Read this manual before using product. Failure

GHR130 & WHR130 GRAIN AUGERS

PTO DRIVE MODELS

ASSEMBLY & OPERATOR MANUAL

Grain Augers included in this manual:

GHR 130-51

GHR 130-61

GHR 130-71

WHR 130-51

WHR 130-61

WHR 130-71

to follow instructions and safety precautions can

result in serious injury, death, or property

damage. Keep manual for future reference.

Part Number: 30662 R1

Revised: Mar/13

This product has been designed and constructed according to general engineering

standardsa. Other local regulations may apply and must be followed by the operator.

We strongly recommend that all personnel associated with this equipment be trained

in the correct operational and safety procedures required for this product. Periodic

reviews of this manual with all employees should be standard practice. For your

convenience, we include this sign-off sheet so you can record your periodic reviews.

Date Employee Signature Employer Signature

a. Standards include organizations such as the American Society of Agricultural and Biological Engineers,

American National Standards Institute, Canadian Standards Association, International Organization for

Standardization, and/or others.

WHEATHEART - GHR & WHR GRAIN AUGERS

GRAIN AUGERS SD

TABLE OF CONTENTS

1. Introduction.......................................................................................................................... 5

2. Safety First............................................................................................................................ 7

2.1. General Safety ......................................................................................................... 8

2.2. Assembly Safety....................................................................................................... 9

2.3. ............................................................................................................................... 10

2.4. Transport & Placement Safety ............................................................................... 10

2.5. PTO Safety............................................................................................................. 10

2.6. Hydraulic Safety..................................................................................................... 11

2.7. Operational Safety.................................................................................................. 11

2.8. Maintenance Safety................................................................................................ 12

2.9. Safety Decals......................................................................................................... 13

2.9.1. Decal Installation...................................................................................... 13

2.9.2. Safety Decal Locations............................................................................. 13

3. Assembly ............................................................................................................................ 17

3.1. Tubes & Flighting ................................................................................................... 17

3.2. Track Shoe & Track Stop....................................................................................... 18

3.3. Intake Hitch ............................................................................................................ 20

3.4. Multi-Stage Driveshaft............................................................................................ 20

3.5. Shaft Drive Gearbox............................................................................................... 21

3.6. Driveshaft Shield.................................................................................................... 22

3.7. Discharge Spout..................................................................................................... 23

3.8. Truss ...................................................................................................................... 23

3.9. Transport Undercarriage ........................................................................................ 26

3.10. Lift Cylinders & Cable........................................................................................... 29

3.11. Hydraulic Hose Attachment.................................................................................. 31

3.12. PTO Driveline....................................................................................................... 32

3.13. Upper Housing Lubrication................................................................................... 32

3.14. Plastic Manual Holder .......................................................................................... 32

3.15. Model Decal Placement ....................................................................................... 33

4. Transport & Placement...................................................................................................... 35

4.1. Transport Procedure .............................................................................................. 35

4.2. Placement Procedure............................................................................................. 36

5. Operation ............................................................................................................................ 39

5.1. Pre-Operational Checklist ...................................................................................... 39

5.2. Auger Drive & Lockout Procedure.......................................................................... 39

5.3. Operating Procedure.............................................................................................. 40

5.3.1. Start-Up & Break-In.................................................................................. 40

5.3.2. Operating With A Full Load ...................................................................... 40

5.3.3. Shutdown.................................................................................................. 41

5.3.4. Lowering & Completion ............................................................................ 42

30662 R1 3

WHEATHEART - GHR & WHR GRAIN AUGERS

GRAIN AUGERS SD

TABLE OF CONTENTS

6. Maintenance & Storage...................................................................................................... 43

6.1. General Maintenance Procedures.......................................................................... 43

6.2. General Storage Procedures.................................................................................. 44

7. Troubleshooting ................................................................................................................. 45

Limited Warranty..................................................................................................................... 47

4 30662 R1

WHEATHEART - GHR & WHR GRAIN AUGERS 1. INTRODUCTION

GRAIN AUGERS SD

1.Introduction

Thank you for purchasing a WHEATHEART grain auger. Before using, please

read this manual and understand the various features of the equipment and

precautions for efficient and safe operation.

Keep this manual handy for frequent reference and to review with new

personnel. A sign-off form is supplied on the inside front cover to record your

safety reviews. Call your local distributor or dealer if you need assistance or

additional information.

