Page 1

®

ENGINEERING COMPANY INC.

51 Winthrop Road

Chester, Connecticut 06412-0684

Phone: (860) 526-9504

Fax: (860) 526-4078

Internet: www.whelen.com

Sales e-mail: autosale@whelen.com

295SLSC1 (200W / 12V / Removable Mic )

Installati on Guide:

Siren Model(s)

295SLSA1 (200W / 12V)

295SLSE1 (200W / 24V)

Canadian Sales e-mai l: auto can@whelen.com

Customer Service e-mail: custserv@whelen.com

DANGER! Sirens produce extremely loud emergency warning tones! Exposure to these

tones without proper and adequate hearing protection, could cause ear damage and/or hearing

loss! The Occupational Safety & Health Administration (www.osha.gov) provides information

necessary to determin e safe exposure times in Occupational Noise E xposure Section 1910.95.

Until you have determined the safe exposure times for your specific application, operators and

anyone else in the immediate vicinity should be require d to wear an a pproved he aring prote ction

device. FAILURE TO FOLLOW THIS RECOMMENDATION COULD CAUSE HEARING LOSS!

Safety First

This document provid es all the nec es sa ry in form at ion to allow your Whelen prod uc t to b e pro perl y a nd s afe ly ins tal le d.

Before beginning the installation and/or operation of your new product, the installation technician and operator must

read this manual completely. Important information is contained herein that could prevent serious injury or damage.

• Proper installation of this product requires the installer to have a good understanding of automotive electronics,

systems and proced ur es.

• If mounting this product requires drilling holes , the installer MUST b e su re th at no vehicle components or other

vital parts could be damaged by the drilling proce ss. Check both side s of the mounting surfac e before drilling

begins. Also de-burr any holes and remove any metal shards or remnants. Install grommets into all wire

passage holes.

• If this manual states that this product may be m ounted with suctio n cups, magnets, tape or Velcro®, clean the

mounting surface with a 50/50 mix of isopropyl alco hol and wa te r and dry thoroughly.

• Do not install this product or route any wires in the deployment area of y our air bag. Equipment mounted or

located in the air bag deployme nt area will damage or reduce the effective ness of the air bag, or be come a

projectile that could cause serious personal injury or death. Refer to your vehicle owner’s manual for the air bag

deployment area. The User/Installer assumes full responsibility to determine proper mounting location, based

on providing ultimate safet y t o al l passenge rs ins id e the vehicle.

• For this product to operate at optimum efficiency, a good electrical connection to chassis ground must be

made. The recommended procedure requires the product ground wire to be connected directly to the NEGATIVE

(-) battery post.

• If this product uses a remote dev ice to activate or c ontrol this product, m ake sure this contro l is located in an

area that allows both the vehicle and the control to be operated safely in any driving condition. DO NOT

ATTEMPT TO ACTIVATE OR CONTROL THIS DEVICE IN A HAZARDOUS DRIVING SITUATION.

• It is recommende d that these instructions be stored in a safe pla ce and

referred to when performing maintenance and/or reinstallation of this

product.

• FAILURE TO FOLLOW THESE SAFETY PRECAUTIONS AND

INSTRUCTIONS COULD RESULT IN DAMAGE TO THE PRODUCT OR

VEHICLE AND/OR SERIOUS INJURY TO YOU AND YOUR PASSENGERS!

ACTIVATION OF THIS

SIREN MAY DAMAGE

UNPROTECTED EARS!

CAUTION

Loud siren noise can cause

hearing damage and/or loss.

Wear

Refer to OSHA Section 1910.95 prior

Protection!

to putting ANY siren into service!

Automotive: Sirens/Switches

For warranty information regarding this product, visit www.whelen.com/warranty

©2007 Whelen Engineering Company Inc.

Form No.14109G (070110)

Page 1

Page 2

Congratulations on selecting the 295SLS Series Siren. This series offers a unique and distinctive collection of features

designed to allow the user to customize the operation of this siren to suit their individual wants or needs.

• Power to drive two, 100-Watt speakers

• Scan-Lock™ Tone Programing

• Hands-Free operation.

