Read this manual before using product. Failure

Wheatheart

POST POUNDER

S2000 MODEL

ASSEMBLY & OPERATION MANUAL

to follow instructions and safety precautions can

result in serious injury, death, or property

damage. Keep manual for future reference.

Part Number: IM15 R1

Revised: Nov/11

This product has been designed and constructed according to general engineering

standardsa. Other local regulations may apply and must be followed by the operator.

We strongly recommend that all personnel associated with this equipment be trained

in the correct operational and safety procedures required for this product. Periodic

reviews of this manual with all employees should be standard practice. For your

convenience, we include this sign-off sheet so you can record your periodic reviews.

Date Employee Signature Employer Signature

a. Standards include organizations such as the American Society of Agricultural and Biological Engineers,

American National Standards Institute, Canadian Standards Association, International Organization for

Standardization, and/or others.

WHEATHEART - POST POUNDER

S2000 MODEL

TABLE OF CONTENTS

1. Introduction.......................................................................................................................... 5

1.1. Feature Overview and Options................................................................................. 6

1.2. Frame Assembly ...................................................................................................... 7

1.3. Mast Assembly......................................................................................................... 8

1.4. Hugger Arm Assembly ............................................................................................. 9

1.5. PTO Kit................................................................................................................... 10

1.6. Hammer Ballast Kit................................................................................................. 11

2. Safety First.......................................................................................................................... 13

2.1. General Safety ....................................................................................................... 14

2.2. Transport & Placement Safety ............................................................................... 15

2.3. Operation Safety .................................................................................................... 16

2.4. Maintenance Safety................................................................................................ 17

2.5. Hydraulic Safety..................................................................................................... 17

2.6. Safety Decal Locations........................................................................................... 18

2.6.1. Decal Installation/Replacement................................................................ 18

2.6.2. Decal Locations........................................................................................ 18

3. Assembly ............................................................................................................................ 21

3.1. Pre-Assembly......................................................................................................... 21

3.2. Assembling the S2000 Post Pounder..................................................................... 22

3.2.1. Prepare the Frame Assembly................................................................... 22

3.2.2. Connect the Mast Assembly to the Frame Assembly............................... 23

3.2.3. Connect the Hugger Arm and Cylinder to The Mast Assembly................ 25

3.2.4. Install Hammer Ballast.............................................................................. 26

3.3. Installing the PTO Kit.............................................................................................. 28

3.3.1. Installing the PTO Kit Oil Filter Assembly................................................. 29

3.3.2. Installing the PTO Kit Hydraulic Tank....................................................... 30

3.3.3. Installing the PTO Pump Support............................................................. 32

3.3.4. Connecting PTO Kit Hydraulic Hoses....................................................... 33

3.3.5. Filling the Hydraulic Tank......................................................................... 34

4. T ranspor t............................................................................................................................. 35

5. Placement ........................................................................................................................... 37

6. Operation ...................................................................................................................

......... 39

6.1. Pre-Operation Checklist......................................................................................... 39

6.2. Drives..................................................................................................................... 40

6.2.1. Standard Hydraulic Drive.......................................................................... 40

6.2.2. PTO Kit Drive............................................................................................ 41

6.3. Lockouts................................................................................................................. 41

6.4. Start-Up and Break-In ............................................................................................ 41

6.4.1. Startup...................................................................................................... 42

6.4.2. Break-In Period (First 10 Hours)............................................................... 42

IM15 R1 3

WHEATHEART - POST POUNDER

S2000 MODEL

6.5. Operating The S2000 Post Pounder ...................................................................... 43

6.5.1. Loading a Post in the Hugger:.................................................................. 43

6.5.2. Driving a Post: .......................................................................................... 44

6.5.3. Shutdown.................................................................................................. 45

7. Maintenance........................................................................................................................ 47

7.1. Changing the Oil Filter (PTO Kit)............................................................................ 48

7.2. Adding or Replacing Hydraulic Fluid (PTO Kit) ...................................................... 48

7.3. Replacing the Mast Seal......................................................................................... 49

8. Storage................................................................................................................................ 51

9. Troubleshooting ................................................................................................................. 53

10. Appendix........................................................................................................................... 55

10.1. Hydraulic system.................................................................................................. 55

Limited Warranty..................................................................................................................... 57

4 IM15 R1

WHEATHEART - POST POUNDER 1. INTRODUCTION

SERIAL NUMBER: _____________________________

DATE PURCHASED: ___________________________

DEALER: ____________________________________

S2000 MODEL

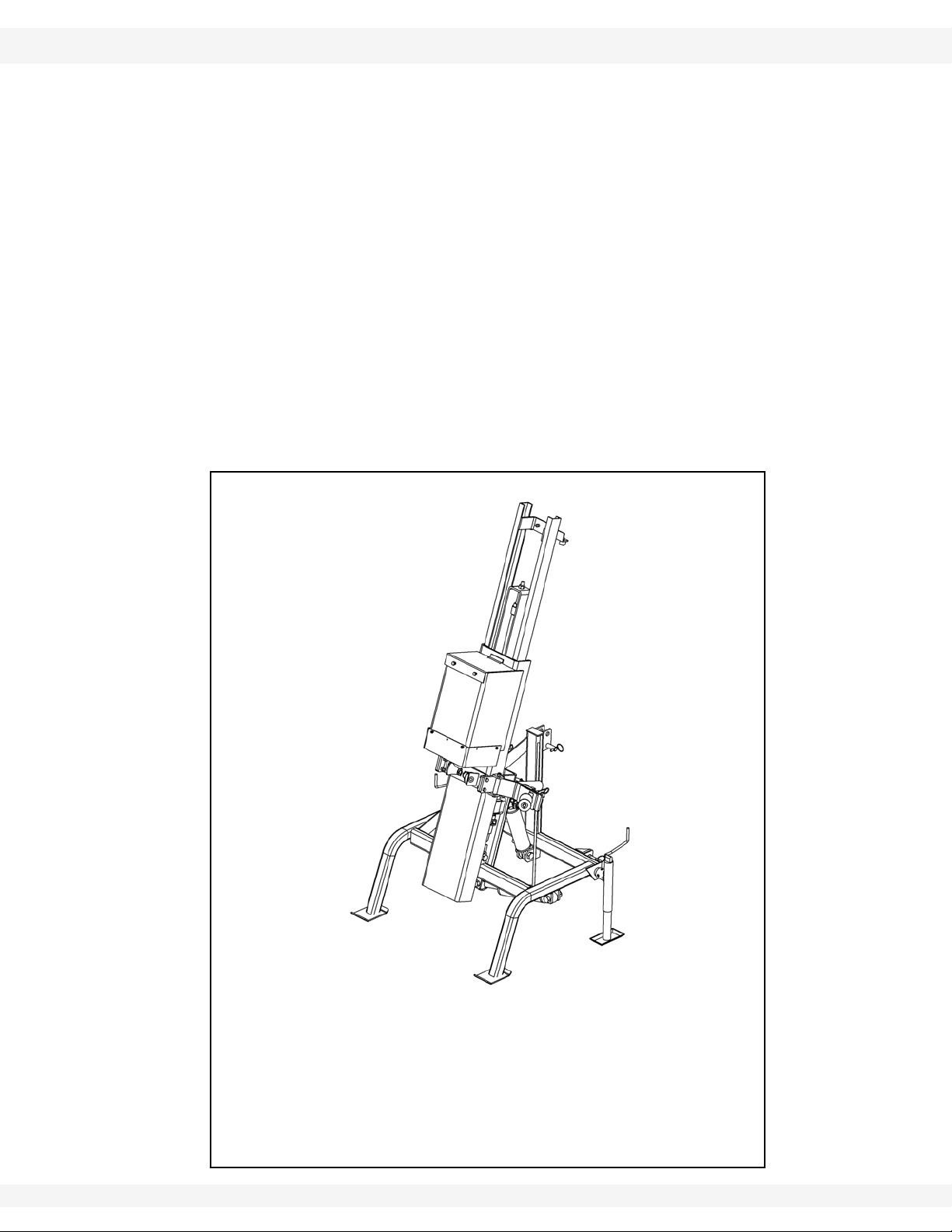

1.Introduction

Congratulations on your choice of a Wheatheart S2000 Post Pounder to

complement your operation. This equipment has been designed and manufactured to meet the needs of the discriminating buyer for the efficient installation of

fence posts.

Safe, efficient, and trouble-free operation of your post pounder requires that you,

and anyone else who will be involved with operating the unit, read and understand all safety instructions and procedures contained within this manual. A signoff form is provided on the inside front cover for your convenience.

Keep this manual handy for frequent reference and to review with new

personnel. Call your Wheatheart distributor or dealer if you need assistance,

information, or additional copies of the manual.

Operator Orientation: The directions left, right, front, and rear, as mentioned

throughout the manual, are as seen from the tractor driver seat and facing in the

direction of travel when the unit is being transported.

IM15 R1 5

1. INTRODUCTION WHEATHEART - POST POUNDER

1.1. FEATURE OVERVIEW AND OPTIONS S2000 MODEL

1.1. FEATURE OVERVIEW AND OPTIONS

The S2000 Post Pounder connects to a tractor’s three-point hitch for mobility and

hydraulic power.

The S2000 Post Pounder is delivered packaged in two separate crates. One

crate contains the mast assembly, and the second crate contains the frame

assembly, the hugger assembly, and two support jacks.

Hydraulic power for the standard version of the S2000 Post Pounder is provided

by connecting directly to the tractor’s hydraulic system, including a return line

that is firmly connected to the tractor’s hydraulic fluid reservoir. See “Dri” on

page 40 for detailed information about hydraulic requirements.

The following options are available for the S2000:

