Read this manual before using product. Failure

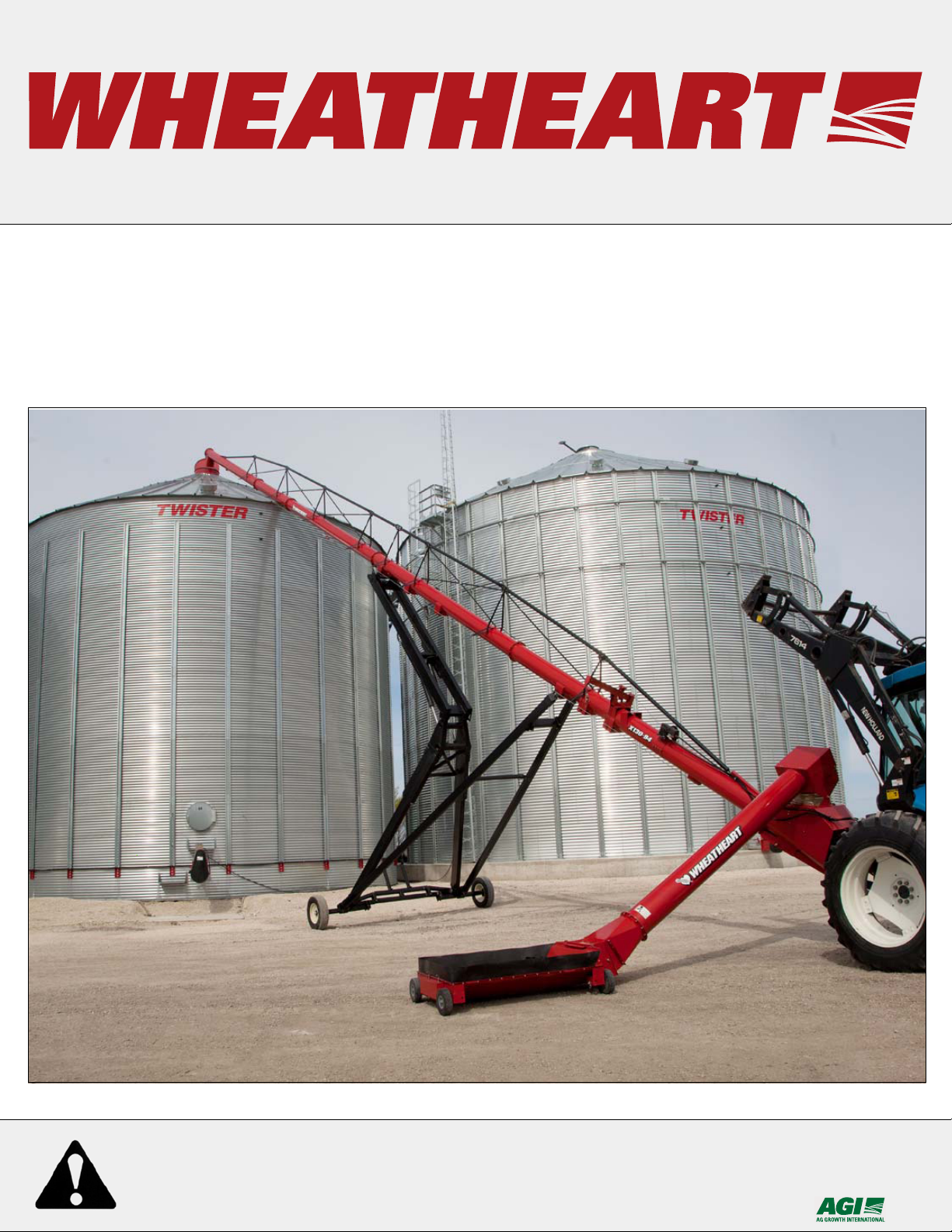

X-SERIES 13" AUGERS

X130-74, X130-84, X130-94

ASSEMBLY AND OPERATION MANUAL

to follow instructions and safety precautions can

result in serious injury, death, or property

damage. Keep manual for future reference.

Part Number: 30787 R1

Revised: 22/7/2013

This product has been designed and constructed according to general engineering

standardsa. Other local regulations may apply and must be followed by the operator.

We strongly recommend that all personnel associated with this equipment be trained

in the correct operational and safety procedures required for this product. Periodic

reviews of this manual with all employees should be standard practice. For your

convenience, we include this sign-off sheet so you can record your periodic reviews.

Date Employee Signature Employer Signature

a. Standards include organizations such as the American Society of Agricultural and Biological Engineers,

American National Standards Institute, Canadian Standards Association, International Organization for

Standardization, and/or others.

WHEATHEART - X13 SERIES AUGERS

X1374, X1384, X1394

TABLE OF CONTENTS

1. Introduction.......................................................................................................................... 7

1.1. Overview .................................................................................................................. 8

1.1.1. Auger Power Source .................................................................................. 8

1.1.2. Grain Transfer Boot.................................................................................... 9

1.1.3. Grain Hopper............................................................................................ 10

1.1.4. Auger Tube Hydraulic Lift......................................................................... 11

2. Safety .................................................................................................................................. 13

2.1. General Safety Information .................................................................................... 13

2.2. Assembly Safety..................................................................................................... 14

2.3. ............................................................................................................................... 15

2.4. Operating Safety .................................................................................................... 15

2.5. Hydraulic Safety..................................................................................................... 15

2.6. PTO Driveline Safety.............................................................................................. 16

2.7. Tire Safety.............................................................................................................. 16

2.8. Transport Safety..................................................................................................... 17

2.9. Storage Safety........................................................................................................ 17

2.10. Maintenance Safety.............................................................................................. 17

2.11. Safety Decals....................................................................................................... 18

2.11.1. Decal Installation.................................................................................... 18

2.11.2. Safety Decal Locations........................................................................... 18

3. Assembly ............................................................................................................................ 23

3.1. General Assembly.................................................................................................. 23

3.2. Identify Auger Tube Sections................................................................................. 25

3.3. Assemble the Main Auger Tube............................................................................. 28

3.4. Install the Boot on the Auger tube.......................................................................... 29

3.5. Install Boot Bearing, Lower Sprocket, and Drive Chain ......................................... 31

3.6. Install the Boot Tow Bar......................................................................................... 32

3.7. Install the Discharge Spout .................................................................................... 33

3.8. Set the Thrust Adjuster........................................................................................... 33

3.9. Apply Logo and Model Decals................................................................................ 34

3.10. Auger Tube Truss Assembly................................................................................ 35

3.10.1. X130-74 Auger Tube Truss Assembly.................................................... 35

3.10.2. X130-84/X130-94 Auger Tube Truss Assembly..................................... 40

3.11. Assemble the Auger Frame................................................................................. 49

3.12. Installing the Hydraulic Cylinders......................................................................... 56

3.13. Assemble Wheel Hubs and Install Tires............................................................... 57

3.14. Attaching the Auger Tube to the Frame............................................................... 58

3.15. Connecting Hydraulic Hose to Cylinders.............................................................. 61

3.16. Install Low Profile Intake Hopper.......................................................................... 65

3.17. Installing the Hopper Lift Arm and Winch............................................................. 69

3.18. Install the Hitch Jack ........................................................................................... 72

3.19. Connecting the PTO Driveline.............................................................................. 72

3.20. Auger-to-Tractor Hookup...................................................................................... 74

30787 R1 3

WHEATHEART - X13 SERIES AUGERS

X1374, X1384, X1394

TABLE OF CONTENTS

4. Transport............................................................................................................................. 77

4.1. Transport Procedure............................................................................................... 77

5. Placement ........................................................................................................................... 81

5.1. Placement Procedure............................................................................................. 81

5.2. Positioning Tractor for Right-angle Drive Operation............................................... 85

6. Operation ............................................................................................................................ 87

6.1. Pre-operation Checklist......................................................................................... 87

6.2. Operator Controls................................................................................................... 88

6.2.1. PTO Drive Operation................................................................................ 89

6.2.2. Hydraulics Operation................................................................................ 89

6.3. Operating Procedures ............................................................................................ 90

6.3.1. Initial Start-Up........................................................................................... 90

6.3.2. Normal Start.............................................................................................. 91

6.3.3. Normal Shutdown..................................................................................... 92

6.3.4. Emergency Stop / Full-Tube Restart ........................................................ 93

6.3.5. Reverser Operation .................................................................................. 94

6.3.6. Lowering & Completion............................................................................. 97

7. Maintenance........................................................................................................................ 99

7.1. Maintenance Intervals ............................................................................................ 99

7.2. Fluids and Lubricants ........................................................................................... 100

7.3. Maintenance Procedures...................................................................................... 100

7.3.1. Visual Inspection..................................................................................... 100

7.3.2. Hydraulic Hose and Coupler Inspection ................................................. 101

7.3.3. Machine Greasing................................................................................... 101

7.3.4. Hopper Lift Cable Inspection .................................................................. 103

7.3.5. Winch and Pulley Servicing.................................................................... 103

7.3.6. Swing Tube Coupler Chain Servicing..................................................... 104

7.3.7. Boot and Hopper Chain Drive Servicing................................................. 105

7.3.8. Gearbox Oil Level................................................................................... 106

7.3.9. Machine Cleaning................................................................................... 107

7.3.10. Tire Pressure Check............................................................................. 107

7.3.11. Wheel Bearings Repack....................................................................... 107

7.3.12. Wheel Bolt Tightening........................................................................... 107

7.3.13. Cable Adjustment (X130-74) ................................................................ 108

7.3.14. Cable Adjustment (X130-84, X130-94)................................................. 109

7.3.15. Changing Gearbox Oil.......................................................................... 110

8. Storage.............................................................................................................................. 111

9. Troubleshooting ............................................................................................................... 113

4 30787 R1

WHEATHEART - X13 SERIES AUGERS

X1374, X1384, X1394

10. Appendix......................................................................................................................... 115

10.1. Specifications..................................................................................................... 115

10.2. Bolt Torque Values ............................................................................................ 116

Warranty Registration ........................................................................................................... 119

Limited Warranty................................................................................................................... 121

30787 R1 5

WHEATHEART - X13 SERIES AUGERS

X1374, X1384, X1394

6 30787 R1

WHEATHEART - X13 SERIES AUGERS 1. INTRODUCTION

X1374, X1384, X1394

1. Introduction

Congratulations on the purchase of your new Wheatheart X13 Series Auger. This

equipment will complement your agricultural operation by safely and efficiently

moving grain, pulse crops, fertilizer, and any other granular materials.

Many of the features incorporated into this machine are the result of suggestions

made by customers like you. Your new Wheatheart auger will serve you well if

you understand how it operates, and if you use it and care for it properly. This

manual is intended to help you learn how to operate and maintain your

equipment in a safe, efficient, and trouble-free manner. Please read this manual

before you use your new grain auger .

This manual covers all X13 Series augers built by Wheatheart Manufacturing.

Use the table of contents as a guide when searching for specific information.

Keep this manual in a safe place for future reference and for ordering

replacement parts.

Should any information remain unclear after thoroughly reviewing this manual,

contact your Wheatheart Dealer for clarification before operating your auger.

Knowing the serial number and date of purchase will save time in getting your

questions answered. Please write down this information in the space provided

below.

30787 R1 7

1. INTRODUCTION WHEATHEART - X13 SERIES AUGERS

1.1. OVERVIEW X1374, X1384, X1394

1.1. OVERVIEW

X13 augers are equipped with standard features that include a hydraulically

controlled main auger tube lift, a low-profile grain hopper (left or right side

operation), service access doors, and a PTO driveline for auger power.

Available option kits include:

• Hydraulic Winch

• Hydraulic Power Swing for Hopper

• Electric Power Swing for Hopper

• Right Angle Drive

• 540 RPM PTO Reverser

• 1000 RPM PTO Drive and Reverser

1.1.1. AUGER POWER SOURCE

The power source for the auger is a standard 540 RPM tractor PTO (see Figure

1.1). An optional Right-Angle PTO Drive kit allows the auger to be powered by a

tractor positioned at a 90 degree angle to the auger (Figure 1.2).

An optional 1000 RPM PTO Drive kit provides a speed reducer that allows use

with 1000 RPM PTO tractors, as well as reverser capability that is used to rotate

the auger flightings in the reverse direction (transferring grain in the auger tube

back to the hopper).

An optional 540 RPM Reverser kit provides a similar reverser capability for

540 RPM PTO connections.

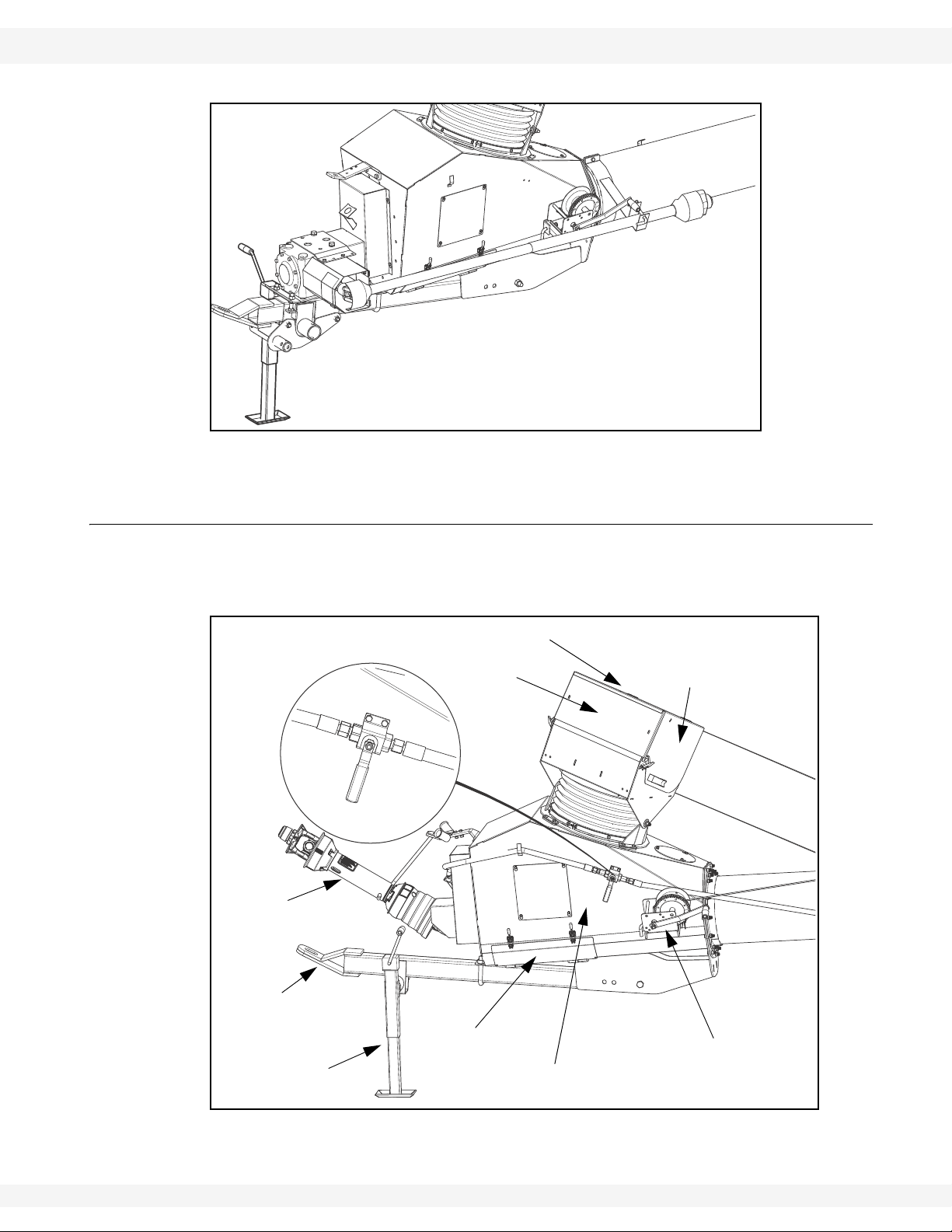

Figure 1.1 Standard PTO Driveline

8 30787 R1

WHEATHEART - X13 SERIES AUGERS 1. INTRODUCTION

GRAIN TRANSFER BOOT

SWING ARM SPOUT HEAD

OVERFLOW

PTO DRIVELINE

HITCH

HITCH JACK

SPOUT HEAD

SERVICE HATCH

CLEAN-OUT HATCH

MANUAL WINCH (HOPPER)

