Read this manual before using product. Failure

SELF-PROPELLED AUGER KIT

WHEATHEART BH & R SERIES

ASSEMBLY & OPERATION MANUAL

to follow instructions and safety precautions can

result in serious injury, death, or property

damage. Keep manual for future reference.

Part Number: 30761 R0

Revised: Jan/12

WHEATHEART - SELF-PROPELLED AUGER KIT

WHEATHEART BH & R SERIES

This product has been designed and constructed according to general engineering

standardsa. Other local regulations may apply and must be followed by the operator.

We strongly recommend that all personnel associated with this equipment be trained

in the correct operational and safety procedures required for this product. Periodic

reviews of this manual with all employees should be standard practice. For your

convenience, we include this sign-off sheet so you can record your periodic reviews.

Date Employee Signature Employer Signature

a. Standards include organizations such as the American Society of Agricultural and Biological Engineers,

American National Standards Institute, Canadian Standards Association, International Organization for

Standardization, and/or others.

2 30761 R0

WHEATHEART - SELF-PROPELLED AUGER KIT

WHEATHEART BH & R SERIES

TABLE OF CONTENTS

1. Introduction.......................................................................................................................... 5

2. Safety First............................................................................................................................ 7

2.1. General Safety ......................................................................................................... 8

2.2. Assembly Safety....................................................................................................... 9

2.3. Operation Safety ...................................................................................................... 9

2.4. Transport & Placement Safety ............................................................................... 11

2.5. Storage Safety........................................................................................................ 12

2.6. Maintenance Safety................................................................................................ 12

2.7. Hydraulic Safety..................................................................................................... 12

2.8. Engine Safety......................................................................................................... 13

2.9. Tire Safety.............................................................................................................. 13

2.10. Safety Decals....................................................................................................... 13

2.10.1. Decal Installation.................................................................................... 13

2.10.2. Safety Decal Locations........................................................................... 14

3. Assembly ............................................................................................................................ 15

3.1. Gear Pump Assembly ............................................................................................ 15

3.2. Pump Guard Assembly .......................................................................................... 15

3.3. Oil Reservoir Assembly.......................................................................................... 16

3.4. Gear Drive Assembly ............................................................................................. 17

3.5. Over-Center Drive.................................................................................................. 18

3.6. Pinion Gear Adjustment ......................................................................................... 19

3.7. Undercarriage Installation ...................................................................................... 19

3.8. Ram Extension Installation..................................................................................... 21

3.9. Cable Installation.................................................................................................... 22

3.10. Winch Assembly................................................................................................... 23

3.10.1. Winch Alignment..................................................................................... 23

3.11. Hose Kit Layout—No Bin Sweep.......................................................................... 24

3.12. Hose Kit Layout With Bin Sweep.......................................................................... 27

3.13. Hose Kit Assembly ............................................................................................... 29

3.14. Cushion Valve Installation.................................................................................... 30

3.15. Hydraulic Filter installation ................................................................................... 31

4. Transport & Placement...................................................................................................... 33

4.1. Transport Procedure .............................................................................................. 33

4.2. Placement Procedure............................................................................................. 34

5. Operation ............................................................................................................................ 35

5.1. Start-Up.................................................................................................................. 35

5.2. Operating Procedure.............................................................................................. 36

30761 R0 3

WHEATHEART - SELF-PROPELLED AUGER KIT

WHEATHEART BH & R SERIES

TABLE OF CONTENTS

6. Maintenance & Storage...................................................................................................... 39

6.1. Maintenance........................................................................................................... 39

6.1.1. Hydraulic Winch Valve.............................................................................. 39

6.1.2. Ram Speed Adjustment............................................................................ 40

6.1.3. Hydraulic Pressure Relief Valve Adjustment............................................ 40

6.1.4. Cushion Valve Adjustment........................................................................ 41

6.2. Storage................................................................................................................... 41

7. Troubleshooting ................................................................................................................. 43

8. Appendix............................................................................................................................. 45

8.1. Bolt Torque Values................................................................................................. 45

8.2. Tightening O-Ring Fittings...................................................................................... 46

8.3. Parts....................................................................................................................... 48

8.3.1. Self-Propelled Auger Kit ........................................................................... 48

8.3.2. Wheel Motor ............................................................................................. 50

8.3.3. Tank Upgrade Kit, 43 L............................................................................. 51

8.3.4. In-Line Hydraulic Oil Filter ....................................................................... 52

8.3.5. Hydraulic Winch & Control Valve.............................................................. 53

Limited Warranty..................................................................................................................... 55

4 30761 R0

WHEATHEART - SELF-PROPELLED AUGER KIT 1. INTRODUCTION

SERIAL NUMBER: _______________________

DATE PURCHASED: _____________________

DEALER NAME: ________________________

WHEATHEART BH & R SERIES

1.Introduction

Congratulations. As the new owner of a Wheatheart self-propelled auger, you will

be working with equipment especially designed to complement and improve your

farming operation. Before using this auger, we recommend that you read this

manual to familiarize yourself with the various features of the machine, and the

necessary precautions for efficient and safe operation. In addition, we suggest

that anyone using this auger be required, as a matter of record, to be familiar

with all safety precautions. A sign-off form is supplied on the inside cover for your

convenience and permanent records.

Keep this manual handy for frequent reference and to review with new

personnel. Call your Wheatheart distributor or dealer if you need assistance,

information, or additional copies of the manual.

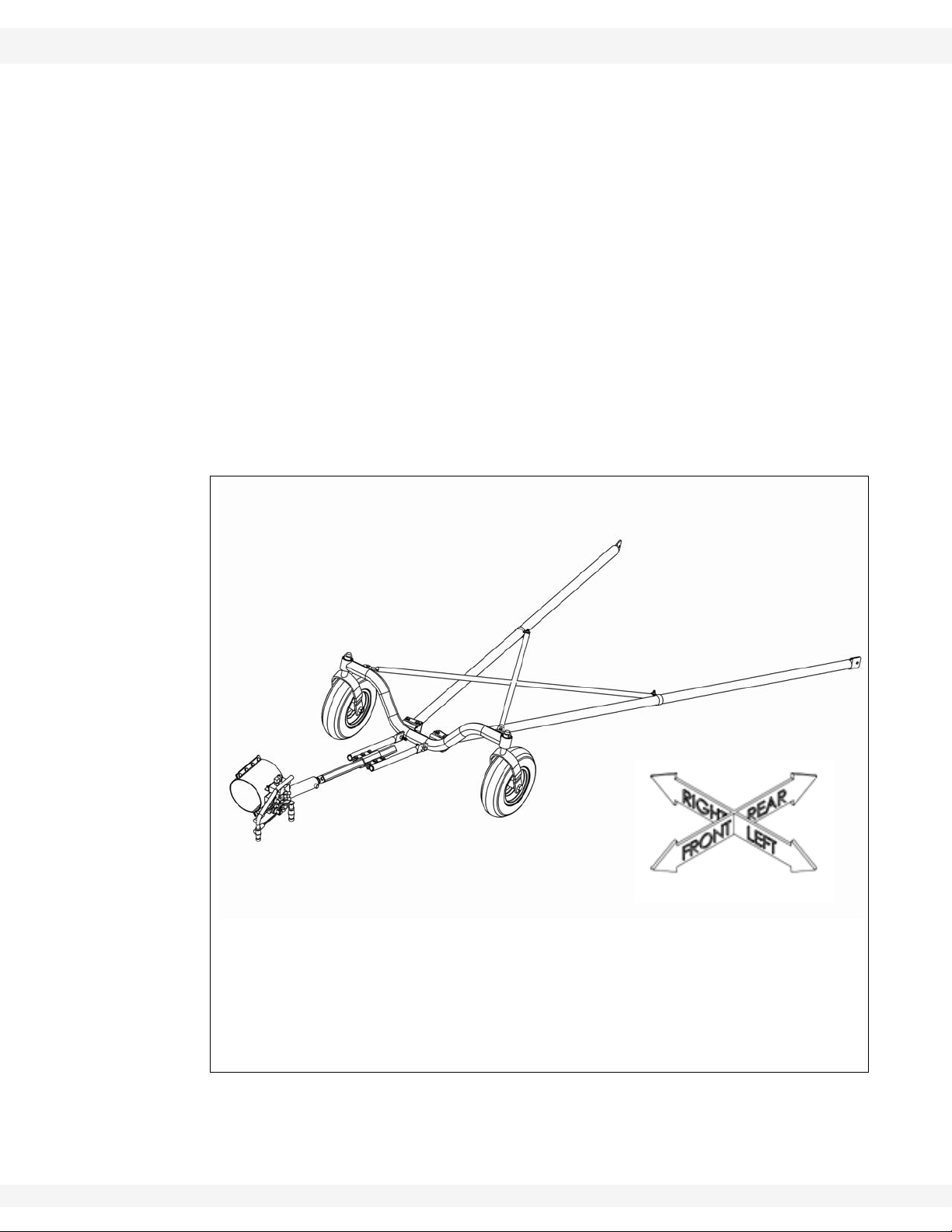

OPERATOR ORIENTATION—The directions left, right, front, and rear, as

mentioned throughout the manual, are as seen from the tractor or towing

vehicle’s driver’s seat, and facing in the direction of travel when the unit is being

transported.

30761 R0 5

1. INTRODUCTION WHEATHEART - SELF-PROPELLED AUGER KIT

WHEATHEART BH & R SERIES

6 30761 R0

WHEATHEART - SELF-PROPELLED AUGER KIT 2. SAFETY FIRST

WHEATHEART BH & R SERIES

2.Safety First

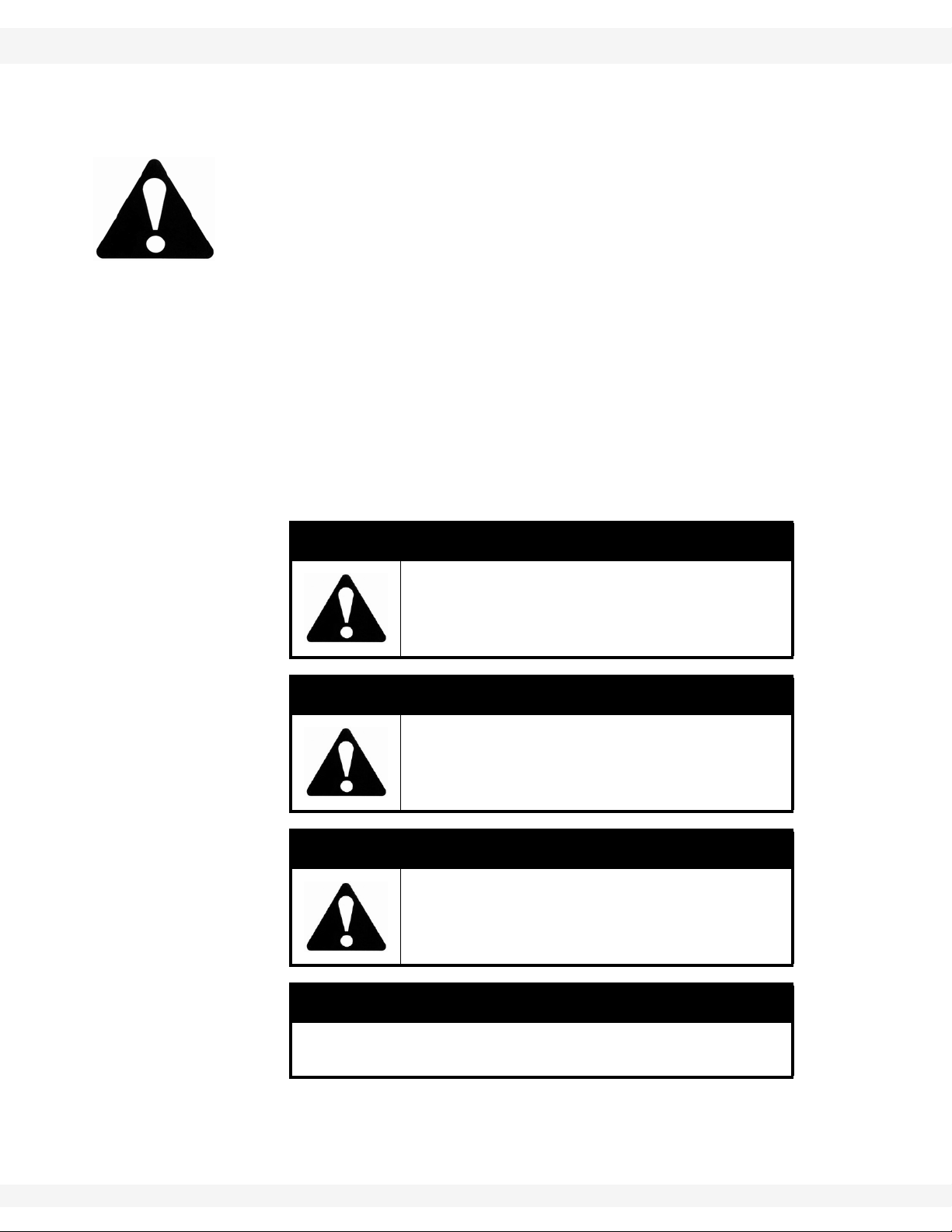

The Safety Alert symbol to the left identifies important safety messages on the

product and in the manual. When you see this symbol, be alert to the possibility of personal injury or death. Follow the instructions in the safety messages.

