Wheatheart Livestock Waterer User Manual

LIVESTOCK WATERER

MODELS: H50, H50L, EH50, EEFH50, SH50, ESH50, C50, EC50, C100,

EC100, C200, EC200

OPERATION MANUAL

NRTL/C

|

|

|

INSTALLATION AND WIRING MUST |

|||

|

|

|

BE IN ACCORDANCE WITH CEC, NEC |

|||

|

|

|

AND LOCAL ELECTRICAL CODES |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Read this manual before using product. Failure |

Part Number: IM11 R1 |

|||

|

|

to follow instructions and safety precautions can |

Revised: 22/3/12 |

|||

|

|

result in serious injury, death, or property |

||||

|

|

damage. Keep manual for future reference. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

This product has been designed and constructed according to general engineering standardsa. Other local regulations may apply and must be followed by the operator. We strongly recommend that all personnel associated with this equipment be trained in the correct operational and safety procedures required for this product. Periodic reviews of this manual with all employees should be standard practice. For your convenience, we include this sign-off sheet so you can record your periodic reviews.

Date |

Employee Signature |

Employer Signature |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

a.Standards include organizations such as the American Society of Agricultural and Biological Engineers, American National Standards Institute, Canadian Standards Association, International Organization for Standardization, and/or others.

WHEATHEART - LIVESTOCK WATERER |

|

|

MODELS: H50, H50L, EH50, EEFH50, SH50, ESH50, C50, EC50, C100, EC100, C200, EC200 |

|

|

TABLE OF CONTENTS |

|

|

1. |

Introduction .......................................................................................................................... |

5 |

2. |

Safety First............................................................................................................................ |

7 |

|

2.1. General Safety ......................................................................................................... |

8 |

|

2.2. Installation Safety ..................................................................................................... |

9 |

|

2.3. Operational & Maintenance Safety........................................................................... |

9 |

|

2.4. Safety Decals ........................................................................................................... |

9 |

|

2.4.1. Decal Installation ........................................................................................ |

9 |

|

2.4.2. Safety Decal Locations............................................................................. |

10 |

3. |

Installation .......................................................................................................................... |

11 |

|

3.1. Location.................................................................................................................. |

11 |

|

3.2. Installation .............................................................................................................. |

11 |

|

3.3. Electrical Installation............................................................................................... |

13 |

4. |

Operation ............................................................................................................................ |

15 |

|

4.1. Thermostat Operation ............................................................................................ |

15 |

|

4.2. Water Level Adjustment ......................................................................................... |

15 |

5. |

Maintenance ....................................................................................................................... |

17 |

|

5.1. General................................................................................................................... |

17 |

|

5.2. De-Icing Waterer .................................................................................................... |

17 |

|

5.3. Thermostat Replacement ....................................................................................... |

17 |

|

5.4. Floating Lid Kit Installation (Optional)..................................................................... |

18 |

6. |

Troubleshooting ................................................................................................................. |

21 |

|

6.1. Heat Problems........................................................................................................ |

21 |

|

6.2. Water Problems...................................................................................................... |

22 |

7. |

Appendix............................................................................................................................. |

23 |

|

7.1. Waterer Parts List................................................................................................... |

23 |

|

7.2. Waterer Specifications ........................................................................................... |

25 |

Warranty.................................................................................................................................. |

27 |

|

IM11 R1 |

3 |

WHEATHEART - LIVESTOCK WATERER

MODELS: H50, H50L, EH50, EEFH50, SH50, ESH50, C50, EC50, C100, EC100, C200, EC200

4 |

IM11 R1 |

WHEATHEART - LIVESTOCK WATERER |

1. INTRODUCTION |

MODELS: H50, H50L, EH50, EEFH50, SH50, ESH50, C50, EC50, C100, EC100, C200, EC200 |

|

1. Introduction

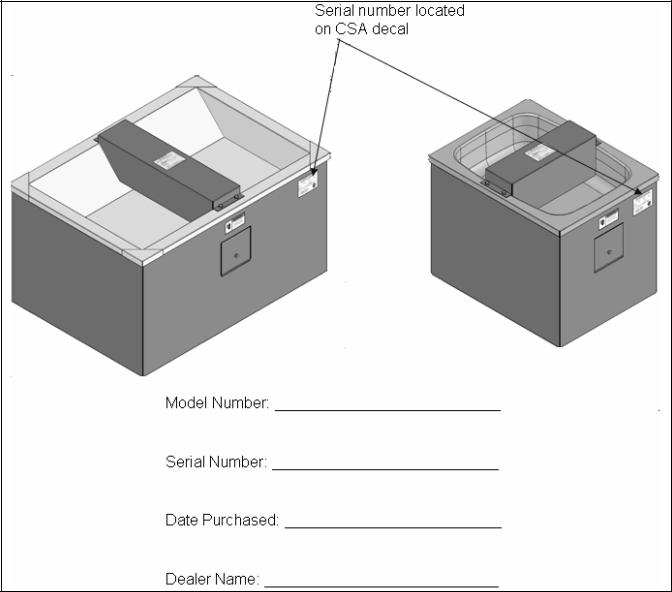

Thank you for your purchase. This CSA approved unit is designed to provide water to livestock in virtually any farm environment, and is built with heavy gauge steel and a durable powder coat finish.

Safe, efficient, and trouble-free operation of your waterer requires that you, and anyone else who will be involved with this unit, read and understand all safety instructions and procedures contained within this manual. A sign-off form is provided on the inside front cover for your convenience.

