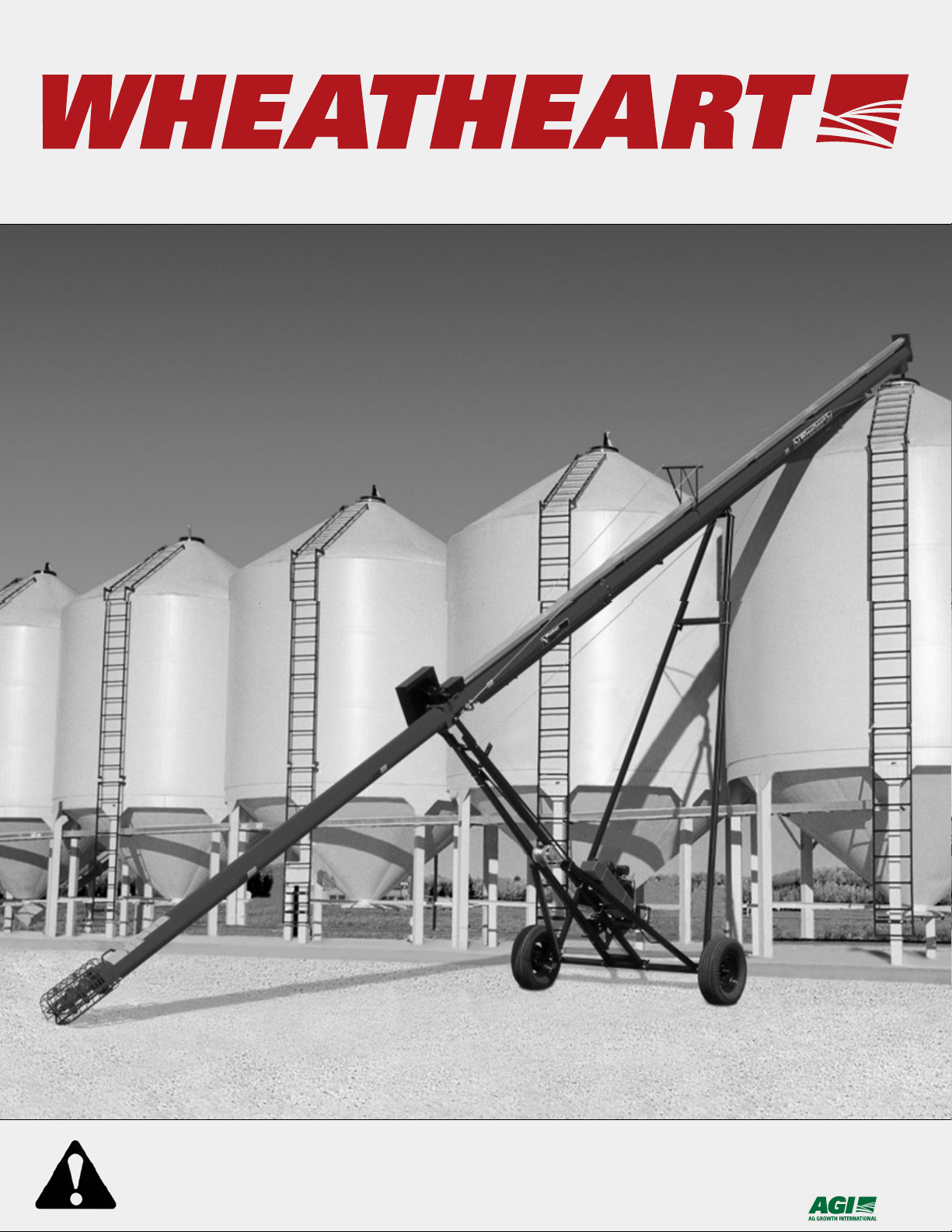

R SERIES AUGERS

R8-36, R8-41, R8-46, R8-51, R10-36, R10-41, & R10-51

OPERATION MANUAL

Read this manual befor

to follow instructions and safety precautions can

result in serious injury, death, or property

damage. Keep manual for future reference.

e using product. Failure

Part Number: 30758 R1

Revised: 7/6/12

This product has been designed and constructed according to general engineering

standardsa. Other local regulations may apply and must be followed by the operator.

We strongly recommend that all personnel associated with this equipment be trained

in the correct operational and safety procedures required for this product. Periodic

reviews of this manual with all employees should be standard practice. For your

convenience, we include this sign-off sheet so you can record your periodic reviews.

Date Employee Signature Employer Signature

a. Standards include organizations such as the American Society of Agricultural and Biological Engineers,

American National Standards Institute, Canadian Standards Association, International Organization for

Standardization, and/or others.