This manual should be regarded as part of the equipment. Suppliers of both new

and second-hand equipment are advised to retain documentary evidence that

this manual was provided with the machine.

Serial number is found on the lower tube, near the angle ring of the

discharge end.

30662 R1 5

1. INTRODUCTION WHEATHEART - GHR & WHR GRAIN AUGERS

GRAIN AUGERS SD

6 30662 R1

WHEATHEART - GHR & WHR GRAIN AUGERS 2. SAFETY FIRST

GRAIN AUGERS SD

2.Safety First

The Safety Alert symbol to the left identifies important safety messages on the

product and in the manual. When you see this symbol, be alert to the possibility

of personal injury or death. Follow the instructions in the safety messages.

Signal Words

Note the use of the signal words DANGER, WARNING, CAUTION, and NOTICE

with the safety messages. The appropriate signal word for each message has

been selected using the definitions below as a guideline.

DANGER

Indicates an imminently hazardous situation

that, if not avoided, will result in serious injury

or death.

WARNING

Indicates a hazardous situation that, if not

avoided, could result in serious injury or

death.

CAUTION

Indicates a hazardous situation that, if not

avoided, may result in minor or moderate

injury.

NOTICE

Indicates a potentially hazardous situation that, if not

avoided, may result in property damage.

30662 R1 7

2. SAFETY FIRST WHEATHEART - GHR & WHR GRAIN AUGERS

2.1. GENERAL SAFETY GRAIN AUGERS SD

2.1. GENERAL SAFETY

Important: This general safety section includes instructions that apply to all safety practices.

Any instructions specific to a certain safety practice (e.g., assembly safety), can

be found in the appropriate section. Always read the complete instructional

sections and not just these safety summaries before doing anything with the

equipment.

YOU are responsible for the SAFE use and maintenance of your equipment.

YOU must ensure that you and anyone else who is going to work around the

equipment understands all procedures and related SAFETY information

contained in all on-product labels and in this manual.

Remember, YOU are the key to safety. Good safety practices not only protect

you, but also the people around you. Make these practices a working part of your

safety program.

• It is the equipment owner, operator, and maintenance personnel’s responsibility to read and understand ALL safety instructions, safety decals, and manuals and follow them when assembling, operating, or maintaining the

equipment. All accidents can be avoided.

• Equipment owners must give instructions and review the information initially

and annually with all personnel before allowing them to operate this product.

Untrained users/operators expose themselves and bystanders to possible

serious injury or death.

• Use this equipment for its intended purposes only.

• Do not modify the equipment in any way that is not authorized by the manufacturer. Unauthorized modification may impair the function and/or safety, and

could affect the life of the equipment. Any modification to the equipment voids

the warranty.

• Do not allow anyone within the work area who doesn’t need to be there.

• Follow all practices to ensure that the workplace is safe.

• Have a first-aid kit available for use should the need arise, and know how to

use it.

• Provide a fire extinguisher for use in case of an accident. Store in a highly visible and accessible place.

• Wear appropriate protective gear . This list includes, but

is not limited to:

• a hard hat

•gloves

• protective shoes with slip-resistant soles

• protective goggles

• hearing protection

• dust mask or respirator

• For Powered Equipment: before servicing, adjusting, or repairing powered

equipment, unplug, place all controls in neutral or off position, stop the engine

or motor , remove ignition key or lock out power source, and wait for all moving parts to stop.

8 30662 R1

WHEATHEART - GHR & WHR GRAIN AUGERS 2. SAFETY FIRST

GRAIN AUGERS SD 2.2. ASSEMBLY SAFETY

• Follow good shop practices:

• keep service area clean and dry

• be sure electrical outlets and tools are properly

grounded

• use adequate light for the job at hand

• Think SAFETY! Work SAFELY!

2.2. ASSEMBLY SAFETY

• Read through the instructions to get to know the sub-assemblies and hardware that make up the equipment.

• Do not take chances with safety. The components are large, heavy, and can

be hard to handle. Always use the proper tools, stands, jacks, and hoists for

the job.

• Read and understand the assembly instructions for the product before proceeding to assemble the product.

• Always have two or more people assembling the equipment. Because of the

weight, do not attempt assembly alone.

30662 R1 9

2. SAFETY FIRST WHEATHEART - GHR & WHR GRAIN AUGERS

2.3. GRAIN AUGERS SD

2.3.

