Page 1

®

ENGINEERING COMPANY INC.

51 Winthrop Road

Chester, Connecticut 06412-0684

Installation Manual:

295HFS4 Series Siren

Phone: (860) 526-9504

Fax: (860) 526-4078

Internet: www.whelen.com

Sales e-mail: autosale@whelen.com

Canadian Sales e-mail: canadiansales@whelen.com

Customer Service e-mail: custserv@whelen.com

DANGER! Sirens produces extremely loud emergency warning tones! Exposure to these

tones without proper and adequate hearing protection, could cause ear damage and/or hearing

loss! The Occupational Safety & Health Administration (www.osha.gov) provides information

necessary to determine safe exposure times in Occupational Noise Exposure Section 1910.95.

Until you have determined the safe exposure times for your specific application, operators and

anyone else in the immediate vicinity should be required to wear an approved hearing protection

device. FAILURE TO FOLLOW THIS RECOMMENDATION COULD CAUSE HEARING LOSS!

Safety First

This document provides all the necessary information to allow your Whelen product to be properly and safely installed.

Before beginning the installation and/or operation of your new product, the installation technician and operator must

read this manual completely. Important information is contained herein that could prevent serious injury or damage.

• Proper installation of this product requires the installer to have a good understanding of automotive electronics,

systems and procedures.

• If mounting this product requires drilling holes, the installer MUST be sure that no vehicle components or other

vital parts could be damaged by the drilling process. Check both sides of the mounting surface before drilling

begins. Also de-burr any holes and remove any metal shards or remnants. Install grommets into all wire

passage holes.

• If this manual states that this product may be mounted with suction cups, magnets, tape or Velcro®, clean the

mounting surface with a 50/50 mix of isopropyl alcohol and water and dry thoroughly.

• Do not install this product or route any wires in the deployment area of your air bag. Equipment mounted or

located in the air bag deployment area will damage or reduce the effectiveness of the air bag, or become a

projectile that could cause serious personal injury or death. Refer to your vehicle owner’s manual for the air bag

deployment area. The User/Installer assumes full responsibility to determine proper mounting location, based

on providing ultimate safety to all passengers inside the vehicle.

• For this product to operate at optimum efficiency, a good electrical connection to chassis ground must be

made. The recommended procedure requires the product ground wire to be connected directly to the NEGATIVE

(-) battery post.

• If this product uses a remote device to activate or control this product, make sure this control is located in an

area that allows both the vehicle and the control to be operated safely in any driving condition. DO NOT

ATTEMPT TO ACTIVATE OR CONTROL THIS DEVICE IN A HAZARDOUS DRIVING SITUATION.

• It is recommended that these instructions be stored in a safe place and

referred to when performing maintenance and/or reinstallation of this

product.

• FAILURE TO FOLLOW THESE SAFETY PRECAUTIONS AND

INSTRUCTIONS COULD RESULT IN DAMAGE TO THE PRODUCT OR

VEHICLE AND/OR SERIOUS INJURY TO YOU AND YOUR PASSENGERS!

ACTIVATION OF THIS

SIREN MAY DAMAGE

UNPROTECTED EARS!

CAUTION

Loud siren noise can cause

hearing damage and/or loss.

Wear

Refer to OSHA Section 1910.95 prior

Protection!

to putting ANY siren into service!

Automotive: Sirens/Switches

For warranty information regarding this product, visit www.whelen.com/warranty

©1995 Whelen Engineering Company Inc.

Form No.13087G (100410)

Page 1

Page 2

WARNING!

DISCONNECTING THE VEHICLE BRAKE LAMP

CIRCUIT USING ANY SIRENS WITH RELAY OUTPUTS

OR SWITCH CONTROLLERS COULD CAUSE

VEHICLE OR PROPERTY DAMAGE, SERIOUS INJURY

OR EVEN DEATH.

DISABLING THIS CIRCUIT IS A VIOLATION OF THE

FEDERAL MOTOR VEHICLE SAFETY STANDARD

FOR THE THIRD BRAKE LIGHT, AS WELL AS REAR

BRAKE LIGHTS.

FUNCTIONS THAT BLACK OUT THE REAR BRAKE

LIGHTS (SOMETIMES CALLED “BRAKE LIGHT CUT

OUT”) MAY INTERFERE WITH THE BRAKE SHIFT

LOCK MECHANISM, AND CAUSE THE VEHICLE TO

MOVE UNEXPECTEDLY AND DANGEROUSLY.