BALL

VALVE

PANEL

X1374, X1384, X1394 1.1. OVERVIEW

Figure 1.2 Right Angle PTO Driveline Kit

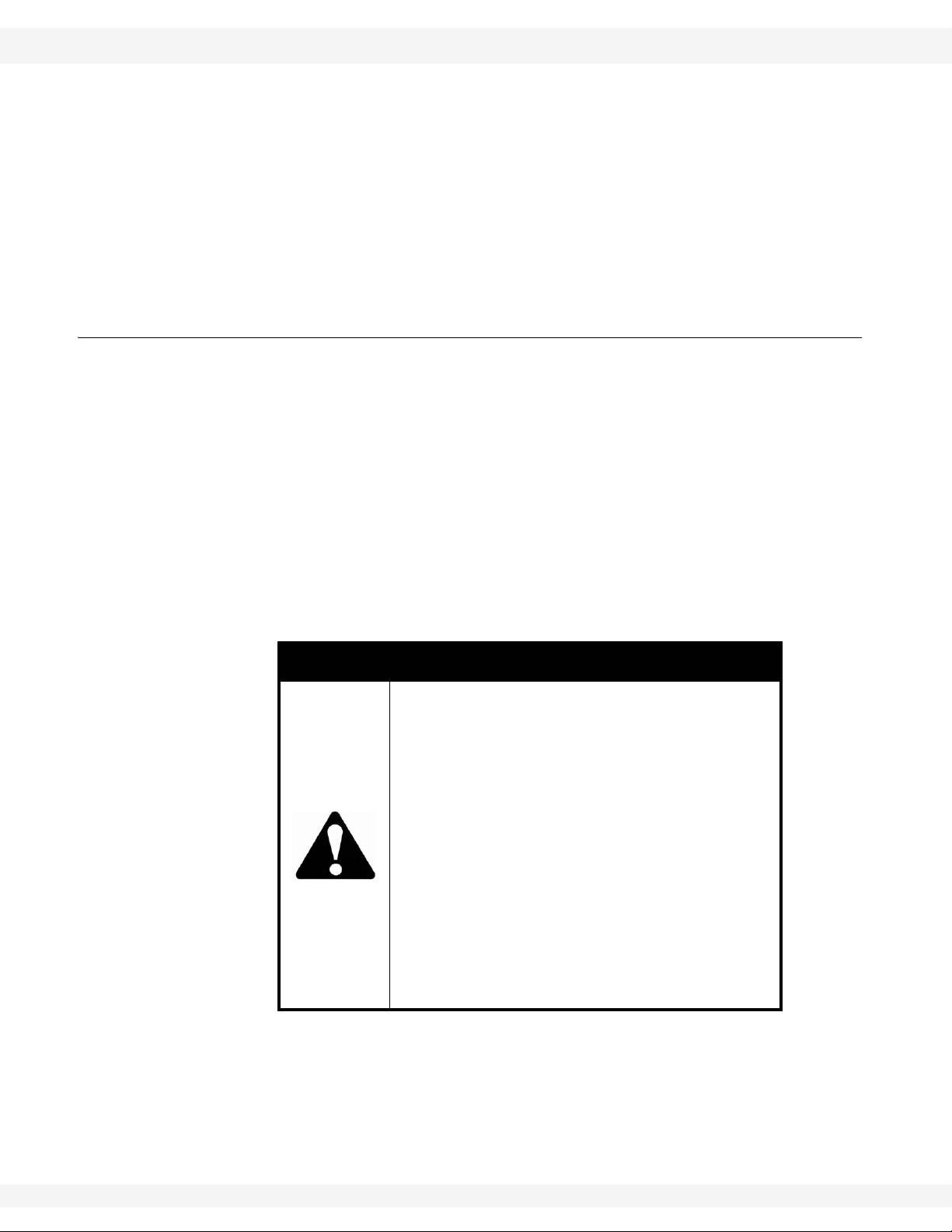

1.1.2. GRAIN TRANSFER BOOT

The grain transfer boot is located at the bottom of the main auger tube, and

contains gearing for power transfer as well as flights for transferring grain.

30787 R1 9

Figure 1.3 Grain Transfer Boot

1. INTRODUCTION WHEATHEART - X13 SERIES AUGERS

1.1. OVERVIEW X1374, X1384, X1394

PTO driveline connection (including connection to the optional 540 RPM PTO

Reverser and 1000 RPM PTO Drive) is provided on the back of the boot, above

the tractor hitch (and hitch jack).

The ball valve used to raise or lower the main auger tube is located on the side of

the boot (see figure below), as is the manual winch used to raise and lower the

grain hopper (see section 6.1. for further information on auger controls).

Several access hatches are provided for maintenance and repair (the swing arm

spout head access hatch is shown below), as well as an overflow panel on the

swing-arm spout head and a clean-out hatch at the bottom of the boot.

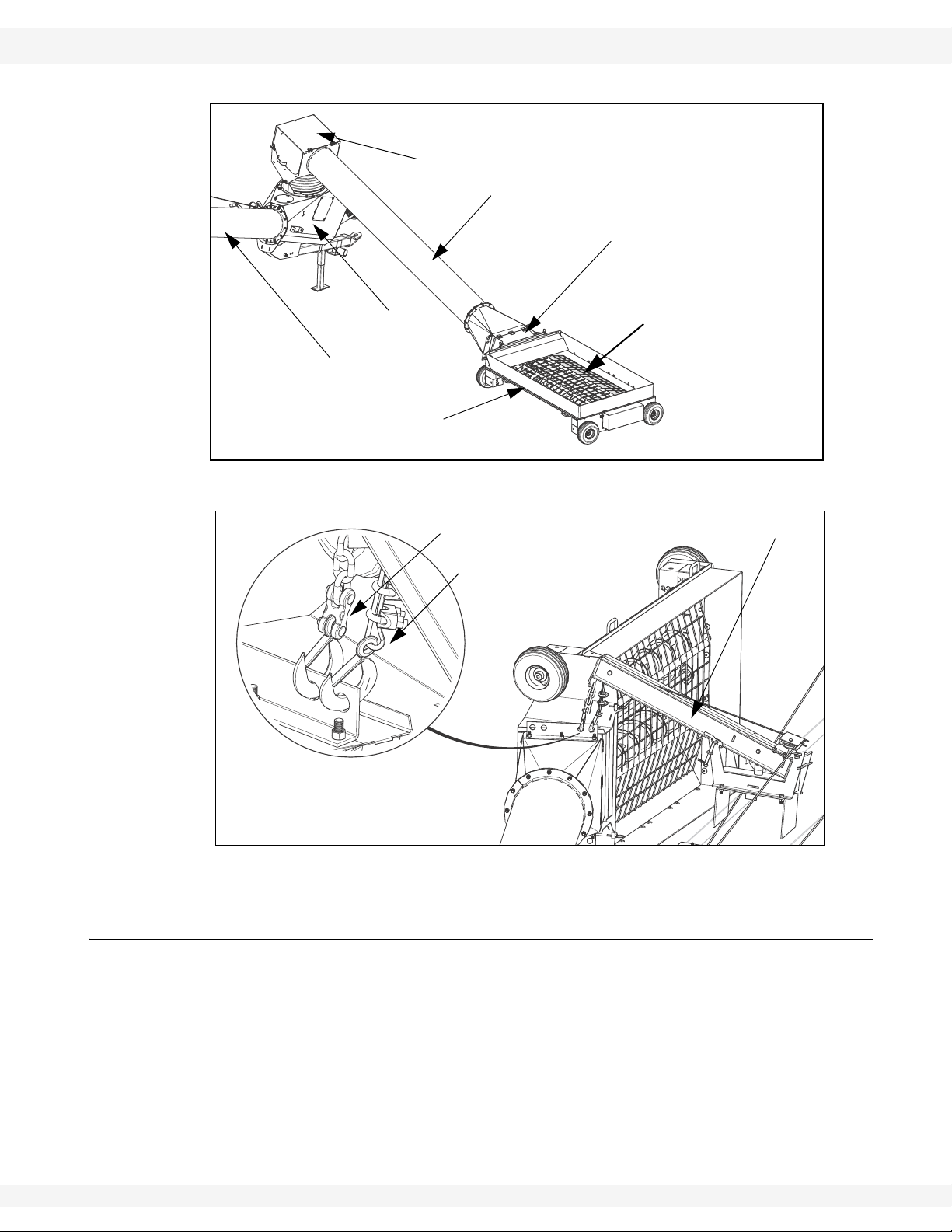

1.1.3. GRAIN HOPPER

The low-profile grain hopper is designed to be rolled into position to receive grain

for transfer through the boot to the auger discharge spout. Ground clearance can

be adjusted by raising or lowering the position of the hopper wheel axles.

The grain hopper must be lifted and secured for transport using the hopper lift

arm, winch (hydraulic or manual operation, according to the installed option), and

transport chain and hook (see Figure 1.5).

The grain hopper provides service to the side of the auger that it is installed on,

but the hopper, lift arm, and winch can be quickly reconfigured to install the

hopper on the other side if required.

Do not approach, open or close the maintenance hatch located on the transition

between the swing are tube and the hopper unless all power to the auger is

locked out.

DANGER

Rotating Auger Hazard

Contact with rotating flighting will result in

amputation or severe laceration.

DO NOT operate with guards removed or

modified.

Keep hands and feet away from rotating

auger.

Tie up long hair and remove jewelry.

DO NOT wear loose-fitting clothing or items

that could become caught.

Shut off and lock out the power source before

unplugging or cleaning.

10 30787 R1

WHEATHEART - X13 SERIES AUGERS 1. INTRODUCTION

INTAKE HOPPER

FLIGHTS AND

SWING ARM

MAINTENANCE HATCH

SPOUT HEAD

MAIN AUGER TUBE

BOOT

FLIGHT GUARDING

WINCH CABLE AND HOOK

SAFETY CHAIN AND HOOK

HOPPER LIFT ARM

X1374, X1384, X1394 1.1. OVERVIEW

Figure 1.4 Grain Hopper

Figure 1.5 Grain Hopper Lifted into Transport Position

1.1.4. AUGER TUBE HYDRAULIC LIFT

The auger tube is raised and lowered using two single-acting hydraulic cylinders

powered by the hydraulic supply of the connected tractor . The main auger tube is

raised by extending the cylinders, and lowered by allowing the cylinders to

retract.

A hydraulic ball valve mounted on the side of the grain pick-up boot controls flow

of hydraulic fluid to the lift cylinders, and with appropriate use of the hydraulic

controls on the connected tractor, allows the main auger tube to be raised,

lowered, or locked at a specific height during operation (see “Operator Controls”

30787 R1 11

on page 79).

1. INTRODUCTION WHEATHEART - X13 SERIES AUGERS

1.1. OVERVIEW X1374, X1384, X1394

12 30787 R1

WHEATHEART - X13 SERIES AUGERS 2. SAFETY

X1374, X1384, X1394 2.1. GENERAL SAFETY INFORMATION

2. Safety

2.1. GENERAL SAFETY INFORMATION

The Safety Alert symbol identifies important safety messages on the product and

in the manual. When you see this symbol, be alert to the possibility of personal

injury or death. Follow the instructions in the safety messages.

Why is SAFETY important?

• Accidents disable and kill.

• Accidents cost.

• Accidents can be avoided.

SIGNAL WORDS: Note the use of the signal words DANGER, WARNING,

CAUTION, and NOTICE with the safety messages. The appropriate signal word

for each message has been selected using the definitions below as a guideline.

DANGER

Indicates an imminently hazardous situation

that, if not avoided, will result in serious injury

or death.

WARNING

Indicates a hazardous situation that, if not

avoided, could result in serious injury or

death.

CAUTION

Indicates a hazardous situation that, if not

avoided, may result in minor or moderate

injury.

NOTICE

Indicates a potentially hazardous situation that, if not

avoided, may result in property damage.

30787 R1 13

2. SAFETY WHEATHEART - X13 SERIES AUGERS

2.2. ASSEMBLY SAFETY X1374, X1384, X1394

YOU are responsible for the SAFE use and maintenance of your equipment.

YOU must ensure that you and anyone else who is going to work around the

equipment understands all procedures and related SAFETY information

contained in this manual.

Remember, YOU are the key to safety. Good safety practices not only protect

you, but also the people around you. Make these practices a working part of your

safety program.

Important: Below are general instructions that apply to all safety practices. Any instructions

specific to a certain safety practice (e.g., Operational Safety), can be found in the

appropriate section. Always read the complete instructional sections and not just

these safety summaries before doing anything with the equipment.

• It is the equipment owner, operator, and maintenance personnel's responsibility to read and understand ALL safety instructions, safety decals, and manuals and follow them when assembling, operating, or maintaining the

equipment. All accidents can be avoided.

• Equipment owners must give instructions and review the information initially

and annually with all personnel before allowing them to operate this product.

Untrained users/operators expose themselves and bystanders to possible

serious injury or death.

• Use this equipment for its intended purposes only.

• Do not modify the equipment in any way without written permission from the

manufacturer. Unauthorized modification may impair the function and/or

safety, and could affect the life of the equipment. Any unauthorized modification of the equipment voids the warranty.

• Do not allow any unauthorized person in the work area.

2.2. ASSEMBLY SAFETY

• Read and understand the instructions to get to know the sub-assemblies and

hardware that make up the equipment before preceding to assemble the

product.

• Do not take chances with safety. The components are large, heavy, and can

be hard to handle. Always use the proper tools, stands, jacks, and hoists for

the job.

• Always have two or more people assembling the equipment. Because of the

weight, do not attempt assembly alone.

14 30787 R1

WHEATHEART - X13 SERIES AUGERS 2. SAFETY

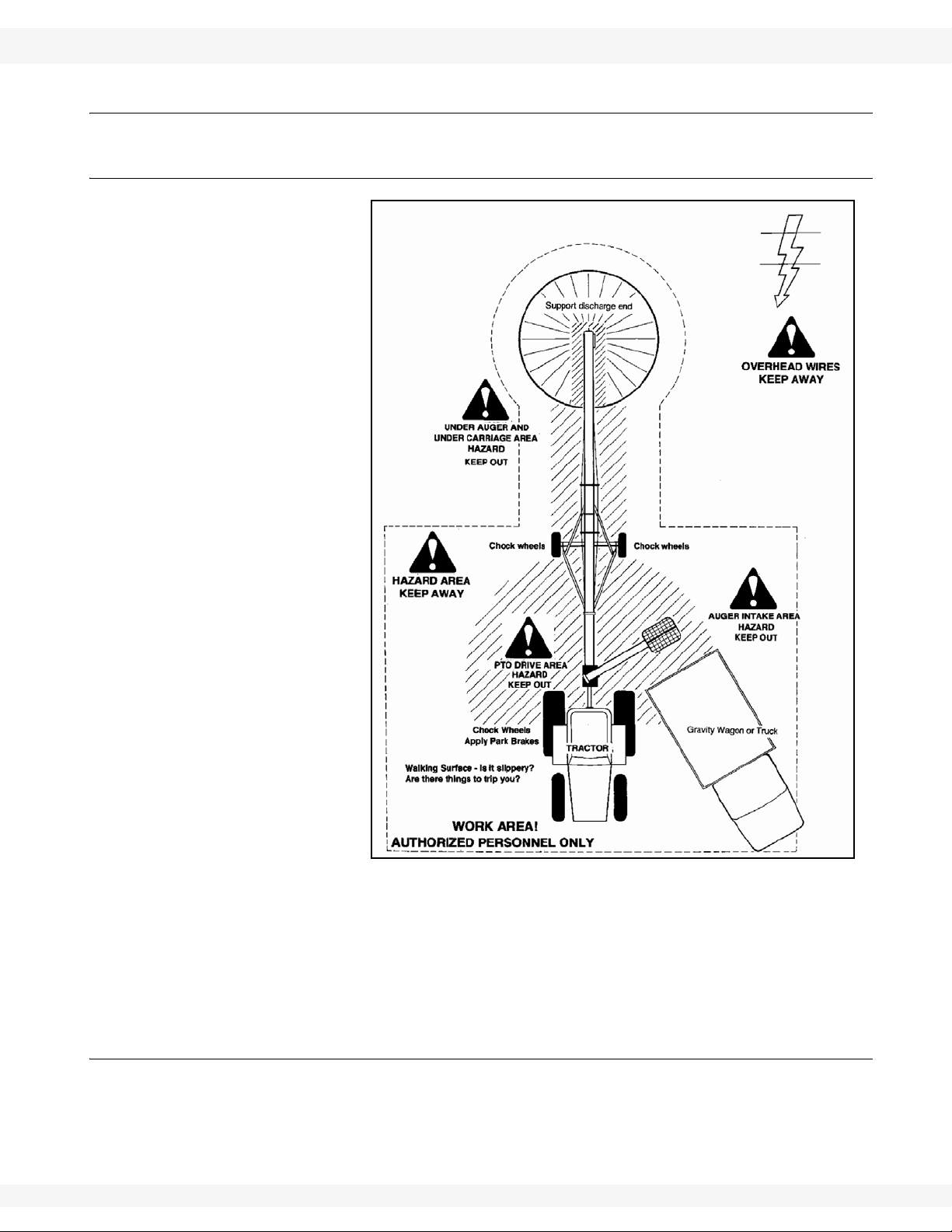

Figure 2.1

X1374, X1384, X1394 2.3.

2.3.

2.4. OPERATING SAFETY

• Ensure guards

are installed

and secure.

• Clear the work

area of

untrained people.

• Clean the

work area to

prevent slipping or tripping.

• Have a fully

equipped first

aid kit and fire

extinguisher

on hand and

know how to

use them.

• Be certain the

PTO driveline

is securely

attached to the

auger and to

the tractor.

• Before starting the tractor,

be certain that

the PTO is in

the off position.

• Keep hands,

feet, hair, and

clothing away

from all moving or rotating parts.

