Part Number: 30875 R0

Revised: 25/4/2014

Read this manual before using product. Failure

to follow instructions and safety precautions can

result in serious injury, death, or property

damage. Keep manual for future reference.

GRAIN AUGERS

X160-85/105/125

ASSEMBLY & OPERATION

This product has been designed and constructed according to general engineering

standardsa. Other local regulations may apply and must be followed by the operator.

We strongly recommend that all personnel associated with this equipment be trained

in the correct operational and safety procedures required for this product. Periodic

reviews of this manual with all employees should be standard practice. For your

convenience, we include this sign-off sheet so you can record your periodic reviews.

Date Employee Signature Employer Signature

a. Standards include organizations such as the American Society of Agricultural and Biological Engineers,

American National Standards Institute, Canadian Standards Association, International Organization for

Standardization, EN Standards, and/or others.

HEATHEART GRAIN AUGERS

W

X160-85, X160-105, X160-125

TABLE OF CONTENTS

1. Introduction .......................................................................................................................... 7

1.1. Overview .................................................................................................................. 8

1.1.1. Grain Transfer Boot and PTO Driveline...................................................... 9

1.1.2. Grain Hopper ............................................................................................ 10

1.1.3. Auger Tube Hydraulic Lift ......................................................................... 12

2. Safety .................................................................................................................................. 13

2.1. General Safety Information .................................................................................... 13

2.2. Assembly Safety..................................................................................................... 14

2.3. Operation Safety .................................................................................................... 15

2.4. PTO Safety............................................................................................................. 17

2.5. Hydraulic Safety ..................................................................................................... 17

2.6. Transport & Placement Safety ............................................................................... 18

2.7. Maintenance Safety................................................................................................ 18

2.8. Safety Decals ......................................................................................................... 19

2.8.1. Decal Installation/Replacement ................................................................ 19

2.8.2. Safety Decal Locations............................................................................. 19

2.8.3. Safety Decal Detail ................................................................................... 26

3. Assembly ............................................................................................................................ 35

3.1. General Assembly .................................................................................................. 35

3.2. Assemble the Auger Tube...................................................................................... 37

3.2.1. Identify and Arrange Auger Tube Sections............................................... 37

3.2.2. Connect Auger Tubes ............................................................................. 40

3.2.3. Install the Hydraulic Lift Cylinders ............................................................ 42

3.2.4. Install the Track Shoe and Track Stop ..................................................... 46

3.2.5. Install the Boot on the Auger Tube ........................................................... 47

3.2.6. Assemble the PTO Shield Assembly........................................................ 49

3.2.7. Install the Speed Reducer on the Boot..................................................... 50

3.2.8. Install the Boot Tow Bar ........................................................................... 53

3.2.9. Install the Discharge Spout....................................................................... 54

3.2.10. Set the Thrust Adjuster........................................................................... 55

3.2.11. Apply Logo and Model Decals on the Auger Tubes ............................... 56

3.3. Install Truss Support Towers and Truss Tubes...................................................... 58

3.4. Install Truss Cables................................................................................................

66

3.5. Assemble the Lower Frame ................................................................................... 68

3.6. Assemble the Wheel Hub and Install Tires ............................................................ 70

30875 R0 3

W

X160-85, X160-105, X160-125

TABLE OF CONTENTS

3.7. Connect the Auger Tube to the Frame ................................................................... 71

3.8. Install Lift Cylinder Cables to the Track shoe ........................................................ 74

3.9. Connect Hydraulic Hoses and Ball Valve ............................................................... 76

3.10. Connect the PTO Driveline................................................................................... 82

3.11. Connect the Intake Hopper to the Swing Tube..................................................... 83

3.12. Connect the Spout Head to the Grain Transfer Boot............................................ 87

3.13. Install the Hopper Lift Arm .................................................................................... 89

3.14. Install the Hydraulic Winch ................................................................................... 90

3.15. Power Swing Assembly ........................................................................................ 93

3.15.1. Connect the Lower Clamp to the Power Swing ...................................... 94

3.15.2. Connect the Wheels on the Power Swing .............................................. 94

3.15.3. Connect the Power Swing Wheel Assembly to the Tube ....................... 95

3.15.4. Connecting the Power Swing Wiring ...................................................... 96

3.16. Install the Hitch Jack ............................................................................................ 99

3.17. Install the Manual Container............................................................................... 100

3.18. Auger-to-Tractor Hookup.................................................................................... 101

HEATHEART GRAIN AUGERS

4. Transport........................................................................................................................... 103

4.1. Transport Position ................................................................................................ 103

5. Placement ......................................................................................................................... 107

5.1. Placement Procedure ........................................................................................... 107

6. Operation .......................................................................................................................... 113

6.1. Operator Controls ................................................................................................. 113

6.2. Pre-Operation ....................................................................................................... 115

6.2.1. Checklist ................................................................................................. 115

6.2.2. PTO Drive ............................................................................................... 116

6.2.3. Hydraulics ............................................................................................... 116

6.2.4. Electric Power Swing Operation ............................................................. 117

6.3. Operating Procedures .......................................................................................... 118

6.3.1. Initial Start-Up ......................................................................................... 119

6.3.2. Normal Start............................................................................................ 120

6.3.3. Normal Shutdown ................................................................................... 121

6.3.4. Emergency Stop / Full-Tube Restart ...................................................... 122

6.3.5. Lowering & Completion........................................................................... 122

6.3.6. Operation in Reverse.............................................................................. 123

4 30875 R0

HEATHEART GRAIN AUGERS

W

X160-85, X160-105, X160-125

7. Maintenance and Storage................................................................................................ 125

7.1. Maintenance Intervals .......................................................................................... 125

7.2. Fluids and Lubricants ........................................................................................... 126

7.3. Maintenance Procedures ..................................................................................... 126

7.3.1. Visual Inspection .................................................................................... 126

7.3.2. Hydraulic Hose and Coupler Inspection ................................................. 127

7.3.3. Machine Greasing .................................................................................. 127

7.3.4. Hopper Lift Cable Inspection .................................................................. 129

7.3.5. Winch and Pulley Servicing .................................................................... 130

7.3.6. Gearbox Coupling Shaft Servicing ......................................................... 130

7.3.7. Hopper Chain Drive Servicing ................................................................ 131

7.3.8. Gearbox Oil Level................................................................................... 132

7.3.9. Machine Cleaning................................................................................... 132

7.3.10. Tire Pressure Check............................................................................. 132

7.3.11. Wheel Bearings Repack ....................................................................... 132

7.3.12. Wheel Bolt Tightening .......................................................................... 133

7.3.13. Truss Cable Adjustment ....................................................................... 133

7.3.14. Changing Gearbox Oil .......................................................................... 134

7.4. Storage................................................................................................................. 134

7.5. Power Swing ........................................................................................................ 135

7.5.1. Power Swing Maintenance ..................................................................... 135

7.5.2. Power Swing Storage ............................................................................ 135

8. T roubleshooting............................................................................................................... 137

9. Appendix........................................................................................................................... 139

9.1. Specifications ....................................................................................................... 139

9.2. Bolt Torque Values............................................................................................... 140

9.3. Remote Transmitter Instructions .......................................................................... 142

Warranty................................................................................................................................ 145

30875 R0 5

W

X160-85, X160-105, X160-125

HEATHEART GRAIN AUGERS

6 30875 R0

WHEATHEART - GRAIN AUGERS 1. INTRODUCTION

X160-85, X160-105, X160-125

1.Introduction

Thank you for purchasing a Wheatheart grain auger. Before using, please read

this manual and understand the various features of the equipment and precautions for efficient and safe operation.

Keep this manual handy for frequent reference and to review with new

personnel. A sign-off form is supplied on the inside front cover to record your

safety reviews. Call your local distributor or dealer if you need assistance or

additional information.

This manual should be regarded as part of the equipment. Suppliers of both new

and second-hand equipment are advised to retain documentary evidence that

this manual was provided with the machine.

Serial Number:

*Serial number is located on the lower tube.

30875 R0 7

1. INTRODUCTION WHEATHEART - GRAIN AUGERS

X160-85, X160-105, X160-125

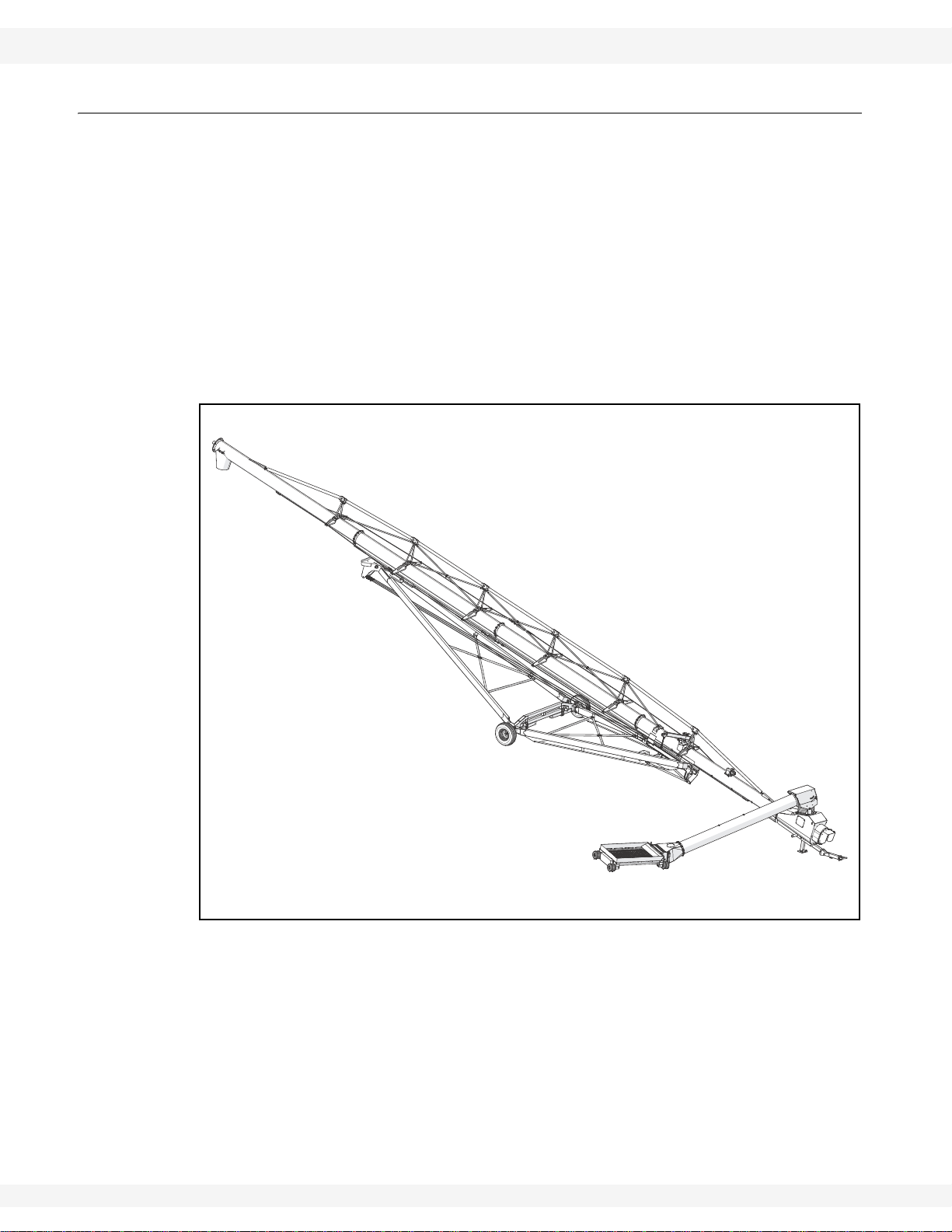

1.1. OVERVIEW

X160 augers are equipped with the following standard features:

• a high-capacity grain transfer boot

• a PTO driveline for auger power.

• a hydraulically controlled main auger tube lift

• a low-profile grain hopper (left or right side operation)

• a hydraulic winch for lifting the intake hopper

• an electric power swing for intake hopper

• a 1000 RPM PTO Drive (with forward and reverse auger direction capability)

Figure 1.1 X160 Series Auger (85’ model shown)

8 30875 R0

WHEATHEART - GRAIN AUGERS 1. INTRODUCTION

SPOUT HEAD

SPOUT HEAD SERVICE COVER

PTO DRIVELINE

HITCH

CLEAN-OUT HATCH

GRAIN TRANSFER BOOT

JACK

AUGER TUBE

LIFT VALVE

SPOUT HEAD

OVERFLOW PANEL

HITCH ANGLE

ADJUSTER

X160-85, X160-105, X160-125

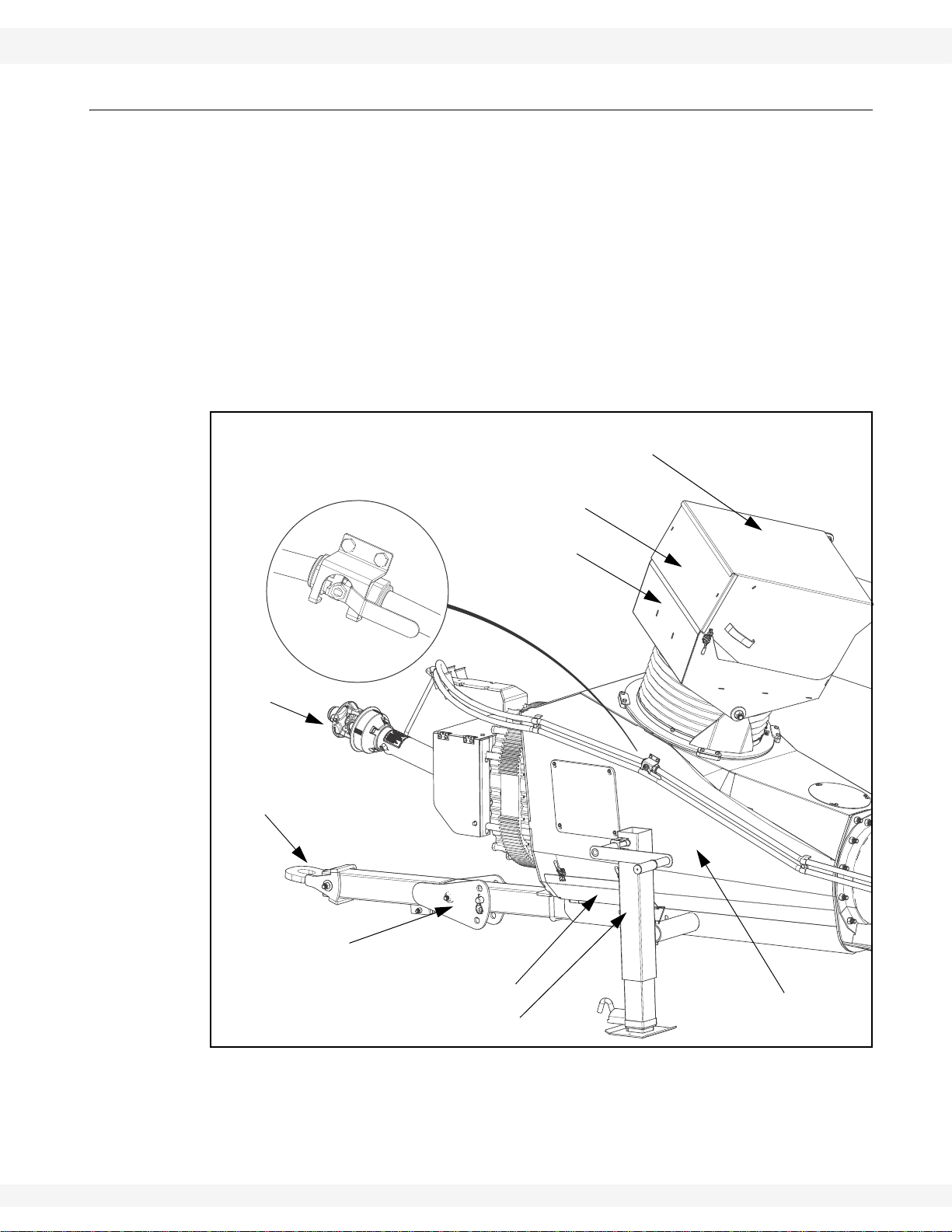

1.1.1. GRAIN TRANSFER BOOT AND PTO DRIVELINE

The grain transfer boot is located at the bottom of the main auger tube, and

contains gearing for power transfer as well as flights for transferring grain.