DISCONNECTING THE BRAKE LIGHTS IN ANY WAY

IS AT YOUR OWN

RISK AND IS NOT RECOMMENDED

BY WHELEN.

Page 2

Page 3

The 295HFS4, although technologically advanced, is simple to

install. An aftermarket center console is recommended for the

mounting location. This not only allows the driver to reach the

controls easily, but also keeps the unit safely out of the path of

the vehicle’s SRS air bag. Follow the console manufacturer’s

instructions for mounting information. If a console-type mount is

not possible, the unit is specially designed for dash (or panel)

mounting. WARNING: Mounting will require drilling. Make sure

that no vehicle components behind the mounting area will be

damaged. If damage is possible, select another location.

INSTALLATION / Amplifier:

1. From inside the trunk, position the amplifier against the ver-

tical trunk wall behind the rear seat and mark off the 4

mounting holes using a scribe or other suitable tool. Be sure

that the remote amplifier fits properly and does not interfere

with any parts of the trunk or seat back.

2. Carefully drill the indicated holes using an appropriately

sized drill bit.

3. Using the supplied sheet metal screws, secure the remote

amplifier to the vertical trunk wall.

12-POSITION INPUT CONNECTOR

RED and BLACK / Power & Ground Wires

WARNING: All customer supplied wires that connect to the

positive terminal of the battery must be sized to supply at

least 125% of the maximum operating current and FUSED

at the battery to carry that load. DO NOT USE CIRCUIT

BREAKERS WITH THIS PRODUCT!

Control Head:

For 6 feet of wire ......................................... 22 AWG wire

For 9.5 feet of wire ...................................... 20 AWG wire

For 15 feet of wire ....................................... 18 AWG wire

Amplifier:

For 6 feet of wire ................................................. 16 AWG

For 9.5 feet of wire .............................................. 14 AWG

For 15.5 feet of wire .................................... 12 AWG wire

1. Insert the wiring harness into its port.

2. Splice the 2 RED (Power) wires together, then extend this

single RED wire toward the vehicle battery. Splice the 2

BLACK (Ground) wires together and extend this single

BLACK wire toward the vehicle battery. To pass the RED

and BLACK wires through, you may have to drill a hole in

the firewall. Be sure there are no components that could be

damaged. Insert a grommet in the hole to protect the wires.

3. Install a 20 amp fuse block (user supplied) on the end of

the RED wires.

NOTE: Remove the fuse from the fuse block before connecting

any wires to the battery.

READ BEFORE INSTALLING!!!

Do not install this product or route any wires in the deployment area of your airbag. Equipment mounted or located in

the airbag deployment area will damage or reduce the

effectiveness of the airbag, or become a projectile that could

cause serious personal injury or death. Refer to your vehicle

owners manual for the air bag deployment area.

The User/Installer assumes full responsibility to determine

proper mounting location, based on providing ultimate safety

to all passengers inside the vehicle. Whelen Engineering Co.

assumes no liability or responsibility for determining individual

applications or exact installation location criteria.

4. Connect the fuse block wire to the POSITIVE (+) terminal

on the battery. There must not be more than two (2) feet of

wire between the fuse block and the battery. As the wire

between the fuse and the battery is “unprotected,” do not

allow this wire to come in contact with any other wires.

5. Connect BLACK wire to factory chassis ground.

YELLOW, ORANGE & BROWN / Speaker Wires

NOTE: This section outlines a two-speaker installation. If a one-

speaker installation is used, cut and cap ORANGE wire, skip

step 3 and connect BROWN wire to NEGATIVE speaker terminal of Speaker #1.

1. Route YELLOW, ORANGE and BROWN wires toward

vehicle’s siren speakers.

2. Connect YELLOW wire to POSITIVE speaker connection

on Speaker #1.

3. Connect ORANGE wire to POSITIVE speaker connection

on Speaker #2.

4. Connect BROWN wire to NEGATIVE speaker connection

on Speaker #2.

5. Splice a wire from the NEGATIVE connection on Speaker

#2 to the NEGATIVE connection on Speaker #1.

BLUE / Radio Rebroadcast Wires

NOTE: The two (2) BLUE wires are used to connect your two-

way radio’s external speaker to the 295HFS4 for radio rebroadcast. This is an optional connection and doesn’t effect other

operations of the 295HFS4.