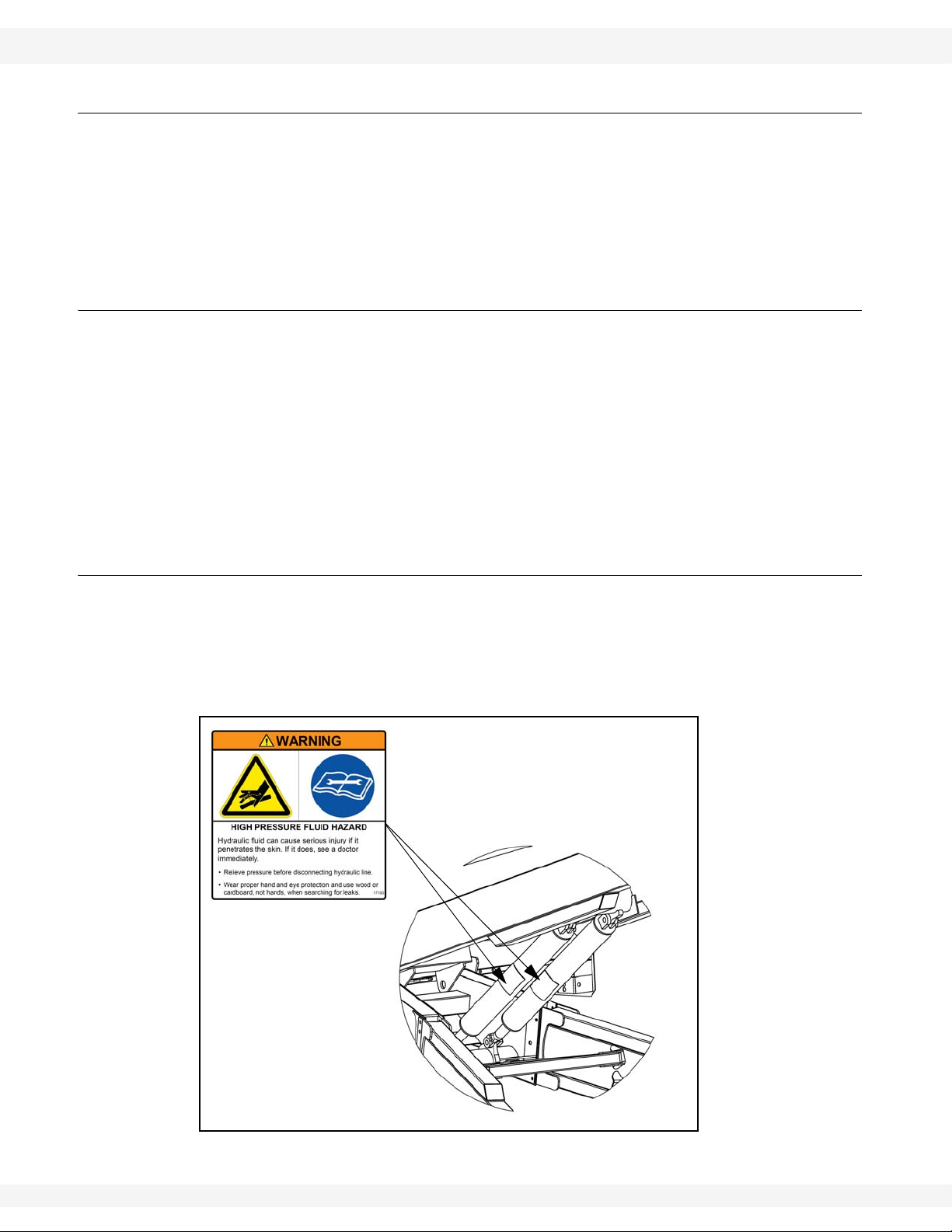

2.5. HYDRAULIC SAFETY

• Always place all tractor hydraulic controls in neutral before disconnecting

from tractor or working on hydraulic system.

• Make sure that all components in the hydraulic system are kept in good condition and are clean.

30787 R1 15

2. SAFETY WHEATHEART - X13 SERIES AUGERS

2.6. PTO DRIVELINE SAFETY X1374, X1384, X1394

• Replace any worn, cut, abraded, flattened, or crimped hoses.

• Do not attempt any makeshift repairs to the hydraulic fittings or hoses by

using tape, clamps, or cements. The hydraulic system operates under

extremely high-pressure. Such repairs create a hazardous and unsafe condition because they will fail suddenly.

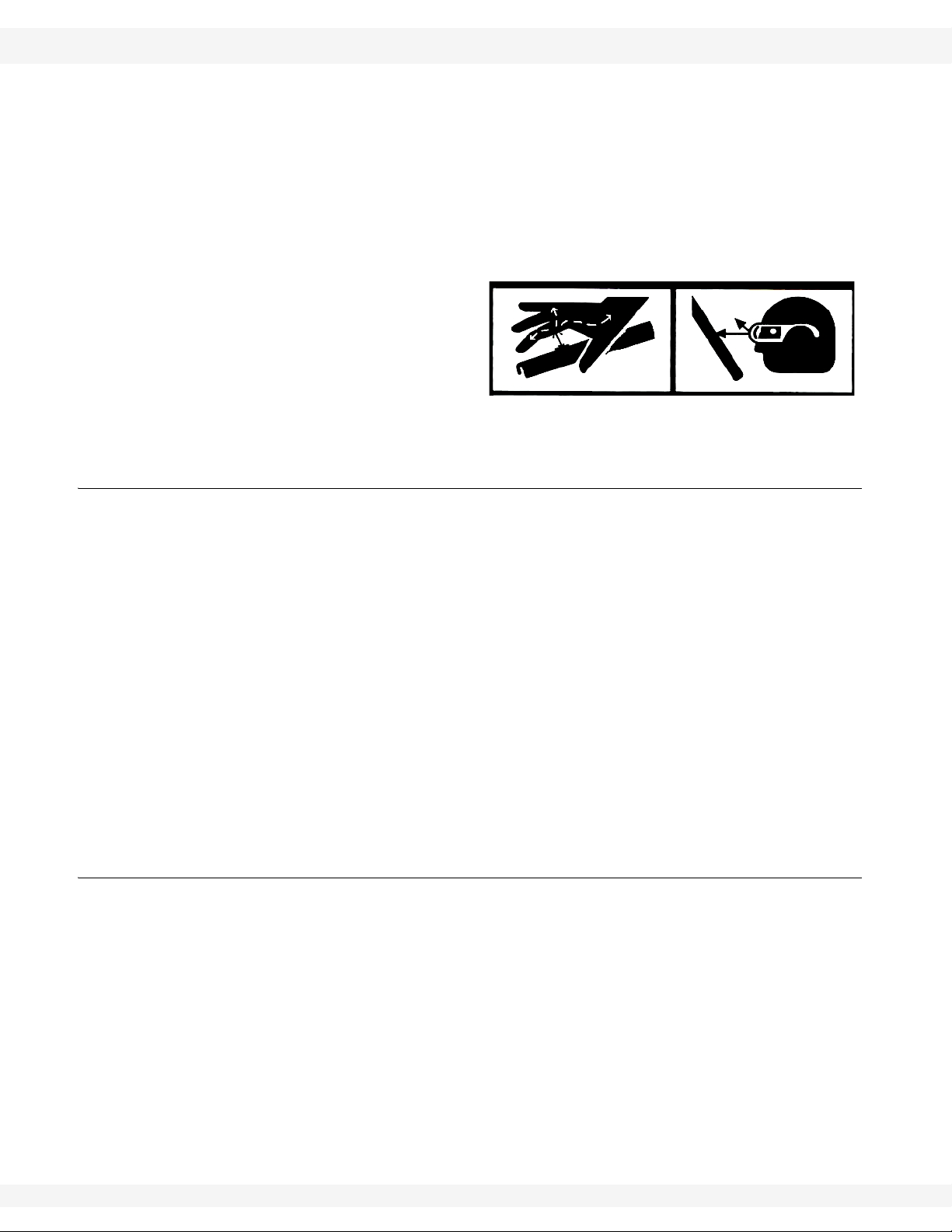

• Wear proper hand and eye protection when searching for a high-pressure

hydraulic leak. Do not use hands. Use a piece of wood or cardboard as a

backstop to isolate and identify a leak.

• If injured by a concentrated

high-pressure stream of

hydraulic fluid, seek medical

attention immediately. Serious infection or toxic reaction

can develop from hydraulic

fluid piercing the skin surface.

2.6. PTO DRIVELINE SAFETY

• To prevent serious injury or death:

• Keep body, hair, and clothing away from rotating PTO driveline.

• Do not operate equipment unless all driveline, tractor, and equipment shields

are in place and in good working order.

• Make certain the driveline shields turn freely on driveline.

• Make certain the driveline is securely attached at both ends.

• Do not exceed operating speed of 540 rpm.

• Keep u-joint angles small and equal. Do not exceed maximum recommended

length for PTO driveline.

• Do not exceed manufacturer’s recommended operating length.

• Set the tractor brake and block wheels on the tractor and the implement to

insure proper spacing of the PTO shaft at all times.

• Make sure driveline is properly secured to prevent damage during transport.

2.7. TIRE SAFETY

• Failure to follow proper procedures when mounting a tire on a wheel or rim

can produce an explosion that may result in serious injury or death.

• Do not attempt to mount a tire unless you have the proper equipment and

experience to do the job.

• Have a qualified tire dealer or repair service perform required tire maintenance.

• When replacing worn tires, make sure they meet the original tire specifications. Never undersize the replacement tire.

• Do not weld to the tire rim with the tire mounted on the rim. This action may

cause an explosion which could result in serious injury or death.

• Inflate tires to the manufacturers's recommended pressure.

16 30787 R1

WHEATHEART - X13 SERIES AUGERS 2. SAFETY

X1374, X1384, X1394 2.8. TRANSPORT SAFETY

2.8. TRANSPORT SAFETY

• Ensure tires are inflated to the tire manufacturer’s recommended pressure.

• Make sure that all lights and reflectors required by the local highway and

transport authorities are in place, are functioning, and can be seen clearly by

all overtaking and oncoming traffic.Check with local authorities regarding

transportation of agricultural equipment on public roads. Obey all applicable

laws and regulations.

• Be sure the unit is hitched securely to the towing vehicle.

• Do not allow riders while transporting.

• Display a Slow Moving Vehicle (SMV) emblem when transporting below 15

mph (24 km/h).

• Use hazard-warning flashers when transporting with a tractor unless prohibited.

• Keep to the right and yield the right-of-way to allow faster traffic to pass.

• Never transport faster than the road terrain or conditions will safely allow.

• Use caution when turning corners or meeting traffic.

• Use caution when approaching height-limiting objects.

• Be especially careful when transporting during times of limited visibility (rain,

snow, fog, dusk, or at night). If you can, wait for a more appropriate time to

move the equipment.

• Do not transport auger on a slope greater than 20°—the auger may overturn.

• The manual winch must be in the locked position. To lock, turn handle clockwise until you hear two clicks. Also ensure that the locking pin and clips are in

place on the hopper lift arm.

2.9. STORAGE SAFETY

• Store in an area away from human activity.

• Do not permit children to play on or around the stored machine.

2.10. MAINTENANCE SAFETY

• Shut off and disable the power source before working on the machine.

• Ensure service area is clean and dry.

• Ensure electrical outlets and tools are properly grounded.

• Use proper tools for the job and wear appropriate safety gear.

• Ensure there is adequate lighting to perform the job safely.

• Place chocks in front and behind the wheels to prevent the machine from rolling.

• Use extra caution when cleaning and servicing augers because flighting

edges can be sharp.

• Follow proper procedures when mounting a tire on a rim. If in doubt, have a

qualified tire repair service perform the required maintenance.

• Install and secure all guards after maintenance work is completed.

30787 R1 17

2. SAFETY WHEATHEART - X13 SERIES AUGERS

DECAL #17100

2.11. SAFETY DECALS X1374, X1384, X1394

2.11. SAFETY DECALS

• Keep safety decals clean and legible at all times.

• Replace safety decals that are missing or have become illegible. See decal

location figures that follow.

• Replaced parts must display the same decal(s) as the original part.

• Safety decals are available from your distributor, dealer, or factory.

2.11.1. DECAL INSTALLATION

1. Decal area must be clean and dry, with a temperature above 50°F (10°C).

2. Decide on the exact position before you remove the backing paper.

3. Align the decal over the specified area and carefully press the small portion

with the exposed sticky backing in place.

4. Slowly peel back the remaining paper and carefully smooth the remaining

portion of the decal in place.

5. Small air pockets can be pierced with a pin and smoothed out using the sign

backing paper.

2.11.2. SAFETY DECAL LOCATIONS

Replicas of the safety decals that are attached to the equipment are shown in the

figure(s) that follow. Proper safety procedures require that you familiarize

yourself with the various safety decals and the areas or particular functions that

the decals apply to, as well as the safety precautions that must be taken to avoid

serious injury, death, or damage.