The power source for the auger is a standard 1000 RPM tractor PTO. The PTO

driveline connections (both forward and reverse directions) are located on the

speed reducer gearbox above the tractor hitch.

The auger tube lift valve used to allow or shut off hydraulic pressure to the main

auger tube lift cylinders, and is located on the side of the boot (see figure below).

See section 6.1. for further information on auger controls.

Several access hatches are provided for maintenance and repair, as well as an

overflow panel on the swing-arm spout head and a clean-out hatch at the bottom

of the boot.

Figure 1.2 Grain Transfer Boot Features

30875 R0 9

1. INTRODUCTION WHEATHEART - GRAIN AUGERS

X160-85, X160-105, X160-125

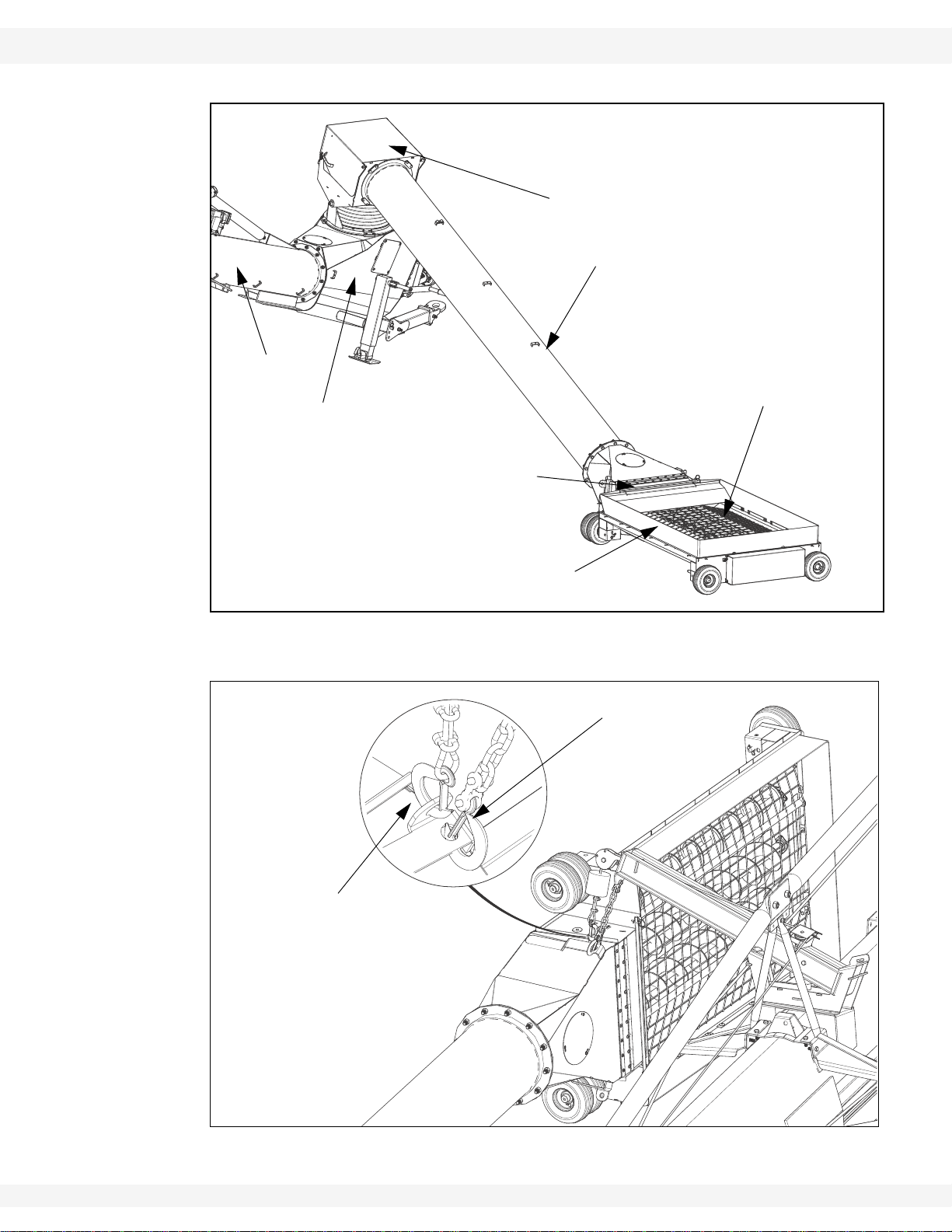

1.1.2. GRAIN HOPPER

The low-profile grain hopper is designed to be rolled into position to receive grain

for transfer through the boot to the auger discharge spout. Ground clearance can

be adjusted by raising or lowering the position of the hopper wheel axles (see

“Connect the Intake Hopper to the Swing Tube” on page 83).

The grain hopper must be lifted and secured for transport using the hopper lift

arm, hydraulic winch, and transport chain and hook (see Figure 1.4).The hopper

lift arm can be reconfigured for lifting on either side of the auger.

Do not approach, open or close the maintenance hatch located on the transition

between the swing are tube and the hopper unless all power to the auger is

locked out.

DANGER

Rotating Auger Hazard

Contact with rotating flighting will result in

amputation or severe laceration.

DO NOT operate with guards removed or

modified.

Keep hands and feet away from rotating

auger.

Tie up long hair and remove jewellery.

DO NOT wear loose-fitting clothing or items

that could become caught.

Shut off and lock out the power source before

unplugging or cleaning.

10 30875 R0

WHEATHEART - GRAIN AUGERS 1. INTRODUCTION

CLEANOUT HATCH

FLIGHTS AND FLIGHT GUARDING

INTAKE HOPPER

SWING ARM

SPOUT HEAD

BOOT

MAIN AUGER

TUBE

SAFETY CHAIN

AND HOOK

WINCH CHAIN

AND HOOK

X160-85, X160-105, X160-125

Figure 1.3 Grain Hopper

Figure 1.4 Grain Hopper Lifted into Transport Position

30875 R0 11

1. INTRODUCTION WHEATHEART - GRAIN AUGERS

X160-85, X160-105, X160-125

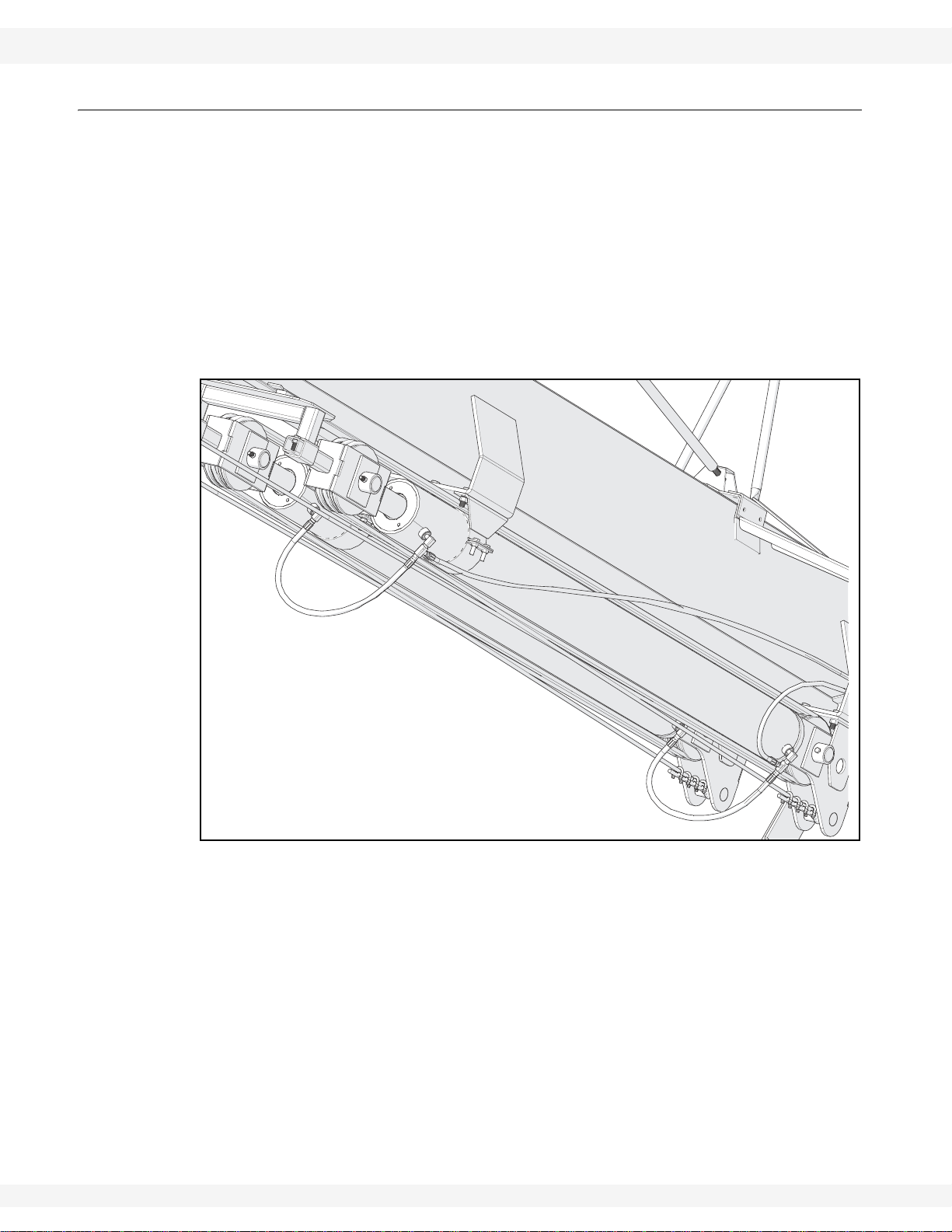

1.1.3. AUGER TUBE HYDRAULIC LIFT

The auger tube is raised and lowered using single-acting hydraulic cylinders

powered by the hydraulic supply of the connected tractor. The main auger tube is

raised by extending the cylinders, and lowered by allowing the cylinders to

retract. (see Figure 1.5).

A hydraulic ball valve mounted on the side of the grain pick-up boot controls flow

of hydraulic fluid to the lift cylinders, and with appropriate use of the hydraulic

controls on the connected tractor, allows the main auger tube to be raised,

lowered, or locked at a specific height during operation (see “Operator Controls”

on page 113).

Figure 1.5 Auger Tube Hydraulic Lift Cylinders

12 30875 R0

WHEATHEART - GRAIN AUGERS 2. SAFETY

X160-85, X160-105, X160-125

2.Safety

2.1. GENERAL SAFETY INFORMATION

The Safety Alert symbol identifies important safety messages on the product and

in the manual. When you see this symbol, be alert to the possibility of personal

injury or death. Follow the instructions in the safety messages.

Why is SAFETY important?

• Accidents disable and kill.

• Accidents cost.

• Accidents can be avoided.

SIGNAL WORDS: Note the use of the signal words DANGER, WARNING,

CAUTION, and NOTICE with the safety messages. The appropriate signal word

for each message has been selected using the definitions below as a guideline.

DANGER

Indicates an imminently hazardous situation

that, if not avoided, will result in serious injury

or death.

WARNING

Indicates a hazardous situation that, if not

avoided, could result in serious injury or

death.

CAUTION

Indicates a hazardous situation that, if not

avoided, may result in minor or moderate

injury.

NOTICE

Indicates a potentially hazardous situation that, if not

avoided, may result in property damage.

30875 R0 13

2. SAFETY WHEATHEART - GRAIN AUGERS

X160-85, X160-105, X160-125

YOU are responsible for the SAFE use and maintenance of your equipment.

YOU must ensure that you and anyone else who is going to work around the

equipment understands all procedures and related SAFETY information

contained in this manual.

Remember, YOU are the key to safety. Good safety practices not only protect

you, but also the people around you. Make these practices a working part of your

safety program.

Important: Below are general instructions that apply to all safety practices. Any instructions

specific to a certain safety practice (e.g., Operational Safety), can be found in the

appropriate section. Always read the complete instructional sections and not just

these safety summaries before doing anything with the equipment.

• It is the equipment owner, operator, and maintenance personnel's responsi-

bility to read and understand ALL safety instructions, safety decals, and man-

uals and follow them when assembling, operating, or maintaining the

equipment. All accidents can be avoided.

• Equipment owners must give instructions and review the information initially

and annually with all personnel before allowing them to operate this product.

Untrained users/operators expose themselves and bystanders to possible

serious injury or death.

• Use this equipment for its intended purposes only.

• Do not modify the equipment in any way without written permission from the

manufacturer. Unauthorized modification may impair the function and/or

safety, and could affect the life of the equipment. Any unauthorized modification of the equipment voids the warranty.

• Do not allow any unauthorized person in the work area.

2.2. ASSEMBLY SAFETY

• Read and understand the instructions to get to know the sub-assemblies and

hardware that make up the equipment before preceding to assemble the

product.

• Do not take chances with safety. The components are large, heavy, and can

be hard to handle. Always use the proper tools, stands, jacks, and hoists for

the job.

• Read and understand assembly instructions before proceeding to assemble

the product.

• Always have two or more people assembling the equipment. Because of the

weight, do not attempt assembly alone.