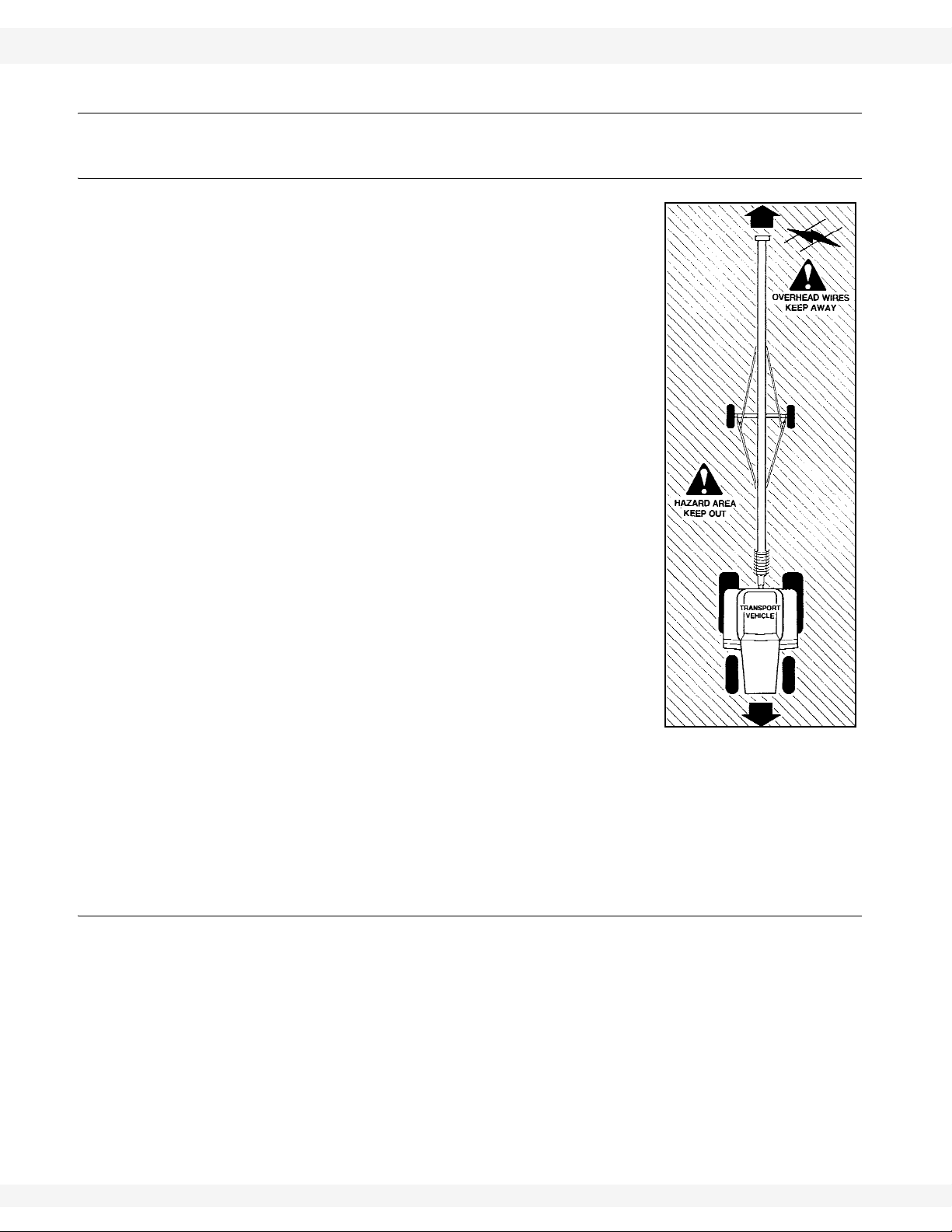

2.4. TRANSPORT & PLACEMENT SAFETY

• Transport auger in full down position with slight tension on cable.

• Properly place hitch pin and securely attach safety

chain. Use a type of hitch pin that will not allow

auger to separate from towing vehicle.

• Always attach an SMV (slow moving vehicle) sign

before transporting auger . Equip the auger with the

necessary lights for transportation where required

by law . Always use hazard warning flashers on the

tractor/towing vehicle when transporting unless

prohibited by law.

• Always travel at a safe speed, never exceeding 15

mph (24 km/hr). Reduce speed on rough surfaces

and be cautious when turning corners or meeting

traffic.

