Read this manual before using product. Failure

SA FLEX AUGER

71’ - 111’

ASSEMBLY & OPERATION MANUAL

to follow instructions and safety precautions can

result in serious injury, death, or property

damage. Keep manual for future reference.

Part Number: 30651 R5

Revised: May/13

This product has been designed and constructed according to general engineering

standardsa. Other local regulations may apply and must be followed by the operator.

We strongly recommend that all personnel associated with this equipment be trained

in the correct operational and safety procedures required for this product. Periodic

reviews of this manual with all employees should be standard practice. For your

convenience, we include this sign-off sheet so you can record your periodic reviews.

Date Employee Signature Employer Signature

a. Standards include organizations such as the American Society of Agricultural and Biological Engineers,

American National Standards Institute, Canadian Standards Association, International Organization for

Standardization, and/or others.

WHEATHEART - SA FLEX AUGER

71’ - 111’

TABLE OF CONTENTS

1. Introduction.......................................................................................................................... 5

2. Safety .................................................................................................................................... 7

2.1. General Safety Information ...................................................................................... 7

2.2. Assembly Safety....................................................................................................... 8

2.3. Operation Safety ...................................................................................................... 8

2.4. PTO Safety............................................................................................................. 11

2.5. Hydraulic Safety..................................................................................................... 11

2.6. Transport and Placement Safety............................................................................ 12

2.7. Maintenance Safety................................................................................................ 13

2.8. Safety Decals......................................................................................................... 13

2.8.1. Decal Installation...................................................................................... 13

2.8.2. Safety Decal Locations............................................................................. 14

3. Assembly ............................................................................................................................ 21

3.1. Tubes & Flighting ................................................................................................... 21

3.2. Flex Frame Components........................................................................................ 26

3.3. Flex Auger Boot...................................................................................................... 27

3.4. Connecting Flex Tube to Flex Frame..................................................................... 29

3.5. Adjustable Towbar.................................................................................................. 30

3.6. Discharge Spout & Thrust Adjuster........................................................................ 31

3.7. Truss 71’–91’.......................................................................................................... 32

3.8. Truss 111’............................................................................................................... 35

3.8.1. Cable Trussing ......................................................................................... 37

3.9. Scissor Lift Frame (71’–91’) ................................................................................... 38

3.9.1. Scissor Frame Assembly.......................................................................... 38

3.9.2. Attaching to Tube ..................................................................................... 45

3.10. Transport Undercarriage (111’)............................................................................ 48

3.11. Lift Cables (111’).................................................................................................. 51

3.12. Lift Cylinder Hydraulic Hoses (111’)..................................................................... 52

3.13. Hydraulics (71’–91’).............................................................................................. 54

3.13.1. Cylinder Installation................................................................................ 54

3.13.2. Hydraulic Cylinder Plumbing .................................................................. 56

3.14. PTO (CV) Driveline............................................................................................... 57

3.15. Low Profile Hopper............................................................................................... 58

3.15.1. Steering Assembly.................................................................................. 60

3.15.2. Attaching Swing to Flex Auger ............................................................... 67

3.15.3. Hopper Lift Arm/Winch ........................................................................... 67

3.15.4. Placing Hopper into Transport Position.................................................. 70

3.16. Flex Auger Hydraulics.......................................................................................... 71

3.16.1. Open-to-Closed-Center Conversion....................................................... 75

3.17. Hitch Jack............................................................................................................. 76

3.18. Auger-to-Tractor Hookup...................................................................................... 76

3.18.1. PTO Driveline / Drawbar......................................................................... 76

3.18.2. Hydraulic Hose Couplers........................................................................ 78

30651 R5 3

WHEATHEART - SA FLEX AUGER

71’ - 111’

TABLE OF CONTENTS

4. Transport & Placement ...................................................................................................... 79

4.1. Transport Procedure............................................................................................... 79

4.2. Placement Procedure............................................................................................. 81

4.2.1. Axle Extension Procedure ........................................................................ 84

5. Operation ............................................................................................................................ 87

5.1. Pre-Operational Checklist....................................................................................... 87

5.2. Auger Drive & Lockout............................................................................................ 87

5.3. Operating Procedure.............................................................................................. 88

5.3.1. Start-Up & Break-In .................................................................................. 88

5.3.2. Operating with a Full Load........................................................................ 90

5.3.3. Shutdown.................................................................................................. 91

5.3.4. Lowering Auger......................................................................................... 92

6. Maintenance & Storage...................................................................................................... 95

6.1. General Maintenance Procedures.......................................................................... 95

6.2. Mechanical Drive System....................................................................................... 97

6.3. Storage................................................................................................................... 98

7. Troubleshooting ................................................................................................................. 99

8. Appendix........................................................................................................................... 103

8.1. Specifications ....................................................................................................... 103

8.2. Bolt Torque Values .............................................................................................. 104

8.3. Lift Cylinder Hydraulics (111’)............................................................................... 105

8.4. How to Charge the Lift System (111’ Only).......................................................... 105

8.4.1. Hydraulic Motor Notes............................................................................ 106

Limited Warranty................................................................................................................... 107

4 30651 R5

WHEATHEART - SA FLEX AUGER 1. INTRODUCTION

71’ - 111’

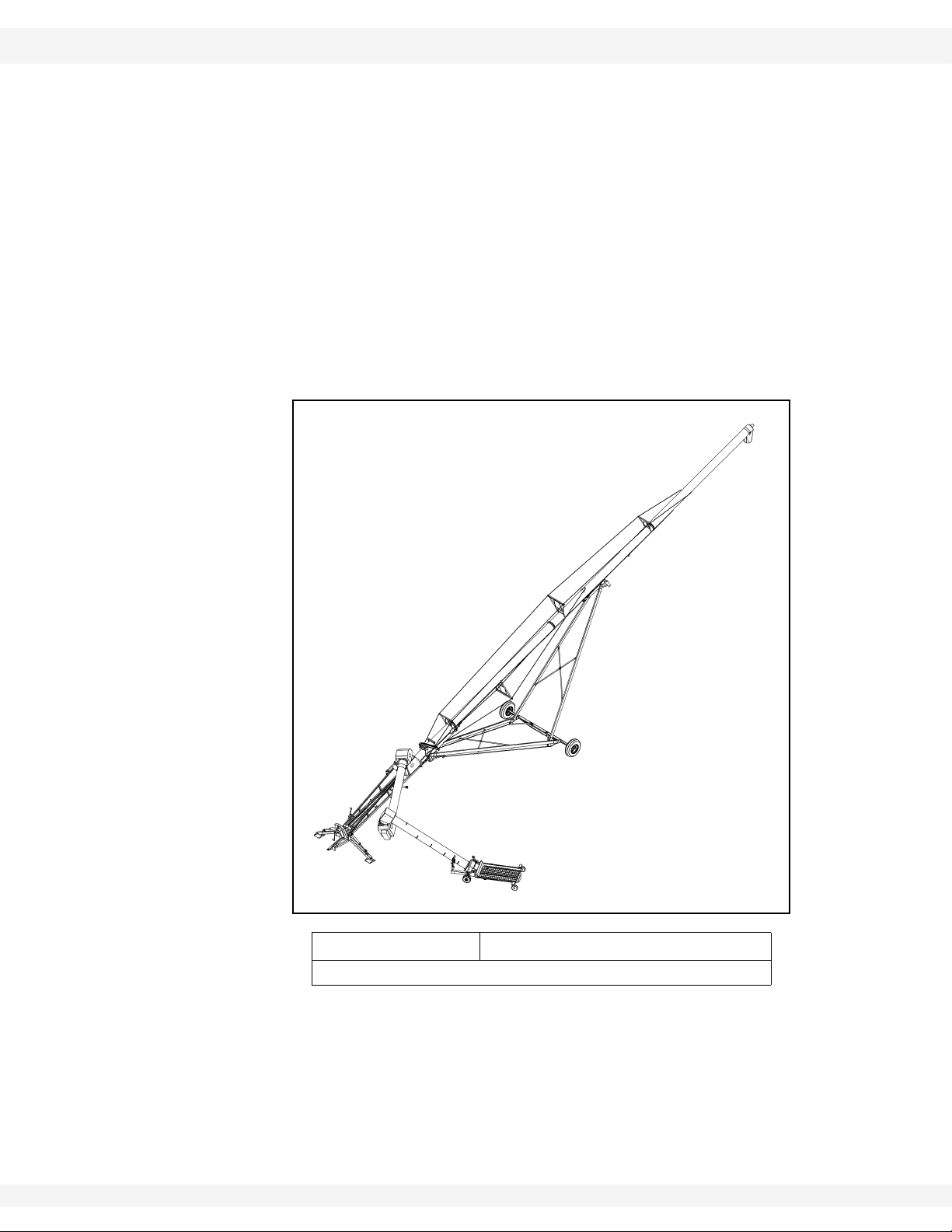

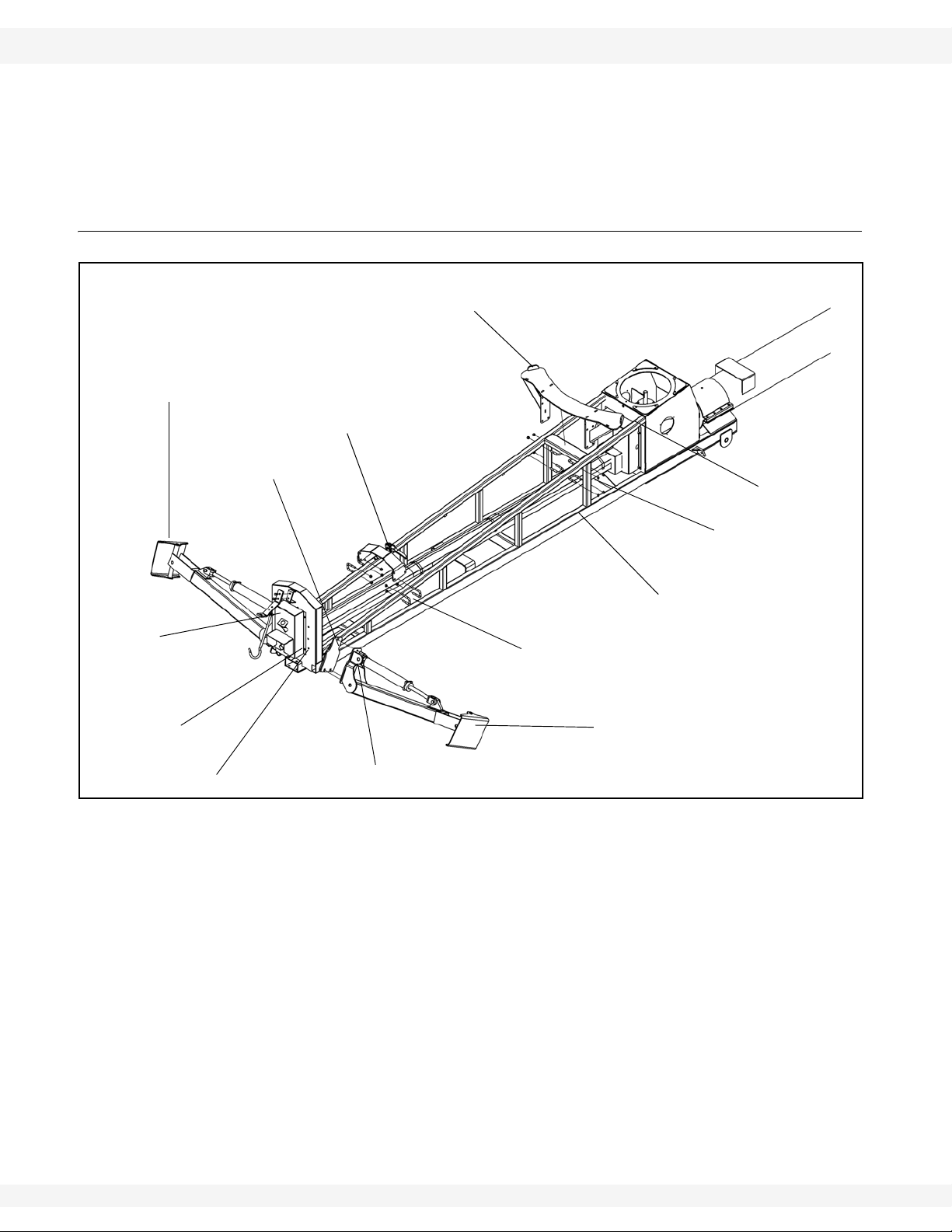

1.Introduction

Thank you for purchasing a Wheatheart grain auger. Before using, please read

this manual and understand the various features of the equipment and precautions for efficient and safe operation.

Keep this manual handy for frequent reference and to review with new

personnel. A sign-off form is supplied on the inside front cover to record your

safety reviews. Call your local distributor or dealer if you need assistance or

additional information.

This manual should be regarded as part of the equipment. Suppliers of both new

and second-hand equipment are advised to retain documentary evidence that

this manual was provided with the machine.

Serial Number:

*Serial number is located on the lower tube.

30651 R5 5

1. INTRODUCTION WHEATHEART - SA FLEX AUGER

71’ - 111’

6 30651 R5

WHEATHEART - SA FLEX AUGER 2. SAFETY

71’ - 111’ 2.1. GENERAL SAFETY INFORMATION

2.Safety

2.1. GENERAL SAFETY INFORMATION

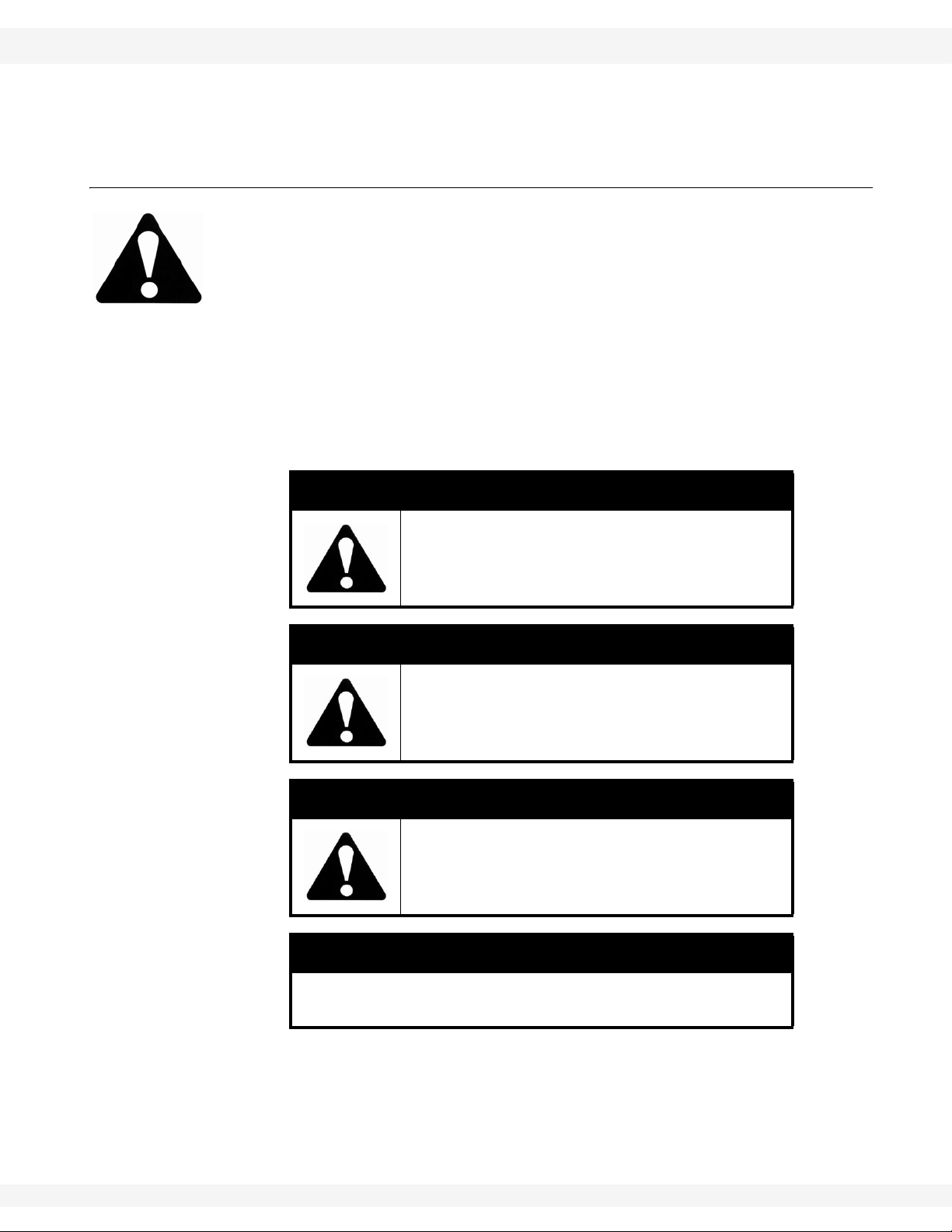

The Safety Alert symbol identifies important safety messages on the product and

in the manual. When you see this symbol, be alert to the possibility of personal

injury or death. Follow the instructions in the safety messages.

Why is SAFETY important?

• Accidents disable and kill.

• Accidents cost.

• Accidents can be avoided.

SIGNAL WORDS: Note the use of the signal words DANGER, WARNING,

CAUTION, and NOTICE with the safety messages. The appropriate signal word

for each message has been selected using the definitions below as a guideline.

DANGER

Indicates an imminently hazardous situation

that, if not avoided, will result in serious injury

or death.

WARNING

Indicates a hazardous situation that, if not

avoided, could result in serious injury or

death.

CAUTION

Indicates a hazardous situation that, if not

avoided, may result in minor or moderate

injury.

NOTICE

Indicates a potentially hazardous situation that, if not

avoided, may result in property damage.

30651 R5 7

2. SAFETY WHEATHEART - SA FLEX AUGER

2.2. ASSEMBLY SAFETY 71’ - 111’

YOU are responsible for the SAFE use and maintenance of your equipment.

YOU must ensure that you and anyone else who is going to work around the

equipment understands all procedures and related SAFETY information

contained in this manual.

Remember, YOU are the key to safety. Good safety practices not only protect

you, but also the people around you. Make these practices a working part of your

safety program.

Important: Below are general instructions that apply to all safety practices. Any instructions

specific to a certain safety practice (e.g., Operational Safety), can be found in the

appropriate section. Always read the complete instructional sections and not just

these safety summaries before doing anything with the equipment.

• It is the equipment owner, operator, and maintenance personnel's responsibility to read and understand ALL safety instructions, safety decals, and manuals and follow them when assembling, operating, or maintaining the

equipment. All accidents can be avoided.

• Equipment owners must give instructions and review the information initially

and annually with all personnel before allowing them to operate this product.

Untrained users/operators expose themselves and bystanders to possible

serious injury or death.

