Page 1

Strobe - 355 Candela, Hazardous Location

XB15

Description:

These listed strobes have been designed for use in potentially

explosive atmospheres and harsh environmental conditions.

The enclosures are suitable for use offshore or onshore, where

light weight combined with corrosion resistance is required.

The housings are manufactured completely from a U.V.

stable, glass reinforced polyester. Stainless steel screws and

mounting bracket are available ensuring a totally corrosionfree product.

The model XB15 contains a polarization diode and four wire

lead connections for fire alarm applications.

Units can be painted to customer specification and supplied

with identification labels.

XB15

Pipe Mount

(with cast guard)

XB15 Direct

Mount (with

wire guard)

Features*:

★ UL listed for USA and Canada

– Hazardous locations:

Class I, Div. 2, Groups A, B, C & D.

Class I, Zone 1, AExd IIC T5/T6

Class II, Div. 2, Groups F & G

– Ordinary locations: Visual-Signal Device

★ ATEX approved

★ NEMA 4x & 6, IP66 & 67

★ Certified temperature –67°F to +158°F (–55°C to

+70°C)

★ 520,000 peak candlepower

★ Pipe mount or direct mount enclosure

★ Corrosion-free GRP

★ Four wire monitored connection

★ Optional stainless steel backstrap (direct mount version

only)

★ Various lens colors

★ Optional relay

★ Optional cast or wire lens guard

★ Up to 3 x 3/4" NPT entries

★ Filament version available (100W max)

*Depends on version

Architects and Engineers Specifications

Strobes for hazardous locations and harsh environments shall be UL and cUL Listed for Class I, Division 2, Groups

A,B,C&D, and Class I, Zones 1, Class II, Div 2, Groups F & G, AExd IIC T5/T6 applications and shall be listed under UL

Standard 1638 for Indoor/Outdoor use. They shall be constructed of lightweight, UV stable glass reinforced polyester,

shall be corrosion resistant, and shall meet NEMA 4x, NEMA 6, IP 66 & IP 67 environmental requirements over a

temperature range of -67°F to +158°F (-55°C to +70°C).

The strobes shall be rated to flash at 1 Hz with 15 joules per flash. Rated current draw shall not exceed 780 mA at 24 vdc.

The strobes shall be available for direct surface mounting or pipe mounting and shall be able to mount in any direction

Note: Due to continuous development of our products, specifications and offerings are subject to change without notice in accordance

with Cooper Wheelock standard terms and conditions.