14 30875 R0

WHEATHEART - GRAIN AUGERS 2. SAFETY

X160-85, X160-105, X160-125

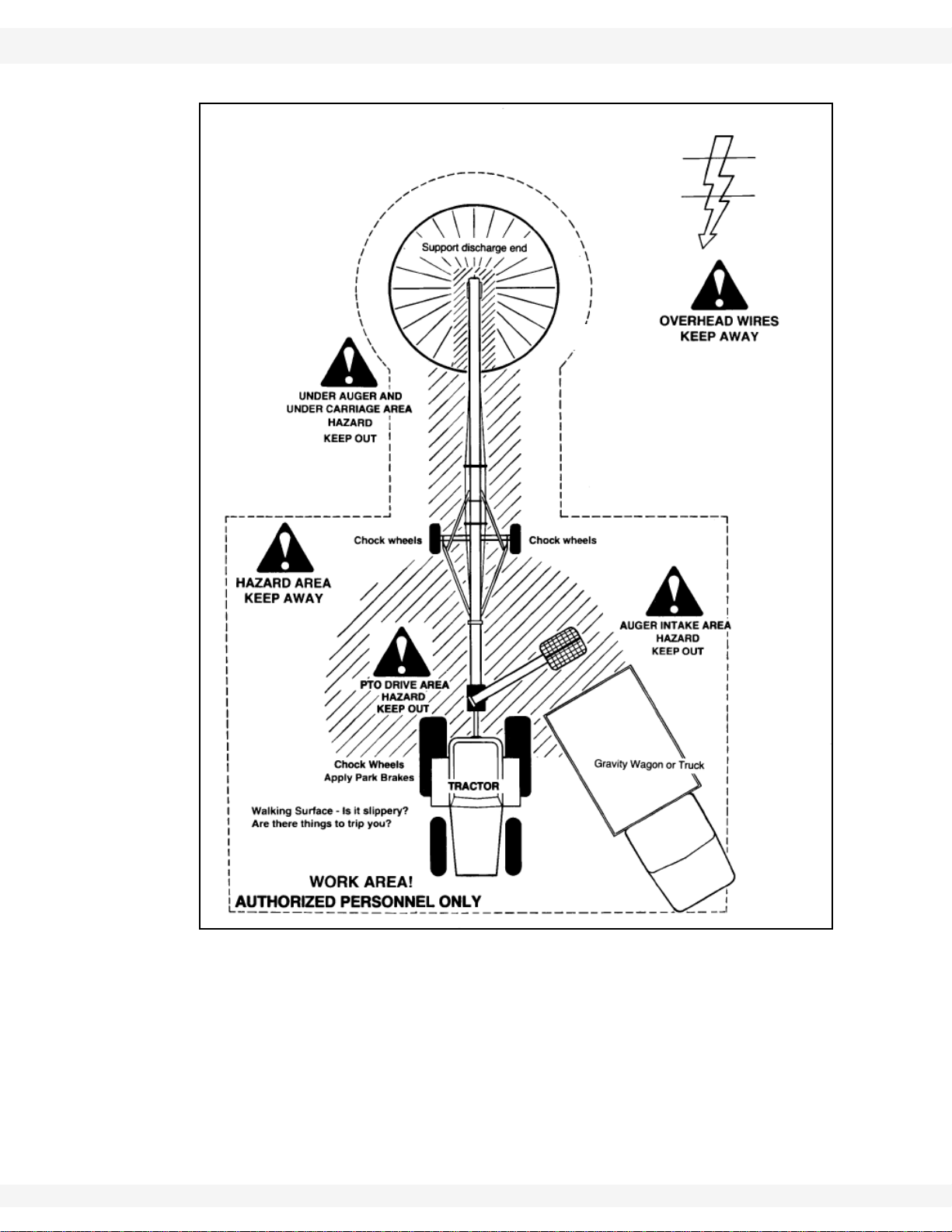

2.3. OPERATION SAFETY

• Have another trained person nearby who can shut down the auger in case of

accident. Always work with a second trained person around augers.

• Do not operate with any of the safety guards removed.

• Keep body, hair, and clothing away from moving parts. Stay away from intake

during operation.

• Inspect lift cable before using auger. Replace if frayed or damaged. Make

sure it is seated properly in cable sheaves and cable clamps are secure.

• Operate auger on level ground free of debris. If ground is uneven, anchor the

auger to prevent tipping or upending.

• Augers are not insulated. Keep away from electrical lines. Electrocution can

occur without direct contact.

• Support the discharge end and/or anchor the intake end before operating to

prevent upending.

• Do not use auger as a hoist.

• Empty auger before raising or lowering.

• Lower auger at completion of operation or when not in use. Auger could drop

rapidly in case of cable break or hydraulic failure (where applicable).

• Keep the work area clean and tidy.

• Do not get on or beneath auger when raising or lowering intake hitch jack, or

when auger is supported by hitch jack.

• Do not operate auger with the service or clean-out doors open or unlatched.

30875 R0 15

2. SAFETY WHEATHEART - GRAIN AUGERS

BIN

X160-85, X160-105, X160-125

Figure 2.1 Operational Safety, Work Areas

16 30875 R0

WHEATHEART - GRAIN AUGERS 2. SAFETY

X160-85, X160-105, X160-125

2.4. PTO SAFETY

• Never use a PTO driveline without a rotating shield in good working order.

• Ensure PTO driveline is securely attached at both ends before operating.

• Before starting tractor, turn power to PTO to the off position (where applicable).

• Keep body, hair, and clothing away from rotating PTO driveline.

• Ensure the PTO driveline shields turn freely on the PTO driveline.

• Do not exceed PTO operating speed of 1000 rpm.

• Keep u-joint angles small and equal. Do not exceed recommended operating

length for PTO driveline.

2.5. HYDRAULIC SAFETY

• Wear proper hand and face protection when searching for hydraulic leaks.

Escaping fluid under pressure can penetrate the skin, causing serious injury

like gangrene. In case of accident, see a doctor immediately.

• Fluid leaks in the hydraulic lift cylinders or hoses will allow the auger to lower

inadvertently. Repair all leaks and breaks immediately. Rupture could cause

damage and/or personal injury.

• A hydraulic lift is faster than a conventional hand crank—always clear area of

personnel before raising or lowering.

• Do not disconnect hydraulic couplers when hydraulic system is pressurized.

For the correct procedure, consult this manual or your tractor manual.

• Relieve pressure before unhooking hydraulic lines.

• Inspect hydraulic fittings and hoses for damage on a daily basis. Repair if

damaged.

• Ensure that the hydraulic line(s) is (are) properly connected and secure.

• Keep hydraulic line(s) away from moving parts.

• Clean connections before connecting to equipment.

30875 R0 17

2. SAFETY WHEATHEART - GRAIN AUGERS

X160-85, X160-105, X160-125

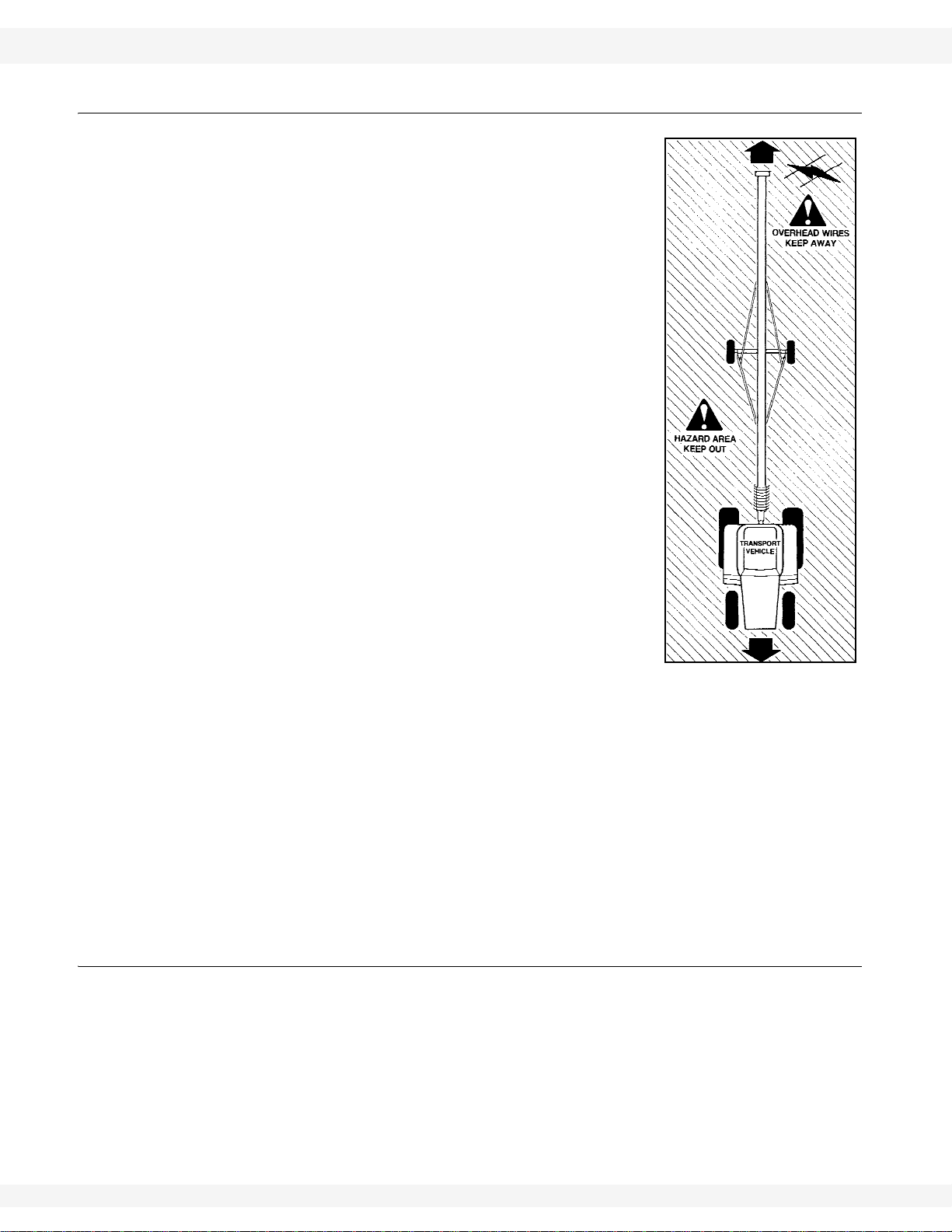

2.6. TRANSPORT & PLACEMENT SAFETY

• Transport auger in full down position with slight tension on cable.

• Properly place hitch pin and securely attach safety

chain. Use a type of hitch pin that will not allow

auger to separate from towing vehicle.

• Always attach an SMV (slow moving vehicle) sign

before transporting auger. Equip the auger with the

necessary lights for transportation where required

by law. Always use hazard warning flashers on the

tractor/towing vehicle when transporting unless

prohibited by law.

• Always travel at a safe speed, never exceeding 15

mph (24 km/hr). Reduce speed on rough surfaces

and be cautious when turning corners or meeting

traffic.

• Before raising/lowering/moving the auger, make

sure the area around the auger is clear of obstructions and/or untrained personnel. Never allow anyone to stand on or beneath auger while

transporting or placing auger.

• Do not transport auger on slopes greater than 20°.

• Wheels must be free to move when raising or lowering auger.

• Never attempt to move auger manually. To do so

will result in serious injury.

• Before moving auger, check and double check for overhead obstructions and/

or electrical wires. Electrocution can occur without direct contact.

• Disconnect PTO driveline from tractor before moving auger or tractor and

secure in transport saddle (where applicable).

• Raise intake feed hopper into transport position and lock hopper lift winch

before transporting or moving auger. Intake feed side of hopper must face

main auger when in transport position.

• Do not operate auger with intake hopper in transport position. This will cause

damage to the u-joint.

2.7. MAINTENANCE SAFETY

• Shut down and lock out all power before attempting maintenance of any kind.

Turn off the tractor and disconnect the PTO driveline and hydraulic hoses

from the tractor.

• After maintenance is complete, replace and secure all safety guards and

safety devices, and if applicable, service doors and cleanout covers.

• Support auger tube before attempting maintenance on the undercarriage

assembly. Auger should be in full down position for maintenance.

18 30875 R0

WHEATHEART - GRAIN AUGERS 2. SAFETY

X160-85, X160-105, X160-125

• Use only genuine Wheatheart replacement parts or equivalent. Replacement

parts such as intake guards, pulley guards, PTO driveline shields, winches,

and lift cables must meet ASABE standards or serious injury may result. Use

of unauthorized parts will void warranty. If in doubt, contact Wheatheart or

your Wheatheart dealer.

• Do not modify any auger components without authorization from Wheatheart.

Modification can be dangerous and result in serious injuries.

2.8. SAFETY DECALS

• Keep safety decals clean and legible at all times.

• Replace safety decals that are missing or have become illegible. See decal

location figures that follow.

• Replaced parts must display the same decal(s) as the original part.

• Replacement safety decals are available free of charge from your distributor,

dealer, or factory.

2.8.1. DECAL INSTALLATION/REPLACEMENT

1. Decal area must be clean and dry, with a temperature above 50°F (10°C).

2. Decide on the exact position before you remove the backing paper.

3. Align the decal over the specified area and carefully press the small portion

with the exposed sticky backing in place.

4. Slowly peel back the remaining paper and carefully smooth the remaining

portion of the decal in place.

5. Small air pockets can be pierced with a pin and smoothed out using the sign

backing paper.