WHEATHEART - R SERIES AUGERS

R8-36, R8-41, R8-46, R8-51, R10-36, R10-41, & R10-51

TABLE OF CONTENTS

1. Introduction .......................................................................................................................... 5

1.1. Pre-Delivery Checklist .............................................................................................. 6

1.1.1. Mechanical ................................................................................................. 6

1.1.2. Safety ......................................................................................................... 6

2. Safety First............................................................................................................................ 7

2.1. General Safety ......................................................................................................... 8

2.2. Operating Safety ...................................................................................................... 9

2.3. Transport Safety....................................................................................................... 9

2.4. Storage Safety........................................................................................................ 10

2.5. Maintenance Safety................................................................................................ 10

2.6. Safety Decal Locations........................................................................................... 12

2.6.1. Decal Installation/Replacement ................................................................ 12

2.6.2. Decal Locations ........................................................................................ 12

3. T ranspor t............................................................................................................................. 15

4. Placement ........................................................................................................................... 19

5. Operation ............................................................................................................................ 21

5.1. Description Of The Equipment ............................................................................... 21

5.2. Operator Controls................................................................................................... 22

5.3. Auger Drive & Lockout ........................................................................................... 23

5.4. Operating Procedures ............................................................................................ 24

5.4.1. Break-in Period......................................................................................... 24

5.4.2. Operation.................................................................................................. 25

5.4.3. Shutdown.................................................................................................. 26

5.4.4. Cleanout ................................................................................................... 27

30758 R1 3

WHEATHEART - R SERIES AUGERS

R8-36, R8-41, R8-46, R8-51, R10-36, R10-41, & R10-51

TABLE OF CONTENTS

6. Maintenance........................................................................................................................ 29

6.1. Fluids & Lubricants ................................................................................................. 29

6.1.1. Storage & Handling................................................................................... 29

6.2. Maintenance Intervals ............................................................................................ 30

6.3. Maintenance Procedures........................................................................................ 30

6.3.1. Visual Inspection....................................................................................... 30

6.3.2. Servicing Upper Chain Drive .................................................................... 31

6.3.3. Greasing Machine..................................................................................... 31

6.3.4. Cleaning Machine ..................................................................................... 32

6.3.5. Repacking Wheel Bearings ...................................................................... 32

6.3.6. Tightening Wheel Bolts............................................................................. 32

6.3.7. Service Engine.......................................................................................... 33

6.3.8. Checking Gear Box Oil Levels.................................................................. 33

6.3.9. Changing Gearbox Oil .............................................................................. 33

6.3.10. Truss Cable Service (R 851 Auger Only) ............................................... 34

6.3.11. PTO Driveline ......................................................................................... 35

6.3.12. Winch (R 841, 846, 1041, and 851 Augers Only) ................................... 35

6.3.13. Replacing Belts....................................................................................... 35

6.3.14. Tightening Belts ...................................................................................... 36

7. Storage................................................................................................................................ 37

8. Troubleshooting................................................................................................................. 39

9. Appendix............................................................................................................................. 41

9.1. Specifications ......................................................................................................... 41

9.2. Bolt Torque Values ................................................................................................ 42

9.3. Tightening Flare Type Tube Fittings....................................................................... 43

9.4. Tightening O-Ring Fittings...................................................................................... 44

Limited Warranty ..................................................................................................................... 45

4 30758 R1

WHEATHEART - R SERIES AUGERS 1. INTRODUCTION

R8-36, R8-41, R8-46, R8-51, R10-36, R10-41, & R10-51

1.Introduction

Congratulations on the purchase of your new Wheatheart R Series Auger. This

piece of equipment will complement your agricultural operation by aiding in the

safe and efficient movement of grain, pulse crops, fertilizer, or any other granular

materials.

Your new Wheatheart auger will serve you well if you understand how it

operates, if you use it properly, and if you care for it properly. This manual is

intended to help you operate your equipment in a safe, efficient, and trouble-free

manner. Please read this manual completely before operating your new grain

auger.

This operator’s manual covers all R Series augers built by Wheatheart Manufacturing, so please use the Table of Contents as a guide when searching for

specific information. Keep this manual in a safe place for future reference.

Should any information remain unclear after thoroughly reviewing this manual,

contact your Wheatheart dealer for clarification before operating your auger.

Knowing the serial number and date of purchase will save time in getting your

questions answered. Please write down this information in the space provided

below.

30758 R1 5

1. INTRODUCTION WHEATHEART - R SERIES AUGERS

1.1. PRE-DELIVERY CHECKLIST R8-36, R8-41, R8-46, R8-51, R10-36, R10-41, & R10-51

1.1. PRE-DELIVERY CHECKLIST

1.1.1. MECHANICAL

• All fasteners tightened.

• Belts present and adjusted to proper tension.

• Upper chain drive adjusted and lubricated.

• Auger rotates freely.

• Tire pressure within manufacturer’s specification.

• Wheel bolt torque within specification.