18 30787 R1

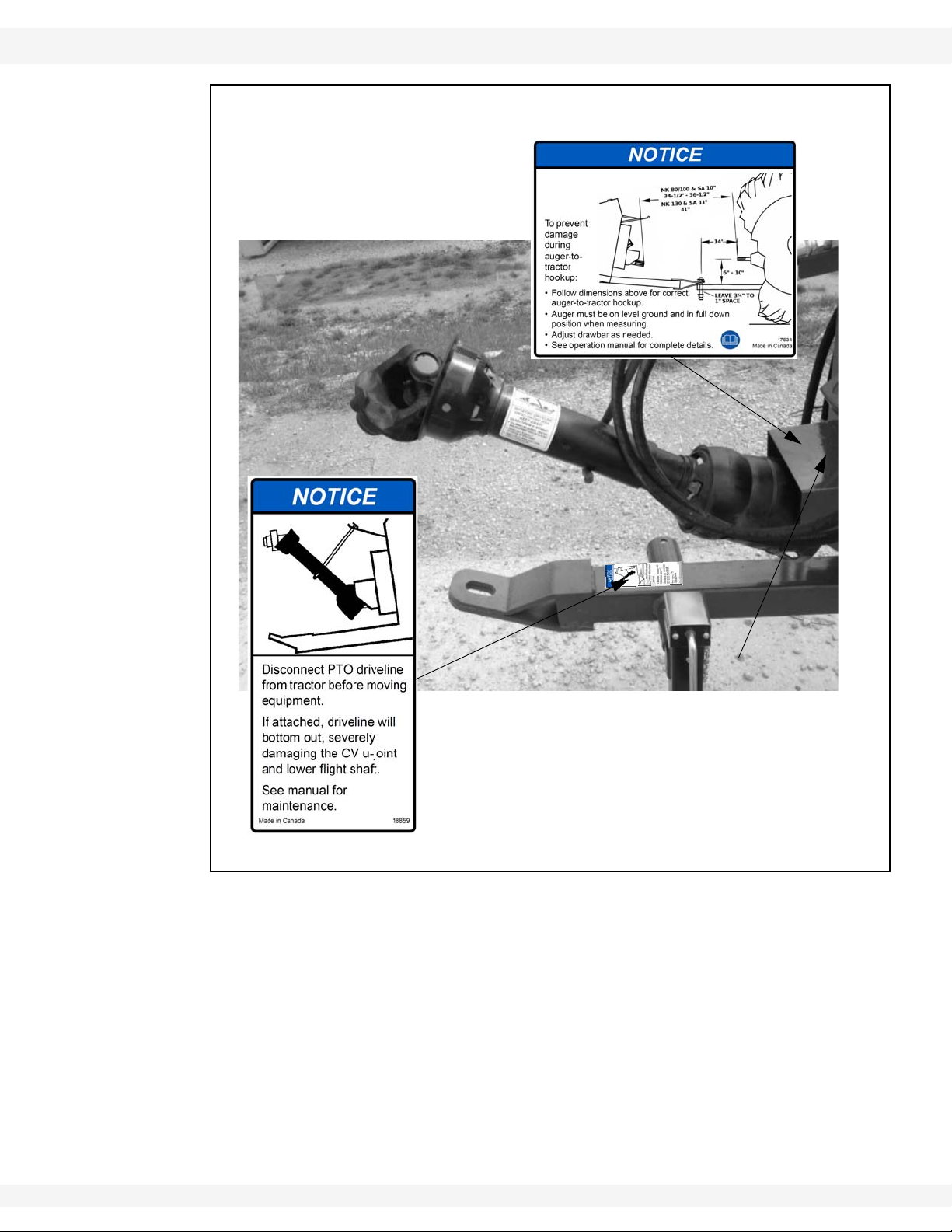

Figure 2.2

WHEATHEART - X13 SERIES AUGERS 2. SAFETY

DECAL #18859

DECAL #17531

X1374, X1384, X1394 2.11. SAFETY DECALS

30787 R1 19

Figure 2.3

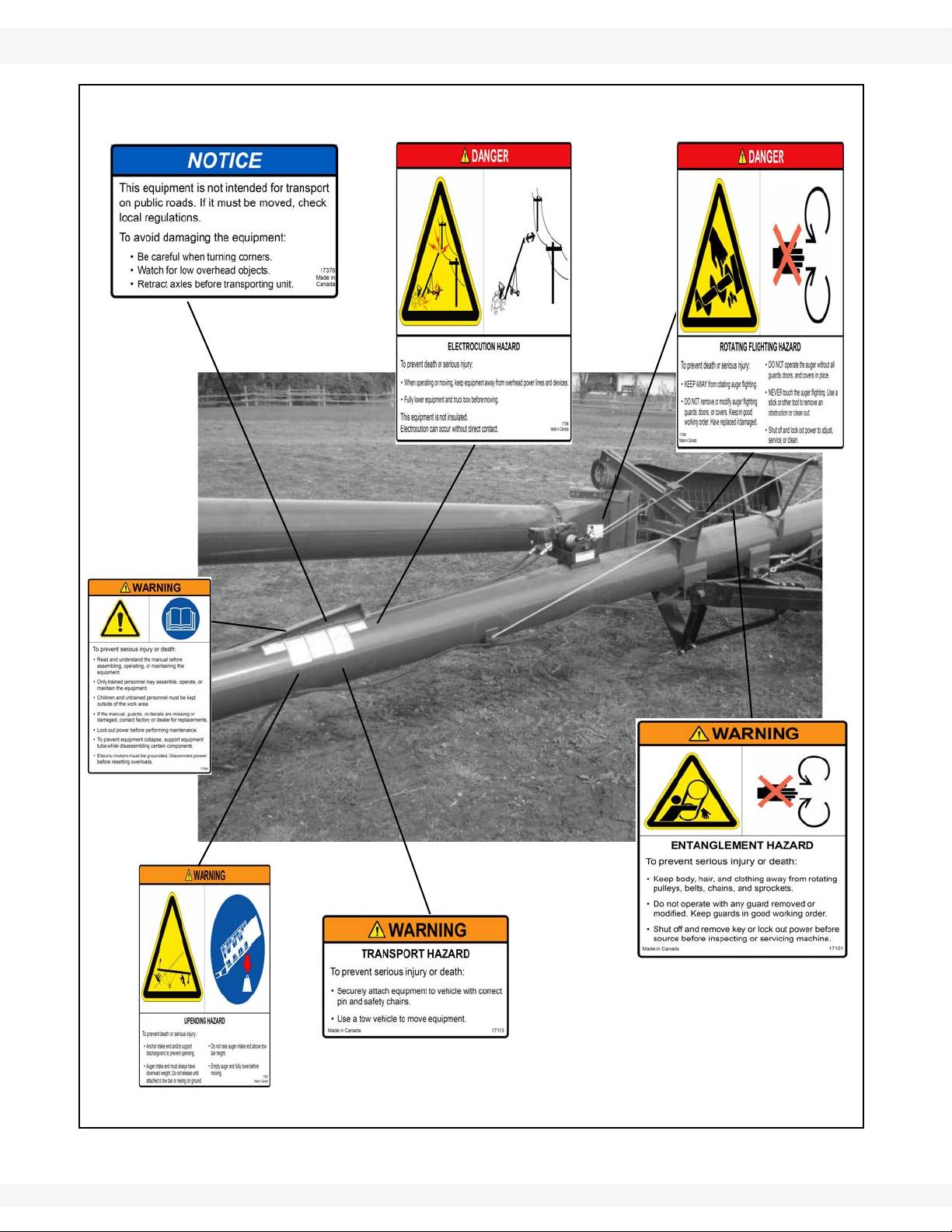

2. SAFETY WHEATHEART - X13 SERIES AUGERS

DECAL #17098

DECAL #17097

DECAL #17096

DECAL #17101

DECAL #17113

DECAL # 17378

DECAL #17398

(LOCATED ON HOPPER

CHAIN GUARD)

2.11. SAFETY DECALS X1374, X1384, X1394

Figure 2.4

20 30787 R1

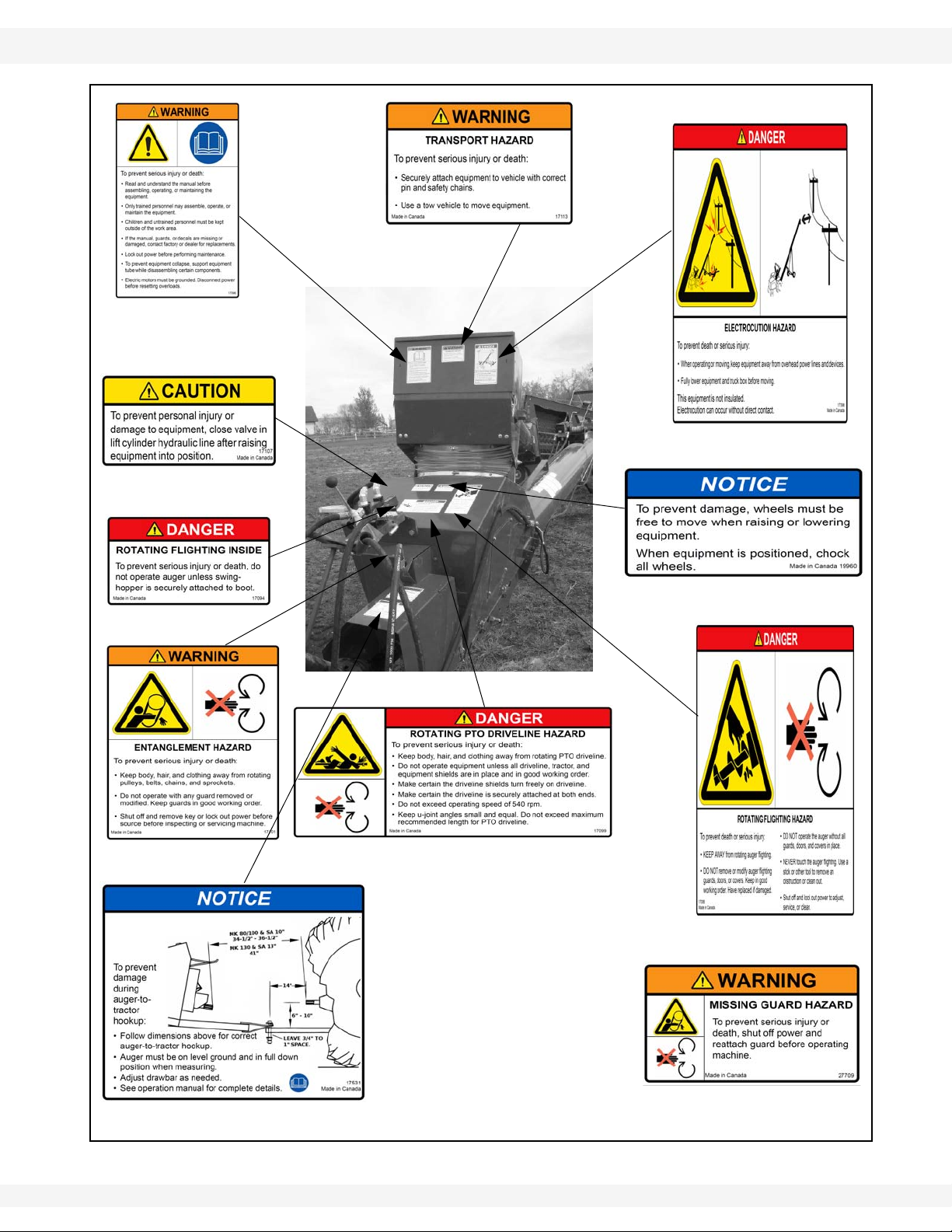

WHEATHEART - X13 SERIES AUGERS 2. SAFETY

DECAL #17099

DECAL #17107

DECAL #19960

DECAL #17531

DECAL #17098

DECAL #17101

DECAL #17094

DECAL #17096

DECAL #17113

DECAL #17398

PLACED ON MACHINE BEHIND

GUARD

DECAL #27709

X1374, X1384, X1394 2.11. SAFETY DECALS

Figure 2.5

30787 R1 21

2. SAFETY WHEATHEART - X13 SERIES AUGERS

DECAL # 27516

2.11. SAFETY DECALS X1374, X1384, X1394

Figure 2.6

22 30787 R1

WHEATHEART - X13 SERIES AUGERS 3. ASSEMBLY

WARNING Before continuing, ensure you have read and underst and the relevant information

in the safety section. Safety information is provided to help prevent serious injury, death, or

property damage.

X1374, X1384, X1394 3.1. GENERAL ASSEMBLY

3. Assembly

Familiarize yourself with all the sub-assemblies and hardware making up the

auger. Do not take chances with safety. The components are large, heavy, and

can be hard to handle. Be sure to use the proper tools, stands, jacks, and hoists

for the job.

Important: These instructions are written on the assumption that 2 or more people will be

available for the assembly procedure. Because of the weight, it is unwise to

attempt assembly of the auger alone.

Note: When tightening all fasteners, see the Appendix for proper torque specifications.

3.1. GENERAL ASSEMBLY

1. Select an assembly area that is level, has a firm or hard surface and is free of

debris. Be sure it is large enough to allow access from all sides when the

components are being assembled.

2. If assembling inside a building, be sure the ceiling is at least 14’ (4.27 m) high

to provide clearance when installing the undercarriage

3. Bring all the tools, blocks, stands, jacks, and hoists to the assembly area

before starting.

4. The following tools and equipment are required to assemble the machine:

• 11-14 support stands (tube section supports, three per tube)

• Four saw horses (1200 lb / 544.3 kg bearing capacity)

• One Standard socket set and wrench set

• One torque wrench

• One standard 25’ (7.62 m) tape measure

• One 2’ level

• One 8” level magnetic

• Two C-clamps or vise grips

• One picker with minimum reach of 12’ (3.66 m) 4000-6000 lb

(1 814 - 2 722 kg) lifting capacity

• One 100’ (30 m) measuring tape

• One tire gauge

• One tire chuck

• 6-10 wood blocks (2x4's or smaller)

• Grease

• Impact wrench and sockets

• Two or more steel punches (for aligning bolt holes)

30787 R1 23

3. ASSEMBLY WHEATHEART - X13 SERIES AUGERS

3.1. GENERAL ASSEMBLY X1374, X1384, X1394

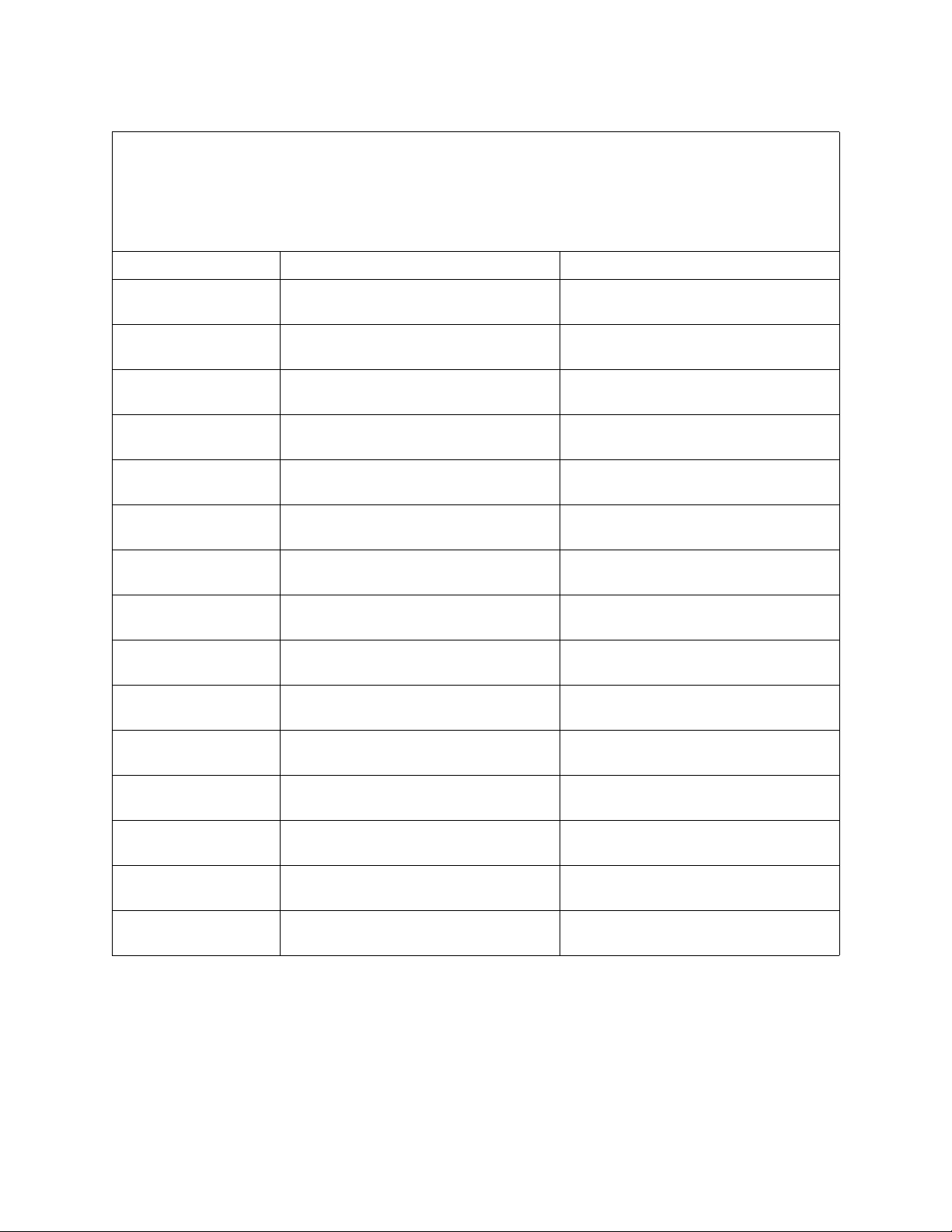

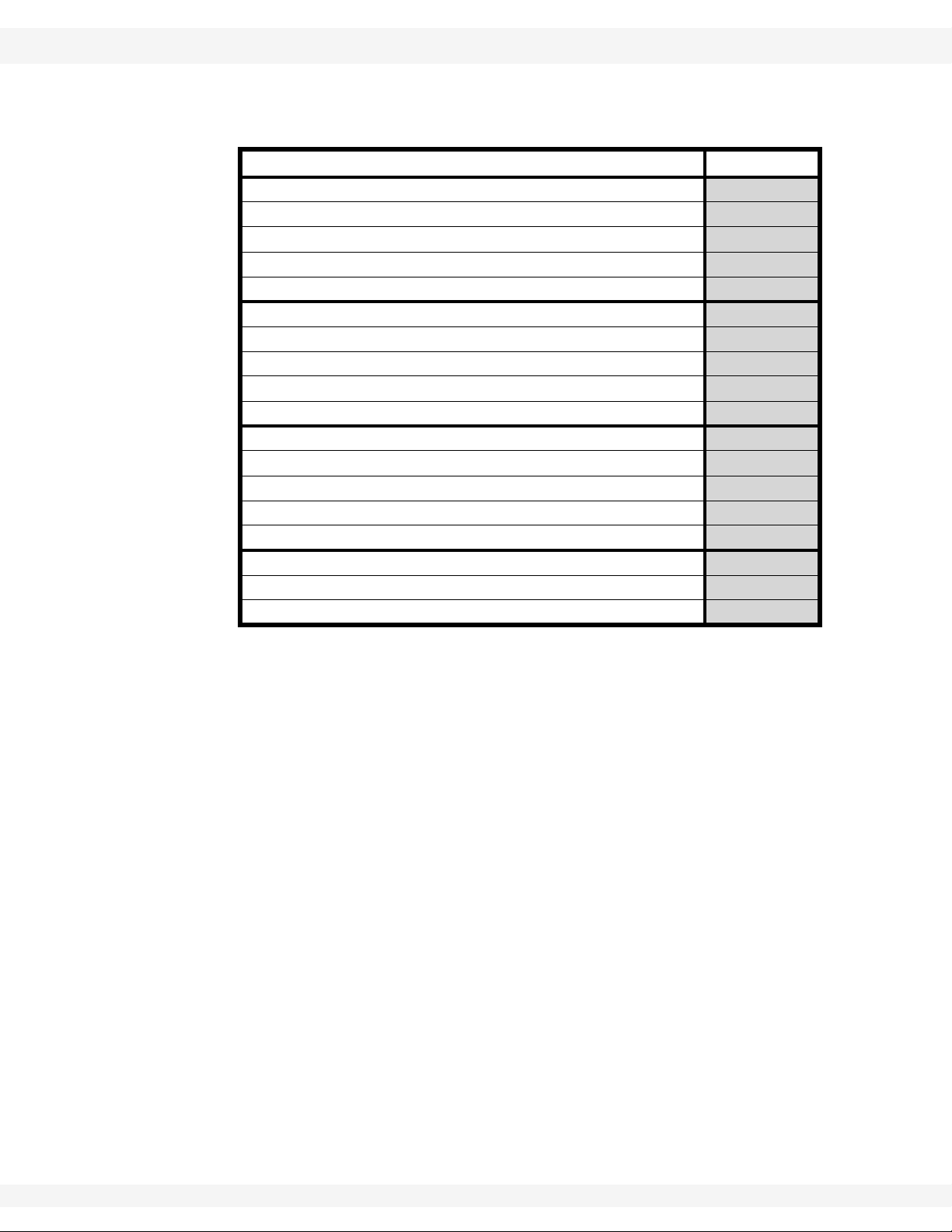

See Table 3.1. for a list of assembly procedures.

