Read this manual before using product. Failure

SELF-PROPELLED POST

POUNDER KIT

TRAILER POST POUNDER MODEL

INSTALLATION & OPERATION MANUAL

to follow instructions and safety precautions can

result in serious injury, death, or property

damage. Keep manual for future reference.

Part Number: IM12 R3

Revised: Nov/12

This product has been designed and constructed according to general engineering

standardsa. Other local regulations may apply and must be followed by the operator.

We strongly recommend that all personnel associated with this equipment be trained

in the correct operational and safety procedures required for this product. Periodic

reviews of this manual with all employees should be standard practice. For your

convenience, we include this sign-off sheet so you can record your periodic reviews.

Date Employee Signature Employer Signature

a. Standards include organizations such as the American Society of Agricultural and Biological Engineers,

American National Standards Institute, Canadian Standards Association, International Organization for

Standardization, and/or others.

WHEATHEART - SELF-PROPELLED POST POUNDER KIT

TRAILER POST POUNDER MODEL

TABLE OF CONTENTS

1. Introduction.......................................................................................................................... 5

1.1. Purpose of the Equipment........................................................................................ 6

2. Safety .................................................................................................................................... 7

2.1. General Safety ......................................................................................................... 8

2.2. Installation Safety..................................................................................................... 8

2.3. Operation Safety ...................................................................................................... 9

2.4. Transport Safety..................................................................................................... 11

2.5. Hydraulic Safety..................................................................................................... 11

2.6. Safety Decals......................................................................................................... 12

2.6.1. Decal Installation...................................................................................... 12

2.6.2. Safety Decal Locations............................................................................. 12

3. Operation ............................................................................................................................ 15

3.1. Placement & Operation Procedure......................................................................... 15

3.2. Transport Preparation ............................................................................................ 17

4. Installation .......................................................................................................................... 19

4.1. Ring Gears............................................................................................................. 19

4.2. Wheel Drives.......................................................................................................... 19

4.3. Front Wheel Assembly........................................................................................... 22

4.4. Spike Installation.................................................................................................... 23

4.5. Valve and Valve Mount .......................................................................................... 24

4.6. Oil Reservoir........................................................................................................... 25

4.7. Hydraulics............................................................................................................... 26

5. Appendix............................................................................................................................. 27

5.1. SP Pounder Parts................................................................................................... 27

5.2. Hydraulics Parts..................................................................................................... 31

5.2.1. SP Pounder Hydraulics With Pilot Auger.................................................. 31

5.2.2. SP Pounder Hydraulics Without Pilot Auger............................................. 33

Limited Warranty..................................................................................................................... 35

IM12 R3 3

WHEATHEART - SELF-PROPELLED POST POUNDER KIT

TRAILER POST POUNDER MODEL

4 IM12 R3

WHEATHEART - SELF-PROPELLED POST POUNDER KIT 1. INTRODUCTION

TRAILER POST POUNDER MODEL

1.Introduction

Thank you for purchasing a Wheatheart Self-Propelled Post Pounder Kit. This

equipment is intended for the installation of fence posts, and will allow you to

perform your work safely and efficiently when you read and follow all of the

instructions contained in this manual. With proper care, your Self-Propelled Post

Pounder Kit will provide you with many years of trouble-free service.

Keep this manual handy for frequent reference and to review with new

personnel. A sign-off form is provided on the inside front cover for your convenience. Call your local distributor or dealer if you need assistance or additional

information.

This manual should be regarded as part of the equipment. Suppliers of both new

and second-hand equipment are advised to retain documentary evidence that

this manual was provided with the machine.

Important: This is a supplemental manual which contains additional information about how

to operate a Self-Propelled Post Pounder Kit and is not a substitute for the Post

Pounder Operator Manual. An operator is not considered trained on how to

operate a Self-Propelled Post Pounder Kit unless they have read and understood

this manual and the Post Pounder Operator Manual.

Important: This is a supplemental manual which contains additional information about how

to operate a Self-Propelled Post Pounder Kit and is not a substitute for the Post

Pounder Operator Manual. An operator is not considered trained on how to

operate a Self-Propelled Post Pounder Kit unless they have read and understood

this manual and the Post Pounder Operator Manual.

IM12 R3 5

1. INTRODUCTION WHEATHEART - SELF-PROPELLED POST POUNDER KIT

1.1. PURPOSE OF THE EQUIPMENT TRAILER POST POUNDER MODEL

1.1. PURPOSE OF THE EQUIPMENT

The Self-Propelled Post Pounder Kit is designed and manufactured for the

efficient installation of fence posts. Before operating near power lines or buried

gas lines, consult local utility companies. Ensure all support legs are secured on

the ground before operating. Use only a tractor, towing vehicle or skid steer

loader of adequate power and capacity to operate the machine. Use in any other

way is considered as contrary to the intended use.

The following are unacceptable misuses of the Self-Propelled Post Pounder Kit.

Damage caused by such misuse is not covered by warranty. When operating or

maintaining the Self-Propelled Post Pounder Kit, NEVER:

• let impact head free fall without pounding a post, if head must be lowered,

shut off and lock out power source and gently actuate hydraulic valve.

• use the hugger to straighten crooked post.

• use hands to isolate and identify leak.

• position a foot under the machine.

• transport without fully retracting the pounder mast head.

• modify the equipment.

This equipment should be operated, serviced, and repaired only by persons who

are familiar with its particular characteristics and who are acquainted with the

relevant safety procedures. Any arbitrary modifications carried out on this

equipment may relieve the manufacturer of liability for any resulting damage or

injury.