• Use this equipment for its intended purposes only.

• Do not modify the equipment in any way without written permission from the

manufacturer. Unauthorized modification may impair the function and/or

safety, and could affect the life of the equipment. Any unauthorized modification of the equipment voids the warranty.

• Do not allow any unauthorized person in the work area.

2.2. ASSEMBLY SAFETY

• Read and understand the instructions to get to know the sub-assemblies and

hardware that make up the equipment before preceding to assemble the

product.

• Do not take chances with safety. The components are large, heavy, and can

be hard to handle. Always use the proper tools, stands, jacks, and hoists for

the job.

• Always have two or more people assembling the equipment. Because of the

weight, do not attempt assembly alone.

2.3. OPERATION SAFETY

• Have another trained person nearby who can shut down the auger in case of

an accident. Always work with a second trained person around augers.

• Do not operate with any of the safety guards removed.

• Keep body, hair, and clothing away from moving p art s. Stay away from intake

during operation.

8 30651 R5

WHEATHEART - SA FLEX AUGER 2. SAFETY

71’ - 111’ 2.3. OPERATION SAFETY

• Inspect lift cable before using auger. Replace if frayed or damaged. Make

sure it is seated properly in the cable sheaves and that cable clamps are

secure.

• Operate auger on level ground free of debris. If ground is uneven, anchor the

auger to prevent tipping or upending.

• Augers are not insulated. Keep away from electrical lines. Electrocution can

occur without direct contact.

• Support the discharge end and/or anchor the intake end before operating to

prevent upending.

• Do not use auger as a hoist.

• Empty auger before raising or lowering.

• Lower auger at completion of operation or when not in use. Auger could drop

rapidly if the cable breaks or if the hydraulics fail (where applicable).

• Do not operate auger with the service or cleanout doors open or unlatched.

• Do not get on or beneath auger when raising or lowering intake hitch jack, or

when auger is supported by hitch jack.

• Do not operate auger with intake hopper in transport position. This will cause

damage to the u-joint.

30651 R5 9

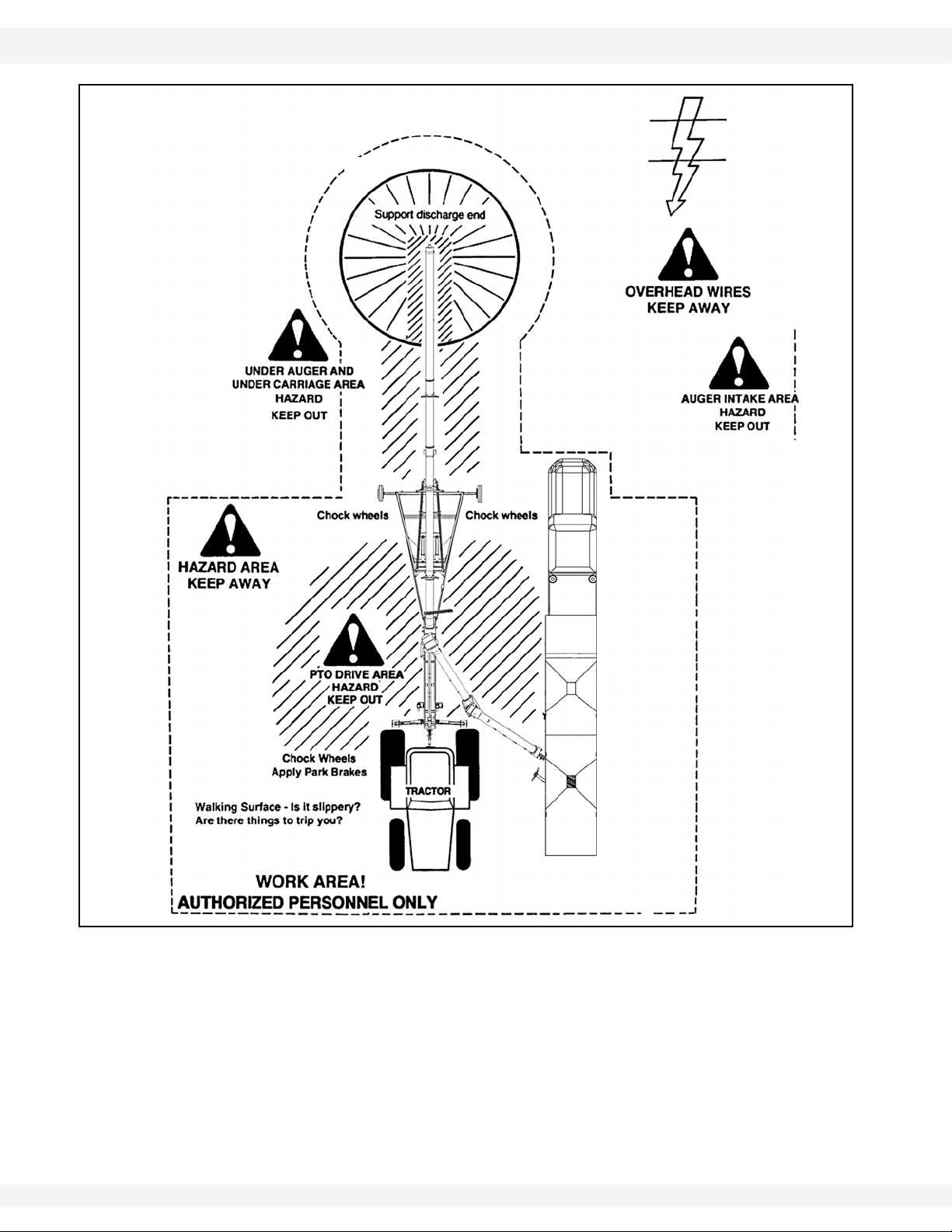

2. SAFETY WHEATHEART - SA FLEX AUGER

BIN

2.3. OPERATION SAFETY 71’ - 111’

Figure 2.1

10 30651 R5

WHEATHEART - SA FLEX AUGER 2. SAFETY

71’ - 111’ 2.4. PTO SAFETY

2.4. PTO SAFETY

• Never use a PTO driveline without a rotating shield in good working order.

• Ensure PTO driveline is securely attached at both ends before operating.

• Before starting tractor, turn power to PTO to the off position (where applicable).

• Keep body, hair, and clothing away from rotating PTO driveline.

• Ensure the PTO driveline shields turn freely on the PTO driveline.

• Do not exceed operating speed of 540 rpm.

• Keep u-joint angles small and equal. Do not exceed recommended operating

length for PTO driveline.

2.5. HYDRAULIC SAFETY

• Wear proper hand and face protection when searching for hydraulic leaks.

Escaping fluid under pressure can penetrate the skin, causing serious injury

like gangrene. In case of accident, see a doctor immediately.

• Fluid leaks in the hydraulic lift cylinders or hoses will allow the auger to lower

inadvertently. Repair all leaks and breaks immediately. Rupture could cause

damage and/or personal injury.

• A hydraulic lift is faster than a conventional hand crank—always clear area of

personnel before raising or lowering.

• Do not disconnect hydraulic couplers when hydraulic system is pressurized.

For the correct procedure, consult this manual or your tractor manual.

• Relieve pressure before unhooking hydraulic lines.

• Inspect hydraulic fittings and hoses for damage on a daily basis. Repair if

damaged.

• Ensure that the hydraulic line(s) is (are) properly connected and secure.

• Keep hydraulic line(s) away from moving parts.

• Clean connections before connecting to equipment.

30651 R5 11

OVERHEAD

WIRES!

KEEP AWAY

HAZARD

AREA!

KEEP

OUT

2. SAFETY WHEATHEART - SA FLEX AUGER

2.6. TRANSPORT AND PLACEMENT SAFETY 71’ - 111’

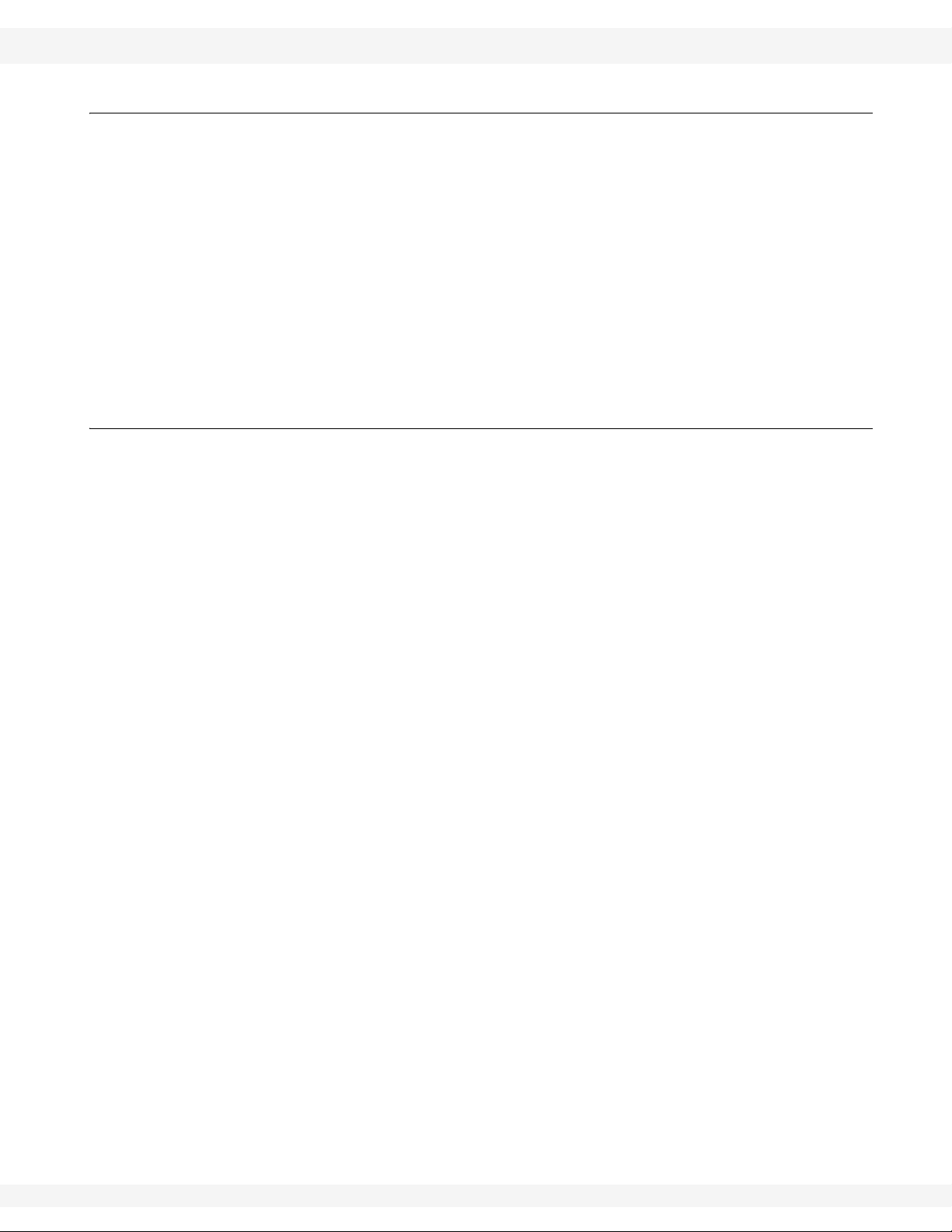

2.6. TRANSPORT AND PLACEMENT SAFETY

• Transport auger in full down

position with slight tension

on cable.

• Properly place hitch pin and

securely attach safety

chain. Use a type of hitch

pin that will not allow auger

to separate from towing

vehicle.

• Always attach an SMV

(slow moving vehicle) sign

before transporting auger .

Equip the auger with the

necessary lights for transportation where required by

law. Always use hazard

warning flashers on the

tractor/towing vehicle when

transporting, unless prohibited by law.

• Always travel at a safe

speed, never exceeding 15

mph (24 km/hr). Reduce

speed on rough surfaces

and be cautious when turning corners or meeting

traffic.

• Before raising/lowering/

moving the auger, make

sure the area around the auger is clear of obstructions and/or untrained personnel. Never allow anyone to stand on or beneath auger while transporting

or placing auger.

• Do not transport auger on slopes greater than 20°.

• Wheels must be free to move when raising or lowering auger.

• Never attempt to move auger manually. To do so will result in serious injury.

• Before moving auger, check for overhead obstructions and/or electrical wires.

Electrocution can occur without direct contact.

• Disconnect PTO driveline from tractor before moving auger or tractor, and

secure in transport saddle (where applicable).

• Raise intake feed hopper into transport position and lock hopper lift winch

before transporting or moving auger . Intake feed side of hopper must face

main auger when in transport position.

• Do not operate auger with intake hopper in transport position. This will cause

damage to the u-joint.

12 30651 R5

WHEATHEART - SA FLEX AUGER 2. SAFETY

71’ - 111’ 2.7. MAINTENANCE SAFETY

• Not intended for transport on public roads. If auger must be moved, check

local length and width regulations. Be careful when turning corners. Watch for

low overhead objects. Retract axles before transporting unit.

Important: The Flex Auger exceeds hitch weight capacity for most trucks and must be towed

with appropriate equipment. A tractor is recommended. Refer to the Specifications Section in the Appendix for details on the weight of this machine. Check

with your local dealer if you are unsure of your towing capacity.

2.7. MAINTENANCE SAFETY

• Shut down and lock out all power before attempting maintenance of any kind.

If applicable, disconnect PTO driveline from tractor or hydraulic hoses on

units with hydraulic drive hoppers.

• After maintenance is complete, replace and secure all safety guards and

safety devices, and if applicable, service doors and cleanout covers.

• Support auger tube before attempting maintenance on the undercarriage

assembly. Auger should be in full down position for maintenance.

• Use only genuine Wheatheart replacement parts or equivalent. Replacement

parts such as intake guards, pulley guards, PTO driveline shields, winches,

and lift cables must meet ASABE standards or serious injury may result. Use

of unauthorized parts will void warranty. If in doubt, contact Wheatheart or

your Wheatheart dealer.

• Do not modify any auger components without authorization from Wheatheart.

Modification can be dangerous and result in serious injuries.

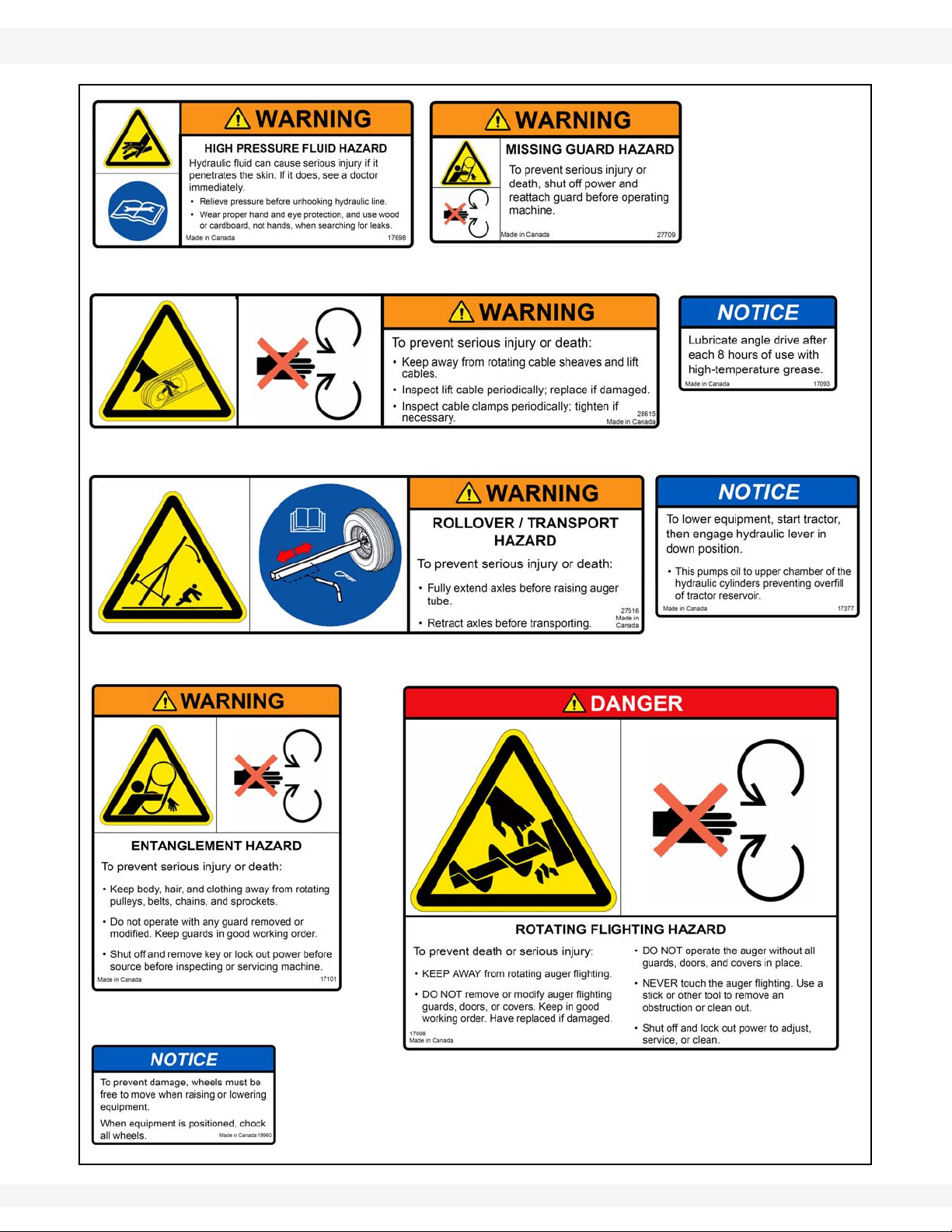

2.8. SAFETY DECALS

• Keep safety decals clean and legible at all times.

• Replace safety decals that are missing or have become illegible. See decal

location figures that follow.

• Replaced parts must display the same decal(s) as the original part.

• Safety decals are available from your distributor, dealer, or factory.

2.8.1. Decal Installation

1. Decal area must be clean and dry, with a temperature above 50°F (10°C).

2. Decide on the exact position before you remove the backing paper.

3. Align the decal over the specified area and carefully press the small portion

with the exposed sticky backing in place.

4. Slowly peel back the remaining paper and carefully smooth the remaining

portion of the decal in place.

5. Small air pockets can be pierced with a pin and smoothed out using the sign

backing paper.