Table 3.1. X13 Auger Assembly Procedures

Procedure Page

Identify Auger Tube Sections page 25

Assemble the Main Auger Tube page 28

Install the Boot on the Auger tube page 29

Install the Boot Tow Bar page 32

Install the Discharge Spout page 33

Set the Thrust Adjuster page 33

Apply Logo and Model Decals page 34

Auger Tube Truss Assembly page 35

Assemble the Auger Frame page 49

Installing the Hydraulic Cylinders page 56

Assemble Wheel Hubs and Install Tires page 57

Attaching the Auger Tube to the Frame page 58

Connecting Hydraulic Hose to Cylinders page 61

Install Low Profile Intake Hopper page 65

Installing the Hopper Lift Arm and Winch page 69

Install the Hitch Jack page 72

Connecting the PTO Driveline page 72

Auger-to-Tractor Hookup page 74

24 30787 R1

WHEATHEART - X13 SERIES AUGERS 3. ASSEMBLY

X1374, X1384, X1394 3.2. IDENTIFY AUGER TUBE SECTIONS

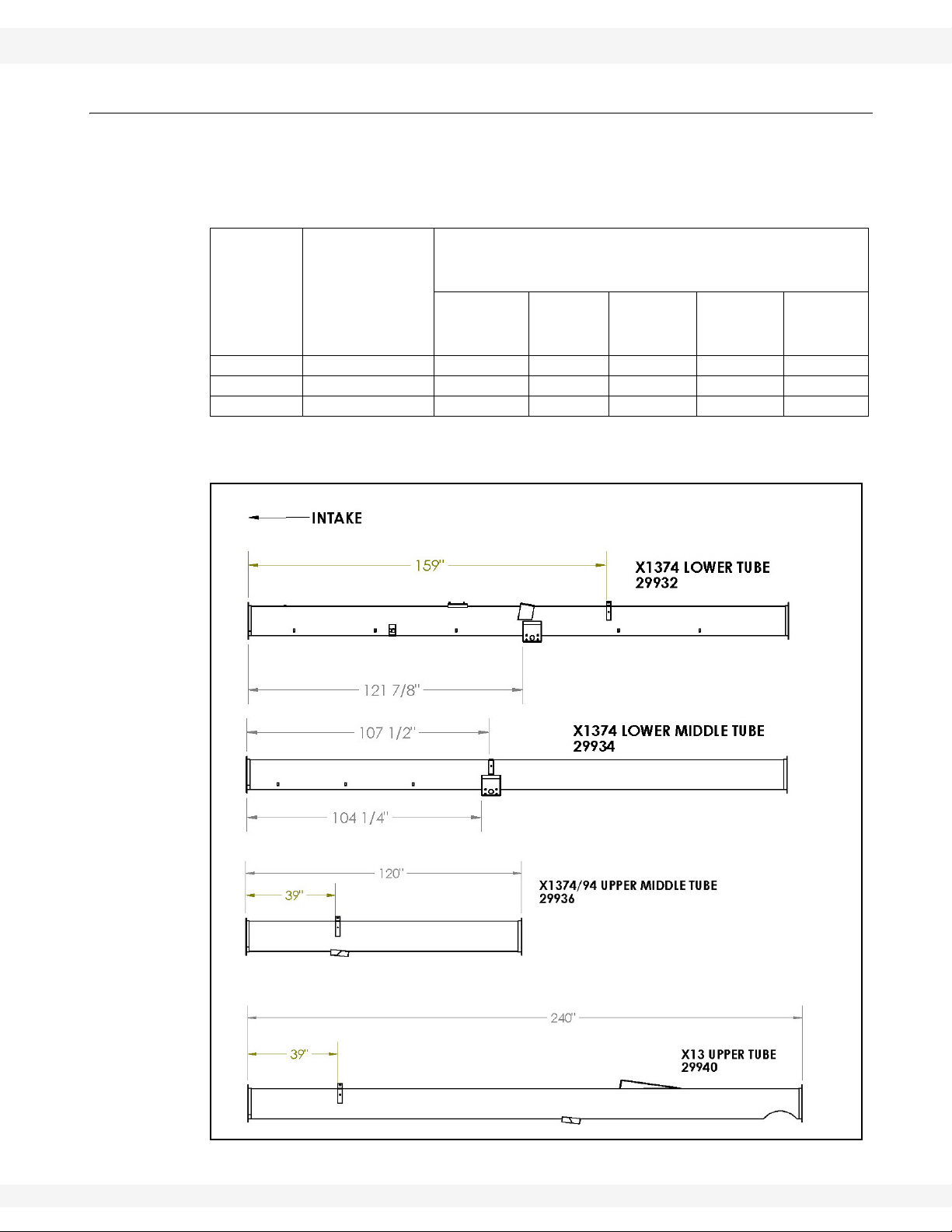

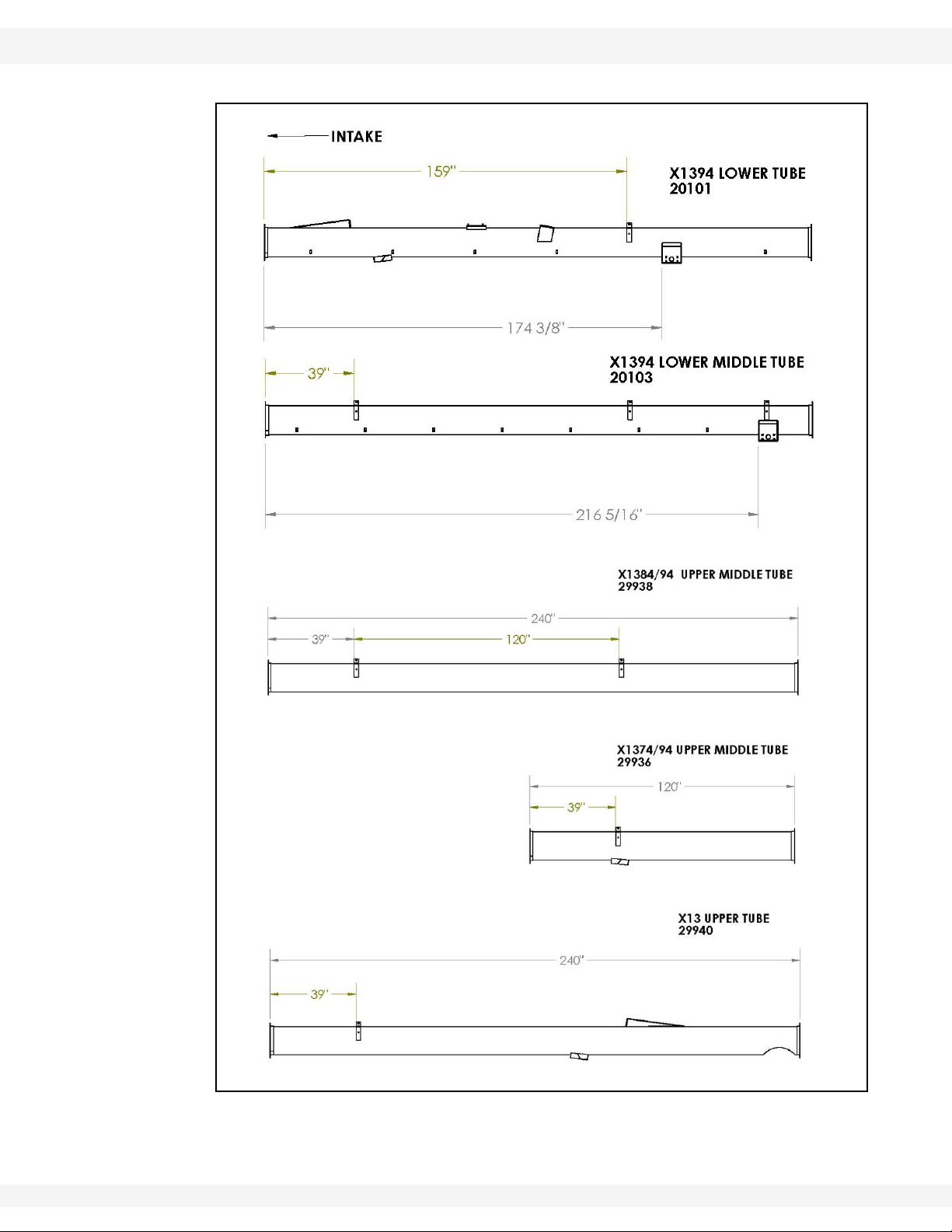

3.2. IDENTIFY AUGER TUBE SECTIONS

Note: See Table 3.2 for the number of tube sections and their part numbers and

lengths. Assemble the auger starting with the discharge section and working

toward the intake section.

Table 3.2 Tube Section Information, by Model

Tube Bundle Part Numbers

Total Number

Model

X130-74 4 29932* 29934* -- 29936** 29940*

X130-84 4 20097* 20099* 29938* -- 29940*

X130-94 5 20101* 20103* 29938* 29936** 29940*

*20’ [6.10 m]

**10’ [3.05 m]

of Tube

Sections

(Starting from Boot [intake] moving toward

Discharge)

Lower

Tube

Lower

Middle

Tube

Middle

Tube

Upper

Middle

Tube

Upper

Tube

Figure 3.1 X130-74 Auger Tube Sections

30787 R1 25

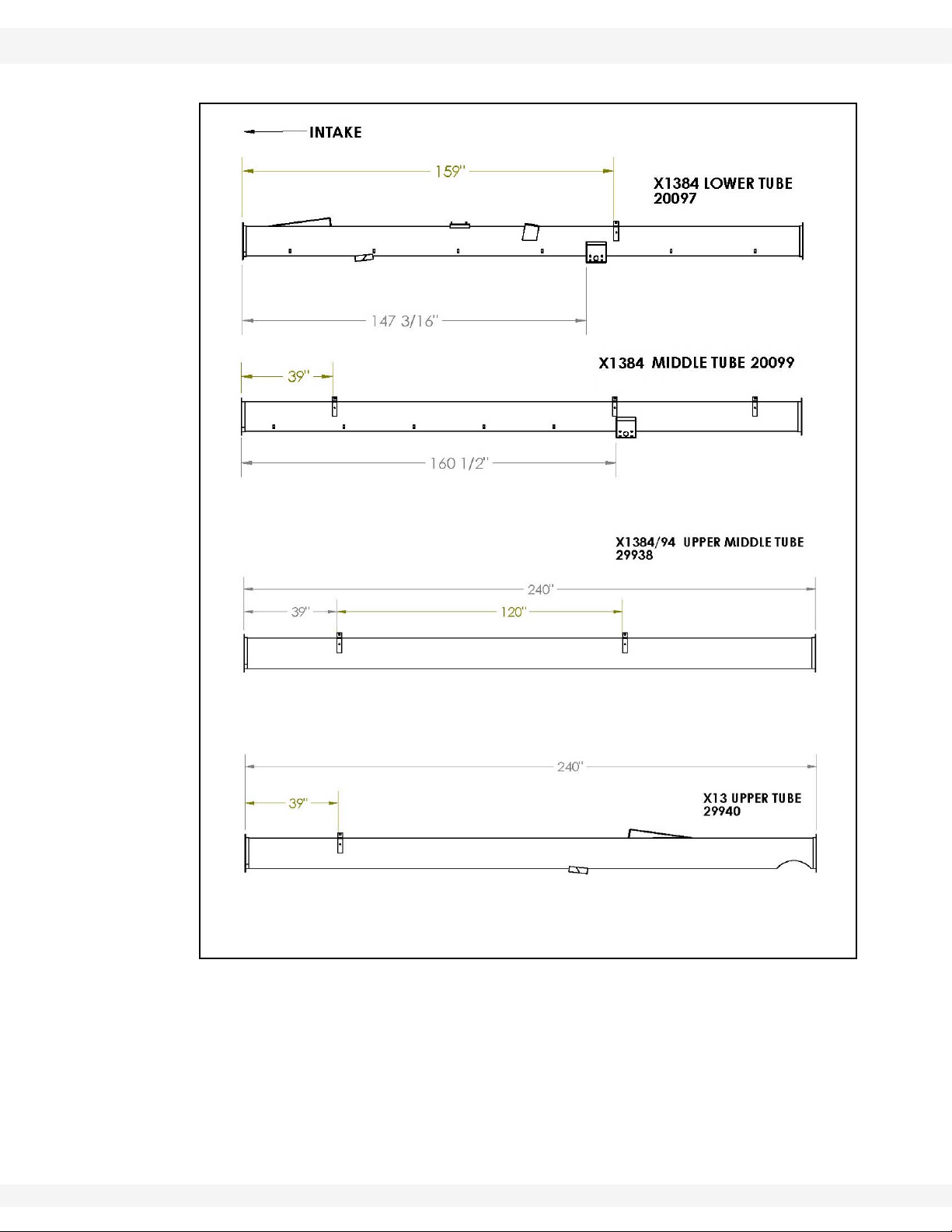

3. ASSEMBLY WHEATHEART - X13 SERIES AUGERS

3.2. IDENTIFY AUGER TUBE SECTIONS X1374, X1384, X1394

Figure 3.2 X130-84 Auger Tube Sections

26 30787 R1

WHEATHEART - X13 SERIES AUGERS 3. ASSEMBLY

X1374, X1384, X1394 3.2. IDENTIFY AUGER TUBE SECTIONS

Figure 3.3 X130-94 Auger Tube Sections

30787 R1 27

3. ASSEMBLY WHEATHEART - X13 SERIES AUGERS

1/2” LOCKNUT

7/16” X 1-1/4” BOLTS

7/16”

1/2” X 4” BOLT

LOCKNUTS

3.3. ASSEMBLE THE MAIN AUGER TUBE X1374, X1384, X1394

3.3. ASSEMBLE THE MAIN AUGER TUBE

See Table 3.3. for a list of hardware required to assemble the main auger tube.

Table 3.3. Parts Required, Assembling the Main Auger Tube

Part Number Description X130-74 X130-84 X130-94

18974 1/2” x 4” bolts 3 3 4

17750 1/2” locknuts 3 3 4

18698 7/16'' X 1-1/4'' bolts 48 48 64

17593 7/16” locknuts 48 48 64

1. Align tube sections on a series of support stands, placing a support stand at

the end of each tube. If possible, make sure that support stand height is

equal across all tubes to ensure that tubes are level with each other.

Otherwise, use some form of shim to keep the tubes level across all of the

support stands.

Important: Always strap tubes to the support stands to prevent the tubes from rolling off the

stands and onto the floor.

2. Working from the spout end (upper tube) to the discharge end (lower tube),

connect the tubes together as shown in Figure 3.4, as described below:

a. Align flightings to ensure a continual spiral of auger surface, and connect

flight shafts with 1/2” x 4” bolts and 1/2” locknuts.

b. As flight shafts are connected, slide tube sections together and secure with

7/16'' X 1-1/4'' GR8 bolts and 7/16” locknuts.

28 30787 R1

Figure 3.4 Connecting Auger Tubes and Flights

WHEATHEART - X13 SERIES AUGERS 3. ASSEMBLY

1/2” LOCKNUT

1/2” X 4” GR8 BOLT

X1374, X1384, X1394 3.4. INSTALL THE BOOT ON THE AUGER TUBE

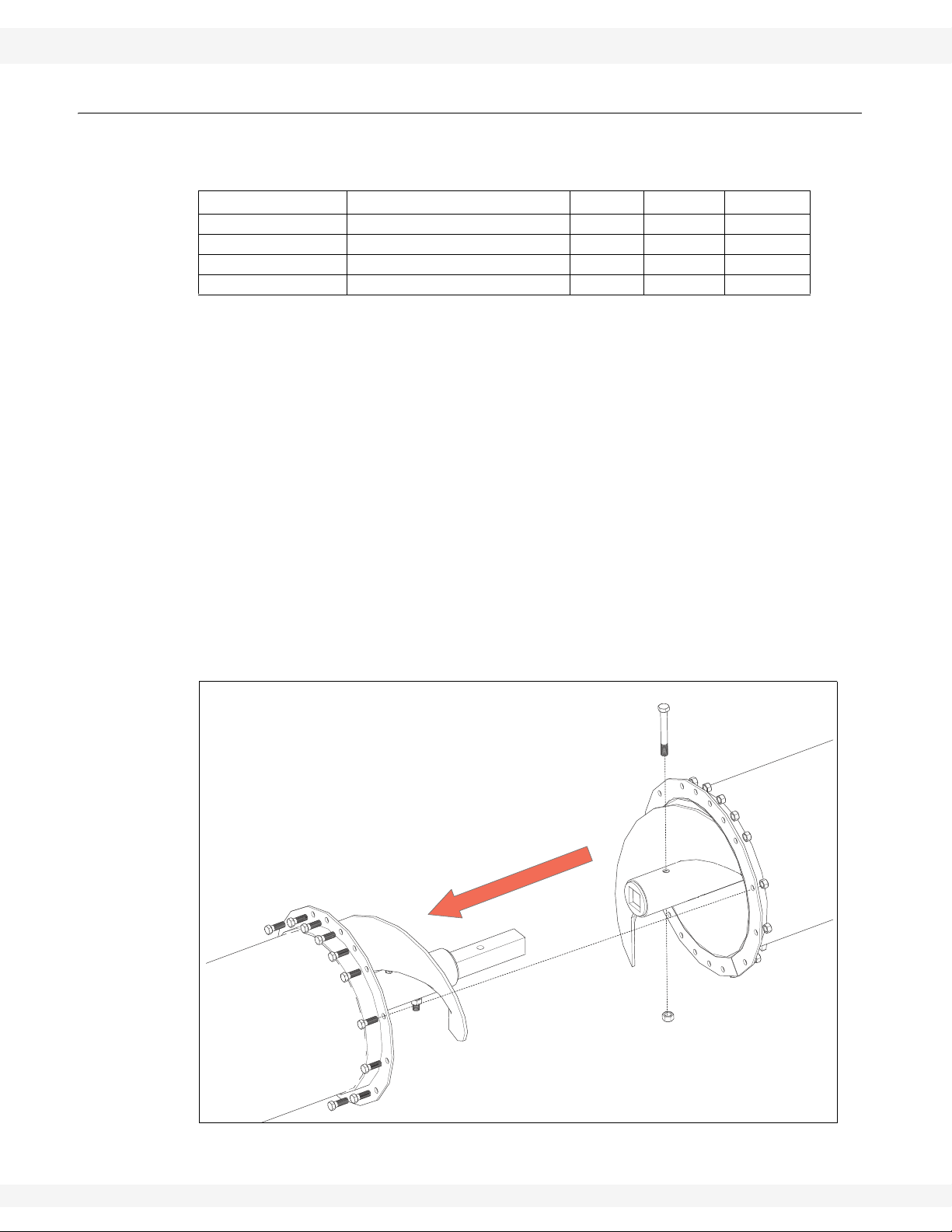

3.4. INSTALL THE BOOT ON THE AUGER TUBE

.\

See Table 3.4. for a list of parts required to install the boot on the auger tube.