6 IM12 R3

WHEATHEART - SELF-PROPELLED POST POUNDER KIT 2. SAFETY

TRAILER POST POUNDER MODEL

2.Safety

The Safety Alert symbol to the left identifies important safety messages on the

product and in the manual. When you see this symbol, be alert to the possibility of personal injury or death. Follow the instructions in the safety messages.

Why is SAFETY important to you?

• Accidents disable and kill.

• Accidents cost.

• Accidents can be avoided.

SIGNAL WORDS

Note the use of the signal words DANGER, WARNING, CAUTION, and NOTICE

with the safety messages. The appropriate signal word for each message has

been selected using the definitions below as a guideline.

The Safety Alert symbol means: “ATTENTION, BE ALERT! YOUR SAFETY IS

INVOLVED”.

DANGER

Indicates an imminently hazardous situation

that, if not avoided, will result in serious injury

or death.

WARNING

Indicates a hazardous situation that, if not

avoided, could result in serious injury or

death.

CAUTION

Indicates a hazardous situation that, if not

avoided, may result in minor or moderate

injury.

NOTICE

Indicates a potentially hazardous situation that, if not

avoided, may result in property damage.

IM12 R3 7

2. SAFETY WHEATHEART - SELF-PROPELLED POST POUNDER KIT

2.1. GENERAL SAFETY TRAILER POST POUNDER MODEL

2.1. GENERAL SAFETY

Important: This general safety section includes instructions that apply to all safety practices.

Any instructions specific to a certain safety practice (e.g., Operational Safety),

can be found in the appropriate section. Always read the complete instructional

sections and not just these safety summaries before doing anything with the

equipment.

YOU are responsible for the SAFE use and maintenance of your equipment.

YOU must ensure that you and anyone else who is going to work around the

equipment understands all procedures and related SAFETY information

contained in this manual.

Remember, YOU are the key to safety. Good safety practices not only protect

you, but also the people around you. Make these practices a working part of your

safety program.

• It is the equipment owner, operator, and maintenance personnel's responsibility to read and understand ALL safety instructions, safety decals, and manuals and follow them when assembling, operating, or maintaining the

equipment. All accidents can be avoided.

• Equipment owners must give instructions and review the information initially

and annually with all personnel before allowing them to operate this product.

Untrained users/operators expose themselves and bystanders to possible

serious injury or death.

• Use this equipment for its intended purposes only.

• Do not modify the equipment in any way without written permission from the

manufacturer. Unauthorized modification may impair the function and/or

safety, and could affect the life of the equipment. Any unauthorized modification of the equipment voids the warranty.

• Do not allow any unauthorized person in the work area.

2.2. INSTALLATION SAFETY

1. Read and understand all safety instructions and all safety decals before

starting.

2. Follow good shop practices.

• Use properly sized tools, stands, jacks and hoists at all times.

• Be sure electrical outlets and tools are properly grounded.

• Use adequate light for the job at hand.

• Use 2 people to handle the heavy bulky components.

• Keep the assembly area neat and clean to prevent slipping or tripping.

• Place safety stands or large blocks under the machine or components

before going beneath the component for assembly

3. Stay away from overhead power lines and obstructions when lifting the

machine during assembly . Contact with power lines can cause electrocution.

Contact with obstructions can damage components or cause them to fail.

4. Tighten all fasteners to their specified torque before using the machine (See

“Specifications & Drive Options” on page 42).

8 IM12 R3

WHEATHEART - SELF-PROPELLED POST POUNDER KIT 2. SAFETY

TRAILER POST POUNDER MODEL 2.3. OPERATION SAFETY

2.3. OPERATION SAFETY

In addition to the information provided in the standard Post Pounder manual:

• Only stand behind the controls when operating the self-propelled pounder .

• Chock wheels or lower spike to prevent machine from rolling and to

improve stability.

• Be careful when backing up machine.

• Ensure that your hands are clear of the hugger. Do not hold post in place

while trying to adjust machine position.

• Keep away from spike while operating.

• Hitch must be fully retracted, placing the spike further back from the frame

and making it less likely to penetrate a foot.

• Keep away from wheel arm while operating.

• Do not operate machine without wheel arm pin in place.

