Page 1

®

ENGINEERING COMPANY INC.

Route 145, Winthrop Road,

Chester, Connecticut 06412

Phone: (860) 526-9504

Fax: (860) 526-4078

Internet: www.whelen.com

Sales e-mail: autosale@whelen.com

Canadian Sales e-mai l: auto can@whelen.com

Customer Service e-mail: custserv@whelen.com

Grille-Master™ Swivel Bracket

for 4E/43-series Lightheads Models

4EGRILP (polished chrome finish)

4EGRILB (black finish)

Safety First

This document provid es all the nec es sa ry in form at ion to allow your Whelen prod uc t to b e pro perl y a nd s afe ly ins tal le d.

Before beginning the installation and/or operation of your new product, the installation technician and operator must

read this manual completely. Important information is contained herein that could prevent serious injury or damage.

• Proper installation of this product requires the installer to have a good understanding of automotive

electronics, systems and proce dures .

• If mounting this product requires drilling hol es, the insta ller MUST be sure that no vehic le compon ents or

other vital parts could be damaged by the drilling process. Check both sides of the mounting surface

before drilling begins. Also de-burr any holes and remove any metal shards or remnants. Install

grommets into all wire passage holes.

• If this product is mounted with tape or Velcro™, clean the moun ting surfa ce with a 50 /50 m ix of isopropyl

(rubbing) alcohol and water and dry thoroughly.

• Do not install this product or route any wires in the deployment area of your air bag. Equipment mounted

or located in the air bag deployment area will damage or reduce the effectiveness of the air bag, or

become a projectile that could cause serious personal injury or death. Refer to your vehicle owners

manual for the air bag deployment area. The User/Installer assumes full responsibility to determine

proper mounting location, based on providing ultimate safety to all passengers inside the vehicle.

• For this product to op erate at opt imum e fficiency, a goo d elec trical c onnection to ch assis ground m ust be

made. The recommended procedure requires the product ground wire to be connected directly to the

Lightheads

NEGATIVE (-) battery post.

• If this product uses a remote device to activate or control this product, make sure that this control is

located in an area that allows both the vehicle and the control to be operated safely in any driving

condition.

• Do not attempt to activate or control this device in a hazardous driving situation.

• This product contains either strobe light(s), halogen light(s), high-intensity LED’s or a combination of

these lights. Do not stare directly into these lights. Momen tary blindness and/or eye damage could result.

• Use only soap and water to clean any outer lens. Use of other chemicals could result in premature lens

cracking (crazing) and discolor ati on. Len s’ in this con ditio n have significantly reduced effectiv ene ss and

should be replaced immediately. Inspect and operate this product regularly to confirm its proper

operation and mounting condition.

• It is recommended that these instructions be stored in a safe place and referred to when performing

maintenance and/or reinstallation of this product.

Automotive:

• FAILURE TO FOLLOW THESE SAFETY PRECAUTIONS AND INSTRUCTIONS COULD RESUL T IN DAMAGE

TO THE PRODUCT OR VEHICLE AND/OR SERIOUS INJURY TO YOU AND YOUR PASSENGERS!

©2001 Whelen Engineering Company Inc.

Form No.13606 (062501)