30651 R5 13

2. SAFETY WHEATHEART - SA FLEX AUGER

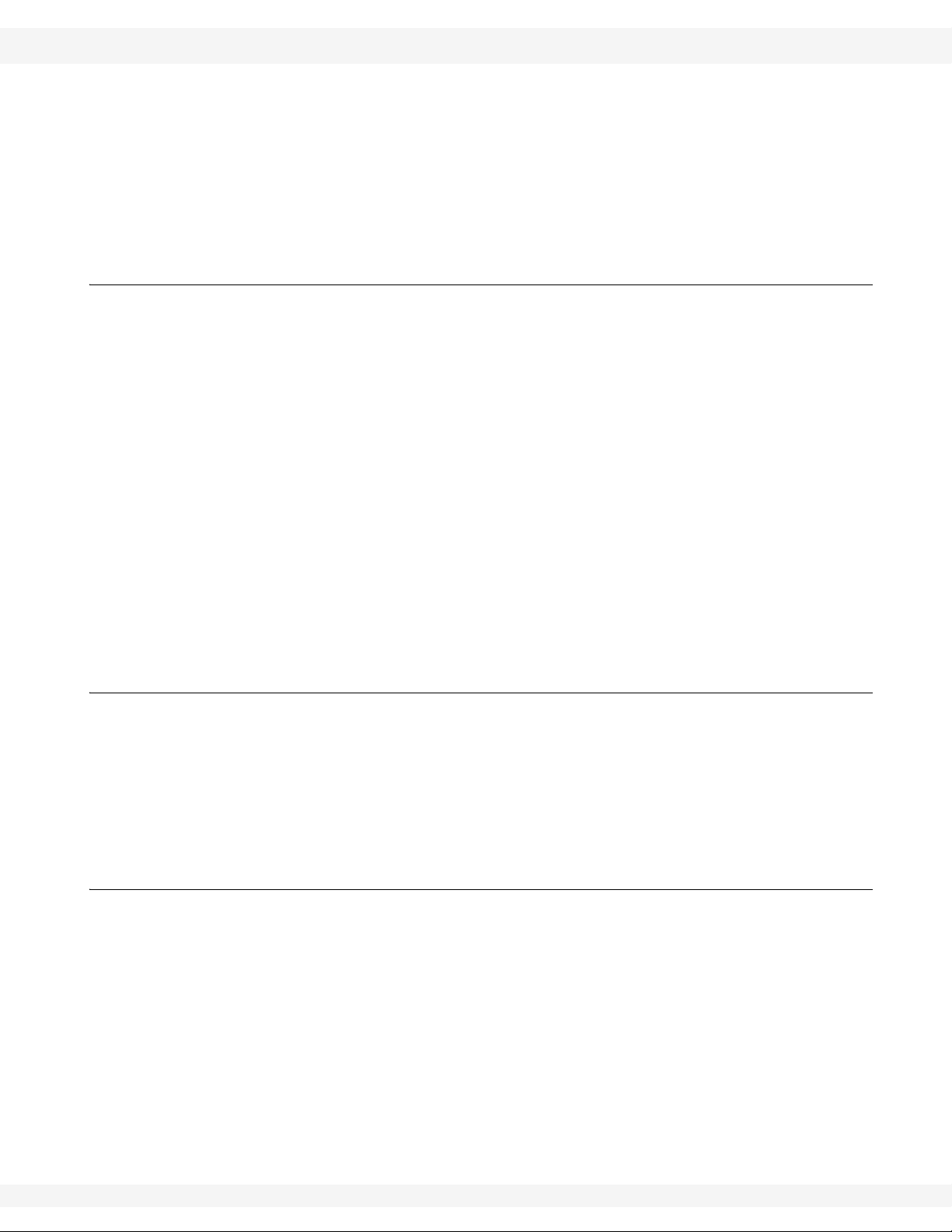

DECAL #17098

DECAL #17093

PLACED ON MACHINE

BEHIND GUARD

DECAL #27709

DECAL #17101

2.8. SAFETY DECALS 71’ - 111’

2.8.2. Safety Decal Locations

Replicas of the safety decals that are attached to the equipment are shown in the

figure(s) that follow. Proper safety procedures require that you familiarize

yourself with the various safety decals and the areas or particular functions that

the decals apply to, as well as the safety precautions that must be taken to avoid

serious injury, death, or damage.

*Wheatheart Manufacturing reserves the right to update safety decals without

notice. Safety decals may not be exactly as shown.

Figure 2.2

14 30651 R5

WHEATHEART - SA FLEX AUGER 2. SAFETY

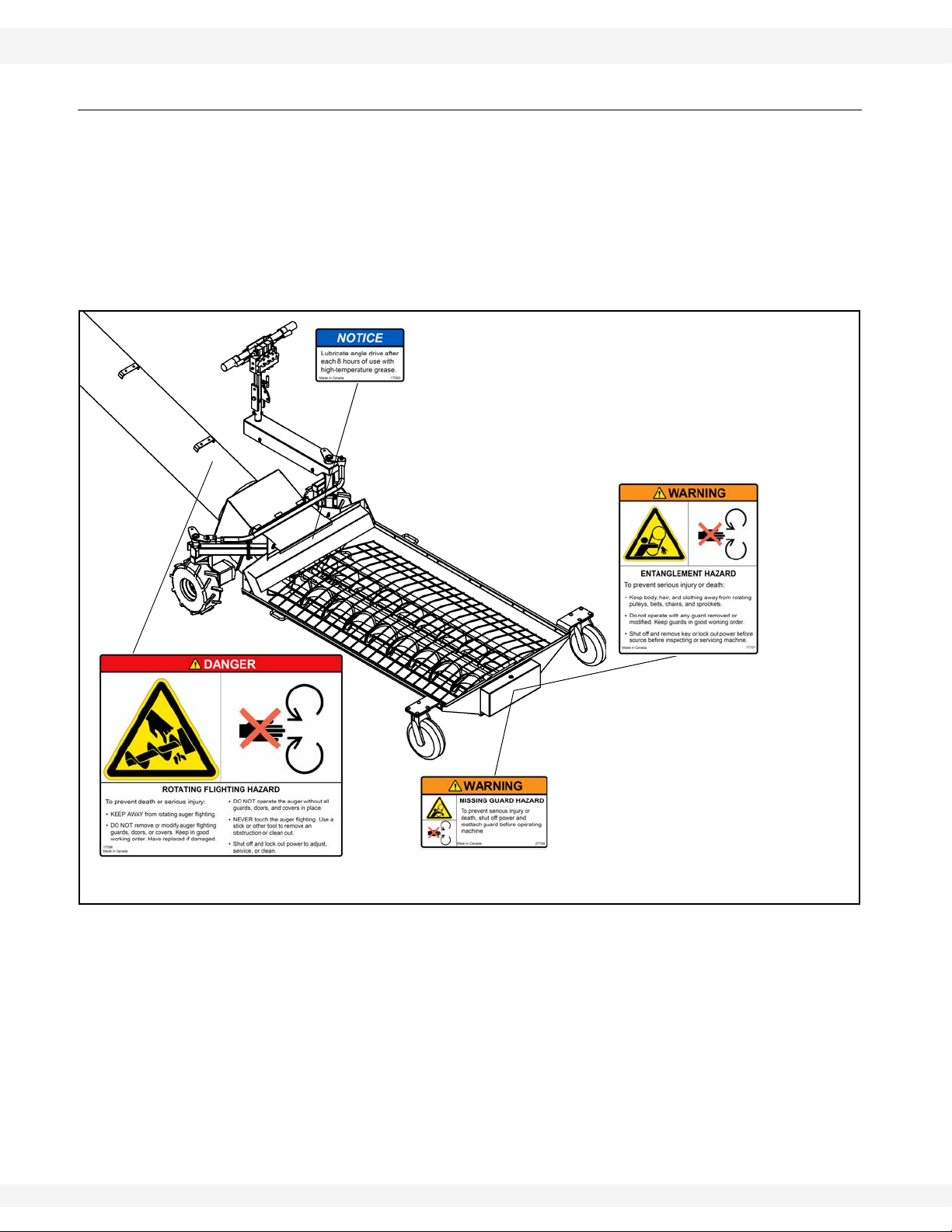

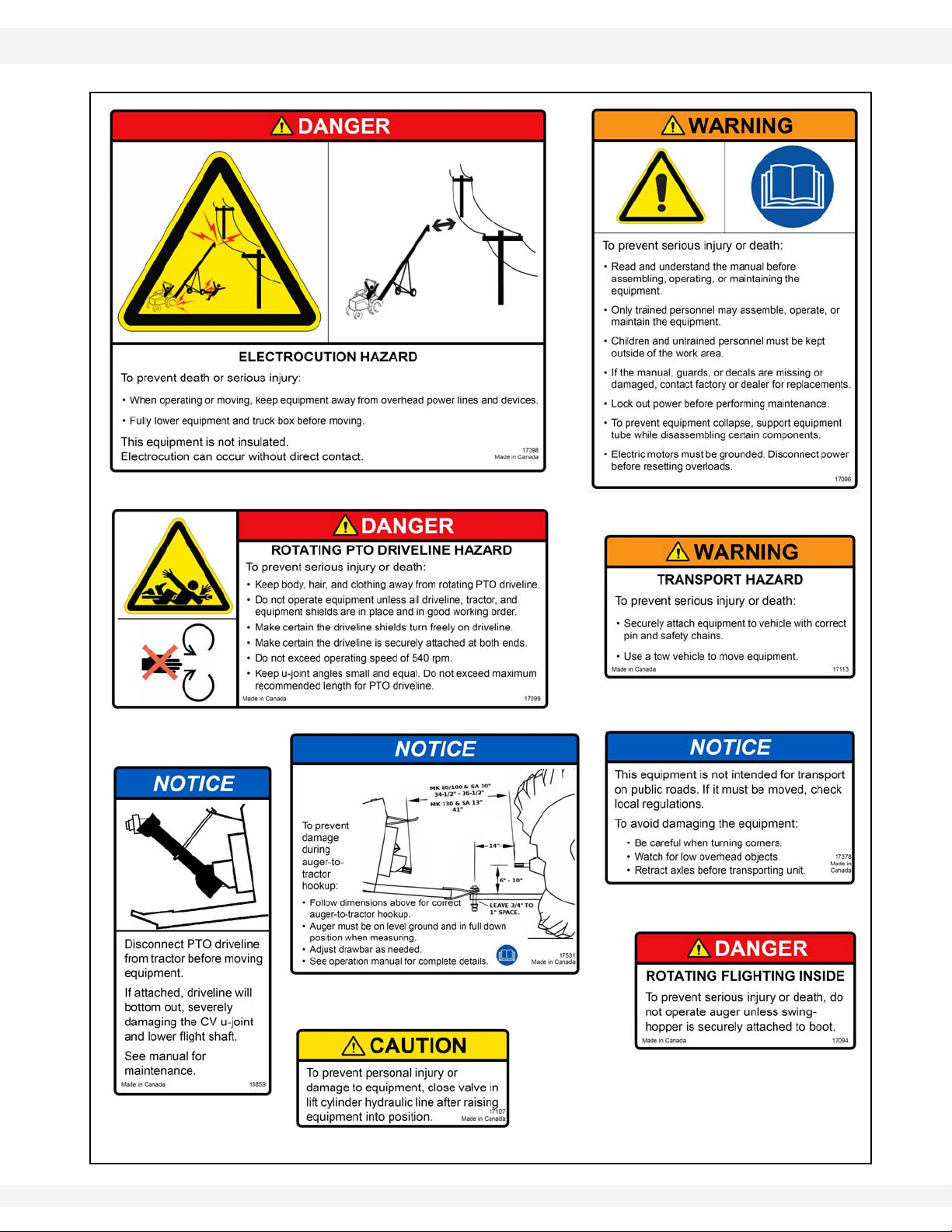

DECAL #17096

DECAL #17398

DECAL #17099

DECAL #17113

DECAL #17378

DECAL #19960

DECAL #17377

SA 111 ONLY

DECAL #17531

DECAL #17107

DECAL #18859

DECAL # 17094

DECAL # 17098

DECAL #17101

71’ - 111’ 2.8. SAFETY DECALS

Figure 2.3

30651 R5 15

2. SAFETY WHEATHEART - SA FLEX AUGER

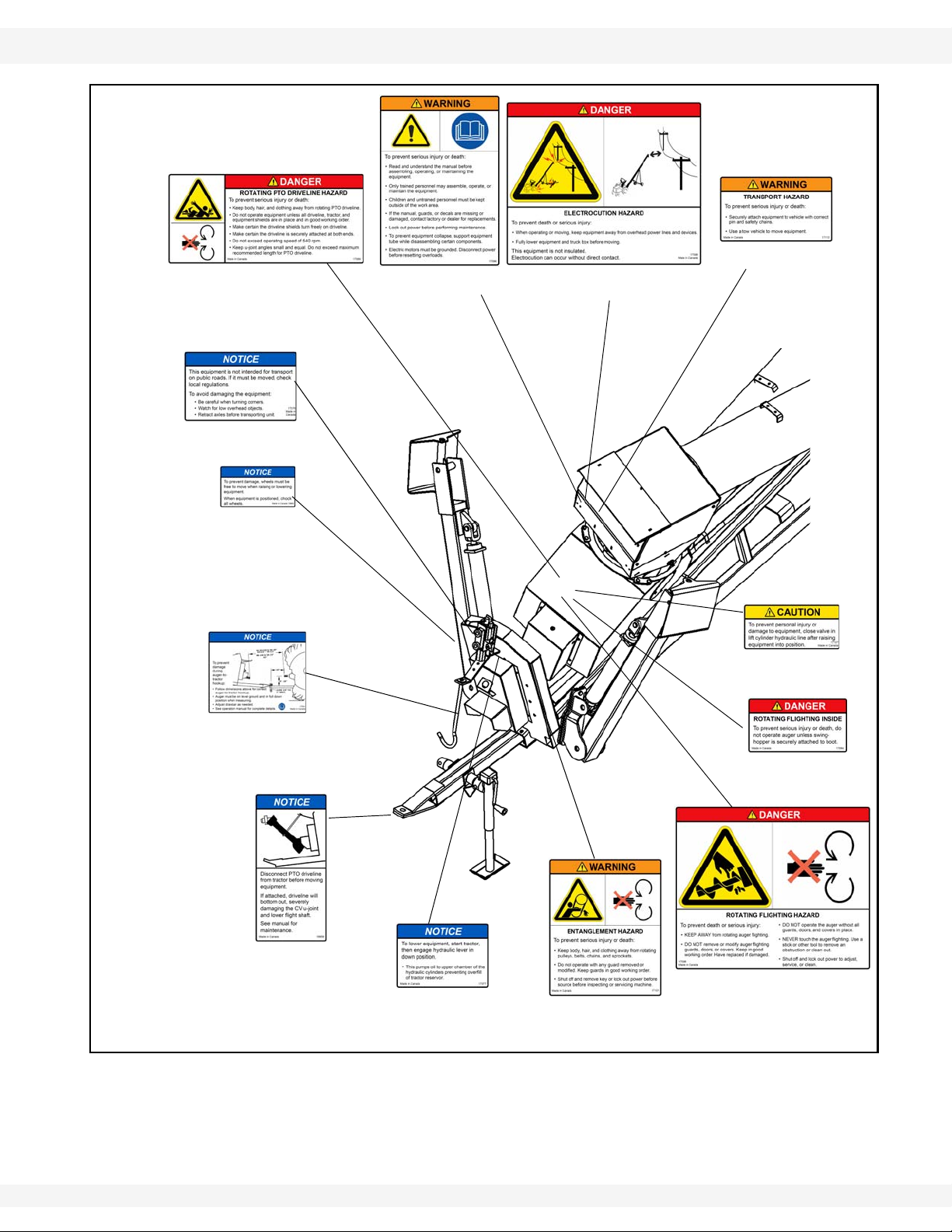

DECAL #17698

DECAL #28615

DECAL

#17100

2.8. SAFETY DECALS 71’ - 111’

Figure 2.4 SA Flex 111’

Figure 2.5 SA Flex 71’, 81’, 91’