• Before raising/lowering/moving the auger, make

sure the area around the auger is clear of obstructions and/or untrained personnel. Never allow anyone to stand on or beneath auger while

transporting or placing auger.

• Do not transport auger on slopes greater than 20°.

• Wheels must be free to move when raising or lowering auger.

• Never attempt to move auger manually. To do so

will result in serious injury.

• Before moving auger, check for overhead obstructions and/or electrical wires.

Electrocution can occur without direct contact.

• Disconnect PTO driveline from tractor before moving auger or tractor and

secure in transport saddle (where applicable).

2.5. PTO SAFETY

• Never use a PTO driveline without a rotating shield in good working order.

• Ensure PTO driveline is securely attached at both ends before operating.

• Before starting tractor, turn power to PTO to the off position (where applicable).

• Keep body, hair, and clothing away from rotating PTO driveline.

• Ensure the PTO driveline shields turn freely on the PTO driveline.

• Do not exceed operating speed of 540 rpm.

• Keep u-joint angles small and equal. Do not exceed recommended operating

10 30662 R1

length for PTO driveline.

WHEATHEART - GHR & WHR GRAIN AUGERS 2. SAFETY FIRST

GRAIN AUGERS SD 2.6. HYDRAULIC SAFETY

2.6. HYDRAULIC SAFETY

• Wear proper hand and face protection when searching for hydraulic leaks.

Escaping fluid under pressure can penetrate the skin, causing serious injury

like gangrene. In case of accident, see a doctor immediately.

• Fluid leaks in the hydraulic lift cylinders or hoses will allow the auger to lower

inadvertently. Repair all leaks and breaks immediately. Rupture could cause

damage and/or personal injury.

• A hydraulic lift is faster than a conventional hand crank—always clear area of

personnel before raising or lowering.

• Do not disconnect hydraulic couplers when hydraulic system is pressurized.

For the correct procedure, consult this manual or your tractor manual.

• Relieve pressure before unhooking hydraulic lines.

• Inspect hydraulic fittings and hoses for damage on a daily basis. Repair if

damaged.

• Ensure that the hydraulic line(s) is (are) properly connected and secure.

• Keep hydraulic line(s) away from moving parts.

• Clean connections before connecting to equipment.