Why is SAFETY important to you?

Three big reasons:

• Accidents disable and kill.

• Accidents cost.

• Accidents can be avoided.

SIGNAL WORDS

Note the use of the signal words DANGER, WARNING, CAUTION, and NOTICE

with the safety messages. The appropriate signal word for each message has

been selected using the definitions below as a guideline.

The Safety Alert symbol means: “ATTENTION, BE ALERT! YOUR SAFETY IS

INVOLVED”.

DANGER

Indicates an imminently hazardous situation

that, if not avoided, will result in serious injury

or death.

WARNING

Indicates a hazardous situation that, if not

avoided, could result in serious injury or

death.

CAUTION

Indicates a hazardous situation that, if not

avoided, may result in minor or moderate

injury.

NOTICE

Indicates a potentially hazardous situation that, if not

avoided, may result in property damage.

30761 R0 7

2. SAFETY FIRST WHEATHEART - SELF-PROPELLED AUGER KIT

2.1. GENERAL SAFETY WHEATHEART BH & R SERIES

2.1. GENERAL SAFETY

Important: This general safety section includes instructions that apply to all safety practices.

Any instructions specific to a certain safety practice (e.g., assembly safety), can

be found in the appropriate section. Always read the complete instructional

sections and not just these safety summaries before doing anything with the

equipment.

YOU are responsible for the SAFE use and maintenance of your equipment.

YOU must ensure that you and anyone else who is going to work around the

equipment understands all procedures and related SAFETY information

contained in this manual.

Remember, YOU are the key to safety. Good safety practices not only protect

you, but also the people around you. Make these practices a working part of your

safety program.

• It is the equipment owner and the operator's responsibility to read and understand ALL safety instructions, safety decals, and manuals and follow them

before assembling, operating, or maintaining the equipment. All accidents

can be avoided.

• Equipment owners must give instructions and review the information initially

and annually with all personnel before allowing them to operate this product.

Untrained users/operators expose themselves and bystanders to possible

serious injury or death.

• Use this equipment for its intended purposes only.

• Do not modify the equipment in any way. Unauthorized modification may

impair the function and/or safety, and could affect the life of the equipment.

Any modification to the equipment voids the warranty.

• Do not allow children, spectators, or bystanders within the work area.

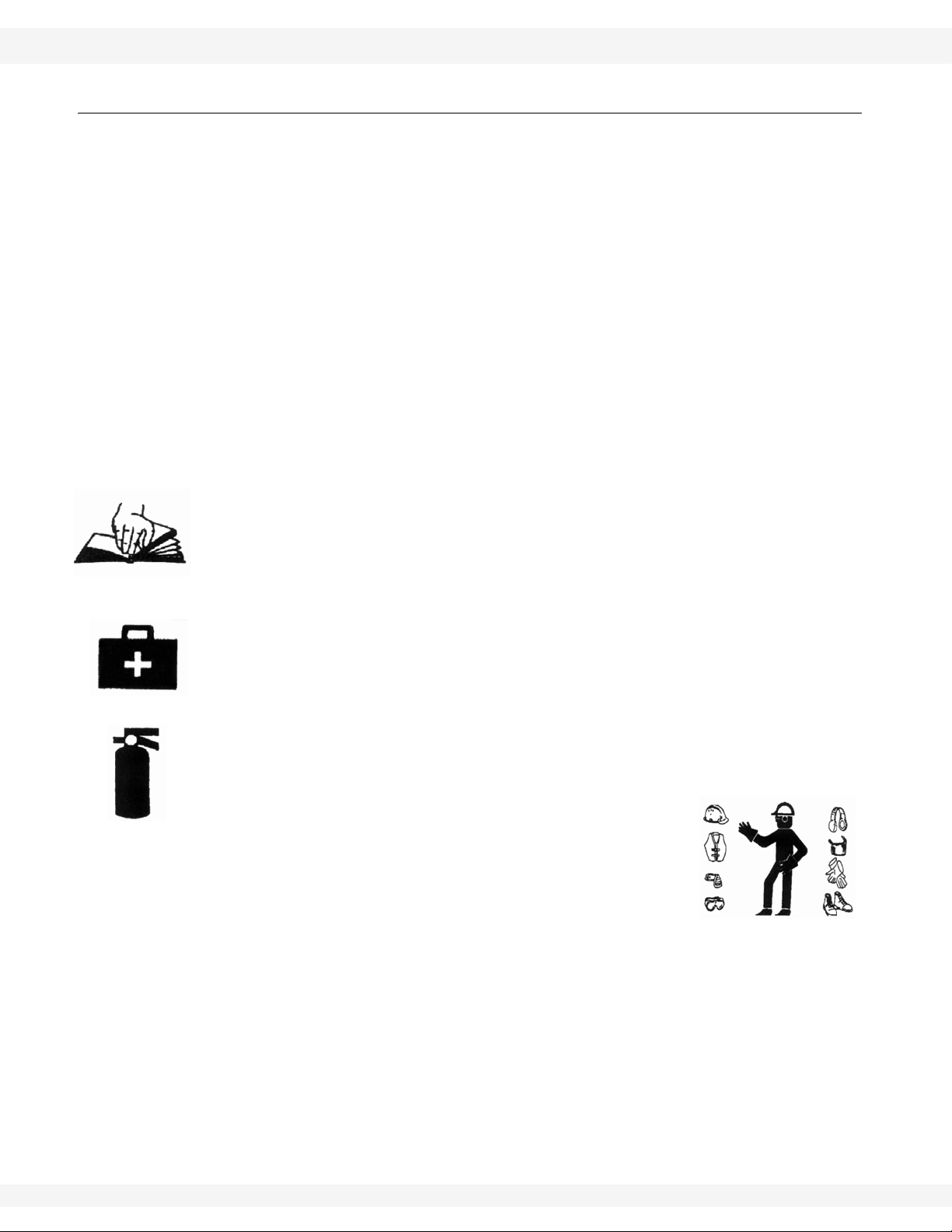

• Have a first-aid kit available for use should the need arise, and know how to

use it.

• Provide a fire extinguisher for use in case of an accident. Store in a highly visible and accessible place.

• Wear appropriate protective gear . This list includes, but

is not limited to:

• a hard hat

•gloves

• protective shoes with slip-resistant soles

• protective goggles

• hearing protection

• dust mask or respirator

• For Powered Equipment: before servicing, adjusting, or repairing powered

equipment, unplug, place all controls in neutral or off position, stop the engine

or motor , remove ignition key or lock out power source, and wait for all moving parts to stop.

8 30761 R0

WHEATHEART - SELF-PROPELLED AUGER KIT 2. SAFETY FIRST

WHEATHEART BH & R SERIES 2.2. ASSEMBLY SAFETY

• Follow good shop practices:

• keep service area clean and dry

• be sure electrical outlets and tools are properly

grounded

• use adequate light for the job at hand

• Think SAFETY! Work SAFELY!

2.2. ASSEMBLY SAFETY

• Read the instructions and familiarize yourself with the subassemblies and

hardware making up the equipment.

• The components are large, heavy, and can be hard to handle. Be sure to use

the proper tools, stands, jacks, and hoists for the job.

• Have 2 people handle the heavy bulky components.

• Place safety stands or large blocks under the machine or components before

going beneath the component for assembly.

• Stay away from overhead power lines and obstructions when lifting the

machine during assembly. Electrocution can occur without direct contact.

Contact with obstructions can damage components or cause them to fail.

)

• Tighten all fasteners to their specified torque before using the machine.

2.3. OPERATION SAFETY

• Have another person nearby who can shut down the equipment in case of

accident.

• Do not operate with any of the safety guards removed.

• Keep body, hair, and clothing away from moving p art s. Stay away from intake

during operation.

30761 R0 9

2. SAFETY FIRST WHEATHEART - SELF-PROPELLED AUGER KIT

2.3. OPERATION SAFETY WHEATHEART BH & R SERIES

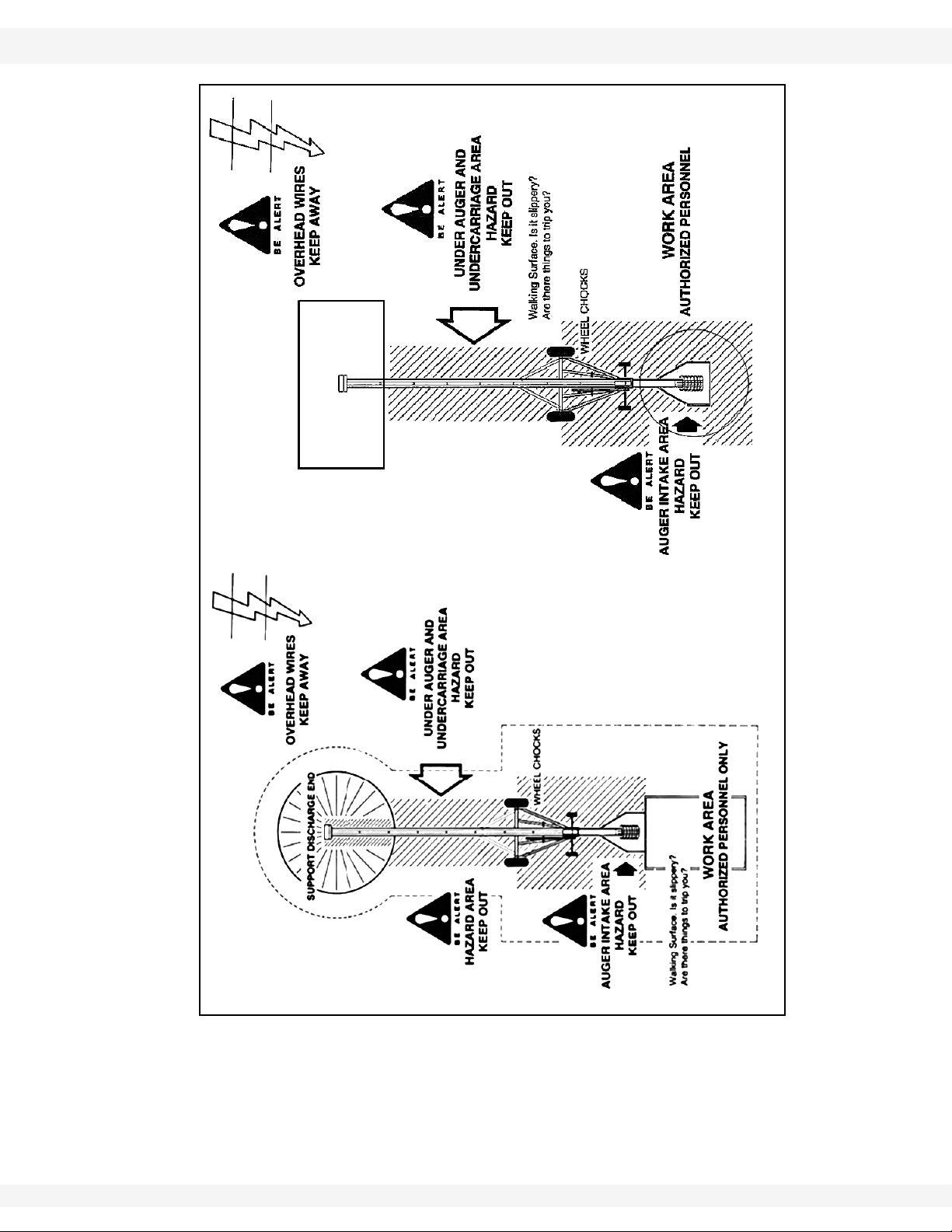

Figure 2.1 Auger Hazard Areas

10 30761 R0

WHEATHEART - SELF-PROPELLED AUGER KIT 2. SAFETY FIRST

Figure 2.2 Work Safety Area

WHEATHEART BH & R SERIES 2.4. TRANSPORT & PLACEMENT SAFETY

2.4. TRANSPORT & PLACEMENT SAFETY

• Before raising/lowering/moving the auger, make sure the

area around the auger is clear

of obstructions and/or unauthorized personnel. Never

allow anyone to stand on or

beneath auger while transporting or placing auger .