Page 1

Page 2

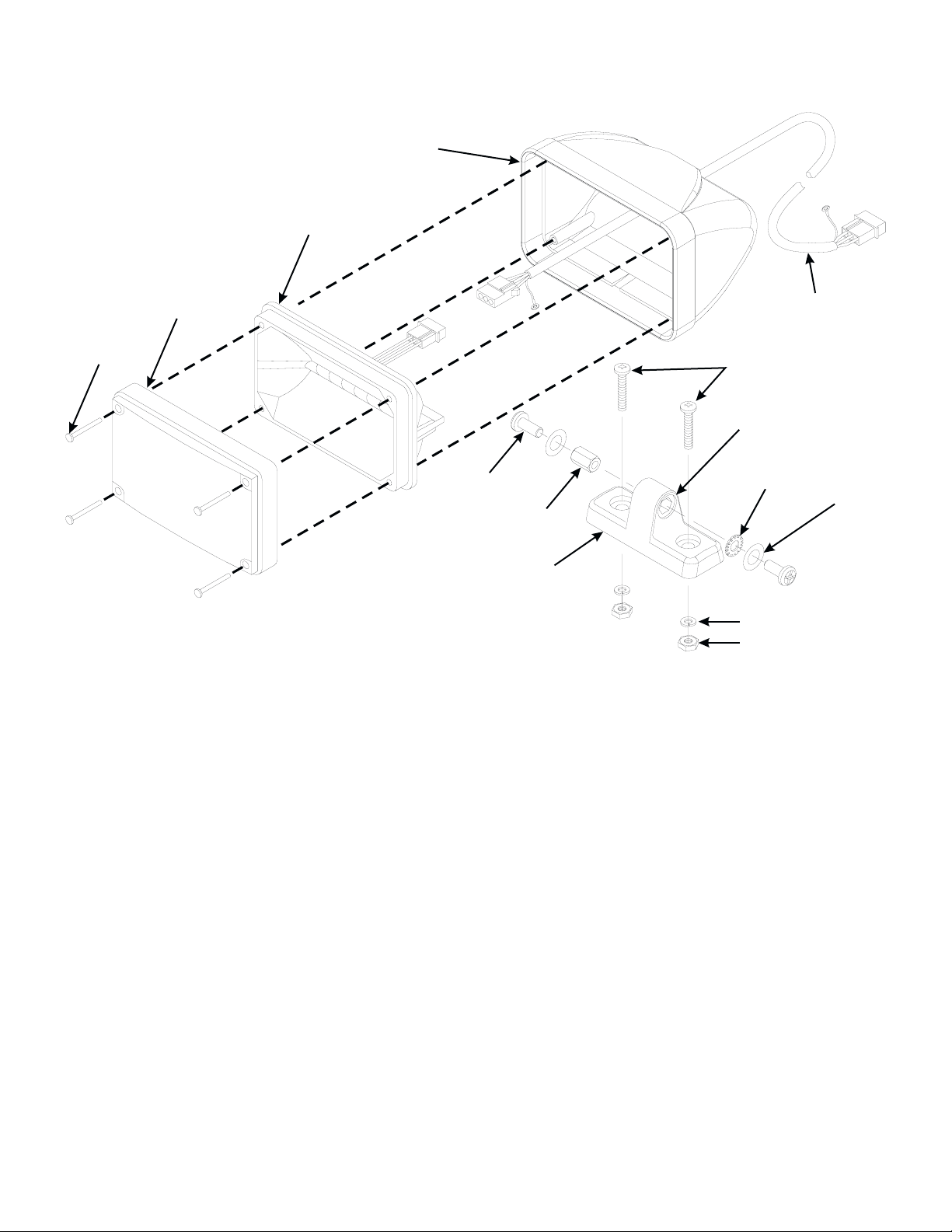

Housing

11-483299-000 (Black)

11-483299-003 (Chrome)

Lighthead

(shown for reference)

Lens

(shown for reference)

#6 - 1 1/4”

PPHSMS

1/4 - 20 x 5/8”

PPHMS

Standoff

20-2012120010

Base

06-161079-001 (Black)

06-161079-014 (Chrome)

(shown for reference)

1/4 - 20 x 1 1/4”

PPHMS

Recessed Area

5/16” External Tooth

Lock Washer

Split Lock Washer

1/4 - 20 Hex Nut

Installation

1. Position the base on the desired mounting surface (see other page for mounting guidlines).

2. Using the base as a template, mark the mounting surface with a suitable tool where the two mounting holes

are to be drilled. Remove the base and drill 2, appropriately sized clearance holes for the mounting bolts .

3. Route the “socketed” end of your lighthead cable from your power supply to the lighthead mounting location.

Make sure that this cable is not connected to any power source!

4. Locate the housing. Insert the cable wires into the lighthead housing through the opening in the rear of the

housing.

5. Insert the “socketed” wire teminals into the proper connector using the information provided with the cable.

Plug this connector into the lighthead connector. Using the #6 - 20 x 1 1/4” sheet metal screws included with

your swivel mount kit, install the lighthead into the housing. Do not allow any excess cable to remain in the

housing cavity.

6. Insert the standoff into the base as shown. Position the external tooth lock washer into the recessed side of

the base. Position the housing so that its mounting flanges straddle the base without disturbing the external

tooth lock washer. Install a flat washer onto both 1/4-20 x 5/8” machine screws. Thread each of these into

either end of the standoff until they lightly bottom out. Do not tighten these yet.

7. Return the Lighthead/Housing/Base assembly to its mounting location and secure firmly as shown using the

supplied hardware. It will be necessary to rotate the housing so that its aim is perpendicular to the mounting

surface in order to install the mounting bolts into the base.

8. With the base secured firmly to the mounting surface, aim the housing in the desired direction and firmly

tighten the hardware at the “swivel” point.

9. Connect the lighthead cable to its power source and test for proper operation.

Lighthead Cable

Flat Washer

Page 2

Loading...

Loading...