• Winch brake and locking mechanism tested, lock engages properly, and

brake prevents freewheeling. There should be at least 3 wraps of cable

around winch drum in the fully down position.

• Winch cable checked for damage such as fraying, kinks, or unraveling. Cable

anchor on winch drum must be tight.

• Gearbox oil level checked.

• Engine oil level checked.

• Machine greased.

• Machine cleaned.

1.1.2. SAFETY

• All guards and shields installed, secured, and functional.

• All safety signs installed and legible.

• Reflectors installed and clean.

• Operating and safety instructions reviewed with owner.

• Operator’s Manual supplied to owner.

6 30758 R1

WHEATHEART - R SERIES AUGERS 2. SAFETY FIRST

R8-36, R8-41, R8-46, R8-51, R10-36, R10-41, & R10-51

2.Safety First

The Safety Alert symbol to the left identifies important safety messages on the

product and in the manual. When you see this symbol, be alert to the possibil-

ity of personal injury or death. Follow the instructions in the safety messages.

Why is SAFETY important to you?

Three big reasons:

• Accidents disable and kill.

• Accidents cost.

• Accidents can be avoided.

SIGNAL WORDS

Note the use of the signal words DANGER, W ARNING, CAUTION, and NOTICE

with the safety messages. The appropriate signal word for each message has

been selected using the definitions below as a guideline.

The Safety Alert symbol means: “ATTENTION, BE ALERT! YOUR SAFETY IS

INVOLVED”.

DANGER

Indicates an imminently hazardous situation

that, if not avoided, will result in serious injury

or death.

WARNING

Indicates a hazardous situation that, if not

avoided, could result in serious injury or

death.

CAUTION

Indicates a hazardous situation that, if not

avoided, may result in minor or moderate

injury.

NOTICE

Indicates a potentially hazardous situation that, if not

avoided, may result in property damage.

30758 R1 7

2. SAFETY FIRST WHEATHEART - R SERIES AUGERS

2.1. GENERAL SAFETY R8-36, R8-41, R8-46, R8-51, R10-36, R10-41, & R10-51

2.1. GENERAL SAFETY

Important: This general safety section includes instructions that apply to all safety practices.

Any instructions specific to a certain safety practice (e.g., assembly safety), can

be found in the appropriate section. Always read the complete instructional

sections and not just these safety summaries before doing anything with the

equipment.

YOU are responsible for the SAFE use and maintenance of your equipment.

YOU must ensure that you and anyone else who is going to work around the

equipment understands all procedures and related SAFETY information

contained in this manual.

Remember, YOU are the key to safety. Good safety practices not only protect

you, but also the people around you. Make these practices a working part of your

safety program.

• It is the equipment owner and the operator's responsibility to read and under-

stand ALL safety instructions, safety decals, and manuals and follow them

before assembling, operating, or maintaining the equipment. All accidents

can be avoided.

• Equipment owners must give instructions and review the information initially

and annually with all personnel before allowing them to operate this product.

Untrained users/operators expose themselves and bystanders to possible

serious injury or death.

• Use this equipment for its intended purposes only.

• Do not modify the equipment in any way. Unauthorized modification may

impair the function and/or safety, and could affect the life of the equipment.

Any modification to the equipment voids the warranty.

• Do not allow children, spectators, or bystanders within the work area.

• Have a first-aid kit available for use should the need arise, and know how to

use it.

• Provide a fire extinguisher for use in case of an accident. Store in a highly visible and accessible place.

• Wear appropriate protective gear. This list includes, but

is not limited to:

• a hard hat

•gloves

• protective shoes with slip-resistant soles

• protective goggles

• hearing protection

• dust mask or respirator

• For Powered Equipment: before servicing, adjusting, or repairing powered

equipment, unplug, place all controls in neutral or off position, stop the engine

or motor, remove ignition key or lock out power source, and wait for all moving parts to stop.

8 30758 R1

WHEATHEART - R SERIES AUGERS 2. SAFETY FIRST

R8-36, R8-41, R8-46, R8-51, R10-36, R10-41, & R10-51 2.2. OPERATING SAFETY

• Follow good shop practices:

• keep service area clean and dry

• be sure electrical outlets and tools are properly

grounded

• use adequate light for the job at hand

• Think SAFETY! Work SAFELY!

2.2. OPERATING SAFETY

• Ensure guards are present and secure.

• Clear the work area of unauthorized persons, particularly small children and

pets.

• Clean the work area to prevent slipping or tripping.

• Ensure a fully equipped first aid kit is on hand and that you know how to use

it.

• Ensure a working fire extinguisher is on hand and that you know how to use

it.

• Be certain the PTO driveline is securely attached to the jackshaft and to the

tractor.

• Before starting tractor, be certain that power to PTO is in the off position

• Keep hands, feet, hair, and clothing away from all moving or rotating parts.