• Siren Interruption Control

• High and Low Voltage Shutdown

• Radio Repeat

• Auxiliary Input Control

• Horn Ring Transfer

• Simulated mechanical siren tones

• Speaker Diagnostics

• “Siren In Use” Output

• LED Backlighting

• Harmonically-rich, composite Airhorn tones

• Title 13-compliant profiles

• Compact Size

• Non-destructive Short Circuit Protection

• Meets Class A Sound Requirements

• External Backlight Control

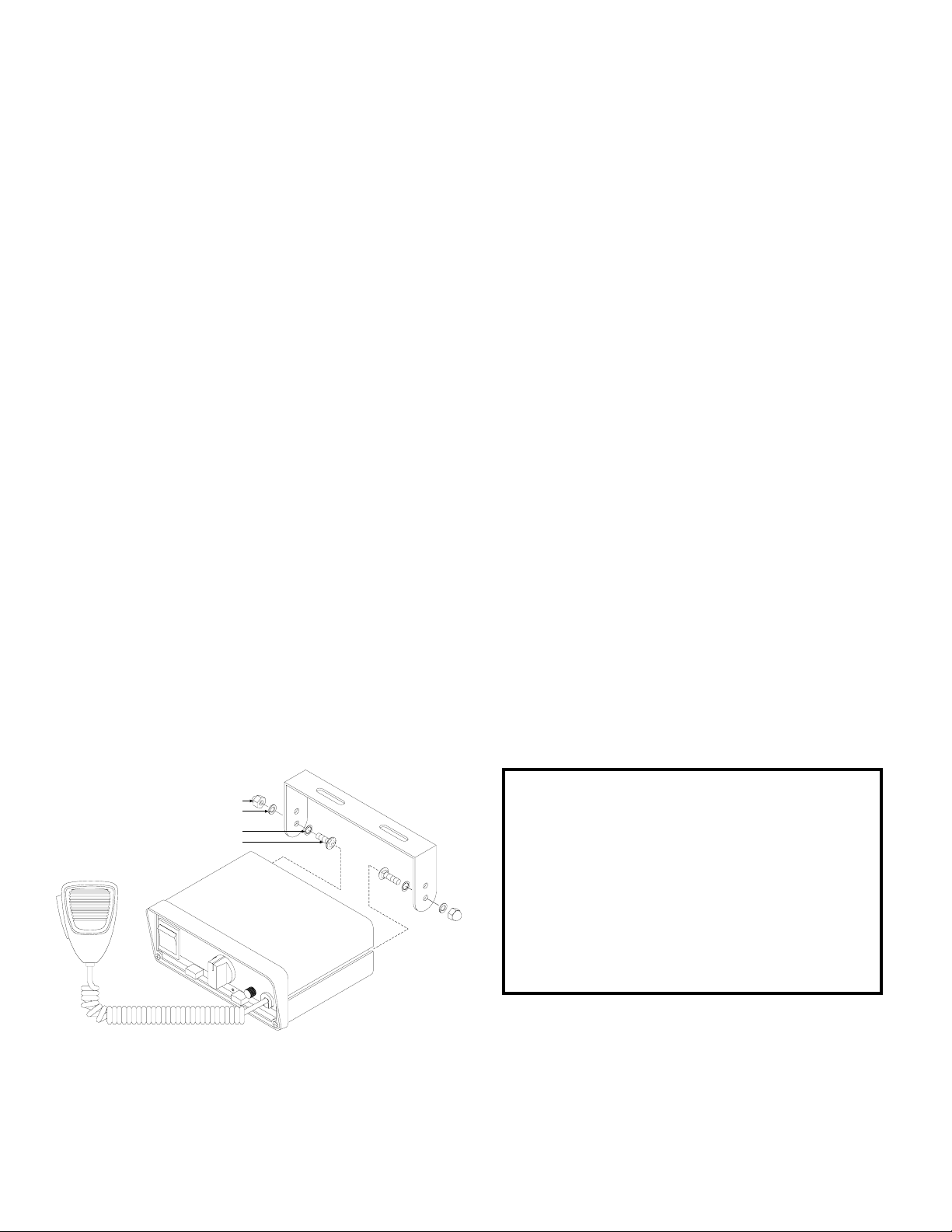

Mounting

The 295SLS is designed to be mounted directly onto the dash or

other surface through the use of a bail strap mounting bracket.

The unit may also be mounted into your vehicle’s console (if so

equipped). Regardless of the style selected, be sure to

observe the air bag warning on the cover of this manual.

Bail Strap Mount

1. Position the bail strap in the selected mounting location.

Using an awl or other suitable tool, scribe the surface where

the mounting holes are to be drilled.

Caution: As mounting this unit will require drilling, it is

absolutely necessary to make sure that no other

vehicle components could be damaged in the

process. Check both sides of the mounting

surface before starting. If damage is likely,

select a different mounting location.

2. Drill the mounting holes in the areas scribed in step 1. The

size of the dri ll bit should be determi ned by the size of the

mounting hardware used and thickness of the mounting

surface.

3. Secure the bail strap to the mounting location.

Note: There are 2 sets of holes on the Bail Strap for

positioning the unit at 2 different heights.

4. Secure the siren to the bail bracket using the provided

hardware as shown below.

5. Tighten the Acorn nut firmly.

Console Mount

Console manufacturers offer mounting kits that include all the

necessary hardware and brackets required to mount this unit into

their console. The console mount brackets are secured onto the

unit the same way the bail bracket is (except for the addition of

two flat washers that must be inserted between the siren and the

bracket). Please refer to the manual included with your console

for specific information on securing the siren/mounting bracket

assembly onto the console.

