Page 1

®

ENGINEERING COMPANY INC.

51 Winthrop Road

Chester, Connecticut 06412-0684

Installation Guide:

4500 Series Lightbar

Phone: (860) 526-9504

Fax: (860) 526-4078

Internet: www.whelen.com

Sales e-mail: autosale@whelen.com

Canadian Sales e-mail: canadiansales@whelen.com

Customer Service e-mail: custserv@whelen.com

Safety First

This document provides all the necessary information to allow your Whelen product to be properly and safely installed.

Before beginning the installation and/or operation of your new product, the installation technician and operator must

read this manual completely. Important information is contained herein that could prevent serious injury or damage.

• Proper installation of this product requires the installer to have a good understanding of automotive electronics,

systems and procedures.

• Whelen Engineering recommends the use of waterproof butt splices and/or connectors if that connector could be

exposed to moisture.

• Failure to use specified installation parts and/or hardware will void the product warranty!

• If mounting this product requires drilling holes, the installer MUST be sure that no vehicle components or other

vital parts could be damaged by the drilling process. Check both sides of the mounting surface before drilling

begins. Also de-burr any holes and remove any metal shards or remnants. Install grommets into all wire passage

holes.

• If this manual states that this product may be mounted with suction cups, magnets, tape or Velcro®, clean the

mounting surface with a 50/50 mix of isopropyl alcohol and water and dry thoroughly.

• Do not install this product or route any wires in the deployment area of your air bag. Equipment mounted or

located in the air bag deployment area will damage or reduce the effectiveness of the air bag, or become a

projectile that could cause serious personal injury or death. Refer to your vehicle owner’s manual for the air bag

deployment area. The User/Installer assumes full responsibility to determine proper mounting location, based on

providing ultimate safety to all passengers inside the vehicle.

• For this product to operate at optimum efficiency, a good electrical connection to chassis ground must be made.

The recommended procedure requires the product ground wire to be connected directly to the NEGATIVE (-)

battery post.

• If this product uses a remote device to activate or control this product, make sure that this control is located in an

area that allows both the vehicle and the control to be operated safely in any driving condition.

• Do not attempt to activate or control this device in a hazardous driving situation.

• This product contains either strobe light(s), halogen light(s), high-intensity LEDs or a combination of these lights.

Do not stare directly into these lights. Momentary blindness and/or eye damage could result.

• Use only soap and water to clean the outer lens. Use of other chemicals could result in premature lens cracking

(crazing) and discoloration. Lenses in this condition have significantly reduced effectiveness and should be

replaced immediately. Inspect and operate this product regularly to confirm its proper operation and mounting

condition. Do not use a pressure washer to clean this product.

• It is recommended that these instructions be stored in a safe place and referred to when performing maintenance

and/or reinstallation of this product.

• FAILURE TO FOLLOW THESE SAFETY PRECAUTIONS AND INSTRUCTIONS COULD RESULT IN DAMAGE TO THE

PRODUCT OR VEHICLE AND/OR SERIOUS INJURY TO YOU AND YOUR PASSENGERS!

Automotive: Lightbars

For warranty information regarding this product, visit www.whelen.com/warranty

©2002 Whelen Engineering Company Inc.

Form No.13738G (040913)

Page 1

Page 2

Lighthead mounting holes, fit onto raised bosses on mounting bracket.

LED LIGHTHEAD

STROBE

LIGHTHEAD

Clips on bracket snap

over edge of lighthead.

Fig. 4

Rotator base

sits on tape

Rotator base

sits

on tape

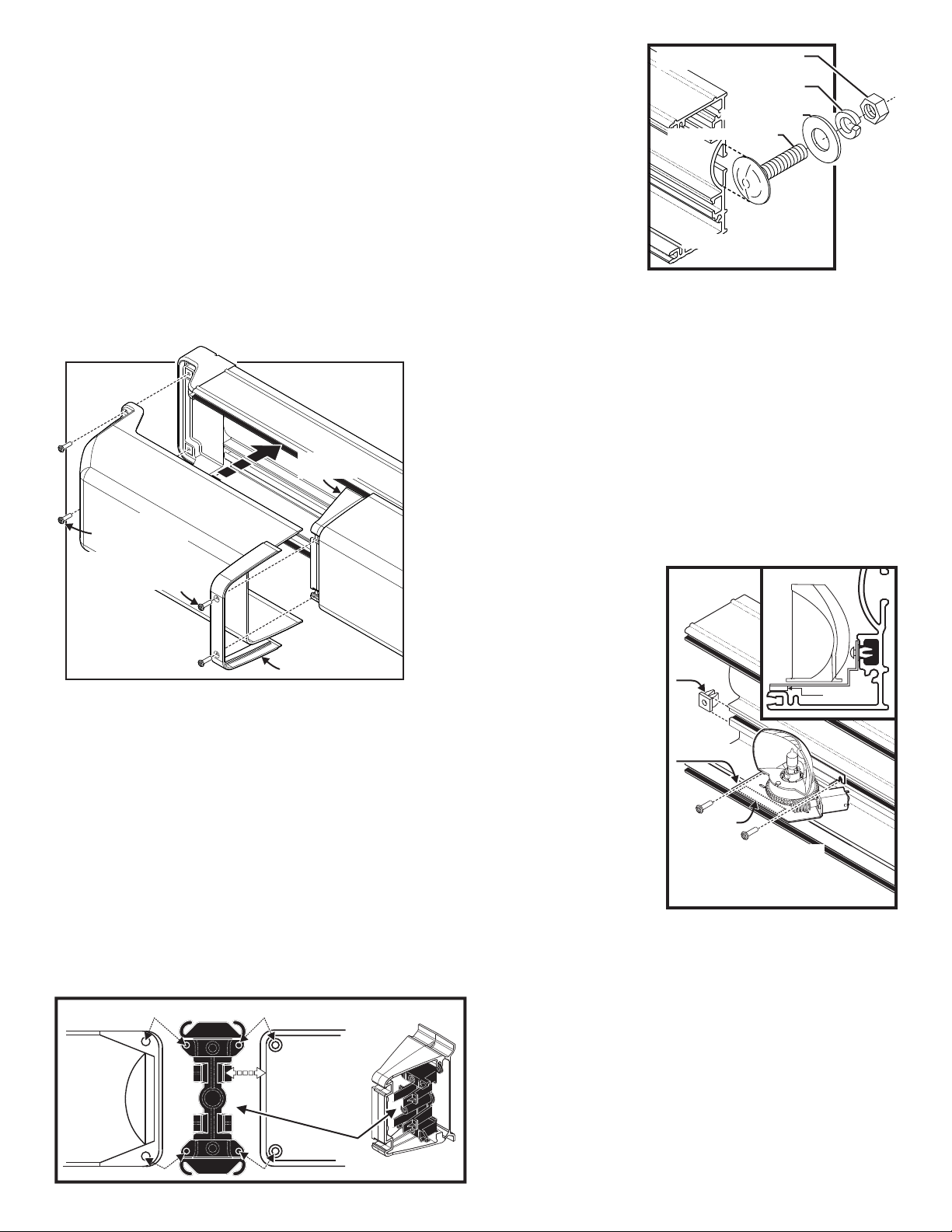

Rotator Removal and Installation

Rotator base

sits on tape

Tape

Fastex

Grommet

Side View

TAPE

Fig. 3

Screws thread into fastex grommet

that is inserted into base.

