24. ActionScan™

25. Steady

NOTE: BOLD = California Title XIII Compliant Pattern Italic = SYNC Patterns

NOTE: PHASE 1 ALWAYS ALTERNATES WITH PHASE 2

Flange Mount (5FLANGEC / 5FLANGEP / 5FLANGEB)

1.74

Flange Mount (5TSMAC / 5TSMAB / 5LSMAB / 5LSMAC)

Grommet (5GROMMET)Mount

1.25”

Radius

5.750

5.20

CUT-OUT

MTG. HOLE FOR #10 SCREW (2 PLCS.)

5.750

1” DIA.

Wire Hole

2.875

MTG. HOLE FOR #10 SCREW (2 PLCS.)

4.25

1.25”

Radius

Connector Pinouts

DEUTSCH 3 POS SOCKET

RED (+VBAT)

POS A -

GREY (SYNC)

POSB-

GROUND

POSC-

WHT/VIO

LOOSE -

(SCAN-LOCK™)

AMP 3 POS PIN

RED (+VBAT)

POS1-

GREY (SYNC)

POS2-

GROUND

POS3-

WHT/VIO

LOOSE -

(SCAN-LOCK™)LOOSE -

Page 2

A

CB

3

12

Page 3

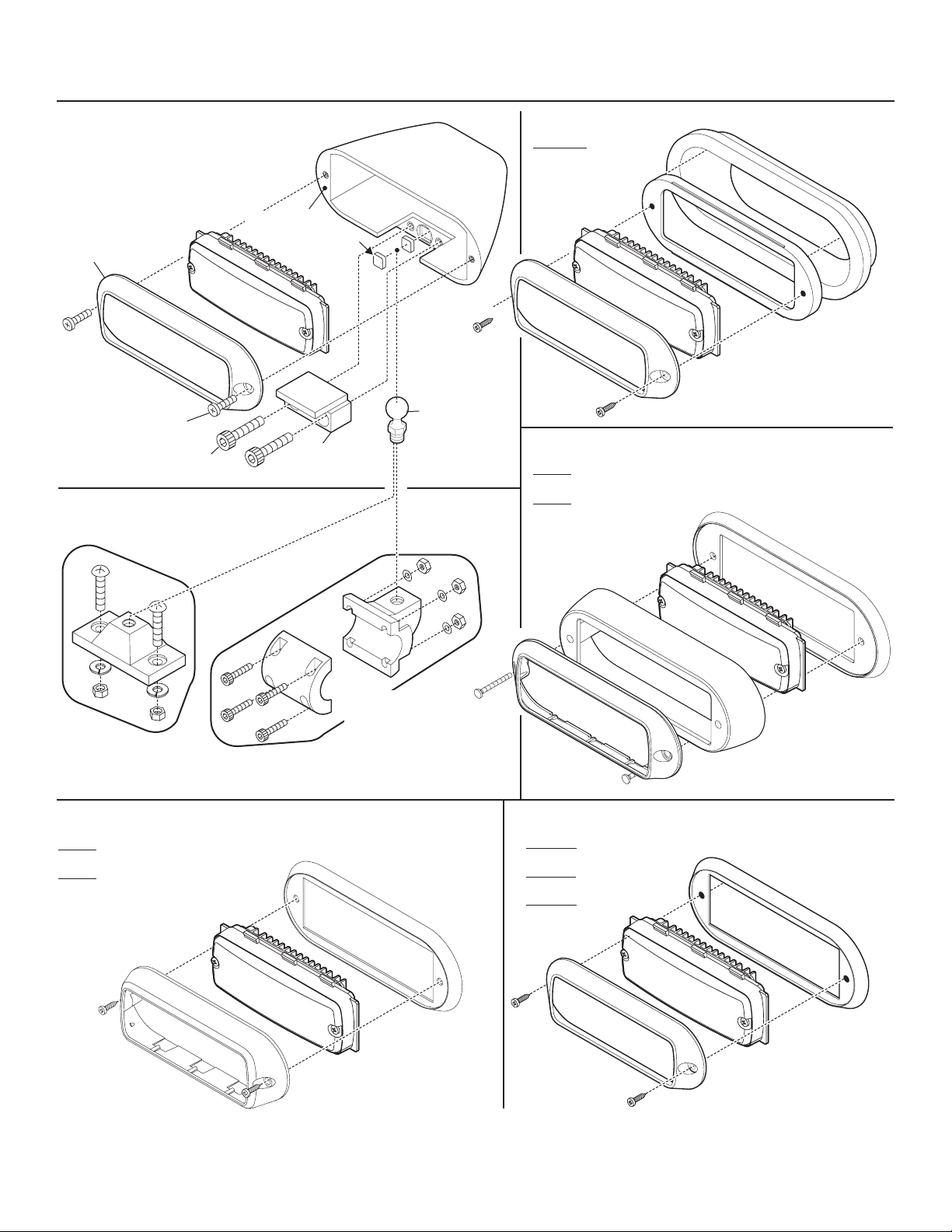

500 Super-LED LIGHTHEAD / MOUNTING KITS

Series ®

Lenses and lightheads shown on this page are for reference only and are not included in mounting kits.

Swivel or Bar Mounts:

These kits

(depending on which kit you purchase)

shown below (except for lightheads & lenses).

include the items shown here, plus

POLISHED CAST

ALUMINUM FLANGE

#10-24 X 3/4"

P. P. H . M . S .

1/4-20 X 1"

CAP SCREW

the items

POLISHED CAST

ALUMINUM HOUSING

FRICTION PAD

LOCKING

MECHANISM

ADJUSTMENT

STUD

Kit: 5GROMMET

5GROMMET

P/N 01-0463308-00

Kit: 5LSMAB & 5LSMAC

5LSMAC Surface Mount Flange Kit

CHROME P/N 01-0464357-015LSMAC

5LSMAB Surface Mount Flange Kit

BLACK P/N 01-0464357-005LSMAB

NOTE: A body cut out is

needed with 5FLANGE

option.

NOTE: No body cut out is

needed with 5LSMAC or

5LSMAB flange options.

Kit: 5HSGPED

Pedestal Swivel Mount

P/N 001-0463338-00

Kit: 5TSMAC & 5TSMAB

5TSMAC Surface Mount Flange Kit

CHROME P/N 01-0463595-015TSMAC

5TSMAB Surface Mount Flange Kit

BLACK P/N 01-0463595-005TSMAB

Kit: 5HSGB1

(7/8" to 1") Round Bar Mount

P/N 01-0463338-01

Kit: 5HSGB125

(1.25") Round Bar Mount

01-0463338-02

P/N

NOTE: No body cut out

is needed with 5TSMAC

& 5TSMAB flange options.

Kit: 5FLANGEB / 5FLANGEC and 5FLANGEP

5FLANGEC

01-0463297-01

P/N

5FLANGEP

01-0463297-02

P/N

5FLANGEB

01-0463297-00

P/N

/ CHROME

/ POLISHED ALUM.

/ BLACK

NOTE: A body cut out is

needed with 5FLANGE

option.

Page 3

Loading...

Loading...