2.3. TRANSPORT SAFETY

• Ensure tires are inflated to the tire manufacturer’s recommended pressure.

• Check with local authorities regarding transportation of agricultural equipment

on public roads. Obey all applicable laws and regulations.

• Make sure that all lights and reflectors required by the local highway and

transport authorities are in place, are functioning, and can be seen clearly by

all overtaking and oncoming traffic.

• Be sure the unit is hitched securely to the towing vehicle.

• Do not allow riders while transporting.

• Display a Slow Moving Vehicle emblem when transporting below 25 mph (40

km/h).

• Use hazard-warning flashers when transporting with a tractor unless prohibited.

• Keep to the right and yield the right-of-way to allow faster traffic to pass.

• Never transport faster than the road terrain or conditions will allow you to do

safely.

• Use caution when making corners or meeting traffic.

• Use caution when approaching height-limiting objects.

• Take special care and precautions when transporting during times of limited

visibility such as rain, snow, fog, dusk, or at night. It is recommended that you

wait for a more appropriate time to move.

• Use caution when turning or cornering.

30758 R1 9

2. SAFETY FIRST WHEATHEART - R SERIES AUGERS

2.4. STORAGE SAFETY R8-36, R8-41, R8-46, R8-51, R10-36, R10-41, & R10-51

• Do not transport auger on a slope greater than 20°. The auger may overturn.

2.4. STORAGE SAFETY

• Store in an area away from human activity.

• Do not permit children to play on or around the stored machine.

2.5. MAINTENANCE SAFETY

• Shut off and disable the power source before working on the machine.

• Ensure service area is clean and dry.

• Ensure electrical outlets and tools are properly grounded.

• Use proper tools for the job.

• Ensure there is adequate lighting to perform the job safely.

• Wear safety gear that is appropriate for the job being performed.

• Use extra caution when cleaning and servicing augers because flighting

edges can become sharp.

• Follow proper procedures when mounting a tire on a rim. If in doubt, have a

qualified tire repair service perform the required maintenance.

• Install and secure all guards after maintenance work is completed.