IMPORTANT! The lightbar should be located a minimum of 16" from any radio antennas!

Removal and

Installation of Lens

and Lenscap

Fig. 2

Remove screws

from end of lenscap

Remove screws and lens

retainer, then remove

lens or lenscap

LENS RETAINER

MOUNTING

BRACKET

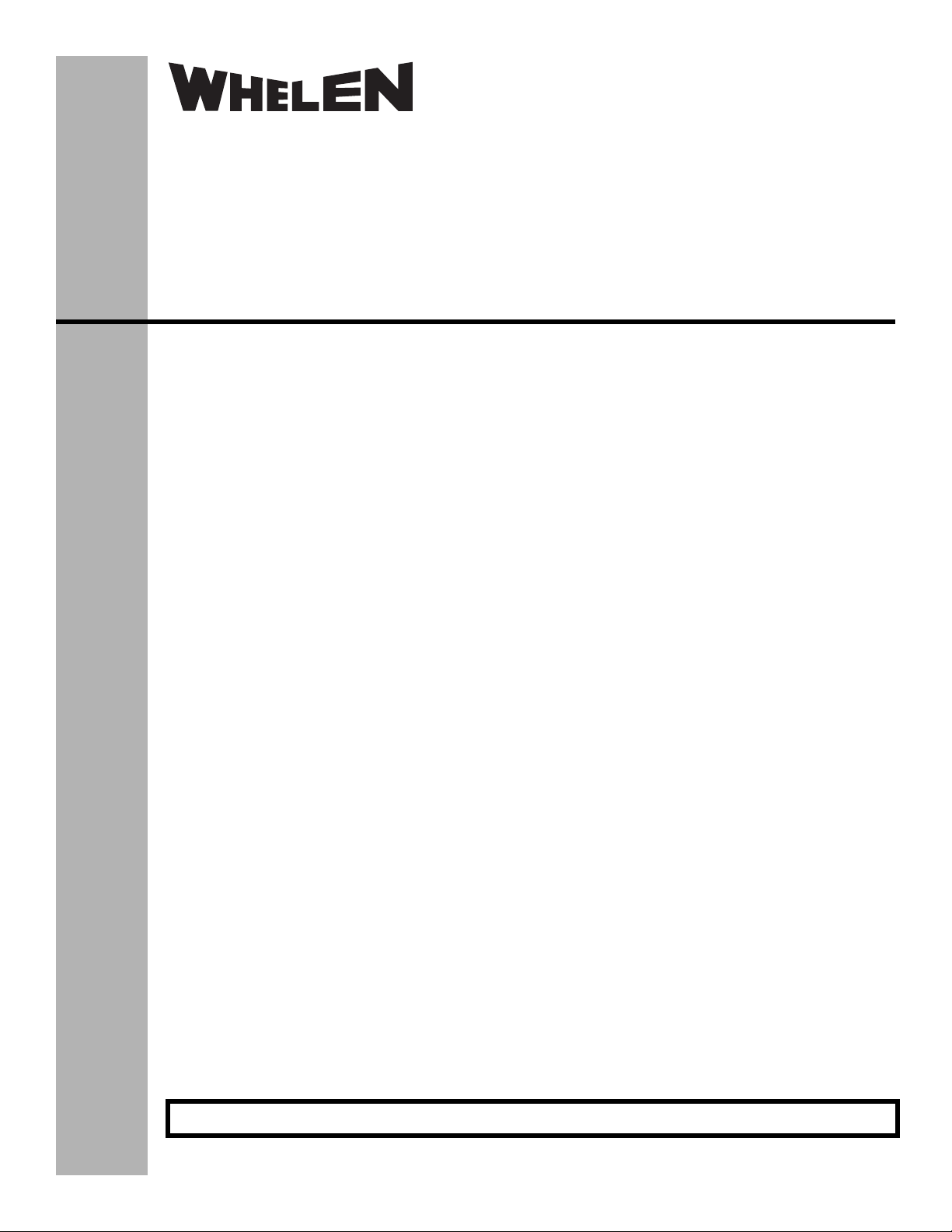

Fig. 1

Mounting the Lightbar

to the vehicle

3/8" X 16 HEX NUT

3/8" LOCKWASHER

3/8" FLATWASHER

3/8 -16 X 1-1/4 STEP BOLT

Installation:

Note: When routing wires, it is important to choose a path that will keep them away from

excessive heat or any vehicle equipment that could compromise the wires integrity.

1. This lightbar mounts with 1-1/4” bolts extending from the rear of the housing. Position the unit in its exact

mounting location and use an awl or other suitable tool to scribe the areas to be drilled (Fig. 1).

2. Remove the lightbar. Using a drill bit sized for a 3/8” step bolt, drill a hole in each of the areas scribed in

step 1. Return the lightbar to its mounting location and secure it to the vehicle with supplied hardware.

Wiring:

WARNING: All Customer supplied wires that connect to the positive terminal of the battery must be

sized to supply at least 125% of the maximum operating current and FUSED at the battery to carry

that load. DO NOT USE CIRCUIT BREAKERS WITH THIS PRODUCT!

IMPORTANT! All Positive input wires must be individually fused. Due to the large number of possible configurations, each with their own

fusing requirements, it is the installation technician's responsibility to determine the maximum current draw for each input wire and fuse that

wire at 125% of that value.

Servicing your lightbar:

NOTE: Before opening your lightbar for service or repair always be sure to

Disconnect the lightbar from it’s power source. (See strobe light warning below.)

Lens or Lenscap: Removal or Installation

1.To remove a lenscap, remove the 2 screws from the end of the lenscap, and the 2

screws from the opposite side that thread through the lens retainer into the lighthead

mounting bracket. Pull the lenscap off (Fig. 2).

2.To remove a lens, remove the 4 phillips head screws that thread through the lens

retainer into the lighthead mounting bracket and then pull the lens off.

lightbar’s harness by unplugging the Amp 2 position pin connector. NOTE: It is easier to remove the

existing rotator from the extrusion if the reflector is facing the front of the lightbar (Fig. 3).