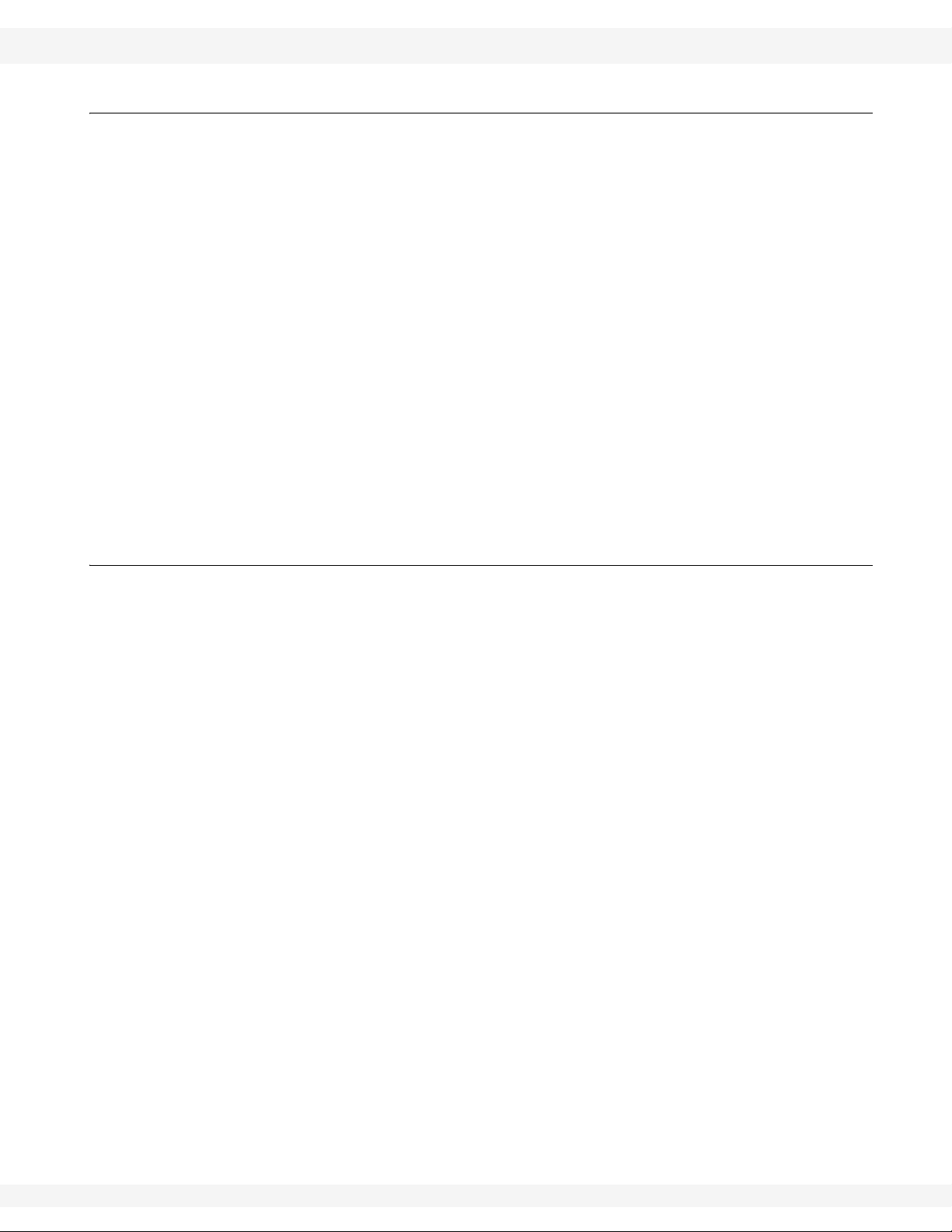

2.7. OPERATIONAL SAFETY

• Have another trained person nearby who can shut down the auger in case of

accident. Always work with a second trained person around augers.

• Do not operate with any of the safety guards removed.

• Keep body, hair, and clothing away from moving p art s. Stay away from intake

during operation.

• Inspect lift cable before using auger. Replace if frayed or damaged. Make

sure it is seated properly in the cable sheaves and that cable clamps are

secure.

• Operate auger on level ground free of debris. If ground is uneven, anchor the

auger to prevent tipping or upending.

• Augers are not insulated. Keep away from electrical lines. Electrocution can

occur without direct contact.

• Support the discharge end and/or anchor the intake end before operating to

prevent upending.

• Do not use auger as a hoist.

• Empty auger before raising or lowering.

• Lower auger at completion of operation or when not in use. Auger could drop

rapidly in case of cable break or hydraulic failure (where applicable).

30662 R1 11

2. SAFETY FIRST WHEATHEART - GHR & WHR GRAIN AUGERS

2.8. MAINTENANCE SAFETY GRAIN AUGERS SD

2.8. MAINTENANCE SAFETY

• Shut down and lock out all power before attempting maintenance of any kind.

If applicable, disconnect PTO driveline from tractor or hydraulic hoses on

units with hydraulic drive hoppers.

• After maintenance is complete, replace and secure all safety guards and

safety devices, and if applicable, service doors and cleanout covers.

• Support auger tube before attempting maintenance on the undercarriage

assembly. Auger should be in full down position for maintenance.

• Use only genuine WHEATHEART replacement parts or equivalent. Replacement parts such as intake guards, pulley guards, PTO driveline shields,

winches, and lift cables must meet ASABE standards or serious injury may

result. Use of unauthorized parts will void warranty. If in doubt, contact

WHEATHEART or your WHEATHEART dealer.

12 30662 R1

Figure 2.1

WHEATHEART - GHR & WHR GRAIN AUGERS 2. SAFETY FIRST

GRAIN AUGERS SD 2.9. SAFETY DECALS

• Do not modify any auger components without authorization from WHEATHEART. Modification can be dangerous and result in serious injuries.

2.9. SAFETY DECALS

• Keep safety decals clean and legible at all times.

• Replace safety decals that are missing or have become illegible. See decal

location figures that follow.

• Replaced parts must display the same decal(s) as the original part.

• Safety decals are available from your distributor, dealer, or factory.

2.9.1. DECAL INSTALLATION

1. Decal area must be clean and dry, with a temperature above 50°F (10°C).

2. Decide on the exact position before you remove the backing paper.

3. Align the decal over the specified area and carefully press the small portion

with the exposed sticky backing in place.