• Wheels must be free to move

when raising or lowering

auger.

• Do not stand between towing

vehicle and grain auger when

hitching.

• Make certain that the hitch pin

is in place and the safety chain

is properly attached. Use a

type of hitch pin that will not

permit auger to separate from

towing vehicle.

• Use extreme care and minimum ground speed when

operating or transporting on

hillsides, over rough ground,

or near ditches or fences.

• Always attach an SMV (slow moving vehicle) sign before transporting auger,

and equip the auger with the necessary lights for transportation where

required by law . Always use hazard warning flashers on the tractor/towing

vehicle when transporting unless prohibited by law.

• Do not allow riders on the machine, towing vehicle, tractor, or skid steer during transport.

• Stay away from overhead obstructions and power lines when operating and

transporting. Electrocution can occur without direct contact.

• Ensure that tires are inflated to the manufacturer's recommended pressure.

• Review the work safety area diagram before starting work.

• Check with local authorities regarding transport on public roads. Obey all

applicable laws and regulations.

• Always travel at a safe speed, never exceeding 15 mph (24 km/hr). Reduce

speed on rough surfaces and use caution when turning corners or meeting

traffic.

• Transport auger in full down position with slight tension on cable.

• Ensure that the wheel drive motors are disengaged before towing.

30761 R0 11

2. SAFETY FIRST WHEATHEART - SELF-PROPELLED AUGER KIT

2.5. STORAGE SAFETY WHEATHEART BH & R SERIES

2.5. STORAGE SAFETY

• Store in an area away from human activity.

• Do not permit children to play on or around the stored machine.

2.6. MAINTENANCE SAFETY

• Before applying pressure to a hydraulic system, make sure all components

are secure, hoses are in good condition, and couplings are tightly connected

and undamaged.

• Relieve pressure from hydraulic circuit before servicing or disconnecting from

tractor.

• Place stands or blocks under the frame before working beneath the machine.

• After maintenance is complete, replace and secure all safety guards and

safety devices, and if applicable, service doors and cleanout covers.

• Remove all tools and unused parts from machine before operation.

• Remove buildup of grease, oil, and debris.

• Inspect all parts. Ensure parts are in good condition and installed properly.

Use only genuine Wheatheart replacement parts or equivalent. Replacement

parts must meet ASAE standards or serious injury may result. Use of

unauthorized parts will void the warranty. If in doubt, contact Wheatheart or your

Wheatheart dealer.

2.7. HYDRAULIC SAFETY

• Always place all hydraulic controls in neutral and relieve system pressure

before disconnecting or working on hydraulic system.

• Keep all components in the hydraulic system tightly secured, clean and in

good condition.

• Replace any worn, cut, abraded, flattened, or crimped hoses.

• Do not attempt any makeshift repairs to the hydraulic fittings or hoses with

tape, clamps, or adhesive. The hydraulic system operates under extremely

high pressure; such repairs will fail suddenly and create a hazardous and

unsafe condition.

12 30761 R0

WHEATHEART - SELF-PROPELLED AUGER KIT 2. SAFETY FIRST

WHEATHEART BH & R SERIES 2.8. ENGINE SAFETY

• Before moving a hydraulic cylinder, ensure that the attached component is

safely secured.

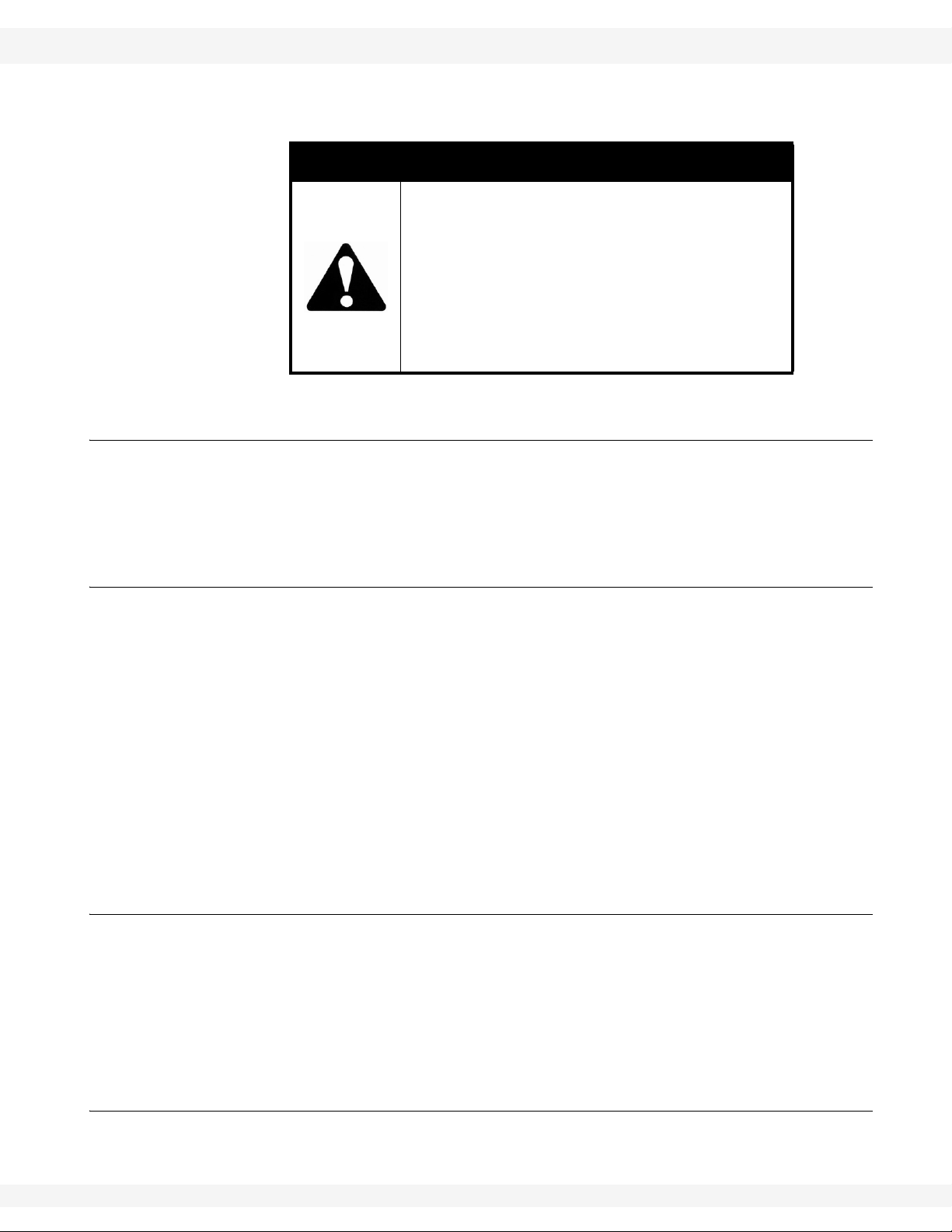

WARNING

Hydraulic fluid can cause serious injury if it

penetrates the skin. If it does, see a doctor

immediately.

• Relieve pressure before disconnecting

hydraulic line.

• Wear proper hand and eye protection and

use wood or cardboard, not hands, when

searching for leaks.

2.8. ENGINE SAFETY

• Be sure to stop engine and remove key or lock out power before inspecting or

servicing engine

• Refer to engine operation manual for further details.

2.9. TIRE SAFETY

• Failure to follow proper procedures when mounting a tire on a wheel or rim

can produce an explosion that may result in serious injury or death.

• Do not attempt to mount a tire unless you have the proper equipment and

experience to do the job.

• Have a qualified tire dealer or repair service perform required tire maintenance.

• When replacing worn tires, make sure they meet the original tire specifications. Never undersize the replacement tire.

• Do not weld to the tire rim with the tire mounted on the rim. This action may

cause an explosion which could result in serious injury or death.

• Inflate tires to the manufacturers's recommended pressure.

2.10. SAFETY DECALS

• Keep safety decals clean and legible at all times.

• Replace safety decals that are missing or have become illegible. See decal

location figures that follow.

• Replaced parts must display the same decal(s) as the original part.

• Safety decals are available from your distributor, dealer, or factory.

2.10.1. DECAL INSTALLATION

1. Decal area must be clean and dry, with a temperature above 50°F (10°C).

30761 R0 13

2. SAFETY FIRST WHEATHEART - SELF-PROPELLED AUGER KIT

Decal # 9700024

Decal # 28128

Decal # 17698

2.10. SAFETY DECALS WHEATHEART BH & R SERIES

2. Decide on the exact position before you remove the backing paper.

3. Align the decal over the specified area and carefully press the small portion

with the exposed sticky backing in place.

4. Slowly peel back the remaining paper and carefully smooth the remaining

portion of the decal in place.

5. Small air pockets can be pierced with a pin and smoothed out using the sign

backing paper.

2.10.2. SAFETY DECAL LOCATIONS

Replicas of the safety decals that are attached to the equipment are shown in the

figure(s) that follow. Proper safety procedures require that you familiarize

yourself with the various safety decals and the areas or particular functions that

the decals apply to as well as the safety precautions that must be taken to avoid

serious injury, death, or damage.

14 30761 R0

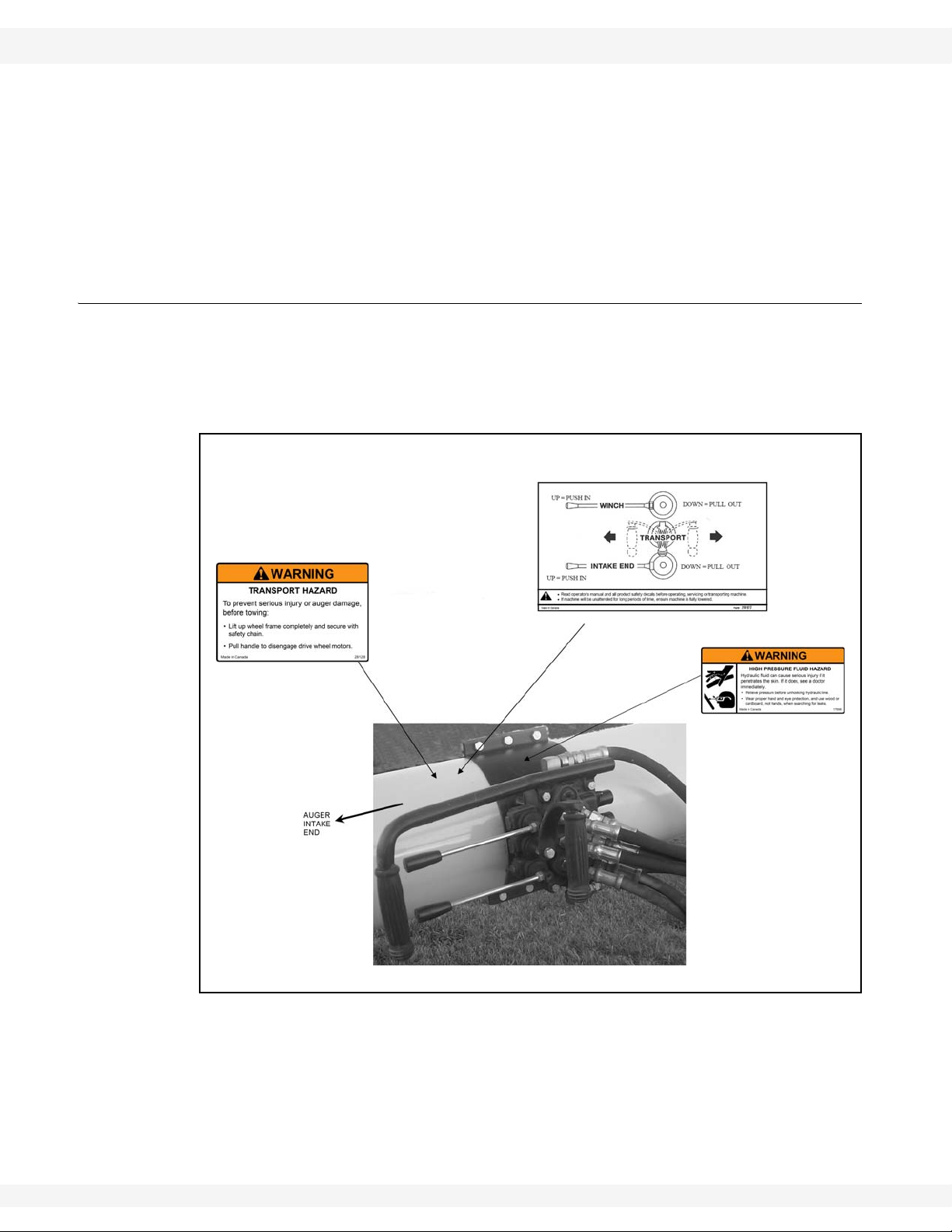

Figure 2.3 Safety Decal Locations

WHEATHEART - SELF-PROPELLED AUGER KIT 3. ASSEMBLY

Warning: Before continuing, ensure you have read and understand the relevant information

in the safety section. Safety information is provided to help prevent serious injury, death, or

property damage.