NOTE: Due to the lack of air flow within a console, prolonged

operation of this siren may require the console to be

modified to improve ventilation.

Microphone Clip

A microphone clip is included with this product. The installer

must refer to the Air Bag Warning below before installing this

clip.

“Acorn” Nut

Split Lock-Washer

Internal-tooth Lock-washer

Carriage Bolt

IMPORTANT AIR BAG WARNING! Do not install

this product or route any wires in the air bag

deployment zone of your vehicle. Equipment

mounted or located in air bag deployment zones will

damage or reduce the effectiv ene ss of the air bag, or

become a projectile that could cause serious

personal injury or death. Refer to your vehicle

owners manual to learn the air bag deployment

zones for the vehicle. The User/Inst a ller ass umes full

responsibility to determine proper mounting

location, based on providing ultimate safety to all

passengers inside the vehicle.

Page 2

Page 3

Wiring:

Power & Ground Wires: RED: Power / BLACK: Ground

WARNING!All customer supplied wires that connect to the positive terminal of the battery must be sized to supply at least

125% of the maximum oper ating curr ent and FUSED

THIS PRODUCT!

1. Splice the 2 RED (Power) wires together, then extend this single RED wire toward the vehicle battery. Splice the 2 BLACK

(Ground) wires together and extend this single BLACK wire toward the vehicle battery. To pass the RED and BLACK wires

through, you may have to dri ll a hole in the firewa ll. Be sure there are no componen ts th at co ul d be da ma ged . Ins ert a grommet in

the hole to protect the wires.

2. Route the R ED and BLACK wires along th e fa cto r y har nes s tow ar ds the battery and insta ll a fu se block (user sup pli ed) on the end

of the RED wire (refer to the wiring sche matic on p age 4 for y our mod el’ s fuse va lue). NOTE: Rem ove the f use from the fuse bl ock

before connecting any wires to the battery.

3. Connect the fu se b loc k wi re to the PO SIT IVE (+) te rmi nal on th e ba ttery . The r e mus t not be m ore t han 2 fee t of w ir e be tw een fuse

block and battery. The wire between the fuse and the battery is “unprotected,” don’t allow it to contact with any wires.

4. Connect the BLACK wire to the factory chassis ground.

Speaker Wires: ORANGE, YELLOW & BROWN

1. Route the ORANGE, YELLOW and BROWN wires toward the vehicle siren speakers, along the factory wire harness and through

the firewall at the same point as the RED and BLACK wires.

2. Connect the YELLOW and ORANGE wires to the POSITIVE connection on speakers #1 & 2 (respectively).

3. Connect the BROWN wire to the NEGATIVE connection on speakers #1 & 2.

Horn Relay Wires: WHITE & GREY

1. Route the WHITE and GREY wires along the factory wire harness and through the firewall at the same point as the RED and

BLACK wires.

2. Route the WHITE and GREY wires to your vehicle’s horn relay. If

possible, follow the factory wire harness to this relay.

3. Locate the wire that connects the vehicle horn to the horn relay and

cut it.

4. Connect the WHITE wire to the wire coming from the horn relay.

5. Connect the GREY wire to the wire coming from the horn.

Radio Rebroadcast (optional): 2 BLUE wires

The two remaining BLUE wires are used to connect your two-way

radio’s external speaker for radio rebroadcast (an optional connection).

NOTE: If your remote speaker is amplified (has a power amp circuit in

the speaker), radio reb road ca st w i ll not work and should n ot b e en ab led .

1. Locate the two wires that connect the external speaker to the twoway radio, cut one of them and splice one of the BLUE wires into

this circuit.

2. Now cut the remai nin g sp eak er w ire and splic e the r ema in ing BLUE

wire into this circuit.

