Page 1

Strobe, 21 Joules, Explosion Proof

XB4

Description:

These high output (21 Joule) strobes have been designed

for use in potentially explosive atmospheres and harsh

environmental conditions. The marine grade alloy or stainless

steel enclosures are suitable for use offshore or onshore,

where light weight combined with corrosion resistance

and strength is required. Units can be painted to customer

specification and fitted with identification labels.

Architects and Engineers Specifications

Features*:

★ UL Listed for USA and Canada

– Hazardous locations:

Class I, Div 1, Groups C & D

Class I, Zone 1, AExd IIB T4

– Ordinary locations: Visual-Signal Device

★ ATEX approved

★ Certified temperature –67°F to +158°F (–55°C to

+70°C)

★ NEMA 4x & 6, IP67 and IP66

★ Various lens colors

★ Twin replaceable tubes

★ Tapered spigot flamepath.

★ 4 wire monitored connection

★ Optional lens guard

★ 24 VDC

★ 110 & 240 VAC

★ Xenon

*Depending on version.

Explosion-proof strobes shall be UL and cUL Listed for Class I, Division 1, Groups C&D, and Class I, Zone 1, AExd

IIB T4 hazardous locations and shall be listed under UL Standard 1638 for Indoor/Outdoor use. The strobes shall

be constructed of marine grade alloy with an epoxy paint finish and shall meet NEMA 4x, NEMA6, IP 66 and IP 67

environmental requirements over a temperature range of -67°F to 158°F (-55°C to 70°C) in hazardous and harsh

environments.

The strobe shall be rated to flash at 1 Hz with 21 joules per flash. Rated current draw shall not exceed 1400 mA at 24

vdc. The strobe shall be capable of direct surface mounting in any direction.

Note: Due to continuous development of our products, specifications and offerings are subject to change without notice in accordance with Cooper Wheelock standard terms and conditions.