WHEATHEART BH & R SERIES 3.1. GEAR PUMP ASSEMBLY

3.Assembly

CAUTION

Ensure the auger is in the fully lowered

position and on a level surface with the

wheels chocked before proceeding with any

assembly.

3.1. GEAR PUMP ASSEMBLY

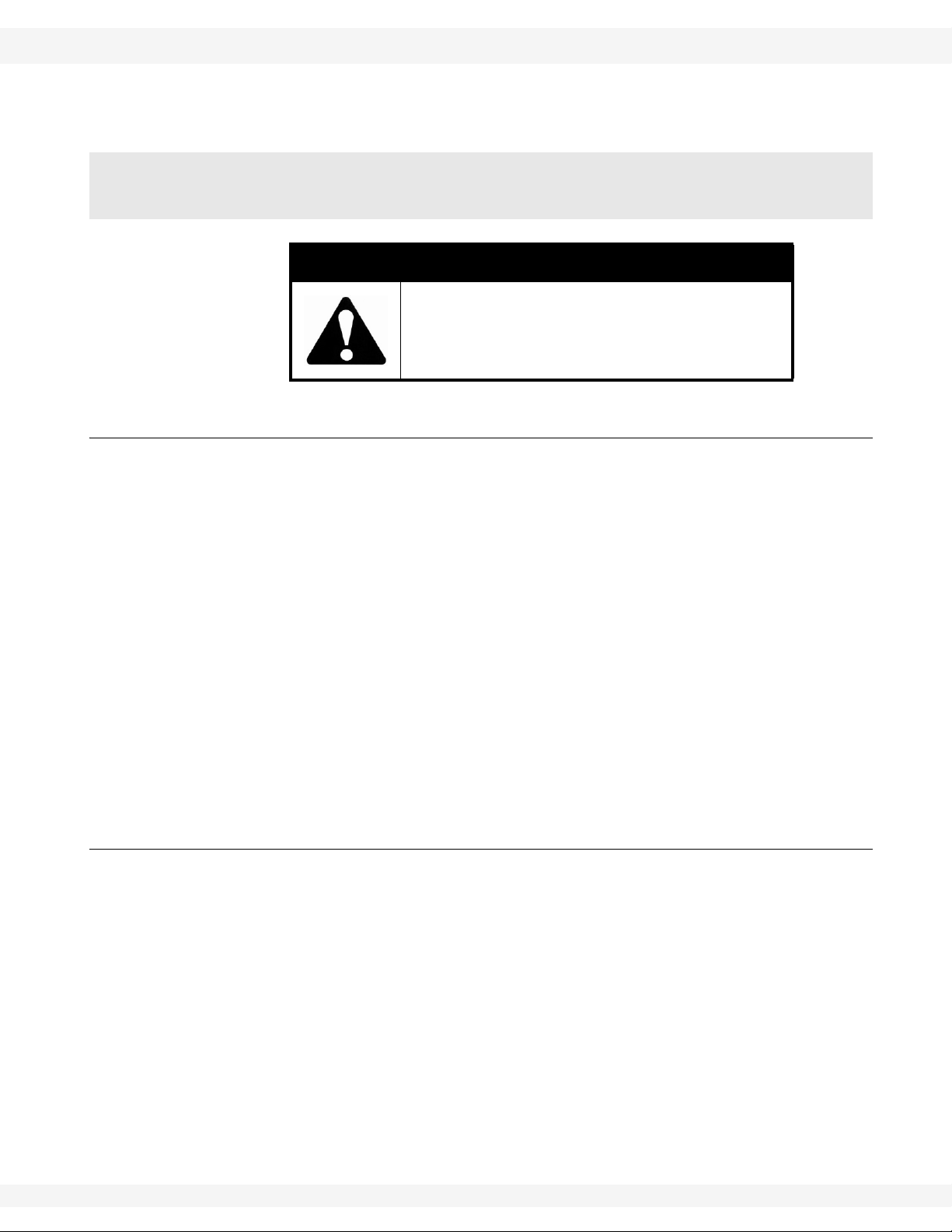

Refer to Figure 3.1 for assembly.

Note: The engine pulley guard is removed from Figure 3.1 for illustrative purposes only.

1. The over-center (o/c) pump bracket comes pre-assembled and is attached to

the engine block with two 3/8” bolts. Use 1” pump shims to provide a flat

mounting surface for the o/c pump bracket (Figure 3.1).

2. Install the single groove engine pulley and 1/2” x 4-1/2” pump pulley so they

are in line.

3. Install the belt and slide the over-center bracket back to increase tension on

the belt.

4. Tighten the 2 bolts holding the over-center bracket to the engine, then push

down on the over-center handle to lock the belt in place. Allow belt to deflect

approximately 3/4” to 1” at the center.

Important: The gear pump placement may be changed, but the pump MUST run counter-

clockwise (when facing pump) at a maximum of 3600 rpm.

3.2. PUMP GUARD ASSEMBLY

1. Bolt the pump guard bracket to the over-center pump bracket (Figure 3.1).

• Install the pump guard bracket at the pump end of the long, adjustable

slot, through the middle of the over-center bracket.

• Place 2 washers between the pump guard bracket, and the over-center

bracket so that the angle of the bracket may be adjusted to the belt.

2. Attach the pump guard to the pump guard bracket.

• Align the pump guard with the belt that runs between the pump and the

engine.

• Ensure that the belt does not contact the pump guard with belt engaged

and disengaged.

30761 R0 15

3. ASSEMBLY WHEATHEART - SELF-PROPELLED AUGER KIT

3.3. OIL RESERVOIR ASSEMBLY WHEATHEART BH & R SERIES

Figure 3.1 Gear Pump Installation Guard

3.3. OIL RESERVOIR ASSEMBLY

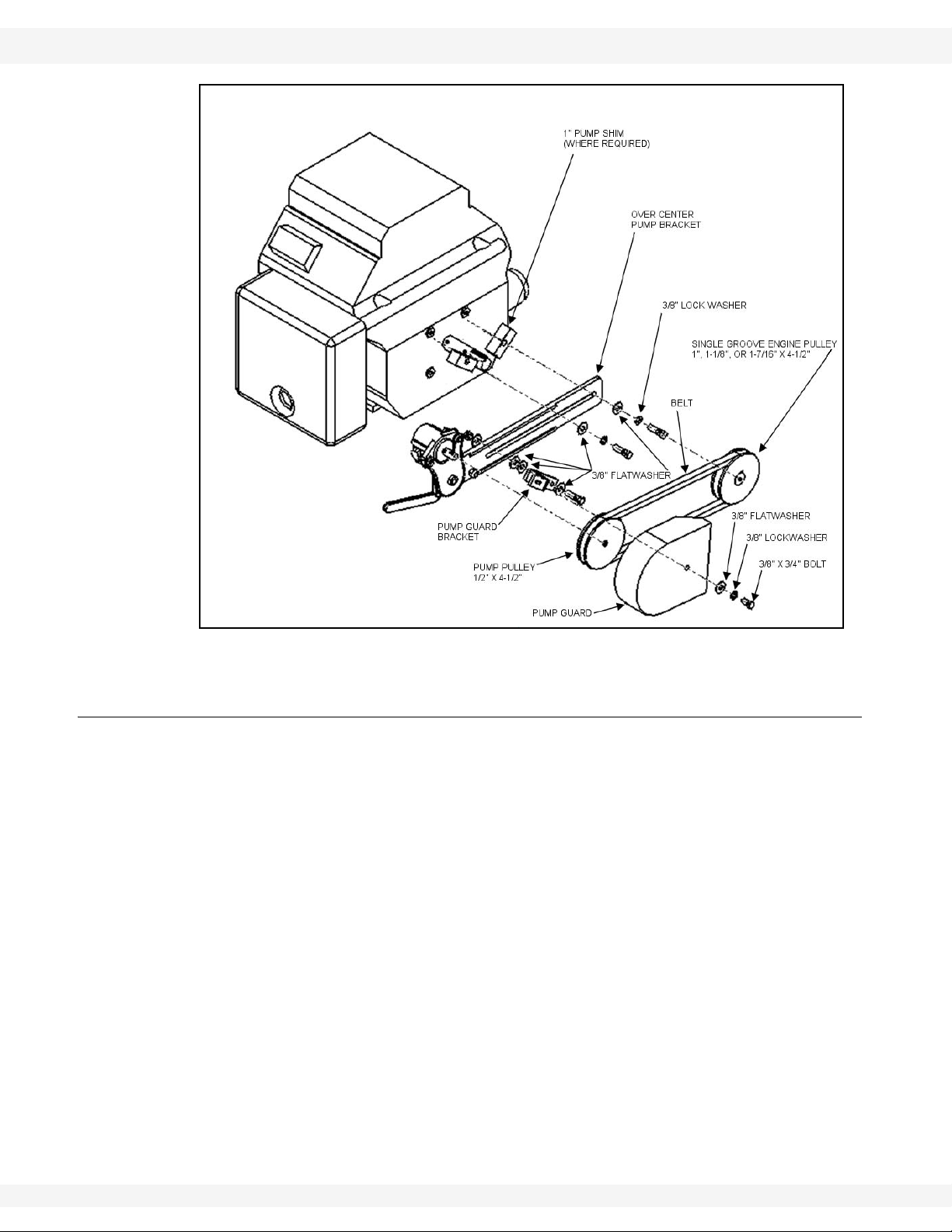

1. Bolt the double tank mount brackets to the frame with 3/8” x 2-5/8” u-bolts

3/8” washers and 3/8” nylock nuts (Figure 3.2).

2. Secure the 22L oil reservoir to the tank mount brackets using the 32” clamp s

provided. The optional 43 L oil reservoir is attached to the double tank mount

brackets using two 25” gear clamps joined together.

• Take care not to crush the oil reservoir when tightening hose clamps.

• The reservoir must be mounted so that the oil level remains above the

gear pump (use general purpose ISO 32 oil).

• To reduce weight at the intake end, mount the tank as close as possible to

the axle of the auger.