Table 3.4. Parts Required, Installing the Boot on the Auger Tube

Part Number Description Amount

29991 X13 boot assembly 1

29999 X13 boot-tube attach plate 1

18698 7/16” X 1-1/4” bolts 21

17593 7/16” locknuts 21

WARNING

Components are heavy and create a crushing

hazard if improperly handled. Be sure to use

proper hoisting equipment and procedures,

and ensure lifting apparatus is secure. Lock

out the lifting apparatus before working

around or under the raised components;

failure to do so may cause serious personal

injury.

Note: The gearbox is sent from the factory filled half way with EP90 gear oil. Before

further assembly, check oil level to make certain the gearbox is half full. Add oil if

necessary. Do not use grease.

1. The boot flighting comes pre installed on the end of the lower tube flighting

shaft (See Figure 3.5). Ensure that the flighting is fastened with a

1/2'' X 4” GR8 bolt and 1/2” locknut before proceeding.

30787 R1 29

Figure 3.5 Check Boot Flight Bolt and Nut

3. ASSEMBLY WHEATHEART - X13 SERIES AUGERS

TUBE FLANGE

BOOT-TUBE

TOP BOOT-TUBE

ATTACH PLATE

BOTTOM BOOT-TUBE ATTACH

PLATE BOLTS (3)

BOLTS (2)

ATTACH PLATE

3.4. INSTALL THE BOOT ON THE AUGER TUBE X1374, X1384, X1394

2. Slip the boot-tube attach plate over the boot flighting. Position the plate with

flat edge facing up (see Figure 3.6), and fasten with five 7/16” x 1-1/4” GR8

bolts inserted from the boot side of the flange and 7/16” locknuts.

3. Slip the boot assembly over the lower flighting shaft and attach it to the

flange on the lower tube with 14 7/16” x 1-1/4” GR8 bolts and

7/16” locknuts (see Figure 3.6).

Figure 3.6 Installing the Boot on the Auger Tube

4. Insert the remaining boot attach plate bolts, secure with locknuts, and tighten

all flange and boot attach plate nuts fully (do not overtighten).

30 30787 R1

WHEATHEART - X13 SERIES AUGERS 3. ASSEMBLY

2” RIM WASHER

DRIVE

5/8” X 2” BOLTS

5/8” LOCKNUTS

LOWER

SPROCKET

SQUARE KEY

LOCK COLLAR

LOWER BEARING

CHAIN

AND FLANGE

X1374, X1384, X1394 3.5. INSTALL BOOT BEARING, LOWER SPROCKET, AND DRIVE CHAIN

3.5. INSTALL BOOT BEARING, LOWER SPROCKET, AND DRIVE CHAIN

See Table 3.5. for a list of part s required to install the boot bearing, lower

sprocket, and drive chain.

Table 3.5. Parts Required, Installing the Boot Bearing, Lower Sprocket,

and Drive Chain

Part Number Description Amount

20084 2” rim washer 1

20015 2” lower bearing, 4-bolt flange, lock collar 1

18541 Square key, 3/8" x 3-3/8" 1

18525 Lower sprocket, 80b18 x 1-3/4” 1

19781

19134

19991 5/8” x 2” bolts 4

19600 5/8” locknuts 4

1. Install the lower sprocket as follows:

a. Slide the 2” wide rim flat washer onto lower flight shaft.

b. Slide the lower bearing over the flighting shaft, and bolt it loosely in place

with four 5/8” X 2” bolts and 5/8” locknuts.

Drive chain (80b37 roller chain)

#80 chain connector

1

1

c. Ensure that the flight shaft shoulder is seated against washer and lower

bearing.

d. Position the lock collar tightly against the bearing, then tighten the collar set

screw against the flighting shaft.

e. Install the 3/8” x 3-3/8” square key on the flighting shaft, then slide the

lower sprocket onto the flighting shaft. Align lower sprocket face with upper

sprocket face using a straight edge, then tighten set screws.

Figure 3.7 Installing Boot Bearing, Sprocket, and Chain

30787 R1 31

3. ASSEMBLY WHEATHEART - X13 SERIES AUGERS

3/4” X 5-1/2” BOLT

3/4” X 3-1/2” X 5” SQUARE U-BOLT

3/4” LOCKNUTS

BOOT

T

O

W

B

A

R

AND 3/4” LOCKNUT

CHANNEL

3.6. INSTALL THE BOOT TOW BAR X1374, X1384, X1394

Note: It is recommended you use a thread locking compound that meets or exceeds

Loctite Blue© on all set screws.

Important: To prevent premature failure of the lower bearing, ensure it has been assembled

in the correct sequence.

2. Loop the drive chain around upper and lower sprockets. Push the flighting

shaft down until the chain is tensioned to within about 1/4” deflection, then

tighten the 4 bolts on the bottom bearing. Oil the chain lightly.

Note: For ease of PTO installation, sprocket shield should be attached after the instal-

lation of the PTO driveline. See “Connecting the PTO Driveline” on page 72.

3.6. INSTALL THE BOOT TOW BAR

See Table 3.6. for a list of parts required to install the boot tow bar.

Table 3.6. Parts Required, Installing the Boot Tow Bar

Part Number Description Amount

29983 Tow bar

29997 3/4” x 5-1/2” bolt

19601 3/4” locknut

28487 3/4” x 3-1/2” x 5” square U-bolt

1

1

3

1

1. Insert the tow bar into the boot channel, and secure the back end loosely with

a 3/4” x 5-1/2” bolt and 3/4” locknut through the back hole in the boot channel

(under the boot).

2. Tightly secure the middle of the tow bar in the channel with a

3/4” x 3-1/2” x 5” square U-bolt and two 3/4” locknuts.

3. Fully tighten the 3/4” nut on the 3/4” x 5-1/2” bolt.

Figure 3.8 Installing the Boot Tow Bar

32 30787 R1

WHEATHEART - X13 SERIES AUGERS 3. ASSEMBLY

SPOUT

7/16” X 1-1/4” BOLTS [18698]

7/16” LOCKNUTS

[17593]

Figure 3.10

X1374, X1384, X1394 3.7. INSTALL THE DISCHARGE SPOUT

3.7. INSTALL THE DISCHARGE SPOUT

1. Align the discharge spout over the opening in the upper tube.

2. Attach the discharge spout with two 7/16” x 1-1/4” GR 8 bolts [18698] and

7/16” locknuts [17593].

Figure 3.9 Installing the Discharge Spout

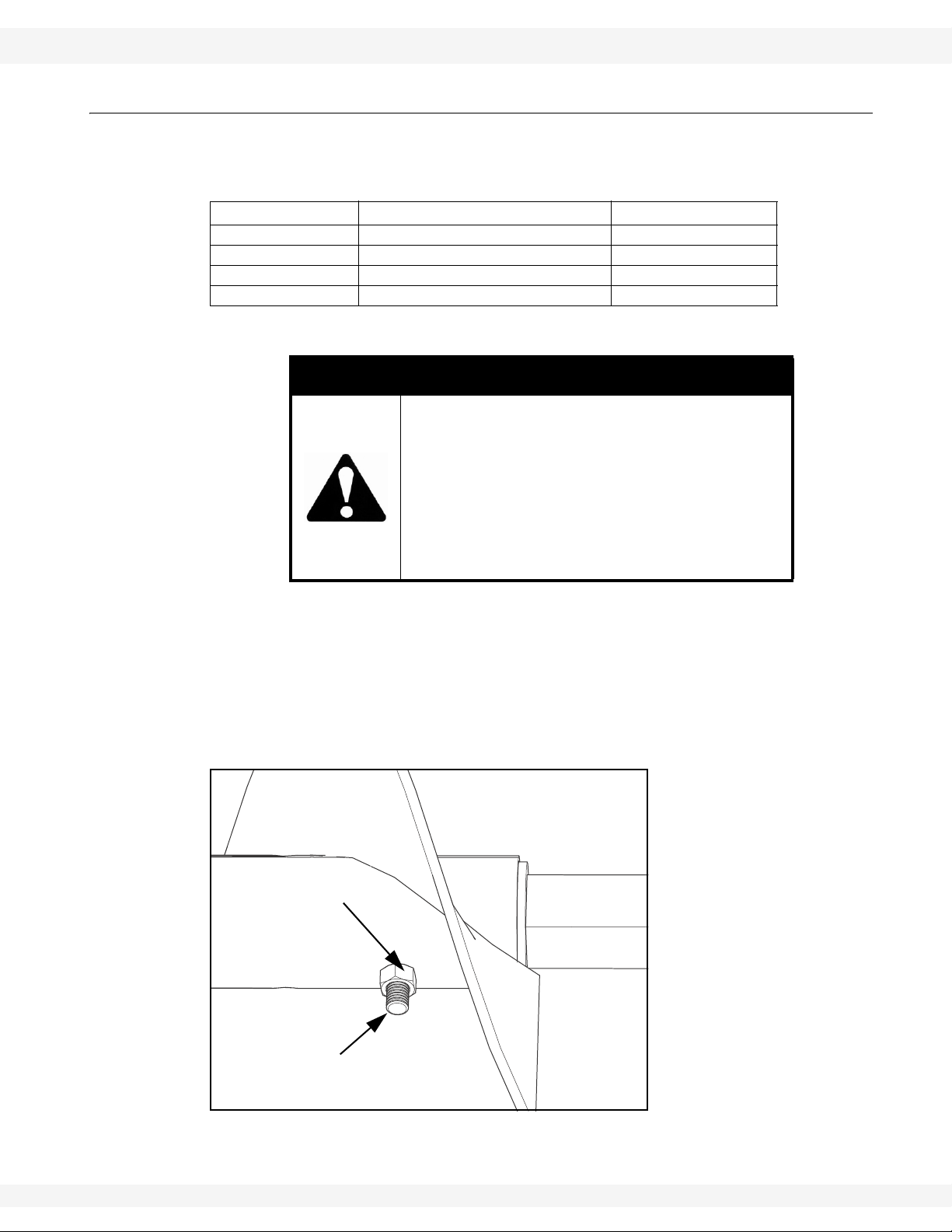

3.8. SET THE THRUST ADJUSTER

1. Remove the upper bearing lock collar (if necessary).

2. Slide the lock collar and bushing onto the shaft and attach the 1-1/2” nut.

3. Turn the nut until it is snug against the bushing, then turn it so that the shaft

moves an additional 1/4” away from the top plate.

4. Secure the lock collar and tighten the set screw.

5. Install the cover over the two longer 5/8” bolt s. Secure with two

5/8” whiz-nuts.

30787 R1 33

3. ASSEMBLY WHEATHEART - X13 SERIES AUGERS

LOWER MIDDLE TUBE

UPPER TUBE

WHEATHEART LOGO, CENTRED ON SIDE OF UPPER TUBE

AUGER MODEL

(DISCHARGE SIDE)

3.9. APPLY LOGO AND MODEL DECALS X1374, X1384, X1394

3.9. APPLY LOGO AND MODEL DECALS

1. Prepare surface by cleaning

thoroughly with soap and water.

Surface must be clean and free of dirt,

grime, rust and oil. To clean oily

surface, wipe with clean cloth and

solvent cleaner or isopropyl alcohol.

2. Position the decal on the tube and

apply masking tape along the top,

creating a gate hinge. Figure A

demonstrates.

3. Remove backing paper from decal 6"

from the top and use the squeegee to

adhere decal to the tube, as seen in

Figure B. Start at the top center of the

decal and work your way outward both

left and right using overlapping

strokes.

4. As you work your way down the decal,

peel back the backing paper 6" at a

time. Repeat Step 3 until the entire

decal has been applied to the tube.

See Figure C as an example.

5. Once the entire decal has been

properly adhered to the tube, carefully

remove tape.

6. Inspect the decal for air pockets; if

found, remove them by punching a tiny

hole with a pin and then squeegee the surface flat.

7. Squeegee the corners and edges of the decal to ensure proper adhesion and

to prevent premature peeling.

34 30787 R1

Figure 3.11 Logo and Model Decal Locations

WHEATHEART - X13 SERIES AUGERS 3. ASSEMBLY

X1374, X1384, X1394 3.10. AUGER TUBE TRUSS ASSEMBLY

3.10. AUGER TUBE TRUSS ASSEMBLY

• X130-74 augers use a double cable truss on the top of the auger tube “X13074 Auger Tube Truss Assembly” on page 35).

• X130-84 and X130-94 augers use a combination of rigid tube trussing on top

of the auger tube and cable trussing on the sides of the auger tube (see

“X130-84/X130-94 Auger Tube Truss Assembly” on page 40).

3.10.1. X130-74 AUGER TUBE TRUSS ASSEMBLY

INSTALL THE X130-74 CABLE BRIDGES

See Table 3.7. for a list of part s required to install the X130-74 cable bridges.

See Figure 3.12 for a detailed diagram.

Table 3.7. Parts Required, Installing X130-74 Cable Bridges

Part Number Description Amount

20017 High truss tower

18988WH Low truss towers

20105 Truss cable attach bracket

18698 7/16” x 1-1/4” GR8 bolts

17593 7/16” locknut

1

2

1

8

8

1. Fasten the three truss towers to the provided brackets (welded to the

appropriate tube sections):

a. Position the high truss tower in the centre position, and position the low

truss towers toward the spout and intake ends.

b. Use two 7/16” x 1-1/4” GR8 bolts and 7/16” locknuts to fasten each cable

bridge in place.

2. Install the truss cable attach bracket as shown in the diagram, using two

7/16” x 1-1/4” GR8 bolts and 7/16” locknuts.

30787 R1 35

3. ASSEMBLY WHEATHEART - X13 SERIES AUGERS

TRUSS CABLE

HIGH TRUSS

LOW

ATTACH BRACKET

7/16” LOCKNUTS

7/16” X 1-1/4” BOLTS

7/16” X 1-1/4” BOLTS

7/16” LOCKNUTS

TRUSS TOWER

LOW

TRUSS TOWER

TOWER

3.10. AUGER TUBE TRUSS ASSEMBLY X1374, X1384, X13 94

Figure 3.12 X130-74 Truss Towers and Truss Cable Attach Brackets

36 30787 R1

WHEATHEART - X13 SERIES AUGERS 3. ASSEMBLY

X1374, X1384, X1394 3.10. AUGER TUBE TRUSS ASSEMBLY

INSTALL THE X130-74 TRUSS CABLES

There are two cable runs on the X130-74, a long cable run between the upper

tube and the lower tube, and a short cable run between the lower tube and the

upper middle tube:

• The first (short) run is made up of a single 73’ cable.

• The second (long) run is made up of two separate cables: one 85’ 6” long

and one 36’ long.

See Table 3.8. for a list of parts required to install the X130-74 truss cables. See

Figure 3.13 for a detailed diagram.

Table 3.8. Parts Required, X130-74 Truss Cables

Part Number Description Amount

27502 73’ cable 1

27503 85’ 6” cable 1

20090 36’ cable 1

17464 Turnbuckle 2

19331 1/2” eyebolts 6

18990 3/8” cable clamps 12

19333 5/16” cable clamps 10

17750 1/2” locknuts 6

Note: X130-74 truss cables should be tightened to provide a 1” upward bow in the

auger tube, as measured at the auger tube spout end.

1. Ensure that the tube is supported by at least 3 stands (one at each end and

one in the middle).

2. Shim the stands (use wood blocks) at the spout end approximately

7” (17.8 cm) higher than the other stands to provide the required curve.

3. For the first (short) cable run, attach an eyebolt to each end of the 73’ truss

cable using two 3/8” cable clamps, doubling-back about

12” (30.5 cm) of cable.

4. Connect one of the eyebolts to one side of the truss cable attach bracket

using a 1/2” locknut threaded fully onto the eyebolt shaft, but not further than

1/4”.

5. Pull the cable:

• over the high (middle) truss tower,

• under the tube and around the middle cable return bracket,

• back over the middle cable bridge,

• and back to the truss cable attach bracket

6. Connect the second eyebolt on the remaining end of the cable to the other

side of the truss cable attach bracket using a 1/2” locknut threaded fully onto

the eyebolt shaft, but not further than 1/4”.

7. For the second (long) cable run:

• Thread the 36’ cable through the cable guide on the underside of the

lower tube, and pull the cable through until there is an equal length of

cable on each side of the tube.

30787 R1 37

3. ASSEMBLY WHEATHEART - X13 SERIES AUGERS

3.10. AUGER TUBE TRUSS ASSEMBLY X1374, X1384, X13 94

• Attach eyebolts to the ends of the 36’ cable [20090] with two 3/8” cable

clamps [18990], using about 10" (25.4 cm) - 12" (30.5 cm) of cable.

Tighten securely.

• Insert each eyebolt into a separate turnbuckles, and secure by threading

on a 1/2” locknut fully onto the eyebolt shaft, but not further than 1/4”.