16 30651 R5

WHEATHEART - SA FLEX AUGER 2. SAFETY

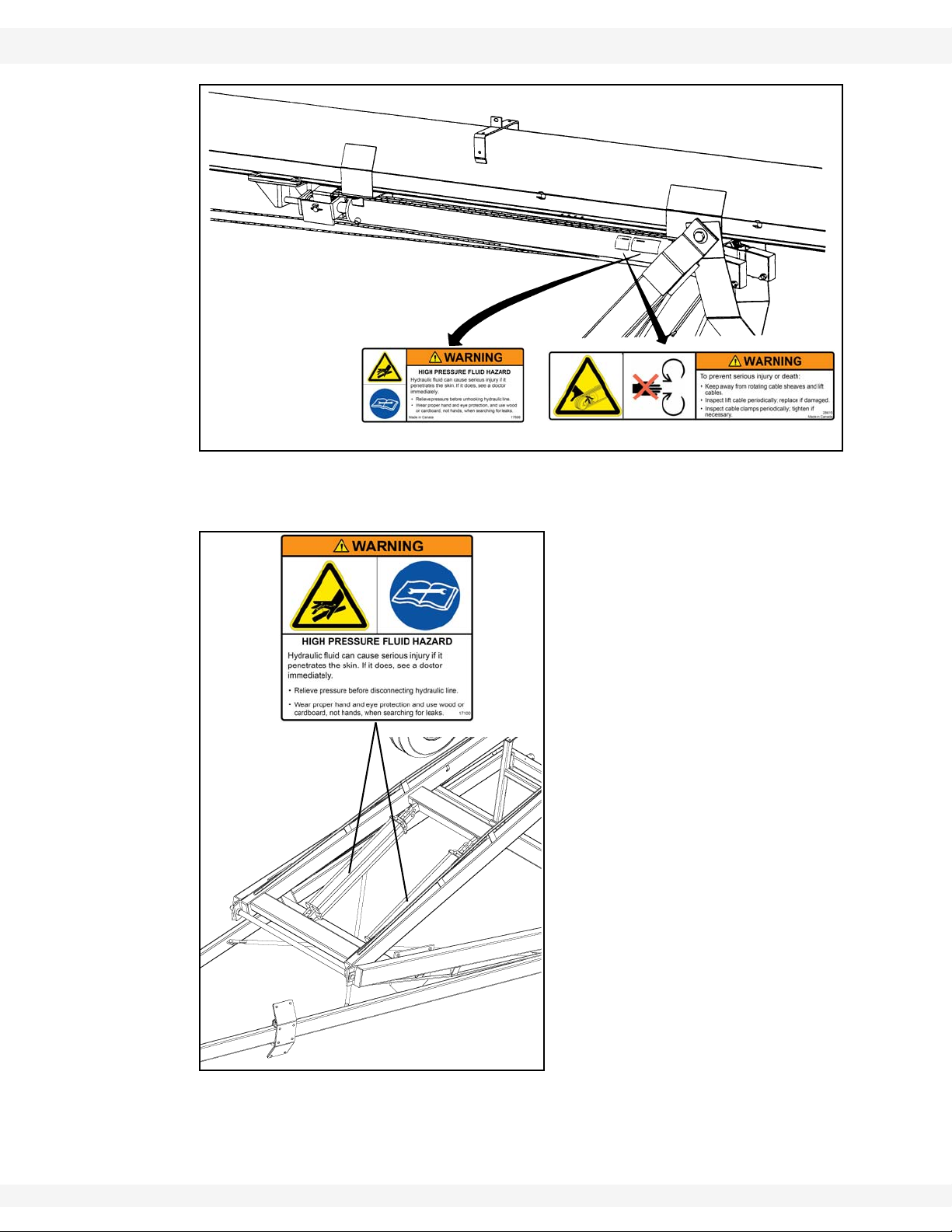

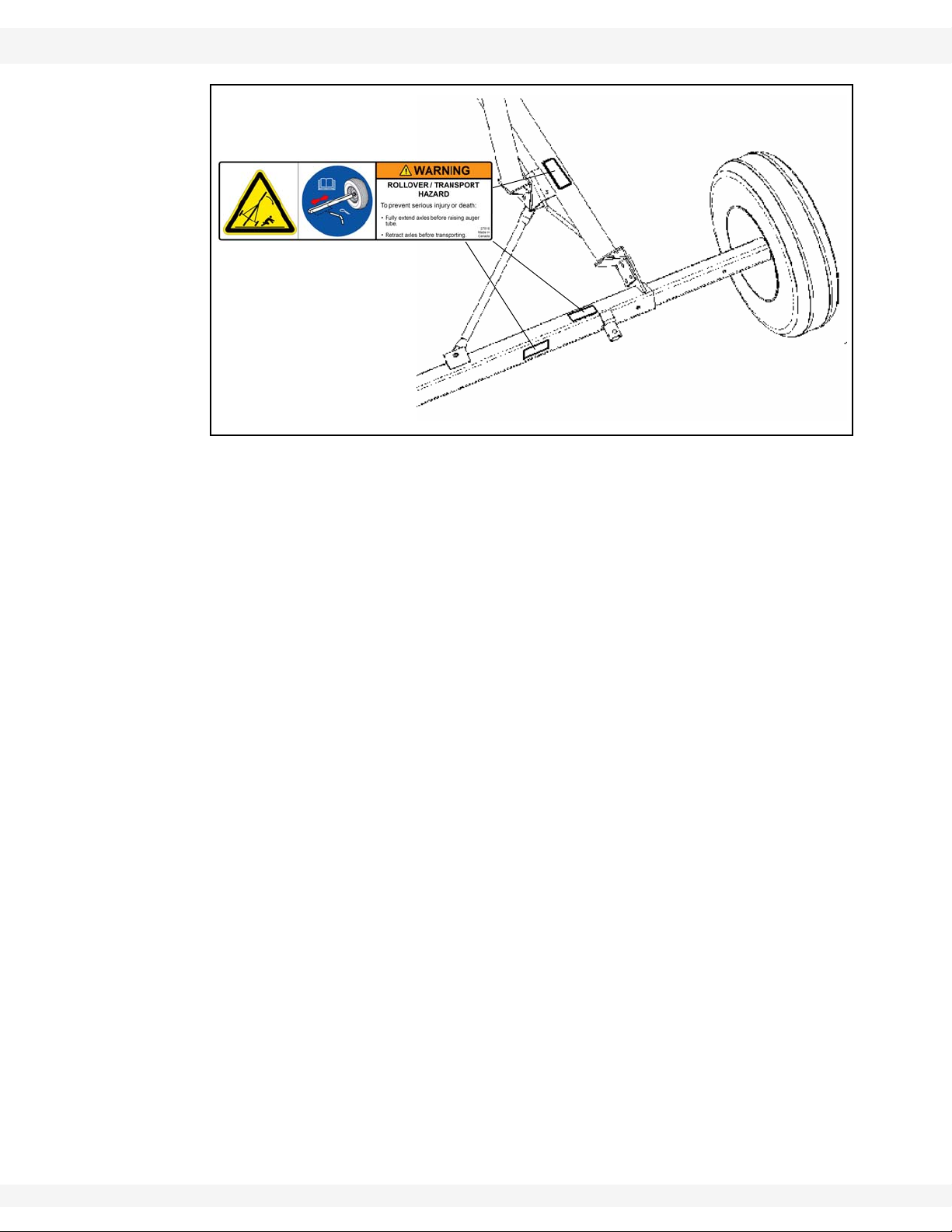

DECAL # 27516

NOTE: THE PLACEMENT OF THIS

DECAL VARIES DEPENDING ON

AUGER MODEL.

71’ - 111’ 2.8. SAFETY DECALS

Figure 2.6

Important: Please review the decals shown. If your auger does not have these decals, they

are available upon request. Please specify which decals you need.

30651 R5 17

2. SAFETY WHEATHEART - SA FLEX AUGER

DECAL # 27516

DECAL # 17698

DECAL # 28615

DECAL # 17093

DECAL # 17101

DECAL # 27709

DECAL # 17098

DECAL # 19960

DECAL # 17377

SA 111 ONLY

2.8. SAFETY DECALS 71’ - 111’

18 30651 R5

WHEATHEART - SA FLEX AUGER 2. SAFETY

DECAL # 17398

DECAL # 17099

DECAL # 17096

DECAL # 17113

DECAL # 17107

DECAL # 17094

DECAL # 18859

DECAL # 17378

DECAL # 17531

71’ - 111’ 2.8. SAFETY DECALS

30651 R5 19

2. SAFETY WHEATHEART - SA FLEX AUGER

2.8. SAFETY DECALS 71’ - 111’

20 30651 R5

WHEATHEART - SA FLEX AUGER 3. ASSEMBLY

WARNING Before continuing, ensure you have read and underst and the relevant information

in the safety section. Safety information is provided to help prevent serious injury, death, or

property damage.

71’ - 111’ 3.1. TUBES & FLIGHTING

3.Assembly

Before beginning assembly, familiarize yourself with all the sub-assemblies and

hardware for the auger. Have all parts on hand and arrange them for easy

access. Carry out assembly in a large, open area with a level surface.

Important: Always have 2 or more people assembling the equipment. Because of the

weight, do not attempt assembly alone.

Augers are available in various combinations. In most cases, the following

instructions will apply to all augers. Where the assembly information varies,

additional instructions will be included, indicated by an arrow.

Before assembling, please check with the customer if they prefer the swing

auger on the right or left side of the auger.

3.1. TUBES & FLIGHTING

Note: When assembling more than 2 sections, start from spout end and work towards

hopper.

1. Position tube sections. Align tube sections on a flat surface or on a series of

benches. See Figure 3.17 for the 71’, 81’ and 91’ and Figure 3.18 for the

111’.

After positioning tube sections, block them to

prevent rolling or dropping. Damage to

equipment or personal injury will result.

WARNING

• The 71’ has 4 tubes; from spout: 240” (6.10 m), 120” (3.05 m), 240” (6.10 m)

and 88” (2.24 m) long.

• The 81’ has 4 tubes; from spout: 240” (6.10 m), 240” (6.10 m), 240” (6.10 m)

and 88” (2.24 m) long.

• The 91’ has 5 tubes; from spout: 240” (6.10 m), 120” (3.05 m), 240” (6.10 m),

240” (6.10 m) and 88” (2.24 m) long.

30651 R5 21

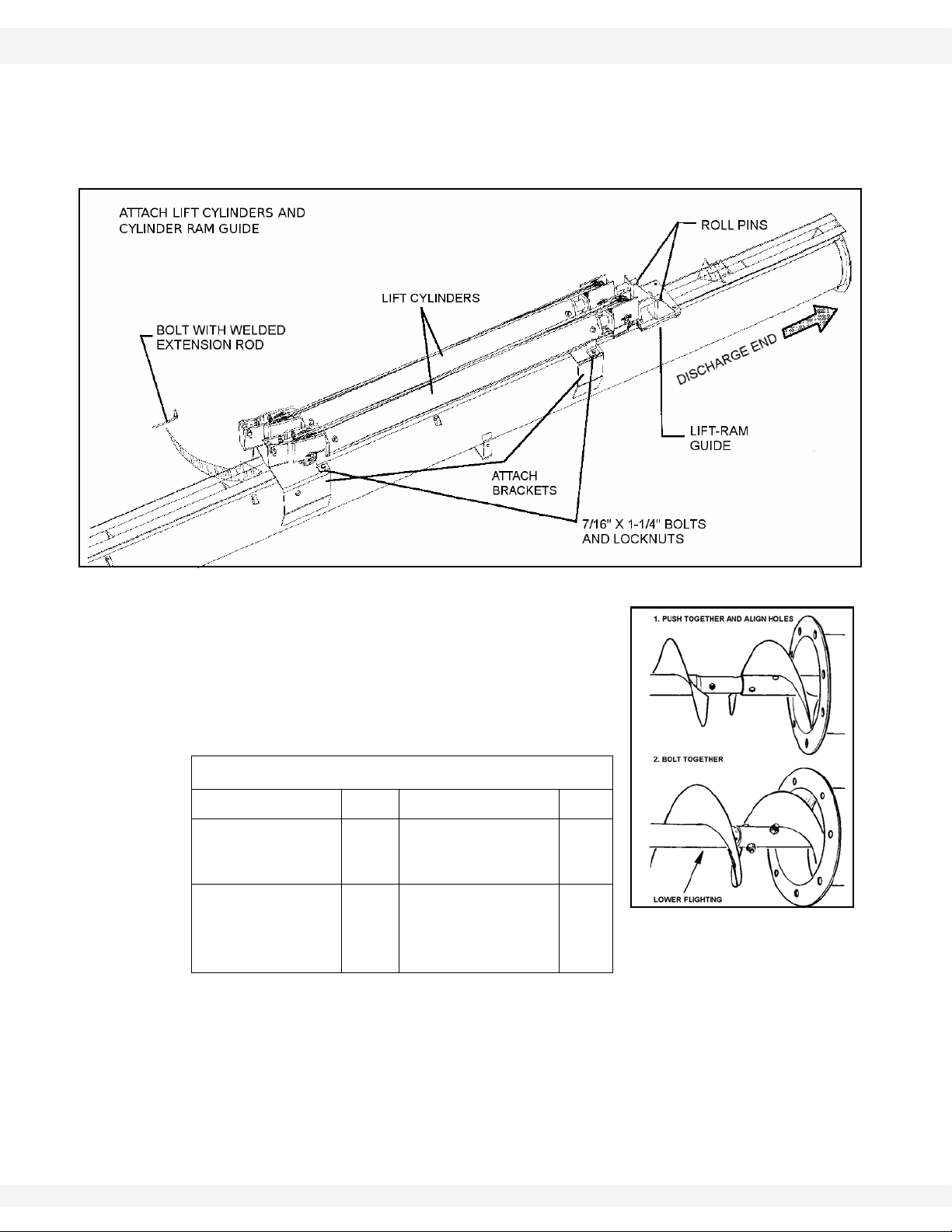

2. 1 11’ Only: To attach lift cylinders, rotate appropriate tube so track is facing

upward as shown in Figure 3.1.

a. Attach the lift cylinders to the attach brackets as shown in Figure 3.1 using

7/16” x1-1/4” bolts and locknuts.

• outside tabs—use regular bolts.

• inside tabs – use bolts with extension rods welded to head.

3. ASSEMBLY WHEATHEART - SA FLEX AUGER

Figure 3.2

3.1. TUBES & FLIGHTING 71’ - 111’

b. Slide the lift ram guide onto track on tube, then insert ram ends into

brackets on guide (Figure 3.1). Secure with two roll pins.

c. Return this tube section to the track down position.

Figure 3.1 111’ Only

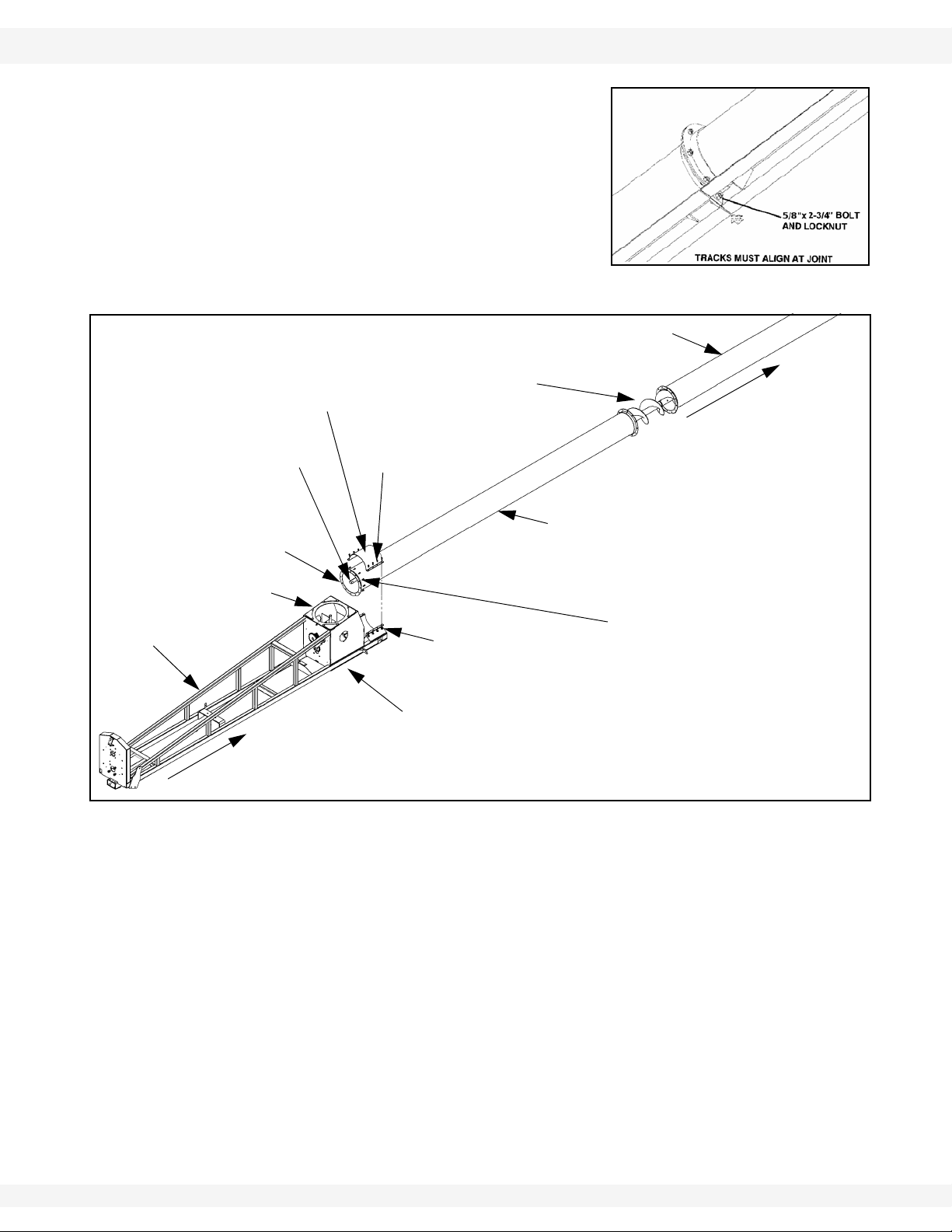

3. Slide lower flight shaft onto upper flight shaft

until flight ends butt together and flighting

spiral matches up (Figure 3.2). Secure with

hardware in Table 3.1. Repeat, if necessary,

for any remaining flight shafts.

Table 3.1

a

2

7/16” x 1-1/4” GR8

bolts and locknuts

1/2” x 1-3/4” GR8

1

bolts and locknuts

(2 top and 2

bottom)

12

4

Details for fastenings:

For Flighting Qty For Tubes Qty

5/8” x 4-1/2” GR8

bolts and locknuts

Track End (111’

Only)

5/8” x 2-3/4” GR8

bolt and locknut

a. Quantity listed is per tube connection.

4. Slide tube sections together and secure. Make sure upper and lower track

ends are aligned (111’ only), and then tighten bolts. Secure with hardware in

Table 3.1.

Important: Do not connect lower auger tube to mid auger tube at this point! (Figure 3.4).

22 30651 R5

WHEATHEART - SA FLEX AUGER 3. ASSEMBLY

Figure 3.3 111’ only

ALIGN END OF TUBE WITH

END OF FLIGHT SHAFT.

LIFT FLEX FRAME UP

INTO PLACE.

SLIDE BACK SO TUBES

CONTACT ONE ANOTHER.

FLEX

FRAME

FLEX

FRAME

BOOT

5/8” X 2-1/4”

BOLTS

5/8” LOCKNUTS

LOWER

AUGER

TUBE

MID-AUGER

TUBE

FLIGHT SHAFT

END

AUGER FLIGHT

TUBE SUPPORT

CLAMP

S

P

O

U

T

7/16” X 1-1/4”

GR8 BOLTS

NOTE: T ubes may not be

exactly as illustrated.