• the PTO Kit

• the Hammer Ballast kit

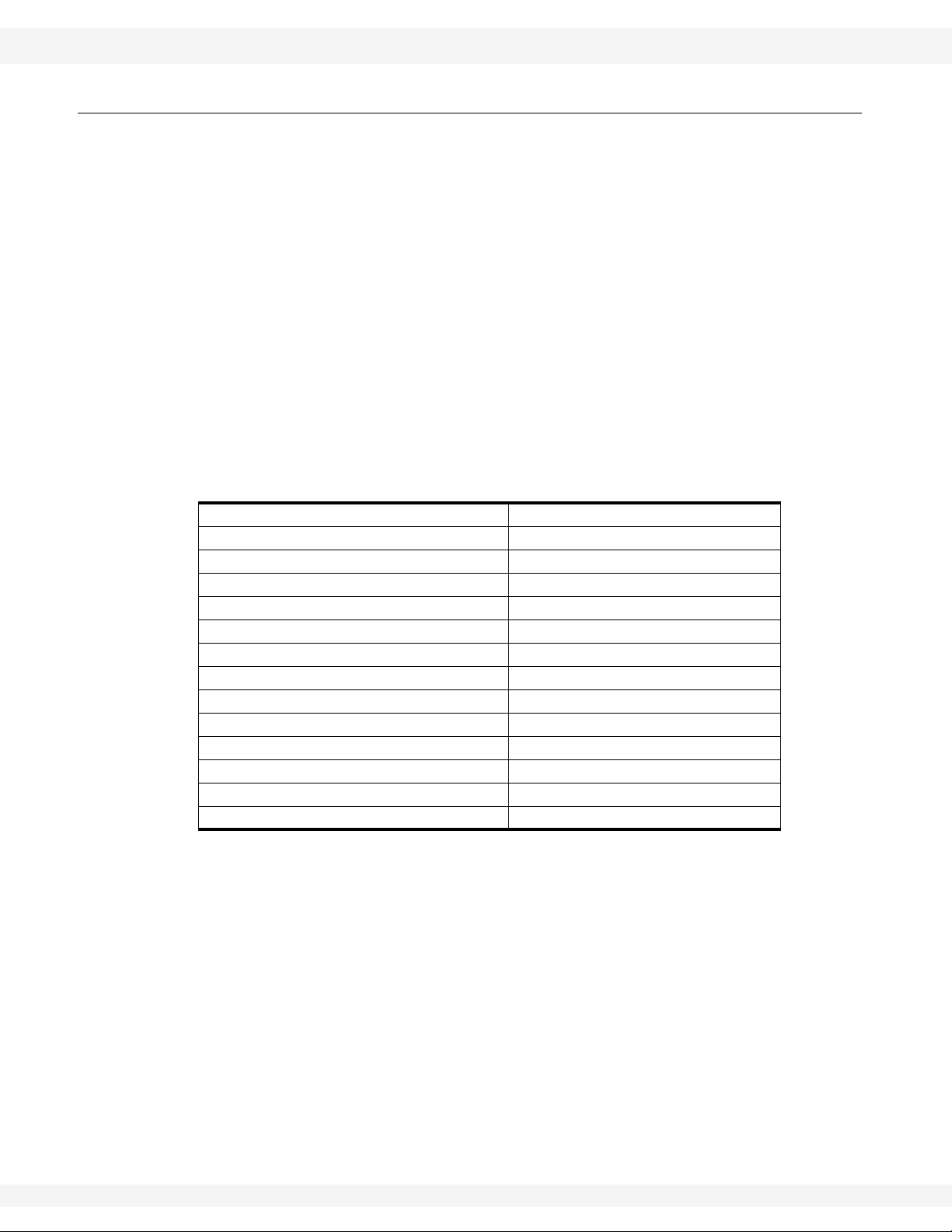

Table 1.1 below lists the S2000 Post Pounder specifications.

Table 1.1 S2000 Post Pounder Specifications

Hammer Weight (without ballast) 320 lbs

Maximum Ballast 280 lbs

Total Weight (without ballast) 720 lbs

Transport Weight (with ballast) 1,000 lbs

Transport Height 8’ 8”

Width 4”1”

Length 3”4”

Hammer Height (Max) 9”4”

Hammer Height (Min) 4’

Hammer Stroke 5’4”

Maximum Post Size (Hugger) 12” diameter

Hydraulic Requirements 7 GPM@1500 PSI

Hammer Tilt Adjustment (front/back) 17º front/back from vertical

Hammer Tilt Adjustment (side-to-side) 16º left/right from vertical

6 IM15 R1

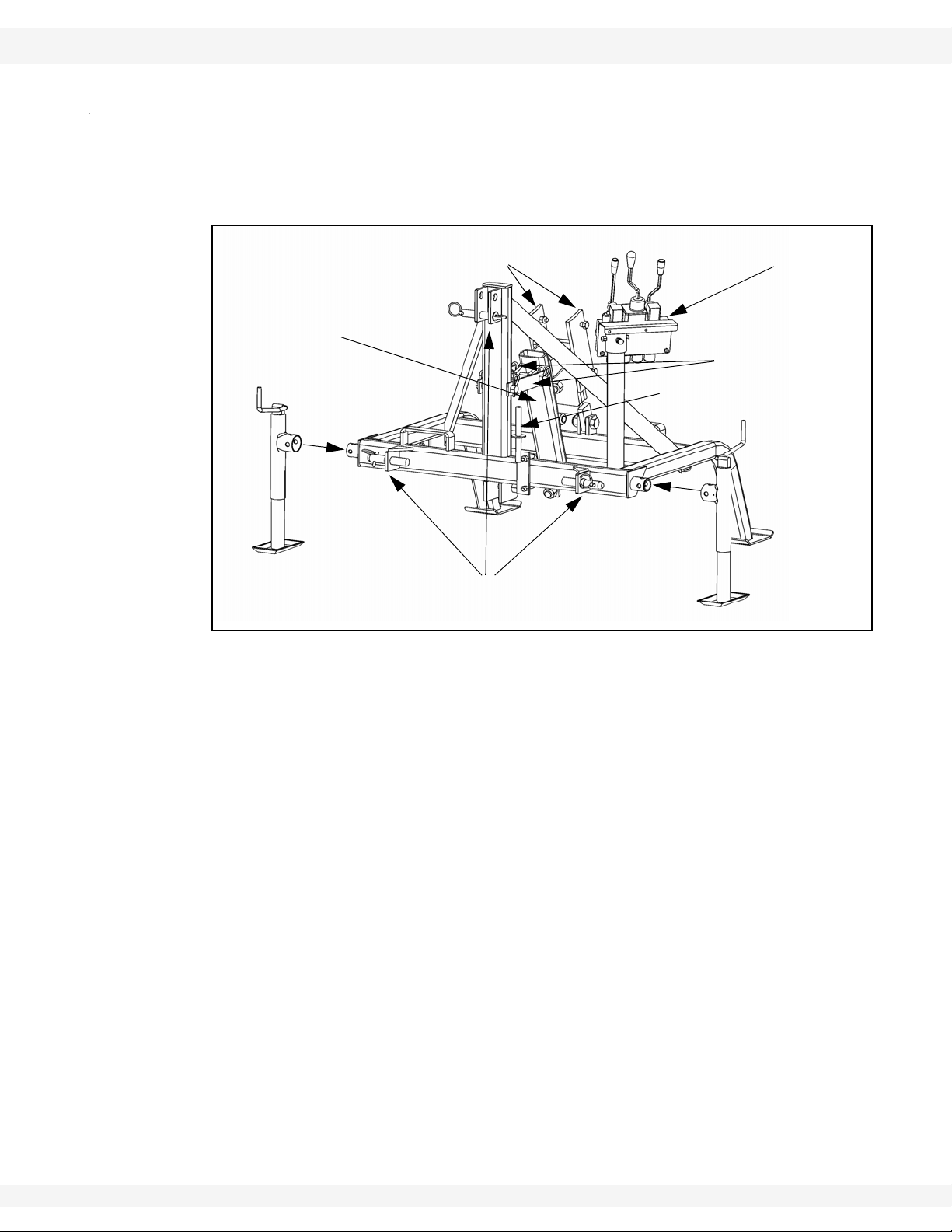

WHEATHEART - POST POUNDER 1. INTRODUCTION

PIVOT ARM

HYDRAULIC CONTROLS

(CLASS II /III THREE-POINT HITCH ATTACHMENTS)

PIVOT ARM

(JACK STAND)

LOCK BARS

PTO PUMP SUPPORT

(OPTIONAL)

(CONTROL VALVE)

MAST ASSEMBLY MOUNT

S2000 MODEL 1.2. FRAME ASSEMBLY

1.2. FRAME ASSEMBLY

The frame assembly is shipped with all hydraulics pre-connected except the

hydraulic hose that must be connected to the mast cylinder. Figure 1.1 shows the

major frame assembly features.

Figure 1.1 Frame Assembly

IM15 R1 7

1. INTRODUCTION WHEATHEART - POST POUNDER

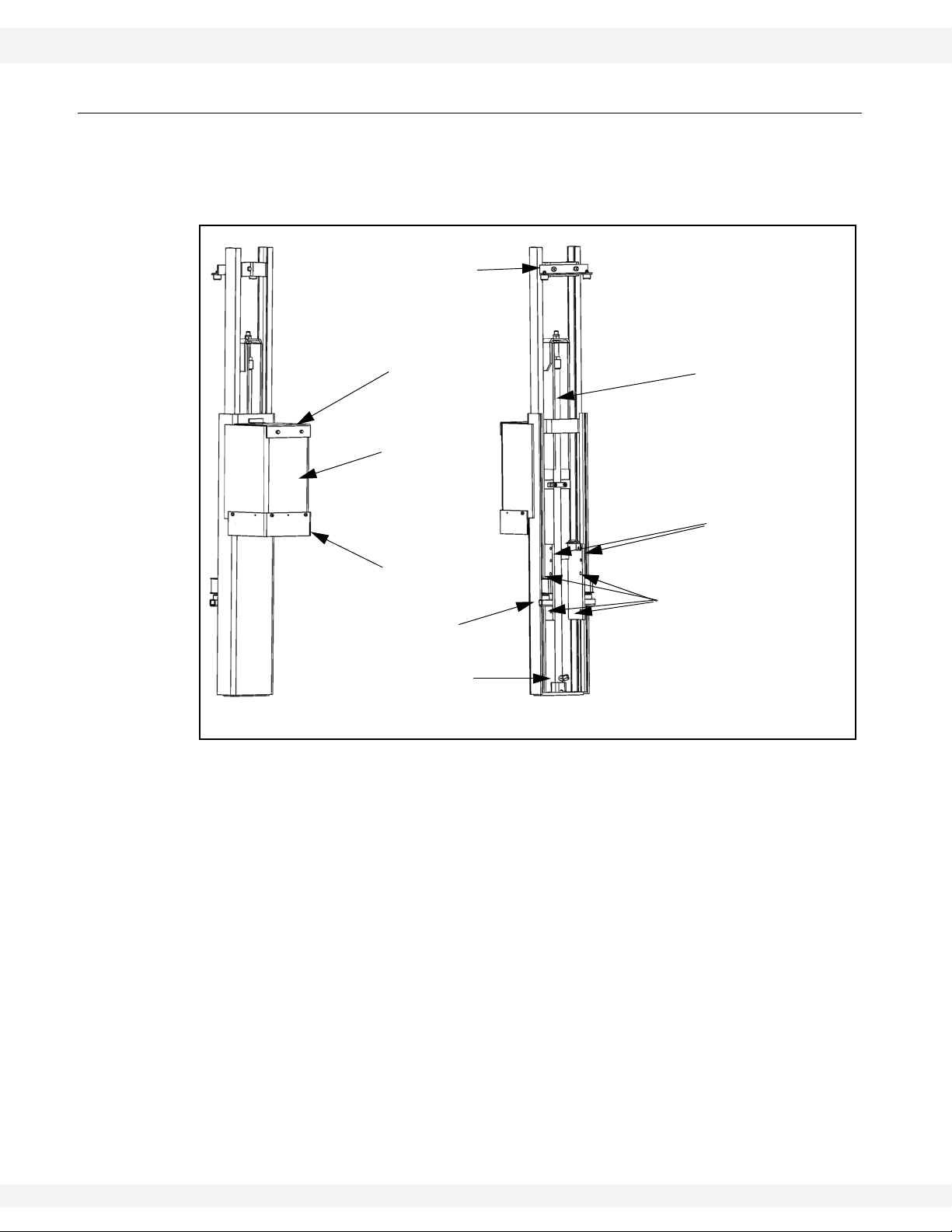

MAST CYLINDER

BALLAST BOX

HAMMER GUARD

MAST CYLINDER

BALLAST BOX COVER

HUGGER BRACKET BOLT HOLES

PIVOT ARM BOLT HOLES

HYDRAULIC CONNECTOR

TOP HAMMER STOP

BOTTOM HAMMER STOP

1.3. MAST ASSEMBLY S2000 MODEL

1.3. MAST ASSEMBLY

The mast assembly mounts on the frame assembly pivot arm, and contains the

mast cylinder, ballast box and hammer, and hammer guard. Figure 1.2 shows the

major features of the assembly.