ATEX

Page 2

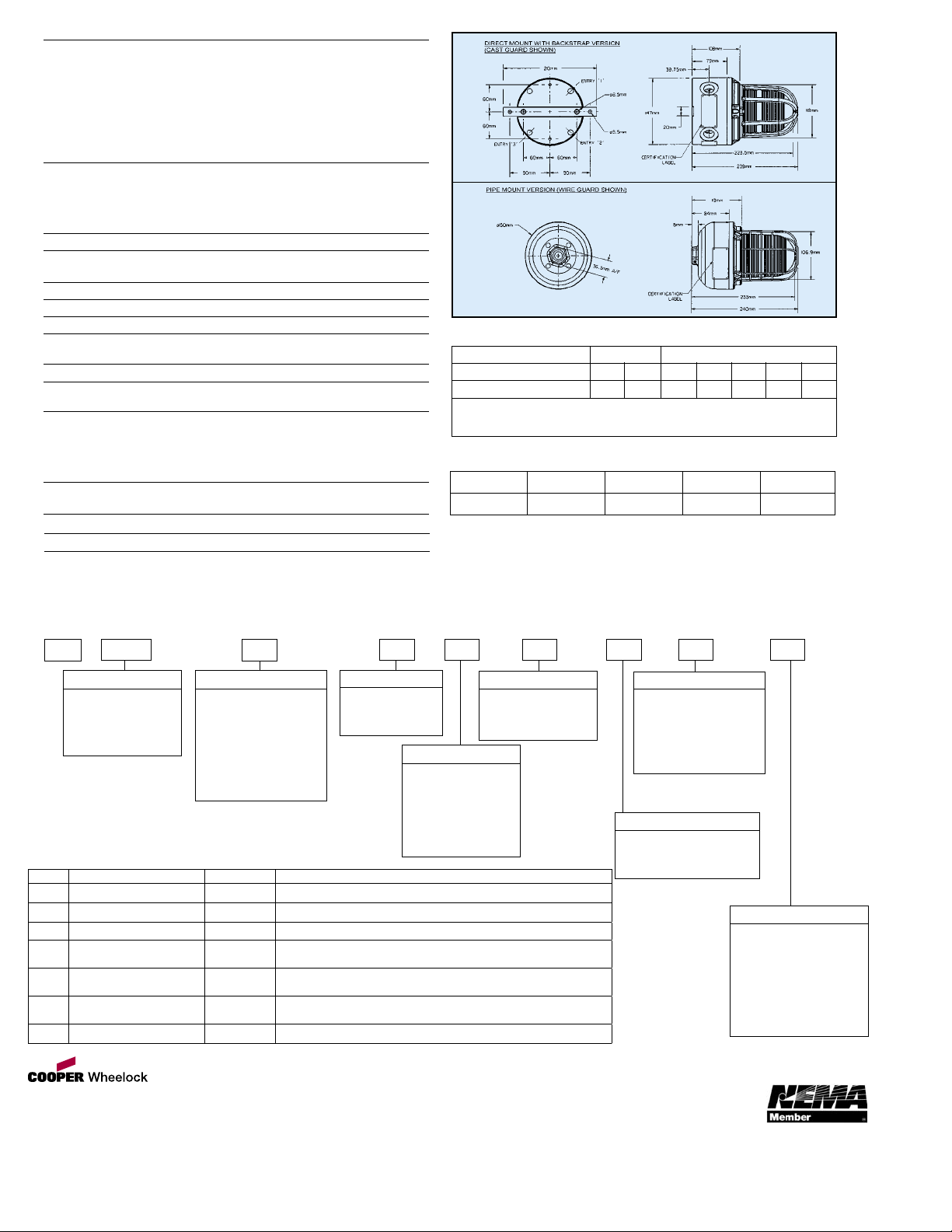

Specification

Certification: UL Listed for USA and Canada:

– Hazardous locations

Class I, Div 2, groups A, B, C & D. Class 1, Zone 1

Class II, Div 2, groups F & G, AExd IIC T4/T5.

UL listing No. E187894.

– Ordinary locations: Visual Signal Device.

CENELEC EN50014 & EN50018.

Material: Body: Glass reinforced polyester.

Lens: Glass.

Backstrap: stainless steel 316.

Wire Guard (optional): Stainless steel wire.

Cast Guard (optional): Aluminium LM25M.

Finish: Natural black or epoxy painted to customer specification.

Voltage: 24, 48V d.c.

110, 120, 230, 240, 254V a.c.

Tube Energy: 15 Joules.

Tube Life: >1 x 106 flashes.

Flash Rate: 60, 80, 120 fpm.

Certified -67°F to +104°F (T6) -55°C to +40°C (T6)

Temperature: -67°F to +131°F (T5) -55°C to +55°C (T5)

Weight: Pipe mount: 5.75lb./2.6kg; Direct mount: 6.5lb./3.0kg.

Ingress NEMA 4x &6, IP66 & IP67.

Protection:

Entries: Supplied as 2 x ¾" NPT (direct mount) or ¾" (pipe mount) as

Other options available:

Up to 3 x ½" NPT or 3 x ¾" NPT (direct mount);

½" NPT (pipe mount) – contact sales office to order.

Terminals: Direct mount: 12 x 14AWG

Pipe mount: 8 x 14AWG

Relay Initiate:

Labels: Tag/Duty label option.

UL listing No. S8128

ATEX Cert. No. Baseefa 04ATEX0009X.

standard.

Available on all units – suitable for 24V d.c. supplies only.

Electrical Ratings:

d.c a.c

Voltage 24 48 110 120 230 240 254

Current (mA) 780 670 400 400 200 200 170

Effective Candela - 330

Tube Energy (Joules) 15 15 15 15 15 15 15

Multiplying Factor for Colored Lenses:

Red Blue Amber Green Yellow

0.15 0.12 0.51 0.49 0.86

Configuration Options:

The following code is designed to help in the selection of the correct unit. Build up the reference number by inserting the

code for each component into the appropriate box.

Lens Lens Unit Other

Model Certification Voltage Flashrate Color Guard Fixing Options Finish

XB15

Certification Code

UL UL

UL (ordinary UW

location)

Voltage Code

24V d.c. 024

48V d.c. 048

110V a.c. 110

120V a.c. 120

230V a.c. 230

240V a.c. 240

254Va.c. 254

Standard Models

Series Model Number Order Code Decription

XB15 XB15UL02406RWPNN 109203-001 330 candela Red Lens, Black finish, 24 VDC

XB15 XB15UL02406RWBNN 109203-002 330 candela Red Lens, Black finish, 24 VDC

XB15 XB15UL02406CWBNR 109203-205 Clear Lens, 330 candela, 24 VDC, Pipe mount, Black finish

XB15 XB15UL12006AWBNN 109202-005

XB15 XB15UL12006AWPNN 109202-006

XB15 XB15UL12006RWBNN 109202-007

Amber Lens, 330 candela, 120 VAC, backstrap mount, Black

finish

Amber Lens, 330 candela, 120 VAC, Pipe mount, Black

finish

Red Lens, 330 candela, 120 VAC, backstrap mount, Black

finish

XB15 XB15UL12006RWPNN 109202-208 Red Lens, 330 candela, 120 VAC, Pipe mount, Black finish

Fpm Code

60 06

80 08

120 12

Color Code

Red R

Blue B

Green G

Amber A

Yellow Y

Clear C

Guard Code

None N

Cast C

Wire W

Option Code

None N

Tag label T

Duty label D

Relay initiate* R

Blanking Plug P

*Suitable for 24V d.c.

supplies only.

Unit Fixing Code

Pipe mount P†

Direct mount D†

Direct w/backstrap B†

†Cont a c t Sales

Office if ½" NPT

is required.

Finish Code

Natural Black N

Red R

Blue B

Yellow Y

Green G

White W

Special Finish S

273 Branchport Avenue

Long Branch, NJ 07740

Phone: (800) 631-2148

Fax: (732) 222-2588

www.cooperwheelock.com

WE ENCOURAGE AND SUPPORT NICET CERTIFICATION

3 YEAR WARRANTY

Made in USA

XB15 04/07

Loading...

Loading...