Keep this manual handy for frequent reference and to review with new personnel. Call your local distributor or dealer if you need assistance, information, or additional copies of the manual.

IM11 R1 |

5 |

1. INTRODUCTION |

WHEATHEART - LIVESTOCK WATERER |

|

MODELS: H50, H50L, EH50, EEFH50, SH50, ESH50, C50, EC50, C100, EC100, C200, EC200 |

6 |

IM11 R1 |

WHEATHEART - LIVESTOCK WATERER |

2. SAFETY FIRST |

MODELS: H50, H50L, EH50, EEFH50, SH50, ESH50, C50, EC50, C100, EC100, C200, EC200 |

|

2. Safety First

The Safety Alert symbol to the left identifies important safety messages on the product and in the manual. When you see this symbol, be alert to the possibility of personal injury or death. Follow the instructions in the safety messages. Why is SAFETY important to you?

Three big reasons:

•Accidents disable and kill.

•Accidents cost.

•Accidents can be avoided.

SIGNAL WORDS

Note the use of the signal words DANGER, WARNING, CAUTION, and NOTICE with the safety messages. The appropriate signal word for each message has been selected using the definitions below as a guideline.

The Safety Alert symbol means: “ATTENTION, BE ALERT! YOUR SAFETY IS INVOLVED”.

DANGER

Indicates an imminently hazardous situation that, if not avoided, will result in serious injury or death.

WARNING

Indicates a hazardous situation that, if not avoided, could result in serious injury or death.

CAUTION

Indicates a hazardous situation that, if not avoided, may result in minor or moderate injury.

NOTICE

Indicates a potentially hazardous situation that, if not avoided, may result in property damage.

IM11 R1 |

7 |

2. SAFETY FIRST |

WHEATHEART - LIVESTOCK WATERER |

|

MODELS: H50, H50L, EH50, EEFH50, SH50, ESH50, C50, EC50, C100, EC100, C200, EC200 |

2.1. GENERAL SAFETY

Important: This general safety section includes instructions that apply to all safety practices. Any instructions specific to a certain safety practice (e.g., assembly safety), can be found in the appropriate section. Always read the complete instructional sections and not just these safety summaries before doing anything with the equipment.

YOU are responsible for the SAFE use and maintenance of your equipment. YOU must ensure that you and anyone else who is going to work around the equipment understands all procedures and related SAFETY information contained in this manual.

Remember, YOU are the key to safety. Good safety practices not only protect you, but also the people around you. Make these practices a working part of your safety program.

•It is the equipment owner and the operator's responsibility to read and understand ALL safety instructions, safety decals, and manuals and follow them before assembling, operating, or maintaining the equipment. All accidents can be avoided.

•Equipment owners must give instructions and review the information initially and annually with all personnel before allowing them to operate this product. Untrained users/operators expose themselves and bystanders to possible serious injury or death.

•Use this equipment for its intended purposes only.

•Do not modify the equipment in any way. Unauthorized modification may impair the function and/or safety, and could affect the life of the equipment.

Any modification to the equipment voids the warranty.

•Do not allow children, spectators, or bystanders within the work area.

•Have a first-aid kit available for use should the need arise, and know how to use it.

•Provide a fire extinguisher for use in case of an accident. Store in a highly visible and accessible place.

•Wear appropriate protective gear. This list includes, but is not limited to:

•a hard hat

•gloves

•protective shoes with slip-resistant soles

•protective goggles

•hearing protection

•dust mask or respirator

•For Powered Equipment: before servicing, adjusting, or repairing powered equipment, unplug, place all controls in neutral or off position, stop the engine or motor, remove ignition key or lock out power source, and wait for all moving parts to stop.

8 |

IM11 R1 |

WHEATHEART - LIVESTOCK WATERER |

2. SAFETY FIRST |

MODELS: H50, H50L, EH50, EEFH50, SH50, ESH50, C50, EC50, C100, EC100, C200, EC200 |

|

•Follow good shop practices:

•keep service area clean and dry

•be sure electrical outlets and tools are properly grounded

•use adequate light for the job at hand

•Think SAFETY! Work SAFELY!

2.2.INSTALLATION SAFETY

•Check all equipment for damage immediately upon arrival. Do not attempt to install a damaged item.

•Have 2 people handle the heavy, bulky components.

2.3.OPERATIONAL & MAINTENANCE SAFETY

•Ensure that electrical cords are in good condition; replace if necessary.

•Ensure the fan inlet is not plugged with any foreign material.

•Keep inlet screen in place at all times.

•Before resuming work, install and secure all guards. Keep guards in good working order.

•Ensure parts are in good condition and installed properly.

2.4.SAFETY DECALS

•Keep safety decals clean and legible at all times.

•Replace safety decals that are missing or have become illegible. See decal location figures that follow.

•Replaced parts must display the same decal(s) as the original part.

•Safety decals are available from your distributor, dealer, or factory.

2.4.1.DECAL INSTALLATION

1.Decal area must be clean and dry, with a temperature above 50°F (10°C).

2.Decide on the exact position before you remove the backing paper.

3.Align the decal over the specified area and carefully press the small portion with the exposed sticky backing in place.

4.Slowly peel back the remaining paper and carefully smooth the remaining portion of the decal in place.

5.Small air pockets can be pierced with a pin and smoothed out using the sign backing paper.

IM11 R1 |

9 |

Loading...

Loading...