8 IM15 R1

Figure 1.2 Mast Assembly Detail

WHEATHEART - POST POUNDER 1. INTRODUCTION

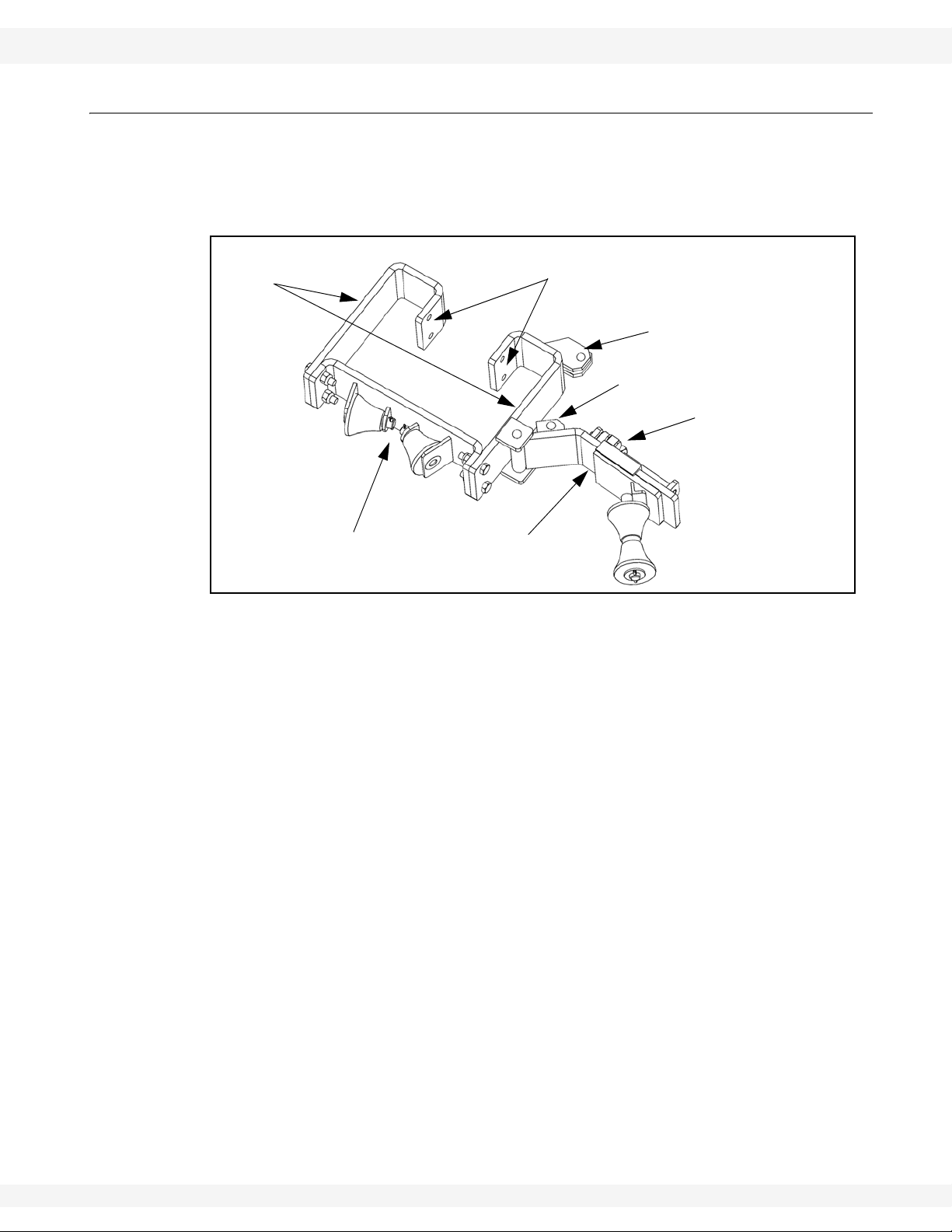

FRONT ROLLER PLATE

HUGGER ARM

MID-CYLINDER BRACKET

CYLINDER ROD-END BRACKET

HUGGER BRACKETS

HUGGER ARM

BOLT HOLES (TO MAST ASSEMBLY)

ADJUSTER BOLT

S2000 MODEL 1.4. HUGGER ARM ASSEMBLY

1.4. HUGGER ARM ASSEMBLY

The hugger arm assembly installs on the mast assembly.The hugger arm opens

and closes hydraulically, and provides posts with support during operation.Figure

1.3 shows the hugger assembly features.

Figure 1.3 Hugger Arm Assembly

IM15 R1 9

1. INTRODUCTION WHEATHEART - POST POUNDER

HYDRAULIC TANK

PTO PUMP

OIL FILTER

1.5. PTO KIT S2000 MODEL

1.5. PTO KIT

The optional PTO Kit (Part Number 2311153) provides the S2000 Post Pounder

with a hydraulic system powered by a hydraulic pump that connects to a tractor

PTO shaft.

The kit contains:

• a hydraulic pump and storage post

• a hydraulic tank and support brackets

• a hydraulic oil filter, filter head, and support bracket

• a hydraulic hose

The PTO Kit’s hydraulic pump provides adequate system pressure when

installed and connected to a 540 RPM PTO.

Installation requires modifying an existing hydraulic hose and installing an

additional hose.

Figure 1.4 PTO Kit Major Parts

10 IM15 R1

WHEATHEART - POST POUNDER 1. INTRODUCTION

BALLAST WEIGHT BODY

BALLAST WEIGHT

HANDLE

S2000 MODEL 1.6. HAMMER BALLAST KIT

1.6. HAMMER BALLAST KIT

The S2000 Post Pounder is equipped with a ballast box that can be filled with

various ballast weights, up to a maximum of 280 lbs.

The hammer ballast used should be heavy enough to drive the post a reasonable

distance with each hammer drop, but not so heavy that the hammer blows risk

damaging smaller posts.

Wheatheart supplies a Hammer Ballast Kit (Part Number 2311154) that includes

six “suitcase” shaped ballast weights. Figure 1.5 shows a single ballast weight

from the kit.

Each individual ballast weight is 45.4 lbs. Use of all six ballast weights meets the

maximum ballast weight of 280 lbs.

Ballast weights should always be placed in the ballast box with the body first and

the handle up. Failure to do so could damage the ballast weight or the ballast box

during operation of the pounder.

Figure 1.5 Single Ballast Weight from Ballast Kit

IM15 R1 11

1. INTRODUCTION WHEATHEART - POST POUNDER

1.6. HAMMER BALLAST KIT S2000 MODEL

12 IM15 R1

WHEATHEART - POST POUNDER 2. SAFETY FIRST

S2000 MODEL

2.Safety First

The Safety Alert symbol to the left identifies important safety messages on the

product and in the manual. When you see this symbol, be alert to the possibility of personal injury or death. Follow the instructions in the safety messages.

Why is SAFETY important to you?

Three big reasons:

• Accidents disable and kill.

• Accidents cost.

• Accidents can be avoided.

SIGNAL WORDS

Note the use of the signal words DANGER, WARNING, CAUTION, and NOTICE

with the safety messages. The appropriate signal word for each message has

been selected using the definitions below as a guideline.

The Safety Alert symbol means: “ATTENTION, BE ALERT! YOUR SAFETY IS

INVOLVED”.

DANGER

Indicates an imminently hazardous situation

that, if not avoided, will result in serious injury

or death.

WARNING

Indicates a hazardous situation that, if not

avoided, could result in serious injury or

death.

CAUTION

Indicates a hazardous situation that, if not

avoided, may result in minor or moderate

injury.

NOTICE

Indicates a potentially hazardous situation that, if not

avoided, may result in property damage.

IM15 R1 13

2. SAFETY FIRST WHEATHEART - POST POUNDER

2.1. GENERAL SAFETY S2000 MODEL

2.1. GENERAL SAFETY

Important: This general safety section includes instructions that apply to all safety practices.

Any instructions specific to a certain safety practice (e.g., assembly safety), can

be found in the appropriate section. Always read the complete instructional

sections and not just these safety summaries before doing anything with the

equipment.

YOU are responsible for the SAFE use and maintenance of your equipment.

YOU must ensure that you and anyone else who is going to work around the

equipment understands all procedures and related SAFETY information

contained in this manual.

Remember, YOU are the key to safety. Good safety practices not only protect

you, but also the people around you. Make these practices a working part of your

safety program.

• It is the equipment owner and the operator's responsibility to read and understand ALL safety instructions, safety decals, and manuals and follow them

before assembling, operating, or maintaining the equipment. All accidents

can be avoided.

• Equipment owners must give instructions and review the information initially

and annually with all personnel before allowing them to operate this product.

Untrained users/operators expose themselves and bystanders to possible

serious injury or death.

• Use this equipment for its intended purposes only.

• Do not modify the equipment in any way. Unauthorized modification may

impair the function and/or safety, and could affect the life of the equipment.

Any modification to the equipment voids the warranty.

• Do not allow children, spectators, or bystanders within the work area.

• Have a first-aid kit available for use should the need arise, and know how to

use it.

• Provide a fire extinguisher for use in case of an accident. Store in a highly visible and accessible place.

• Wear appropriate protective gear . This list includes, but

is not limited to:

• a hard hat

•gloves

• protective shoes with slip-resistant soles

• protective goggles

• hearing protection

• dust mask or respirator

• For Powered Equipment: before servicing, adjusting, or repairing powered

equipment, unplug, place all controls in neutral or off position, stop the engine

or motor , remove ignition key or lock out power source, and wait for all moving parts to stop.