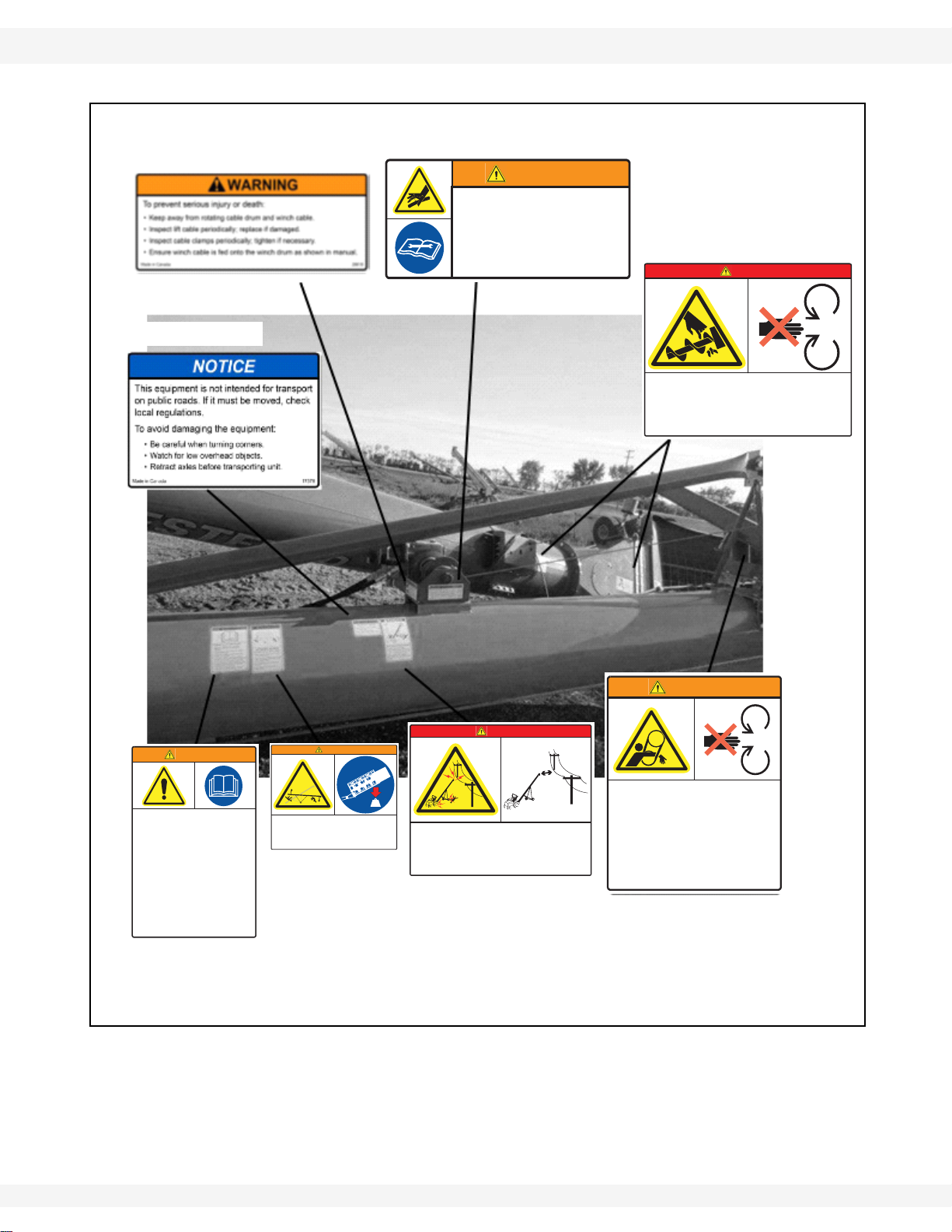

2.8.2. SAFETY DECAL LOCATIONS

Replicas of the safety decals that are attached to the equipment and their

messages are shown in the figure(s) that follow. Safe operation of the equipment

requires that you familiarize yourself with the various safety decals and the areas

or particular functions that the decals apply to, as well as the safety precautions

that must be taken to avoid serious injury, death, or damage.

Please review the decals shown. If your auger does not have these decals, they

are available upon request. Please specify which decals you need.

30875 R0 19

2. SAFETY WHEATHEART - GRAIN AUGERS

X160-85, X160-105, X160-125

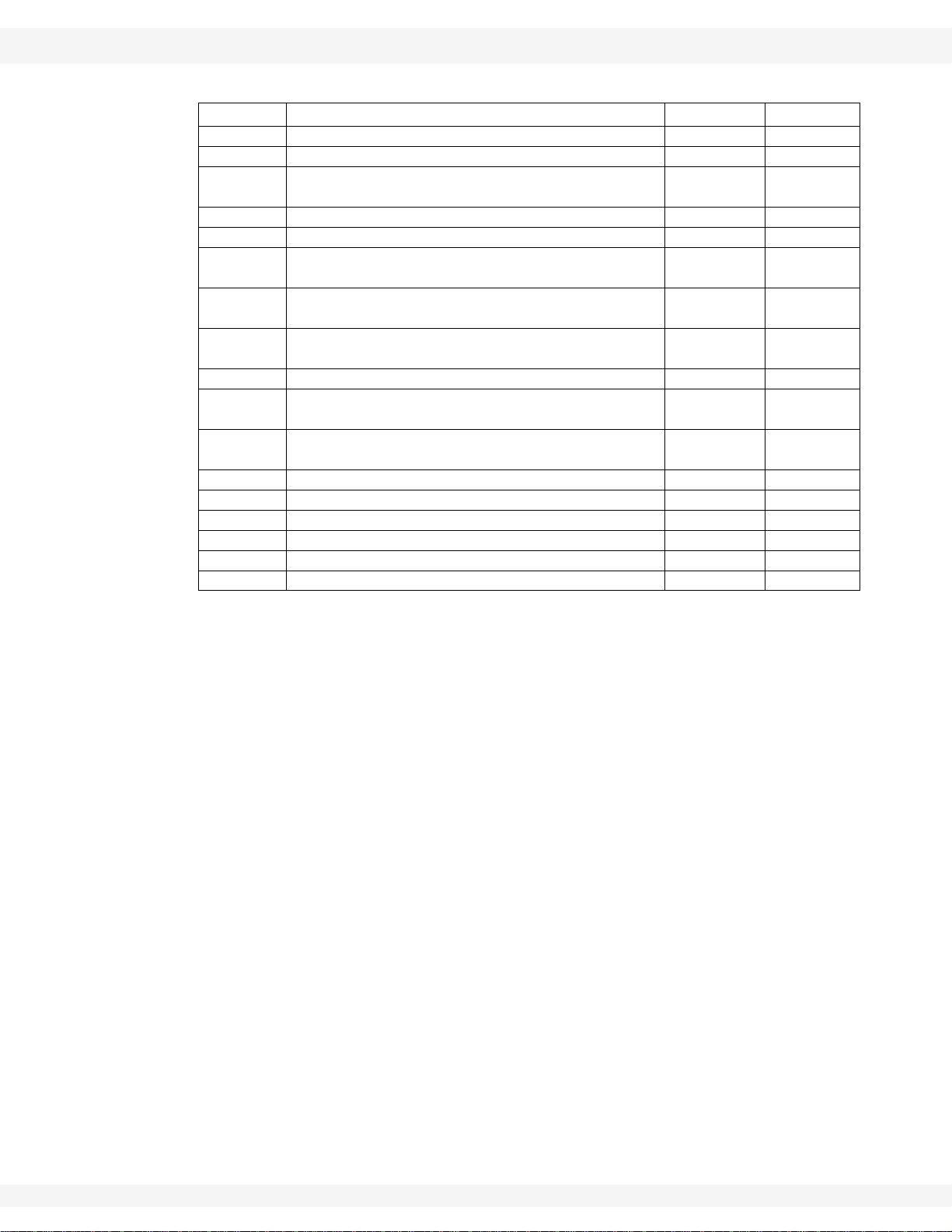

Table 2.1. Safety Decal Description, Detail, and Location Information

Number Description Detail Location

20806 High pressure fluid hazard (Warning) Figure 2.7 Figure 2.2

20809 Rotating cable sheaves hazard (Warning) Figure 2.8 Figure 2.2

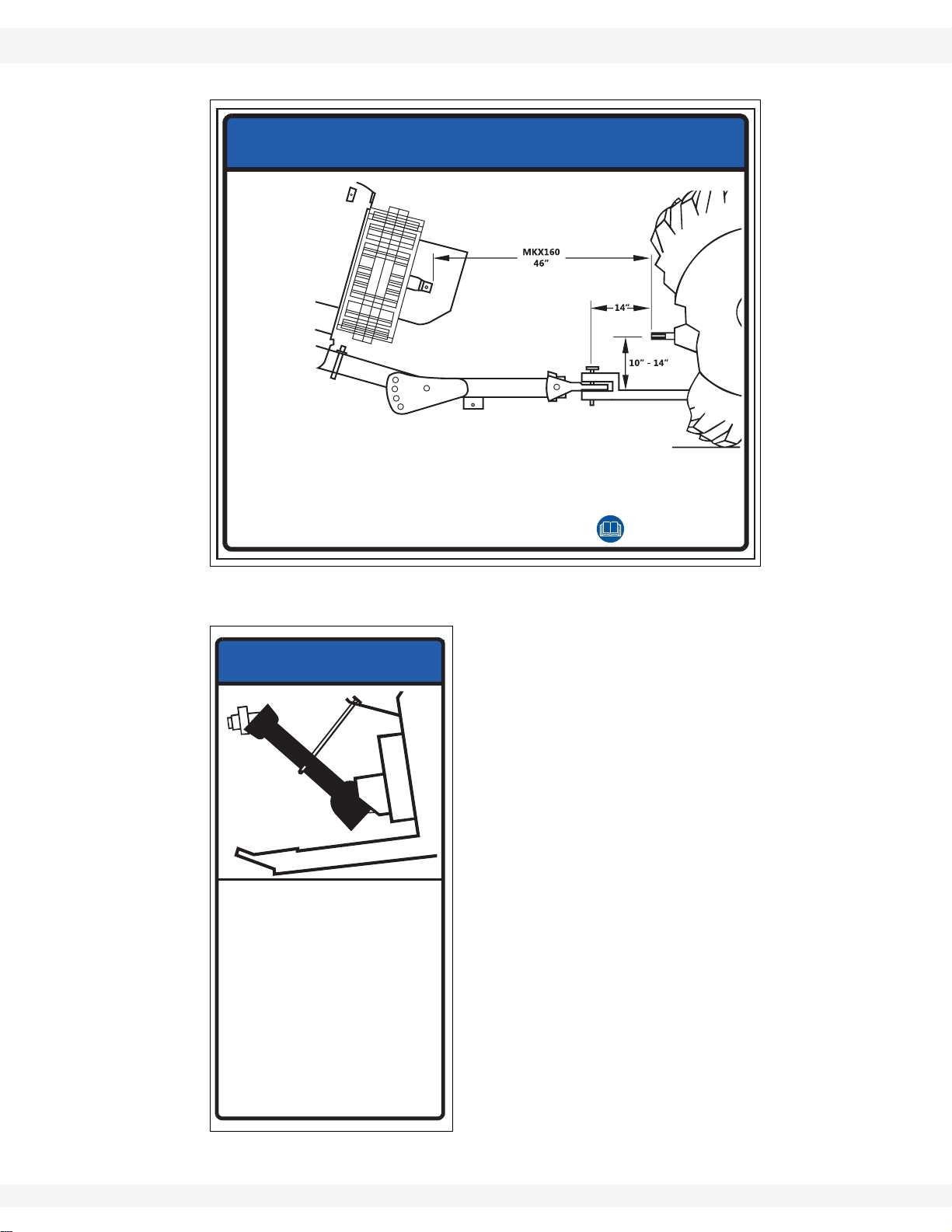

21074 Auger-to-tractor hookup (Notice) Figure 2.9

Figure 2.3

Figure 2.5

18859 Disconnect PTO driveline (Notice) Figure 2.10 Figure 2.3

17378 Transport restrictions (Notice) Figure 2.11 Figure 2.3

20816 Electrocution hazard (Danger) Figure 2.12

20813 Rotating flighting hazard (Danger) Figure 2.13

20807 Serious injury or death hazards (Warning) Figure 2.14

Figure 2.4

Figure 2.5

Figure 2.4

Figure 2.5

Figure 2.4

Figure 2.5

20811 Upending hazard (Warning) Figure 2.15 Figure 2.4

20804 Transport hazard, hitching and towing (Warning) Figure 2.16

17101 Entanglement hazard (Warning) Figure 2.17

Figure 2.4

Figure 2.5

Figure 2.4

Figure 2.5

17107 Close lift valve after raising (Caution) Figure 2.18 Figure 2.5

17094 Rotating flighting, grain transfer boot (Danger) Figure 2.19 Figure 2.5

19960 Chocking/unchocking wheels (Notice) Figure 2.20 Figure 2.5

20818 Rotating PTO driveline hazard (Danger) Figure 2.21 Figure 2.5

20803 Reattach missing guards (Warning) Figure 2.22 Figure 2.5

20812 Rollover/transport hazard (Warning) Figure 2.23 Figure 2.6

* Wheatheart reserves the right to update safety decals without notice. Safety

decals may not be exactly as shown.

20 30875 R0

WHEATHEART - GRAIN AUGERS 2. SAFETY

WARNING

To prevent serious injury or death:

• Keep away from rotating cable sheaves and lift

cables.

• Inspect lift cable periodically; replace if damaged.

• Inspect cable clamps periodically; tighten if

necessary.

20809

Made in Canada

DECAL #20809

DECAL #20806

X160-85, X160-105, X160-125

Figure 2.2 Hydraulic Safety Decal Locations

WARNING

HIGH PRESSURE FLUID HAZARD

Hydraulic fluid can cause serious injury if it

penetrates the skin. If it does, see a doctor

immediately.

• Relieve pressure before unhooking hydraulic line.

• Wear proper hand and eye protection, and use wood

or cardboard, not hands, when searching for leaks.

60802adanaC ni edaM

30875 R0 21

2. SAFETY WHEATHEART - GRAIN AUGERS

• Follow dimensions above for correct

auger-to-tractor hookup.

To prevent

damage

during

auger-totractor

hookup:

• Adjust drawbar as needed.

• See operation manual for complete details.

• Auger must be on level ground and in full down

position when measuring.