10 30758 R1

WHEATHEART - R SERIES AUGERS 2. SAFETY FIRST

R8-36, R8-41, R8-46, R8-51, R10-36, R10-41, & R10-51 2.5. MAINTENANCE SAFETY

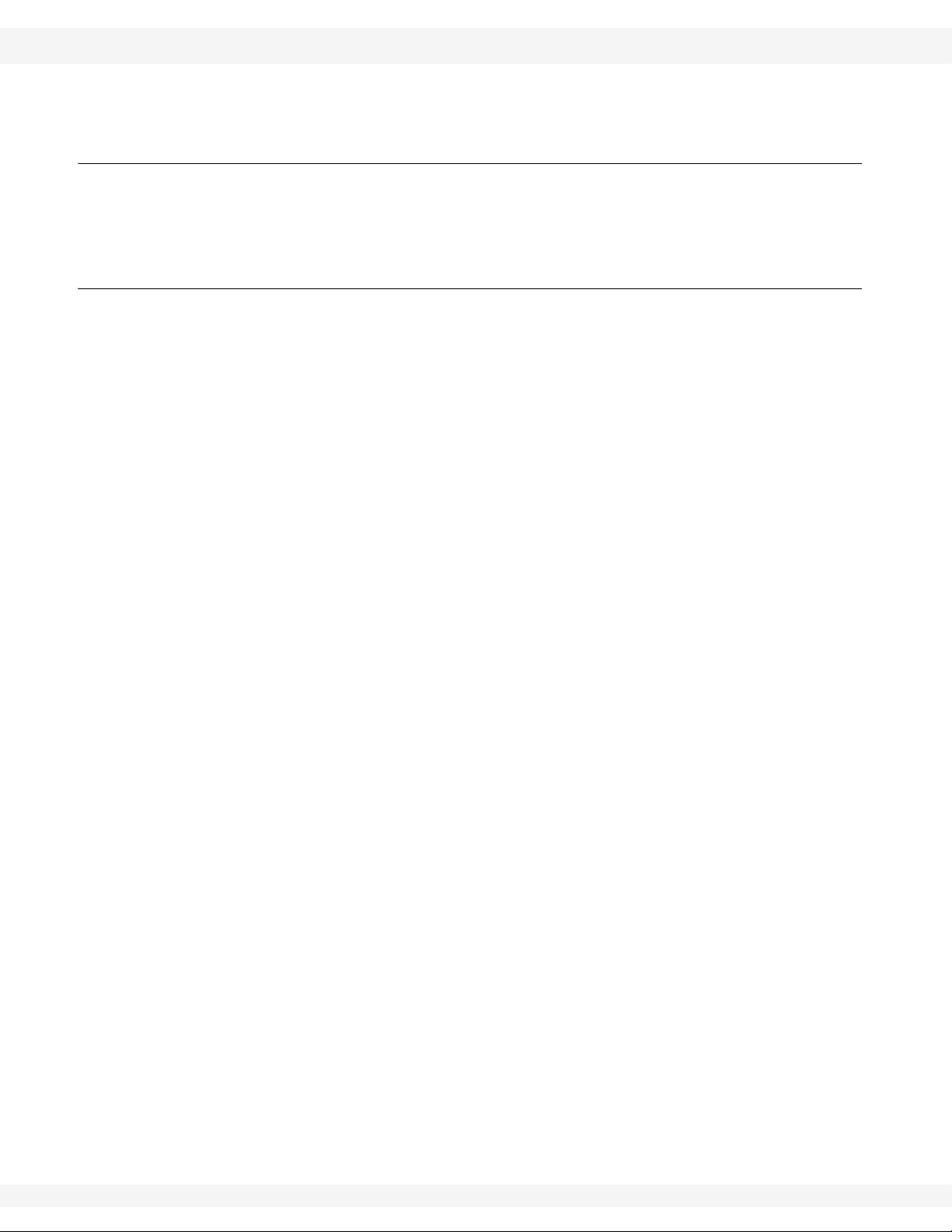

Figure 2.1 Safety Work Area

30758 R1 11

2. SAFETY FIRST WHEATHEART - R SERIES AUGERS

2.6. SAFETY DECALS R8-36, R8-41, R8-46, R8-51, R10-36, R10-41, & R10-51

2.6. SAFETY DECALS

• Keep safety decals clean and legible at all times.

• Replace safety decals that are missing or have become illegible. See decal

location figures that follow.

• Replaced parts must display the same decal(s) as the original part.

• Safety decals are available from your distributor, dealer, or factory.

2.6.1. DECAL INSTALLATION

1. Decal area must be clean and dry, with a temperature above 50°F (10°C).

2. Decide on the exact position before you remove the backing paper.

3. Align the decal over the specified area and carefully press the small portion

with the exposed sticky backing in place.

4. Slowly peel back the remaining paper and carefully smooth the remaining

portion of the decal in place.

5. Small air pockets can be pierced with a pin and smoothed out using the sign

backing paper.

2.6.2. SAFETY DECAL LOCATIONS

Replicas of the safety decals that are attached to the equipment are shown in the

figure(s) that follow. Proper safety procedures require that you familiarize

yourself with the various safety decals and the areas or particular functions that

the decals apply to as well as the safety precautions that must be taken to avoid

serious injury, death, or damage.