4. Loosen the two screws that secure the rotator base to the extrusion (2 or 3 turns) and lift the rear of the

rotator base then remove the rotator from the extrusion.

Installation of a New Rotator:

1. Remove any adhesive tape on the lightbar base left from the old rotator.

2. Remove the backing from the piece of 2-sided tape and apply it to the lightbar base in the same location

as the previous tape (Fig. 3).

3. Plug the new rotator into the old rotator’s harness plug.

4. Place the new rotator inside the extrusion in the same area the old rotator was removed from but don’t

tighten the screws yet.

5. Remove the backing from the tape and press the rotator base down onto the lightbar base firmly, being careful not pinch any wires between the base

and extrusion, then tighten the mounting screws.

6. Reconnect lightbar to power and test for proper operation then return any lenscaps or lenses you had to remove.

Removing an Existing Rotator:

1. Disconnect the lightbar from power.

WAR NIN G: For lightbars with

strobe lights, wait a minimum of 10

minutes before proceeding.

2. Remove the lens or lenscap in front of

the rotator you wish to replace.

3. Disconnect the rotator from the

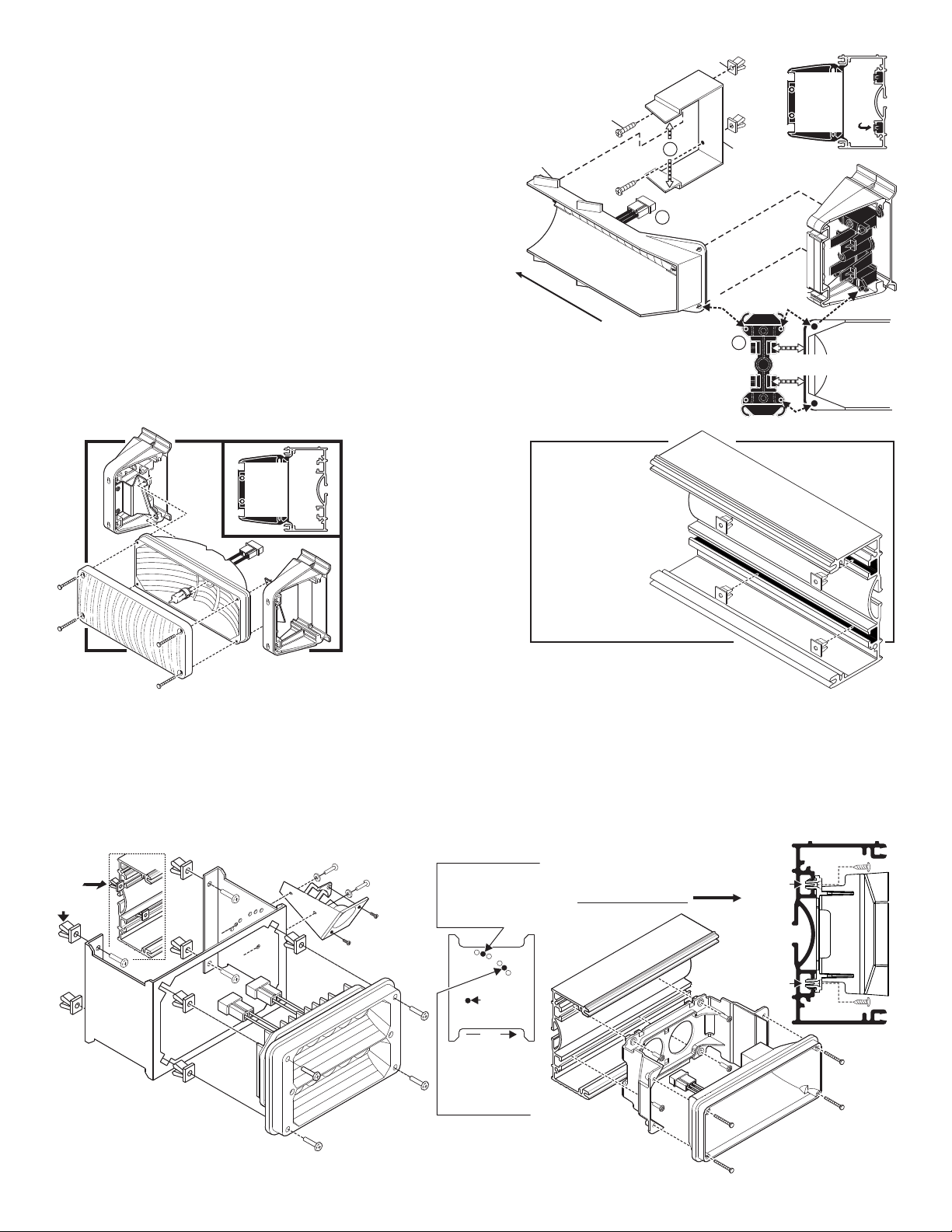

Servicing Lightheads: Strobe, Halogen or LED

WARNING: The strobe light power supply is a high voltage device. Do

not touch or remove the strobe tube assembly while in operation. Wait 10

minutes after disconnecting the unit from its power source before

starting any work or trouble shooting.

Removal and Installation

1. Disconnect the lightbar from it’s power source.

2. To remove the lighthead, first remove the lens or lenscap necessary to

access the lighthead you wish to service or replace.

Page 2

Page 3

CORNER

STROBE

SUPPORT

BRACKET

SCREW, #6

X 3/8" PPHSMS

LIGHTHEAD

TAB

#6 FASTEX SCREW GROMMETS

(Install into lightbar base)

END OF LIGHTBAR

Bracket slides

into lightbar

LIGHTBAR BASE

Fastex

grommet

Clips snap over

edge of lighthead.

CORNER STROBE

Snap Lighthead mtg. holes

onto bosses on bracket.

Snap

Lighthead mtg. holes

onto

bosses on bracket.

B

C

Fig. 5

A

Snap Lighthead mtg. holes

onto bosses on bracket.

Fig. 7

Load

Light

Mounting

Bracket

Slide

grommets

into base

A Single light MR11

bracket (each side) is

mounted in the single

and the center hole of

the bottom 3 holes.

A Double light MR11

bracket (center mount)

is mounted in the single

and center hole of

the top 3 holes.

SIDE VIEW

OF BRACKET

Front

Single hole

400 Linear Split LED with MR11 Load Light / TA only

Fig. 8

Side view / Base Extrusion

Housing

snaps

into base

extrusion

Housing

is then

secured

to base

using

supplied

screws

Halogen, Strobe or LED

Lighthead

(

New style housing

)

3. Now pull the clips back on the mounting bracket that secure the lighthead as

Fig. 6

Options secure to

fastex grommets

inserted into extrusion.

Installing

Options into

Extrusion

you lift the lighthead off of the raised bosses on the bracket (Fig. 4).