21074

Made in Canada

DECAL #21074

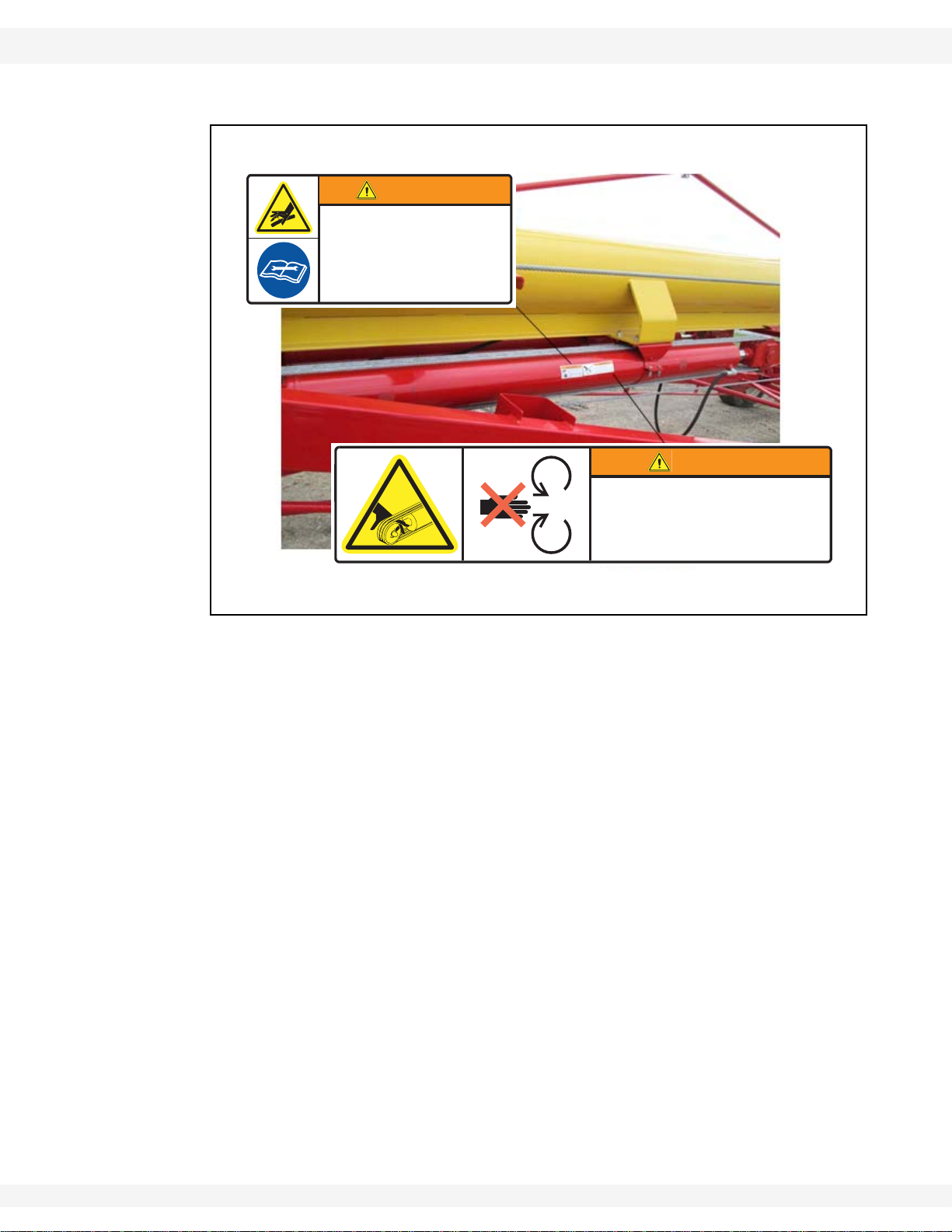

DECAL #18859

X160-85, X160-105, X160-125

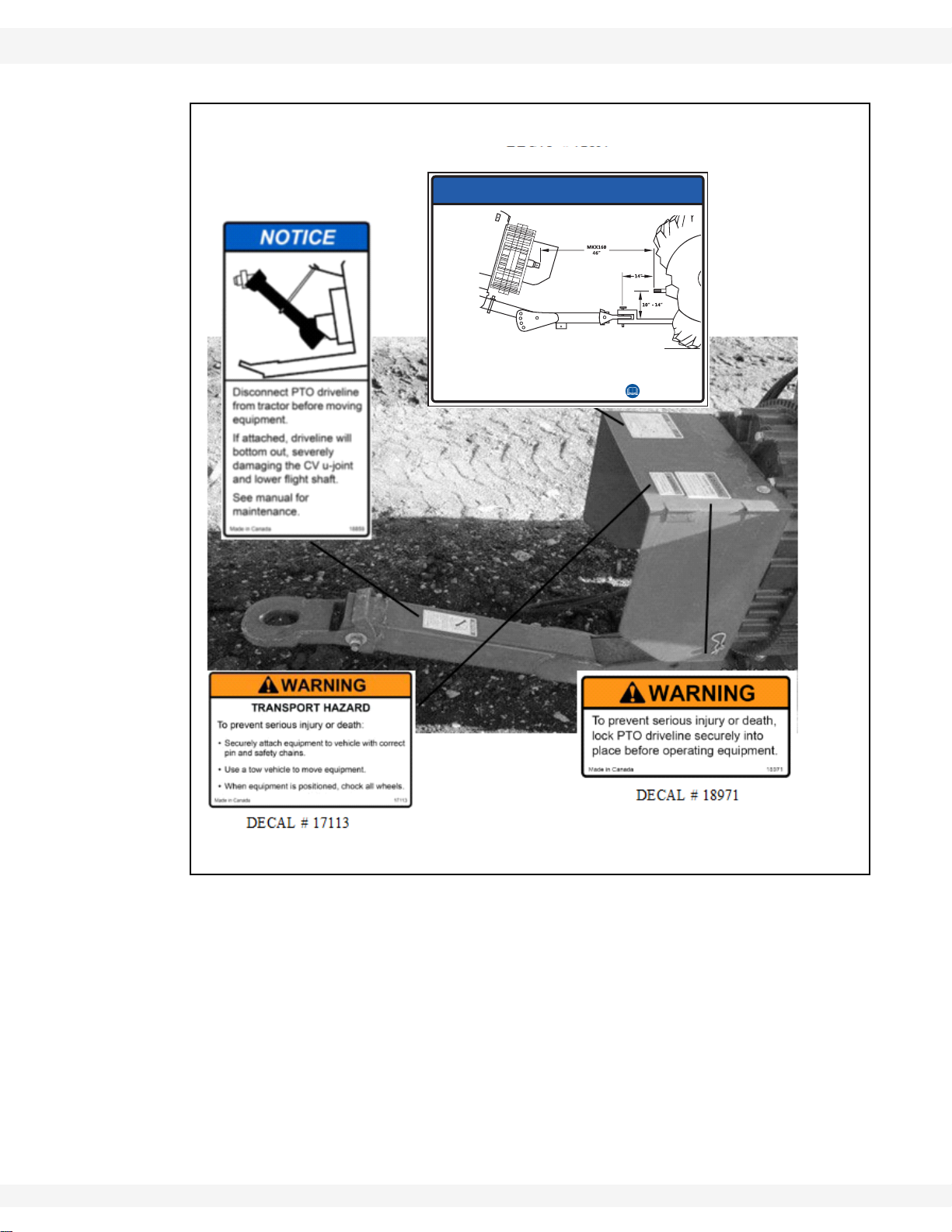

Figure 2.3 PTO and Towbar Safety Decal Locations

NOTICE

22 30875 R0

WHEATHEART - GRAIN AUGERS 2. SAFETY

WARNING

HIGH PRESSURE FLUID HAZARD

Hydraulic fluid can cause serious injury if it

penetrates the skin. If it does, see a doctor

immediately.

• Relieve pressure before unhooking hydraulic line.

• Wear proper hand and eye protection, and use wood

or cardboard, not hands, when searching for leaks.

60802adanaC ni edaM

DECAL #20806

DECAL # 17378

DECAL #20811

WARNING

UPENDING HAZARD

To prevent death or serious injury:

• Anchor intake end and/or support

discharge end to prevent upending.

• Auger intake end must always have

downward weight. Do not release until

attached to tow bar or resting on ground.

• Do not raise auger intake end above tow

bar height.

• Empty auger and fully lower before

moving.

20811

Made in Canada

DECAL #20811

DECAL #20807

WARNING

To prevent serious injury or death:

• Read and understand the manual before

assembling, operating, or maintaining the

equipment.

• Only trained personnel may assemble, operate, or

maintain the equipment.

• Children and untrained personnel must be kept

outside of the work area.

• If the manual, guards, or decals are missing or

damaged, contact factory or dealer for replacements.

• Lock out power before performing maintenance.

• To prevent equipment collapse, support equipment

tube while disassembling certain components.

• Electric motors must be grounded. Disconnect power

before resetting overloads.

Made in Canada 20807

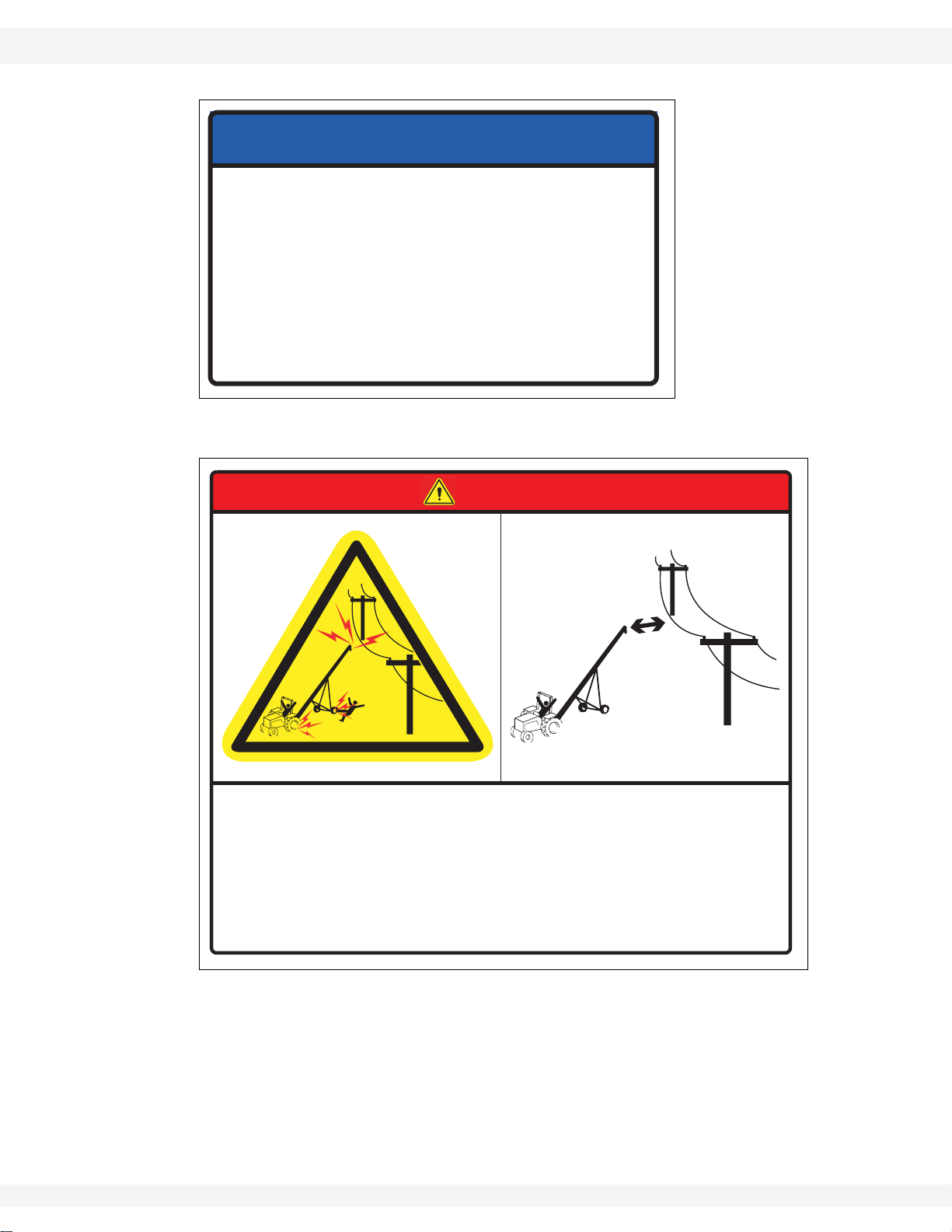

DANGER

ELECTROCUTION HAZARD

To prevent death or serious injury:

• When operating or moving, keep equipment away from overhead power lines and devices.

• Fully lower equipment and truck box before moving.

This equipment is not insulated.

Electrocution can occur without direct contact.

20816

Made in Canada

DECAL #20816

DECAL #20813

DECAL # 28616

PLACED ON HOPPER

CHAIN COVER

X160-85, X160-105, X160-125

Figure 2.4 Auger Tube and Hopper Safety Decal Locations

DANGER

ENTANGLEMENT HAZARD

To prevent serious injury or death:

• Keep body, hair, and clothing away from rotating

pulleys, belts, chains, and sprockets.

• Do not operate with any guard removed or

modified. Keep guards in good working order.

• Shut off and remove key or lock out power before

source before inspecting or servicing machine.

Made in Canada

To prevent death or serious injury:

• KEEP AWAY from rotating auger flighting.

• DO NOT remove or modify auger flighting

20813

Made in Canada

ROTATING FLIGHTING HAZARD

guards, doors, or covers. Keep in good

working order. Have replaced if damaged.

WARNING

• DO NOT operate the auger without all

guards, doors, and covers in place.

• NEVER touch the auger flighting. Use a

stick or other tool to remove an

obstruction or clean out.

• Shut off and lock out power to adjust,

service, or clean.

20804

30875 R0 23

2. SAFETY WHEATHEART - GRAIN AUGERS

PLACED BEHIND GUARDS

WARNING

MISSING GUARD HAZARD

To prevent serious injury or

death, shut off power and

reattach guard before operating

machine.

20803

Made in Canada

DECAL #20818

DANGER

ELECTROCUTION HAZARD

To prevent death or serious injury:

• When operating or moving, keep equipment away from overhead power lines and devices.

• Fully lower equipment and truck box before moving.

This equipment is not insulated.

Electrocution can occur without direct contact.

20816

Made in Canada

DECAL #20816

DANGER

ROTATING FLIGHTING HAZARD

To prevent death or serious injury:

• KEEP AWAY from rotating auger flighting.

• DO NOT remove or modify auger flighting

guards, doors, or covers. Keep in good

working order. Have replaced if damaged.

• DO NOT operate the auger without all

guards, doors, and covers in place.

• NEVER touch the auger flighting. Use a

stick or other tool to remove an

obstruction or clean out.

• Shut off and lock out power to adjust,

service, or clean.

20813

Made in Canada

DECAL #20813

WARNING

To prevent serious injury or death:

• Read and understand the manual before

assembling, operating, or maintaining the

equipment.

• Only trained personnel may assemble, operate, or

maintain the equipment.

• Children and untrained personnel must be kept

outside of the work area.

• If the manual, guards, or decals are missing or

damaged, contact factory or dealer for replacements.

• Lock out power before performing maintenance.

• To prevent equipment collapse, support equipment

tube while disassembling certain components.

• Electric motors must be grounded. Disconnect power

before resetting overloads.

Made in Canada 20807

DECAL #20807

DECAL #20803

DECAL #17107

DECAL #19960

DECAL #17904

Figure 2.5 Boot Safety Decal Locations

X160-85, X160-105, X160-125

24 30875 R0

DANGER

ROTATING PTO DRIVELINE HAZARD

To prevent serious injury or death:

• Keep body, hair, and clothing away from rotating PTO driveline.

• Do not operate equipment unless all driveline, tractor, and

equipment shields are in place and in good working order.

• Make certain the driveline shields turn freely on driveline.

• Make certain the driveline is securely attached at both ends.

• Do not exceed operating speed of 540 rpm.

• Keep u-joint angles small and equal. Do not exceed maximum

recommended length for PTO driveline.

Made in Canada 20818

WHEATHEART - GRAIN AUGERS 2. SAFETY

WARNING

ROLLOVER / TRANSPORT

HAZARD

To prevent serious injury or death:

• Fully extend axles before raising auger

tube.

• Retract axles before transporting.

20812

Made in

Canada

DECAL #20812

NOTE: TWO DECALS

ARE REQUIRED, ONE

ON EACH SIDE OF

THE AXLE

X160-85, X160-105, X160-125

Figure 2.6 Lower Frame Safety Decal Location

30875 R0 25

2. SAFETY WHEATHEART - GRAIN AUGERS

WARNING

HIGH PRESSURE FLUID HAZARD

Hydraulic fluid can cause serious injury if it

penetrates the skin. If it does, see a doctor

immediately.