at the battery to carry that load. DO NOT USE CIRCUIT BREAKERS WITH

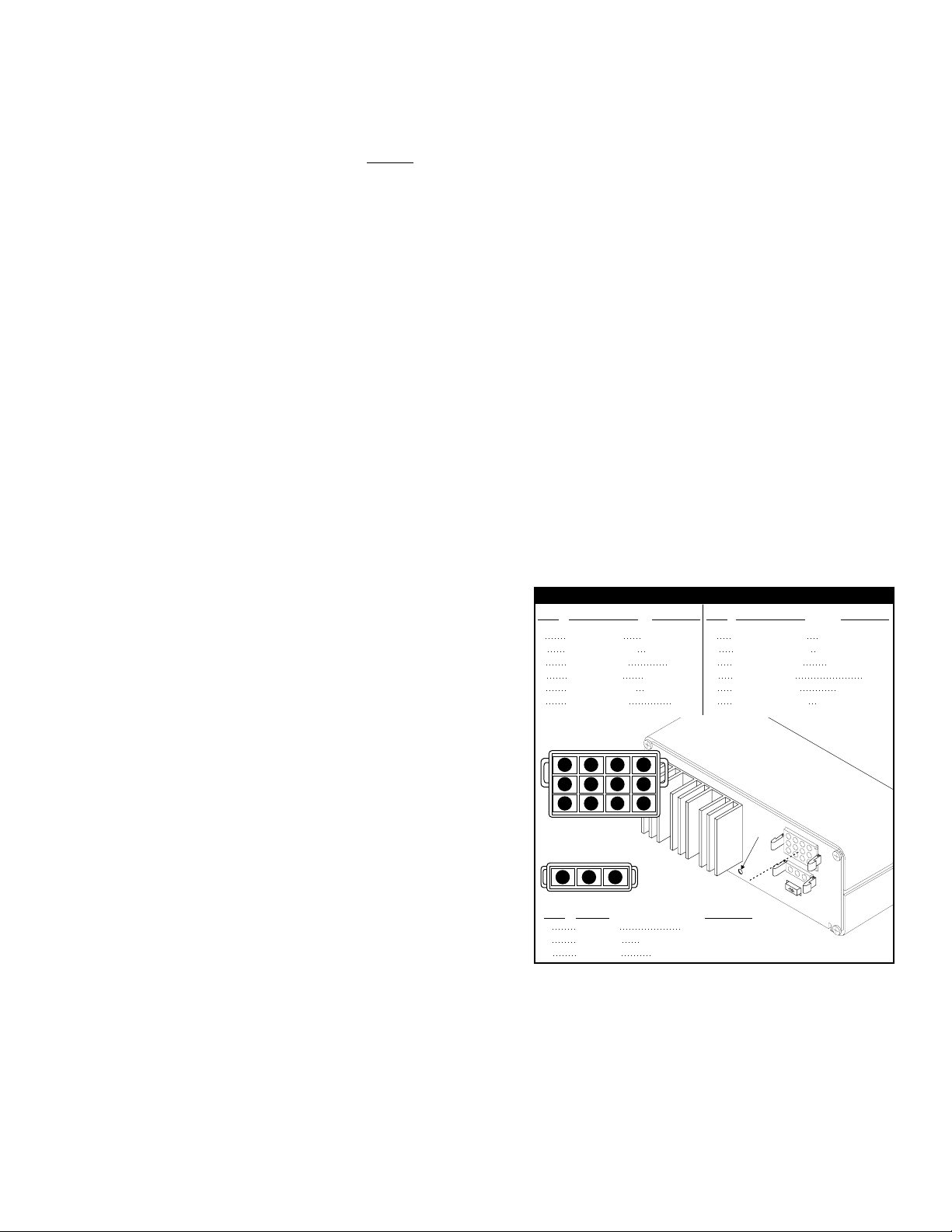

INPUT CONNECTORS

COLOR / GAGE

PIN#

1

RED 14GA/

2

BLACK / 14GA

3

BLUE / 18GA

4

RED / 14GA

5

BLACK / 14GA

6

BLUE / 18GA

INPUT CONNECTOR

(REAR VIEW)

3

6

2

5

1

4

3-POS. CONNECTOR

(REAR VIEW)

123

COLOR

PIN#

1

WHT/YEL

2

WHT/ORG

3

WHT/GRN

FUNCTION

()

+ BATTERY

(-) GROUND

RADIO

(+) BATTERY

(-) GROUND

RADIO

12

9

8711

10

BACKLIGHTING

“SIREN IN USE” OUTPUT

SIREN INTERRUPTION

PIN# FUNCTION

COLOR / GAGE

7

BROWN / 16GA

8

ORANGE / 16GA

9

VIOLET / 18GA

10

GRAY / 18GA

11

WHITE / 18GA

12

YELLOW / 16GA

FUNCTION

Scan-Lock

Switch

SPEAKER COM

SPEAKER #2 (+)

AUX. ENABLE

HORN

HORN RING

SPEAKER #1 (+)

Page 3

Page 4

Connecting to a Remote ControlHead: (Optional)

This unit may be connected to an existing

control head, such as the Whelen PCCS9NP

or equivalent. This is an optional connection

that enables the WAIL tone to be activated

through the use of a PCCS9NP button or

switch. If this connection is not chosen, cut

the VIOLET wire and cap it to prevent

accidental grounding of the wire.

All Fuses & Fuse Blocks are to

WIRING DIAGRAM

HORN

TO HORN

BUTTON

RELAY

NOTE:

be supplied by the Customer. NOT

use circuit breakers with this product!