4. Being careful not to pull out any wires, lift the lighthead out of the lightbar base,

disconnect its connector from the lightbar wiring harness, then lift the lighthead out

of the lightbar.

5. To reinstall the lighthead, plug the lightheads connector into the lightbar, snap

it back into the brackets and replace any lenses or lenscaps you removed.

Corner Strobe / Removal:

1. Disconnect the lightbar from it’s power source and remove the endcap in front of

the lighthead you wish to replace or service (See strobe warning).

2. Spread the ends of the corner strobe support bracket (A) apart to disengage it

from the tab on the lighthead, and lift this end of the lighthead out (Fig. 5).

3. Pull the clips back on the mounting bracket (B) as you lift the lighthead off of

the two raised bosses on the bracket, then carefully lift the lighthead out of the

lightbar base and disconnect the power cord (C), and remove the lighthead from the

lightbar.

Corner Strobe / Installation:

1. Plug the lighthead into the wiring harness (C).

2. Insert the end of the bracket into the 2 bosses, and snap the side of the lighthead into the clips in the bracket (B), then

snap the lighthead tab into the corner strobe support bracket (A) and replace the endcap. Reconnect to power.

Halogen Lighthead,

Load Light / Rear

Facing / Removal:

1. Disconnect the lightbar from

it’s power source and

remove the lens and/or

endcap in front of the

lighthead you wish to

service.

2. Unscrew the 4 lens screws

which hold the lighthead to

its 2 brackets (Fig 6).

3. Disconnect the lighthead

from power, then remove

the lighthead from the

lightbar.

Halogen Lighthead, Load Light / Rear Facing / Installation:

1. Plug the lightheads connector into the lightbar harness.

2. Attach the lighthead (and lens) to its mounting brackets using the lens screws you removed.

3. Replace the lightbar lenses or endcaps and the installation is complete.

Page 3

Page 4

MODEL 45ADDHAL

ITEM PART NUMBER DESCRIPTION

QTY

2

3

4

5

6

1

700 REFLCT 2 WIRE 2 POS AMP.-

12V 60W SNAP-IN-LAMP-

SCREW / #6 x 1-1/4" PPHSMS

LENS CLEAR OPTIC/

BRACKET MOUNTING/

SCREW #8 x 1/2" PPHSMS/

700 SERIES HALOGEN

15-081416-080

07-284353-000

02-0484303-02

15-061416-200

34-0041987-07

02-0383709-02

68-1183582-3S

1

1

1

4

4

1

MODEL 45ADDAST

01-0440624-25

13-062C40-16J

07-26C091-000

46-0941245-00

02-0363171-00

15-061416-060

26-0215001-03

02-0484303-16

02-0342933-00

07-263103-000

CABLE ASSEMBLY - 25'

ASS'Y. / CORNER LINEAR STROBE

BRACKET / CORNER STROBE

HARNESS ASS'Y. / STROBE

SUB ASS'Y. / MOUNTING BRACKET

ASS'Y. / CORNER LINEAR STROBE

BRACKET / LIGHTHEAD MOUNTING

SCREW / #6 x 3/8" PPHSMS

SCREW GROMMET

TY WRAP - 3"

ITEM PART NUMBER DESCRIPTION

QTY

2

3

4

5

6

7

8

9

1

2

1

1

1

1

1

1

1

2

MODEL 45ADROTA

ITEM PART NUMBER DESCRIPTION

QTY

2

3

4

1

68-5463532-00

"V" MIRROR BRACKET

5

HALF MIRROR LEFT

TAPE / METALIZED

HALF MIRROR RIGHT

ROTATING REFLECTOR

ROTATOR

02-0342949-00

02-0484303-01

02-0342945-00

02-0342949-01

68-5943171-01

1

1

1

1

A/R

8

9

1

5

6

2

4

3

7

MODELS: 45ADLS8* / 45ADL8*

NOTE: When two model 45ADROTA are

placed adjacent to one another, the left

and right mirrors are replaced with the

V mirror (ITEM #5) as shown.

Rotator

shown for

reference

Rotator

shown for

reference

Left mirror

shown for

reference

5

Mounting

bracket

shown for

reference

MODEL 792H & MODEL 45000PTI

2

3

ITEM PART NUMBER DESCRIPTION

QTY QTY

4

5

6

7

8

1

07-263401-000

01-5015970-29

01-0417074-00

13-104111-063

46-0968085-25

16-100220-500

14-104066-100

15-061416-060

01-5015970-29

13-062C40-16J

1

BOLT 10-24 X 5/8" CARRIAGE S//S

ASS'Y / 3M LC EMIT CABLE / 25' CONXALL

BRACKET MOUNTING 792/4500/

MODEL 792H OPTICOM EMITER

OPTION PREWIRE PLUS FOR OPTICOM/

NUT 10-24 CAD PLATED WHIZ/

WASHER #10 FLAT .631 x .060 / THK SS//

SCREW #6 x 3/8" PPHSMS/

SCREW GROMET #6/#8 FASTEX/

MODEL 792H OPTICOM EMITER

4

4

2

2

2

1

1

3

2

1

Mounting

bracket

shown for

reference

Mounting

bracket

shown for

reference

4

TO EXTRUSION

8

4

2

7

6

5

1

3

TO

EXTRUSION

6

5

4

3

2

1

TO

EXTRUSION

SUB ASS'Y., 700 LINEARLED - AMB

SCREW, #6 x 1-1/4" PPHSMS

BRACKET, MOUNTING

SCREW, #8 x 1/2" PPHSMS

700 SERIES LINEAR LED - AMB

1

4

1

07-284353-000

02-0484303-03

15-061416-200

01-0286419412

15-081416-080

4

4

1

1

4

4

1

1

4

4

1

1

4

02-0484303-04

02-0484303-05

02-0484303-06

700 SERIES LINEAR LED - BLU

700 SERIES LINEAR LED STDY - WHT

700 SERIES LINEAR LED STDY - RED

01-0286419422

SUB ASS'Y., 700 LINEAR LED - BLU

01-0286419432

SUB ASS'Y., 700 LINEAR - WHTLED

01-0286419452

SUB ASS'Y., 700 LINEAR - REDLED

SUB ASS'Y., 700 LINEAR - GRNLED

01-0286419442

1

4

4

1

02-0484303-36

700 SERIES LINEAR LED STDY - GRN

444

1114411

4 444 4

1

1

1

1

1

SUB ASS'Y., 700 LIN STDY - GRNLED

SUB ASS'Y., 700 LIN LED STDY - RED

SUB ASS'Y., 700 LIN STDY - BLULED

SUB ASS'Y., 700 LIN STDY - AMBLED

SUB ASS'Y., 700 LIN STDY - WHTLED

01-0286419253

01-0286419233

01-0286419223

01-0286419213

01-0286419243

700 SERIES LINEAR STDY -AMBLED

02-0484303-40

700 SERIES LINEAR STDY - GRNLED

700 SERIES LINEAR STDY - BLULED

700 SERIES LINEAR STDY - WHTLED

700 SERIES LINEAR LED STDY - RED

02-0484303-43

02-0484303-41

02-0484303-42

02-0484303-44

2

3

ITEM PART NUMBER DESCRIPTION

QTY QTY QTY QTY

12

13

14

4

5

6

8

9

10

11

1

QTYQTYQTYQTYQTYQTY

2

8

7

1

TO EXTRUSION

6

5

4

1211 14

10 13

9

3

Page 4

Page 5

EXTRUSION is shown

for reference only.