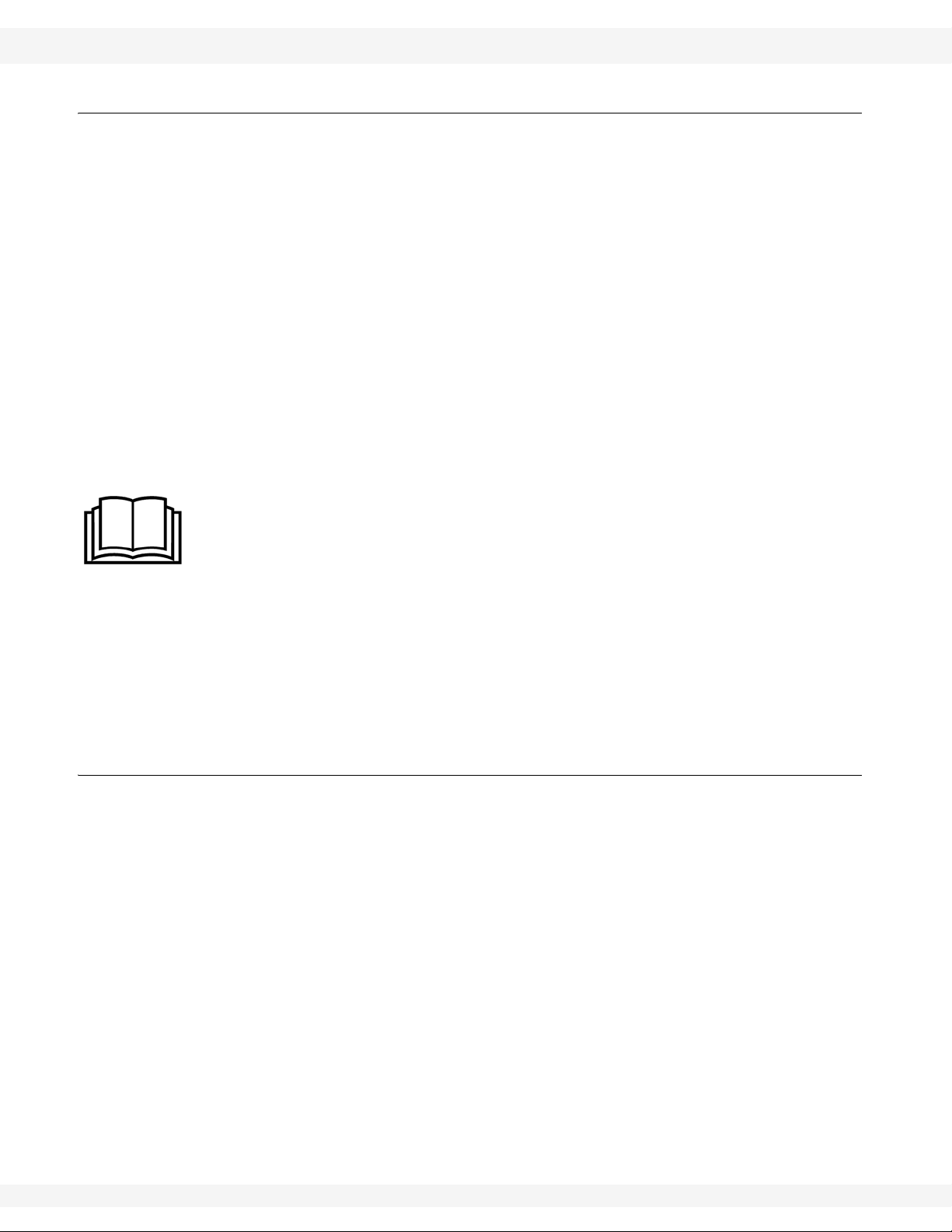

• Review the work safety area diagram (Figure 2.1) before using this equipment.

IM12 R3 9

2. SAFETY WHEATHEART - SELF-PROPELLED POST POUNDER KIT

OPERATOR ONLY AT

CONTROLS!

FLYING DEBRIS

HAZARD

CRUSHING ZONE!

KEEP CLEAR

CRUSHING

HAZARD!

WORK AREA!

TRAINED PERSONNEL ONLY!

2.3. OPERATION SAFETY TRAILER POST POUNDER MODEL

Figure 2.1 Work Safety Area

10 IM12 R3

WHEATHEART - SELF-PROPELLED POST POUNDER KIT 2. SAFETY

TRAILER POST POUNDER MODEL 2.4. TRANSPORT SAFETY

2.4. TRANSPORT SAFETY

In addition to the information in the standard post pounder manual:

• Lower spike or chock wheels to reduce risk of machine rolling and to improve

stability when attaching it to a tow vehicle.

• Raise spike and secure cylinder lock when transporting.

• Ensure jack is in transport position when towing machine.

• Review the work safety area diagram (Figure 2.1) before transporting.

2.5. HYDRAULIC SAFETY

• Always place all hydraulic controls in neutral and relieve system pressure

before disconnecting or working on hydraulic system.

• Keep all components in the hydraulic system tightly secured, clean and in

good condition.

• Replace any worn, cut, abraded, flattened, or crimped hoses.

• Do not attempt any makeshift repairs to the hydraulic fittings or hoses with

tape, clamps, or adhesive. The hydraulic system operates under extremely

high pressure; such repairs will fail suddenly and create a hazardous and

unsafe condition.

• Before moving a hydraulic cylinder, ensure that the attached component is

safely secured.

WARNING

Hydraulic fluid can cause serious injury if it

penetrates the skin. If it does, see a doctor

immediately.

• Relieve pressure before disconnecting

hydraulic line.

• Wear proper hand and eye protection and

use wood or cardboard, not hands, when

searching for leaks.

IM12 R3 11

2. SAFETY WHEATHEART - SELF-PROPELLED POST POUNDER KIT

2.6. SAFETY DECALS TRAILER POST POUNDER MODEL

2.6. SAFETY DECALS

• Keep safety decals clean and legible at all times.

• Replace safety decals that are missing or have become illegible. See decal

location figures that follow.

• Replaced parts must display the same decal(s) as the original part.

• Safety decals are available from your distributor, dealer, or factory.

2.6.1. DECAL INSTALLATION

1. Decal area must be clean and dry, with a temperature above 50°F (10°C).

2. Decide on the exact position before you remove the backing paper.

3. Align the decal over the specified area and carefully press the small portion

with the exposed sticky backing in place.

4. Slowly peel back the remaining paper and carefully smooth the remaining

portion of the decal in place.

5. Small air pockets can be pierced with a pin and smoothed out using the sign

backing paper.