1. Locate the two wires that connect the external speaker to

the vehicle’s two-way radio.

2. Cut one of these wires and splice one of the BLUE wires

into this circuit.

3. Cut the remaining speaker wire and splice the remaining

BLUE wire into this circuit.

NOTE:Radio rebroadcast will NOT

speakers. If your remote speaker contains a power amp circuit

in the speaker assembly, do not enable radio rebroadcast.

work with amplified remote

Page 3

Page 4

MOUNTING and WIRING the CONTROL HEAD

1. Remove front, driver’s side rocker sill plate and kick panel.

2. Fold the floor covering so that access is gained to the fac-

tory wire harness routed under the driver’s seat area.

3. Extend the wires from the control head as described in the

following sections.

8-POSITION SIREN CONNECTOR

RED / Power

1. Insert the 8-position siren connector into its port.

2. Route RED wire to POSITIVE (+) battery terminal.

3. Install a 5 amp fuse block (user supplied) on the end

of the RED wire. Remove the fuse from the fuse block

before connecting any wires to the battery.

YELLOW / Dimmer Control

1. Route YELLOW wire along factory wire harness toward

driver’s side rocker sill plate.

2. Follow factory wire harness towards firewall. Do not go

beyond the firewall.

3. Connect YELLOW wire to the dashlight dimmer circuit

located under the dashboard. Depending on the vehicle,

there are several good locations to access this circuit.

Example; the ashtray courtesy light in a Crown Victoria is

connected to the dimmer circuit and is easily accessible.

WHITE & GREY / Horn Relay Wires

1. Route WHITE and GREY wires along factory wire harness

and through firewall at the same point as the RED and

BLACK wires.

2. Locate your vehicle’s horn relay and route the WHITE and

GREY wires to this. If possible, follow the factory wire

harness to this relay.

3. Cut the wire that connects the vehicle horn to horn relay.

4. Connect WHITE wire to wire coming from horn relay.

5. Connect the GREY wire to wire coming from horn.

BLACK-WHITE / Remote Siren Tone Activation

Slide switch position #3 can be configured to automatically activate siren tones by connecting it to the AUX ENABLE input

(WHITE / GREEN on P2).

CONTROL HEAD COMMUNICATION CABLE

1. Connect the Control Head Communication Cable to the 3-

position connector coming from the 8-position siren

connector (VIOLET, BLACK & GREEN).

2. With rear seat and drivers sill plate still removed, route the

Communication Cable towards the driver side sill plate.

3. Following the factory harness, route the Communication

Cable towards the remote amplifier.

4. Insert the pinned wires into the 12-position connector

located on the back of the remote amplifier as shown in the

Wiring Diagram on page 6.

9-POSITION CONTROL HARNESS

NOTE: The push-button and slide switch control wires are

designed to activate relays with a coil rating no greater than 250

ma. Do not attempt to connect these wires to any circuit that

carries a higher rating.

GREEN, GREY, BLUE & BROWN

Slide-Switch Control

1. Route and connect GREEN wire (slide switch position #1)

to desired lightbar function control wire.

2. Route and connect GREY wire (slide switch position #2)

to desired lightbar function control wire.

3. Route and connect BLUE wire (slide switch position #3)

to desired lightbar function control wire.

4. Route and connect BROWN wire to +12 VDC fused

@ 3 amps (customer supplied fuse).

VIOLET, WHITE, YELLOW, ORANGE & WHITE-BLACK

Push-Button Control Wires

The 295HFS4 push button switches control the following wires:

P-BUTTON #1 . . . . . . . . . . . . . . . . . . . . . . . . WHITE / BLACK

P-BUTTON #2 . . . . . . . . . . . . . . . . . . . . . . . . WHITE

P-BUTTON #3 . . . . . . . . . . . . . . . . . . . . . . . . YELLOW

P-BUTTON #4 . . . . . . . . . . . . . . . . . . . . . . . . ORANGE

P-BUTTON #5 See “Connecting the 4-Position Input Assembly”

P-BUTTON #6 . . . . . . . . . . . . . . . . . . . . . . . . VIOLET

NOTE: P-button #6 is a momentary switch. This is best used for

momentary-use circuits such as low power control, trunk release

or gun lock.