3-6

3-6

15

3-6

7

11

7

10

12

8

9

6-10

3-6

2-6

2-6

6-10

Extrusion shown for reference only

MODEL 45KRS

ITEM PART NUMBER DESCRIPTION

QTY

1

2

3

4

5

6

7

8

9

BRACKET MOUNTING/

SCREW / #8 x 1/2" PPHSMS

SCREW / #6 x 1" PPHSMS

OPTION / KKK REAR STROBE PKG. 4500 SERIES

LENS / CLEAR NON OPTIC 16.57 / 4500 SERIES

LENS / RED NON OPTIC 16.57 / 4500 SERIES

LENS AMBER NON OPTIC 16.57 / 4500 SERIES/

-2

07-284353-000

02-0484303-15

68-3983799-30

68-3983799-50

15-081416-080

15-061416-160

68-3983799-10

ASS'Y 700 LINEAR REFLECTOR/

02-0362641-00

46-0941245-00

HARNESS ASS'Y. / STROBE

01-0440624-25

CABLE ASSEMBLY - 25'

46-0941248-00

HARNESS ASS'Y / STROBE CENTER

02-0483910-00

SUB ASS'Y / LOAD LIGHT 4500 SERIES

10

11

1

3

1

12

12

3

3

2

1

1

MODEL: 45FLASH

2

3

ITEM

PART NUMBER

DESCRIPTION

QTY

1

4500 OPTION / ADD INTERNAL FLASHER

ASSY / FLASHER INPUT HARNESS

ASSY / HARNESS / 400 LED with FLASHER

ASS'Y / 2 CHANNEL FLASHER / 4500 SERIES LED

1

1

1

46-0764668-00

02-0343046-00

02-0484303-32

46-0743203-00

14

1

1

2

3

1

12 13

MODEL: 45KRL

2

3

ITEM

PART NUMBER

DESCRIPTION

QTY

4

5

6

7

8

1

9

10

11

12

13

14

68-3983799-10

68-3983799-50

02-0342934-00

07-263579-000

13-062C40-16J

15-081416-080

07-284354-000

46-0784112-04

01-026B807-50

15-061416-160

01-0286361255

01-0286361211

4

2

2

4

16

8

4

1

2

2

-1

2

1

SCREW GROMET, #6/#8 FASTEX

SCREW, 8 X 1/2 PPHSMS

BRACKET, MTG 400 SERIES LIGHTHEAD

SCREW, 6X1 PPHSMS TYPE A

SUB ASS'Y, 400 LINEAR LED SPLIT / RED/RED

SUB ASS'Y, 400 LINEAR LED SPLIT / AMB/AMB

UPPER LED ADAPTER

LENS, AMBER NON OPTIC 16.57"/4500 SERIES

LENS, RED NON OPTIC 16.57"/4500 SERIES

SUB ASS'Y, BRACKET & BASE

BRACKET, SUPPORT CORNER STROBE

ASS'Y CORNER LED RED AMP/4500 SERIES

02-0483910-00

SUB ASS'Y, LOAD LIGHTS /4500 SERIES

4

15-061416-060

SCREW, 6 X 3/8 PPHSMS 410 SS TYPE A

OPTION KKK LED PACKAGE/ REAR

02-0484303-18

3-6

NOTE: Lightheads shown in standard

positions.

LOAD LIGHTS: position adjacent to

CENTER LEDs.

6

MODEL 45ADDSTR

ITEM

PART NUMBER DESCRIPTION

QTY

700 LINEAR REFLECTOR

SCREW, #6 x 1" PPHSMS

BRACKET, MOUNTING

SCREW, #8 x 1/2" PPHSMS

4

4

07-284353-000

15-061416-160

02-0362641-00

15-081416-080

46-0941245-00

HARNESS ASS'Y., STROBE

1

01-0440624-25

CABLE ASSEMBLY - 25'

A/R

46-0941248-00

HARNESS STROBE CTR

2

3

4

5

6

7

1

700 SERIES LINEAR STROBE

A/R

1

02-0484303-07

1

1

TO

EXTRUSION

4

7

3

5

2

7

MODEL: 45LRLOAD

POWER TO PASSENGER

SIDE LOAD LIGHT.

2

11

8

6

5

4

3

1

12

13

9

10

LR11 LOAD LIGHT OPTION

2

6

2

6

6

6

02-0484303-48

07-286741-000

56-043625-000

07-26C834-000

68-5944082-31

02-016B644-30

68-7744081-00

BRACKET, MTG LR11 LOAD LT DBL 4500

THERMAL PAD, CO-THERM LR11

REFLECTOR, TIR LR11 LOAD LIGHT 4500

DIFFUSER, LR11 LOAD LIGHT 4500 SERIES

18

8

8

13-062C40-16J

14-062216-160

15-061416-060

SCREW GROMMET, #6/#8 FASTEX

SCREW, 6 X 3/8 PPHSMS 410 SS TYPE A

6

39-0402313-04

HOUSING, 2 POS PIN COMM MATE-N-LOK

BRACLET, MTG LR11 LOAD LT SNGL 4500

PCB 3 LED LR11 WHT ALLEY/TD XP-E

4

14-062216-061

SCREW, 6-32 X 3/8 PPHMS SEMS W/IT LK WSHR SS

SCREW, 6-32 X 1" PPHMS SS

1

2

46-0744083-00

46-0941243-00

ASSY, HARNESS LR11 LOAD LIGHT 4500

ASS'Y, SCENE LIGHT HARNESS

02-0484303-50

LR11 LOAD LIGHT W/O INPUT HARNESS

2

2

6

6

6

6

18

8

8

6

4

2

ITEM

PART NUMBER

DESCRIPTION

QTY QTY

2

3

11

12

13

4

5

6

7

8

9

10

1

13

POWER TO

PASSENGER

SIDE LOAD

LIGHT.