12 30758 R1

WHEATHEART - R SERIES AUGERS 2. SAFETY FIRST

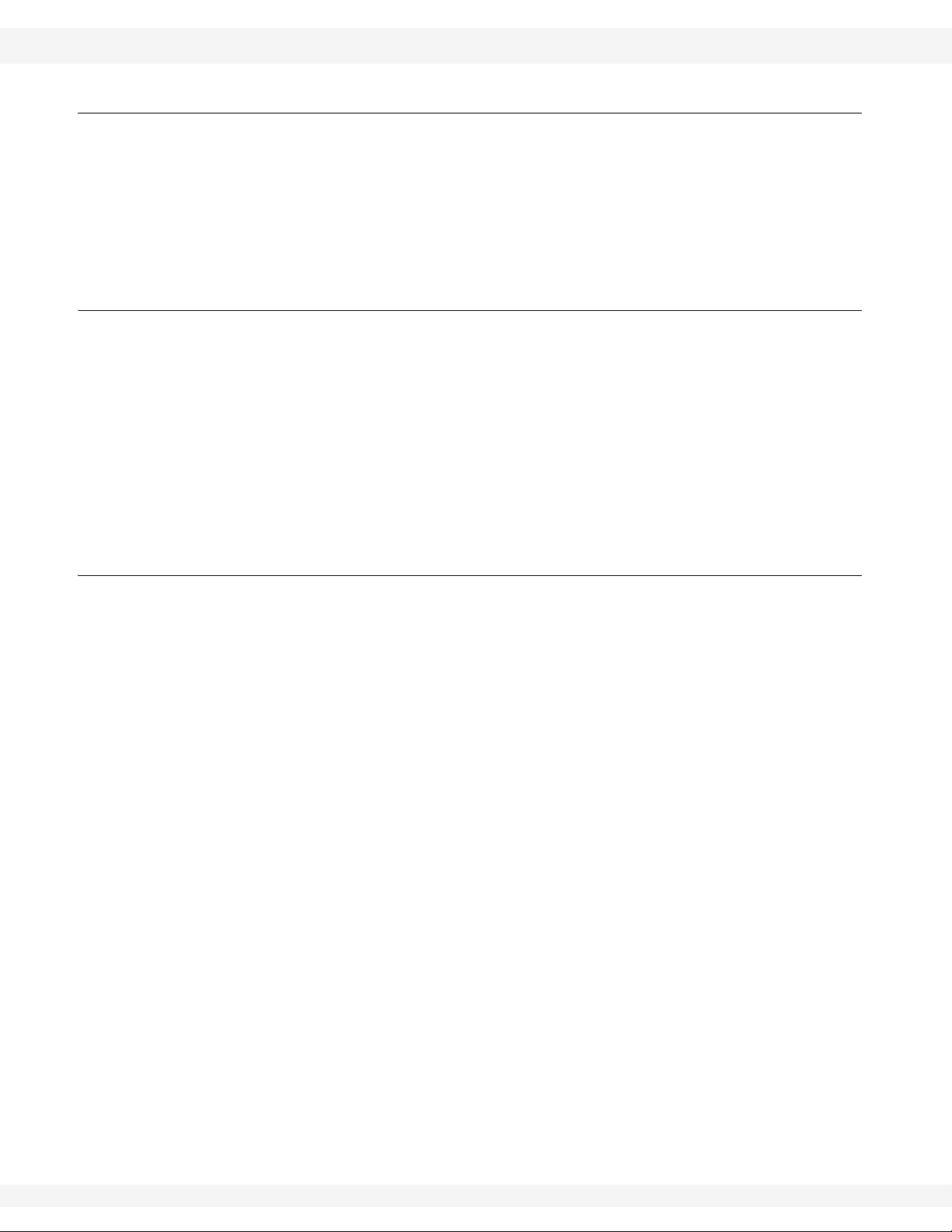

DECAL #17102

DECAL #17098

DECAL #17101

DECAL #17097

DECAL #19960

DECAL #17109

DECAL #17096

DECAL #17113

R8-36, R8-41, R8-46, R8-51, R10-36, R10-41, & R10-51 2.6. SAFETY DECALS

Figure 2.2 Safety Decals

30758 R1 13

2. SAFETY FIRST WHEATHEART - R SERIES AUGERS

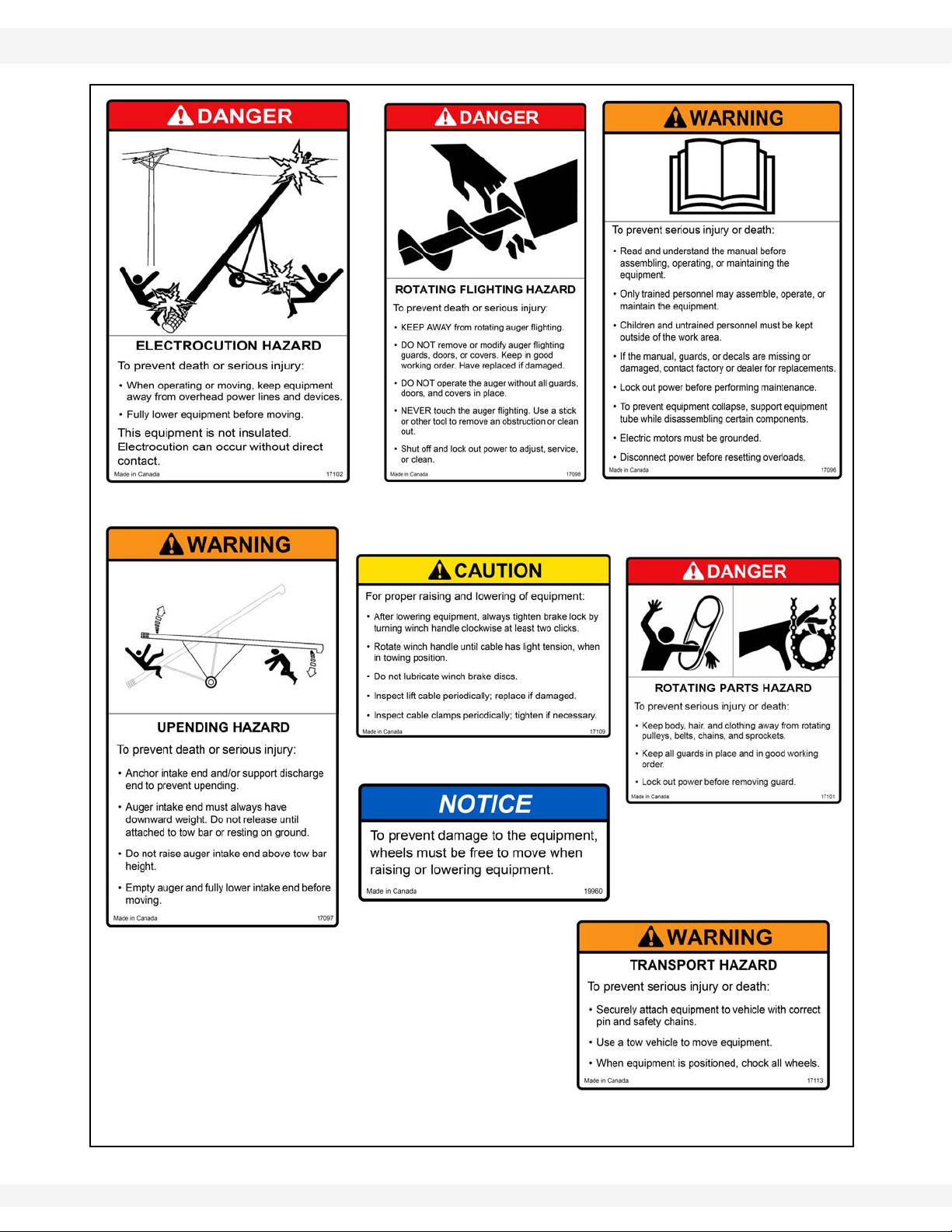

DECAL # 17096

DECAL # 19960

DECAL # 17109

DECAL #17097

DECAL #17102

DECAL #17098

DECAL #17101

DECAL # 17113

2.6. SAFETY DECALS R8-36, R8-41, R8-46, R8-51, R10-36, R10-41, & R10-51

Figure 2.3 Safety Decal Locations

If safety signs have been damaged, removed, or become illegible, or if parts are

replaced without safety signs, new signs must be applied. New safety signs are

available from your authorized dealer.

14 30758 R1

WHEATHEART - R SERIES AUGERS 3. TRANSPORT

Warning: Before continuing, ensure you have read and understand the relevant information

in the safety section. Safety information is provided to help prevent serious injury, death, or

property damage.

R8-36, R8-41, R8-46, R8-51, R10-36, R10-41, & R10-51

3.Transport

DANGER

Electrocution hazard:

• This auger is not insulated.

• Keep auger away from overhead power

lines and devices.

• Electrocution can occur without direct

contact.

• Fully lower auger before moving.

Failure to keep away will result in serious

injury or death.

NOTICE

Empty the auger before transporting. Transporting a full

auger will place excessive loads on the tube assembly,

frame, axle assembly, hitch, and towing unit.

If auger wheels are partially or fully buried in snow or grain,

do not attempt to move auger until snow or grain has been

cleared away from auger wheels.

WHEN TRANSPORTING:

WARNING

Failure to secure the unit prior to transporting

could cause a serious hazard to the occupants of

the towing vehicle or of other vehicles.

To reduce the risk of injury or death to people using this equipment, follow basic

safety precautions:

• Ensure tires are inflated to the tire manufacturers’ recommended pressure.

• Check with local authorities regarding transportation of agricultural equipment