8. Starting at the lower tube, pull the 85’6” cable:

• over the low and high truss towers (fasten loosely with 5/16” cable

clamps)

• under the tube and around the cable return bracket at the upper tube (fasten loosely with a 5/16” cable clamp)

• back over the truss towers on the opposite side (fasten loosely with 5/16”

cable clamps), providing equal lengths of cable on both sides of the tube.

Important: The 85’ 6” cable must be installed on the outside of the high (middle) truss tower .

9. Insert an eyebolt into the unconnected side of each of the turnbuckles (whose

other sides are connected to the 36’ cable), and secure by threading on a 1/2”

locknut fully onto the eyebolt shaft, but not further than 1/4”.

10. Thread the end of each side of the 85’6” cable through the appropriate

turnbuckle eyebolt, and pull the cable snug. Double-back the cable and

secure in place with 2 cable clamps doubling-back about 12”

(30.5 cm) of cable.

Note: If there isn’t enough cable, loosen the clamps on the opposite eyebolt and adjust

the cable. Retighten clamps.

Important: Truss cables must be tightened to provide a 1” upward bow on the spout end.

Blocks and shims can be used to elevate the spout to help create the required

bow while tightening the truss cables, but the 1” bow is measured with the spout

end unsupported.

11. Tighten the eyebolts on the second (long) cable run evenly to take the

remaining slack out of the truss cable. Once this cable run is tightened,

repeat for the first (short) cable run.

12. Check for proper side-to-side alignment and then tighten the cable clamps on

the cable bridges and the cable return brackets.

38 30787 R1

WHEATHEART - X13 SERIES AUGERS 3. ASSEMBLY

1

/

2

”

L

O

C

K

N

U

T

E

Y

E

B

O

L

T

C

A

B

L

E

G

U

I

D

E

S

3

/

8

”

C

A

B

L

E

C

L

A

M

P

S

E

Y

E

B

O

L

T

S

T

U

R

N

B

U

C

K

L

E

3

/

8

”

C

A

B

L

E

C

L

A

M

P

S

C

A

B

L

E

R

E

T

U

R

N

5

/

1

6

”

C

A

B

L

E

C

L

A

M

P

B

R

A

C

K

E

T

7

3

’

C

A

B

L

E

8

5

’

6

”

C

A

B

L

E

5

/

1

6

”

C

A

B

L

E

C

L

A

M

P

S

5

/

1

6

”

C

A

B

L

E

C

L

A

M

P

3

6

’

C

A

B

L

E

X1374, X1384, X1394 3.10. AUGER TUBE TRUSS ASSEMBLY

Figure 3.13 X130-74 Truss Cable Installation

30787 R1 39

3. ASSEMBLY WHEATHEART - X13 SERIES AUGERS

3.10. AUGER TUBE TRUSS ASSEMBLY X1374, X1384, X13 94

3.10.2. X130-84/X130-94 AUGER TUBE TRUSS ASSEMBLY

INSTALL X130-84/X130-94 TRUSS TOWERS AND TRUSS TUBES

See Table 3.9. for a list of part s required to install the X130-84/X130-94 truss

towers and truss tubes, as well as for figure references that apply to the

diagrams below.

• For the X130-84 models, see Figure 3.14 and Figure 3.15.

• For the X130-94 models, see Figure 3.16 and Figure 3.17.

Note: Due to rigidity of the tubular trussing, X130-84 and X130-94 truss tubes should

be tightened to provide only a small upward bow (approximately 1”) at the auger

tube spout end.

Note: When assembling the truss system, do not fully tighten any bolts until specifi-

cally instructed to do so.

1. Attach p airs of low and high truss tower brackets to the truss-attach

brackets welded to auger tube, using four of 7/16” x 1-1/4” bolts and locknuts

per pair.

2. Thread a 1” hex nut as far as possible onto the threaded rod end of a long

adjuster tube.

3. Insert the threaded rod end of the long adjuster tube into the truss tube

anchor, and bolt the opposite end to a truss joiner plate that has been first

bolted to the adjacent low truss tower.

4. Thread an second 1” nut a short distance onto the threaded rod end of the

long adjuster tube.

5. Work from one end of the tube toward the centre and install:

a. Install tube truss joiner plates between truss tower pairs.

Note: Truss towers connect to their truss joiner plate using a 1/2” x 1-1/2” bolt and

locknut.

Note: T russ joiner plates must be oriented correctly when installed. Always ensure that

the three 7/16” bolt holes should be closest to the discharge spout, and the 5/8”

bolt hole should be closest to the boot.

b. long tubes between truss joiner plates bolted between high truss pairs;

Note: Truss tubes connect to truss joiner plates using three 7/16'' x 1-3/4'' bolts and

locknuts where there are three bolt holes on the end of the tube, and with a

single 5/8'' x 2'' bolt and locknut where there is a single bolt hole at the end of the

tube. A four-hole truss adjuster plate is required.

c. cross-brace tubes between truss joiner plates and tabs between truss

tower pairs (keep cross-brace bolts loose until Step 13.)

Note: A single cross-brace tube is positioned between the low truss towers and

adjacent high truss towers. Two cross braces tubes are required between two

adjacent

high truss towers.

Note: Cross-brace tubes use 1/2” x 1-1/2” bolts and locknuts at the truss joiner plate

and at the tab between truss tower pairs.

6. Install the tube adjust plate, and attach the short adjuster tube to it as follows:

a. bolt the tube adjust plate between the high truss tower bracket pair (see

the diagram for your specific model);

40 30787 R1

WHEATHEART - X13 SERIES AUGERS 3. ASSEMBLY

X1374, X1384, X1394 3.10. AUGER TUBE TRUSS ASSEMBLY

b. thread a 1” nut fully onto the threaded rod end of a short adjuster tube,

then insert threaded rod into the truss tube adjuster plate;

c. thread a second 1” nut a short distance onto the threaded rod.

7. Repeat the above process for the discharge side of the tube.

8. Ensure that the 1” nuts on the long and short adjuster tubes are loose. Pairs

of 1” nuts on adjuster tubes (short and long) should be rotated away from

each other to ensure that the nuts are not placing any tension on the truss

tubes or truss brackets.

9. Ensure that auger tube sections are supported in such a way that the tube is

as straight as possible. Use additional supports, shims, and blocks as

required.

10. Long adjust tubes:

• Rotate the 1" hex nut pairs on both long adjust tubes toward each other

until they lock together tightly on either side of their respective truss tube

anchors (spout end and boot end).

• When fully tightened, the truss tower brackets should remain positioned at

a 90 degree angle with respect to the auger tube, and should not lean to

either side.

11. Short adjust tubes:

• Tighten the two 1" hex nuts on the inside of the tube adjust plate until

there is enough tension in the truss tubes to create a slight upward bow in

the tube (1” as measured from the tube support and the top of the tube,

just before the tube cap).

• When tightening the nuts, alternate between the two nuts frequently

enough to ensure that they are tightened equally, and that the same

amount of threaded rod is exposed on each side.

• Rotate the remaining 1” nuts on the short adjuster tubes until they lock

tightly on each side of the tube adjust plate.

12. Install pairs of cross-brace clamps where the cross-brace tubes cross in an

“X” pattern using two 7/16” x 1-1/4” bolts and locknuts, and tighten fully.

13. Fully tighten cross-brace tube nuts at the truss joiner plates and at the tab

between truss tower pairs.

14. Check that all nuts are firmly tightened.

30787 R1 41

3. ASSEMBLY WHEATHEART - X13 SERIES AUGERS

3.10. AUGER TUBE TRUSS ASSEMBLY X1374, X1384, X13 94

Table 3.9. X130-84 and X130-94 Truss Towers and Tubes Parts Reference

Fig Ref Part # Part Description MKX130-84 MKX130-94

1 17459WH Low truss tower bracket 4 4

2 17460WH High truss tower bracket 10 12

3 20047WH Long adjuster tube 2 2

4 n/a Truss tube anchor 1 1

5 20341WH Truss joiner plate, triple 6 7

6 20337WH Truss tube 4 5

7 20078WH Cross-brace tube 6 8

8 17405 Cross-brace clamps 4 6

9 20036 Truss tube adjuster plate 7 7

10 20046 Short truss tube adjuster tube 2 2

11 20338 Four-hole truss adjuster plate 6 7

12 20080 1” nut 8 8

13

14

15

16

18698

17593

19981

17593

19991

19600

19589

17750

7/16” x 1-1/4” bolts

7/16” locknuts

7/16” x 1-3/4” bolts

7/16” locknuts

5/8” X 2” bolt

5/8” locknut

1/2'' X 1-1/2” bolt

1/2” locknut

32 36

18 21

6 7

18 22

42 30787 R1

WHEATHEART - X13 SERIES AUGERS 3. ASSEMBLY

1

2

2

2

2

2

1

13

13

X1374, X1384, X1394 3.10. AUGER TUBE TRUSS ASSEMBLY

Figure 3.14 X130-84 Truss Towers

30787 R1 43

3. ASSEMBLY WHEATHEART - X13 SERIES AUGERS

6

16

6

15

14

7

8

8

3

6

10

10

6

6

3

5

10

6

11

7

14

1

1

16

16

5

6

7

15

9

10

7

7

7

5

7

3

13

6

11

7

10

16

4

3

12

12

12

12

15

14

3.10. AUGER TUBE TRUSS ASSEMBLY X1374, X1384, X13 94

Figure 3.15 X130-84 Truss Tubes

44 30787 R1

WHEATHEART - X13 SERIES AUGERS 3. ASSEMBLY

1

2

2

2

2

2

1

2

13

13

X1374, X1384, X1394 3.10. AUGER TUBE TRUSS ASSEMBLY

Figure 3.16 X130-94 Truss Towers

30787 R1 45

3. ASSEMBLY WHEATHEART - X13 SERIES AUGERS

5

7

8

16

11

16

11

3

6

10

10

6

7

7

6

3

7

6

6

12

12

6

3

7

8

6

6

5

11

14

12

9

15

5

7

7

10

12

10

10

6

4

3

14

15

16

15

11

14

16

13

3.10. AUGER TUBE TRUSS ASSEMBLY X1374, X1384, X13 94

Figure 3.17 X130-94 Truss Tubes

46 30787 R1

WHEATHEART - X13 SERIES AUGERS 3. ASSEMBLY

X1374, X1384, X1394 3.10. AUGER TUBE TRUSS ASSEMBLY

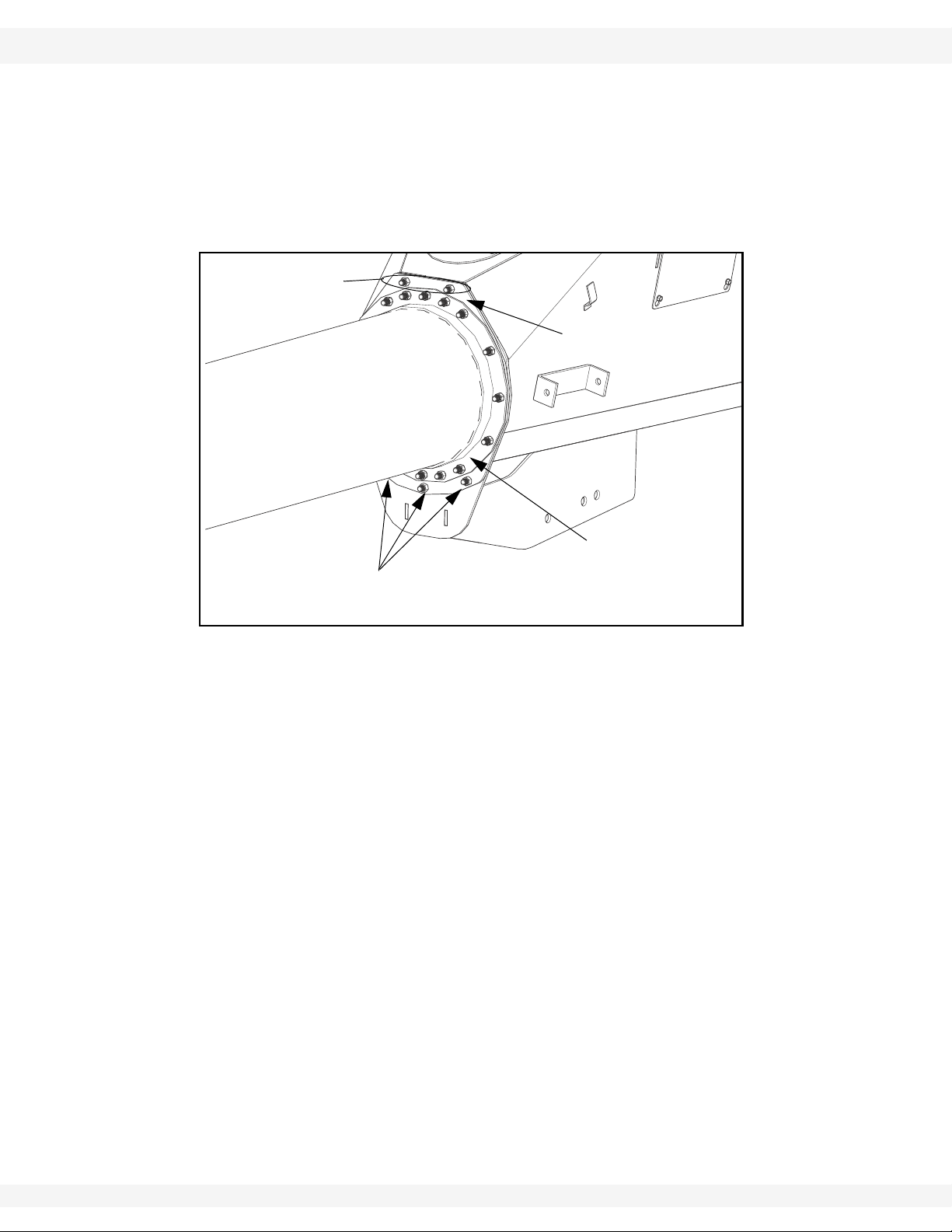

INSTALL X130-84/X130-94 CABLE TRUSSING

See Table 3.10. for a list of parts required to install the X130-84/X130-94 truss

cables, as well as for figure references that apply to the Figure 3.18 (X130-84

shown, X130-94 is similar).

1. Attach eyebolts to both ends of a truss cable with two 3/8” cable clamp s using

about 10" (25.4 cm) - 12" (30.5 cm) of cable. Tighten securely.

2. Thread the cable through the cable return bracket on the underside of the

lower tube, and pull the cable through until there is an equal length of cable

on each side of the tube. Secure the cable to the cable return bracket with a

5/16” cable clamp.

3. Insert the cable eyebolts into separate turnbuckle bodies and secure with 1/2”

locknuts threaded fully onto the eyebolt shaft, but not further than 1/4”.

4. Attach eyebolts to the unconnected ends of both turnbuckle bodies, and

secure with 1/2” locknuts threaded fully onto the eyebolt shaft, but not further

than 1/4”.

5. Thread the second cable through the cable return bracket on the underside of

the upper tube, and pull the cable through until there is an equal length of

cable on each side of the tube.

6. Pull the ends of both cables over the truss cable supports, loosely attaching

the truss cables to each truss cable support with a 5/16” cable clamps.

7. Thread the unconnected ends of the second cable through the unconnected

eyebolts on the turnbuckle bodies, pull tight, and then secure with two

3/8” cable clamps. Tighten securely.

8. Tighten the cables by adjusting the eyebolt locknuts. These cables must be

very tight.

9. Tighten the 5/16” cable clamps at the lower tube and upper tube cable return

brackets.

10. If the tube has a curve to one side, tighten the turnbuckle on the opposite

side, while loosening the other turnbuckle slightly if required.

11. Tighten the cable clamps on all cable supports and arms.

Table 3.10. Parts Required, X130-84 and X130-94 Truss Cables

Fig Ref Part # Part Description MKX130-84 MKX130-94

1

2 18990 3/8” cable clamp 8 8

3 20085 70’ Cable 2 2

4 n/a Lower tube cable return bracket 1 1

5 19333 5/16” cable clamp 16 18

6 17464 Turnbuckle 2 2

7 n/a Upper tube cable return bracket 1 1

8 n/a Truss cable supports 7 7

30787 R1 47

19331

17750

Eyebolt

1/2” locknut

4

4

4

4

3. ASSEMBLY WHEATHEART - X13 SERIES AUGERS

8

5

4

5

4

2

1

6

1

2

3

7

3

5

7

3.10. AUGER TUBE TRUSS ASSEMBLY X1374, X1384, X13 94

Figure 3.18 X130-84, X130-94 Truss Cables

48 30787 R1

WHEATHEART - X13 SERIES AUGERS 3. ASSEMBLY

X1374, X1384, X1394 3.11. ASSEMBLE THE AUGER FRAME

3.11. ASSEMBLE THE AUGER FRAME

Table 3.11. provides a list of parts required to assemble the auger frame.