2.6.2. SAFETY DECAL LOCATIONS

Replicas of the safety decals that are attached to the equipment are shown in the

figure(s) that follow. Proper safety procedures require that you familiarize

yourself with the various safety decals and the areas or particular functions that

the decals apply to, as well as the safety precautions that must be taken to avoid

serious injury, death, or damage.

12 IM12 R3

WHEATHEART - SELF-PROPELLED POST POUNDER KIT 2. SAFETY

WARNING NOTICE

RUN-OVER HAZARD

To prevent injury:

• Lower spike or chock wheels to

prevent machine from rolling.

• Be careful when backing up

machine.

To prevent damage:

• Secure handle in chain lock before

towing.

• When pounding posts, lower spike

to stabilize machine.

9700083

TURN

REVERSE

SPIKE

ENGAGED

DRIVE WHEELS

TURN

TO

RAISE

LEVER

FORWARD

BOTH

ENGAGED

SINGLE

LEVERS

LOWER

TO

ENGAGED

SINGLE

LEVER

BOTH

LEVERS

ENGAGED

TRAILER POST POUNDER MODEL 2.6. SAFETY DECALS

Figure 2.2 Safety Decal Locations

IM12 R3 13

2. SAFETY WHEATHEART - SELF-PROPELLED POST POUNDER KIT

2.6. SAFETY DECALS TRAILER POST POUNDER MODEL

14 IM12 R3

WHEATHEART - SELF-PROPELLED POST POUNDER KIT 3. OPERATION

Warning: Before continuing, ensure you have read and understand the relevant information

in the safety section. Safety information is provided to help prevent serious injury, death, or

property damage.

Figure 3.1

Note:

TRAILER POST POUNDER MODEL 3.1. PLACEMENT & OPERATION PROCEDURE

3.Operation

3.1. PLACEMENT & OPERATION PROCEDURE

Note: All control functions are illustrated on the machine with instructional decals, see

Figure 2.4. Take time to learn the controls prior to operating the machine.

1. Fully engage the wheel

drive over-centers

(Figure 3.1). Start

the engine.

2. Remove the lock from

the spike cylinder and

secure to the side of the

spike for operation

(Figure 3.2).

3. Remove the locking pin

from the wheel arm

mount (Figure 3.3) and

move the arm down into

working mode (Figure

3.1). Replace the

locking pin under the

hitch to secure the

wheel arm in working

position (Figure 3.3).

Do not operate without

locking pin in place.

4. Once the machine is in

operating position, feather the hydraulic controls to maneuver the machine

(see Figure 3.4 for controls).

5. Fully retract the hitch to enhance the turning radius of the machine. This will

also place the spike in a safer position.

WARNING

Stay away from spike when operating

machine. If a foot is under the machine during

operation, the spike could penetrate it.

IM12 R3 15

3. OPERATION WHEATHEART - SELF-PROPELLED POST POUNDER KIT

MOVE

CYLINDER

LOCK TO

SIDE OF

SPIKE FOR

OPERATION

Figure 3.2

SPIKE

Transport

Position

Operation

Position

LOCKING PIN

LOCKING PIN

HAIRPIN

HAIRPIN

Figure 3.3

WHEEL ARM

MOUNT

WHEEL ARM

MOUNT

3.1. PLACEMENT & OPERATION PROCEDURE TRAILER POST POUNDER MODEL

6. When on a hill/slope, or if the machine moves ahead or back when pounding,

use the spike to secure the pounder in place (Figure 3.4). See Post Pounder

manual for details on operation.

CAUTION

Chock wheels or lower spike to prevent

Note: When building a new fence, it is much easier to operate the machine in reverse

so you can look down the line while pounding the post. This ensures the line is

machine from rolling and to improve stability.

straight.

WARNING

Run-Over Hazard! To prevent injury be

careful when backing up machine.

16 IM12 R3

WHEATHEART - SELF-PROPELLED POST POUNDER KIT 3. OPERATION

SPIKE

RIGHT DRIVE WHEEL

LEFT DRIVE WHEEL

Figure 3.5

CHAIN LOCK

TRAILER POST POUNDER MODEL 3.2. TRANSPORT PREPARATION

3.2. TRANSPORT PREPARATION

Figure 3.4

1. Remove the safety pin under the hitch and lift

the arm up into transport mode (Figure 3.3).

Replace pin.

2. Fully disengage the wheel drive over-centers

(Figure 3.5) and lock into position with the

chain lock.

3. Raise spike and install cylinder lock with

1/4” X 3” locking pin (see Figure 3.6).

4. Adjust valve position by loosening the

appropriate bolt. Swing into transport position

and lock in place.

IM12 R3 17

3. OPERATION WHEATHEART - SELF-PROPELLED POST POUNDER KIT

MOVE CYLINDER

LOCK TO TOP OF

SPIKE PRIOR TO

TRANSPORTING

3.2. TRANSPORT PREPARATION TRAILER POST POUNDER MODEL

NOTICE

To prevent damage to equipment when transporting, lock

spike in position before transporting, and disengage wheel

drive over-centers, making sure they are in the lock

position.

Figure 3.6

18 IM12 R3

WHEATHEART - SELF-PROPELLED POST POUNDER KIT 4. INSTALLATION

Warning: Before continuing, ensure you have read and understand the relevant information

in the safety section. Safety information is provided to help prevent serious injury, death, or

property damage.