4. Slowly peel back the remaining paper and carefully smooth the remaining

portion of the decal in place.

5. Small air pockets can be pierced with a pin and smoothed out using the sign

backing paper.

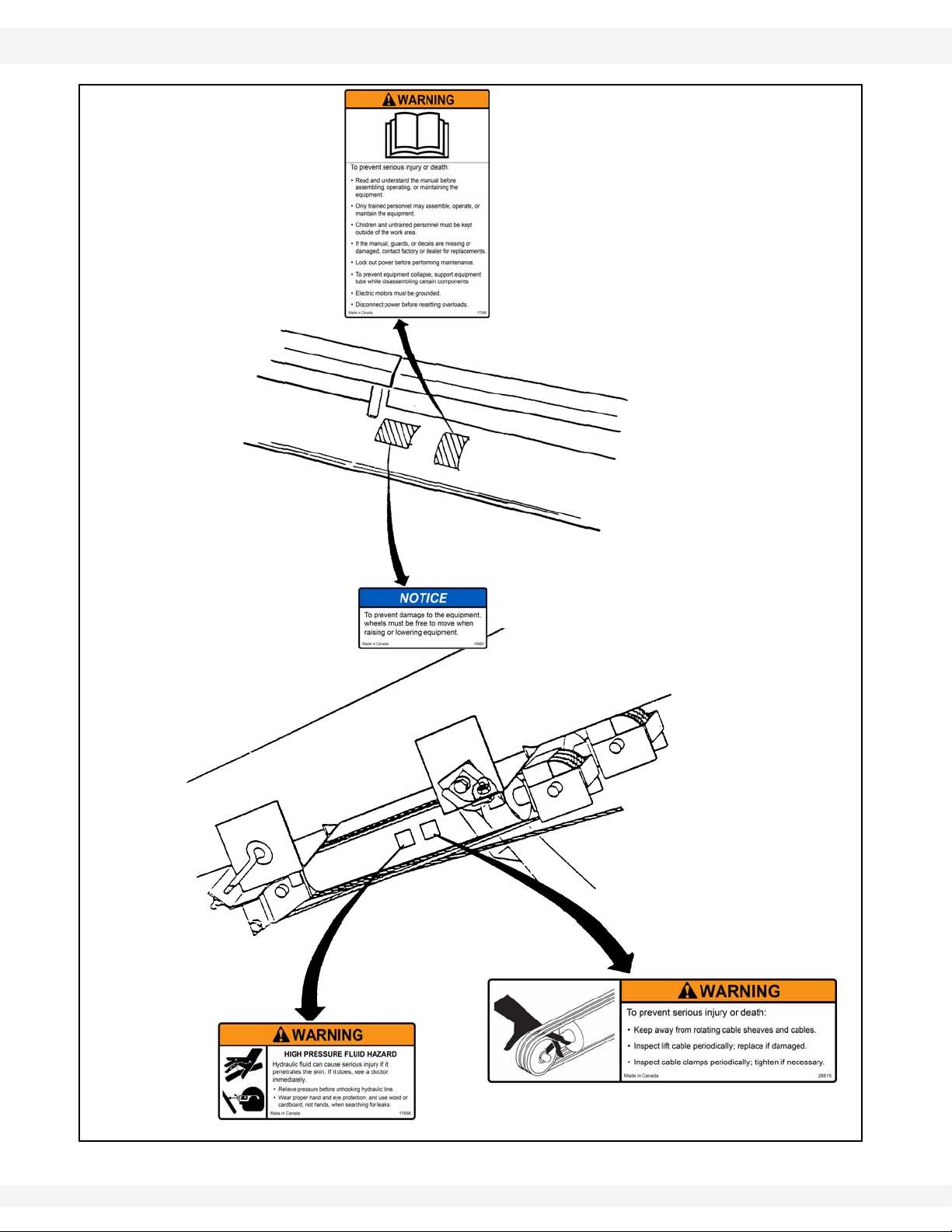

2.9.2. SAFETY DECAL LOCATIONS

Replicas of the safety decals that are attached to the equipment are shown in the

figure(s) that follow. Proper safety procedures require that you familiarize

yourself with the various safety decals and the areas or particular functions that

the decals apply to as well as the safety precautions that must be taken to avoid

serious injury, death, or damage.

* WHEATHEART reserves the right to update safety decals without notice.

Safety decals may not be exactly as shown.