• Relieve pressure before unhooking hydraulic line.

• Wear proper hand and eye protection, and use wood

or cardboard, not hands, when searching for leaks.

60802adanaC ni edaM

WARNING

To prevent serious injury or death:

• Keep away from rotating cable sheaves and lift

cables.

• Inspect lift cable periodically; replace if damaged.

• Inspect cable clamps periodically; tighten if

necessary.

20809

Made in Canada

X160-85, X160-105, X160-125

2.8.3. SAFETY DECAL DETAIL

Figure 2.7 Decal #20806

Figure 2.8 Decal #20809

26 30875 R0

WHEATHEART - GRAIN AUGERS 2. SAFETY

• Follow dimensions above for correct

auger-to-tractor hookup.

To prevent

damage

during

auger-totractor

hookup:

• Adjust drawbar as needed.

• See operation manual for complete details.

• Auger must be on level ground and in full down

position when measuring.

21074

Made in Canada

NOTICE

Disconnect PTO driveline

from tractor before moving

equipment.

If attached, driveline will

bottom out, severely

damaging the CV u-joint

and lower flight shaft.

See manual for

maintenance.

95881adanaC ni edaM

X160-85, X160-105, X160-125

NOTICE

Figure 2.9 Decal 21074

30875 R0 27

Figure 2.10 Decal 18859

2. SAFETY WHEATHEART - GRAIN AUGERS

NOTICE

This equipment is not intended for transport

on public roads. If it must be moved, check

local regulations.

To avoid damaging the equipment:

• Be careful when turning corners.

• Watch for low overhead objects.

• Retract axles before transporting unit.

17378

Made in

Canada

DANGER

ELECTROCUTION HAZARD

To prevent death or serious injury:

• When operating or moving, keep equipment away from overhead power lines and devices.

• Fully lower equipment and truck box before moving.

This equipment is not insulated.

Electrocution can occur without direct contact.

20816

Made in Canada

X160-85, X160-105, X160-125

Figure 2.11 Decal 17378

Figure 2.12 Decal 20816

28 30875 R0

WHEATHEART - GRAIN AUGERS 2. SAFETY

X160-85, X160-105, X160-125

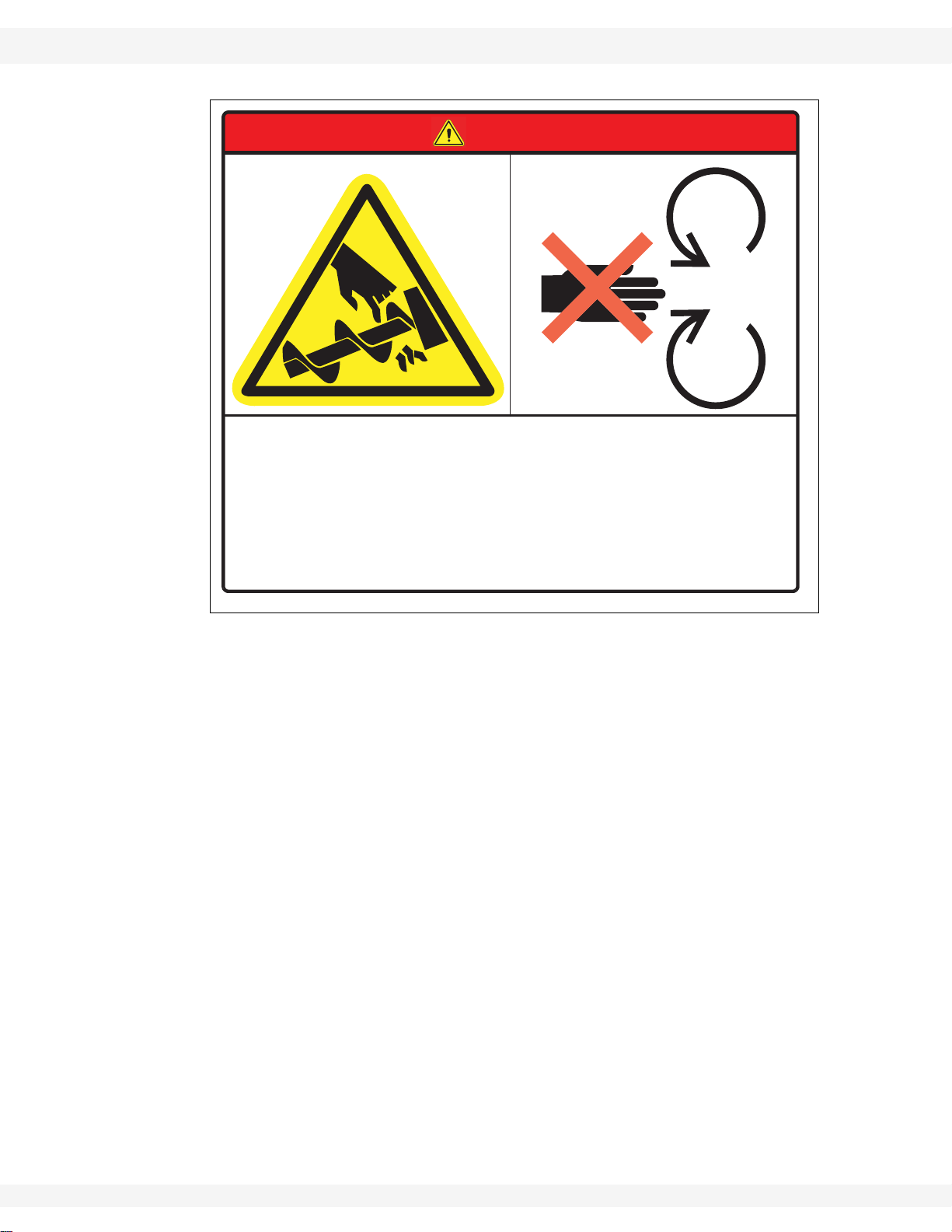

DANGER

ROTATING FLIGHTING HAZARD

To prevent death or serious injury:

• KEEP AWAY from rotating auger flighting.

• DO NOT remove or modify auger flighting

guards, doors, or covers. Keep in good

working order. Have replaced if damaged.

20813

Made in Canada

Figure 2.13 Decal 20813

• DO NOT operate the auger without all

guards, doors, and covers in place.

• NEVER touch the auger flighting. Use a

stick or other tool to remove an

obstruction or clean out.

• Shut off and lock out power to adjust,

service, or clean.

30875 R0 29

2. SAFETY WHEATHEART - GRAIN AUGERS

X160-85, X160-105, X160-125

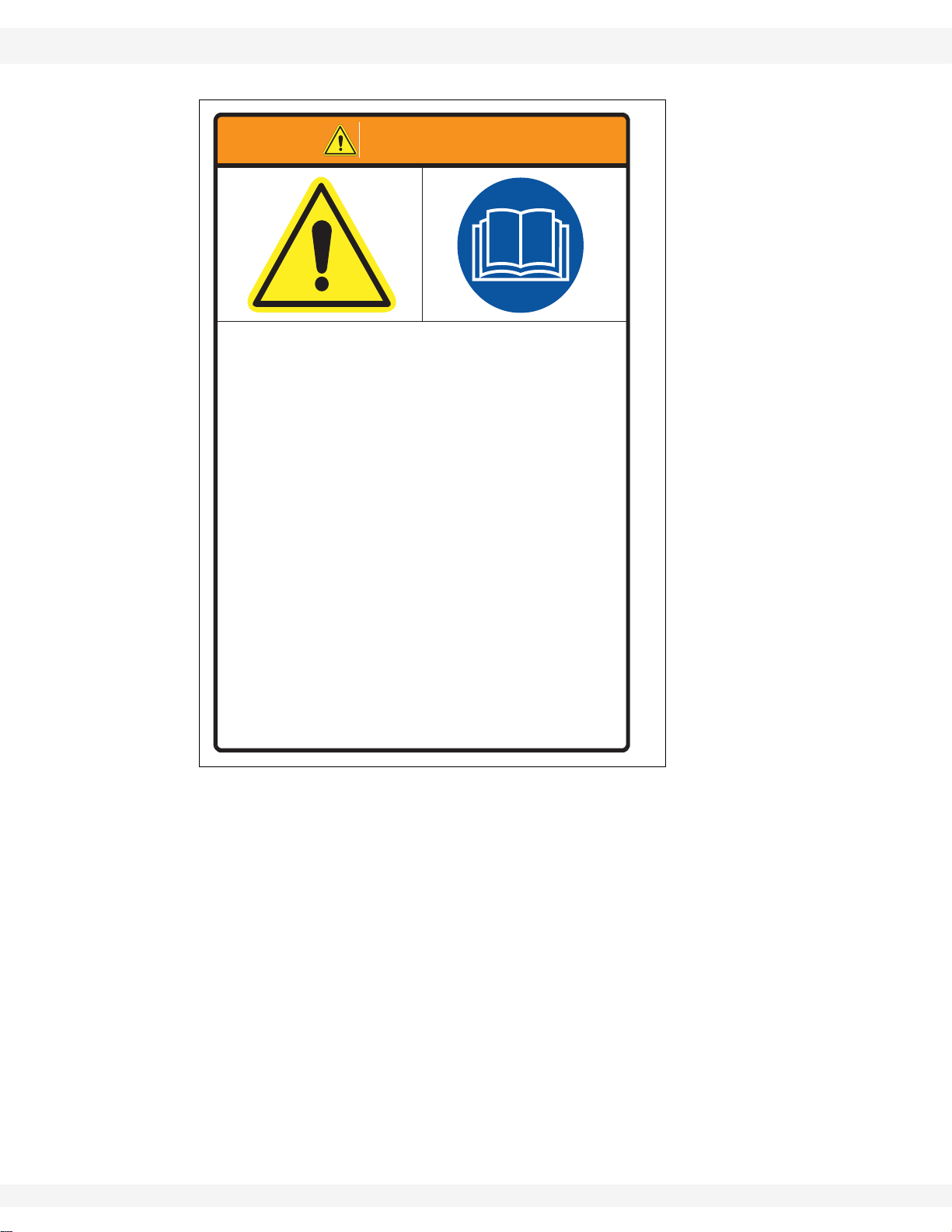

WARNING

To prevent serious injury or death:

• Read and understand the manual before

assembling, operating, or maintaining the

equipment.

• Only trained personnel may assemble, operate, or

maintain the equipment.

• Children and untrained personnel must be kept

outside of the work area.

• If the manual, guards, or decals are missing or

damaged, contact factory or dealer for replacements.

• Lock out power before performing maintenance.

• To prevent equipment collapse, support equipment

tube while disassembling certain components.

• Electric motors must be grounded. Disconnect power

before resetting overloads.

Made in Canada 20807

Figure 2.14 Decal 20807

30 30875 R0

WHEATHEART - GRAIN AUGERS 2. SAFETY

X160-85, X160-105, X160-125

WARNING

UPENDING HAZARD

To prevent death or serious injury:

• Anchor intake end and/or support

discharge end to prevent upending.

• Do not raise auger intake end above tow

bar height.

• Auger intake end must always have

downward weight. Do not release until

attached to tow bar or resting on ground.

• Empty auger and fully lower before

moving.

Figure 2.15 Decal 20811

WARNING

TRANSPORT HAZARD

To prevent serious injury or death:

• Securely attach equipment to vehicle with correct

pin and safety chains.

• Use a tow vehicle to move equipment.

20811

Made in Canada

31171adanaC ni edaM

Figure 2.16 Decal 17113

30875 R0 31

2. SAFETY WHEATHEART - GRAIN AUGERS

(LOCATED ON HOPPER

CHAIN GUARD)

X160-85, X160-105, X160-125

WARNING

ENTANGLEMENT HAZARD

To prevent serious injury or death:

• Keep body, hair, and clothing away from rotating

pulleys, belts, chains, and sprockets.

• Do not operate with any guard removed or

modified. Keep guards in good working order.

• Shut off and remove key or lock out power before

source before inspecting or servicing machine.

Made in Canada

20804

Figure 2.17 Decal 20804

CAUTION

To prevent personal injury or

damage to equipment, close valve in

lift cylinder hydraulic line after raising

equipment into position.

Figure 2.18 Decal 17107

Made in Canada

17107

32 30875 R0

WHEATHEART - GRAIN AUGERS 2. SAFETY

DANGER

ROTATING FLIGHTING INSIDE

To prevent serious injury or death, do

not operate auger unless swinghopper is securely attached to boot.

49071adanaC ni edaM

NOTICE

To prevent damage, wheels must be

free to move when raising or lowering

equipment.

When equipment is positioned, chock

all wheels.

Made in Canada 19960

DANGER

ROTATING PTO DRIVELINE HAZARD

To prevent serious injury or death:

• Keep body, hair, and clothing away from rotating PTO driveline.

• Do not operate equipment unless all driveline, tractor, and

equipment shields are in place and in good working order.

• Make certain the driveline shields turn freely on driveline.

• Make certain the driveline is securely attached at both ends.

• Do not exceed operating speed of 540 rpm.

• Keep u-joint angles small and equal. Do not exceed maximum

recommended length for PTO driveline.

Made in Canada 20818

X160-85, X160-105, X160-125

Figure 2.19 Decal 17094

Figure 2.20 Decal 19960

30875 R0 33

Figure 2.21 Decal 20818

2. SAFETY WHEATHEART - GRAIN AUGERS

PLACED ON MACHINE BEHIND GUARD

WARNING

ROLLOVER / TRANSPORT

HAZARD

To prevent serious injury or death:

• Fully extend axles before raising auger

tube.

• Retract axles before transporting.

20812

Made in

Canada

X160-85, X160-105, X160-125

WARNING

MISSING GUARD HAZARD

To prevent serious injury or

death, shut off power and

reattach guard before operating

machine.

Made in Canada

Figure 2.22 Decal 20803

Figure 2.23 Decal 20812

20803

34 30875 R0

WHEATHEART - GRAIN AUGERS 3. ASSEMBLY

WARNING Before continuing, ensure you have read and understand the relevant information

in the safety section. Safety information is provided to help prevent serious injury, death, or

property damage.

X160-85, X160-105, X160-125

3.Assembly

Before beginning assembly, familiarize yourself with all the sub-assemblies and

hardware making up the auger. Have all parts on hand and arrange them for

easy access. Carry out assembly in a large open area with a level surface.

Important: Always have 2 or more people assembling the equipment. Because of the

weight, do not attempt assembly alone.

Augers are available in various combinations. In most cases, the following

instructions will apply to all augers. Where the assembly information varies,

additional instructions will be included and will be indicated with an arrow.

3.1. GENERAL ASSEMBLY

1. Select an assembly area that is level, has a firm or hard surface and is free of

debris. Be sure it is large enough to allow access from all sides when the

components are being assembled.

2. If assembling inside a building, be sure the ceiling is at least 17’ (5.18 m) high

to provide clearance when installing the undercarriage

3. Bring all the tools, blocks, stands, jacks, and hoists to the assembly area

before starting.