TRAILER POST POUNDER MODEL 4.1. RING GEARS

4.Installation

4.1. RING GEARS

1. Jack up and block the frame. Make sure it sits level.

2. Remove the wheels.

3. Deflate tires and break the bead so the tire will not melt during the welding

process.

4. Buff or grind off paint where ring gears will be welded in place.

5. With the wheel rim lying flat, insert ring gear into the inside of each rim. Use a

rubber mallet to ensure the ring gears are square to the inside of each rim

(Figure 4.4).

Important: To ensure ring gears are installed square, place a straight edge on each gear

and measure the distance to the tire rim in 2 places. Then, rotate the straight

edge 90° and measure again. If measurements are the same, then ring gear is

square inside the rim. Use a rubber mallet to level the ring gear if necessary.

6. Tighten the 4 set screws in rotation to lock the ring gear evenly into place on

each rim.

7. With ring gears now in correct position, weld 1” at each set screw (Figure

4.4).

4.2. WHEEL DRIVES

1. Remove the wheel hubs from the spindle (Figure 4.1).

2. Slide an axle cap assembly over each of the two spindles.

Note: Removing the hydraulic motor from the axle cap assembly will make the welding

process easier.

3. Measure 1-1/4” from each of the 4” x 4” spindle backing plates to the inside of

the axle caps (Figure 4.1).

Note: It may be necessary to grind down the gussets on the spindle slightly to obtain

the 1-1/4” measurement.

4. Put a level on the end of each axle cap and tack it in place. Ensure axle caps

are square with frame.

5. Install the rest of the over-center assemblies.

IM12 R3 19

4. INSTALLATION WHEATHEART - SELF-PROPELLED POST POUNDER KIT

1-1/4”

BETWEEN

BACKING

PLATE &

AXLE CAP

CHECK EDGE IS

VERTICAL USING

LEVEL

GUSSETS

AXLE CAP

ASSEMBLY

4.2. WHEEL DRIVES TRAILER POST POUNDER MODEL

Figure 4.1

6. Reinstall the wheel hubs and wheels and engage the over-center handle

(Figure 4.2). Make sure that the pinion gear and ring gear mesh fully,

providing maximum tooth contact. Check also that the pinion clears the ring

gear when the handle is pulled up (disengaged).

Figure 4.2

20 IM12 R3

WHEATHEART - SELF-PROPELLED POST POUNDER KIT 4. INSTALLATION

Figure 4.3

OVER-CENTER

HANDLE (LIFTED)

CHAIN LOCK

Figure 4.4

WELD 1” AT

EACH SET

SCREW

RING GEAR

TRAILER POST POUNDER MODEL 4.2. WHEEL DRIVES

Note: The hydraulic motors have 4

bolts that attach to each motor

mount. The 2 outer bolts must

be checked so they do not rub

against the ring gear. If they do,

the axle cap will need to be

moved back slightly toward the

frame. Ensure motor is oriented

as shown in Figure 4.3.

7. Double-check that pinion

gears and ring gears line up

properly. Remove wheels

and weld axle caps solid to

the spindles.

8. Lift over-center handle.

9. Line up chain locks to hold

each handle and weld in

place (Figure 4.3).

Note: Removing wheels will make it easier to line up chain locks.

10. Weld the axle caps solid to

the frame.

11. Touch up paint and re-install

the over-center assemblies

and the wheels.

IM12 R3 21

4. INSTALLATION WHEATHEART - SELF-PROPELLED POST POUNDER KIT

WHEEL ARM

ASSEMBLY

3/4”X6” BOLT

PIN

1/2” LOCKNUT

1/2” x 4-1/16” x 5-1/2” U-BOLT

TIE DOWN

HANDLE

WHEEL ARM MOUNT

16-1/2”

HAIRPIN

3/4” LOCKNUT

3/8” X 2-3/4”

BOLT

7/16” FLAT

WASHER

3/8” FLAT

WASHER

3/8” FLAT

WASHER

3/8” NUT

RIGHT

SPRING

STEP A

STEP B

STEP C

STEP D

HITCH

LEFT

SPRING

4.3. FRONT WHEEL ASSEMBLY TRAILER POST POUNDER MODEL

4.3. FRONT WHEEL ASSEMBLY

Figure 4.5

22 IM12 R3

WHEATHEART - SELF-PROPELLED POST POUNDER KIT 4. INSTALLATION

1/2” X 5” BOLT

1/2” LOCKNUT

1/2”x1”x5”

U-BOLT

1/2”

LOCKNUT

TRAILER POST POUNDER MODEL 4.4. SPIKE INSTALLATION

1. Install the wheel arm mount over the tie-down handle on the hitch at 16-1/2”

from the front of the hitch. Note that the front 1/2” x 4-1/16” x 5-1/2” u-bolt is

inside the tie-down handle, as shown in STEP A in Figure 4.5. Make sure it is

square to the hitch and tighten with two 1/2” locknuts.

2. Install the right and left springs on the wheel arm mount as shown in STEP B

in Figure 4.5 and connect with hardware shown.

3. Install the wheel arm over the springs as shown in Step C in Figure 4.5 and

secure with a 3/4” x 6” bolt and 3/4” locknut. Make sure the wheel rotates

freely. If it hits the hitch, move the mount forward so the wheel will

clear.

4. Secure the assembly in the working position as shown in STEP D in Figure

4.5 with pin and hairpin.

4.4. SPIKE INSTALLATION

Figure 4.6

1. Remove the bolt from the hitch tube.

2. Place the spike on the hitch tube on the back and line up the holes. Put the

1/2” x 5” bolt through the hole (Figure 4.6).