16 30761 R0

WHEATHEART - SELF-PROPELLED AUGER KIT 3. ASSEMBLY

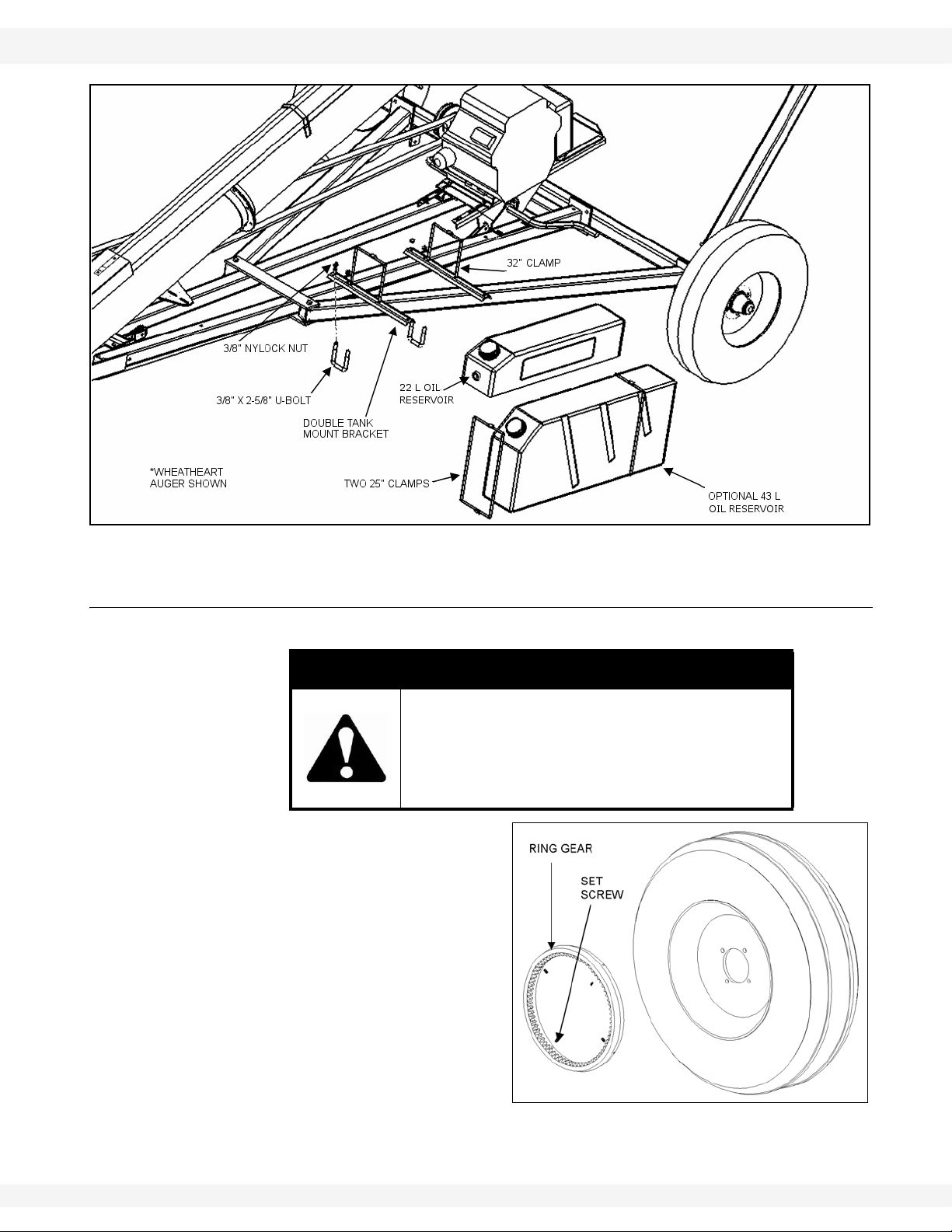

Figure 3.3 Ring Gear Installation

WHEATHEART BH & R SERIES 3.4. GEAR DRIVE ASSEMBLY

Figure 3.2 Hydraulic Reservoir Installation

3.4. GEAR DRIVE ASSEMBLY

Before removing the tires from the auger,

ensure the auger is in the fully lowered

position. Position the auger on a flat level

surface and block the axle to fully support the

auger while removing the wheels.

1. Remove tires from auger.

2. Insert ring gear into rim

(Figure 3.3). Use a hammer to

be sure the ring gear seats

evenly into the rim.

3. Tighten the 4 set screws in

rotation to lock gear evenly

into place.

4. Hit the ring gear with a

hammer again at each set

screw and retighten in

rotation.

5. Put tires back on auger.

CAUTION

30761 R0 17

3. ASSEMBLY WHEATHEART - SELF-PROPELLED AUGER KIT

Figure 3.4

Figure 3.5

3.5. OVER-CENTER DRIVE WHEATHEART BH & R SERIES

3.5. OVER-CENTER DRIVE

1. Once the wheel is bolted to the hub, the over-center drive assembly can be

installed.

2. Position the axle cap of the over-center drive assembly squarely on the axle

tube as shown in Figure 3.4.

3. With the pinion gear flush with the ring gear (Figure 3.6), bolt the axle cap to

the axle tube.

Figure 3.6 Over-Center Assembly Positioning

18 30761 R0

WHEATHEART - SELF-PROPELLED AUGER KIT 3. ASSEMBLY

WHEATHEART BH & R SERIES 3.6. PINION GEAR ADJUSTMENT

3.6. PINION GEAR ADJUSTMENT

For gear depth alignment, refer to Figure 3.7.

NOTICE

Failure to ensure proper gear meshing will result in gear

damage.

The pinion gear should mesh with the ring gear to provide maximum tooth

contact (Figure 3.6).

If the pinion gear does not mesh fully with the ring gear, adjust the handle slot

bolt (which bolts to the drive mount clamp) so full meshing of pinion gear is

achieved when handle is in over-center position (Figure 3.7).

Gear teeth binding: If the handle will not ‘lock’ into over-center position, loosen

the slot bolt nuts and slide the handle away from the tire.

Insufficient Meshing: If the pinion gear will barely mesh with the ring gear,

loosen the slot bolt jam nuts and slide the handle towards the tire until the pinion

gear teeth mesh with the ring gear teeth without binding.

Figure 3.7 Over-Center Assembly Adjustment

3.7. UNDERCARRIAGE INSTALLATION

Important: Pre-Assembly: When assembling the frame pipes, ram extension, and cylinder

under the auger, the components should form a straight line from the axle to the

ram mount ring when the auger is fully lowered.

1. Lower the auger completely.

2. Attach transport frame pipes to axle tabs on the auger axle frame as shown

in Figure 3.9 using the bolts and locknuts provided.

3. The clevis end of the transport pipe fits inside the clevis on the v-frame.

Attach using the bolts and locknuts provided.

30761 R0 19

3. ASSEMBLY WHEATHEART - SELF-PROPELLED AUGER KIT

3.7. UNDERCARRIAGE INSTALLATION WHEATHEART BH & R SERIES

4. In the location noted in Figure 3.8, bolt the control panel ring to the auger

tube approximately to the measurements in Table 3.1. Do not tighten the

bolts yet.

Note: The ram mount ring and the control ring normally get mounted together as one

unit. The only exception are the 46’ and 51’ auger models. For these models, two

extra tube half clamps are provided.

5. Mount the ram mount ring to the tube as indicated ahead of the control ring;

refer to Figure 3.8.

6. Connect the fully retracted cylinder to the tab on the ram mount ring and the

ram extension.

7. The ram extension slides into the a-frame attached to the tabs on the v-frame

as shown in Figure 3.10. The ram extension length must be set at the proper

distance from the ram mounting a-frame for proper operation of the transport

kit. To set the ram extension length, elevate the v-frame to adequately clear

the ground, but not interfere with the auger support arms.

8. Elevate the v-frame, undercarriage pipes, and ram assembly to form a

straight line (transport position) as shown in Figure 3.8. Tighten the control

ring and ram mount ring bolts.

Figure 3.8 Control Ring Installation

Table 3.1 Recommended Transport Pipe Length

Auger R 8 x 36 R 8 x 41 R 8 x 46 R 8 x 51 R 10 x 36 R 10 x 41

A 79” 84-1/2” 85” 92-1/2” 76-3/4” 84-1/2”

B 83” 88-1/2” 115” 123” 80-3/4” 88-1/2”

C 27-1/4” 24-1/4” 37-1/2” 43” 24” 26-3/8”

Transport

Pipe

Ram Exten-

sion

20 30761 R0

86” 120” 120” 144” 92” 120”

15” 15” 28” 28” 15” 15”

WHEATHEART - SELF-PROPELLED AUGER KIT 3. ASSEMBLY

WHEATHEART BH & R SERIES 3.8. RAM EXTENSION INSTALLATION

Figure 3.9 Self-Propelled Auger Frame Installation

9. One end of the crossbrace is attached to the v-frame tab, the other is

attached to the transport tube using clamp bands (Figure 3.9).

10. When attaching to the v-frame, be sure to mount one crossbrace to the top

side of the v-frame tab, and the other to the bottom.

3.8. RAM EXTENSION INSTALLATION

The ram extension slides into the a-frame attached to the tabs on the v-frame.

The ram extension length must be set at the proper distance from the ram

mounting a-frame for proper operation of the transport kit (see Figure 3.8, Table

3.1 (measurement “C”) and Figure 3.10 (measurement “C”)).

30761 R0 21

3. ASSEMBLY WHEATHEART - SELF-PROPELLED AUGER KIT

3.9. CABLE INSTALLATION WHEATHEART BH & R SERIES

Figure 3.10 Ram Extension Installation

3.9. CABLE INSTALLATION

1. Loop cable over top of drum, through hole in drum end, through cable clamp,

and then tighten with two 3/8” set screws (Figure 3.12).

Important: Cable must enter winch on the top side of drum and must have a minimum of 3

wraps on the drum when auger is in the transport position.

Note: On augers equipped with a lower angle-iron track stop, the cable must be

FOR NEW INSTALLATIONS, USE STEPS 2 AND 3

2. Thread lift cable under and around roller on track shoe then back to the cableattach rod welded to lower end of track (Figure 3.11).

threaded between track stop and auger tube so the cable rests on top of the

track stop (Figure 3.11).

3. Wrap cable 1-1/2 times around the cable attach rod and secure with two

1/4” cable clamps. Position cable clamps as shown (Figure 3.11). Tighten

cable clamps securely.

4. Rotate drum until cable is taut. Ensure drum is rotating in direction shown in

Figure 3.11 when raising auger.

5. Tie up winch motor hydraulic hose as needed to prevent damage to the hose.

6. Check gearbox for oil—make certain it is half full.

22 30761 R0

WHEATHEART - SELF-PROPELLED AUGER KIT 3. ASSEMBLY

WHEATHEART BH & R SERIES 3.10. WINCH ASSEMBLY

Figure 3.11

3.10. WINCH ASSEMBLY

1. Lower auger completely and remove the hand winch on the lower auger

frame.

2. Place the winch on the frame as shown in Figure 3.12 using the

measurement in Table 3.3.

Important: The hydraulic winch position should be adjusted until the drum is 1” away from

the auger tube when in transport position. Use Table 3.3 to position winch.

3. Attach 2 u-bolts to frame and secure to hydraulic winch. Do not tighten.

4. Angle the winch so it lines up with the cable wrapping around the track roller .

Tighten all nuts.

3.10.1. WINCH ALIGNMENT

To check the alignment of the winch, watch the cable wrapping on the drum as

the auger is raised. Proper alignment is achieved when the cable indexes

properly, meaning that it fills each row on the drum evenly and does not pile up

against one side.

If the cable does not index properly , lower the auger fully until there is slack in the

cable. Loosen the nuts on the u-bolts. Adjust the winch, retighten nuts, and

retest.

30761 R0 23

3. ASSEMBLY WHEATHEART - SELF-PROPELLED AUGER KIT

3.11. HOSE KIT LAYOUT—NO BIN SWEEP WHEATHEART BH & R SERIES

Figure 3.12 Winch Positioning

Table 3.3 Winch Positioning

AUGER DIM 'A'

8” x 51’ 5-1/2"

8” x 36’ 3-3/4"

10” x 36’ 1/2"

10” x 46’ 5-7/8"

10” x 41’ 6-5/8"

WARNING

Falling auger hazard.

To prevent serious injury or death while

winching, ensure winch cable is fed onto the

winch drum as shown above, and replace

cable if frayed or damaged.

3.11. HOSE KIT LAYOUT—NO BIN SWEEP

Refer to Table 3.4, and Figure 3.13 and 3.14.

SP TRANSPORT INCLUDES:

• hoses (A, B, C, D, F1, F2, G1, G2, I1, I2, J1, J2), winch valve, winch

hoses (H1, H2)

24 30761 R0

WHEATHEART - SELF-PROPELLED AUGER KIT 3. ASSEMBLY

WHEATHEART BH & R SERIES 3.11. HOSE KIT LAYOUT—NO BIN SWEEP

Figure 3.13 Wheatheart Hydraulic Schematic, SP Transport Kit without Bin

Sweep Option

Table 3.4 Wheatheart Hydraulic Hose Lengths, SP Transport Kit without Bin Sweep

Option

Item Description 8x51 8x46

A Hose, HYD, 3/4 x 52, no ends, 1W 1 1 1 1

B Hose, HYD, 1/2 x 279, 1/2MNPT x 1/2MNPT, 1W 1 - - B Hose, HYD, 1/2 x 247, 1/2MNPT x 1/2MNPT, 1W - 1 - B Hose, HYD, 1/2 x 201, 1/2MNPT x 1/2MNPT, 1W - - 1 B Hose, HYD, 1/2 x 173, 1/2MNPT x 1/2MNPT, 1W - - - 1

C Hose, HYD, 1/2 x 204, 1/2MNPT x 1/2MNPT, 1W 1 - - C Hose, HYD, 1/2 x 150, 1/2MNPT x 1/2MNPT, 1W - 1 - C Hose, HYD, 1/2 x 112, 1/2MNPT x 1/2MNPT, 1W - - 1 C Hose, HYD, 1/2 x 80, 1/2MNPT x 1/2MNPT, 1W - - - 1

D Hose, HYD, 1/2 x 60, 1/2MNPT x 1/2FNPSM, 1W 1 1 1 1

F1 Hose, HYD, 3/8 x 49, 6FJIC x 3/8MNPT, 1W 1 - - F1 Hose, HYD, 3/8 x 31, 6FJICS x 3/8MNPT, 1W - 1 - F1 Hose, HYD, 3/8 x 23, 6FJICS x 3/8MNPT, 1W - - 1 1

F2 Hose, HYD, 3/8 x 63, 6FJIC x 3/8MNPT, 1W 1 - - F2 Hose, HYD, 3/8 x 47, 6FJICS x 3/8MNPT, 1W - 1 - F2 Hose, HYD, 3/8 x 33, 6FJICS x 3/8MNPT, 1W - - 1 1