71’ - 111’ 3.1. TUBES & FLIGHTING

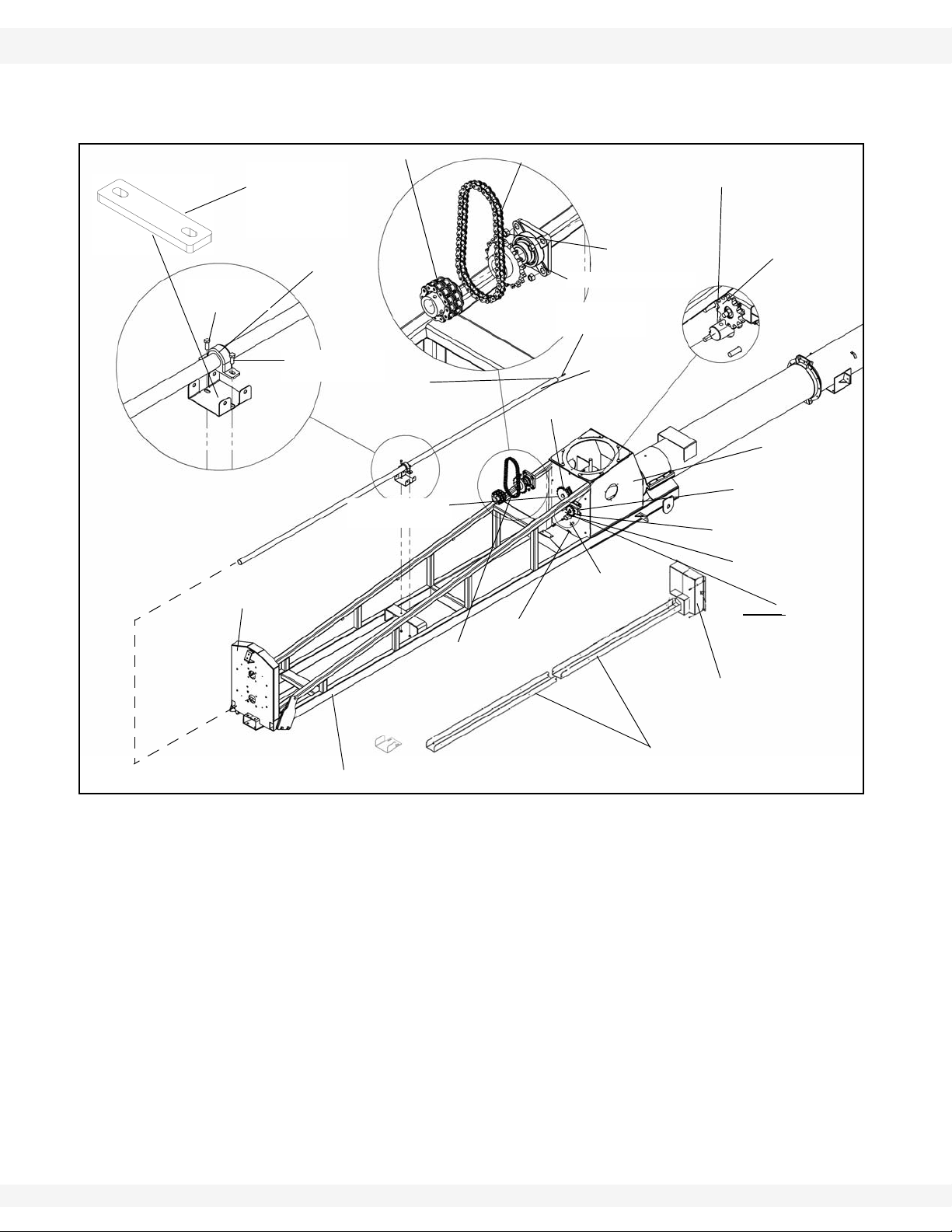

5. 111’ only: Bolt the track ends together

(Figure 3.3).

6. Adjust lower auger tube out until it is flush

with the flight shaft end (see Figure 3.4).

7. Lift the flex frame up underneath the lower

tube and secure on benches.

8. Push the flex frame toward the spout to

slide the auger flight through the front of the

flex frame boot.

Figure 3.4

Important: Steps 11. to 19. must be completed in the order listed to prevent premature

Important: Grease zerk should be located on left side of bearing.

30651 R5 23

9. Connect flex frame assembly to lower auger tube flange with twelve 7/16” x

1-1/4” GR8 bolts and locknuts.

10. Secure tube support clamp to tube with eight 5/8” x 2-1/4” GR8 bolts and

locknuts.

failure of the lower bearing. Refer to Figure 3.5.

11. Slide lower bearing onto flight stub and secure boot loosely with four 5/8” x

1-3/4” bolts and 5/8” locknuts.

12. Loosen setscrew on lock collar and slide it onto the lower flight. Leave lock

collar loose for now.

13. Seat flight shaft shoulder against washer and lower bearing, see Figure 3.5.

Do not tighten bearing bolts until after Step 18.

3. ASSEMBLY WHEATHEART - SA FLEX AUGER

3/8” X 2-1/2”

ROLL PIN

FLEX FRAME

BOOT

LOWER

FLIGHT SHAFT

FLEX FRAME

UPPER

DRIVESHAFT

5/8”

LOCKNUTS

WIDE RIM FLAT

WASHER

3/8” - 3-1/2”

SQUARE KEY

ROLLER

CHAIN

CHAIN

TIGHTENER

CHAIN

TIGHTENER

SPROCKET

5/8” X 1-3/4”

BOLTS

NOTE: GREASE

ZERK TO LEFT

SIDE

3/8” X 2-1/2” ROLL PIN

THROUGH THIS HOLE IN

LOWER FLIGHT STUB SHAFT

ADD SHIMS AS

REQUIRED TO

LEVEL

DRIVESHAFT

CHAIN COUPLER

ROLLER CHAIN

5/8” LOCKNUT

1-3/4” WOODEN

BEARING

3/8” X 2-1/4”

BOLT

LOWER BEARING

UPPER BEARING

& SPROCKET

END PLATE

3/8” X 2-1/4”

BOLT

3/8” X 1-3/4”

SQUARE KEY

LOWER DRIVESHAFT

GUARD

SPROCKET COVER

3.1. TUBES & FLIGHTING 71’ - 111’

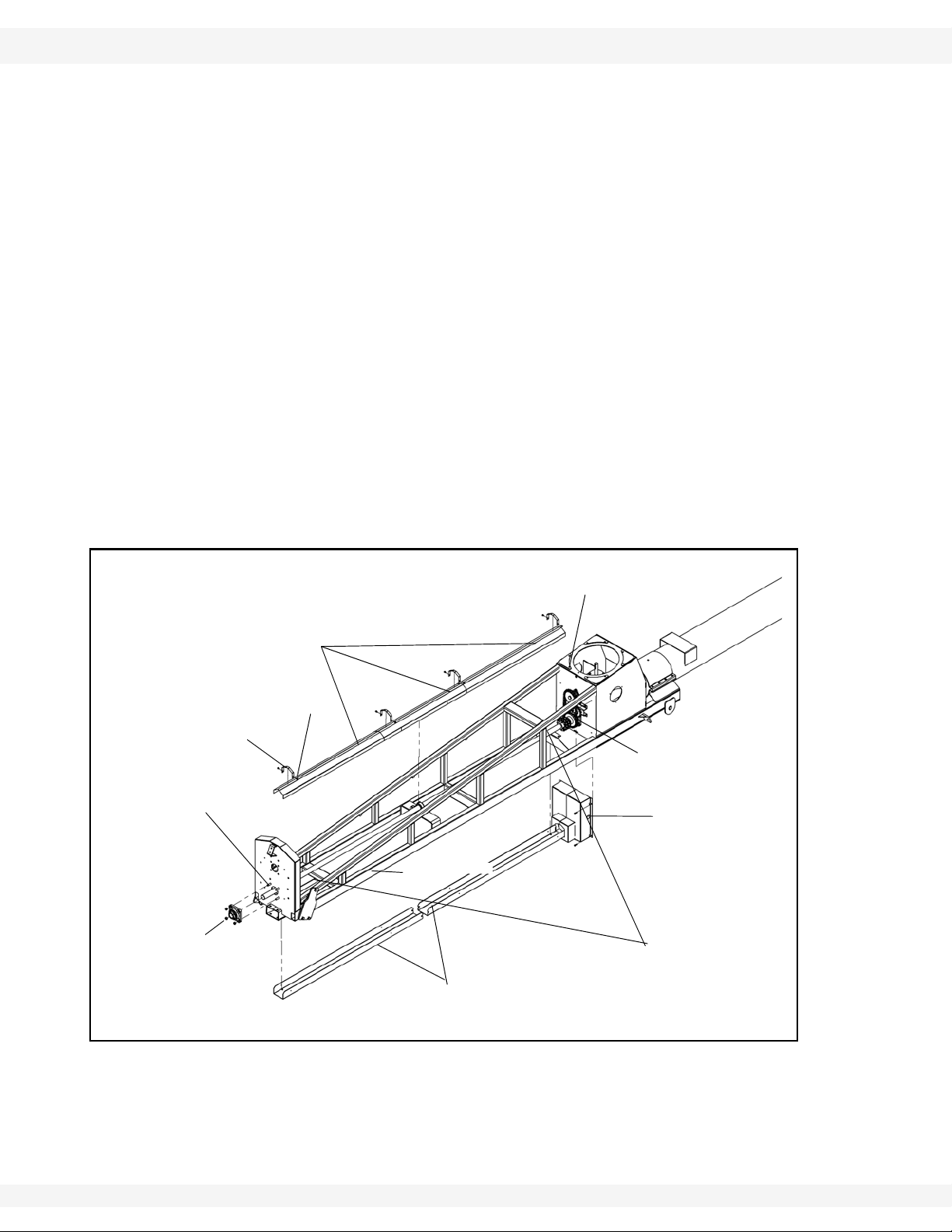

14. Now, slide the middle and lower tube sections together and secure with

twelve 7/16” x 1-1/4” bolts and locknuts.

Figure 3.5

Note: The driveshaft ends are different. Make sure the end with the hole is at the lower

15. Install 3/8” x 3-1/2” square key and slide lower sprocket onto lower flight

shaft.

16. Align upper sprocket with lower sprocket and chain tensioner sprocket using

straight edge, then tighten setscrews and locking collar on upper bearing.

17. Loosen chain tightener sprocket and install roller chain on upper and lower

sprockets. Secure with connecting link and clip.

18. Oil chain lightly and tension.

19. Tighten 5/8” locknuts on the lower bearing. Tighten collar on lower bearing

and tighten setscrew.

20. Install two sections of lower driveshaft guard as well ad the driveshaft guard

extension with 3/8” x 1” carriage bolts and 3/8” x 1” bolts and flange nuts.

Tighten the guard extension and lower half of the guard. Leave the top half

hand tight until the two piece chain guard is in place. Figure 3.5.

end of the flex frame.

24 30651 R5

WHEATHEART - SA FLEX AUGER 3. ASSEMBLY

SPROCKET

COVER

FLEX FRAME

SMS #14 X 5/8”

WITH

WASHERHEAD

DRIVESHAFT

SHIELD

STRAP

DRIVESHAFT

SHIELDS

5/8” LOCKNUTS

LOWER

DRIVESHAFT

GUARD

5/8” X 1-3/4”

BOLTS

FLEX FRAME

BOOT

LOWER

FLIGHT SHAFT

3/8” X1” CARRIAGE

BOLTS

71’ - 111’ 3.1. TUBES & FLIGHTING

21. Place bracket under middle of driveline with spacer and use shims provided

to level.

22. To install chain coupler (shipped assembled):

a. On the two half-sprockets: check to make sure the keyways are NOT lined

up. If they are, disassemble the chain coupler and offset the keyways, then

reassemble.

b. Slide the chain coupler onto the lower flight stub shaft, and attach it using

3/8” x 2-1/2” roll pin.

c. Install the 3/8” x 1-3/4” square key onto the solid driveshaft, and slide the

driveshaft into the opposite end of the chain coupler . Slide it in 1-3/4”, until

the end of the driveshaft is flush with the end of the sprocket.

d. Secure both sides of the chain coupler using the setscrews; tighten

securely.

e. Disassemble the 1-3/4” wooden bearing (as supplied). Re-assemble the

bearing around the solid driveshaft, and attach it to the frame using two

3/8” x 2-1/4” bolts and locknuts provided. Use shims as necessary; wood

bearing is there for support only, DO NOT force shims into place. Once

satisfied with driveline alignment, tighten bolts and locknuts securely.

Figure 3.6

30651 R5 25

23. Secure the driveshaft to the front plate of the flex frame with a 1-3/4” bearing

and flange and four 5/8” x 1-3/4” bolts and locknuts. Secure lower driveshaft

with locking collar and setscrew.

24. Grease zerk should be located on left side of bearing.

3. ASSEMBLY WHEATHEART - SA FLEX AUGER

1/2” X 2” X 3-1/4”

U-BOLT

LEFT OUTRIGGER LEG

1/2” X 1-1/2”

CARRIAGE BOLT

5/16” LOCKNUT

RIGHT OUTRIGGER LEG

SPROCKET

GUARD

5/16” X 3/4”

BOLT

5/16” X 3/4”

BOLT

ROLLER SUPPORT

TRANSPORT REST

1/2” LOCKNUT

1/2” LOCKNUT

1/2” X 2” X 3-1/4” U-BOLT

3.2. FLEX FRAME COMPONENTS 71’ - 111’

25. Attach sprocket covers to flex frame boot with four 5/16” x 3/4” bolts and

locknuts.

26. Place two 60” and one 48” driveline guards over shaft and secure to flex

frame with driveshaft shield straps and SMS #14 x 5/8” with washerhead.

3.2. FLEX FRAME COMPONENTS

Figure 3.7

Important: There is a left and a right outrigger leg. Ensure they are installed with ports facing

26 30651 R5

1. Install outrigger legs. Insert 1/2” x 1-1/2” carriage bolts pointing inward to

prevent interference with hydraulic cylinder.

the discharge.

2. Place roller support inside key stops on flex frame, see Figure 3.7. The four

1/2” x 2” x 3-3/4” u-bolts are attached around the upright tubes, as shown in

Figure 3.7. Ensure that these u-bolts are tightened securely.

3. Install sprocket guard on boot with four 5/16” x 3/4” bolts. Ensure that tabs on

2 piece sprocket guard are fit into the slots on either side of the lower guard.

Tighten the top half of the lower guard.

4. Attach the transport rest to flex frame with four 1/2” X 2” x 3-1/4 u-bolts and

locknuts. Leave flex tube support transfer rest untightened until after the flex

tube is installed.

WHEATHEART - SA FLEX AUGER 3. ASSEMBLY

Figure 3.8

ROTATE FLEX BOOT

AS SHOWN BY

ARROW FOR LEFT

SIDE USE

BOOT SPINNER PLATE

Note:

7/16” X 1-1/4”

BOLTS

7/16” WASHERS & LOCKNUTS

Figure 3.9

Important:

71’ - 111’ 3.3. FLEX AUGER BOOT

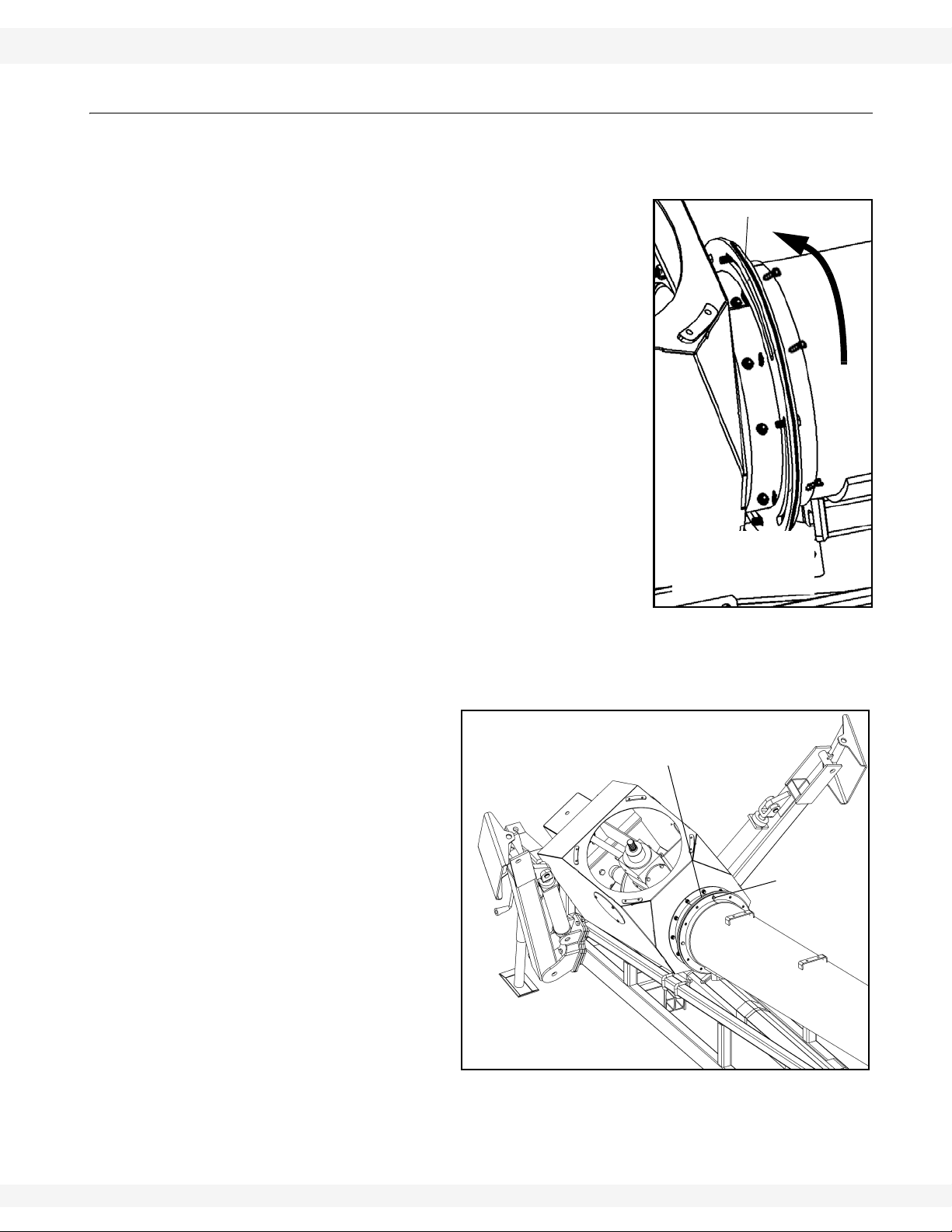

3.3. FLEX AUGER BOOT

.

Complete assembly in the order listed to prevent premature failure of the lower

bearing. Refer to Figure 3.8 to 3.10.

1. Attach boot spinner plates.

a. Insert plates between boot spinner and

upper flex tube bundle.

b. Mount onto the four 7/16” x 1-3/4” bolts

welded to the tube.

c. Fasten with 7/16” locknuts and 7/16”

washers.

d. Do not tighten all the way.

e. Ensure boot is angled on the same side as

swing tube is to be installed.

f. Secure with eight 7/16” x 1-1/4” bolts with

locknuts and washer.

Flex boot can be rotated to the left or the right side

of the auger. Figure 3.9 and 3.10 show setup for

swing on right side of the auger, as viewed from

the intake end facing toward the spout. To install

the flex boot on left side, rotate boot to left side

2. Place 1-3/4” wide rim washer and 1-3/4”

Grease zerk should be

located on left side of

bearing.

3. Install square key and

4. Align lower sprocket with

5. Install roller chain on

bearing and flange on flight shaft with 5/8” x 1-3/4” bolts and locknuts. Do not

tighten until Step 5.

slide lower sprocket onto

flight shaft.

upper sprocket using

straight edge, then

tighten set screws.

sprockets and adjust

tension to about 1/4”

(0.64 cm) deflection.

Tighten the 4 bolts on

lower bearing and

secure lock collar. Oil

chain lightly.