3. Insert 1/2” x 4” x 5” u-bolt in the front holes and tighten the 1/2” nuts.

IM12 R3 23

4. INSTALLATION WHEATHEART - SELF-PROPELLED POST POUNDER KIT

Figure 4.7

HANDLES

5/16” x 2-1/2” BOLTS

SP VALVE MOUNT ARM

1/2” X 1”

BOLT

SP VALVE MOUNT PLATE

1/2”X1” BOLT

POUNDER VALVE

MOUNT ARM

CONTROL MOUNT HOLDER

4.5. VALVE AND VALVE MOUNT TRAILER POST POUNDER MODEL

4.5. VALVE AND VALVE MOUNT

Refer to Figure 4.8.

1. Loosen the 1/2” x 1” bolt on the

pounder valve mount arm (bolt not

shown) and remove.

2. Slide the SP valve mount arm over

the lower pipe on the pounder valve

mount arm and put it back in the

control mount holder. Set the pounder

control valve back into position and

retighten the bolt.

3. Install the handles into the valve and

attach to the SP valve mount plate

with three 5/16” x 2-1/2” bolts and

locknuts.

4. Move the SP valve mount arm into the

operating position and tighten the

bolts (Figure 4.7).

24 IM12 R3

Figure 4.8

WHEATHEART - SELF-PROPELLED POST POUNDER KIT 4. INSTALLATION

Figure 4.9

SP KIT OIL

RESERVOIR

3/8” NUT

3/8” x 1” BOLT

BRACKET

POST

BIN

1

-

7

/

8

”

TRAILER POST POUNDER MODEL 4.6. OIL RESERVOIR

4.6. OIL RESERVOIR

1. Drain oil and remove existing oil

reservoir (not shown).

2. Insert the SP oil reservoir on the

bracket and bolt it in place with four

3/8” x 1” bolts and 3/8” nuts.

3. Align the bracket and tank assembly so

the tank clears the post bin by approximately 1-7/8” (Figure 4.10).

4. Tack the new bracket on the post bin,

ensure it is even with the bottom and

back end.

5. Make sure the bracket is level and weld

it solid.

IM12 R3 25

Figure 4.10

Note: Tank hydraulic fittings must face toward the motor mount.

4. INSTALLATION WHEATHEART - SELF-PROPELLED POST POUNDER KIT

FITTINGS

MUST FACE

IN THIS

DIRECTION

4.7. HYDRAULICS TRAILER POST POUNDER MODEL

4.7. HYDRAULICS

Note: Hydraulic fittings must face in the direction shown in Figure 4.11.

Figure 4.11

Important: Refer to the Hydraulics Parts for hydraulic hose routing.