G1,G2 Hose, HYD, 3/8 x 267, 6FJIC x 3/8MNPT, 1W 2 - - G1,G2 Hose, HYD, 3/8 x 231, 6FJICS x 3/8MNPT, 1W - 2 - G1,G2 Hose, HYD, 3/8 x 187, 6FJICS x 3/8MNPT, 1W - - 2 -

8/10

x 41

8/10

x 36

30761 R0 25

3. ASSEMBLY WHEATHEART - SELF-PROPELLED AUGER KIT

3.11. HOSE KIT LAYOUT—NO BIN SWEEP WHEATHEART BH & R SERIES

Table 3.4 Wheatheart Hydraulic Hose Lengths, SP Transport Kit without Bin Sweep

Option

Item Description 8x51 8x46

8/10

x 41

8/10

x 36

G1,G2 Hose, HYD, 3/8 x 159, 6FJICS x 3/8MNPT, 1W - - - 2

H1,H2 Hose, HYD, 3/8 x 148, 6FJIC x 1/2MNPT, 1W 2 - - H1,H2 Hose, HYD, 3/8 x 122, 6FJICS x 1/2MNPT, 1W - 2 - H1,H2 Hose, HYD, 3/8 x 96. 6FJICS x 1/2MNPT, 1W - - 2 H1,H2 Hose, HYD, 3/8 x 84, 6FJICS x 1/2MNPT, 1W - - - 2

I1 Hose, HYD, 3/8 x 65, 3/8MNPT x 3/8MNPT, 1W 2 2 2 2

J1 Hose, HYD, 3/8 x 35, 3/8MNPT x 3/8MNPT, 1W 2 2 2 2

Figure 3.14 Hydraulic Hose Routing

26 30761 R0

WHEATHEART - SELF-PROPELLED AUGER KIT 3. ASSEMBLY

WHEATHEART BH & R SERIES 3.12. HOSE KIT LAYOUT WITH BIN SWEEP

3.12. HOSE KIT LAYOUT WITH BIN SWEEP

Refer to Table 3.5, Figure 3.15.

SP TRANSPORT KIT INCLUDES:

• hoses (A, B, E, F1, F2, G1, G2, H1, H2, I1, I2, J1, J2), winch valve, winch

hoses (H1, H2)

BIN SWEEP OPTION INCLUDES:

• hoses (D, C, L, K), relief valve

Figure 3.15 Wheatheart Hydraulic Schematic - SP Transport Kit with Bin Sweep Option

30761 R0 27

3. ASSEMBLY WHEATHEART - SELF-PROPELLED AUGER KIT

3.12. HOSE KIT LAYOUT WITH BIN SWEEP WHEATHEART BH & R SERIES

Table 3.5 Wheatheart Hydraulic Hose Lengths - SP Transport Kit with Bin Sweep Option

Item Description 8x51 8x46

8/10x

41

8/10x

36

A Hose, HYD, 3/4 x 52, no ends, 1W 1 1 1 1

B

B

B

B

C,D

Hose, HYD, 1/2 x 279, 1/2MNPT x 1/2MNPT,

1W

Hose, HYD, 1/2 x 247, 1/2MNPT x 1/2MNPT,

1W

Hose, HYD, 1/2 x 201, 1/2MNPT x 1/2MNPT,

1W

Hose, HYD, 1/2 x 173, 1/2MNPT x 1/2MNPT,

1W

Hose, HYD, 3/8 x 120, 3/8MNPT x 3/8MNPT,

1W

1 - - -

- 1 - -

- - 1 -

- - - 1

2 - - -

C,D Hose, HYD, 3/8 x 94, 3/8MNPT x 3/8MNPT, 1W - 2 - C,D Hose, HYD, 3/8 x 68, 3/8MNPT x 3/8MNPT, 1W - - 2 C,D Hose, HYD, 3/8 x 56, 3/8MNPT x 3/8MNPT, 1W - - - 2

E

Hose, HYD, 1/2 x 60, 1/2MNPT x 1/2FNPSM,

1W

1 1 1 1

F1 Hose, HYD, 3/8 x 49, 6FJIC x 3/8MNPT, 1W 1 - - F1 Hose, HYD, 3/8 x 31, 6FJICS x 3/8MNPT, 1W - 1 - F1 Hose, HYD, 3/8 x 23, 6FJICS x 3/8MNPT, 1W - - 1 1

F2 Hose, HYD, 3/8 x 63, 6FJIC x 3/8MNPT, 1W 1 - - F2 Hose, HYD, 3/8 x 47, 6FJICS x 3/8MNPT, 1W - 1 - -

F2 Hose, HYD, 3/8 x 33, 6FJICS x 3/8MNPT, 1W - - 1 1

G1,G2 Hose, HYD, 3/8 x 267, 6FJIC x 3/8MNPT, 1W 2 - - G1,G2 Hose, HYD, 3/8 x 231, 6FJICS x 3/8MNPT, 1W - 2 - G1,G2 Hose, HYD, 3/8 x 187, 6FJICS x 3/8MNPT, 1W - - 2 G1,G2 Hose, HYD, 3/8 x 159, 6FJICS x 3/8MNPT, 1W - - - 2

H1,H2 Hose, HYD, 3/8 x 148, 6FJIC x 1/2MNPT, 1W 2 - - H1,H2 Hose, HYD, 3/8 x 122, 6FJICS x 1/2MNPT, 1W - 2 - H1,H2 Hose, HYD, 3/8 x 96, 6FJICS x 1/2MNPT, 1W - - 2 H1,H2 Hose, HYD, 3/8 x 84, 6FJICS x 1/2MNPT, 1W - - - 2

I1,I2 Hose, HYD, 3/8 x 65, 3/8MNPT x 3/8MNPT, 1W 2 2 2 2

J1,J2 Hose, HYD, 3/8 x 35, 3/8MNPT x 3/8MNPT, 1W 2 2 2 2

K,L Hose, HYD, 3/8 x 16, 3/8MNPT x 3/8MNPT, 1W 2 2 2 2

28 30761 R0

WHEATHEART - SELF-PROPELLED AUGER KIT 3. ASSEMBLY

WHEATHEART BH & R SERIES 3.13. HOSE KIT ASSEMBLY

3.13. HOSE KIT ASSEMBLY

Refer to Figures 3.11 - 3.16.

1. Assemble hoses as illustrated.

2. Keep free of dirt while assembling.

3. Keep pressure and return sides aligned.

4. Tighten after being satisfied that the hoses are in the proper position.

5. Check operation.

6. Secure hoses in place with the cable ties supplied

Important: Before disassembling the hoses, fully lower the auger and relieve the oil

pressure.

WARNING

The SP Transport unit MUST operate as

indicated on the control panel decal. The

auger MUST move in the direction that the

handle is moved.

SERIOUS OPERATOR INJURY could occur

if the transport unit and hydraulic hoses are

not assembled correctly. If necessary,

disconnect the hoses and re-assemble.

Figure 3.16 Control Ring Hydraulic Hose Connections

NOTICE

Do not over-tighten!

Over-tightening hose fittings can crack the fitting or motor

body and cause the fittings to leak, and will void the motor

warranty.

30761 R0 29

3. ASSEMBLY WHEATHEART - SELF-PROPELLED AUGER KIT

3.14. CUSHION VALVE INSTALLATION WHEATHEART BH & R SERIES

3.14. CUSHION VALVE INSTALLATION

Connect the hoses as shown in Figure 3.17 and 3.18, ensuring that the hoses

are not crossed. Connect the lower cushion block hoses to the lower ports on

each hydraulic motor as shown.

NOTICE

Do not over-tighten fittings! Over-tightening

hose fittings can crack the fittings or motor

body and will void the warranty.

Figure 3.17 Cushion Block Installation

Figure 3.18 Cushion Block Installation Schematic

30 30761 R0

WHEATHEART - SELF-PROPELLED AUGER KIT 3. ASSEMBLY

WHEATHEART BH & R SERIES 3.15. HYDRAULIC FILTER INSTALLATION

3.15. HYDRAULIC FILTER INSTALLATION

When connecting the hydraulic filter, make sure that it is properly installed. An

arrow is engraved in the filter head indicating the direction of oil flow. The filter

MUST be installed with the oil flowing in the same direction as the arrow

indicates.

The filter goes in the return line right before the tank.

Figure 3.19 Hydraulic Filter

30761 R0 31

3. ASSEMBLY WHEATHEART - SELF-PROPELLED AUGER KIT

3.15. HYDRAULIC FILTER INSTALLATION WHEATHEART BH & R SERIES

32 30761 R0

WHEATHEART - SELF-PROPELLED AUGER KIT 4. TRANSPORT & PLACEMENT

Warning: Before continuing, ensure you have read and understand the relevant information

in the safety section. Safety information is provided to help prevent serious injury, death, or

property damage.

WHEATHEART BH & R SERIES 4.1. TRANSPORT PROCEDURE

4.Transport & Placement

4.1. TRANSPORT PROCEDURE

Note: Use only a tractor or towing vehicle of adequate power and capacity to transport

the machine.

Follow this procedure when placing the unit into its transport position:

1. Attach the auger intake to the towing vehicle with a minimum 1/2” diameter

pin with retainer clip and safety chain.

2. Fully raise the v-frame assembly by retracting the hydraulic cylinder. For

transportation on public roadways, secure the v-frame to the auger frame to

prevent it from accidentally dropping.

3. Before transporting, disengage the over-center handle at each wheel (Figure

4.1) by pulling up on the handle.

Figure 4.1 Over-Center Transport and Working Position

NOTICE

Ensure that the over-center bolts are tight enough to

prevent the handle from engaging. If they are not tight

enough, damage to the gears and motor will result.

30761 R0 33

4. TRANSPORT & PLACEMENT WHEATHEART - SELF-PROPELLED AUGER KIT

4.2. PLACEMENT PROCEDURE WHEATHEART BH & R SERIES

4.2. PLACEMENT PROCEDURE

Follow this procedure when placing the machine into its working position:

1. Be sure there is enough clearance from overhead obstructions, power lines,

or other equipment to move the machine into its working position.

2. Position machine in the desired area. For operating instructions, see Section

5.2.

WHEN PLACING UNDER HOPPER BOTTOM BINS:

1. Ensure the wheel v-frame can easily pass through the hopper bin vertical

legs.

2. Ensure the wheel v-frame does not have to travel over an obstruction.

3. Auger intake is centered between the hopper bin vertical legs. This ensures

that the operator has adequate clearance for auger operation.

4. Ensure the auger gearbox will not contact the hopper cone when in it’s final

position.

WHEN PLACING INTO FLAT BOTTOM BINS:

1. Ensure the wheel v-frame won’t contact the side of the bin when auger is in

its final position.

2. Ensure the door of the bin is not obstructed.

3. Ensure the auger intake will fit through the bin access door.

34 30761 R0

WHEATHEART - SELF-PROPELLED AUGER KIT 5. OPERATION

Warning: Before continuing, ensure you have read and understand the relevant information

in the safety section. Safety information is provided to help prevent serious injury, death, or

property damage.

WHEATHEART BH & R SERIES 5.1. START-UP

5.Operation

Operators must observe safety procedures at all times and follow the pre-operational checklist before each start-up.

PRE-OPERATION CHECKLIST

Before operating each time, the operator must follow the checklist, which should

confirm the following:

• Follow the service schedule.

• Check hydraulic system oil level.

• Ensure that all hydraulic lines are free from damage, and that all fittings

are tight.

• Visually inspect the unit for damage to components. Replace or repair any

damaged or questionable parts.

• Check that all guards are installed, secured, and functioning as intended.

• Check the worksite and clean up the area, if needed.

• Ensure that the auger is securely attached to the towing vehicle or tractor.

5.1. START-UP

Although there are no operational restrictions on the machine when used for the

first time, it is recommended that the following mechanical items be checked:

BEFORE STARTING:

• Read power unit operational manual.

• Inspect hydraulic hose fittings for leaks. Tighten if necessary, and replace

worn or damaged hoses.

• Inspect hydraulic mount bolts for tightness.

DURING THE FIRST FEW MINUTES:

• Ensure unit is running properly.

• Some air may be trapped in the hydraulic system; slowly activate hydraulic control valves to ensure all air is out of the system.

WARNING

Shut off and remove key or lock out power

source before inspecting or servicing the

machine.

30761 R0 35

5. OPERATION WHEATHEART - SELF-PROPELLED AUGER KIT

5.2. OPERATING PROCEDURE WHEATHEART BH & R SERIES

AFTER OPERATING OR TRANSPORTING FOR 1/2 HOUR:

• Retorque all fasteners and hardware.