30651 R5 27

3. ASSEMBLY WHEATHEART - SA FLEX AUGER

HALF BAND

7/16”

LOCKNUTS

PIVOT

SUPPORT

FLEX TUBE

7/16” X 1-1/4” BOLT

FLIGHT SHAFT

3/8” X 3-1/2”

SQUARE KEY

LOWER SPROCKET

1-3/4” WIDE

RIM WASHER

5/16” X 3/4” BOLT”

CHAIN

GUARD

9”

UPPER

SPROCKET

F

L

E

X

B

O

O

T

LOWER

SPROCKET

NOTE:

GREASE

ZERK TO

LEFT SIDE

ROLLER CHAIN

7/16” X 1-1/4”

BOLT

1-3/4” BEARING &

FLANGE

SPOUT PLATE

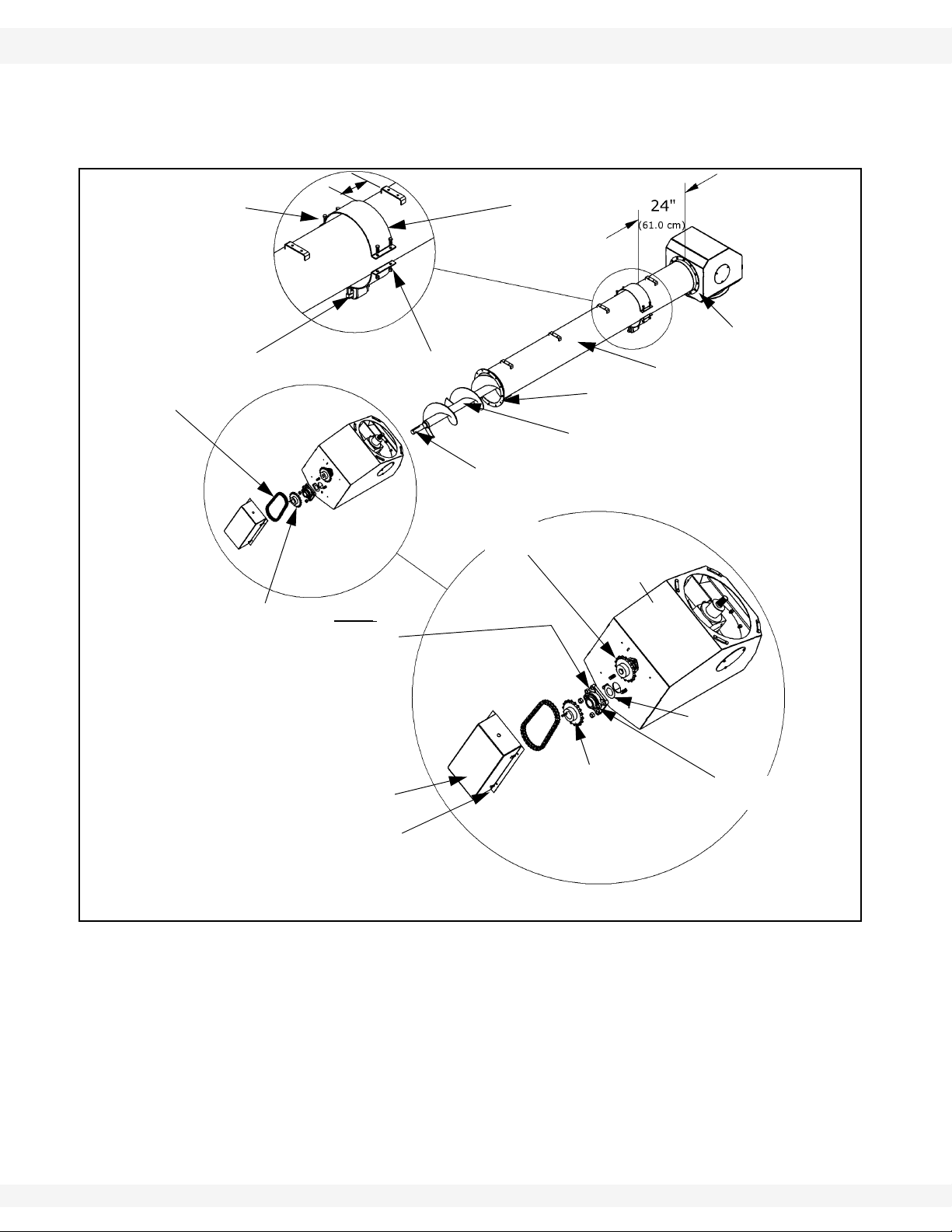

3.3. FLEX AUGER BOOT 71’ - 111’

6. Bolt chain guard on boot with four 5/16” x 3/4” bolts and locknuts.

7. Bolt half band and pivot support together with 7/16” x 1-1/4” bolts and

locknuts on flex tube, 24” (61.0 cm) from spout plate. See Figure 3.10.

Figure 3.10

28 30651 R5

WHEATHEART - SA FLEX AUGER 3. ASSEMBLY

FLEX TUBE

HYDRAULIC

CYLINDER

2-1/2” X 16”

UPPER PIVOT PLATE

WITH GREASE FITTINGS

7/16” X 1-3/4”

BOLT AND 7/16”

FLAT WASHER

LOWER PIVOT

PLATE

FOUR GALVANIZED

SPACERS

FLEX FRAME

FLEX TUBE SUPPORT

FLEX TUBE

BOOT

CYLINDER

BRACKET

FLEX SPOUT

GEARBOX SHAFT

WIDE RIM FLAT WASHER,

AND 1/4” X 1-1/4” KEY

FLEX FRAME

BOOT

SPRING PIN

7/16” LOCKNUT

TWO

GALVANIZED

SPACERS

71’ - 111’ 3.4. CONNECTING FLEX TUBE TO FLEX FRAME

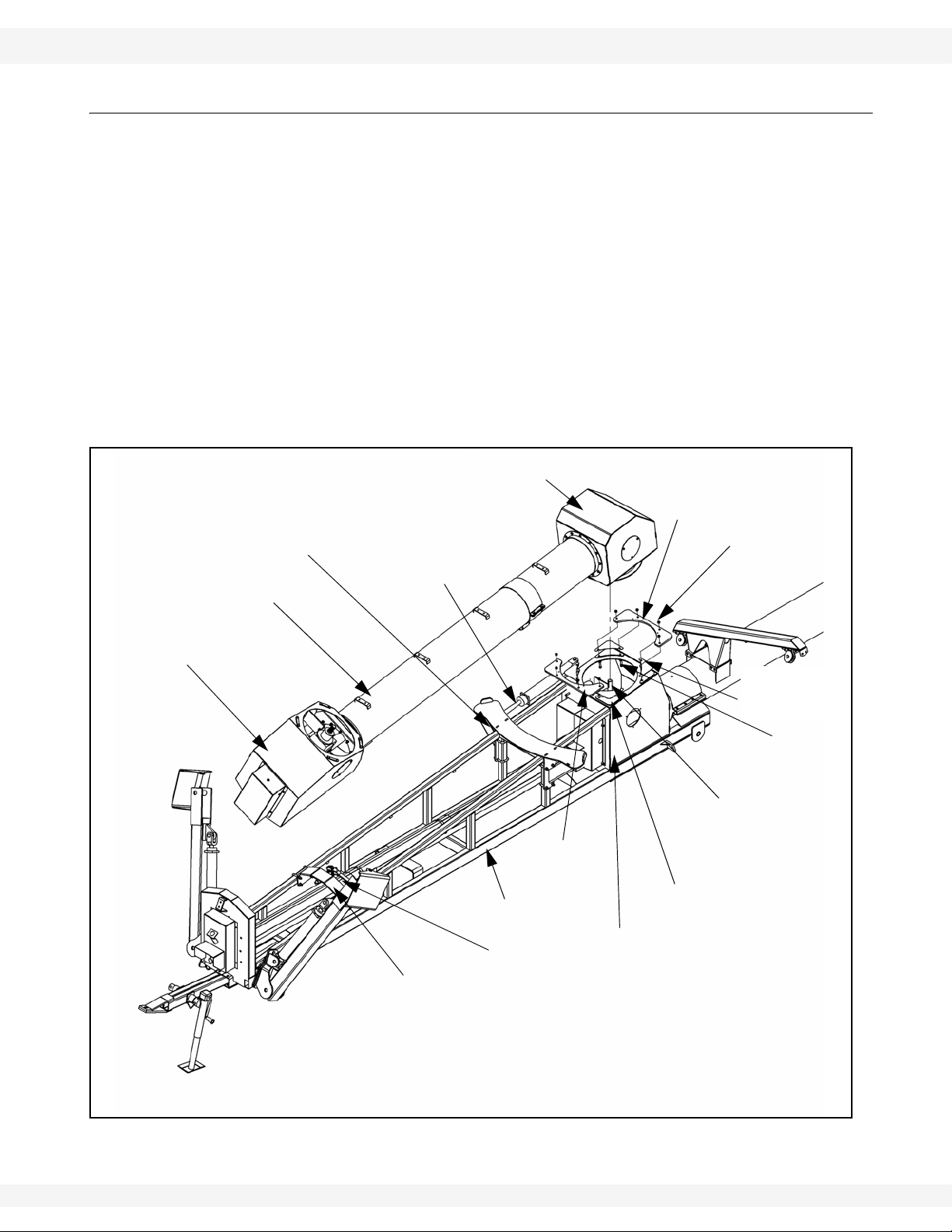

3.4. CONNECTING FLEX TUBE TO FLEX FRAME

1. Place wide rim flat washer and 1/4” x 1-1/4” key on the gearbox shaft.

2. Place upper flex tube on flex frame as shown aligning u-joint in flex tube

spout on the gearbox in the boot.

3. Place 6 galvanized spacers (4 in front, 2 in back) and 2 pivot plates on flex

frame boot. Secure flex spout on flex frame with 7/16” x 1-3/4” bolts and

locknuts.

• Upper plate has grease nipples on it; the lower plate does not.

• Grease nipples are in bolt bag and need to be installed.

Important: Pivot plates must be installed as illustrated.

4. Install 2-1/2” x 16” cylinder to flex spout and cylinder bracket as shown in

Figure 3.11. Use two 1/4” x 1-3/4” cotter pins to assemble cylinder pin and

use snap rings provided to assemble clevis pin.

Figure 3.11

30651 R5 29

3. ASSEMBLY WHEATHEART - SA FLEX AUGER

Figure 3.12

LOCK PIN

TRANSPORT

LATCH

Figure 3.13

3.5. ADJUSTABLE TOWBAR 71’ - 111’

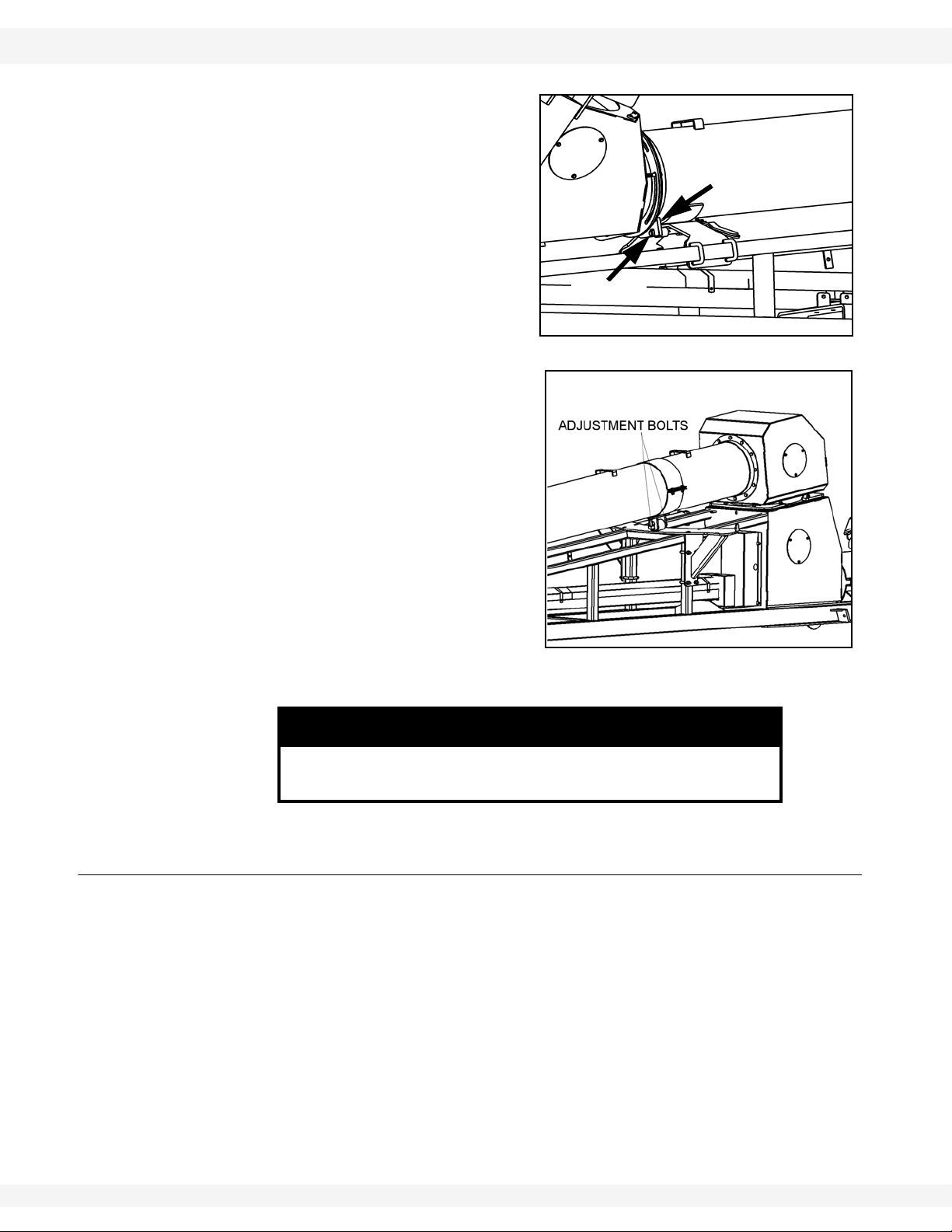

5. Adjust the position of the flex tube

support, so that the lock pin sticks

through the transport latch approximately 1/16” (1.6 mm). Tighten ubolts and locknuts and secure. See

Figure 3.12.

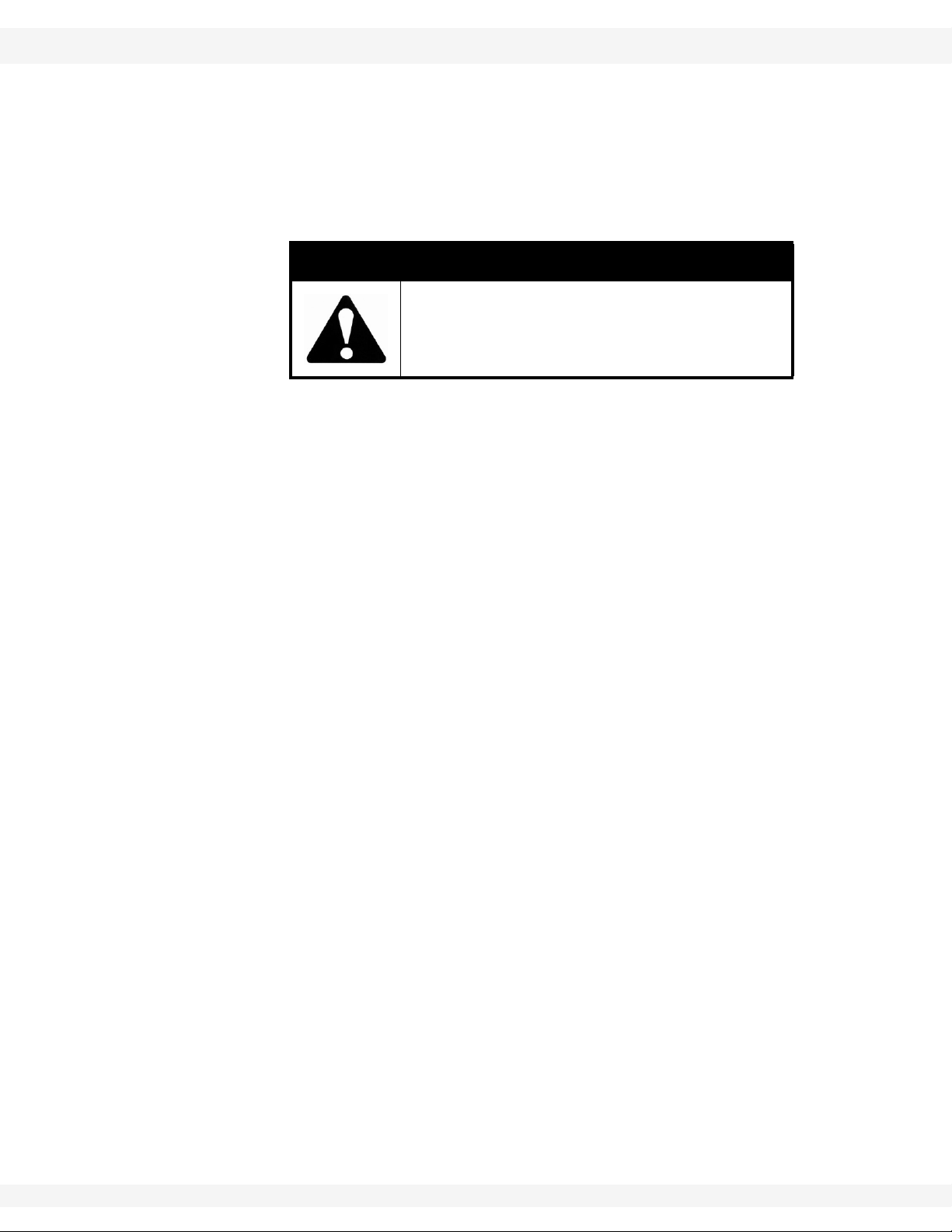

6. Use a hoist to lift the lower end of

flex tube slightly and adjust the

position of the pivot roller with the

1/2” x 2-1/2” adjustment bolts to

carry the weight of the flex tube. See

Figure 3.13.

Failure to lift the flex tube when adjusting the pivot roller can

result in damage to the roller and/or flex tube.

3.5. ADJUSTABLE TOWBAR

Important: Adjust the towbar if a speed-reducing gearbox is used with the system. In this

The Flex has an adjustable towbar. The towbar is installed as seen in Figure

3.14.

1. Insert the adjustable towbar into the boot channel. Secure by placing a 3/4” x

6-1/2” long bolt and locknut through the back hole in the boot channel, under

the flex frame.

2. Insert a 5/8” x 4-1/2” long bolt and locknut vertically into the hole at the front

of the boot so that the towbar comes straight out from the flex frame.

• This bolt must be inserted from the bottom with the nut on top.

case, the towbar is extended and pinned on an angle using the vertical bolt. This

will line up the PTO with the PTO connection on the gearbox.

NOTICE

30 30651 R5

WHEATHEART - SA FLEX AUGER 3. ASSEMBLY

ADJUSTABLE

TOWBAR

BOOT CHANNEL

3/4” X 6-1/2”

BOLT &

LOCKNUT

5/8” X 4-1/2”

BOLT &

LOCKNUT

PTO CRADLE

BRACKET

71’ - 111’ 3.6. DISCHARGE SPOUT & THRUST ADJUSTER

3. Install the PTO cradle bracket on the front plate of the flex frame. Attach

bracket with two 7/16” x 1-1/4” bolts and locknuts.