26 IM12 R3

WHEATHEART - SELF-PROPELLED POST POUNDER KIT 5. APPENDIX

TRAILER POST POUNDER MODEL 5.1. SP POUNDER PARTS

5.Appendix

5.1. SP POUNDER PARTS

IM12 R3 27

5. APPENDIX WHEATHEART - SELF-PROPELLED POST POUNDER KIT

5.1. SP POUNDER PARTS TRAILER POST POUNDER MODEL

ITEM PART NO. DESCRIPTION QTY

1

2300149COM TRAILER FRAME ON RUBBER,HH,GAS

2

2300183 CASTER WHEEL ASSY,SP POUNDER

3

2300206 WHEEL ARM MOUNT

4

2300207 WHEEL ARM, SP POUNDER

5

9900976 U-BOLT SQ 1/2 NC x 4-1/16 x 5.5 Gr.5 PLT

6

9900945 NUT JAM 1/2 UNC NYLOCK GR5 PLT

7

0200015F RT SP PNDER OC ASSY, COMP. 1SIDE W/MTR/PINION

8

2330208 STEEL HYD TANK

9

0200015F SP PNDER OC ASSY, COMP. 1SIDE W/MTR/PINION

10

2300156 VALVE MNT, SP POUNDER

11

2330100 VALVE MOUNT PLATE-SP POUNDER

12

2330209 STEEL HYD TANK MOUNT

13

9900214 BREATHER CAP, SLIP ON, CHROME

14

1600007 CONTROL LEVER,SD5 VALVE

15

9700083 DCL, VLV CNTRL,SP POUNDER

16

2330214 CHAIN,5/16X2.5X2 LINKS

17

9900201 BOLT, 1/2 X 2-1/4 UNC GR.5 PLD

18

9900697 BOLT HEX 3/8 X 2-3/4 UNC GR5 PLT

19

9900115 BOLT HEX 3/4 X 6 UNC GR5 PLT

20

9900695 NUT NYLOCK 3/4 UNC GR5 PLT

21

9900699 BOLT, 3/8 X 1 UNC GR 5 PLD

22

0601007 NUT NYLOCK 3/8 UNC GR5 PLT

23

9900524 BOLT HEX 5/16 X 2-1/2 UNC GR5 PLT

24

9900520 NUT NYLOCK 5/16 UNC GR5 PLT

25

9900560 BOLT, 1/2 X 2-1/4 UNC GR.5 PLD

26

9900538 NUT NYLOCK 1/2 UNC GR5 PLT

27

9900510 BOLT HEX 3/8 X 2-1/4 UNC GR5 PLT

28

2300152 SP POUNDER SPIKE, INNER SLIDE

29

2300153 SP POUNDER, BOLT ON SPIKE OUTER SLIDE

30

0200308 CYL,2 X 15.625 X 1.125 ROD,1 @ END

31

2330215 CYLINDER GUARD

32

2330216 PIN, LOCKING, 1/4X3

33

2301006 ASSEMBLY, TIRE, 15", COMPLETE

34

2300163 STAND, VALVE BODY

35

P0521001 HOPPER SPRING LEFT

36

P0521002 HOPPER SPRING RIGHT

37

2330213 HITCH PIN, 3/4" X 6-1/2",C/W CLIP

38

2330112 BATTERY/GAS TANK KIT,18HP SP POUND

39

0601008 WASHER FLAT 3/8 PLD

40

9900555 WASHER FLAT 7/16 PLD

41

0200334 RING GEAR W/ SET SCREWS

42

1600041A VALVE,SERIES CIRCUIT,3 SPOOL,NO LEV

1

1

1

1

3

7

1

1

1

1

1

1

1

3

1

2

2

2

1

1

4

7

3

3

1

1

1

1

1

1

1

1

1

1

1

1

1

1

10

2

2

1

28 IM12 R3

WHEATHEART - SELF-PROPELLED POST POUNDER KIT 5. APPENDIX

TRAILER POST POUNDER MODEL 5.1. SP POUNDER PARTS

WHEEL, TANK AND BATTERY PARTS

IM12 R3 29

5. APPENDIX WHEATHEART - SELF-PROPELLED POST POUNDER KIT

5.1. SP POUNDER PARTS TRAILER POST POUNDER MODEL

Wheel Assembly

ITEM PART NO. DESCRIPTION QTY

2 707693 TIRE ASSY,18X9.50-8,6PR,6"HUB 1

3 707691 BOLT W/GREASE GROOVE, VICTORY CAS 1

4 707688 CASTOR HUB SLEEVE, VICTORY 1

5 707689 SPACER, VICTORY CASTOR WHEE L ZERK 1

6 707690 PIPE,1-1/4 SCH40 BK (1.66ODX1.380ID 1

7 2300028 ZERK 5/16 PRESS-IN STYLE(YELOW ZINC 1

8 2330219 CASTER FORK, SP POUNDER 1

9 700499 Caster cap tube 1

11 254001 PIN,QUICK,3/8 X 2-1/2 SQ WIRE 1

12 86754A NUT LOCK JAM 3/4 UNC GR5 PLT 1

17 9900683 WASHER FLAT 1/4 PLT 2

Tank and Battery Assembly

ITEM PART NO. DESCRIPTION QTY

1 4503042 BATTERY TRAY 1

2 2330107 TANK MNT BOTTOM 1

3 2330107B TANK MNT BOTTOM BENT 1

4 2330111 ANGLE, 1.5 X 1.5 X 21.5 1

5 2330106 FUEL TANK TRAY W/ TABS 1

7 1200008 GAS TANK ONLY,W/FITTING,LID & GAUGE 1

8 9900067 Battery, 12 Volt 1

9 1200024 CLAMP HOSE 1/4" 2

10 1200027 FTG,STL,1/4MNPT X 1/4HB 1

11 4500071 UBOLT SQ 1/4NCX8-1/4X9-3/4X4THD PLD 1

13 9900558 BOLT HEX 1/2 X 1 UNC GR5 PLT 4

14 9900538 NUT NYLOCK 1/2 UNC PLT 6

15 9900562 NUT NYLOCK 1/4 UNC PLT 2

16 9900647 BOLT HEX 1/2 X 4 UNC GR5 PLT 2

17 9900683 WASHER FLAT 1/4 PLT 2

NOT SHOWN

9900093 CABLE, BATTERY (12V) 1 ONLY (36") 2

9900261 TARP STRAP, 15"(19" HOOK TO HOOK) 2

H14G HOSE,1/4" GASLINE 24

30 IM12 R3

WHEATHEART - SELF-PROPELLED POST POUNDER KIT 5. APPENDIX

TRAILER POST POUNDER MODEL 5.2. HYDRAULICS PARTS

5.2. HYDRAULICS PARTS

5.2.1. SP POUNDER HYDRAULICS WITH PILOT AUGER

IM12 R3 31

5. APPENDIX WHEATHEART - SELF-PROPELLED POST POUNDER KIT

5.2. HYDRAULICS PARTS TRAILER POST POUNDER MODEL

ITEM PART NO. DESCRIPTION QTY

1 H34X56 HYD HOSE 3/4 X 56 12MPSX10MB 1W 1

1A H34X26 HYD HOSE 3/4 X 26 12MP 1W 1

2 H12X110P2W HYD HOSE 1/2 X 110 8MP-8MP 1W 1

3 H12X52P HYD HOSE 1/2 X 52 8MP-8MP 1W 1

4 H12X42P HYD HOSE 1/2 X 42 8MP-8MP 1W 1

5 H12X58P HYD HOSE 1/2 X 58 8MP-8MP 1W 1

6 H12X60P HYD HOSE 1/2 X 60 8MP-8MP 1W 1

7 H38X96P HYD HOSE 3/8 X 96 6MP-8MP 1W 3

8 H38X78P HYD HOSE 3/8 X 78 6MP-8MP 1W 1

9 H38X104P HYD HOSE 3/8 X 104 6MP-8MP 1W 1

10 H38X100P HYD HOSE 3/8 X 100 6MP-8MP 1W 1

11 H12X32P HOSE,HYD,1/2X32,1/2MNPT X 1/2MNPT,1W 1

12 H34X32P HYD HOSE 3/4 X 32 10MB 1W 1

13 9900054 HYD FIT 8MB-FPX 5