4 POSITION INPUT ASSEMBLY

RED . . . . . . . . . . . . . . . . . . . . . . .To +12 VDC fused @ 3 amps

(customer supplied fuse)

BLACK . . . . . . . . . . . . . . . . . . . . .To CHASSIS GROUND

WHITE-GREEN . . . . . . . . . . . . . .AUX ENABLE (Optional)

If desired, splice to the BLACK/WHITE wire of the 8-position

siren connector. This enables remote siren tone activation from

slide switch position #3.

BLACK-WHITE . . . . . . . . . . . . . Controlled by Push-button #5.

NOTE: This push-button control wire is designed to activate a

relay with a coil rating no greater than 250 ma. Do not attempt to

connect this wire to any circuit that carries a higher rating.

Page 4

Page 5

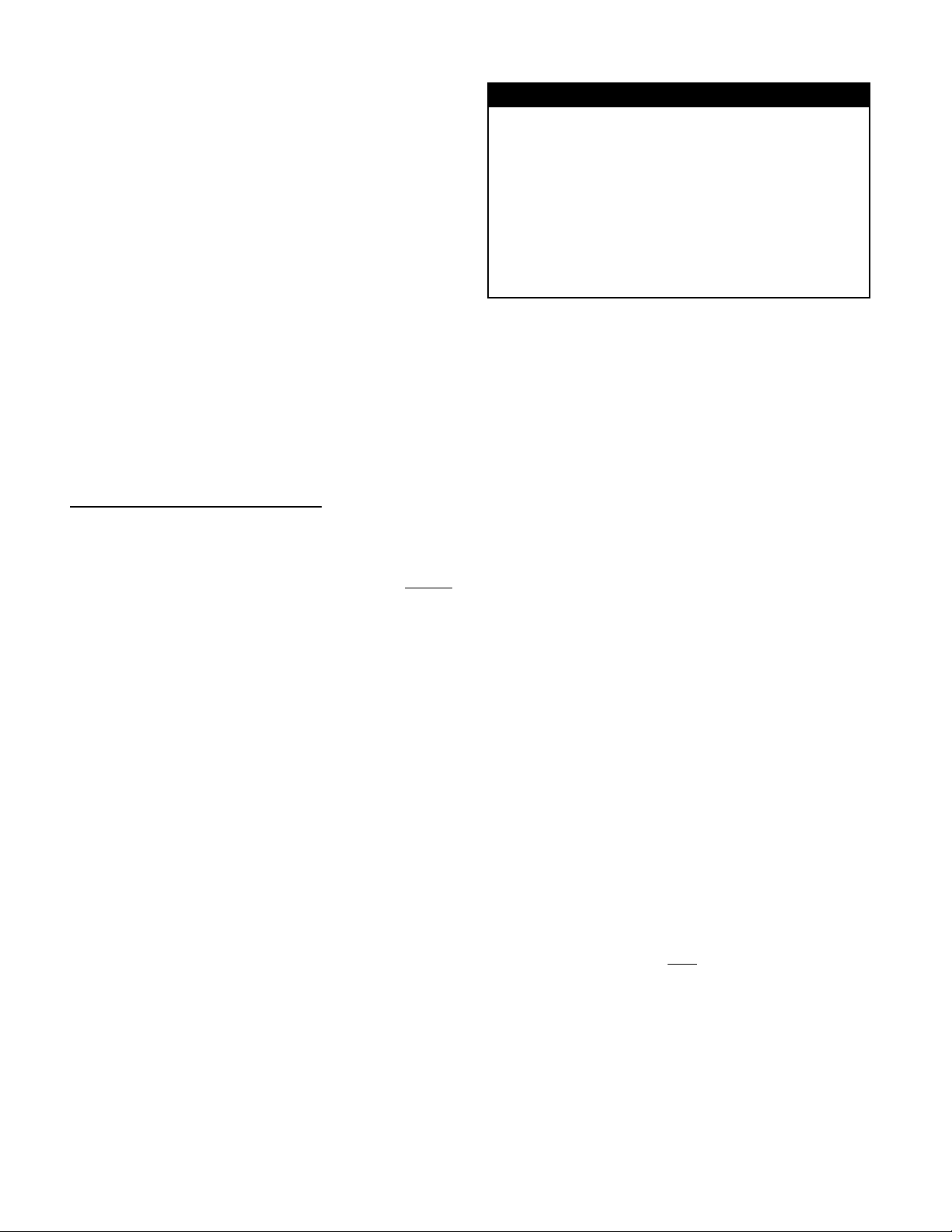

To Adjust the Radio Repeat Levels: Before using the

295HFS4, the Radio Repeat output volume and microphone

volume (PA) must be adjusted to satisfactory operating levels.