• Check all safety decals are installed and legible. Apply new ones if

needed.

• Check all guards are installed and working as intended.

• Retorque all wheel bolts (if applicable).

AFTER 3 HOURS:

• Change oil for best results.

AFTER 5 AND 10 HOURS:

• Check all hydraulic hoses and fittings for leaks. Tighten fittings where

required, and replace worn or damaged hoses.

• Retorque all wheel bolts (if applicable), fasteners, and hardware.

5.2. OPERATING PROCEDURE

Important: Ensure the over-center handle at each wheel is fully engaged by pushing down

on the handle at each wheel and checking that the gears fully mesh (see Section

3.6. for adjustment if necessary).

1. With the engine at idle, use the hydraulic controls (Figure 5.1, and 5.2) to

fully lower the auger with the winch control lever on the valve before moving

the auger into position.

2. Raise the auger intake end off the ground using the hydraulic ram control

lever on the valve.

3. Move the auger into place by moving the wheel move control forward or

backward to control the direction of travel. Steering is accomplished by

grasping the handle bar and either leaning in or pulling away from the auger.

Steering is easier if the auger is in motion.

4. When unloading a bin, aim the auger intake into the bottom of the center of

the bin. Use the winch control lever and hydraulic ram control lever to

help position the auger.

5. When loading a bin, use the winch control to raise the auger to the desired

height. Use the hydraulic ram control to raise the intake of the auger off the

ground as the auger is winched up. Turn the wheel move control to change

the direction of travel. Leave extra clearance for making wide turns.

Note: Refer to Section 6.1.1. for winch valve kickout adjustment, 6.1.4. for cushion

valve adjustment, and 6.1.2. for adjustment of the ram speed.

CAUTION

Do not attempt to move the auger on uneven

or hilly terrain. The mover will not perform well

under these conditions and could damage the

machine or injure the operator.

36 30761 R0

WHEATHEART - SELF-PROPELLED AUGER KIT 5. OPERATION

WHEATHEART BH & R SERIES 5.2. OPERATING PROCEDURE

Figure 5.1 Hydraulic Control Valve Decal

Figure 5.2 Hydraulic Control Valve

30761 R0 37

5. OPERATION WHEATHEART - SELF-PROPELLED AUGER KIT

5.2. OPERATING PROCEDURE WHEATHEART BH & R SERIES

38 30761 R0

WHEATHEART - SELF-PROPELLED AUGER KIT 6. MAINTENANCE & STORAGE

Warning: Before continuing, ensure you have read and understand the relevant information

in the safety section. Safety information is provided to help prevent serious injury, death, or

property damage.

WHEATHEART BH & R SERIES 6.1. MAINTENANCE

6.Maintenance & Storage

6.1. MAINTENANCE

Before performing any maintenance on this unit, shut off and remove key or lock

out power source.

1. Periodically check for wear and proper meshing of the ring gear and pinion.

See Section 3.6.

2. Change oil annually to remove any accumulation of dirt or condensation in

the system. Replace with T ype A automatic transmission oil. Do not over-fill

reservoir. Leave 1/2 quart (0.47L) space to allow for level fluctuation.

3. Inspect hoses and fittings. Replace as required.

6.1.1. HYDRAULIC WINCH VALVE

The hydraulic winch option allows the operator to safely and easily lower and

raise the auger.

The winch is equipped with a factory preset safety valve that allows the winch to

completely raise the auger, but it will stop once the auger is fully raised.

The safety valve is non-adjustable and does not require any maintenance.

The only item that an operator must inspect is the cable, and if this cable is

frayed or worn, it must be replaced.

Important: Winch speed is adjusted at the factory. Cold temperatures may cause the winch

to operate slowly.

Figure 6.1 Hydraulic Winch

30761 R0 39

6. MAINTENANCE & STORAGE WHEATHEART - SELF-PROPELLED AUGER KIT

6.1. MAINTENANCE WHEATHEART BH & R SERIES

WARNING

Winch cable must be wound onto the drum of

the winch from the top of the drum. This

ensures the safe and proper operation of the

hydraulic winch.

6.1.2. RAM SPEED ADJUSTMENT

Ram speed is regulated at the control valve. The adjustable stroke limiter screws

and lock nuts set the speed of ram travel individually in each direction (Figure

6.2).

Adjust the stroke limiter screws and lock nuts until the desired rate of travel is

achieved.

• Turning the screws in results in a slower speed.

• Turning the screws out results in a faster speed.

Figure 6.2 Three Spool Valve Adjustment

6.1.3. HYDRAULIC PRESSURE RELIEF VALVE ADJUSTMENT

Note: Before adjusting, ensure auger is fully lowered (intake and discharge ends) and

that the auger is on a level surface.

If the controls are “jerky” or act too fast, it may be necessary to increase the

hydraulic pressure on the self-propelled auger kit. To do this, follow the steps

below (Figure 6.2).

1. Ensure auger engine is idling and that the auger flighting is disengaged

before adjusting.

2. To decrease hydraulic pressure: loosen jam nut on 3 spool valve (bottom

right side of valve) and turn adjustment screw out (counter-clockwise) 1/4

turn. Tighten jam nut.

40 30761 R0

WHEATHEART - SELF-PROPELLED AUGER KIT 6. MAINTENANCE & STORAGE

WHEATHEART BH & R SERIES 6.2. STORAGE

3. To increase hydraulic pressure: repeat step 2. except turn adjustment

screw in (clockwise) 1/4 turn. Tighten jam nut.

6.1.4. CUSHION VALVE ADJUSTMENT

To control the speed of the mover, the adjustable needle valve (Figure 6.3) can

be:

• screwed in for increased speed (adjust by 1/8 turn increments)

• screwed out for decreased speed (adjust by 1/8 turn increments)

Figure 6.3 Cushion Valve Adjustment

6.2. STORAGE

To ensure a long, trouble-free life, prepare unit for storage after the season’s use

following the procedure below:

• Store the machine on a level surface, free of debris, and in an area away

from human activity. Store in a dry place, or use a tightly secured tarp to

protect the equipment from the weather.

• Ensure that the unit is in transport position.

• Remove all residual material and clean the machine thoroughly.

• Inspect the unit at stress points for cracks.

• Repair or replace any worn or damaged components to prevent any

unnecessary downtime at the start of the next season.

• Touch up paint nicks and scratches to prevent rusting.

• Check hydraulic fittings, hoses, lines, couplers, and valves. Tighten any

loose fittings. Replace any hose that is badly cut, nicked, abraded, or is

separating from the crimped end of the fitting. Secure the hoses to the

machine.

• Inspect and tighten all fasteners; replace fasteners if required.

• Check tire inflation.

• Retract all cylinders or grease exposed shafts.

• Inspect hydraulic cylinders for leaks; replace seals if necessary

30761 R0 41

6. MAINTENANCE & STORAGE WHEATHEART - SELF-PROPELLED AUGER KIT

6.2. STORAGE WHEATHEART BH & R SERIES

42 30761 R0

WHEATHEART - SELF-PROPELLED AUGER KIT 7. TROUBLESHOOTING

WHEATHEART BH & R SERIES

7.Troubleshooting

PROBLEM CAUSE SOLUTION

• loose/cracked fittings • tighten/replace fittings

Valve is leaking.

Machine operates slowly.

Hydraulic winch will not

raise auger.

Hydraulic cylinder leaking. • worn seal • replace seal

Winch coupler spins off

(Dutton winch).

Auger doesn’t drive.

Pinion gear slipping or

binding.

• worn hose • replace hose

• valve spools are worn • replace valve

•oil is hot • check oil level and add oil if

required (use general purpose

ISO 32 hydraulic oil)

• blockage in hydraulic lines • suction hose blocked or kinked

• power source is not produc-

ing enough oil volume and/

or pressure

• cushion block needs adjust-

ing

• Filter plugged (if equipped) • Change filter.

• relief valve pressure set too

low

• oil level is too low • check oil level

• pump is worn out • replace pump

• internal winch parts worn • replace worn parts

• damage or obstruction on

tracking

• cushion block needs adjust-

ing

• pinion gear not adjusted

properly

• speed up the engine to produce

more flow/pressure

• the power unit may not have

enough capacity to operate

properly

• adjust valve on cushion block by

turning inward 1/8 of a turn at a

time, refer to “Cushion Valve

Adjustment” on page 41

• adjust relief valve pressure,

refer to “Hydraulic Pressure

Relief Valve Adjustment” on

page 40

• check tracking for damage or

obstructions

• adjust needle valve by turning

clockwise 1/8 of a turn - try and

repeat if necessary, refer to

“Cushion Valve Adjustment” on

page 41.

• Adjust the pinion gear. See “Pinion Gear Adjustment” on

page 19.

30761 R0 43

7. TROUBLESHOOTING WHEATHEART - SELF-PROPELLED AUGER KIT

WHEATHEART BH & R SERIES

44 30761 R0

WHEATHEART - SELF-PROPELLED AUGER KIT 8. APPENDIX

WHEATHEART BH & R SERIES 8.1. BOLT TORQUE VALUES

8.Appendix

8.1. BOLT TORQUE VALUES

The tables shown below give correct torque values for various bolts and

capscrews. Tighten all bolts to the torque specified in the chart unless otherwise

noted. Check tightness of bolts periodically , using bolt torque chart as your guide.

Replace hardware with the same strength bolt.

Table 8.1 Imperial Bolt Torque

BOLT

DIAMETER

1/4" 8 6 12 9 17 12

5/16" 13 10 25 19 36 27

3/8" 27 20 45 33 63 45

7/16" 41 30 72 53 100 75

1/2" 61 45 110 80 155 115

9/16" 95 60 155 115 220 165

5/8" 128 95 215 160 305 220

3/4" 225 165 390 290 540 400

7/8" 230 170 570 420 880 650

1" 345 225 850 630 1320 970

(Nm) (lb-ft) (Nm) (lb-ft) (Nm) (lb-ft)

Figure 8.1 Pattern for Tightening Wheel Bolts

30761 R0 45

8. APPENDIX WHEATHEART - SELF-PROPELLED AUGER KIT

8.2. TIGHTENING O-RING FITTINGS WHEATHEART BH & R SERIES

Table 8.2 Metric Bolt Torque

BOLT DIAMETER

M3 0.5 0.4 1.8 1.3

M4 3 2.2 4.5 3.3

M5 6 4 9 7

M6 10 7 15 11

M8 25 18 35 26

M10 50 37 70 52

M12 90 66 125 92

M14 140 103 200 148

M16 225 166 310 229

M20 435 321 610 450

M24 750 553 1050 774

(Nm) (lb-ft) (Nm) (lb-ft)

M30 1495 1103 2100 1550

M36 2600 1917 3675 2710

Torque figures indicated above are valid for non-greased or non-oiled threads

and head unless otherwise specified. Therefore, do not grease or oil bolts or

capscrews unless otherwise specified in this manual. When using locking

elements, increase torque values by 5%.

8.2. TIGHTENING O-RING FITTINGS

1. Inspect o-ring and seat for dirt or obvious defects.

2. On the angle fittings, back the lock nut off until washer bottoms out at top of

groove.

3. Hand-tighten fitting until back up washer or washer face (if straight fitting)

bottoms on face and o-ring is seated.

4. Position angle fittings by unscrewing no more than one turn.

5. Tighten straight fittings to torque shown.

6. Tighten while holding body of fitting with a wrench.

46 30761 R0

WHEATHEART - SELF-PROPELLED AUGER KIT 8. APPENDIX

WHEATHEART BH & R SERIES 8.2. TIGHTENING O-RING FITTINGS

Table 8.3 “O” Ring Fittings

Tube Size

OD (in.)

Nut Size Across

Flats (in.)

Torque

Values

a

(Nm)

3/8 1/2 8 6 2 1/3

7/16 9/16 12 9 2 1/3

1/2 5/8 16 12 2 1/3

9/16 11/16 24 18 2 1/3

3/4 7/8 46 34 2 1/3

7/8 1 62 46 1-1/2 1/4

1-1/16 1-1/4 102 75 1 1/6

1-3/16 1-3/8 122 90 1 1/6

1-5/16 1-1/2 142 105 3/4 1/8

1-5/8 1-7/8 190 140 3/4 1/8

7/8 2-1/8 217 160 1/2 1/12

a. The torque values shown are based on lubricated connections as in reassemble.