on public roadways. Obey all applicable laws and regulations.

• Make sure that all lights and reflectors required by law are in place, functioning, and can be seen by all overtaking and oncoming traffic.

• Ensure the unit is hitched securely to the towing vehicle.

30758 R1 15

3. TRANSPORT WHEATHEART - R SERIES AUGERS

R8-36, R8-41, R8-46, R8-51, R10-36, R10-41, & R10-51

• Display a SMV (slow moving vehicle) emblem when transporting slower than

25 mph (40 km/hr). Never transport faster than road, terrain, or conditions will

allow you to safely.

WARNING

A vehicle imbalance between the towing

vehicle and the machine could reduce your

vehicle’s stability, handling, and braking

ability, and could lead to an upset or collision.

Transport at a speed that road conditions

allow, to a maximum speed of 20 mph

(32 km/h)

• Take special care and precautions when transporting during times of limited

visibility such as rain, snow, fog, dusk, or at night. It is recommend that you

wait for a more appropriate time to move.

• Use hazard-warning lights when transporting with a tractor, unless prohibited.

• Keep to the right and yield the right-of-way to allow faster traffic to pass.

• Use caution when turning corners or meeting traffic.

• Be aware of height limiting objects.

• Do not transport the auger on a slope greater than 20°. The auger may overturn.

DANGER

Upending Hazard:

Do not raise auger intake above tow bar

height.

Empty auger and lower fully before moving.

Failure to do so will result in serious injury or

death.

The Wheatheart auger is designed to be easily and conveniently readied for

transport. Follow this procedure when converting the machine from operating to

transport configuration.

1. Make sure work area is clear of any obstructions before lowering.

2. Connect the auger to the towing vehicle and use a retainer to lock the hitch

draw pin in place.

3. Place the belts under tension.

4. Remove all wheel chocks.

5. Lower the auger until the roller track shoe is resting on the down position

stop, and there is slight tension on the lift cable.

6. Lock the winch into place by turning the handle clockwise until 2 clicks are

heard.