+12V

Do

OPERATING THE CONTROLS:

Power Switch

This switch has two positions: Down (Off) and Up (On). When

this switch is Off, the unit will not function. When the switch is

On, the siren is functional and may be activated at the

operator’s discretion. This switch also activates control head

backlighting. NOTE: If the unit is connected to the vehicle’s

horn ring circuit, the vehicle horn is disabled when the power

switch is in the ON position.

MAN Button

The Manual button generates a variety of tones, depending

on what position the rotary knob is in. For further explanation

of this button’s function, refer to “Rotary Switch Operations.”

POWER

PEAKERS

12

POWER

SPEAKERS

12

MAN

MAN 1

RAD

MAN 2

MAN

RAD

MAN

12-POS.IINPUT CONNECTOR

20 AMP FUSE (12V)

10 AMP FUSE (24V)

295SLS*1 Siren

WHITE

11

GREY

10

YELLOW

12

ORANGE8

BROWN

7

BLUE

3

BLUE

6

VIOLET

9

5

BLACK

2

BLACK

RED

4

RED

1

3

WHT/GRN

WHT/ORG

2

WHT/YEL

1

CUT WIRE HERE

(TO PCDS-9 or EQUIV.)

(+)

(-)

Battery

Siren Interruption

Negative (-) Activation

To “Siren In Use” Icon

Input on Video Camera

To Dashboard

Lighting Control

Voltage

AUXILIARY

ENABLE

CONNECTION

(OPTIONAL)

CHASSIS

GROUND

VEHICLE

100W

100W

RADIO

TO 2-WAY

HORN

SPEAKER #1

SPEAKER #2

SPEAKER

T2

AD

F

MAN 1

RAD

N

T3

HORN

T1

RAD

MAN 2

MIC VOL.

T2

T3

HORN

PA Volume (MIC)

With the vehicle in an enclosed area, turn the siren on and

speak into the microphone. While speaking, turn knob

clockwise t o increase the volu me. Continue to incr ease the

PA volume until audio feedback occurs. Turn counterclockwise to eliminate feedback.

®

Horn Button

Holding the HORN button on generates a AIRHORN tone

when the siren is powered up.

MIC VOL.

Rotary Switch

HF

T1

T2

T3

RAD

The Rotary Knob controls the siren functions. There are 7

positions that may be selected. Each position and its function

is outlined under “Rotary Switch Operations.”

H

3-POS.IINPUT CONNECTOR

Page 4

Page 5

Diagnostic Indicators:

This unit has two diagnostic indicators on the front panel which

are used to indicate fa ult con dit ions with your siren syste m. Th e

following table lists the typ e of fau lt and t he i ndica tors respo nse.

If the indicator is on steady while a tone is in use, this implies

that there is no fault with the associated speaker output.

Fault Condition Diagnostic Indicators Response

Under Voltage Speaker LED #1 will be in a

DoubleFlash mode (2 quick flashes

followed by a longer pause) and the

siren tones will not operate.

Over Voltage Speaker LED #2 will be in a

DoubleFlash mode (2 quick flashes

followed by a longer pause) and the

siren tones will not operate.

Speaker #1

Short Circuit Speaker LED # 1 will be in a

SingleFlash mode (the LED will be on

and off an equal amount of time) and

the siren tones will not operate.

POWER

SPEAKERS

12

SI TEST® & Diagnostic Indicators

SI TEST

allows the operator to confirm the proper

MAN

operation of the siren speakers connected

RAD

MAN

to the unit without activating an audible

siren tone. To initiate the SI TEST® cycle,

set the rotary knob to the RAD position.

Now press and release the MAN button. As

the siren is tested, its diagnostic indicator

will turn on steady for about 1.5 seconds if

no problems are detected. If the indicator

flashes or does not light at all, a problem

with either the siren, speakers or wiring has

been detected. Check the wire connections

of the failed speaker and repeat the SI

TEST®. If the speaker fails again, have the

siren inspected by a qualified technician.

WARNING:

generating a ultra-high frequency tone

through each speaker. Although these

tones are inaudible to humans, be sure

there is nobody wit hin 5 fe et of th e spea kers

when SI TEST® is running.

® is a diagnostic feature and

Installed speak ers are t ested b y

Speaker #2

Short Circuit Speaker LED #2 will be in a

Radio Repeat Volume (RAD)

HF

2

T1

T2

T3

HORN

RAD

Locate the Radio Repeat adjustment port as

shown. Set the volume level of the vehicle’s

two-way radio to it’s normal operating

MIC

volume. Turn the Rotary Knob to RAD to

activate Radio Repeat. Insert the screwdriver

in the Radio Repeat adjustment port and turn

clockwise to increase the volume.

Speaker #1

Open Circuit Speaker LED #1 will be off (having a

SingleFlash mode (the LED will be on

and off an equal amount of time) and

the siren tones will not operate.

single speaker system will always

cause this condition for the speaker

output not in use) all tones will

continue to operate.