3.6. DISCHARGE SPOUT & THRUST ADJUSTER

Figure 3.14

• Attach discharge spout with

7/16” x 1-1/4” bolts and locknuts.

• The thrust adjuster is designed

to transfer some pressure from

the lower flight bearing to the

upper flight bearing.

• Remove cover and 5/8”

whiz nuts.

• Loosen the set screw on

the lock collar and disengage the lock collar from

the bearing to allow free

movement of the flight

shaft.

• Turn the 1-1/2” nut until it is snug against the bushing, then turn it so that

the flight shaft moves an additional 1/4” (0.64 cm).

• Secure the lock collar and tighten the set screw.

• Re-install the cover over the two longer 5/8” bolts. Secure with two 5/8”

whiz nuts.

30651 R5 31

3. ASSEMBLY WHEATHEART - SA FLEX AUGER

WELD ON

TAB

3.7. TRUSS 71’–91’ 71’ - 111’

3.7. TRUSS 71’–91’

1. Fasten the 3 cable bridges (5) to the brackets (6) with two 7/16” x 1-1/4” GR5

bolts (3) and 7/16” locknuts (4) per cable bridge. Refer to Figure 3.15.

Important: 1371 and 1381 Only: The largest cable bridge is 35” (0.89 m) high and attaches

to the center bracket. The other 2 cable bridges are 17” high and attach to the

outside brackets.

1391 Only: The largest cable bridge is 35” (0.89 m) high and attaches to the

center bracket. The other 2 cable bridges are 32” (0.81 m) high and attach to the

outside brackets.

Refer to Figure 3.16 and 3.17 for remaining steps.

2. Leave a stand at each end of the tube sections but remove the rest of the

stands and let the tube deflect under its own weight.

Note: 1371 auger uses two cables 58’ (17.7 m) and 91’ (27.7 m) long.

1381 auger uses two cables 75’ (22.9 m) and 115’ (35.1 m) long.

1391 auger uses two cables 90’ (27.4 m) and 134’ (40.8 m) long.

3. Attach an eyebolt (1) to one end of each truss cable (2 and 3) with two 3/8”

cable clamps (4) doubling-back about 12” (0.30 m) of cable. Insert the

eyebolts into the appropriate weld on tab (5) and thread on a 1/2” locknut (6)

a short way.

Figure 3.15

32 30651 R5

WHEATHEART - SA FLEX AUGER 3. ASSEMBLY

71’ - 111’ 3.7. TRUSS 71’–91’

4. Pull the long truss cable (2):

• over the cable bridges (7)

• around the cable return bracket (8)

• back over the cable bridges (7)

• back to the cable anchor racket (5)

5. Pull the short truss cable (3):

• over the middle cable bridge (7)

• around the cable return bracket (8)

• back over the middle cable bridge (7)

• back to the cable anchor bracket (5)

Important: The long truss cable (2) must be installed on the outside of the middle bridge (7).

6. Use loosely attached 5/16” cable clamps to hold the cable in place — 2 cable

clamps per cable bridge and two clamps on the cable return bracket.

Note: Do not tighten the cable clamps at this time.

7. Place another eyebolt in each weld on tab and thread on a 1/2” locknut a

short way.

8. Thread the end of each truss cable through the appropriate eyebolt and pull

the cable snug. Double-back the cable and secure in place with two 3/8”

cable clamps as in Step 2.

Figure 3.16

30651 R5 33

3. ASSEMBLY WHEATHEART - SA FLEX AUGER

STANDARD SUPPORT

TRUSS BRACKET

HIGH TRUSS

SUPPORT BRACKETS

ANCHOR BRACKET

STANDARD SUPPORT

TRUSS BRACKET

HIGH TRUSS

SUPPORT BRAKCET

ANCHOR BRACKET

71’

81’

HIGH TRUSS

SUPPORT BRAKCET

TRUSS SUPPORT

BRAKCET

TRUSS SUPPORT

BRAKCET

ANCHOR BRACKET

91’

3.7. TRUSS 71’–91’ 71’ - 111’

Note: If there isn’t enough cable, loosen the clamps on the opposite eyebolt and adjust

the cable. Retighten clamps.

9. Tighten the eyebolts on the long cable (2) evenly to take the remaining slack

out of the truss cable. Once the long cable (2) is tightened, repeat for the

short cable (3).

10. Check for proper side-to-side alignment and then tighten the cable clamps on

the cable bridges and the cable return brackets.

Figure 3.17 Flex 71’, 81’, and 91’ Auger Complete Truss Layout

34 30651 R5

WHEATHEART - SA FLEX AUGER 3. ASSEMBLY

71’ - 111’ 3.8. TRUSS 111’

3.8. TRUSS 111’

When assembling the truss system, do not tighten any bolts until all components are in place. Refer to Figure 3.18 on page 36 for correct positioning of the

truss components.

1. Loosely attach the 2 low pairs of truss towers (D) and 57 (111') high pairs of

truss towers (C) to the truss-attach brackets welded to auger tube with 7/16”

x 1-1/4” bolts and locknuts.

2. Loosely join the ends of two 10' (3.05 m) truss tubes (A) and two crossbrace

tubes (B) between the top end of each pair of high truss towers using 1/2” x

2-3/4” bolts and locknuts.

3. Thread a 3/4” nut onto each adjust-tube, then insert threaded end into trussanchors on lower and upper auger tubes. Join the adjust tubes (E) and 10'

truss tubes (A) at the two low (D) truss towers with 1/2” x 2-3/4” bolts and

locknuts.

Note: A single crossbrace tube is positioned between the low (D) truss towers and

adjacent high (C) truss towers.

4. Loosely join all the crossbrace tubes to t abs welded to top of truss-attach

brackets using 1/2” x 1-1/2” bolts and locknuts.

Note: Attach these tubes to same side of tab as they are attached to the truss tower.

5. Tighten all bolts and nuts.

6. Install the 5 (111') pairs of x-clamps where the crossbrace tubes meet with

two 7/16” x 1" bolts and locknuts on each.

7. Thread a second 3/4” nut on the end of the adjust tube, then adjust the

threaded adjust tubes until upper and lower auger tubes have a slight upward

bow. Lock the adjust nuts against bracket.

30651 R5 35

3. ASSEMBLY WHEATHEART - SA FLEX AUGER

3.8. TRUSS 111’ 71’ - 111’

Figure 3.18

36 30651 R5

WHEATHEART - SA FLEX AUGER 3. ASSEMBLY

Figure 3.19 111‘Auger

10-12”

(25.4 - 30.5 cm)

ADJUST

BRACKET

EYEBOLT

NUT

3/8” CABLE CLAMPS

71’ - 111’ 3.8. TRUSS 111’

3.8.1. CABLE TRUSSING

1. Attach an eyebolt to one end of each of two

truss side cables with two 3/8” cable clamps using

about 10” (25.4 cm) to 12” (30.5 cm) of cable.

Tighten securely (Figure 3.20).

2. Insert eyebolts into tabs located on flex frame.

Secure with 1/2” locknut (Figure 3.19).

3. Loosely attach the truss cables to each cable

support arm with a 5/16” cable clamp as shown in

Figure 3.18.

4. Attach remaining eyebolts to adjust bracket and

thread on 1/2” locknuts about 1/2” (Figure 3.20).

5. Thread loose ends of the cable through each

eyebolt, pull tight, then secure with two 3/8” cable

clamps (Figure 3.20). Tighten securely.

6. Adjust tension of side truss cable by tightening

the eyebolts at the adjust brackets. These cables

must be very tight. Also adjust for side alignment.

7. Now tighten all of the cable clamps at cable

supports and arms.

Figure 3.20

30651 R5 37

3. ASSEMBLY WHEATHEART - SA FLEX AUGER

3.9. SCISSOR LIFT FRAME (71’–91’) 71’ - 111’

Figure 3.21

3.9. SCISSOR LIFT FRAME (71’–91’)

3.9.1. SCISSOR FRAME ASSEMBLY

WARNING

Components are heavy and create a crushing

and pinching hazard if improperly handled. Be

sure to use proper hoisting equipment and

procedures, and ensure lifting apparatus is

secure. Lockout the lifting apparatus before

working around or under the raised

components. Failure to do so may cause

serious personal injury .

Note: Refer to Table 3.2 and Figure 3.24 – 3.29 for the length of each auger

component.

38 30651 R5

WHEATHEART - SA FLEX AUGER 3. ASSEMBLY

71’ - 111’ 3.9. SCISSOR LIFT FRAME (71’–91’)

1. Wheel hub assembly:

a. Remove any dirt or paint from spindle and hub.

b. Thoroughly pack wheel bearings and cups with a good grade of bearing

grease.

c. Place large bearing into hub and carefully tap in seal.

d. Slip hub onto spindle and insert small bearing.

e. Tighten slotted spindle nut until hub drags slightly. Back off nut about 1/4

turn until hub turns freely.

f. Install cotter pin and dust cap.

Note: Installing tires may not leave you with enough clearance to position and attach

undercarriage once auger tube is raised. If so, install wheels after assembly is

complete.

g. Check that pressure of pre-inflated tires matches pressure indicated on tire

sidewall. Mount wheels on hubs and attach with six 1/2” x 1-3/4” wheel

bolts.

Figure 3.22

2. Mount wheels (1) to hubs (2) on axle extension (3) with 6 wheel bolts (4).

Note: Before mounting the wheels, check to make sure the hub and wheel mounting

surfaces are free from rust and debris.

3. Finger tighten the wheel bolts and verify that the wheel is sitting flush on the

hub. Torque the wheel bolts to 80 ft-lb (±10 ft-lb) of torque while using the

appropriate criss-cross pattern; refer to Appendix for specifications. If in

doubt, have a qualified tire repair service perform required maintenance.

4. For 71’, 81’, and 91’ augers, insert axle extensions (5) into axle (3) and pin it

in place using a 3/8” x 5-1/2” pin (6) and hitch pin (7).

30651 R5 39

3. ASSEMBLY WHEATHEART - SA FLEX AUGER

3.9. SCISSOR LIFT FRAME (71’–91’) 71’ - 111’

5. Attach the lower arms (8) to the axle (3) using two 3/4” x 3-1/2” x 5” u-bolts

(9) and four 3/4” locknuts (10). Space the lower arms evenly on the axle at

102” (2.59 m). (Figure 3.29).

6. Tighten the u-bolts evenly by alternating between the top and bottom

locknuts.

7. Place a board across the lower arms to support the lower scissor arms.

8. Bolt the lower scissor arms (14 and 15) to the axle (3) with 1” x 3” bolts (16)

and 1” locknuts (17).

Note: Ensure the arms are located on the correct side. The hole in the axle tab should

be at the bottom.

9. Attach the lower cylinder mount (18) to the lower scissor arms (14 and 15)

using 1” x 6” x 5” u-bolts (19) and 1” locknuts (20) on 71’, 81’, 91’. See

Figure 3.27.

10. Position the brace between the tab stops. Don’t tighten.

11. Attach the lower x-brace (21) to the lower scissor arms (14 and 15) using

1” x 6” x 5” u-bolts (22) and 1” locknuts (23) on the 71’, 81’, and 91’.

12. Position the brace against the tab stops so the tabs are on the axle side of

the lower x-brace. Don’t tighten.

13. Pin the upper scissor (24) to the lower scissor arms (14 and 15) using a

1-1/2” x 4-1/2” bolts (25), 1-1/2” SAE flat washer (26), and 1-1/2” locknut (27).

• Use two 1-1/2” SAE washers (28) as spacers between the upper and

lower scissor tabs.

14. Tighten the locknuts (20) on the u-bolts (19) for the lower cylinder mount (18):

a. Start with the locknuts closest to the axle.

b. While tightening, ensure that the lower cylinder mount (18) butts up against

the tab stops on the lift arms (14 and 15) using the same procedure as in

Steps 5. and 6.

c. Tighten the remaining u-bolts and repeat the procedure for the lower x-

brace (21).

15. Attach skid plate and back plate to axle arm 65” (1.65 m) from the axle arm

with 1/2 X 1-1/4 bolts and 1/2” locknuts. See Figure 3.23.

40 30651 R5

WHEATHEART - SA FLEX AUGER 3. ASSEMBLY

65”

(1.65 M)

SKID PLATE

1/2 X 1-1/4” BOLT

SKID BACK PLATE

71’ - 111’ 3.9. SCISSOR LIFT FRAME (71’–91’)

Figure 3.23

30651 R5 41

3. ASSEMBLY WHEATHEART - SA FLEX AUGER

3.9. SCISSOR LIFT FRAME (71’–91’) 71’ - 111’

Figure 3.24

42 30651 R5

WHEATHEART - SA FLEX AUGER 3. ASSEMBLY

U

V

W

TOP VIEW

SIDE VIEW

71’ - 111’ 3.9. SCISSOR LIFT FRAME (71’–91’)

Figure 3.25 TOP VIEW

Figure 3.26 Top & Side View

30651 R5 43

3. ASSEMBLY WHEATHEART - SA FLEX AUGER

3.9. SCISSOR LIFT FRAME (71’–91’) 71’ - 111’

Figure 3.27 Top View

Figure 3.28 Top View

Figure 3.29

44 30651 R5

WHEATHEART - SA FLEX AUGER 3. ASSEMBLY

71’ - 111’ 3.9. SCISSOR LIFT FRAME (71’–91’)

Table 3.2

Model U V W X Y Z

71’

81’

91’

167”

(4.24 m)

178”

(4.52 m)

220”

(5.59 m)

89”

(2.26 m)

71”

(1.80 m)

112”

(2.84 m)

149” w/ Trussing

(3.78 m)

167-3/4” w/ Trussing

(4.26 m)

189-1/2” w/ Trussing

(4.81 m)

60-1/8”

(1.52 m)

59-13/16”

(1.52 m)

58-7/16”

(1.48 m)

229”

(5.82 m)

288”

(7.32 m)

353”

(8.97 m)

102”

(2.59 m)

102”

(2.59 m)

102”

(2.59 m)

3.9.2. ATTACHING TO TUBE

1. Remove the stand from the intake end of the auger and raise the discharge

end with a block and tackle or a front end loader and a strong sling or chain

at point “A” (Figure 3.31). Height should be sufficient so the frame can be

positioned under the tube.

WARNING

Components are heavy and create a crushing

and pinching hazard if improperly handled. Be

sure to use proper hoisting equipment and

procedures, and ensure lifting apparatus is

secure before working around or under the

raised components. Failure to do so may

cause serious personal injury.

2. Position the frame under the tube assembly.

3. Lower the tube to align the upper scissor with the bracket closest to the

center cable bridge on the tube (29).

• Secure in place using 1” x 2-1/2” bolts (30) and 1” locknuts (31).

• Use two 1” SAE washers (32) as spacers between the tabs and the

bracket (1 for each side). See Figure 3.24.

30651 R5 45

3. ASSEMBLY WHEATHEART - SA FLEX AUGER

3.9. SCISSOR LIFT FRAME (71’–91’) 71’ - 111’

4. Raise the tube at point “A” so the discharge end is approximately 10’ off the

ground.

• Attach a lifting device at point “B” on the scissor-lift frame and lift until the

axle arms (8) are aligned with the lower bracket (first bracket from the

intake end) on the tube (33).

• Tighten with 1” x 2-1/2” bolts (30) and 1” locknuts (31). Use 1” SAE washers (32) as spacers between the tabs and the bracket (one for each side).

See Figure 3.24.

WARNING

Do not remove tube support until instructed to

do so in step 12.

5. Attach axle arms to flex frame as shown in Figure 3.30. Start by passing a 1”

x 5” bolt through the axle arm, stabilizer bracket, 1” flat washers and the push

the bolt through the hole in the flex frame. Secure on the backside with a 1”

locknut. This is a pivot point, tighten only to snug. Repeat this process for the

opposite side.

Note: It may aid alignment to use a stand to hold up the axle arms.

6. Install the short crossmember by placing it between the lower arms. Attach a

stabilizer side plate to each end of the short crossmember and secure with

four 3/4” x 4-1/2” bolts and locknuts. Only put the nuts on the end of the bolts

for now.

7. Attach the stabilizer braces to the short crossmember using a 5/8” x 2” bolt

and locknut. Leave the bolts loose for now.

Note: The bend angle of the stabilizer brace is different at each end. Attach the end

with a smaller bend to the short crossmember.

8. Secure the two stabilizer brackets and stabilizer braces using a 5/8” x 2-1/2”

bolt and locknut. The stabilizer braces should sandwich the brackets. The

short crossmember may have to be moved around to get the bolt in.

9. Bolt the remaining hole in the two stabilizer brackets together with a 5/8” x

1-3/4” bolt and locknut.

10. Push the short crossmember toward the stabilizer brackets until it fits gently

between the two frames, do not wedge the short crossmember in between

the lower arms too tight.

11. Tighten all the bolts in the stabilizer and crossmember making sure nothing

moves. Ensure the 1” lower arm bolt is left only snug, as it remains a pivot.

46 30651 R5

WHEATHEART - SA FLEX AUGER 3. ASSEMBLY

STABILIZER

BRACKET

STABILIZER

BRACE

SHORT

CROSSMEMBER

3/4” X 4-1/2”

BOLT

AXLE ARM

SIDE PLATE

5/8” X 2”

BOLT &

LOCKNUT

3/4” LOCKNUT

5/8” X 2-1/2”

BOLT &

LOCKNUT

5/8” X 1-3/4” BOLT

& LOCKNUT

FLEX FRAME

1” X 5” BOLT &

1” FLAT WASHER

71’ - 111’ 3.9. SCISSOR LIFT FRAME (71’–91’)

Figure 3.30

12. Remove the lifting device at point “B” and raise the auger at point “A” so the

transport brace (34) can be attached. Use eight 1/2” x 1-1/2” bolts (35) and

1/2” locknuts (36). See Figure 3.24.

13. Lower the auger until the transport brace (34) is resting on the lower

x-brace (21) and remove the lifting device at point “A”. See Figure 3.31.

14. Fasten the x-brace tubes (11) to the axle arms (8) and secure with 1/2” x

1-1/2” bolts (12) and locknuts (13). See Figure 3.24.

Figure 3.31

30651 R5 47

3. ASSEMBLY WHEATHEART - SA FLEX AUGER

3.10. TRANSPORT UNDERCARRIAGE (111’) 71’ - 111’

3.10. TRANSPORT UNDERCARRIAGE (111’)

See Figure 3.32.

1. With truss on axle positioned as shown in Figure 3.32, fasten the lower reach

arms to brackets on axle with four 5/8” x 2" bolts and locknuts on each side.