Torque

Values

a

(Lb-ft)

# of Turns to

Tighten (Flats)

(After Finger

Tightening) (Turn)

30761 R0 47

8. APPENDIX WHEATHEART - SELF-PROPELLED AUGER KIT

8.3. PARTS WHEATHEART BH & R SERIES

8.3. PARTS

8.3.1. SELF-PROPELLED AUGER KIT

48 30761 R0

WHEATHEART - SELF-PROPELLED AUGER KIT 8. APPENDIX

WHEATHEART BH & R SERIES 8.3. PARTS

Table 8.4

Item Part No. Description Qty

1 0200322WH WHEEL V FRAME ASSY, W/ BEARINGS 1

2 9900248 LOCKING COLLAR, 1" 2

3 0200314WH WHEEL YOKE 2

4 0200006 1" ID BALL BEARING 4

5 29748WH 2012 RAM MOUNTING A-FRAME ASSEMBLY 1

6 29747WH RAM MOUNTING CLAMP 1

7A 29741WH RAM EXTENSION PIPE, 15" (8/10-36'/41') 1

7B 29743WH RAM EXTENSION PIPE, 28" (8-46'/51') 1

8A 0200319-86WH TRANSPORT FRAME PIPE (8-36') 2

8B 0200319-92WH TRANSPORT FRAME PIPE (10-36') 2

8C 0200319-120WH TRANSPORT FRAME PIPE (8/10-41', 8-46') 2

8D 0200319-144WH TRANSPORT FRAME PIPE (8-51') 2

9 0200320WH CROSSBRACE PIPE 2

10 0200321WH CROSSBRACE, CLAMPBAND (2") 2

10A 27242WH CROSSBRACE, CLAMPBAND (2.5") 2

11 9900316 TIRE AND RIM (4.8-8") 2

12 0200308 CYL, 2"x15.625x1.125" ROD, 1

13 28263 BOLT, 3/4" x 6" GR5 PLTD 2

14 19975 BOLT, 3/8" x 1-1/4" GR5 PLTD 16

15 27816 BOLT, 1/2" x 2" GR5 PLTD 4

16 18699 BOLT, 3/8" x 2-1/2"" GR5 PLTD 1

17 29979 BOLT, 3/8" x 2" GR5 PLTD 2

18 19599 NYLON LOCKNUT, 1/2" PLTD 5

19 19601 NYLON LOCKNUT, 3/4" PLTD 2

20 17402 NYLON LOCKNUT, 3/8" PLTD 19

21 19598 NYLON LOCKNUT, 7/16" PLTD 8

22 17392 FLAT WASHER, 3/8" 32

23 9900339 1" ROUND POLY PLUG 2

24 0200334 RING GEAR W/ SET SCREWS 2

25 0200350 CUSHION BLOCK, COMPLETE 1

26 0200303WH CONTROL HANDLE W/ GRIP 1

27 0200007-4 HANDLE GRIP 2

28 0200305WH BAR HANDLE W/ GRIP 1

29 19965 BOLT, 5/16" x 2-3/4" GR2 PLTD 3

30 19980 NYLON LOCKNUT, 5/16" PLTD 3

31 19603 LOCKWASHER, 5/16" 1

32 9900852 BOLT HEX M8 x 1.25" GR8.8 PLT 1

33 1600007 CONTROL LEVER, SD5 VALVE 2

34A 29756WH 8" HALF CLAMP, VALVE MOUNT, (8" WIDE) 1

34B 29775WH 10" HALF CLAMP, VALVE MOUNT, (8" WIDE) 1

30761 R0 49

8. APPENDIX WHEATHEART - SELF-PROPELLED AUGER KIT

8.3. PARTS WHEATHEART BH & R SERIES

Table 8.4

Item Part No. Description Qty

35A 29749WH 8" HALF CLAMP RAM MOUNT (8" WIDE) 1

35B 29774WH 10" HALF CLAMP RAM MOUNT (8" WIDE) 1

36A 29750WH 8" HALF CLAMP (8" WIDE) (NOT SHOWN) 2

36B 29773WH 10" HALF CLAMP (8" WIDE) (NOT SHOWN) 2

37 19542 BOLT, 7/16" x 1" GR5 PLTD 16

38 28184 FTG ELB, 1/2" MNPT TO 3/8" FSW 2

39 28504 FTG ELB 45°, 6MORB x 6MJIC 6

40 1600006 3 SPOOL VALVE, 2 HANDLES, NO FTGS 1

41 990050 BOLT, 1/2" x 2-1/4" GR5 PLTD 1

8.3.2. WHEEL MOTOR

Table 8.5

Item Part No. Description Qty

1 0200348 SQR Axle Cap for O/Center (Bolt on) 1

2 0200347 Axle Clamp, Bolt on for 2-1/2" SQR Tubing 2

3 0200007-1 Handle No Grip, SP O/C 1

4 P1211303 Rubber Handle Cover 1/4” x 1” 1

5 0200338A Motor Bracket Drilled 1

6 0200009 Spring, Over Center 1

7 19599 Nut Nylock 1/2” UNC Plt 3

8 27816 Bolt Hex 1/2” x 2” UNC GR5 Plt 1

50 30761 R0

WHEATHEART - SELF-PROPELLED AUGER KIT 8. APPENDIX

WHEATHEART BH & R SERIES 8.3. PARTS

Table 8.5

Item Part No. Description Qty

9 28261 Nut Flange 1/2” 2

10 17401 Washer Flat, 1/2”, Plt 3

11 17746 Bolt Hex 1/2” x 1-1/2” UNC GR5 Plt 1

12 0200008-2 Over-Center Link SP Wheel Move, Bent 1

13 17807 Carriage Bolt 1/2” x 1-1/2” 2

14 9900980 Carriage Bolt - FT 3/”8 x1-1/4” 4

15 17402 Nut Nylock 3/8” UNC Plt 4

16 28183 Motor, HYD, 4.6 RS, 1/2NPTF, 3/8" Hole 1

17 9900664 Bolt Hex 3/8” x 2” UNC GR5 Plt 4

18 19604 Washer, 3/8” Lock, Plt 4

19 0200332A Pinion Gear, Drilled *

20 9901242-2 Pin, Roll, 3/8” x 1-1/2” Spring 1

21 28284 FTG, STL, ELB, 1/2MNPT x 3/8FNPSM 2

8.3.3. TANK UPGRADE KIT, 43 L

Table 8.6

Item Part No. Description Qty

1 1200011 Cap, Reservoir and Gas Tank 1

2 9900233 Tank, 43 L Reservoir, Drilled, no Cap 1

9900237 Tank, 43 L Reservoir, w/FTGS/Cap *

3 9900232 FTG, AL, 1BLKHD x 1/2MNPT 1

4 9900240 O-Ring, #318 2

5 9900052-2 Bushing, 1” Machinery 18GA 2

30761 R0 51

8. APPENDIX WHEATHEART - SELF-PROPELLED AUGER KIT

8.3. PARTS WHEATHEART BH & R SERIES

Table 8.6

Item Part No. Description Qty

6 9900760 Nut Jam 1” UNF Plt 2

7 9900331 FTG, STL, ELB, 1/2MNPT x 1/2FNPSM 1

8 9900021 FTG, AL, 1” BLKHD x 3/4” HB 1

9 9900216-1 Clamp, Reservoir #116, 25” 4

10 H12X42PS Hose, HYD, 1/2 x 42,1/2FNPSM x1/2FNPSM,1W 1

11 0200025 Tank Upgrade Kit, Complete *

8.3.4. IN-LINE HYDRAULIC OIL FILTER

Table 8.7

Item Part No. Description Qty

1 9900994 Filter HYD, 10 Micron, 3/4" FNPT 1

2 17402 Nut Nylock 3/8” UNC Plt 2

3 9900038 U-Bolt SQ 3/8”NC x 2-5/8” x 3-3/4” x 1-1/4” Thd 1

4 2300053 FTG, STL, 3/4MNPT x 1/2FNPSM 2

5 9900800 Bolt Hex 1/4” x 3/4” UNC GR5 Plt 2

6 9900783 Washer Lock 1/4” Plt 2

7 2300202 Filter Mount 1

8 9900993 Filter Head, In-line, 3/4" FNPT 1

52 30761 R0

WHEATHEART - SELF-PROPELLED AUGER KIT 8. APPENDIX

WHEATHEART BH & R SERIES 8.3. PARTS

8.3.5. HYDRAULIC WINCH & CONTROL VALVE

Table 8.8

Item Part No. Description Qty

1 17628 Winch Frame Weld't 1

2 17625 Gearbox, 20:1, 60WPuds 1

3 0700023 Valve, Winch, Relief Block, Manifold 1

4 0700024 Valve, Winch, Non-Adj Relief (Manifold) 1

5 17626 Motor, HYD, 3.2 RS, Man, 1/4" Key 1

6 17629 Winch Drum Wldt 1

7 28744 Bolt, 7/16” x 1-1/2” UNC GR5 Pld 4

8 19598 Nut Nylock 7/16” UNC GR5 Plt 4

9 18097 1" Rim Washer 1

10 18496 Rope Keeper Kit 1

11 18955 Bolt, 3/8” x 1” UNC GR5 Pld 4

12 19604 Washer, 3/8” Lock, Plt 4

13 17631 Bolt, 5/16” x 2-1/2” UNC GR5 Pld 4

14 17105 DCL, Warn, Rotating Cable Sheaves (not shown) 1

15 17108 DCL, Warn, Inspect Cable (not shown) 1

16 17698 DCL, Warn, High-Pressure Fluid HAZ (not shown) 1

17 28129 DCL, Warn, Falling Auger Hazard (not shown) 1

18 1100625 FTG, ELB, 3/8MNPT x 1/2FNPSM 2

19 19222 Zerk, 5/16”, Press-in Style (Yellow Zinc) 1

20 19149 Bushing, BRS, 1”ID x 1-1/4”OD x 1-3/4” WF 1

21 28455 U-Bolt SQ 3/8” NC x 2-5/8” x 3-3/4” x 1-1/4” Thd GR5 Plt 2

22 17402 Nut Nylock 3/8” UNC GR5 Plt 4

23 17392 Washer Flat 3/8” Plt 4

30761 R0 53

8. APPENDIX WHEATHEART - SELF-PROPELLED AUGER KIT

8.3. PARTS WHEATHEART BH & R SERIES

54 30761 R0

LIMITED WARRANTY

Wheatheart warrants to the buyer that the new machinery is free from defects in material and

workmanship.

This warranty is only effective for any new machinery that has not been altered, changed,

repaired, or treated since its delivery to the buyer, other than by Wheatheart or its authorized

dealers or employees, and does not apply to accessories, attachments, tools, or parts sold or

operated with the new machinery if they have not been manufactured by Wheatheart.

Wheatheart shall only be liable for defects in the material or workmanship attributed to faulty

material or bad workmanship that can be proved by the buyer, and specifically excludes liability

for repairs arising as a result of normal wear and tear of the new machinery or in any other manner whatsoever, and without limiting the generality of the foregoing, excludes application or

installation of parts not completed in accordance with Wheatheart operation manual, specifications, or printed instructions.

A Warranty Registration Form and Inspection Report must be completed at the time of delivery

and returned to Wheatheart Manufacturing within thirty (30) days.

Warranty Period

Private Farm Use One (1) year from date of purchase.

Commercial, Custom, or Rental Use Ninety (90) days from date of purchase.

Replacement Parts Ninety (90) days from date of replacement

Defective parts are subject to inspection by a Wheatheart representative prior to approval of a

warranty claim. All returned parts must be sent to the factory, freight pre-paid, in order to qualify

for warranty replacement. Repaired or replaced parts will be returned freight collect.

If these conditions are fulfilled, Wheatheart shall at its own cost and its own option either repair

or replace any defective parts provided that the buyer shall be responsible for all expenses

incurred as a result of repairs, labor , part s, transporta tion, or any other work, unless Wheatheart

has authorized such expenses in advance. Normal wear and service items such as belts,

hoses, flashing, etc. are excluded from warranty.

The warranty shall not extend to any repairs, changes, alterations, or replacements made to the

new equipment other than by Wheatheart or its authorized dealers or employees.

This warranty extends only to the original owner of the new equipment.

This warranty is limited to the terms stated herein and is in lieu of any other warranties whether

expressed or implied, and without limiting the generality of the foregoing, excluded all warranties, expressed or implied, or conditions whether statutory or otherwise as to quality and fitness

for any purpose of the new equipment, Wheatheart disclaims all liability for incidental or consequential damages.

This machine is subject to design changes and Wheatheart shall not be required to retro-fit or

exchange items on previously sold units except at its own option.

WARRANTY VOID IF NOT REGISTERED

Wheatheart

Part of the Ag Growth International Inc. Group

P.O. Box 39

Rosenort, Manitoba, Canada R0G 1W0

Phone: (866) 467-7207 (Canada & USA)

Fax: (866) 768-4852

website: www.wheatheart.com

email: sales@wheatheart.com

© Ag Growth International Inc. 2013

Printed In Canada

Loading...

Loading...