To adjust this level, a small, flat-blade screwdriver is needed.

Locate the Radio Repeat adjustment port (potentiometer) to the

left of the 12-position input port on the back of the remote amplifier. Set the volume level of the vehicle’s two-way radio to it’s

normal operating volume. Turn the Rotory Knob on the control

head to RAD to activate Radio Repeat. Insert the screwdriver in

the Radio Repeat adjustment port and turn in a clockwise direction to increase the sound level.

Microphone

PIER

Volume Adjust.

Radio Rebroadcast

Adjustment Screw

BACK of AMPLIFIER

20 AMP

SPK1

FRONT of CONTROL HEAD

VOLSPK2

Microphone Volume (PA) Locate the microphone adjustment

port (potentiometer) below the microphone cord. With the vehicle in an enclosed area, turn the Rotory Knob to PA and speak

into the microphone. While speaking, turn the screwdriver in a

clockwise direction to increase the volume. Continue to

increase the PA volume until audio feedback occurs, then turn

the screwdriver in a counter-clockwise direction until the feedback is eliminated.

Operating the 295HFS4 Controls:

Power Switch This switch has two posi-

tions: Down / Off and Up / On. When this

ON

POWER

ON MAN

switch is in the Off position, the unit will not

function. When the switch is in the On position the siren is functional and may be activated at the operator’s discretion. NOTE: If

the 295HFS4 is connected to the vehicle’s

horn ring circuit, the vehicle horn is disabled

when the 295HFS4 power is ON.

MAN Button The Manual button generates a variety of tones, depending on what

position the rotary knob is in. For further

explanation of this button’s function, refer to

PA

the Rotary Switch Operations section of this

RAD

manual.

WAIL

YELP

T3

SPK1

SI-TEST

of the 295HFS4 and allows the operator to

confirm the proper operation of the siren

speakers connected to the 295HFS4 without activating an audible siren tone. To ini-

VOLSPK2

tiate the SI-TEST cycle, set the rotary knob

®

SI-TEST is a diagnostic feature

to the RAD position. Now press and hold the

MAN button for at least 5 seconds. As the

siren is tested, its diagnostic indicator will

turn on if no problems are detected. If the indicator doesn’t light,

a problem with either the siren or its connectors has been

detected. Check the wire connections for the failed speaker and

repeat the SI-TEST. If the speaker fails the test again, have the

siren itself inspected by a qualified technician.

NOTE: Installed speakers are tested by generating an ultrahigh frequency tone through each speaker. Although these

tones are inaudible to humans, be sure that there is nobody

®

within at least 5 feet of the speakers when SI-TEST

is running.

DIAGNOSTIC INDICATORS: This unit has two diagnostic indicators on the front panel which are used to indicate fault conditions with your siren system. The table on the next page lists

the type of fault and the indicators response. If the indicator is

on steady while a tone is in use, this implies that there is no

fault with the associated speaker output.

Fault Condition Diagnostic Indicators Response

Under Voltage Speaker LED #2 will be in a double flash

mode (2 quick flashes followed by a longer

pause) and siren tones will not operate.

Over Voltage Speaker LED #1 will be in a double flash

mode (2 quick flashes followed by a longer

pause) and siren tones will not operate.

Speaker #1 Speaker LED # 1 will be in a single flash

Short Circuit mode (the LED will be on and off an

equal amount of time) and siren tones will

not operate.

Speaker #2 Speaker LED #2 will be in a single flash

Short Circuit mode (the LED will be on and off an

equal amount of time) and siren tones will

not operate.

Speaker #1 Speaker LED #1 will be off (having a

Open Circuit single speaker system will always cause

this condition for the speaker output not in

use) all tones will continue to operate.

Speaker #2 Speaker LED #2 will be off (having a

Open Circuit single speaker system will always cause

this condition for the speaker output not in

use) all tones will continue to operate.

Rotary Knob The Rotary Knob controls

HF

MAN

PA

the siren and PA (Public Address) functions

WAIL

of the 295HFS4. There are 7 positions that

may be selected. Each position and it’s function is outlined in the Rotary Switch Opera-

T3

ACTIVATION OF THIS

SIREN MAY DAMAGE

UNPROTECTED EARS!

tions section.

FUNCTION

CAUTION

Loud siren noise can cause

Wear

Protection!

hearing damage and/or loss.