Table 3.11. Parts Required, Assemble Auger Frame

X130-74 X130-84 X130-94 Description Amount

20035 20035 20035 3-piece axle 1

29912 29917 29922 Frame arm 2

29951 29951 29951 Stabilizer cross member 1

29954 29954 29954 Transport stand 1

20241 20241 20241 Scissor support 1

29914 29919 29924 Lower scissor 2

20049 20049 20049 Lower scissor attach pin 2

18097 18097 18097 1” rim washer 4

18098 18098 18098 1/4” x 1-3/4” cotter pin 4

29910 29910 29910 Bowtie 1

29911 29911 29911 Bowtie cross brace 1

29916 29921 29926 Upper scissor 1

20240 20240 20240 Transport rest 1

29929 29929 29929 Scissor pin 2

29962 29962 29962 Frame attach spacer 2

19975 19975 19975 3/8” x 1-1/4” bolt 4

17402 17402 17402 3/8” locknut 4

19589 19589 19589 1/2” x 1-1/2” bolt 22

19974 19974 19974 1/2 x 1-3/4” bolt 4

17750 17750 17750 1/2” locknut 26

19592 19592 19592 3/4” x 2” bolt 8

19601 19601 19601 3/4” locknut 8

19991 19991 19991 5/8” x 2” bolts 8

19600 19600 19600 5/8” locknuts 8

18698 18698 18698 7/16” x 1-1/4” bolt 2

17593 17593 17593 7/16” nut 2

n/a n/a n/a 4” wood blocks (2x4, similar) 2

30787 R1 49

3. ASSEMBLY WHEATHEART - X13 SERIES AUGERS

3.11. ASSEMBLE THE AUGER FRAME X1374, X1384, X1394

WARNING

Components are heavy and create a crushing

and pinching hazard if improperly handled. Be

sure to use proper hoisting equipment and

procedures, and ensure lifting apparatus is

secure. Lockout the lifting apparatus before

working around or under the raised

components. Failure to do so may cause

serious personal injury .

1. Ensure the workspace is clear and large enough to accommodate assembly

of the auger.

2. Lower the assembled 3-piece axle to the floor, supported on two 4" blocks

under each side, and positioned so that the lower frame arm flanges face

toward the assembly area.

3. Install frame arms on each side of the 3-piece axle:

a. Position frame arms so that the pin-flange ends are angled toward the

centre of the work area, and position the opposite ends (flanged, with bolt

holes) so that the frame arm flange bolt holes align with the 3-piece axle

bolt holes.

b. Use four 3/4'' x 2'' bolts and 3/4'' locknuts to connect each lower frame arm

to respective axle end flanges.

c. Support the frame arms along their length with 4” blocks.

4. Install the stabilizer cross member (bolt loosely, until tube is dropped into

place) using four 1/2'' x 1-1/2'' bolts and 1/2'' locknuts on each side.

5. Install the scissor rest (bolt loosely, until tube is dropped into place) using

1/2'' x 1-1/2'' bolts and 1/2'' locknuts.

6. Install the transport stand on the 3-piece axle using four 3/8'' x 1-1/4'' bolts

and 3/8'' locknuts for each tube. Ensure that the transport stand is oriented

as shown in the diagram.

50 30787 R1

WHEATHEART - X13 SERIES AUGERS 3. ASSEMBLY

3-PIECE AXLE

SCISSOR REST

TRANSPORT STAND

STABILIZER

1/2” X 1-1/2” BOLT

1/2” LOCKNUT

3/8” X 1-1/4” BOLTS

3/8” LOCKNUTS

3/4” X 2” BOLTS

3/4” LOCKNUTS

1/2” X 1-1/2” BOLTS

1/2” LOCKNUTS

CROSS MEMBER

F

R

A

M

E

A

R

M

F

R

A

M

E

A

R

M

X1374, X1384, X1394 3.11. ASSEMBLE THE AUGER FRAME

Figure 3.19 Assembling the Lower Frame Arms to the 3-Piece Axle

30787 R1 51

3. ASSEMBLY WHEATHEART - X13 SERIES AUGERS

1” SAE WASHER

1/4” X 1-3/4” COTTER PIN

LOWER SCISSOR

ATTACH PIN

1/4” X 1-3/4” COTTER PIN

1” SAE WASHER

LOWER SCISSOR

3.11. ASSEMBLE THE AUGER FRAME X1374, X1384, X1394

7. Elevate the frame arm with a support stand placed under the stabilizer cross

member, and place another support stand so it can be used to support the

bowtie end of the lower scissor arms as they are installed.

8. Lift the lower scissors into position, with the narrow ends positioned at the

pins flanges on the 3-piece axle, and the wide ends elevated on the support

stands. Use lower scissor attach pins to attach the narrow ends of the arms

to the flanges on the 3-piece axle, and secure each pin with a 1” SAE washer

and 1/4” x 1-3/4” cotter pin.

52 30787 R1

Figure 3.20 Installing the Lower Scissors

WHEATHEART - X13 SERIES AUGERS 3. ASSEMBLY

1/2” X 1-1/2” BOLT

5/8” LOCKNUTS

1/2” LOCKNUT

5/8” X 2” BOLTS

1/2” X 1-1/2”

1/2” LOCKNUT

BOWTIE

BOWTIE

CROSS BRACE

BOLT

X1374, X1384, X1394 3.11. ASSEMBLE THE AUGER FRAME

9. Lift the bowtie into place, and bolt it to the lower scissors with eight

5/8'' x 2'' bolts and 5/8'' locknuts per side. A steel punch may be necessary to

align bolt holes.

10. Install the bow tie cross-brace using four 1/2'' x 1-1/2'' bolts and 1/2''

locknuts.

30787 R1 53

Figure 3.21 Installing the Bowtie and Bowtie Cross-Brace

3. ASSEMBLY WHEATHEART - X13 SERIES AUGERS

1/2” LOCKNUTS

1/2” X 1-3/4” BOLTS

7/16” LOCKNUT

UPPER SCISSOR

SCISSOR PIN

SCISSOR

SUPPORT

7/16” X 1-1/4 BOLT

3.11. ASSEMBLE THE AUGER FRAME X1374, X1384, X1394

11. Install the upper scissor:

a. Install the scissor support on the upper scissor using 1/2'' x 1-3/4'' GR8

bolts and 1/2'' locknuts.

b. Lift and position the upper scissor with pin flanges aligned with pin flanges

of the bowtie.

c. Connect the upper scissor to the lower scissors with a greased scissor pin

inserted in each side of the bowtie.

d. Lock the scissor pins in place with 7/16'' x 1-1/4'' bolts and 7/16'' locknuts.

Figure 3.22 Attaching the Scissor Support and the Upper Scissor

54 30787 R1

WHEATHEART - X13 SERIES AUGERS 3. ASSEMBLY

1/2” X 1-1/2” BOLTS

1/2” LOCKNUTS

FRAME ATTACH SPACER

TUBE

ATTACH

BRACKET

X1374, X1384, X1394 3.11. ASSEMBLE THE AUGER FRAME

12. Use four 1/2 x 1-1/2 bolts and four 1/2” locknuts to loosely install four frame

attach spacers on the four upper and lower tube attach brackets (the sp acers

must be free to move during the tube installation process).

Note: The frame attach spacer bolts should remain loose until after the tube has been

installed on the frame, then tightened fully.

Figure 3.23 Installing Frame Attach Spacers on Tube Attach Brackets

13. Mount wheels to hubs on axle with 6 wheel bolts (See “Assemble Wheel

Hubs and Install Tires” on page 57.)

Note: Before installing the wheels check to make sure the hub and wheel mounting

surfaces are free from rust and debris.

14. Install tires, finger tighten the wheel bolts, and verify that the wheel is sitting

flush on the hub. Torque the wheel bolts to 80 ft-lb (±10 ft-lb) of torque while

using the appropriate criss-cross pattern, refer to the Appendix for specifications. If in doubt have a qualified tire repair service perform the required

maintenance.

15. Install hydraulic cylinders (See “Installing the Hydraulic Cylinders” on

page 56.)

30787 R1 55

3. ASSEMBLY WHEATHEART - X13 SERIES AUGERS

SECURE WITH 1” X 3-3/8” CYLINDER PINS

AND 1” EXTERNAL HITCH CLIPS

3.12. INSTALLING THE HYDRAULIC CYLINDERS X1374, X1384, X1394

3.12. INSTALLING THE HYDRAULIC CYLINDERS

1. Position the cylinders on the cylinder lugs. The rod end of the cylinder must

be attached to the bowtie so that the rod extends towards the intake (Figure

3.31).

Note: The cylinder ports must face each other.

2. Pin the cylinder in place using 1” x 3-3/8” cylinder pins and 1” external hitch

clips (see Figure 3.24).

Figure 3.24 Installing Hydraulic Cylinders

56 30787 R1

WHEATHEART - X13 SERIES AUGERS 3. ASSEMBLY

Figure 3.25 Wheel Hub Parts

X1374, X1384, X1394 3.13. ASSEMBLE WHEEL HUBS AND INSTALL TIRES

3.13. ASSEMBLE WHEEL HUBS AND INSTALL TIRES

For each axle extension (29961) and hub assembly (17013) pair:

1. Remove any dirt from spindle and hub.

2. Thoroughly pack wheel bearings and cups with a good grade of bearing

grease.

3. Place large bearing into hub and carefully tap in seal.

4. Slip hub onto the axle extension spindle and insert small bearing and washer.

5. Tighten slotted spindle nut until hub drags slightly. Back off nut about 1/4 turn

until hub turns freely.

6. Install cotter pin and dust cap.

Note: Installing tires may not leave you with enough clearance to position and attach

undercarriage once auger tube is raised. If so, install wheels after assembly is

complete.

7. Inflate tires to recommendations on tire side wall. Wheels may be mounted

on hubs at this time using 6 wheel bolts.

8. Raise the three-piece axle, fully insert the axle extension and wheel, and

secure the axle extension with an axle pin (20008) and a 7/16”-3/4”, 1/8” DIA

hairpin (19463).

30787 R1 57

3. ASSEMBLY WHEATHEART - X13 SERIES AUGERS

3.14. ATTACHING THE AUGER TUBE TO THE FRAME X1374, X1384, X1394

3.14. ATTACHING THE AUGER TUBE TO THE FRAME

Table 3.12. provides a list of parts required to attach the auger tube to the frame.

Table 3.12. Parts Required, Attaching the Auger Tube to the Frame

X130-74/84 X130-94 Description Amount

29950 29950 Stabilizer brackets 2

29952 29953 Stabilizer braces 2

29995 29995 1-3/4” x 19” lower frame attach pin 2

28584 28584 5/16” x 2-1/2” roll pin 4

20079 20079 1-3/4” x 18” upper scissor frame attach pin 2

28584 28584 5/16” x 2-1/2” roll pin 2

27589 27589 5/8” x 2-1/2” bolts 1

19991 19991 5/8” x 2” bolts 1

19600 19600 5/8” locknuts 2

WARNING

Components are heavy and create a crushing

and pinching hazard if improperly handled. Be

sure to use proper hoisting equipment and

procedures, and ensure lifting apparatus is

secure before working around or under the

raised components. Failure to do so may

cause serious personal injury.

1. Ensure that the four frame attach spacers are loosely installed on the upper

and lower tube attach brackets (see Figure 3.23).

2. Arrange a strong sling around the auger tube. Attach the sling to a crane,

block and tackle, or a front end loader, and lift the auger tube high enough to

remove the stands from underneath the auger.

3. Move tube over top of the assembled frame, ensuring that the tube is

centered on the scissor frame before proceeding.

4. Connect tube to the lower frame arms:

a. Lift the lower frame arms to align with the lower frame attach spacers.

b. Grease the 1-3/4" x 19" lower frame attach pin.

c. Insert stabilizer brackets between the lower frame arm and the tube frame

attach spacers, and insert them through the lower frame arm tube

connection flange holes, stabilizer brackets, and through the frame attach

spacers.

d. Secure the lower frame attach pin with 5/16" x 2-1/2" roll pins.

58 30787 R1

WHEATHEART - X13 SERIES AUGERS 3. ASSEMBLY

5/16” X 2-1/2” ROLL PIN

1-3/4” X 19” LOWER FRAME

ATTACH PIN

STABILIZER

BRACKETS

5/8” X 2” BOLT

5/8” LOCKNUT

5/8” X 2” BOLT

5/8” LOCKNUT

5/8” X 2-1/2” BOLT

5/8” LOCKNUT

X1374, X1384, X1394 3.14. ATTACHING THE AUGER TUBE TO THE FRAME

Figure 3.26 Inserting the Lower Frame Attach Pins

Figure 3.27 Stabilizer Braces (Installed)

5. Attach the two stabilizer braces between the Stabilizer brackets and the

stabilizer cross members as follows: use a 5/8" x 2" bolt [19991] and locknut

[19600] and a 5/8" x 2-1/2" bolt [27589] and locknut [19600] to connect the

stabilizer braces to the S tabilizer brackets, and connect the remaining ends of

the stabilizer braces to the stabilizer cross member (one on each side, using

30787 R1 59

the end flanges at the frame) with two 5/8" x 2" bolts and locknuts.

3. ASSEMBLY WHEATHEART - X13 SERIES AUGERS

1-3/4” X 18” UPPER SCISSOR

FRAME ATTACH PIN

5/16” X 2-1/2” ROLL PIN

[28584]

FRAME ATTACH SPACER

3.14. ATTACHING THE AUGER TUBE TO THE FRAME X1374, X1384, X1394

6. Connect tube to the scissor lift:

e. Adjust the tube height and frame position until the upper frame attach

spacers are aligned with the tube connection flange holes at the top of the

upper scissor arm.

f. Grease the 1-3/4" x18” upper scissor frame att ach pin, and insert it through

the upper scissor flange hole (one on either side), through the frame attach

spacer, and then through the frame spacer and upper scissor flange hole

on the opposite side.

g. Secure the upper scissor attach pins with two 5/16” x 2-1/2” roll pins.

h. Lower the scissor lift until it rests lightly on the frame.

60 30787 R1

Figure 3.28 Connecting Tube to the Scissor Lift

WHEATHEART - X13 SERIES AUGERS 3. ASSEMBLY

Note:

Important:

X1374, X1384, X1394 3.15. CONNECTING HYDRAULIC HOSE TO CYLINDERS

3.15. CONNECTING HYDRAULIC HOSE TO CYLINDERS

Table 3.13. provides a list of parts required to connect hydraulic hose to the lift

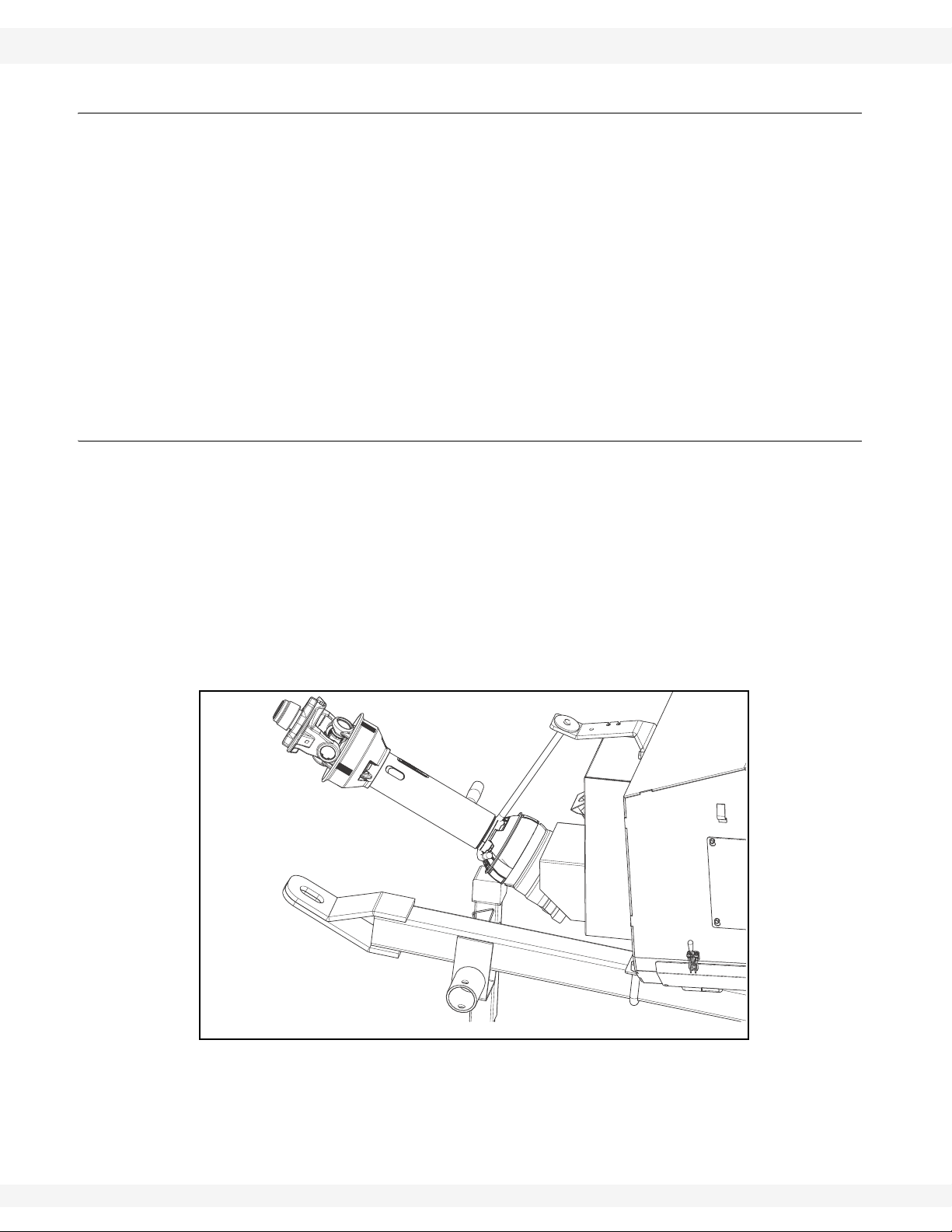

cylinders.