14 IM15 R1

WHEATHEART - POST POUNDER 2. SAFETY FIRST

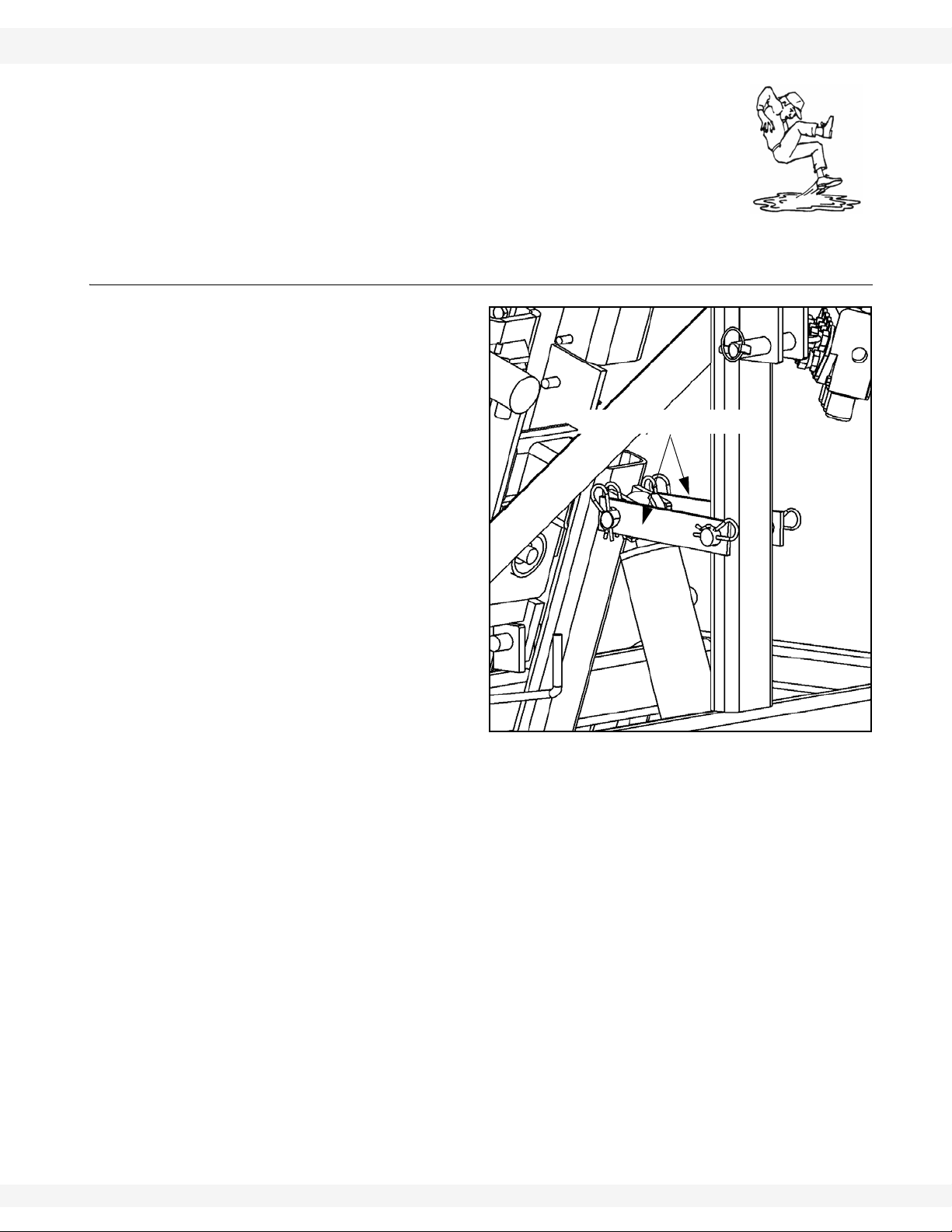

Figure 2.1 Transport Lock Bars

TRANSPORT LOCK BARS

S2000 MODEL 2.2. TRANSPORT & PLACEMENT SAFETY

• Follow good shop practices:

• keep service area clean and dry

• be sure electrical outlets and tools are properly

grounded

• use adequate light for the job at hand

• Think SAFETY! Work SAFELY!

2.2. TRANSPORT & PLACEMENT SAFETY

• Check with local authorities

regarding transport on public roads. Obey all applicable

laws and regulations.

• Consult tractor operator’s

manual to ensure adequate

towing and lifting capacities.

• Attach pounder to a Category II or III 3-point hitch.

• Ensure transport locks are in

place (see Figure 2.1).

• Ensure that clearances

between pounder and tractor

are maintained during raising, lowering, and positioning.

• Always travel at a safe

speed. Use caution when

turning corners or meeting

traffic.

• Use extreme care and minimum ground speed when operating or transporting on hillsides, over rough

ground, or near ditches or fences.

• Make sure the SMV (slow moving vehicle) emblem and all the lights and

reflectors that are required by local authorities are in place, are clean, and

can be seen by all traffic.

• Do not allow riders on the equipment or towing vehicle during transport.

• Keep away from overhead and buried power lines. Arcing and possible electrocution can occur without direct contact.

• Keep away from buried gas lines. Gas leaks and explosions can occur if gas

lines are ruptured by posts.

• Before transporting, position the ballast box into the fully lowered position.

• Keep jacks raised during transport and normal operation (lower jacks when

storing pounder or operating with hammer at extreme angle).

• Consult local utility companies before operating machine near overhead or

buried power lines / gas lines to confirm line location.

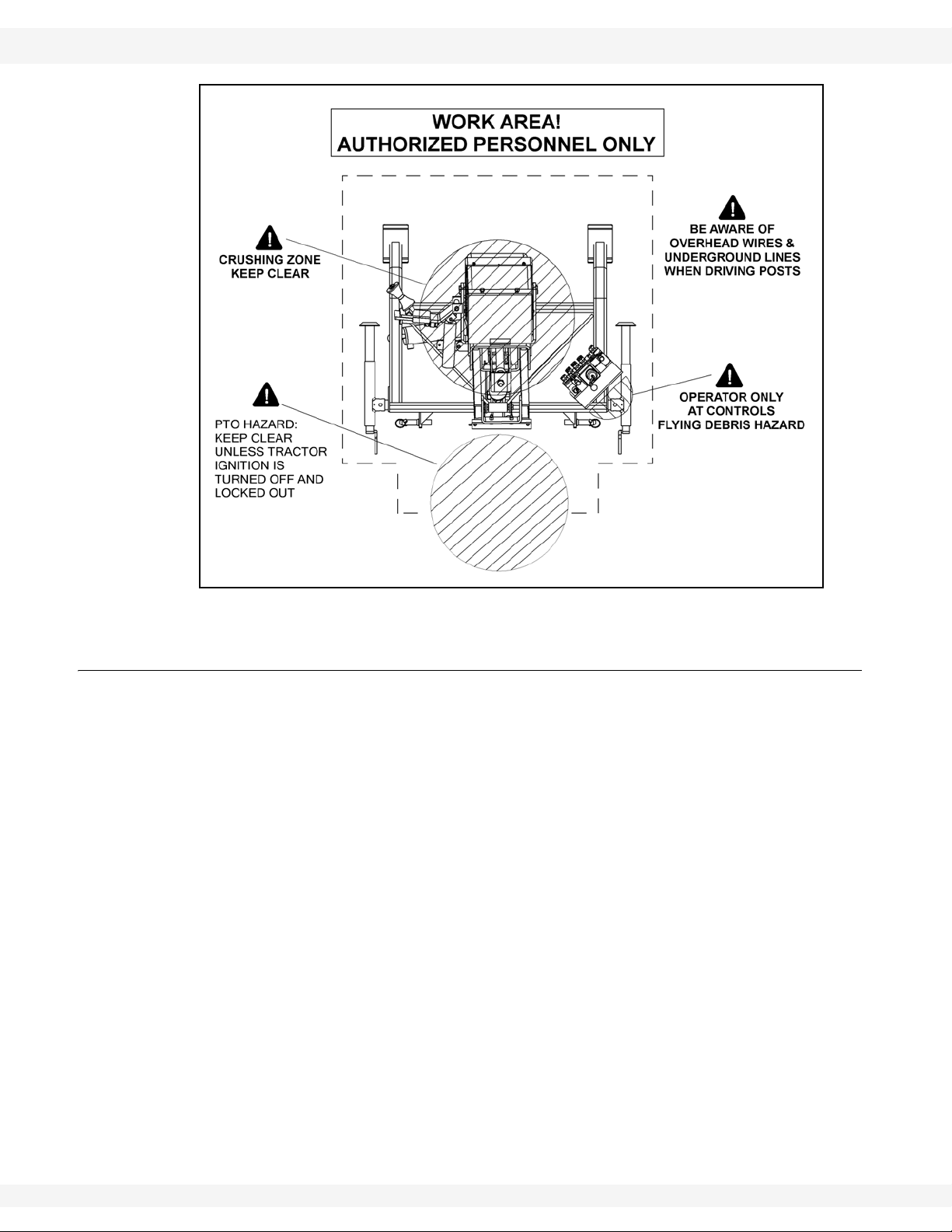

• Review the work safety area diagram (Figure 2.2) before starting work.

IM15 R1 15

2. SAFETY FIRST WHEATHEART - POST POUNDER

2.3. OPERATION SAFETY S2000 MODEL

Figure 2.2 Work Safety Areas

2.3. OPERATION SAFETY

• Have another person nearby and prepared to shut down the equipment in

case of an emergency or accident.

• Do not operate with any of the safety guards removed.

• Keep body, hair, and clothing away from moving parts. Stay away from hammer during operation.

• Do not modify the factory-installed position of the hydraulic control valve

assembly.

• Engage park brake on tractor during operation to prevent movement of the

pounder and tractor.

• Ensure both feet of the pounder frame firmly contact the ground during operation to prevent damage to equipment.

• Do not place more than 280 lbs of weight in ballast box. An overloaded ballast will cause excessive stress on the hydraulic system and can damage the

equipment and/or potentially injure operators.

• Keep jacks raised during transport and normal operation (lower jacks when

storing pounder or operating with hammer at an extreme angle).

16 IM15 R1

WHEATHEART - POST POUNDER 2. SAFETY FIRST

S2000 MODEL 2.4. MAINTENANCE SAFETY

2.4. MAINTENANCE SAFETY

• Before applying pressure to a hydraulic system, make sure all components

are secure, hoses are in good condition, and couplings are tightly connected

and undamaged.

• Relieve pressure from hydraulic circuit before servicing or disconnecting from

tractor.

• Place stands or blocks under the frame before working beneath the machine.

• After maintenance is complete, replace and secure all safety guards and

safety devices, and if applicable, service doors and cleanout covers.

• Remove all tools and unused parts from machine before operation.

• Remove buildup of grease, oil, and debris.

• Inspect all parts. Ensure parts are in good condition and installed properly.

Use only genuine Wheatheart replacement parts or equivalent. Replacement

parts must meet ASAE standards or serious injury may result. Use of

unauthorized parts will void the warranty. If in doubt, contact Wheatheart or your

Wheatheart dealer.

2.5. HYDRAULIC SAFETY

• Always place all hydraulic controls in neutral and relieve system pressure

before disconnecting or working on hydraulic system.

• Keep all components in the hydraulic system tightly secured and in good condition and clean.

• Replace any worn, cut, abraded, flattened, or crimped hoses.

• Do not attempt any makeshift repairs to the hydraulic fittings or hoses with

tape, clamps, or concrete. The hydraulic system operates under extremely

high pressure; such repairs will fail suddenly and create a hazardous and

unsafe condition.

• Before moving a hydraulic cylinder, ensure that the attached component is

safely secured.

Hydraulic fluid can cause serious injury if it

penetrates the skin. If it does, see a doctor

immediately.

WARNING

• Relieve pressure before disconnecting

hydraulic line.

• Wear proper hand and eye protection and

use wood or cardboard, not hands, when

searching for leaks.

IM15 R1 17

2. SAFETY FIRST WHEATHEART - POST POUNDER

2.6. SAFETY DECAL LOCATIONS S2000 MODEL

2.6. SAFETY DECAL LOCATIONS

• Keep safety decals clean and legible at all times.

• Replace safety decals that are missing or have become illegible. See decal

locations that follow .

• Replaced parts must display the same decal(s) as the original part.

• Safety decals are available from your distributor, dealer, or factory.

2.6.1. DECAL INSTALLATION/REPLACEMENT

1. Decal area must be clean and dry, with a temperature above 50°F (10°C).

Use a solvent to remove all traces of oil from manufacturing before applying

decal.

2. Decide on the exact position before you remove the backing paper.

3. Align the decal over the specified area and carefully press the small portion

with the exposed sticky backing in place.

4. Slowly peel back the remaining paper and carefully smooth the remaining

portion of the decal in place.

5. Small air pockets can be pierced with a pin and smoothed out using the decal

backing paper.

2.6.2. DECAL LOCATIONS

Replicas of the safety decals that are attached to the equipment are shown in the

figure(s) that follow. Proper safety procedures require that you familiarize

yourself with the various safety decals and the areas or particular functions that

the decals apply to as well as the safety precautions that must be taken to avoid

serious injury, death, or equipment damage.