ATEX

Page 2

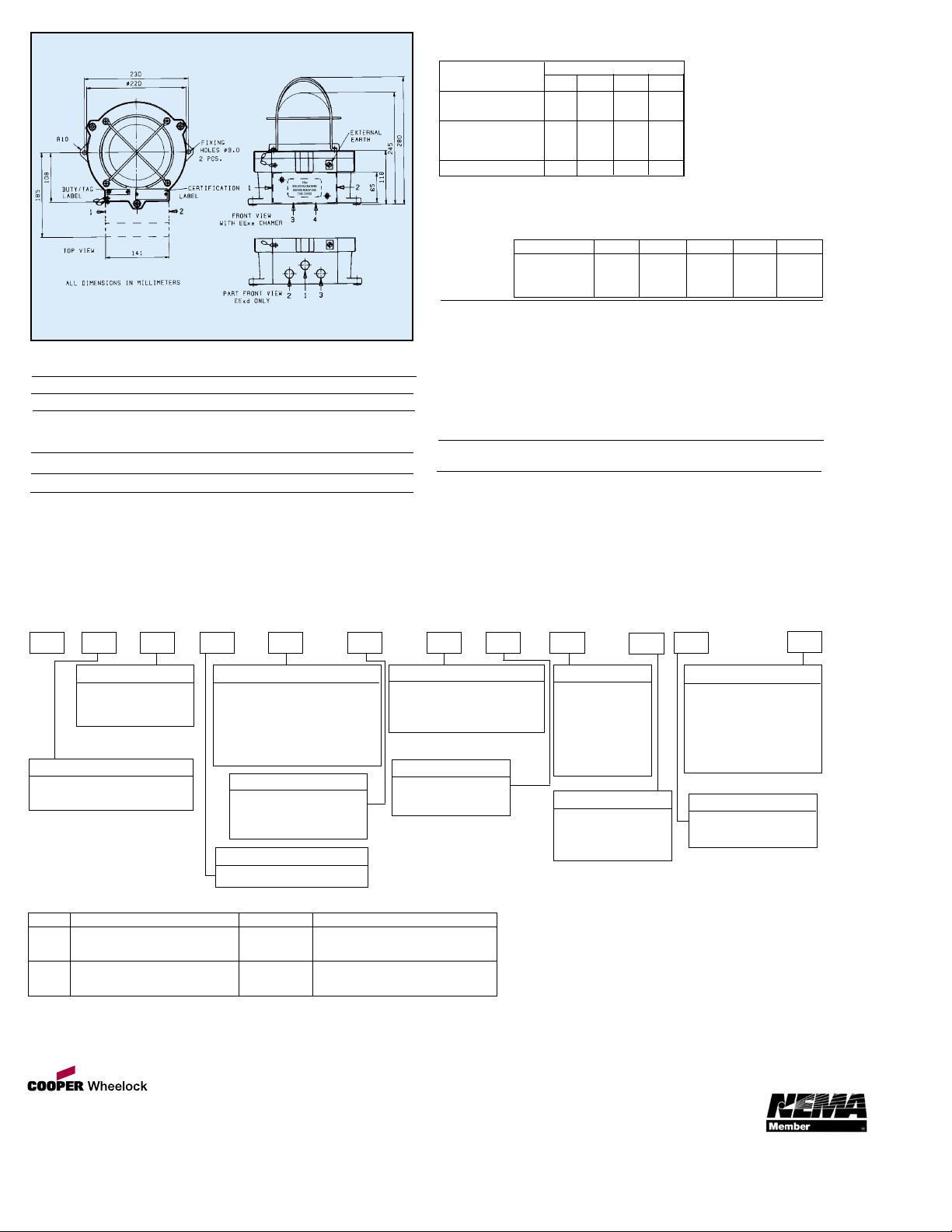

Terminals: Up to 8 x 8 AWG

Entries: Up to 3 x 1/2" or 3/4" NPT

Materials: LM25TF Marine Grade Alloy body.

Grade 316 ANC4B Stainless Steel body.

Toughened Wellglass.

Weights: LM25: 14.5lb./6.6kg. Stainless Steel: Add 18.5lb./8.5kg.

Finish: Red epoxy paint finish as standard or to customer's specification.

Specification

DC AC 50/60 Hz

Voltage

Tube Energy

(Joules)

Peak Current

Consumption

(mA)

Effective Intensity (Cd) 355 355 355 355

NOTE: The above figures (Cd) are for a clear lens @ 1Hz flash rate.

The photometric data has been verified by BSI. A report is available if required.

FOR COLORED LENSES

Certification: UL Listed for USA and Canada

– Hazardous locations:

Class I, Div 1 Groups C-D

Class I, Zone 1

AExd 11B T4

Listing No. E187894.

– Ordinary locations: Visual-Signal Device.

Listing No. S8128.

ATEX approved: EExd IIC T5

Cert. No. Baseffa 02ATEX0224X

Certified Temperature:

Color Red Blue Amber Green Yellow

Multiplying

Factor 0.15 0.12 0.51 0.49 0.86

(Approximate)

Ingress Protection: NEMA 4x & 6, IP66 & 67

24 110 240 254

21 21 21 21

1400 350 185 210

–67°F to +158°F (–55°C to +70°C)

Configuration Options:

The following code is designed to help in the selection of the correct unit. Build up the reference number by inserting the code for each

component into the appropriate box.

Cable Flash Other Lens Lens Tag/Duty

Type Certification Voltage Terminals Entries Rate Options Guard Color Label Material Finish

XB4

Voltage Code

24VDC B

110VAC E

240VAC H

Entries Code

1

/2" NPT *D

3

/4" NPT *E

*prefix entry size (see

Options Code

None A

Yes* Y

*Please specify

diagram above) with entry

Certification Code

UL UL

UL

(ordinary locations)

UW

position code e.g. 1D2D.

Flash Rate Code

60/min. 06

Lens Guard Code

None N

Yes Y

120/min. 12

240/min. 24

Terminals & Type Code

8 x 8 AWG 8D

Standard Models

Series Model Number Order Code Decription

XB4 XB4ULB8D2E3E06ANRN1R 109205-001

XB4 XB4ULB8D2E3E06ANCN1R 109205-001

Strobe, Red Lens, 21 Joules, 24

VDC, Red finish

Strobe, Clear Lens, 21 Joules,

24 VDC, Red finish

Color Code

Red R

Blue B

Green G

Yellow Y

Amber A

Clear C

Duty Label Code

None N

Yes* Y

*(Please specify)

Finish Code

Red R

Blue B

Yellow Y

Grey G

White W

Other – specify S

Material Code

Stainless steel 0

Alloy 1

273 Branchport Avenue

Long Branch, NJ 07740

Phone: (800) 631-2148

Fax: (732) 222-2588

www.cooperwheelock.com

WE ENCOURAGE AND SUPPORT NICET CERTIFICATION

3 YEAR WARRANTY

Made in USA

XB4 04/07

Loading...

Loading...