Speaker #2

Open Circuit Speaker LED #2 will be off (having a

single speaker system will always

cause this condition for the speaker

output not in use) all tones will

continue to operate.

Page 5

Page 6

Rotary Switch Operations

This section will outline the operation of the siren in the factory

default configuration. Refer to the Scan-L ock™ sect ion on the

following page for information and procedures on how to

customize the operation of this siren.

RAD (Radio Repeat) - When the rotary knob is in the RAD

position, any signal that is received by the vehicle’s two-way

radio will be simultaneously broadcast over the vehicle’s

loudspeaker (the unit must be connected to the tw o-way radio as

outlined in this manual).

With the Rotary Switch in this Position:

• Activating the HORN button will produce the AIRHORN tone

until released.

• Pressing the MAN button will start SI TEST® as described on

Page 5.

• Activating the HORN RING input will produce the AIRHORN

tone until the MAN switch is released.

• Activating the AUX ENABLE input has no effect.

MAN 1 (Manual Siren #1) - When the rotary switch is in this

position the si ren is in a standby st ate where no tones hav e bee n

activated, but is waiting for another action to be taken by the

operator.

With the Rotary Switch in this Position:

• Activating the HORN button will produce the AIRHORN tone

until released.

• Pressing the MAN button will produce the AIRHORN tone until

the MAN switch is released.

• Activating the HORN RING input will produce the AIRHORN

tone until the HORN RING input is released.

• Activating the AUX enable input will produce a repeating WAIL

tone.

MAN 2 (Manual Siren #2) - When the rotary switch is in this

position the siren is in a standb y state. No tones will be activated

until another action is taken by the operator.

With the Rotary Switch in this Position:

• Activating the HORN button will produce the AIRHORN tone

until released.

• Pressing the MAN switch will produce a WAIL tone. This tone

will ramp up to peak frequency and stop when the MAN switch

is released.

• Activating the HORN RING input will produce a WAIL tone. This

tone will ramp up to peak frequency and stop when the HORN

RING input is released.

• Activating the AUX enable input will produce a repeating WAIL

tone.

HF (Hands-Free Operation) - When the rotary knob is in the HF

position, the siren functions are placed in a standby mode. Siren

tones are activated by a s ing le “t ap” o n th e MAN button or on the

vehicle’s steering wheel horn ring (if the vehicle’s horn has been

wired to the HORN RING input). The first tap produces a “Wail”

tone (a steady rise and fall tone). A second tap produc es a “Yelp”

tone (a fast rise and fall to ne) . A third tap produc es a pierce r ton e

(an extremely fast rise and fall tone). The next tap returns the

siren to a wail tone and the cycle repeats itself. Two quick

successive taps will stop the siren.

With the Rotary Switch in this Position:

• Activating the HORN button will produce the AIRHORN tone

until released.

• Pressing the MAN button will produce the HF cycle as

described above.

• Activating the HORN RING input will produce the HF cycle as

described above.

• Activating the AUX ENABLE input will start the HF cycle.

Releasing the AUX ENABLE will stop the cycle.

T1 (Tone #1) - When the rotary knob is in the T1 position, a

steady, rise and fall tone (WAIL) is produced.

With the Rotary Switch in this Position:

• Activating the HORN button will produce the AIRHORN tone

until released.

• Pressing the MAN button will change the siren tone to a yelp

pattern (a fast rise and fall tone). Pressing the MAN button a

second time returns it back to WAIL.

• Activating the HORN RING input will change the siren tone to

YELP. Activating the HORN RING input again to return to a

WAIL tone.

• Activating the AUX ENABLE input has no effect.

T2 (Tone #2) - When the rotary knob is in the T2 position, a fast,

rise and fall tone (YELP) is produced.

With the Rotary Switch in this Position:

• Activating the HORN button will produce the AIRHORN tone

until released.

• Pressing the MAN button will produce the PIERCER tone.

Pressing the MAN switch a second time returns it back to

YELP.

• Activating the HORN RING input will produce the AIRHORN

tone until the HORN RING input is released.

• Activating the AUX ENABLE input has no effect.

T3 (Tone #3) - When the rotary knob is in the T3 position, an

extremely fast, rise and fall tone is produced.

With the Rotary Switch in this Position:

• Activating the HORN button will produce the AIRHORN tone

until released.

• Pressing the MAN button will result in the AIRHORN tone until

the MAN button is released.

• Pressing the HORN RING input will result in the AIRHORN tone

until the HORN RING input is released.

• Activating the AUX ENABLE will have no effect.

12-Volt Models 24-Volt Models

INPUT VOLTAGE . . . . . . . . . . . . . . . . . . . . 12 VDC ±20% 24 VDC ±20%

INPUT CURRENT. . . . . . . . . . . . . . . . . . .16 AMPS (TYP.) 8 AMPS (TYP.)