18 IM15 R1

WHEATHEART - POST POUNDER 2. SAFETY FIRST

S2000 MODEL 2.6. SAFETY DECAL LOCATIONS

Figure 2.3 Safety Decal Locations

IM15 R1 19

2. SAFETY FIRST WHEATHEART - POST POUNDER

2.6. SAFETY DECAL LOCATIONS S2000 MODEL

20 IM15 R1

WHEATHEART - POST POUNDER 3. ASSEMBLY

Warning: Before continuing, ensure you have read and understand the relevant information

in the safety section. Safety information is provided to help prevent serious injury, death, or

property damage.

S2000 MODEL 3.1. PRE-ASSEMBLY

3.Assembly

The following procedures and instructions are necessary to ensure proper and

safe assembly of your S2000 Post Pounder.

To assemble the S2000 Post Pounder, perform the following procedures in the

order that they are listed here:

• “Pre-Assembly” on page 21

• “Assembling the S2000 Post Pounder” on page 22

• “Installing the PTO Kit” on page 28 (optional)

3.1. PRE-ASSEMBLY

Upon receiving your shipment:

• Open shipping crates and arrange components on a flat, open workspace.

• Remove bolts on ballast box cover and remove the hardware bag from inside

the ballast box.

• Count components and refer to shipping list to ensure no part is missing.

Contact your dealer or Wheatheart in the event of missing parts.

• Ensure that you have a clear and safe work area, with access to power and

lighting if required.

• Review “General Safety” on page 14.

The following equipment will be needed during assembly:

• a lifting device suitable to support the mast assembly during installation

• safety equipment (e.g. steel toe boots, gloves, goggles)

• vise grips

• mallet

• pry bar

• wrench set (standard/imperial)

• hacksaw or chop saw for cutting hydraulic hose (for PTO Kit only)

IM15 R1 21

3. ASSEMBLY WHEATHEART - POST POUNDER

INSERT LOCK PIN

INSERT LOCK PIN

(TEMPORARY SUPPORT)

(TEMPORARY SUPPORT)

3.2. ASSEMBLING THE S2000 POST POUNDER S2000 MODEL

3.2. ASSEMBLING THE S2000 POST POUNDER

Important: Always have two or more people assembling the equipment. Due to the weight of

the components, do not attempt assembly alone.

Important: Lock bars prevent front-back tilt and limit side-to-side tilt of the pounder mast

during transport and storage. Lock bars should also remain in place during

assembly.

WARNING

Do not attempt assembly without a lifting

device. Components are heavy and present a

crushing hazard which can cause serious

injury or death.

To assemble the S2000 Post Pounder, perform the following procedures in the

order that they are listed:

• “Prepare the Frame Assembly” on page 22

• “Connect the Mast Assembly to the Frame Assembly” on page 23

• “Connect the Hugger Arm and Cylinder to The Mast Assembly” on page 25

• “Install Hammer Ballast” on page 26

3.2.1. PREPARE THE FRAME ASSEMBLY

1. Temporarily support the frame assembly under the frame near the jack stand

locations.

Figure 3.1 Preparing the Frame Assembly

22 IM15 R1

WHEATHEART - POST POUNDER 3. ASSEMBLY

SECURE SLING TO ANGLE IRON HAMMER STOP

BALLAST BOX

S2000 MODEL 3.2. ASSEMBLING THE S2000 POST POUNDER

2. Connect the jack stands to the frame assembly, and secure the jack stands

using the supplied lock pins and hair pins.

3. Remove the temporary supports from the assembly, and adjust the jack

stand legs until the frame assembly is level.

3.2.2. CONNECT THE MAST ASSEMBLY TO THE FRAME ASSEMBLY

1. Position the mast assembly with the ballast box facing upward on a surface

that will protect the back of the assembly from abrasion (e.g. plywood, wood

support blocks, or the bottom of the assembly’s shipping crate).

2. Secure a sling around the centre of the angle iron hammer stop at top of

mast assembly, and attach the sling to a lifting device.

Figure 3.2 Lifting Sling Attachment Point

CAUTION

Secure sling only around the angle iron

hammer stop. Securing at another point could

cause mast to slide when lifted, potentially

damaging equipment or causing injury.

3. Slowly lift the mast assembly into an upright position, then raise or lower it

over the frame assembly until the four mast assembly bolt holes (located on

tabs on the back of the assembly) are as closely aligned with the four bolt

holes on the pivot arm as possible.

4. Connect the mast assembly to the frame assembly using 5/8” x 2” fine-thread

bolts through each bolt hole and secure with 5/8” fine-thread locknuts (see

Figure 3.3). Further alignment of the bolt holes may require very small

adjustments to the height of the mast assembly, or adjustments to the

position of the frame assembly. A pry bar and mallet may be required to

adjust the two assemblies into proper position.

IM15 R1 23

3. ASSEMBLY WHEATHEART - POST POUNDER

MAST CYLINDER

MAST CYLINDER

MAST BOTTOM

HYDRAULIC CONNECTOR

(BACK VIEW)

3.2. ASSEMBLING THE S2000 POST POUNDER S2000 MODEL

Figure 3.3 Connecting Mast Assembly to the Frame Assembly

5. Connect the mast cylinder hydraulic hose to the fitting located at the base of

the mast cylinder.

Figure 3.4 Mast Cylinder Connector Location

24 IM15 R1

WHEATHEART - POST POUNDER 3. ASSEMBLY

FRONT ROLLER PLATE

HUGGER ARM

HUGGER BRACKETS

BOLT HOLES

BOLTS REMOVED

(TO MAST)

MID-CYLINDER BRACKET

FRONT CYLINDER BRACKET

LOCATIONS

HUGGER BOLT

MAST LEVEL

S2000 MODEL 3.2. ASSEMBLING THE S2000 POST POUNDER

3.2.3. CONNECT THE HUGGER ARM AND CYLINDER TO THE MAST ASSEMBLY

1. The hugger assembly comes with the hugger brackets loosely connected to

the front roller plate for ease of shipping. In order to fit the hugger arm around

the mast assembly , first remove the two bolts that secure the front roller plate

to the hugger bracket that is not connected to the hugger arm.

Figure 3.5 Hugger Arm Assembly, Preparation For Installation

Figure 3.6 Hugger Installed on the Mast Assembly

2. Align the four hugger bracket bolt holes with the bolt holes on the mast

assembly.

IM15 R1 25

3. ASSEMBLY WHEATHEART - POST POUNDER

1/2” X 2-1/4 BOLTS

LOCKNUTS

FRONT CYLINDER BRACKET

MID-CYLINDER BRACKET

3.2. ASSEMBLING THE S2000 POST POUNDER S2000 MODEL

3. Secure hugger brackets to the mast assembly with four bolts and locknuts,

but before securing the top-right bolt, place the mast level into place on the

bolt. In order to be roughly accurate, the face of the level should be flush with

the upper edge of the hugger bracket.

4. Secure the front roller plate to the hugger bracket by re-attaching and

tightening the previously removed front roller plate bolts.

5. Ensure that all hugger bracket and front roller plate bolts are tight.

Figure 3.7 Connecting the Hugger Arm Cylinder

6. Position the hugger cylinder so the hydraulic connectors face downward, and

7. Insert the cylinder rod end into the front cylinder bracket (directly on the

3.2.4. INSTALL HAMMER BALLAST

1. Remove the two 1/2”x1-1/2” bolts that secure the ballast box cover to the

2. Fill the ballast box with either:

insert the appropriate mid-cylinder mounting tab into the mid-cylinder

bracket, and fasten with a 1/2” x 2-1/4” bolt and locknut.

hugger arm) and fasten with a 1/2” x 2-1/4” bolt and locknut.

ballast box, and place the bolts and cover aside (see Figure 3.8).

a. pre-weighed ballast of a suitable material (e.g. rebar, slugs, bolts, ball

bearings),

b. or optional “suitcase” ballasts that can be ordered from Wheatheart (Part

Number 2311154). Each ballast weighs 45.4 lbs.

26 IM15 R1

WHEATHEART - POST POUNDER 3. ASSEMBLY

PLACE BALLAST INSIDE

BALLAST BOX COVER

1/2” X 1-1/2” BOLTS

BALLAST BOX

S2000 MODEL 3.2. ASSEMBLING THE S2000 POST POUNDER

WARNING

Do not overfill ballast box. An overloaded

ballast will cause excessive stress on the

hydraulic system and can damage the

equipment and/or potentially injure operators.

Do not exceed 280 lb maximum total ballast

weight.

3. Any extra space in the ballast box can be shimmed with light-weight material

to prevent noise caused by uncontrolled movement of the ballast weights

during operation.

4. Replace the ballast box cover and secure it with the two 1/2” x 1-1/2” bolts

(see Figure 3.8).

Figure 3.8 Installing Hammer Ballast Weights

IM15 R1 27

3. ASSEMBLY WHEATHEART - POST POUNDER

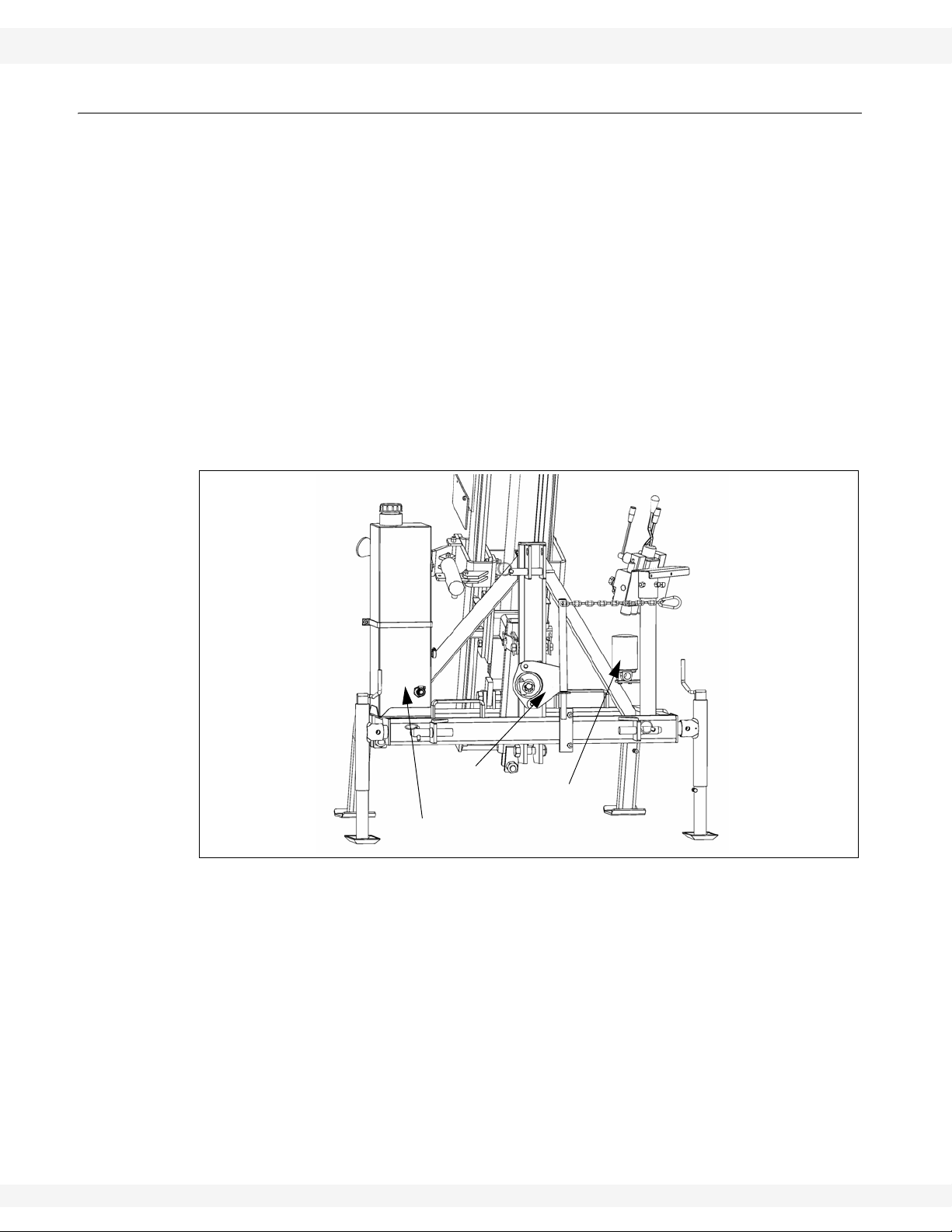

12”

U-BOLT

9”

U-BOLT

3”

U-BOLT

PTO PUMP

SUPPORT POST

OIL FILTER

ASSEMBLY

HYDRAULIC

TANK

3.3. INSTALLING THE PTO KIT S2000 MODEL

3.3. INSTALLING THE PTO KIT

The optional PTO Kit provides the S2000 Post Pounder with a hydraulic system

that is powered by the tractor’s PTO.