4. The following tools and equipment are required to assemble the machine:

• 11-14 support stands (tube section supports, three per tube)

• Four saw horses (2000 lb / 907 kg bearing capacity)

• One standard socket set and wrench set

• One torque wrench

• One standard 25’ (7.62 m) tape measure

• One 2’ level

• One 8” level (magnetic grip)

• Two C-clamps or vise grips

• One forklift with a 6000 lb lifting capacity

• One picker with minimum reach of 12’ (3.66 m) 8000-10000 lb lifting

capacity

• One 100’ (30 m) measuring tape

• One tire gauge

• One tire chuck

• 6-10 wood blocks (2x4's cut at 4’ lengths)

• High-quality SAE approved extreme pressure rated bearing grease

• Impact wrench and sockets

• 2+ steel punches (for aligning bolt holes)

30875 R0 35

3. ASSEMBLY WHEATHEART - GRAIN AUGERS

X160-85, X160-105, X160-125

• 1/2” drive impact wrench (recommended)

• 1/2” extension

• 3/8”, 5/8”, 3/4”, and 15/16” sockets for 1/2” drive

• 3/8”, 5/8”, 3/4” and 15/16” flat wrenches

See Table 3.1. for a list of assembly procedures.

Table 3.1. Assembly Procedures

Procedure Page

Identify and Arrange Auger Tube Sections page 37

Connect Auger Tubes page 40

Install the Hydraulic Lift Cylinders page 42

Install the Track Shoe and Track Stop page 46

Install the Boot on the Auger Tube page 47

Assemble the PTO Shield Assembly page 49

Install the Speed Reducer on the Boot page 50

Install the Boot Tow Bar page 53

Install the Discharge Spout page 54

Set the Thrust Adjuster page 55

Apply Logo and Model Decals on the Auger Tubes page 56

Install Truss Support Towers and Truss Tubes page 58

Install Truss Cables page 66

Assemble the Lower Frame page 68

Assemble the Wheel Hub and Install Tires page 70

Connect the Auger Tube to the Frame page 71

Install Lift Cylinder Cables to the Track shoe page 74

Connect Hydraulic Hoses and Ball Valve page 76

Connect the PTO Driveline page 82

Connect the Intake Hopper to the Swing Tube page 83

Connect the Spout Head to the Grain Transfer Boot page 87

Install the Hopper Lift Arm page 89

Install the Hydraulic Winch page 90

Power Swing Assembly page 93

Install the Hitch Jack page 99

Install the Manual Container page 100

Auger-to-Tractor Hookup page 101

36 30875 R0

WHEATHEART - GRAIN AUGERS 3. ASSEMBLY

LOWER TUBE

UPPER TUBE

UPPER

MIDDLE TUBE

20717

20716

20719

GRAIN

TRANSFER

BOOT

MIDDLE TUBE

20718

X160-85, X160-105, X160-125

3.2. ASSEMBLE THE AUGER TUBE

3.2.1. IDENTIFY AND ARRANGE AUGER TUBE SECTIONS

1. Align tube sections on a series of support stands, placing a support stand at

the end of each tube (see Figure 3.1 through Figure 3.3 for correct tube

positioning, according to auger model).

2. As tubes sections are added, make sure that support stands are at equal

heights across all tubes to ensure that tubes are level with each other.

Otherwise, use some form of shim to keep the tubes level across all of the

support stands.

Important: 3. Strap tubes to the support stands to prevent the tubes from rolling off the

stands.

Figure 3.1 X160-85 Tube Identification and Order

30875 R0 37

3. ASSEMBLY WHEATHEART - GRAIN AUGERS

UPPER TUBE

UPPER MIDDLE TUBE

MIDDLE TUBE

LOWER MIDDLE TUBE

LOWER TUBE

20718

20717

20734

20730

20719

GRAIN

TRANSFER

BOOT

X160-85, X160-105, X160-125

Figure 3.2 X160-105 Tube Identification and Order

38 30875 R0

WHEATHEART - GRAIN AUGERS 3. ASSEMBLY

LOWER TUBE

LOWER MIDDLE TUBE

MIDDLE TUBE

MIDDLE TUBE

UPPER MIDDLE TUBE

UPPER TUBE

20730

20717

20717

20718

20719

20734

GRAIN

TRANSFER

BOOT

X160-85, X160-105, X160-125

Figure 3.3 X160-125 Tube Identification and Order

30875 R0 39

3. ASSEMBLY WHEATHEART - GRAIN AUGERS

1

2

3

5

5

5

USE A STRAIGHT-EDGE

TO ALIGN TRACKS TO ENSURE

A SMOOTH PATH FOR THE

TRACK SHOE

X160-85, X160-105, X160-125

3.2.2. CONNECT AUGER TUBES

Important: Always strap tubes to the support stands to prevent the tubes from rolling off the

stands.

Note: Assemble the auger tube starting with the discharge section and working toward

the intake section.

1. Bolt tube sections together (see Figure 3.5 for details), working from the

spout end (upper tube) toward the discharge end (lower tube):

a. Align flightings to ensure a continual spiral of auger surface, and connect

flight shafts with 5/8” x 4-1/2” bolts and 5/8” locknuts.

b. As flight shafts are connected, slide tube sections together and secure with

eleven 5/8” x 1-1/2” GR8 bolts and 5/8” locknuts. Use three 5/8” x 3” GR8

bolts and locknuts for the flange section where the two sections of tube

track meet (see Figure 3.4), or a single 5/8” x 2-1/2” GR8 bolt where tube

track meets a flanged section without a tube track (see Figure 3.5).

Table 3.2 Connecting Auger Tube Sections and Flights

Diagram # Description Part #

Tube Connection

(Track-to-Track)

1 5/8” x 4-1/2” bolt 18545 1 1

2 5/8” x 1-1/2” bolt 19590 11 11

3 5/8” x 3” bolt 21463 3 0

4 5/8” x 2-1/2” bolt 27589 0 1

5 5/8” nut 19600 15 13

Tube Connection

(Track-to-Flange)

Figure 3.4 Track-to-Track Tube Section Connections

40 30875 R0

WHEATHEART - GRAIN AUGERS 3. ASSEMBLY

1

2

4

1

5

5

5

X160-85, X160-105, X160-125

Figure 3.5 Track-to-Flange Tube Section Connection

30875 R0 41

3. ASSEMBLY WHEATHEART - GRAIN AUGERS

X160-85, X160-105, X160-125

3.2.3. INSTALL THE HYDRAULIC LIFT CYLINDERS

• See “Install the X160-85 Hydraulic Lift Cylinders” below for information on

installing hydraulic lift cylinders on X160-85 augers.

• See “Install the X160-105/125 Hydraulic Lift Cylinders” on page 44 for

information on installing hydraulic lift cylinders on X160-105/125 augers.

INSTALL THE X160-85 HYDRAULIC LIFT CYLINDERS

1. Identify the tube section where the hydraulic lift cylinders install, and note the

location of the cylinder mounts.

2. Slide the cylinder rod guide onto the end of the track closest to where the lift

cylinders install. Ensure that gussets of ram guide are facing the discharge

end.

Note: The hydraulic lift cylinders must be positioned with the rod end towards the

discharge end of auger.

Important: Always use a fork lift to lift hydraulic cylinders during installation.

3. Use a sling around all 3 cylinders, and align cylinders to tube, as shown. Lift

up hydraulic cylinders to position, and fasten hydraulic cylinders to cylinder

attach brackets and back-arm bracket with eight 3/4” x 2” GR5 bolts and

locknuts.

Note: 4. Slide the cylinder rod guide toward the lift cylinders until the rod ends pass

through the three holes provided on the cylinder rod guide, and then insert a

5/16” x 2” roll pin into the hole on the end of each cylinder rod to prevent

separation of rods and cylinder arm guide.

5. Ensure all bolts are fully tight.

Table 3.3 Install the X160-85 Hydraulic Lift Cylinders

Diagram # Description Part # Quantity

1 Back-arm bracket n/a 1

2 Cylinder-mount bracket n/a 1

3 Hydraulic cylinder assembly 20733 1

4 Cylinder rod guide 20707 1

5 3/4” x 2” bolts 19592 8

6 3/4” nuts 19601 8

7 5/16” x 2” roll pin 18079 3

42 30875 R0

WHEATHEART - GRAIN AUGERS 3. ASSEMBLY

1

2

3

5

5

5

5

6

6

6

6

4

7

X160-85, X160-105, X160-125

Figure 3.6 Installing the Lift Cylinders (X160-85)

30875 R0 43

3. ASSEMBLY WHEATHEART - GRAIN AUGERS

13

12

X160-85, X160-105, X160-125

INSTALL THE X160-105/125 HYDRAULIC LIFT CYLINDERS

1. Identify the tube section where the hydraulic lift cylinders install, and note the

location of the tube cylinder mounts.

2. Ensure that the tube cylinder mounts are facing down.

3. Fasten two rear cylinder attach brackets to the rear cylinder mounts with eight

5/8” x 2” GR8 bolts and locknuts.

4. Loosely fasten the two front cylinder attach brackets and half clamps to the

front of the cylinders with eight 1/2” x 1-3/4” bolts and locknuts (see Figure 3.7

below).

Figure 3.7 Installing Front Cylinder Attach Brackets

5. Slide the cylinder rod guide onto the end of the track closest to where the lift

cylinders install.

Note: The hydraulic lift cylinders must be positioned with the rod end towards the

discharge end of auger.

6. For each hydraulic cylinder:

a. Use forklift to lift the rear end of the cylinder and position it at a rear

cylinder attach bracket. Insert a hydraulic cylinder pin into the hole, and

secure with a 7/16” x 3-1/2” bolt and locknut. Tighten securely.

b. Use the forklift to lift and support the front end of the cylinder in place on a

front cylinder mount, and adjust the front cylinder attach bracket and half

clamp to align with the bolt boles in the front cylinder mounts.

c. Fasten the front cylinder attach bracket to the front cylinder mount using

four 5/8” x 2” bolts and locknuts.

d. Tighten the four 1/2” x 1-3/4” bolts and locknuts that fasten the cylinder

attach bracket and half clamp together.

6. Slide the cylinder rod guide toward the lift cylinders until the rod ends pass

through the two holes provided on the cylinder ram guide, and then secure

with a 1/2” X 1-1/2” bolt and a 1/2” locknut to prevent separation of rods and

cylinder arm guide.

44 30875 R0

WHEATHEART - GRAIN AUGERS 3. ASSEMBLY

1A

2

8

13

11

9

7

10

2

14

14

5

3

3

1B

11

13

13

12

6

7

6

X160-85, X160-105, X160-125

Table 3.4 Install the X160-105/125 Hydraulic Lift Cylinders

Diagram # Description Part # Quantity

1A Rear cylinder-mount n/a 1

1B Front cylinder mount n/a 1

2 Rear cylinder-attach brackets 20749 2

3 Front cylinder-attach brackets 20735 2

4 Hydraulic cylinder 20799 2

5 Cylinder rod guide 20751 1

6 5/8” x 2” GR8 bolts 19991 16

7 5/8” x locknuts 19600 16

8 7/16” x 3-1/2” bolt 19547 2

9 7/16” locknut 19598 2

10 Cylinder pin 20744 2

11 1/2 x 1-1/2” bolt 19589 2

12 1/2 x 1-3/4” bolt 19974 8

13 1/2” locknut 19599 10

14 Half clamp 20736 2

Figure 3.8 Installing the Lift Cylinders (X160-105/125)

30875 R0 45

3. ASSEMBLY WHEATHEART - GRAIN AUGERS

85’ MODEL

105’ MODEL

125’ MODEL

SPOUT END

INTAKE END

1

2

4

3

5

X160-85, X160-105, X160-125

3.2.4. INSTALL THE TRACK SHOE AND TRACK STOP

Important: See Figure 3.9 for track stop positions for specific auger models.

Figure 3.9 Track Stop Positions

1. Slide the track shoe onto the track.

2. Slide track shoe along full length of track to make sure there is no binding,

and that track ends are properly aligned where tube sections meet.

3. Attach the track stop using six 3/4” x 3” GR8 bolts, two track stop spacer

plates, and six 3/4” locknuts.

Table 3.5 Track Shoe and Track Stop

Diagram # Description Part # Quantity

1 Track shoe 20647 1

2 Track stop 20670 1

3 3/4” x 3” GR8 bolts 19978 6

4 3/4” nylon locknut 19601 6

5 Track stop spacer plate 21037 2

Figure 3.10 Track Shoe and Track Stop

46 30875 R0

WHEATHEART - GRAIN AUGERS 3. ASSEMBLY

X160-85, X160-105, X160-125

3.2.5. INSTALL THE BOOT ON THE AUGER TUBE

.\

WARNING

Components are heavy and create a crushing

hazard if improperly handled. Be sure to use

proper hoisting equipment and procedures,

and ensure lifting apparatus is secure. Lock

out the lifting apparatus before working

around or under the raised components;

failure to do so may cause serious personal

injury.

Note: The gearbox is sent from the factory filled half way with gear oil. Before further

assembly, check oil level to make certain the gearbox is half full. Add oil if

necessary. Do not use grease.

Note: The boot flighting comes pre-installed on the end of the lower tube flighting shaft.

1. Remove the 7/8” x 6” bolt and locknut that secures the boot flighting to the

lower shaft flighting. Place the bolt and nut aside for use refastening the

flighting later in the procedure.

2. Position the boot plate against the boot with flat edge facing up (See Figure

3.11), and fasten with two 5/8” x 1-1/2” GR8 bolts at the top of the plate

inserted from the boot side of the flange and 5/8” locknuts.

3. Slip the boot assembly over the boot flight/lower flighting assembly, angling

the boot where required for fit, and rotating the boot flighting during inserting

until the boot, boot attach plate, and lower tube flange are aligned and in full

contact.

4. Attach the boot to the lower tube flange according to the following bolt usage:

a. eight 5/8” x 2” GR8 bolts and locknuts (four on each side),

b. three 5/8” x 1-1/2” GR8 bolts and locknuts (at the top),

c. three 5/8” x 2-1/2” GR8 bolts and locknuts (at the bottom).

5. Fasten the boot flighting to the lower tube flighting using the 7/8” x 6” bolt and

locknut removed in Step 1.

Table 3.6 Install the Boot on the Auger Tube

Diagram # Description Part # Quantity

1 Grain transfer boot 20604 1

2 Boot attach plate 20679 1

3 5/8 x 1-1/2” 19590 5

4 5/8 x 2” 19991 8

5 5/8 x 2-1/2” 27589 3

6 5/8” locknut 19600 16

30875 R0 47

3. ASSEMBLY WHEATHEART - GRAIN AUGERS

3,6

5,6

4,6

1

2

X160-85, X160-105, X160-125

Figure 3.11 Install Boot on Auger Tube

48 30875 R0

WHEATHEART - GRAIN AUGERS 3. ASSEMBLY

6

5

1

2

1

3

4

3

4

X160-85, X160-105, X160-125

3.2.6. ASSEMBLE THE PTO SHIELD ASSEMBLY

1. As shown in Figure 3.12, align the PTO shield front on the PTO shield rear

and secure it with three 5/16” x 3/4” bolts [19538] and 5/16” whiz nuts.