30662 R1 13

2. SAFETY FIRST WHEATHEART - GHR & WHR GRAIN AUGERS

DECAL

#17096

DECAL

#19960

DECAL #28615

DECAL #17698

2.9. SAFETY DECALS GRAIN AUGERS SD

Figure 2.2

14 30662 R1

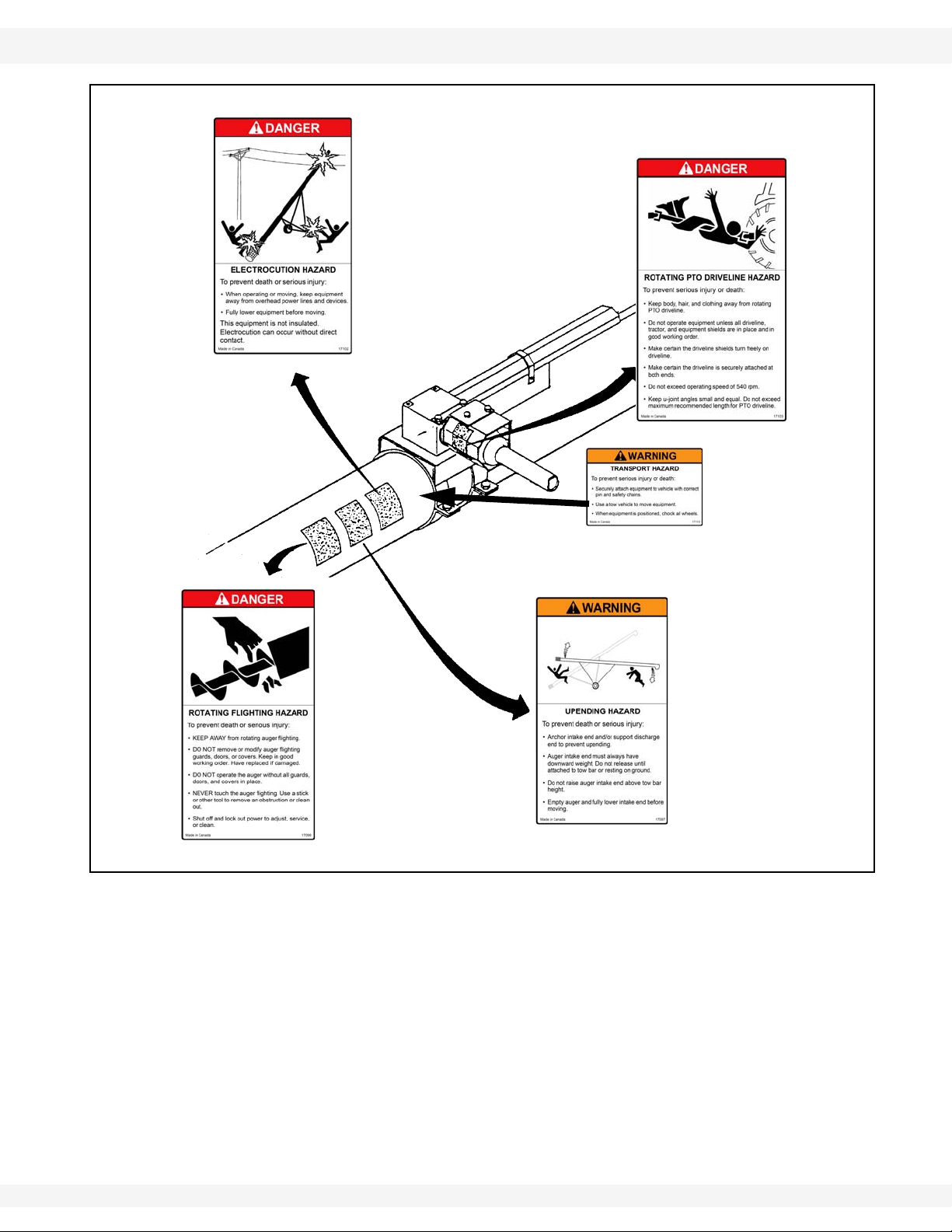

WHEATHEART - GHR & WHR GRAIN AUGERS 2. SAFETY FIRST

DECAL

#17102

DECAL #17103

DECAL

#17098

DECAL

#17097

DECAL #17113

GRAIN AUGERS SD 2.9. SAFETY DECALS

Figure 2.3

30662 R1 15

Loading...

Loading...