To install the PTO Kit, perform the following procedures in the order that they are

listed:

• “Installing the PTO Kit Oil Filter Assembly” on page 29

• “Installing the PTO Kit Hydraulic Tank” on page 30

• “Installing the PTO Pump Support” on page 32

• “Connecting PTO Kit Hydraulic Hoses” on page 33

• “Filling the Hydraulic Tank” on page 34

Figure 3.9 PTO Kit, Part Mounting Locations

28 IM15 R1

WHEATHEART - POST POUNDER 3. ASSEMBLY

OIL FILTER

OIL FILTER HEAD

5/16” X 1” BOLTS

1/2” NYLOCK NUTS

U-BOLT

OIL FILTER BRACKET

S2000 MODEL 3.3. INSTALLING THE PTO KIT

3.3.1. INSTALLING THE PTO KIT OIL FILTER ASSEMBLY

1. Connect the oil filter head to the oil filter bracket using two 5/16” x 1” bolts.

2. Secure the filter bracket and oil filter head to the frame assembly with a

U-bolt and two 1/2” nylock nuts (Figure 3.9 shows the mounting location of

the oil filter assembly).

3. Ensure a good seal between the oil filter and the oil filter head by rubbing a

small amount of clean hydraulic oil on the oil filter’s rubber seal. Install the

oil filter by carefully aligning the threads of each part together, and then

rotating the oil filter clock-wise until a tight seal is achieved.

IM15 R1 29

Figure 3.10 Installing the Oil Filter Assembly

3. ASSEMBLY WHEATHEART - POST POUNDER

1/2” NYLOCK NUTS

HYDRAULIC TANK BRACKET

U-BOLT

3.3. INSTALLING THE PTO KIT S2000 MODEL

3.3.2. INSTALLING THE PTO KIT HYDRAULIC TANK

1. Position the hydraulic tank support bracket on the frame assembly (Figure

3.9 shows the mounting location).

2. Connect the hydraulic tank support bracket to the frame assembly using the

supplied U-bolt (see Figure 3.11).

Figure 3.11 Installing the Hydraulic Tank Support Bracket

3. Place the hydraulic tank in the hydraulic tank support bracket with the lowest

of the two hydraulic connectors facing the three-point hitch, and secure the

tank with the tank strap using the two hex bolts and 5/16 nylock nuts (See

Figure 3.12).

30 IM15 R1

WHEATHEART - POST POUNDER 3. ASSEMBLY

HYDRAULIC TANK

TANK STRAP

2 X 5/16” NYLOCK NUT

2 X 5/16” HEX BOLT

FLUID RETURN

(TO OIL FILTER)

FLUID SUPPLY

(TO PTO PUMP)

S2000 MODEL 3.3. INSTALLING THE PTO KIT

Figure 3.12 Fastening the Hydraulic Tank

IM15 R1 31

3. ASSEMBLY WHEATHEART - POST POUNDER

PTO PUMP

U-BOLT

1/2” NYLOCK NUTS

THREE-POINT HITCH

CENTRE POST

SUPPORT

3.3. INSTALLING THE PTO KIT S2000 MODEL

3.3.3. INSTALLING THE PTO PUMP SUPPORT

1. Facing the three-point hitch, position the PTO pump support on the frame

assembly with the U-bolt centre three inches to the right of the edge of the

hitch centre-post (Figure 3.9 shows the mounting location).

2. Secure the PTO Pump support to the frame assembly using the U-bolt and

two 1/2” nylock nuts.

Figure 3.13 Installing the PTO Pump Support

32 IM15 R1

WHEATHEART - POST POUNDER 3. ASSEMBLY

HYDRAULIC PRESSURE

FLUID RETURN

(H12X72P TO PTO PUMP)

H34X25 TO OIL FILTER

(H34X84 REMOVED)

S2000 MODEL 3.3. INSTALLING THE PTO KIT

3.3.4. CONNECTING PTO KIT HYDRAULIC HOSES

Use the following procedure to connect the hydraulic hoses to the new components included in the PTO Kit. Refer to Figure 10.2 in the Appendix for a det ailed

hydraulic diagram.

1. Connect the hydraulic pressure hose from the control valve to the PTOdriven hydraulic pump’s pressure port.

2. Disconnect the fluid return hose (Part Number H34X84) from the fluid return

connector on the control valve (see Figure 3.14 below).

Figure 3.14 Hose Connections on the Control Valve

3. Divide the return hose into two lengths by measuring, marking, and cutting

4. Clean any debris left over from the end and interior of the two hoses, and

5. Connect the 3/4” NPT connector of the new hydraulic hose supplied with the

the hose 37” from the 1/2” NPT connector.

connect the two lengths as follows:

a. Connect the 1/2” NPT connector on the 37” length of hose to the oil filter

connector closest to the hydraulic tank. Connect the other end of the hose

to the hydraulic tank’s fluid return connector (the highest of the two

connectors), and secure it with the supplied hose clamp.

b. Connect the 3/4” NPT connector on the remaining length of hose to the

fluid intake connector on the hydraulic pump. Connect the other end of the

hose to the hydraulic tank’s supply connector (the lowest of the two

connectors), and secure it with the supplied hose clamp.

kit (H34X25) to the control valve return connector. Connect the remaining

1/2” connector to the other oil filter connector.

IM15 R1 33

3. ASSEMBLY WHEATHEART - POST POUNDER

3.3. INSTALLING THE PTO KIT S2000 MODEL

3.3.5. FILLING THE HYDRAULIC TANK

For general operation, Wheatheart recommends an ISO viscosity 32 heavy duty

industrial hydraulic mineral oil.

After all PTO kit components have been installed correctly, fill the hydraulic tank

with hydraulic oil as follows:

1. Remove the hydraulic tank cap.

2. Add hydraulic oil to the hydraulic tank, but do not overfill (leave space at the

top of the tank).

3. Slowly extend and retract all hydraulic cylinders until air is displaced from the

hydraulic system.

4. Add additional fluid to make up for air displaced from hoses, but do not

overfill the tank.

5. Replace and tighten the tank cap.

34 IM15 R1

WHEATHEART - POST POUNDER 4. TRANSPORT

Warning: Before continuing, ensure you have read and understand the relevant information

in the safety section. Safety information is provided to help prevent serious injury, death, or

property damage.

S2000 MODEL

4.Transport

Follow this procedure when placing the unit into its transport position:

CAUTION

Ensure hitch connection points on tractor and

pounder are level and aligned with each other

before proceeding, to prevent tipping the

pounder and potential injury.

1. Slowly back the tractor up to pounder, leaving at least 6” clearance between

tractor Category II or III 3-point hitch and pounder.

2. Adjust height of 3-point hitch, ensuring that attach points on tractor are not

lower than attach points on pounder.

3. Slowly back tractor up to pounder the remaining distance and attach to

Category II or III 3-point hitch with supplied hitch pins.

4. Once pounder is fully attached to tractor, lift jacks into transport position and

secure with hairpins.

5. Raise the pounder to a safe transport height using the 3-point hitch.

6. Before transporting, ensure hammer/ballast box is positioned in the fully

lowered position, and the mast is fully tipped back and secured by lockbars.

7. Make sure the SMV (Slow Moving Vehicle) emblem and lights and reflectors

that are required by the local authorities are in place, clean, and clearly

visible to all traffic.

8. Consult with local authorities regarding transport on public roads. Obey all

applicable laws and regulations.

Important: Use caution when turning corners or meeting traffic.

WARNING

Do not attempt to move the unit by hand. Only

move when hitched securely to tractor.

WARNING

Use extreme care and use minimum ground

speed when operating or transporting on

hillsides, over rough ground, or near ditches

or fences.

IM15 R1 35

4. TRANSPORT WHEATHEART - POST POUNDER

S2000 MODEL

36 IM15 R1

WHEATHEART - POST POUNDER 5. PLACEMENT

Warning: Before continuing, ensure you have read and understand the relevant information

in the safety section. Safety information is provided to help prevent serious injury, death, or

property damage.

S2000 MODEL

5.Placement

Follow this procedure when placing pounder into its working position:

WARNING

Stay away from overhead or buried power

lines. Arcing and possible electrocution can

occur without direct contact.

WARNING

Consult local utility companies for location of

buried power lines and gas lines before

operating machine.

1. Review the work area safety diagram (Figure 2.2) prior to starting work.

Follow all set-up instructions and do not allow any unauthorized people into

the working area.

2. Be sure there is enough clearance from overhead obstructions, power lines,

or other equipment to move the machine into its working position.

3. Position machine in the desired post area.

4. Lower the 3-point hitch and ensure that both of the post pounder’s support

legs are securely on the ground.

CAUTION

Pounder must have both support legs

securely on the ground before using machine.

5. Set park brake on tractor before dismounting.

WARNING

Use extreme care and minimum ground speed

when operating or transporting on hillsides,

over rough ground, or near ditches or fences.

IM15 R1 37

5. PLACEMENT WHEATHEART - POST POUNDER

S2000 MODEL

38 IM15 R1

WHEATHEART - POST POUNDER 6. OPERATION

Warning: Before continuing, ensure you have read and understand the relevant information

in the safety section. Safety information is provided to help prevent serious injury, death, or

property damage.

S2000 MODEL 6.1. PRE-OPERATION CHECKLIST

6.Operation

NOTICE

Ensure that pounder is attached to equipment that has

sufficient capacity to tow or lift the machine.

CAUTION

Pounder must have both support legs

securely on the ground before using machine.

WARNING

Use extreme care and minimum ground

speed when operating or transporting on

hillsides, over rough ground, or near ditches

or fences.

6.1. PRE-OPERATION CHECKLIST

Efficient and safe operation of this unit requires that each operator reads and

understands the operating procedures and all related safety precautions outlined

in this manual.

Before operating the unit, and each time thereafter, the following should be

reviewed:

• Follow the service schedule.

• Check hydraulic system oil level.

• Ensure that all hydraulic lines are free from damage, and that all fittings

are tight.

• Visually inspect the unit for damage to components. Replace or repair any

damaged or questionable parts.

• Check the work site and clean up the area, if needed.

• Use only a tractor of adequate power and capacity to operate the

machine.