2. Insert the hair pin to lock PTO shield with base.

3. Set the assembled PTO shield assembly aside for use during the installation

of the speed reducer.

Table 3.7 Assemble the PTO Shield Assembly

Diagram # Description Part # Quantity

1 PTO shield rear 20746 1

2 PTO shield front 20745 1

3 5/16” x 3/4” bolts 19538 3

4 5/16” whiznuts 19595 3

5 Lock pin n/a 1

6 Hairpin 19463 1

Figure 3.12 Assemble the PTO Shield Assembly

30875 R0 49

3. ASSEMBLY WHEATHEART - GRAIN AUGERS

X160-85, X160-105, X160-125

3.2.7. INSTALL THE SPEED REDUCER ON THE BOOT

1. Lift the speed reducer and carefully slide it over the gearbox and lower

flighting shafts and against the face of the boot.

Important: Use the supplied lifting lug on the speed reducer.

2. Fasten the speed reducer gearbox, PTO shield, and PTO transport strap to

boot using twelve 1/2” x 11-1/2” GR5 bolts and 1/2” locknuts (see Figure 3.13

for details).

3. Install the lower flight stop as follows ( Figure 3.14):

a. Use a wrench to rotate the lower flight bearing case on the speed reducer

until the bearing case keyway aligns with the lower flight shaft keyway.

b. Insert a 3/8”x3-3/8” square key into the shaft keyway.

c. Slide the lower flight stop over the lower flight shaft, and secure it in place

with a 7/16” x 3-1/2” GR5 bolt and 7/16” locknut.

4. Install the upper gearbox shaft square key as follows ( Figure 3.14):

a. Rotate the upper gearbox shaft bearing case until the bearing case keyway

aligns with the upper gearbox shaft keyway.

b. Insert the 3/8” x 1-3/4” square key into the shaft keyway.

c. Secure the square key with a keyway lock washer, a 3/8” lock washer, and

a 3/8” x 1-1/2” GR5 bolt.

Table 3.8 Install the Speed Reducer on the Boot

Diagram # Description Part # Quantity

1 Speed reducer 20558 1

2 Upper gearbox shaft n/a 1

3 Lower flight gearbox shaft n/a 1

4 PTO driveline strap 20705 1

5 PTO shield n/a 1

6 1/2” x 11-1/2” GR5 bolts 20777 12

7 1/2” locknuts 19599 12

8 Upper gearbox bearing case n/a 1

9 Upper gearbox shaft n/a 1

10 Lower flight bearing case n/a 1

11 Lower flight gearbox shaft n/a 1

12 Lower flight stop 20680 1

13 3/8” x 3-3/8” square key 11910 1

14 7/16” x 3-1/2” GR5 bolt 19547 1

15 7/16” locknut 19598 1

16 3/8” x 1-3/4” square key 17066 1

17 Keyway lock washer 20764 1

18 3/8” lock washer 19604 1

19 3/8” x 1-1/2” GR5 bolt 9900637 1

50 30875 R0

WHEATHEART - GRAIN AUGERS 3. ASSEMBLY

X160-85, X160-105, X160-125

Figure 3.13 Installing the Speed Reducer

30875 R0 51

3. ASSEMBLY WHEATHEART - GRAIN AUGERS

8

10

9

11

15

13

16

17

18

19

14

12

X160-85, X160-105, X160-125

Figure 3.14 Install the Shaft Square Keys and Lower Flight Stop

52 30875 R0

WHEATHEART - GRAIN AUGERS 3. ASSEMBLY

1

1

2

3,4

5

6

X160-85, X160-105, X160-125

3.2.8. INSTALL THE BOOT TOW BAR

1. Insert the tow bar into the boot channel (see Figure 3.15), and secure the

back end loosely with a 3/4” x 6-1/2” bolt and 3/4” locknut through the hole in

the boot channel.

2. Tightly secure the middle of the tow bar in channel with a 3/4” x 4-1/16” x

5-3/4” U-bolt and two 3/4” locknuts.

3. Fully tighten the 3/4” nut on the 3/4” x 6-1/2” bolt.

Table 3.9 Install the Boot Tow Bar

Diagram # Description Part # Quantity

1 Tow bar 20694 1

2 Boot channel n/a 1

3 3/4” x 6-1/2” bolt 19593 1

4 3/4” locknut 19601 1

5 3/4” x 4-1/16” x 5-3/4” U-bolt 20684 1

6 3/4” locknuts 19601 2

Figure 3.15 Installing the Boot Tow Bar

30875 R0 53

3. ASSEMBLY WHEATHEART - GRAIN AUGERS

1

2

3

3

4

X160-85, X160-105, X160-125

3.2.9. INSTALL THE DISCHARGE SPOUT

DISCHARGE SPOUT

1. Align the discharge spout over the opening in the upper tube.

2. Attach the discharge spout with two 5/8” x 3” GR5 bolts [17745] and 5/8”

locknuts [19600] on each side.

Table 3.10 Install the Boot Tow Bar

Diagram # Description Part # Quantity

1 Discharge spout 53090 1

2 Opening in upper tube n/a 1

3 5/8” x 3” GR5 bolts 17745 1

4 5/8” locknuts 19600 1

Figure 3.16 Installing the Discharge Spout

54 30875 R0

WHEATHEART - GRAIN AUGERS 3. ASSEMBLY

X160-85, X160-105, X160-125

3.2.10. SET THE THRUST ADJUSTER

1. Remove the upper bearing lock collar (if necessary).

2. Slide the lock collar and bushing onto the shaft and attach the 1-1/2” nut.

3. Turn the nut until boot flight stop snug against the speed reducer gearbox,

then keep turning it until all tube flights are turning with the shaft.

4. Secure the lock collar and tighten the set screw.

5. Install the cover over the two longer 5/8” bolts. Secure with two 5/8” whiznuts.

Figure 3.17 Set the Thrust Adjuster

30875 R0 55

3. ASSEMBLY WHEATHEART - GRAIN AUGERS

X160-85, X160-105, X160-125

3.2.11. APPLY LOGO AND MODEL DECALS ON THE AUGER TUBES

1. Prepare surface by cleaning

thoroughly with soap and water.

Surface must be clean and free of dirt,

grime, rust and oil. To clean oily

surface, wipe with clean cloth and

solvent cleaner or isopropyl alcohol.

2. Position the decal on the tube and

apply masking tape along the top,

creating a gate hinge. Figure A

demonstrates.

3. Remove backing paper from decal 6”

from the top and use the squeegee to

adhere decal to the tube, as seen in

Figure B. Start at the top center of the

decal and work your way outward both

left and right using overlapping

strokes.

4. As you work your way down the decal,

peel back the backing paper 6” at a

time. Repeat Step 3 until the entire

decal has been applied to the tube.

See Figure C as an example.

5. Once the entire decal has been

properly adhered to the tube, remove

tape hinge from front of decal. Remove

the front application tape at a sharp

180° angle.

6. Inspect the entire decal for air pockets; if found, remove them by punching a

tiny hole with a pin and then squeegee the surface flat.

7. As a final process, squeegee the corners and edges of the decal to ensure

proper adhesion and to prevent premature peeling.

56 30875 R0

WHEATHEART - GRAIN AUGERS 3. ASSEMBLY

LOWER MIDDLE TUBE

UPPER TUBE

WESTFIELD LOGO, CENTRED ON SIDE OF UPPER TUBE

AUGER MODEL

(DISCHARGE SIDE)

X160-85, X160-105, X160-125

Figure 3.18 Logo and Model Decal Locations (X160-105)

30875 R0 57

3. ASSEMBLY WHEATHEART - GRAIN AUGERS

X160-85, X160-105, X160-125

3.3. INSTALL TRUSS SUPPORT TOWERS AND TRUSS

TUBES

Note: Due to rigidity of the tubular trussing, do not put an upward bow in the auger.

Assemble trussing with main auger tube straight/level and well supported over its

length. When assembling the truss system, DO NOT tighten any bolts until all

components are in place.

• See Figure 3.19 and Figure 3.22 for the X160-85.

• See Figure 3.20 and Figure 3.23 for the X160-105.

• See Figure 3.21 and Figure 3.24 for the X160-125.

When assembling the truss system, do not tighten any bolts until all compo-

nents are in place.

1. As shown in the appropriate figures (Figure 3.19, Figure 3.20, Figure 3.21),

attach pairs of low and high truss tower brackets to the truss-attach brackets

welded to the auger tube, using eight 1/2” x 1-1/2” bolts and locknuts per

truss tower pair.

2. Thread a 1” hex nut as far as possible onto the threaded rod end of a truss

adjust tube.

3. Insert the threaded rod end of the truss adjust tube into the truss anchor

bracket, and bolt the opposite end to a tube connect plate that has been first

bolted to the adjacent truss pair.

4. Thread an second 1” hex nut a short distance onto the threaded rod end of

the truss adjuster tube.

5. According to the diagram for your specific model, work from one end of the

tube toward the opposite end:

a. Install tube connect plates between truss tower pairs.

Note: Truss towers connect to their tube connect plate using two 1/2” x 2-1/2” bolt and

locknut.

Note: Five-bolt and seven-bolt tube connect plates are used in specific locations. When

installing the seven-bolt connect plates, ensure that the three 1/2” bolt holes

should be closest to the boot, and the 3/4” bolt hole should be closest to the

discharge spout.

b. Install truss tubes between tube connect plates.

c. Install short and long cross-brace tubes.

Note: Single cross-brace tubes are used between the two truss towers closest the

ends of the main auger tube, and two cross-brace tubes are required between all

other truss tower sets.

d. Install the remaining truss adjust tube.

6. Tighten all truss, tube, and cross-brace bolts and nuts, but do not tighten the

1” hex nuts on the truss adjust tubes.

7. Install pairs of cross-brace clamps where the cross-brace tubes cross in an

”X” pattern using two 7/16” x 1-1/4” bolts and locknuts.

8. Adjust the “outer” 1” hex nuts on the truss adjust tube until the truss tubes are

tight and the auger tube is straight (ie. appears flat and well aligned, and

does not have any noticeable bow).

58 30875 R0

WHEATHEART - GRAIN AUGERS 3. ASSEMBLY

X160-85, X160-105, X160-125

9. Rotate the loose “inner” 1” hex nuts on the truss adjust tubes toward the

“outer” nut until they are locked tightly against their respective truss anchor

brackets.

Table 3.11. Truss Towers and Tubes Parts Reference

Fig Ref Part Description Part #

1

2

Low truss tower

High truss tower

1/2” x 1-1/2” bolts

1/2” locknuts

3 Truss anchor brackets n/a

4 1” hex nut 20080

5 Long truss adjust tube 20722

6 Five-bolt tube connect plate 20737

7

1/2” x 1-3/4” bolts

1/2” locknuts

8 Truss tube 20723

9

10

Seven-bolt tube connect plate (left)

Seven-bolt tube connect plate (right)

3/4” x 2-1/2” bolt

3/4” locknut

11 Truss cross brace, long 20725

12 Truss cross brace, short 20778

13

1/2” x 2-1/2” bolt

1/2” locknut

14 Cross-brace clamps 17655

15

7/16” x 1-1/4” Bolt

7/16” locknut

16 3/4” hex nut 19997

20659

20658

19589

19599

19974

19599

20720

20721

28446

19601

20772

19599

18698

19598

30875 R0 59

3. ASSEMBLY WHEATHEART - GRAIN AUGERS

2

2

LOW

LOW

HIGH

HIGH

HIGH

HIGH

2

X160-85, X160-105, X160-125

Figure 3.19 X160-85 Truss Tower Brackets

60 30875 R0

WHEATHEART - GRAIN AUGERS 3. ASSEMBLY

2

2

HIGH

HIGH

HIGH

HIGH

HIGH

LOW

LOW

2

HIGH

X160-85, X160-105, X160-125

Figure 3.20 X160-105 Truss Tower Brackets

30875 R0 61

3. ASSEMBLY WHEATHEART - GRAIN AUGERS

2

2

HIGH

HIGH

HIGH

HIGH

HIGH

HIGH

HIGH

LOW

LOW

2

HIGH

X160-85, X160-105, X160-125

Figure 3.21 X160-125 Truss Tower Brackets

62 30875 R0

WHEATHEART - GRAIN AUGERS 3. ASSEMBLY

5

7

7

10

13

14

1

8

13

12

11

5

8

6

4

8

6

16

16

11

11

13

10

8

5

8

8

9

8

8

4

11

1

15

11

14

5

11

9

X160-85, X160-105, X160-125

Figure 3.22 X160-85 Truss Tubes

30875 R0 63

3. ASSEMBLY WHEATHEART - GRAIN AUGERS

5

7

7

10

13

14

1

8

13

12

11

5

8

6

4

8

6

16

16

11

11

13

10

8

5

8

8

9

8

8

4

11

1

15

11

14

5

11

9

8

8

X160-85, X160-105, X160-125

Figure 3.23 X160-105 Truss Tubes

64 30875 R0

WHEATHEART - GRAIN AUGERS 3. ASSEMBLY

4

5

7

7

10

13

14

1

8

13

12

11

5

8

6

8

6

16

16

11

11

13

10

8

5

8

8

9

8

8

4

11

1

15

11

14

5

11

9

8

8

8

8

X160-85, X160-105, X160-125

Figure 3.24 X160-125 Truss Tubes

30875 R0 65

3. ASSEMBLY WHEATHEART - GRAIN AUGERS

X160-85, X160-105, X160-125

3.4. INSTALL TRUSS CABLES

See Figure 3.25 for details (X160-85 shown, other models are similar).

1. Attach eyebolts (1) to both ends of a truss cable (3) with two 1/2” cable

clamps (2), using about 10” (25.4 cm) to 12” (30.5 cm) of cable. Tighten

securely.

2. Thread the cable through the cable return bracket (4) on the underside of the

lower tube, and pull the cable through until there is an equal length of cable

on each side of the tube. Secure the cable to the cable return bracket with a

1/2” cable clamp (5), ensuring that the cable clamp is loose enough that the

cable remains free to move.

3. Insert the cable eyebolts into separate turnbuckle bodies (6) and secure with

3/4” locknuts threaded fully onto the eyebolt shaft, but not further than 1/4”.

4. Attach eyebolts (1) to the unconnected ends of both turnbuckle bodies, and

secure with 3/4” locknuts threaded fully onto the eyebolt shaft, but not further

than 1/4”.

5. Thread the second truss cable (3) through the cable return bracket (7) on the

underside of the upper tube, and pull the cable through until there is an equal

length of cable on each side of the tube.

6. Pull the ends of both cables over the truss cable supports (8), and secure the