7

6

8

4

2

3

5

10

9

12

11

1

LR11 LOAD LT OPT. 13 DEGREE

02-0484303-51

07-286741-000

56-043625-000

07-26C834-000

68-5944082-31

02-016B644-30

68-7744081-00

BRKT, MTG LR11 LOAD LT DBL 4500

THERMAL PAD, CO-THERM LR11

REFLECTOR, TIR LR11 LOAD LT 4500

DIFFUSER, LR11 LOAD LT 4500 SERIES

13-062C40-16J

14-062216-160

15-061416-060

SCREW GROMMET, #6/#8 FASTEX

SCREW, 6 X 3/8 PPHSMS 410 SS TYPE A

39-0402313-04

HSNG, 2 POS PIN COMM MATE-N-LOK

BRKT, MTG LR11 LOAD LT SNGL 4500

PCB 3 LED LR11 WHT ALLEY/TAKEDN XP-E

14-062216-061

SCREW, 6-32 X 3/8 PPHMS SEMS W/IT LOCK WSHR SS

SCREW, 6-32 X 1" PPHMS SS

46-0744083-00

46-0941243-00

HARNESS LR11 LOAD LIGHT 4500

ASS'Y, SCENE LIGHT HARNESS

MODEL: 45LRLOAD / 13 DEGREE

2

3

ITEM

PART NUMBER

DESCRIPTION

QTY

4

5

6

7

8

1

9

10

11

4

2

6

2

6

6

6

18

8

6

8

1

2

12

13

Page 5

Page 6

MODEL: 45ADRB*

2

3

ITEM

PART NUMBER

DESCRIPTION

QTY

1

4500 SOLID STATE ROTATOR

SOLID STATE ROTATOR

414

01-026E607-_0

02-0484303-__

SCREW GROMMET

13-062C40-16J

SCREW, #6 x 3/8" PPHSMS

15-061416-060

GREY

WHT/ORG

VIOLET

WHT/VIO

BLK

RED

3

6

5

4

2

1

1

2

1

2

4500

HARNESS

CUSTOMERS

WIRING

(OPTIONAL)

TO ROTATOR

CRUISE

POWER

GROUND

SCANLOCK

SYNC

LOW POWER

4

3

MODEL 45KFH

ASS'Y. 12V 60W SNAP-IN-LAMP/-

ASS'Y. 700 REFLECTOR 2 WIRE/2 POS AMP/

KKK FRONT HALOGEN PKG. 4500 SERIES

LENS RED NON OPTIC 16.57 / 4500 SERIES/

LENS CLEAR NON OPTIC 16.57 / 4500 SERIES/

68-3983799-30

02-0484303-120

68-3983799-50

SCREW #6 x 1-1/4" PPHSMS/

LENS CLEAR OPTIC/

SCREW #8 x 1/2" PPHSMS/

BRACKET MOUNTING/

34-0041987-07

68-1183582-3S

15-061416-200

02-0383709-02

15-081416-080

07-284353-000

ITEM PART NUMBER DESCRIPTION

QTY

2

3

4

5

6

1

3

3

12

12

1

-1

7

8

3

3

MODEL: 45KFL

6-10

11 12

6-10

2-6

3-6

2-6

3-6

1

1

MODEL: 45FL*

1

1

1

1

1

2

3

DESCRIPTION

4

5

6

7

8

1

1111

4444

9

QTY

1

4

22222

11111

1

PART NUMBER

QTY QTY QTY QTY

02-0484303-30

02-0484303-29

02-0484303-27

02-0484303-28

02-0484303-31

15-081416-080

07-284354-000

15-061416-160

01-0386361222

01-0386361211

46-0784112-04

01-0386361244

01-0386361255

01-0386361233

8 X 1/2 PPHSMS

6 X 1 PPHSMS TYPE "A"

400 LINEAR LED AMB AMP

400 LINEAR LED BLU AMP

400 LINEAR LED WHT AMP

400 LINEAR LED GRN AMP

400 LINEAR LED RED AMP

S. ASY / 400 LED SPLIT RED-RED

S ASY 400 LED SPLIT GRN GRN./ -

S ASY 400 LED SPLIT WH WH./ T-T

S ASY 400 LED SPLIT BLU BLU./ -

BRACKET MTG 400 LTHD/

S ASY 400 LED SPLIT AMB AMB./ -

HARNESS UPPER LED ADAPT/.

NOTE: Lightheads shown in standard positions.

Position Load Lights adjacent to center halogen.

MODEL 45KRH

LENS / AMB NON OPTIC 16.57 / 4500 SER.

BRACKET MOUNTING/

LENS CLEAR OPTIC/

SCREW #8 x 1/2" PPHSMS/

700 REFLECTOR 2 WIRE 2 POS AMP/

ASS'Y. 12V/60W SNAP-IN-LAMP/

SCREW #6 x 1-1/4" PPHSMS/

KKK REAR HALOGEN PKG. 4500 SER.

LENS CLR NON OPTIC 16.57 / 4500 SER/.

LENS / RED NON OPTIC 16.57 / 4500 SER.

07-284353-000

68-1183582-3S

02-0484303-14

68-3983799-30

68-3983799-50

68-3983799-10

15-081416-080

02-0383709-02

15-061416-200

34-0041987-07

ITEM PART NUMBER DESCRIPTION

QTY

2

3

4

5

6

1

7

8

9

333

12

1

-2

12

3

1

SUB ASS'Y / LOAD LIGHTS / 4500 SER.

02-0483910-00

10

1

15

1

3-8

3-8

2

9

3-8

10

SCREW 6X1 PPHSMS TYPE A/

UPPER LED ADAPTER

OPTION KKK FRONT LED PACKAGE/

SUB ASS'Y 400 LINEAR LED SPLIT / WHT-WHT/

SUB ASS'Y 400 LINEAR LED SPLIT / RED RED/-

12

2

2

2

16

4

4

ASS'Y CORNER LED RED AMP 4500 SERIES/

SCREW 6X3/8 PPHSMS 410 SS TYPE A//

SCREW GROMET #6 #8 FASTEX/-

15-061416-060

15-061416-160

01-026B807-50

02-0484303-17

02-0386361233

02-0386361255

46-0784112-04

13-062C40-16

4

07-284354-00

BRACKET MTG 400 SERIES LIGHTHEAD/

68-3983799-30

68-3983799-50

02-0342934-00

07-26C091-000

1

2-12

LENS / CLEAR NON OPTIC 16.57" 4500 SERIES/

LENS RED NON OPTIC 16.57" 4500 SERIES//

SUB ASS'Y BRACKET & BASE/

BRACKET CORNER STROBE/

2

3

ITEM

PART NUMBER

DESCRIPTION

QTY

4

5

6

7

8

1

9

10

11

12

TO

EXTRUSION

TO

EXTRUSION

TO

EXTRUSION

1

3-8

2

3-8

TO

EXTRUSION

8

2

9

3

1

5

6

7

4

Lightheads shown in standard

positions. Extrusion shown

for reference only.