14 9900909 HYD FIT ORIFICE 1/16”, 8MB-FPX 6

15 9900331 HYD FIT ELBOW 8MP-8FPX90 5

16 9900096

ELBOW 10MORB X 1/2FNPSM

a

1

17 0200326 FTG, STL 45, 6MORBX6MKIC 4

18 9900012 FTG,STL,ELB,8MORBX1/2FNPSM 4

19 9900302 FTG,STL,6MORB X 3/8FNPSM 4

20 9900284 FTG,ELB,3/8MNPT X 3/8FNPSM,1/16 ORF 2

21 9900791 FTG,STL,TEE,3/8F/M/FNPT 2

22 9900296 FTG,STL,ELB,10MORBX3/8FNPSM 1

23 9900204 FTG,STL,10MORB X 1/2FNPSM 1

24 9900296 FTG,STL,ELB,10MORBX3/8FNPSM 5

25 H38X21 HOSE,HYD,3/8 X 21",3/8M/MNPT 1

26 H38X28 HOSE,HYD,3/8 X 28",3/8M/MNPT 1

27 H38X144 HOSE,HYD,3/8 X 144",3/8MNPTX6FJIC 4

28 H38X112PP HOSE,HYD,3/8X112,1/2MNPT X 3/8MNPT,1W 2

29 H38X52PP HOSE,HYD,3/8X52,1/2MNPT X 3/8MNPT,1W 2

30 H38X120PP HOSE,HYD,3/8X120,3/8MNPT X 1/2MNPT,1W 2

32 H12X72P HOSE,HYD,1/2X72,1/2MNPT X 1/2MNPT,1W 1

33 H12X32P HOSE,HYD,1/2X32,1/2MNPT X 1/2MNPT,1W 1

34 9900761 FTG,STL,ELB,3/8MNPTX3/8FNPSM 2

35 9900208 FTG,STL,3/4HB X 3/4MNPT 2

36 9900902 6MORBX1/2FNPSM 6

37 9900992 FTG,STL,ELB,3/4MNPT X 3/4FNPSM 1

38 9900215 CLAMP, GEAR #012 (3/4” HOSE) 2

a. Replaces 9900204, HYD FIT 10MB-8FPX in existing hydraulics.

32 IM12 R3

WHEATHEART - SELF-PROPELLED POST POUNDER KIT 5. APPENDIX

TRAILER POST POUNDER MODEL 5.2. HYDRAULICS PARTS

5.2.2. SP POUNDER HYDRAULICS WITHOUT PILOT AUGER

IM12 R3 33

LIMITED WARRANTY

Wheatheart warrants to the buyer that the new machinery is free from defects in material and workmanship.

This warranty is only effective for any new machinery that has not been altered, changed, repaired, or

treated since its delivery to the buyer, other than by Wheatheart or its authorized dealers or employees, and does not apply to accessories, attachments, tools, or parts sold or operated with the new

machinery if they have not been manufactured by Wheatheart.

Wheatheart shall only be liable for defects in the material or workmanship attributed to faulty material

or bad workmanship that can be proved by the buyer, and specifically excludes liability for rep airs arising as a result of normal wear and tear of the new machinery or in any other manner whatsoever, and

without limiting the generality of the foregoing, excludes application or installation of parts not completed in accordance with Wheatheart operation manual, specifications, or printed instructions.

A Warranty Registration Form and Inspection Report must be completed at the time of delivery and

returned to Wheatheart Manufacturing within thirty (30) days.

Warranty Period

Private Farm Use One (1) year from date of purchase.

Commercial, Custom, or Rental Use Ninety (90) days from date of purchase.

Replacement Parts Ninety (90) days from date of replacement

Defective parts are subject to inspection by a Wheatheart representative prior to approval of a warranty claim. All returned parts must be sent to the factory, freight pre-paid, in order to qualify for warranty replacement. Repaired or replaced parts will be returned freight collect.

If these conditions are fulfilled, Wheatheart shall at its own cost and its own option either repair or

replace any defective parts provided that the buyer shall be responsible for all expenses incurred as a

result of repairs, labor , parts, transport ation, or any other work, unless Wheatheart has authorized such

expenses in advance. Normal wear and service items such as belts, hoses, flashing, etc. are excluded

from warranty.

The warranty shall not extend to any repairs, changes, alterations, or replacements made to the new

equipment other than by Wheatheart or its authorized dealers or employees.

This warranty extends only to the original owner of the new equipment.

This warranty is limited to the terms stated herein and is in lieu of any other warranties whether

expressed or implied, and without limiting the generality of the foregoing, excluded all warranties,

expressed or implied, or conditions whether statutory or otherwise as to quality and fitness for any purpose of the new equipment, Wheatheart disclaims all liability for incidental or consequential damages.

This machine is subject to design changes and Wheatheart shall not be required to retro-fit or

exchange items on previously sold units except at its own option.

WARRANTY VOID IF NOT REGISTERED

Wheatheart

Printed in Canada

Part of the Ag Growth International Inc. Group

P.O. Box 151

902 South St. Road 32

Union City, Indiana

Phone: 1-800-354-9502 or 1-765-964-4631

Fax: (765) 964-3529

Toll Free: (877) 934-0649 (Canada & USA)

website: www.wheatheart.com

email: sales@wheatheart.com

© Ag Growth International Inc. 2013

Loading...

Loading...