2. Attach short crossmember loosely with two 5/8” x 2" bolts and locknuts,

sandwiching flat braces (B) between crossmember and frame bracket. Do

not tighten bolts until undercarriage is beneath tube assembly (Figure 3.34).

3. Secure the tubing crossbraces to welded lugs on lower reach arms with two

1/2” x 1-1/4” bolts and locknuts, plus a third one where the braces cross. Add

a tie tube between the bottom welded lugs. Use three 1/2” x 1-1/4” bolts and

two 1/2” x 1/3/4” bolts and 1/2” locknuts.

4. Attach the axle crossbraces with two 1/2” x 1-1/4” bolts and locknuts each.

5. Insert axle extensions into axle and pin in place using a saddle pin and hair

pin.

6. Wheel hub assembly:

a. Remove any dirt from spindle and hub.

b. Thoroughly pack wheel bearings and cups with a good grade of bearing

grease.

c. Place large bearing into hub and carefully tap in seal.

d. Slip hub onto spindle and insert small bearing and washer.

e. Tighten slotted spindle nut until hub drags slightly. Back off nut about 1/4

turn until hub turns freely.

f. Install cotter pin and dust cap.

Note: Installing tires may not leave you with enough clearance to position and attach

undercarriage once auger tube is raised. If so, install wheels after assembly is

complete.

7. Inflate to recommendations on tire side wall. Wheels may be mounted on

hubs at this time using 6 wheel bolts. Finger tighten the wheel bolts and verify

that the wheel is sitting flush on the hub. Torque the wheel bolts to 80 ft-lb

(±10 ft-lb) of torque while using the appropriate criss-cross pattern; refer to

Appendix for specifications. If in doubt, have a qualified tire repair service

perform required maintenance.

8. Fasten upper lift arms to lower reach arms using two 15/16” spacer bushings,

flat washers, and 1" x 3-1/2” bolts and locknuts. Tighten securely; lift arms

pivot on the spacer bushings (Figure 3.33).

48 30651 R5

WHEATHEART - SA FLEX AUGER 3. ASSEMBLY

(120” LONG)

(3.05 m)

(3.18 m)

71’ - 111’ 3.10. TRANSPORT UNDERCARRIAGE (111’)

.

Figure 3.32

30651 R5 49

3. ASSEMBLY WHEATHEART - SA FLEX AUGER

3.10. TRANSPORT UNDERCARRIAGE (111’) 71’ - 111’

Figure 3.33

9. Lower auger intake to the ground.

10. Raise the upper end of

auger with a block and

tackle or a front-end

loader. Securely attach

a strong sling or chain

about 36" above

trackstop. Secure tube

to prevent it from turning

while lifting. Raise

sufficiently to clear

undercarriage.

NOTICE

Do not remove tube support until assembly in this section

has been completed.

11. Place undercarriage beneath tube assembly.

12. Position stabilizer braces (A) (Figure 3.34) and attach lower reach arms to

bracket on tube with long spacer bushings (1-1/8” long), flat washers, and 1"

x 3-1/2” bolts and locknuts. Tighten securely. Reach arms pivot on the

spacer bushings.

50 30651 R5

WHEATHEART - SA FLEX AUGER 3. ASSEMBLY

Figure 3.35

71’ - 111’ 3.11. LIFT CABLES (111’)

Figure 3.34

13. Fasten flat braces (B)

to first set of holes

(furthest from intake)

on stabilizer braces (A)

with one 5/8” x 2" bolt

and locknut. Place one

5/8” x 1-1/8” bolt and

locknut in other hole of

stabilizer brace.

14. Attach upper lift arms to

center hole on the liftassist arms (Figure

3.35) with two 15/16”

medium spacers, flat

washers, and two 1" x

3-1/2” bolts and

locknuts. Tighten securely; lift arms will pivot on the spacer bushings.

15. Lower discharge end of auger slowly until track shoe rests against trackstop

and the lift-assist arm rests against track.

3.11. LIFT CABLES (111’)

Important: Lift cables may stretch with use. Check frequently and adjust when necessary.

30651 R5 51

1. Seat lift-assist arm against the track and place both lift cylinders in full down

position (fully retracted).

2. Thread the lift cables over the respective pulleys on the lift-assist arm, pull

cables tight, and secure with three 3/8” cable clamps on each cable. Tighten

securely. Do not crisscross cables (Figure 3.36).

3. ASSEMBLY WHEATHEART - SA FLEX AUGER

3.12. LIFT CYLINDER HYDRAULIC HOSES (111’) 71’ - 111’

Note: Although the lift cables are factory installed on the lift cylinders, make certain the

cable clamps at the cylinders are secure and the cables are properly seated in

the cable sheaves before attaching the cables to the lift-assist arm.

CAUTION

Track shoe must rest against trackstop when

adjusting cable.

If this isn’t done, auger can raise higher than

designed to, resulting in damage to auger and

possible injury to personnel.

Figure 3.36

3.12. LIFT CYLINDER HYDRAULIC HOSES (111’)

Note: Right or left side of auger , as referred to in this section, is determined by standing

at intake end facing top discharge end.

• Lower fittings refer to those closer to intake end of auger.

• Upper fittings refer to those closer to discharge end of auger.

Note: Use thread sealant (not supplied) on all hydraulic connections.

1. Position both elbow fittings on right cylinder. The lower one should face

forward and downward at approximately 45°. The upper one should face

rearward and downward at approximately 45° (Figure 3.37). Make certain

they are tight.

2. Secure the solid connector end of the short (17" / 0.43 m) cylinder-connector

hydraulic hose to the lower elbow fitting.

52 30651 R5

WHEATHEART - SA FLEX AUGER 3. ASSEMBLY

71’ - 111’ 3.12. LIFT CYLINDER HYDRAULIC HOSES (111’)

3. Secure the solid connector end of the long (32" / 0.81 m) cylinder-connector

hydraulic hose to the upper elbow fitting.

Note: Before attaching short connector hydraulic hose to left side lift cylinder, make

certain lift cables are tightly stretched and that this hose is positioned beneath

the lift cable on the left side lift cylinder (Figure 3.37). If lift cable is not installed

above this hose, it could result in the hose wearing through during operation,

causing a hazardous situation.

WARNING

Wear on hose can cause auger to drop

suddenly, causing serious injury or death.

4. Position the elbow fittings on the left cylinder. The lower one should face

forward and downward at approximately 45°. The upper one should face

rearward and upward at approximately 10°.

5. Secure the tee fittings to the left cylinder elbow fittings and position them as

shown in Figure 3.37. Make certain they are securely tightened.

6. Secure the swivel ends of the upper (32" / 0.81 m) and lower (17" / 0.43 m)

cylinder-connector hoses to the tees as shown.

7. Check upper 32" (0.81 m) cylinder-connector hose position to ensure there is

8-1/2” (0.22 m) clearance to lift cables as shown in Figure 3.37.

8. Attach the 392" (9.96 m) long pressure hose with shutoff valve to the lower

tee fitting (nearest auger intake).

9. Attach the 473" (12.0 m) long return hose without shutoff valve to the upper

tee fitting (nearest auger discharge end).

10. Thread hoses through back arm attach bracket as shown in Figure 3.37.

30651 R5 53

3. ASSEMBLY WHEATHEART - SA FLEX AUGER

BACK ARM

BRACKET

3.13. HYDRAULICS (71’–91’) 71’ - 111’

Figure 3.37

11. Place both hoses into retaining brackets welded to side of auger tube and

boot. Bend tops of brackets over slightly to hold hoses in place.

Important: Protect hose ends from dirt.

12. Recheck that bolts on undercarriage, lift cylinders, and cable clamps are

tight, then remove auger tube support.

3.13. HYDRAULICS (71’–91’)

3.13.1. CYLINDER INSTALLATION

Note: See Table 3.3 for the appropriate cylinders.

1. The transport brace (item 34 from Figure 3.24) must be installed and

supporting the frame.

2. Position the cylinders (1) on the cylinder lugs (2). The rod end of the

cylinders must be attached to the lower cylinder mount so that the rod

extends towards the intake (Figure 3.38).

Note: The ports need to be facing each other, see Figure 3.39.

54 30651 R5

WHEATHEART - SA FLEX AUGER 3. ASSEMBLY

71’ - 111’ 3.13. HYDRAULICS (71’–91’)

3. Pin the cylinders in place using 1” x 3-3/8” cylinder pins (3) and 1” external

hitch clips (4) (Figure 3.38).

Figure 3.38

V

Table 3.3

Auger Cylinder

71’ 4" x 36"

81’ 4" x 40"

91’ 4-1/2” x 40"

30651 R5 55

3. ASSEMBLY WHEATHEART - SA FLEX AUGER

3.13. HYDRAULICS (71’–91’) 71’ - 111’

3.13.2. HYDRAULIC CYLINDER PLUMBING

Note: Refer to Appendix for hydraulic fitting tightening specifications. Use pipe sealant

on all joints. See Table 3.4 for the proper hose length.

1. Remove plugs from the hydraulic cylinder.

2. Install elbow (2) into cylinder port.

3. Attach tee (4) to cylinder port. See Figure 3.39.

4. Attach the hydraulic hose end (5) to tee (4) (Figure 3.39).

5. Install hydraulic hose 3/8” x 2’ (1).

6. Lay the hose (8) (Figure 3.39) along the upper scissor and tube (Figure

3.40).

7. Secure the hydraulic hose along the top of the upper scissor and on the tube

using the welded hose clips.

8. Provide slack or a loop between each secured point.

9. Bend tops of welded clips over slightly to retain hose.

Important: Do not make bends in hydraulic hose too tight. The bends must have a radius of

at least 4” to prevent failure of the hose.

10. Install the ball valve (6), coupling (3), and optional pioneer tip (7) on the

hydraulic hose end (5) (Figure 3.39).

Table 3.4

Auger Hose Length

71’ 53’

(16.2 m)

81’ 58-1/2’

(17.8 m)

91’ 67’

(20.42 m)

Figure 3.39

56 30651 R5

WHEATHEART - SA FLEX AUGER 3. ASSEMBLY

71’ - 111’ 3.14. PTO (CV) DRIVELINE

Figure 3.40

3.14. PTO (CV) DRIVELINE

1. Clean PTO driveline and drive shaft ends of any paint or dirt.

Important: Ensure that a 3/8” x 3-1/2” square key is installed in the drive shaft before

attaching PTO driveline.

2. Slide plain end of PTO driveline onto drive shaft. Make sure that the holes for

the 3/8” roll pin are lined up and square key is in place.

30651 R5 57

3. ASSEMBLY WHEATHEART - SA FLEX AUGER

3.15. LOW PROFILE HOPPER 71’ - 111’

3. Making sure eyes are protected, carefully tap in roll pin. Tighten set screw .

4. Slide PTO transport saddle through support strap on boot and rest PTO

driveline in it until connected to tractor .

Figure 3.41

3.15. LOW PROFILE HOPPER

1. Attach the pivot-connector to the top hole in hopper with two 5/8” x 1-1/2”

bolts and locknuts. Do not over-tighten. Tighten snug only; these bolts act

as pivot points (Figure 3.43).

2. Loosely secure service door with 2 square latch-washers and 3/8” locknuts.

Note: Do not tighten until hopper assembly is completed.

3. Clean dirt from inside u-joint on hopper and flight shaft end, then insert

Woodruff key, see Figure 3.42.

4. Raise and support hopper tube at about 59" (1.5 m) under spout.

5. Open service door on hopper, then bring tube and hopper together guiding

flight shaft into u-joint.

6. Secure tube to pivot-connector on hopper with twelve 7/16” x 1-1/4” bolts and

locknuts.

58 30651 R5

WHEATHEART - SA FLEX AUGER 3. ASSEMBLY

FLIGHT SHAFT END

U-JOINT

HOLES FOR 5/8” X 1-1/2”

BOLTS AND LOCKNUTS

7/16” LOCKNUT

7/16” X 1-1/4” BOLTS

71’ - 111’ 3.15. LOW PROFILE HOPPER

Figure 3.42

Figure 3.43

7. Tighten set screws on u-joints, then close and secure the service door,

tighten 3/8” locknuts and 3/8” square latch washers.

8. Remove the two 5/16” whiznuts that secure the chain drive guard. Attach the

2-piece rubber extension to inside of hopper lip with 5/16” x 3/4” bolts and

whiznuts and the flat iron straps provided, plus the 2-piece extension

connector plates. Replace bolts, see Figure 3.43.

9. Attach two swivel wheels to the two hopper corners with eight 3/8” x 1”

carriage bolts and 3/8” whiz nuts (Figure 3.47).

30651 R5 59

3. ASSEMBLY WHEATHEART - SA FLEX AUGER

Figure

3.45

Figure

3.46

Figure

3.47

3.15. LOW PROFILE HOPPER 71’ - 111’

3.15.1. STEERING ASSEMBLY

Important: Hoppers can be set up for use on right or left side of auger. Figure 3.44 to 3.48

illustrate the right side as viewed when standing at the hopper looking toward the

spout. Figure 3.49 to 3.52 illustrate the left side as viewed when standing at the

hopper looking toward the spout.

1. Bolt short and long castor arms to hopper with four 3/8” x 1” bolts and 3/8”

flange nuts for each arm (Figure 3.45 and 3.46).

2. Insert steering shaft and motor castors through bearings on each castor arm.

Figure 3.44 Right Side Setup

60 30651 R5

WHEATHEART - SA FLEX AUGER 3. ASSEMBLY

3/8” X 2” BOLT

STEERING

SHAFT

STEERING

LINKAGE

3/8” X 1” BOLT

MOTOR

CASTOR

SPROCKET

FOLDABLE HANDLE

3/8” FLANGE NUT

STEERING COVER

STEERING CHAIN

SPROCKET

LONG CASTOR ARM

3/8” FLANGE NUT

1/4” X 1” WOODRUFF KEY

5/16” WHIZNUT

STEERING STOP

5/16” WHIZ NUT

STEERING LINKAGE

HOPPER

DRIVE

WHEEL

HYDRAULIC MOTOR

3/8” X 1” BOLT

3/8” FLANGE NUT

3/8” X 1-1/4” BOLT

AND LOCKWASHER

3/8” X 1” BOLT

AND

LOCKWASHER

NOTE: PORTS TO THIS SIDE

7/16” LOCKNUT

7/16” X 1-1/4” BOLT

SHORT CASTOR ARM

STEERING ARM

WELDMENT

MOTOR CASTOR

1/4” X 1” WOODRUFF KEY

71’ - 111’ 3.15. LOW PROFILE HOPPER

Figure 3.45 Right Side Setup

Figure 3.46 Right Side Setup

30651 R5 61

3. ASSEMBLY WHEATHEART - SA FLEX AUGER

3/8” x 1” CARRIAGE BOLT

HOPPER

3/8” WHIZ NUT

SWIVEL WHEEL

STEERING STOP

(UNDER SIDE)

STEERING STOP

3.15. LOW PROFILE HOPPER 71’ - 111’

Figure 3.47 Right Side Setup

Figure 3.48 Steering Stop Placement on Right Side Setup

62 30651 R5

WHEATHEART - SA FLEX AUGER 3. ASSEMBLY

Figure 3.50

Figure 3.51

Figure 3.52

71’ - 111’ 3.15. LOW PROFILE HOPPER

Figure 3.49 Left Side Setup

30651 R5 63

3. ASSEMBLY WHEATHEART - SA FLEX AUGER

3/8” X 2” BOLT

STEERING COVER

3/8” FLANGE NUT

SPROCKET

STEERING SHAFT

1/4” X 1” WOODRUFF KEY

5/16” WHIZNUT

STEERING STOP

FOLDABLE HANDLE

STEERING CHAIN

SPROCKET

MOTOR CASTOR

LONG CASTOR

ARM

3/8” FLANGE NUT

3/8” X 1” BOLT

STEERING

LINKAGE

STEERING STOP

5/16” WHIZ NUT

STEERING

LINKAGE

7/16”

LOCKNUT

STEERING ARM WELDMENT

7/16” X 1-1/4”

BOLT

1/4” X 1” WOODRUFF KEY

SHORT CASTOR ARM

HOPPER DRIVE

WHEEL

MOTOR CASTOR

HYDRAULIC MOTOR

3/8” X 1” BOLT AND

LOCKWASHER

NOTE: PORTS TO THIS SIDE

3/8” X 1-1/4”

BOLT AND

LOCKWASHER

3/8” FLANGE NUT

3/8” X 1” BOLT

3.15. LOW PROFILE HOPPER 71’ - 111’

Figure 3.50 Left Side Setup

Figure 3.51 Left Side Setup

64 30651 R5

WHEATHEART - SA FLEX AUGER 3. ASSEMBLY

HOPPER

3/8” X 1” CARRIAGE

BOLT

3/8” WHIZ NUT

SWIVEL WHEEL

STEERING STOP

(UNDER SIDE)

STEERING STOP

71’ - 111’ 3.15. LOW PROFILE HOPPER

Figure 3.52 Left Side Setup

30651 R5 65

Figure 3.53 Steering Stop Placement on Left Side Setup

3. Insert a sprocket on the steering shaft and on motor castor on the long castor

arm (on side with steering assembly). Connect sprockets with steering chain

and secure with connecting link and clip.

4. Place steering cover over chain and secure in place with eight 5/16” whiz nuts

(one whiz nut on each side of cover , 4 places).

3. ASSEMBLY WHEATHEART - SA FLEX AUGER

Figure 3.54 Right Side Setup

B

A

MAIN AUGER TUBE

STEERING ARM

WELDMENTS

STEERING

LINKAGE

NOTE: THE STEERING ARM WELDMENTS MUST

POINT TOWARD THE MAIN AUGER TUBE.

Figure 3.55 Left Side Setup

NOTE: THE STEERING ARM WELDMENTS MUST

POINT TOWARD THE MAIN AUGER TUBE.

MAIN AUGER TUBE

STEERING

LINKAGE

STEERING ARM

WELDMENT

B

A

3.15. LOW PROFILE HOPPER 71’ - 111’

5. Insert foldable handle over steering shaft; secure in place with a 3/8” x 2” bolt

and 3/8” flange nut. See Figure 3.45 for right side setup or Figure 3.50 for left

side setup.

6. Place steering stops on each steering shaft but do not tighten set screws until

Step 13.

7. Slide steering arm weldments over motor castors, secure in place with 1/4” x

1” key. Tighten setscrews on each side.

8. Points A and B on steering

arm weldments should point

at main auger. See Figure

3.54 for right side set-up, and

see Figure 3.55 for left side

set-up.

9. Place steering linkage on

holes nearest hopper on

steering arm weldments, see

Figure 3.54, or Figure 3.55.

Adjustment is built into

steering linkage to align tires

parallel to each other if

required. Secure with two

7/16” x 1-1/4” bolts and two

7/16” locknuts. Nuts should

be tight enough to hold

linkage in place but allow it to

move easily when using the steering arm.