Refer to OSHA Section 1910.95 prior

to putting ANY siren into service!

Page 5

Page 6

Rotary Switch Operations

RAD (Radio Repeat) - When the rotary knob is in the RAD posi-

tion, any signal that is received by the vehicle’s two-way radio will

be simultaneously broadcast over the vehicle’s loudspeaker (unit

must be connected to the two-way radio as outlined in this manual).

With the Rotary Switch in this Position:

• Pressing the MAN button will result in SI TEST®.

• Activating the HORN RING input results in the AIRHORN tone

until the HORN RING input is released.

• Activating the AUX ENABLE input has no effect.

PA (Public Address) - When the rotary switch is in this position

the siren is in a standby state where no tones have been

activated, but is waiting for another action to be taken by the operator. This position is often the best choice when public address is

required.

With the Rotary Switch in this Position:

• Pressing the MAN button will result in the AIRHORN tone until

the MAN switch is released.

• Activating the HORN RING input will result in the AIRHORN

tone until the HORN RING input is released.

• Activating the AUX ENABLE input will result in a repeating

WAIL tone.

MAN (Manual Siren) - When the rotary switch is in this position

the siren is in a standby state where no tones have been

activated, but is waiting for another action to be taken by the operator. This position is often the best choice when manual operation

of the siren is desired.

With the Rotary Switch in this Position:

• Pressing the MAN switch will result in a WAIL tone ramping up

to peak frequency and stopping when the MAN switch is

released.

• Activating the HORN RING input will result in a WAIL tone

ramping up to the peek frequency and stopping when the

HORN RING input is released.

• Activating the AUX enable input will result in a repeating WAIL

tone.

HF (Hands-Free Operation) - When the rotary knob is in the HF

position, the siren functions are placed in a stand-by mode. Siren

tones are activated by a single tap on the MAN button or a single

tap on the vehicle’s steering wheel horn ring (if the vehi-

cle’s horn has been wired to the HORN RING input). The first tap

produces a WAIL tone (a steady rise and fall tone). A second tap

produces a YELP tone (a fast rise and fall tone.) A

third tap produces a PIERCER™ tone (an extremely fast rise and

fall tone). The next tap returns the siren to a wail tone and the

cycle repeats itself. Two quick successive taps will stop the siren.

With the Rotary Switch in this Position:

• Pressing the MAN button will result in the HF cycle as described

above.

• Activating the HORN RING input will result in the HF cycle as

described above.

• Activating the AUX ENABLE input will start the HF cycle.

WAIL (Wail Tone) - When the rotary knob is in the WAIL position,

a steady, rise and fall tone (wail) is produced.

With the Rotary Switch in this Position:

• Pressing the MAN button will change the siren tone to a yelp

pattern. (a fast rise and fall tone) Pressing the MAN button a

second time returns it back to a wail tone.

• Activating the HORN RING input will change the siren tone to a

yelp pattern. (a fast rise and fall tone) Activating the HORN

RING input again returns it back to a wail tone.

• Activating the AUX ENABLE input has no effect.

YELP (Yelp Tone) - When the rotary knob is in the YELP

position, a fast, rise and fall tone is produced.

With the Rotary Switch in this Position:

• Pressing the MAN button will result in the AIRHORN tone until

the MAN button is released.

• Pressing the HORN RING button will result in the AIRHORN

tone until the HORN RING button is released.

• Activating the AUX ENABLE input has no effect.

T3 (Piercer

position, an extremely fast, rise and fall tone is produced. May be

used for HI / LO and auto sequence in some applications.

With the Rotary Switch in this Position:

TM

Tone) When the rotary knob is in the T3

• Pressing the MAN button will result in the AIRHORN tone until

the MAN button is released.

• Pressing the HORN RING button will result in the AIRHORN

tone until the HORN RING button is released.

• Activating the AUX ENABLE will have no effect.

295HFS4 SPECIFICATIONS

INPUT VOLTAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12.5 VDC

INPUT CURRENT @15 VDC @ 5.5 OHMS . . . . . . . . . 16 AMPS MAX.

INPUT FUSE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 AMPS

SPEAKER IMPEDANCE . . . . . . . . . . . . . . . . . . . . . . . 5.5 OHMS MIN.

OPERATING TEMPERATURE . . . . . . . . . . . . . . . . . . . -30° C. TO +60° C.