INPUT FUSE. . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 AMPS 10 AMPS

SPEAKER IMPEDANCE. . . . . . . . . . . . . . .11 OHMS MIN. 11 OHMS MIN.

OPERAT ING TEMPERATURE . . . . . . .-30° C. TO +80° C. -30° C. TO +80° C.

STORAGE TEMPERATURE. . . . . . . . .-40° C. TO +70° C. -40° C. TO +70° C.

HUMIDITY. . . . . . . . . . . . . . . . . . . 99% (Non-Condensing) 99% (Non-Condensing)

Page 6

ACTIVATION OF THIS

SIREN MAY DAMAGE

UNPROTECTED EARS!

CAUTION

Loud siren noise can cause

Wear

Protection!

hearing damage and/or loss.

Refer to OSHA Section 1910.95 prior

to putting ANY siren into service!

Page 7

Scan-Lock™ Programing Procedures

With Scan-Lock, the tonal operation of the siren can be

customized to fit the users needs. A momentary switch,

accessed through a small hole on the back of the siren, is used

to change the default siren tones as outlined below. A nonconductive tool (such as the tip of a pen) should be used to

actuate this switch.

To change the primary tone for rotary switch positions T1,

T2, and T3: Put the rotary switch in the position that you wish to

change. Press and release the Scan-Lock switch. Each time the

Scan-Lock switch is pressed and released, the next available

tone will be broadcast (see “Tone List For Rotary Switch

Positions T1, T2 & T3”). When the desired tone is generated, it

will automatically be saved for that rotary switch position.

To change the override tone for rotary switch positions T1,

T2. and T3: Put the rotary switch in the position that you wish to

change. Press and ho ld the M AN b utto n on the front panel on th e

siren. Press and release the Scan-Lock switch. Each time the

Scan-Lock switch is pressed and released, the next available

tone will be broadcast (s ee “Overrid e Tone List For Rotary Switch

Positions T1, T2 & T3”). When the desired tone is present, it will

automatically be saved as the override tone for that rotary switch

position. Release the MAN button.

To change one of the tones in the hands free cycle as

described in the “Rotary Switch Operations” section of this

manual: Put the rotary switch in the HF position. Using the MAN

button on the front panel on the siren, advance to the tone that

you wish to change. Press and release the Scan-Lock switch.

Each time the Scan-Lock switch is pressed and released, the

next available tone will be broadcast (see “Tone List For Hands

Free Operation”). When the desired tone is generated, it will

automatically be saved for that hands-free cycle position.

To change the tone for rotary switch positions MAN1 or

MAN2: Put the rotary switch in the position that you wish to

change. Press and ho ld the M AN b utto n on the front panel on th e

siren. Press and release the Scan-Lock switch. Each time the

Scan-Lock switch is pressed and released, the next available

tone will be broadcast (see “Tone List For MAN1 & MAN2

Operation”). When the desired tone is generated, it will

automatically be saved for that rotary switch position. Release

the MAN button.

To change the override tone for rotary switch position RAD:

Put the rotary switch in the RAD position. Press and hold the

MAN button on the front panel on the siren. Press and release

the Scan-Lock switch. Each time the Scan-Lock switch is

pressed and released, the next available tone will be broadcast

(see “Override Tone List For RADIO Rotary Switch Position”).

When the desired tone is generated, it will automatically be

saved for that rotary switch position. Release the MAN button.

T o c hang e the tone for the HORN butto n: Put the rotary switch

in the MAN2 position. Press and hold the HORN button on the

front panel of the siren. Press and release the Scan-Lock switch.

Each time the Scan-Lock button is pressed and released, the

next available tone will be broadcast (see “Tone List for HORN

Button”). When the desired tone is generated, it is automatically

saved for HORN Button activation.

To Enable Title 13 Operat ion Mode - P lace the Rot ary Switch

into a stand-by position (MAN1, MAN2, HF) and turn the unit

OFF. While holding both the Scan-Lock™ switch and the MAN

button down, turn the unit ON. A set of Title 13-compliant tones

are now available. Note that AIRHORN is not allowed to override

the primary warning tones while in this mode.

Siren Interruption Configuration - The siren interruption

feature can be configured to operate in 2 modes:.

PAUSE: Grounding the WHT/GRN wire will deactivate the siren

and removing ground from the WHT/GRN wire will reactivate the

siren. CANCEL: (Factory default) Grounding the WHT/GRN wire

will deactivate the siren, however, removing ground from the

WHT/GRN wire will not reactivate the siren. The operator must

reset the siren by placing the rotary switch into one of the

standby positions (HF, MAN1 or MAN2).