TO

EXTRUSION

1

2

3

Page 6

Page 7

8

1

7

LOAD

LIGHT

Wire Harness / MR11 Load Lights

Extrusion

To Control Head

(not shown)

For Reference

For Reference

Grommet shown for reference

FLASHER

TA

NOTE: Model 45TA8

shown. For Model 45TA6

drop out the center two

lightheads.

EXTRUSION,

CORNER LEDs and

CENTER LENS are shown

for reference only.

2 1

1 2

WHT/RED

WHT/RED

RED

RED

WHT/ORG

YELLOW

WHT/YEL

ORANGE

CABLE ASSY

BLUE

WHT/GRN

WHT/BLU

GREEN

LOAD

LIGHT

VIOLET

WHT/VIO

WHT/VIO

VIOLET

2 1

1 2

2 1

2 1

1 2

2 1

1 2

2 1

1 2

2 1

1 2

2 1

1 2

2 1

1 2

2 1

1 2

2 1

1 2

2 1

1 2

2 1

1 2

2 1

1 2

2 1

1 2

2 1

1 2

2 1

1 2

2 1

1 2

2 1

1 2

1 21 2 1 2 1 2

123

321

123

321

123

321

BLACK

BLUE

2 1 2 1 2 1 2 1 2 1 2 1

RED

RED

RED

RED

TA1

TA1

TA2

AMB

TA3

AMB

TA4

AMB

TA5

AMB

TA6

TA6

GRN

BLK

8

9

RED

RED

RED

RED

TRAFFIC ADVISOR OPTION W/MR-11 LOAD LIGHTS

4

5

1

4 4 4 4 4 4 4

07-284353-000

15-061416-160

02-0362641-00

15-081416-080

46-0941245-00

01-0440624-25

68-3983799-30

68-3983799-50

02-0484303-13

ASS'Y 700 LINEAR REFLECTOR/

SCREW #6 x 1" PPHSMS/

SCREW #8 x 1/2" PPHSMS/

HARNESS ASS'Y STROBE/

CABLE ASSEMBLY - 25'

LENS CLEAR NON OPTIC 16.57 / 4500 SERIES/

LENS RED NON OPTIC 16.57 / 4500 SERIES/

BRACKET MOUNTING/

46-0941248-00

HARNESS ASS'Y / STROBE CENTER

MODEL 45KFS

ITEM PART NUMBER DESCRIPTION

QTY

2

3

4

5

6

7

8

1

9

1

-1

3

3

12

12

2

3

1

KKK FRONT STROBE PKG. 4500 SERIES

5-9

5-9

5-9

5-9

4

2

3

9

5

4

7

8

6

3 3

10

11

5-9

5-9

5-9

MODEL: 45TA with MR11 Load Lights

2

3

DESCRIPTION

4

5

6

7

1

8

02-0484303-35

PART NUMBER

QTY

1

1

2

6

1

1

01-0269809-06

01-0669813-00

02-0342933-00

02-0386361211

02-0463931-00

46-0743112-00

1

1

1

46-0769810-05

46-0743119-00

4500 T/A FLASHER 6 LAMP

400 LIN. LED SPLT AMB AMB-

TADCTL1 CTRLHD DOMINATOR TA/

SUB ASS'Y MOUNTING BRACKET/

MR11 LOAD LTS / 4500 SERIES

HARNESS MR11 LOAD LIGHTS

CABLE T/A OPTION

HARNESS 4500 TA6 DBL RED-ORG-YEL//

MODEL 45TA MR11 LOAD LTS/

46-0769810-06

HARNESS 4500 TA6 DBL VIO BLU GRN//--

9

6

MODELS: 45TA6 / 45TA8

ITEM PART NUMBER DESCRIPTION

QTY QTY

1

2

1

3-6

3-6

7

7

3-6

7

9

5

1

4

MOUNTING BRKT. 400 . LTHD

SUB AS'Y / 400 LED SPLIT AMB-AMB

SCREW / #6 X 1" PPHSMS

4500 INTERNAL HARNESS / TA

8 LAMP TA/ 4500 SERIES

HOUSING / AMP 12 POS. PIN

6 LAMP TA/ 4500 SERIES

TA CONTROL HEAD 12V LED

CABLE ASS'Y / 9-C 35' 4" STRIP

39-0412014-14

07-284354-000

15-061416-160

01-0386361211

01-0683850-00

46-0784545-00

46-0741346-35

Y HARNESS 6" ASSEMBLY

SCREW / #8 X 1/2" PPHSMS

WASHER 1/2" I.D.

16-1766430-08

46-0784112-04

15-081416-080

26-0121053-00

CLAMP 3/8"

2

3

4

5

6

7

8

1

02-0484303-34

02-0484303-33

1

9

10

11

1

1

2

24

6

6

12

6

1

1

1

1

1

2

32

8

8

16

8

1

1

Page 7

Page 8

OPTION GTT EMITTER

ITEM PART NUMBER DESCRIPTION

QTY

2

3

4

5

6

1

15-061416-060

13-062C40-16J

46-0743825-25

07-26B390-023

01-1317921-01

02-0484303-39

15-045216-060

1

REF

4

1

4

4

GTT LED EMITTER

MTG BRKT GTT LED MODULE

SCREW, #6 X 3/8" PPHSMS

SCREW GROMET, #6 / #8 FASTEX

CABLE GTT LED EMITTER 25'

SCREW, 4 X 3/8 PFH PLASTI-LOC

EMITTER, LED GTT

32 33

34

35

23

24

19

25

17

18

22

32 33

34

35

32 33

34

35

14

26 27

28

31

31

30

30

31

30

31

16

15

30

28

29

12

3

13 37

4

56

12

89

7

10 11

CAUTION! DO NOT LOOK DIRECTLY AT

THESE LED’S WHILE THEY ARE ON.

MOMENTAR Y BLINDNESS AND/OR EYE

DAMAGE COULD RESULT!

IMPORTANT WARNING!