STORAGE TEMPERATURE . . . . . . . . . . . . . . . . . . . . -40° C. TO +70° C.

HUMIDITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99% (NON CONDENSING)

SIREN / SQUARE WAVE

TONES SIREN FREQUENCY SWEEP RATE

WAIL . . . . . . . . . . . . . . 800 TO 1600 Hz. . . . . . . . . . . . .12 CYCLES PER MIN.

YELP. . . . . . . . . . . . . . 800 TO 1600 Hz. . . . . . . . . . . . .180 CYCLES PER MIN.

PIERCER . . . . . . . . . . 800 TO 1600 Hz . . . . . . . . . . . . .800 CYCLES PER MIN.

AIR HORN. . . . . . . . . .COMPOSITE . . . . . . . . . . . . . . CONSTANT

HI/LOW (OPTIONAL) .550 TO 650 Hz . . . . . . . . . . . . . 60 CYCLES PER MIN.

OUTPUT VOLTAGE @ 15 VDC @ 11 OHMS . . . . . . . 32 V RMS MAX.

OUTPUT POWER @ 15 VDC @ 11 OHMS . . . . . . . . . 105 WATTS MAX.

OUTPUT POWER @ 15 VDC @ 5.5 OHMS . . . . . . . . 185 WATTS MAX.

AUDIO (SINE WAVE)

AUDIO BANDWIDTH @ 25 WATTS. . . . . . . . . . . . . . . 300 Hz TO 10 KHz ±3db

DISTORTION @ 25 WATTS @ 1 KHz . . . . . . . . . . . . . 1% MAX.

OUTPUT VOLTAGE @ 15 VDC @ 11 OHMS . . . . . . . 24 VRMS MAX.

OUTPUT POWER @ 15 VDC @ 11 OHMS . . . . . . . . . 50 WATTS

RADIO INPUT LEVEL @ R44 MAX. @24 VRMS . . . . +10db ±3db

SI-TEST® - RADIO/MANUAL BUTTON . . . . . . . . . . . . FREQ. - 18 KHz

Page 6

Page 7

BLACK - POS 9

RED - POS 10

GREEN - POS 11

WS295HFRS 12V

REMOTE AMPLIFIER

P/N 01-0862062-00

3

6

9

2

5

8

1

4

7

12-POSITION INPUT

CONNECTOR

(REAR VIEW)

WS295HFS4 R/H 12V W/ HI/LOW ASSY.

P/N 01-0862070-01

WS295HFS4 R/H 12V W/PIERCER™ ASSY.

P/N 01-0862070-00

4-POSITION INPUT

CONNECTOR (P2)

P/N 46-0725500-00

12

11

10

9-POSITION CONTROL

CONNECTOR (P1)

P/N 46-0725628-00

WS295HFFS COMMUNICATIONS CABLE

P/N 46-0741631-00

8-POSITION SIREN

CONNECTOR (P3)

P/N 46-0745705-00

P1 = 9-POSITION CONTROL CONNECTOR

P2 = 4-POSITION INPUT CONNECTOR

P3 = 8-POSITION SIREN CONNECTOR

RED

BLACK

WHITE / GREEN

(AUX ENABLE)

BLACK / WHITE

RED

VIOLET

3 AMP FUSE

GREEN

BLACK

BLACK

20 AMP FUSE

GREEN

VIOLET

BLACK

BLACK

RED

RED

To LIGHTBAR

BLK / WHT

P2-4

P2-1

P2-2

P2-3

P3-2

P3-8

P3-4

P3-3

P3-1

9

11

10

2

5

1

4

P1

12 VDC

WS295HFS4

P3-6

P3-7

REMOTE CONTROL HEAD

P3-5

12

8

7

3

6

12 VDC

AMPLIFIER

WS295HFRS

98765432110

YELLOW

YELLOW

ORANGE

BROWN

WHITE

GREY

BLUE

BLUE

BUTTON

RELAY

DIMMER RHEOSTAT

OPTION or + 12 VDC

HORN

TO HORN

YELLOW

ORANGE

BROWN

BLUE

BLUE

+12V

CUT

WIRE

HERE

TO TWO-WAY

RADIO SPEAKER

VEHICLE

HORN

11 O HM

SPEAKER

#1

11 OHM

SPEAKER

#2

(+)

Battery

(-)

WIRING DIAGRAM

NOTE: All fuses and fuse holders

are customer supplied.NOTE:

Page 7

Loading...

Loading...