To change the siren interruption mode - Place the rotary

switch into a standby position (HF, MAN1 or MAN2) and turn the

unit OFF. While holding both the Scan-Lock and AIRHORN

button in turn the power switch on.

To Restore the Factory Default Configuration - Place the

Rotary Switch into a stand-by position (MAN1, MAN2, HF) and

turn the unit OFF. While holding the Scan-Lock switch down, turn

the unit ON. The factory default configuration is now restored.

Tone List For Rotary Switch Positions T1, T2 & T3:

TONE OFF

WAIL*

YELP*

PIERCER

Y-249*

HI/LOW

SIMULATED

MECHANICAL

PULSED AIRHORN

AIRHORN HI/LOW

ALTERNATE WAIL*

ALTERNATE YELP*

WOOP

WARBLE

* California Title 13-Compliant Siren Tones.

Tone List For Hands Free Operation:

WAIL

YELP

PIERCER

Y-249

HI/LOW

SIMULATED

MECHANICAL

PULSED AIRHORN

AIRHORN HI/LOW

ALTERNATE WAIL

ALTERNATE YELP

WOOP

WARBLE

Tone List For HORN Button:

TONE OFF

AIRHORN COMMAND CODE

AIRHORN LOW COMMAND CODE

Page 7

Override T one List For Rotary Switch Positions T1, T2 & T3:

TONE OFF

WAIL

YELP

PIERCER

Y-249

HI/LOW

SIMULATED

MECHANICAL

PULSED AIRHORN

AIRHORN HI/LOW

ALTERNATE WAIL

ALTERNATE YELP

WOOP

WARBLE

AIRHORN

LOW FREQ. AIRHORN

Tone List For MAN1 & MAN2 Operation:

TONE OFF

MANUAL SIMULATED MECHANICAL COAST-TO-STOP

MANUAL SIMULATED MECHANICAL STOP

MANUAL WAIL COAST-TO-ST OP

MANUAL WAIL STOP

AIRHORN

LOW FREQ. AIRHORN

Override Tone List For Rotary Switch Position Radio:

TONE OFF

AIRHORN COMMAND CODE

AIRHORN LOW COMMAND

CODE

Page 8

Wire Gauge

Calculation Chart

Wire Gauge (AWG)

22

5

10

INS.

15

INS. INS.

20

INS.

25

INS.

30

INS.

35

INS.

40

INS.

45

INS.

50

INS.

55

INS.

60

INS.

65

INS.

70

INS.

75

INS.

80

INS.

85

INS.

90

INS.

95

Current Draw (AMPS)

100

INS.

6

3

INS.

INS. INS.

INS.

INS.

INS.

INS.

INS.

INS.

INS.

INS.

INS.

INS.

INS.

INS.

INS.

INS.

20

9.5

5

3

18

15

7.5

INS.

INS.

INS. INS.

INS. INS.

INS. INS.

INS. INS.

INS. INS.

INS. INS.

INS. INS. INS.

INS. INS. INS.

INS. INS. INS.

INS. INS. INS.

INS. INS. INS.

INS. INS. INS.

16

24.5

12

5

4

3

3.5

14

39

19.5

8

13

6

9.5

5

4

3

8

6.5

5.5

5

4.5

4

3.5

3

3

3

12

62

31

20.5

15.5

12.5

10.5

9

7.5

7

6

5.5

5

5

4.5

4

4

3.5

3.5

3.5

3

10

98

49

32.5

24.5

19.5

16.5

14

12.5

11

10

9

8

7.5

7

6.5

6

6

5.5

5

5

8

156

78

52

39

31

26

22.5

19.5

17.5

15.5

14

13

12

11

10.5

10

9

8.5

8

8

6

248

124

82.5

62

49.5

41.5

35.5

31

27.5

25

22.5

20.5

19

17.5

16.5

15.5

14.5

14

13

12.5

4

395

197

131

98.5

79

66

56.5

49.5

44

39.5

36

33

30.5

28

26.5

24.5

23

22

21

19.5

2

629

314

209

157

125

104

89.5

78.5

69.5

63

57

52.5

48.5

45

42

39

37

35

33

31.5

All Distances Shown Are In FeetINS. = Insufficient

To use this chart...

1. Determine the amount of current being drawn through the wire. Locate this number in the vertical left-hand

column. If the current value is between adjacent values, use the higher number.

2. Follow this row until the length of the installed wire is shown. If the exact length is between adjacent values, use

the higher number. Follow this column upwards to find the recommended size (gage) for this wire.

In the example shown below, the size for a wire with an installed length of 36 feet, through which 22 amps of current

will be drawn, must be determined.

A row for 22 amps is not shown, so the row for 25 amps will be used. Follow this row to the right. A column for 36 feet

is not shown, so the column for 49.5 feet will be used. Following this column to the top will show that the size of this

wire must be at least 6 gage.

Page 8

Loading...

Loading...