• Check that all guards are installed, secured, and functioning as intended.

Do not operate with missing or damaged guards. Keep guards in good

working order.

IM15 R1 39

6. OPERATION WHEATHEART - POST POUNDER

6.2. DRIVES S2000 MODEL

• Ensure that the pounder is attached to the tractor 3-point hitch with hitch

pins and secured with hairpins.

• Consult local utility companies to identify the location of buried power/gas

lines.

WARNING

Shut off and remove key or lock out power

source before inspecting or servicing the

machine.

DRI

6.2. DRIVES

This unit requires hydraulic power either:

• by direct connection to the tractor’s hydraulic system (standard)

• or by connecting the S2000’s optional integrated hydraulic pump to the tractor’s 540 RPM PTO shaft (PTO Kit installed).

The S2000 Post Pounder is designed to operate with a hydraulic flow rate of

7 GPM@1500 PSI. This provides an acceptable hammer-rise rate of around

three seconds.

If lower flow or pressure are supplied, operation may become slower, sluggish, or

fail entirely.

If flow/pressure is too high, the hammer may rise with too much force and speed,

and there is a risk of damage to the equipment and injury of the operator.

If the hammer lifts too quickly or too slowly, adjust the hydraulic supply from the

tractor, or the PTO speed.

6.2.1. STANDARD HYDRAULIC DRIVE

If you use the tractor’s hydraulic system directly, you must run the post pounder’s

hydraulic fluid return line directly to the tractor’s hydraulic fluid reservoir.

Always fasten the return line in such a way that the end of the hose cannot slip

out of the tractor’s reservoir.

Hydraulic pressure is supplied and regulated by the tractor, apart from an

adjustable pressure relief valve in the post pounder control valve.

40 IM15 R1

WHEATHEART - POST POUNDER 6. OPERATION

S2000 MODEL 6.3. LOCKOUTS

6.2.2. PTO KIT DRIVE

If you use the tractor’s PTO to drive the hydraulic pump supplied in the optional

PTO Kit, ensure that the pump connector is firmly fastened using the connector’s

push-pin shaft lock, and that the arm of the pump assembly is secured to the

tractor (e.g. at the hitch or draw bar using the attached chain.

WARNING

Do not connect or disconnect the PTO pump

while the tractor is on. Always shut off the

tractor, and lock out the ignition before

placing any part of yourself close to the

tractor PTO.

6.3. LOCKOUTS

Before performing any maintenance or servicing, ensure that:

• the tractor is turned off and locked out by removing the ignition key,

• the tractor’s park brake is engaged, and

• the post pounder hammer is in the down position.

Before removing a lockout and supplying power to the post pounder, ensure that:

• all personnel are at a safe distance from the equipment

• the tractor’s parking brake is engaged

• the Pounder’s hydraulic fluid return line is securely fastened, and the end of

the hose cannot slip out of the tractor’s fluid reservoir during operation.

6.4. START-UP AND BREAK-IN

Although there are no operational restrictions on the machine when used for the

first time, it is recommended that some mechanical items should be checked as

a precaution.

Check the hydraulic fluid return line regularly

to ensure that it is directly fastened and

draining into the tractor’s hydraulic fluid

reservoir.

WARNING

IM15 R1 41

6. OPERATION WHEATHEART - POST POUNDER

6.4. START-UP AND BREAK-IN S2000 MODEL

6.4.1. STARTUP

BEFORE STARTING:

• Read power unit operational manual.

• Inspect hydraulic hose fittings for leaks. Tighten if necessary, and replace

worn or damaged hoses.

• Inspect hydraulic mount bolts for tightness.

DURING THE FIRST FEW MINUTES:

• Ensure unit is running properly.

• Some air may be trapped in the hydraulic system; slowly activate hydraulic control valves to ensure all air is out of the system.

• Check hammer raise speed. An ideal hammer-raise time is around three

seconds. If the hammer lifts too quickly or too slowly, adjust the hydraulic

supply from the tractor, or the PTO speed. If the hammer raises with

excessive speed, lower the hydraulic volume/pressure to meet the S2000

hydraulic specifications. If the hammer raises too slowly, increase system

volume/pressure, but do not exceed the system limit of 1500 PSI.

6.4.2. BREAK-IN PERIOD (FIRST 10 HOURS)

AFTER OPERATING FOR FIRST 1/2 HOUR (OR TRANSPORTING):

• Re-torque all fasteners and hardware.

• Check all safety decals are installed and legible. Apply new ones if

needed.

• Check all guards are installed and working as intended.

AFTER OPERATING FOR FIRST 5 AND 10 HOURS:

• Check all hydraulic hoses and fittings for leaks. Tighten fittings where

required, and replace worn or damaged hoses.

• Re-torque all fasteners and hardware.

42 IM15 R1

WHEATHEART - POST POUNDER 6. OPERATION

S2000 MODEL 6.5. OPERATING THE S2000 POST POUNDER

6.5. OPERATING THE S2000 POST POUNDER

Note: Remove and store all lock bars before operating.

WARNING

The Park brake must be engaged on tractor

when pounding posts. If it is not engaged, the

tractor and post pounder could move during

pounder operation and injure the operator.

WARNING

Do not operate the post pounder unless the

hydraulic return line is firmly secured and

draining to the tractor’s fluid reservoir.

6.5.1. LOADING A POST IN THE HUGGER:

1. Using hydraulic controls, raise ballast box and open hugger (Figure 6.1).

Note: See hydraulic valve instructional decal for control details.

WARNING

Keep hands clear of hammer when driving

post. Always use the post hugger to hold the

post in position.

2. Place the post standing up straight against roller plate cones. Ensure that

your hands are clear of hugger. Close the hugger arm to clamp post (Figure

6.1). Some adjustment of the roller arm may be required to hold the post

firmly.

3. To adjust hugger, turn the adjuster bolt on the hugger arm until the roller arm

cones are centered on the post.

4. If various sizes of posts are to be used on a job, the hugger arm may need to

be adjusted to fit at each substantial change of post size.

5. Post is now ready for driving.

IM15 R1 43

6. OPERATION WHEATHEART - POST POUNDER

HUGGER OPEN,

POST PLACED

HUGGER CLOSED,

POST SECURED

6.5. OPERATING THE S2000 POST POUNDER S2000 MODEL

Figure 6.1 Securing a Post with the Hugger

6.5.2. DRIVING A POST:

1. Use hydraulic controls to position mast in the desired position. With the post

held securely in hugger, raise ballast box approximately 1’ to 2’ above the

post before driving the post down. This partial stroke is used to set the post.

WARNING

Do not place more than 280 lbs of weight in

ballast box. An overloaded ballast will cause

excessive stress on the hydraulic system and

can damage the equipment and/or potentially

injure operators.

WARNING

Do not operate the post pounder unless the

hydraulic return line is firmly secured and

draining to the tractor’s fluid reservoir.

44 IM15 R1

WHEATHEART - POST POUNDER 6. OPERATION

S2000 MODEL 6.5. OPERATING THE S2000 POST POUNDER

2. For large posts: raise ballast box as much as needed to safely drive the

post.

For small posts: use shorter strokes because full strokes will damage small

posts.

3. Continue driving the post until the desired post height is achieved.

NOTICE

Do not use the hugger to straighten crooked posts.

Damage to the hugger may result.

NOTICE

Do not raise ballast box at excessive speed. Doing so

could damage the hammer stop or mast frame. Always

reduce the impact at the top hammer stop by slowing the

hammer speed before it reaches the top.

Note: If pounding posts with mast tilted near its maximum (both front-back and side-to-

side tilt), one or both of the jacks may be lowered to provide extra stability.

6.5.3. SHUTDOWN

1. After completing the job, ensure that hammer/ballast box is lowered

completely.

2. Lean mast back into transport position.

3. Shut off flow of oil from the tractor to the post pounder (standard hydraulics),

or turn off the tractor’s PTO.

4. Turn off and lock out the tractor ignition.

5. Reattach lock bars to mast assembly and secure with hairpins.

6. Disconnect hydraulic lines between the Pounder and the tractor (if

applicable), and secure them to the Pounder.

7. Disconnect the hydraulic pump from the tractor’s PTO, and place it on the

PTO storage post (PTO Kit only).

8. Ensure that the jacks stands are secured in storage position (rotated to align

with the frame and secured with a lockpin).

WARNING

DO NOT let ballast box free-fall without

pounding a post.

If the hammer must be lowered without

driving a post, slowly lower the hammer using

the control lever.

IM15 R1 45

6. OPERATION WHEATHEART - POST POUNDER

6.5. OPERATING THE S2000 POST POUNDER S2000 MODEL

46 IM15 R1

WHEATHEART - POST POUNDER 7. MAINTENANCE

Warning: Before continuing, ensure you have read and understand the relevant information

in the safety section. Safety information is provided to help prevent serious injury, death, or

property damage.

S2000 MODEL

7.Maintenance

Before performing any maintenance on this unit:

• shut off and remove key or lock-out the power source,

• ensure ballast box is lowered completely, and mast is secured with lock bars.

Table 7.1 Standard Maintenance Schedule

MAINTENANCE DAILY WEEKLY ANNUALLY

Check cylinder bolts for tightness

Tighten cylinder cap

Check hugger plastic rollers (replace if damaged)

Check mast bolts for tightness

Check top hammer stop bolts for tightness

Check for cracks in frame

Check that all hitch, linch and link pins are secured by hair-

pins where required

Check for main pivot pin tightness

Inspect PTO pump condition

Inspect hydraulic cylinder seals

Inspect hydraulic hoses and connectors

Inspect hydraulic oil (level and condition)

Change oil filter

a

- - --

- - - --

- - - - --

--

Add or change hydraulic oil

a. Annually or more often, according to usage. See “Changing the Oil Filter (PTO Kit)” on page 48.

b. As required. See “Adding or Replacing Hydraulic Fluid (PTO Kit)” on page 48.

b

---

IM15 R1 47

7. MAINTENANCE WHEATHEART - POST POUNDER

7.1. CHANGING THE OIL FILTER (PTO KIT) S2000 MODEL

7.1. CHANGING THE OIL FILTER (PTO KIT)

Change the hydraulic oil filter once a year (minimum), and more often according

to the number of hours of use specified by the oil filter manufacturer.

Wheatheart ships the S2000 Post Pounder equipped with an LHA Products

SPE-15-10, 10-micron filter (rating Beta 10>2). This filter can be replaced by the

same product, or by an oil filter of equivalent performance and physical characteristics.

LHA recommends that you replace the filter after the first 100 hours of operation,

and then after every 250 hours of use. Replacement recommendations for equivalent filters may differ.

NOTICE

Failure to replace the oil filter regularly will contribute to

wear of hydraulic components, and may decrease the

effective life span of the hydraulic fluid.

7.2. ADDING OR REPLACING HYDRAULIC FLUID (PTO KIT)

You will be required to top up the hydraulic tank occasionally to make up for fluid

losses that may occur (e.g. changing the oil filter or other hydraulic components).

When adding hydraulic oil to the hydraulic tank, make sure that the oil you are

adding is compatible with the oil already in the tank.

NOTICE

Topping up the hydraulic tank with an incompatible oil may

decrease the post pounder’s performance, and may

damage hydraulic components.

Drain and replace the hydraulic fluid when it has exceeded its recommended

number of hours of usage. The effective lifespan of a hydraulic oil depends on

the way the post pounder has been maintained and operated, as well as the

specifications of the oil used. Refer to the hydraulic oil manufacturer’s specifications for information about effective oil lifespan.