1 2

12

12

12

Length of Lightbar

ICC Light Requirements

01-0684303___

PART NUMBER KEY:

ICC LIGHT REQUIREMENTS

1 = A =

R =

Without ICC Lights With AMB ICC Lights

With RED ICC Lights

NOTE: 52", 60" & 72" Lightbars available

without ICC Lights or with Center ICC Lights

only (RED or AMBER)

1 2

1 2

1 2

GREEN

BLK/WHT

BLK/WHT

RED

VIOLET

BLACK

ORANGE

GREY

BLACK

ROTATOR

LED or

HALOGEN

ROTATOR

LED or

HALOGEN

ROTATOR

LED or

HALOGEN

ROTATOR

LED or

HALOGEN

ROTATOR

LED or

HALOGEN

ROTATOR

LED or

HALOGEN

ROTATOR

LED or

HALOGEN

1 21 21 2 1 2 1 2 1 2

BLK/WHT

BLACK

BROWN

YELLOW

BLK/WHT

1 2

BLACK

ROTATOR

LED or

HALOGEN

1 2

BLUE

4500 SERIES WIRING

36

YEL +12VDC/

VIO +12VDC/

BLK/WHT GND/

BLK/WHT GND/

BLK GND/

BRN +12VDC/

RED +12VDC/

GRN / +12VDC

BLK/WHT GND/

BLU +12VDC/

BLK GND/

ORG +12VDC/

BLK G D/N

BLK GROUND/

BLK GND/

GRY +12VDC/

ROTATOR

L E D o r

HALOGEN

(

OUTBOARD

)

ROTATOR

LED or

HALOGEN

INBOARD

()

ROTATOR

LED or

HALOGEN

CENTER

()

ROTATOR

LED or

HALOGEN

(INBOARD)

1212121212121212

21

01-0684303122

01-0684303138

01-0684303144

01-0684303_76

01-0684303_82

01-0684303_72

01-0684303_60

01-0684303_84

01-0684303_86

01-0684303_90

01-0684303_88

11-463582-100

EXTRUSION, 17.31" ICC MTG. HOLESw

ithout

1

01-0684303_52

EXTRUSION, 33.67" ICC MTG. HOLESw

ithout

11-463582-106

1

1

11-463582-109

1

11-463582-001

1

1

1

1

1

1

1

1

11-463582-027

EXTRUSION, 39.67" ICC MTG. HOLESw

ithout

EXTRUSION, 47.67" withICC MTG. HOLES

11-463582-016

EXTRUSION, 55.67" with ICC MTG. HOLES

11-463582-002

EXTRUSION, 67.67" with ICC MTG. HOLES

11-463582-023

EXTRUSION, 71.67" with ICC MTG. HOLES

222222222222

02-0342932-00

MOUNTING BASE ASSEMBLY

11-463582-003

EXTRUSION, 77.67" with ICC MTG. HOLES

11-463582-005

EXTRUSION, 79.67" with ICC MTG. HOLES

11-463582-026

EXTRUSION, 81.67" with ICC MTG. HOLES

EXTRUSION, 83.67" with ICC MTG. HOLES

11-463582-028

EXTRUSION, 85.67" with ICC MTG. HOLES

444444444444

14-104286-16J

SCREW, #10-24 x 1.25" SHOULDER PHTX TRI PT

44444444444

2

01-0441771-00

KIT, EXTRUSION STEP BOLT MTG. 1-1/4"

111111111111

10-0522977-01

LABEL, P/N/M/N/S/N

1

21122121211221212112211

21-11263204-0

02-0320397-00

GROMMET, 1" SLIM LINE

LOUVER, 1" W/FILTER

686

13.61

2222

3

5

666

11.28 9.28 7.94

9.46

22222

1

33

5.616.61

8.13 7.13

2.88

4.44

222

MOUNTING BRACKET ASSEMBLY

02-0342933-00

38-0316275-00

38-0522954-00

GASKET, REAR EXTRUSION

SEAL, CORD 3/16"

68-3983813-**

LENSCAP

14.27

15.7915.46

13.94

15.13

14.80

13.28

14.47

12.95

13.47

11.95

12.8010.80

8

A/R A/R

68-3963615-**

LENSCAP, SPLIT

444444444444

15-06121B-082

SCREW, #6 x 1/2" PPHSMS (BLACK)

77

55

8866

555

4

222

-

666

5

333

1

68-3983799-**

02-0342941-00

A/R

16

A/R

A/R16A/R

12

A/R A/R

A/R

12

A/R

A/R

12

A/R

12

12

10 6 6 6

2

02-0483903-A0

15-08121B-082

02-0483903-R0

A/R

A/R

A/R A/R

02-0483903CA0

A/R

A/R A/R A/R

02-0483903CR0

A/R A/RA/R A/R A/R A/RA/R A/R A/R A/R

46-0764014-00

1111 1111

01-0684303_94

1

11-463582-030

EXTRUSION, 89.67" with ICC MTG. HOLES

A/R A/R A/R A/R A/R A/R A/R A/R A/R A/R

21-3117552-00

HOLE PLUG, 9.65MM GROOVE DIA./RUBBER BLK

11

46-0941569-00

ASS'Y, CENTER ROTATORS, HARNESS

222

46-0941244-00

ASS'Y, ROTATORS HARNESS

2

4

4

1

1

2

2

A/R

4

1

A/R

A/R

7

16.46

14.94

8

8

16

1

A/R

4

2

4

A/R

2

1

14.61

16.13

8

2

16

7

4

8

A/R

A/R

1

01-0684303_92

11-463582-029

1

EXTRUSION, 87.67" WITH ICC MTG. HOLES

2

3

ITEM

PART NUMBER

DESCRIPTION

QTYQTY QTYQTY QTY QTY QTY

11

12

13

14

15

16

20

28

17

25

21

29

18

26

22

30

19

27

23

31

24

32

4

5

6

7

8

9

10

1

33

QTYQTYQTY QTY QTY QTY QTY

34

35

36

LENS

ASS'Y LENS GASKET/RETAINER/

ASS'Y LED ICC LIGHTS - AMBER/

SCREW #8 x 1/2" PPHSMS BLACK//

ASS'Y LED ICC BRAKE LIGHTS - RED//

ASS'Y C R LED ICC LIGHTS - AMBER/T

ASS'Y C R LED ICC BRAKE LTS - RED/T /

ASS'Y / HARNESS

4500 SERIES LT BAR-22" w

ithout ICC LT.

4500 SERIES LT BAR-38"

without ICC LT.

4500 SERIES LT BAR-44""

without ICC LT.

4500 SERIES LT BAR-52"

/ See P/N Key

4500 SERIES LT BAR-60"

/ See P/N Key

4500 SERIES LT BAR-72"

/ See P/N Key

4500 SERIES LT BAR-76"

/ See P/N Key

4500 SERIES LT BAR-82"

/ See P/N Key

4500 SERIES LT BAR-84"

/ See P/N Key

4500 SERIES LT BAR-86"

/ See P/N Key

4500 SERIES LT BAR-88"

/ See P/N Key

4500 SERIES LT BAR-90"

/ See P/N Key

4500 SERIES LT BAR-94"

/ See P/N Key

4500 SERIES LT BAR-92"

/ See P/N Key

37

5

4

3

2

1

6

Page 8

Loading...

Loading...