See “Filling the Hydraulic Tank” on page 34 for hydraulic oil recommendations.

NOTICE

Failure to change the hydraulic fluid after it has exceeded its

recommended life span will lead to increased wear and

damage of hydraulic components.

48 IM15 R1

WHEATHEART - POST POUNDER 7. MAINTENANCE

S2000 MODEL 7.3. REPLACING THE MAST SEAL

7.3. REPLACING THE MAST SEAL

The mast seal kit consists of the following (see Figure 7.1):

• a large O-ring (1)

• a small O-ring (2)

• a buffer (3)

• a polypak (4)

• a dust seal (5)

Figure 7.1 S2000 Mast Seal Kit

Note: Ensure that O-rings are not twisted when placed into the cylinder mast cap.

Twisted O-rings will result in a faulty seal and may cause leaks.

1. Place the large O-ring (1) through the bottom (threaded side) of the mast

cylinder cap (6) into the first groove above the threads.

2. Through the bottom of the mast cylinder cap (6), install the small O-ring (2)

and the buffer (3) into the next recession above the large O-ring (1).

Important: Ensure that the lip on the buffer faces the pressure side (down).

3. Install the polypak (2) into the second groove from the top (wrench side) of

the mast cylinder cap (4). Ensure that the side of the polypak (2) with the oring embedded into it faces the pressure side (down).

4. Insert the dust seal (5) into the top recession with tapered side facing up.

IM15 R1 49

7. MAINTENANCE WHEATHEART - POST POUNDER

7.3. REPLACING THE MAST SEAL S2000 MODEL

50 IM15 R1

WHEATHEART - POST POUNDER 8. STORAGE

Warning: Before continuing, ensure you have read and understand the relevant information

in the safety section. Safety information is provided to help prevent serious injury, death, or

property damage.

S2000 MODEL

8.Storage

To ensure a long, trouble-free life, the following procedure should be followed

when preparing the unit for storage after the season’s use.

• Lock out all power.

• Store the machine on a level surface, free of debris, and in an area away

from human activity. Store in a dry place, or use a tightly secured tarp to

protect the equipment from the weather.

• Ensure that the unit is in transport position.

• Remove all residual material and clean the machine thoroughly.

• Inspect the unit at stress points for cracks.

• Repair or replace any worn or damaged components to prevent any

unnecessary downtime at the start of the next season.

• Touch up paint nicks and scratches to prevent rusting.

• Check hydraulic fittings, hoses, lines, couplers, and valves. Tighten any

loose fittings. Replace any hose that is badly cut, nicked, abraded, or is

separating from the crimped end of the fitting. Secure the hoses to the

machine.

• Inspect and tighten all fasteners; replace fasteners if required.

• Inspect mast cylinder head nut and other hydraulic cylinders for leaks.

Replace seals if necessary.

• Retract all cylinders or grease exposed shafts.

IM15 R1 51

8. STORAGE WHEATHEART - POST POUNDER

S2000 MODEL

52 IM15 R1

WHEATHEART - POST POUNDER 9. TROUBLESHOOTING

S2000 MODEL

9.Troubleshooting

PROBLEM CAUSE SOLUTION

Loose/cracked fittings Tighten/replace fittings

Valve is leaking

Hydraulic cylinder

leaking

Mast cylinder is

leaking

Mast tilts too

slowly

Hammer rises too

quickly

Hammer rises too

slowly

or

Hammer raises

part way, sticks,

and stops

Hammer drops too

slowly

Hammer drops

quickly, but does

not deliver enough

force to drive post

Worn hose Replace hose

Valve spools are worn Replace valve

Worn seal Replace seal

Loose cylinder cap

Head nut is loose Tighten nut

Worn seal Replace seal

Low system flow/pres-

sure

Hydraulic oil level is low Check oil level and add oil if required

Hydraulic line blocked or

kinked

Mechanical binding

Excessive system flow/

pressure

Low system flow/pres-

sure

Oil too hot

Hydraulic line blocked or

kinked

Mechanical binding

Excessive ballast Reduce ballast weight to 280 lbs or less

Mechanical binding

Return line restricted

(blocked, kinked, or otherwise impeded)

Ballast too light Increase ballast weight, but do not exceed 280 lbs.

Hidden obstruction in soil

Soil too hard, post too

large

Tighten cap bolts and monitor leak. If leak persists,

replace cylinder seal

Increase PTO speed or hydraulic flow from tractor

1) Suction blocked hose(s)

2) Replace kinked hose(s)

Check for any obstructions to mast movement,

including hoses, lock bars.

Decrease PTO speed or hydraulic flow from tractor

Increase PTO speed or hydraulic flow from tractor

Tank level low, wrong oil used, oil is contaminated,

or ambient temperature is high for rate of operation.

1) Suction blocked hose

2) Replace kinked hose

Check for any cause of binding or obstruction

between mast parts. Check mast assembly for misalignment, bent mast, broken welds, loose or missing bolts, misaligned components.

Check for any obstructions to mast movement,

including hoses, lock bars.

Suction out blocked lines, and replace kinked hoses

or non-Wheatheart connectors that might obstruct

flow.

Large tree roots or rocks can impede or stop post

from being driven. Reposition post and attempt

again.

It is possible that some combinations of very hard

soils combined with large post diameters will make

pounding a post slow or impossible.

Solution: pre-drill post holes or cut a point on the end

of the post.

IM15 R1 53

9. TROUBLESHOOTING WHEATHEART - POST POUNDER

S2000 MODEL

54 IM15 R1

WHEATHEART - POST POUNDER 10. APPENDIX

S2000 MODEL 10.1. HYDRAULIC SYSTEM

10.Appendix

10.1. HYDRAULIC SYSTEM

Figure 10.1 shows the standard S2000 hydraulic diagram, and Table 10.1

describes the hydraulic connections.

Figure 10.1 S2000 Post Pounder Standard Hydraulic Diagram

Table 10.1 Hydraulic Hose Connections, Standard S2000

REF PART NO. DESCRIPTION LOCATION

1 H34X84 3/4X84,1/2MNPT X 3/4MNPT return, valve to tractor

2 H12X48P2W 1/2X48,1/2MNPT X 1/2MNPT valve to mast cylinder

3 H38X52 3/8X52,1/2MNPT X 1/2MNPT tilt cylinder lower, rod end

4 H38X55 3/8X55,1/2MNPT X 1/2MNPT tilt cylinder lower, cap end

5 H38X40P1 3/8X40,1/2MNPT X 1/2MNPT tilt cylinder top, rod end

6 H38X40P1 3/8X40,1/2MNPT X 1/2MNPT tilt cylinder top, cap end

7 H38X69 3/8X69,3/8MNPT X 1/2MNPT hugger, rod end

8 H38X65 3/8X65,3/8MNPT X 1/2MNPT hugger, cap end

9 H12X72P 1/2X72,1/2MNPT X 1/2MNPT pressure, valve to tractor

IM15 R1 55

10. APPENDIX WHEATHEART - POST POUNDER

10.1. HYDRAULIC SYSTEM S2000 MODEL

Figure 10.2 shows the S2000 PTO Kit Hydraulic diagram, and Table 10.2

describes the hydraulic connections.

Figure 10.2 S2000 Post Pounder Hydraulic Diagram, with PTO Kit Installed

Table 10.2 Hydraulic Hose Connections, PTO Kit

REF PART NO. DESCRIPTION LOCATION

1 H34X25 (new) 3/4X25,1/2MNPT X 3/4MNPT return, valve to filter

2 H12X48P2W 1/2X48,1/2MNPT X 1/2MNPT valve to mast cylinder

3 H38X52 3/8X52,1/2MNPT X 1/2MNPT tilt cylinder lower, rod end

4 H38X55 3/8X55,1/2MNPT X 1/2MNPT tilt cylinder lower, cap end

5 H38X40P1 3/8X40,1/2MNPT X 1/2MNPT tilt cylinder top, rod end

6 H38X40P1 3/8X40,1/2MNPT X 1/2MNPT tilt cylinder top, cap end

7 H38X69 3/8X69,3/8MNPT X 1/2MNPT hugger, rod end

8 H38X65 3/8X65,3/8MNPT X 1/2MNPT hugger, piston end

9 H12X72P 1/2X72,1/2MNPT X 1/2MNPT pressure, valve to PTO pump

10 H34X84* (partial) 3/4X37,1/2MNPT return, to tank from filter

11 H34X84** (partial) 3/4X47,3/4MNPT supply, from tank to PTO pump

* First part of hose H34X84, cut 37 inches from the 1/2” NPT connector

**Second part of hose H34X84, approximately 47” in length.

56 IM15 R1

LIMITED WARRANTY

Wheatheart warrants to the buyer that the new machinery is free from defects in material and

workmanship.

This warranty is only effective for any new machinery that has not been altered, changed,

repaired, or treated since its delivery to the buyer, other than by Wheatheart or its authorized

dealers or employees, and does not apply to accessories, attachments, tools, or parts sold or

operated with the new machinery if they have not been manufactured by Wheatheart.

Wheatheart shall only be liable for defects in the material or workmanship attributed to faulty

material or bad workmanship that can be proved by the buyer, and specifically excludes liability

for repairs arising as a result of normal wear and tear of the new machinery or in any other manner whatsoever, and without limiting the generality of the foregoing, excludes application or

installation of parts not completed in accordance with Wheatheart operation manual, specifications, or printed instructions.

A Warranty Registration Form and Inspection Report must be completed at the time of delivery

and returned to Wheatheart Manufacturing within thirty (30) days.

Warranty Period

Private Farm Use One (1) year from date of purchase.

Commercial, Custom, or Rental Use Ninety (90) days from date of purchase.

Replacement Parts Ninety (90) days from date of replacement

Defective parts are subject to inspection by a Wheatheart representative prior to approval of a

warranty claim. All returned parts must be sent to the factory, freight pre-paid, in order to qualify

for warranty replacement. Repaired or replaced parts will be returned freight collect.

If these conditions are fulfilled, Wheatheart shall at its own cost and its own option either repair

or replace any defective parts provided that the buyer shall be responsible for all expenses

incurred as a result of repairs, labor , part s, transporta tion, or any other work, unless Wheatheart

has authorized such expenses in advance. Normal wear and service items such as belts,

hoses, flashing, etc. are excluded from warranty.

The warranty shall not extend to any repairs, changes, alterations, or replacements made to the

new equipment other than by Wheatheart or its authorized dealers or employees.

This warranty extends only to the original owner of the new equipment.

This warranty is limited to the terms stated herein and is in lieu of any other warranties whether

expressed or implied, and without limiting the generality of the foregoing, excluded all warranties, expressed or implied, or conditions whether statutory or otherwise as to quality and fitness

for any purpose of the new equipment, Wheatheart disclaims all liability for incidental or consequential damages.

This machine is subject to design changes and Wheatheart shall not be required to retro-fit or

exchange items on previously sold units except at its own option.

WARRANTY VOID IF NOT REGISTERED

Wheatheart

Printed in Canada

Part of the Ag Growth International Inc. Group

P.O. Box 151

902 South St. Road 32

Union City, Indiana

Phone: 1-800-354-9502 or 1-765-964-4631

Fax: (765) 964-3529

Toll Free: (877) 934-0649 (Canada & USA)

website: www.wheatheart.com

email: sales@wheatheart.com

© Ag Growth International Inc. 2013

Loading...

Loading...