7. Place the PTO driveline in the transport saddle and secure (PTO drive only).

16 30758 R1

WHEATHEART - R SERIES AUGERS 3. TRANSPORT

SAFETY CHAIN

• The safety chain should be threaded through the handle on the lower

tube, and wrapped around the auger tube before attaching to the towing

vehicle.

• The loop should form a cradle that will prevent the auger from digging

into the road surface or upsetting, should a breakaway occur.

• Ensure there is no more slack in the chain than required for turning.

• When not in use, store the safety chain in a clean, dry place. Replace

the safety chain if one or more links or end fittings are broken,

stretched, or otherwise damaged, or deformed.

R8-36, R8-41, R8-46, R8-51, R10-36, R10-41, & R10-51

8. Install the safety chain between the auger and the frame of the towing unit.

Important: The chain must have a load rating at least as high as the auger weight.

CAUTION

After lowering auger, always turn winch

handle clockwise at least 2 clicks to tighten

brake lock.

Maintain control of winch handle at all times.

Maintain light cable tension when in towing

position.

Do not put lubrication on brake disc.

Check cable before each use and replace if

frayed or damaged.

Make certain that cable clamps are securely

tightened.

30758 R1 17

3. TRANSPORT WHEATHEART - R SERIES AUGERS

R8-36, R8-41, R8-46, R8-51, R10-36, R10-41, & R10-51

18 30758 R1

WHEATHEART - R SERIES AUGERS 4. PLACEMENT

Warning: Before continuing, ensure you have read and understand the relevant information

in the safety section. Safety information is provided to help prevent serious injury, death, or

property damage.

R8-36, R8-41, R8-46, R8-51, R10-36, R10-41, & R10-51

4.Placement

DANGER

Electrocution hazard:

• This auger is not insulated.

• Keep auger away from overhead power

lines and devices.

• Electrocution can occur without direct

contact.

• Fully lower auger before moving.

Failure to keep away will result in serious

injury or death.

When placing the auger, follow these instructions and see Figure 4.1.

1. Check for power lines or any obstructions that may damage the auger.

2. Move the machine under the truck or storage facility.

3. Place the auger on a firm, level surface.

4. Chock the wheels before augering any products.

5. Always use a vehicle or mover to move the auger. Never move it by hand.

6. Do not place anything under the wheels to add height to the auger.

7. To prevent upending or the wind upsetting the auger: when operating the

auger in raised position, rest the discharge end on the bin roof or tie it down

to the bin. When operating the auger in a free-standing position, anchor the

intake end.

.

Figure 4.1

30758 R1 19

4. PLACEMENT WHEATHEART - R SERIES AUGERS

R8-36, R8-41, R8-46, R8-51, R10-36, R10-41, & R10-51

20 30758 R1

WHEATHEART - R SERIES AUGERS 5. OPERATION

Warning: Before continuing, ensure you have read and understand the relevant information

in the safety section. Safety information is provided to help prevent serious injury, death, or

property damage.

R8-36, R8-41, R8-46, R8-51, R10-36, R10-41, & R10-51 5.1. DESCRIPTION OF THE EQUIPMENT

5.Operation

5.1. DESCRIPTION OF THE EQUIPMENT

The Wheatheart Auger is designed to efficiently handle grain, pulse crops, or

other granular materials. The auger comes field-ready and equipped with such

features as reinforced, low-pitch flighting at the intake for high capacity and

longer wear, a belt engaging lever that can be operated from either side, and a

frame design that allows for extra bottom reach for bin load-out applications.

Many features incorporated into this machine are the result of suggestions made

by customers like you. Read this manual carefully to learn how to operate the

machine safely and how to adjust it to provide maximum efficiency. By following

the operating instructions in conjunction with a good maintenance program, your

auger will provide many years of trouble-free service.

30758 R1 21

5. OPERATION WHEATHEART - R SERIES AUGERS

5.2. OPERATOR CONTROLS R8-36, R8-41, R8-46, R8-51, R10-36, R10-41, & R10-51

5.2. OPERATOR CONTROLS

Figure 5.1

The belt engaging lever, winch, and engine are located as shown in Figure 5.2.

Please refer to engine manual for engine controls.

Figure 5.2 Winch

22 30758 R1

WHEATHEART - R SERIES AUGERS 5. OPERATION

R8-36, R8-41, R8-46, R8-51, R10-36, R10-41, & R10-51 5.3. AUGER DRIVE & LOCKOUT

Figure 5.3 Belt Engaging Lever & Engine

5.3. AUGER DRIVE & LOCKOUT

Correct operation of the Wheatheart auger requires pre-inspection of the drive

system, operator knowledge on how to shut down the system, and a general

monitoring of the system during operation.

GAS ENGINE

DRIVE SYSTEM

Before starting the motor, ensure that:

1. The gas tank is properly closed.

2. The belt release is disengaged so that the belts are released from the motor

pulley.

3. The area surrounding the auger is properly ventilated.

4. Pulley shields are in place and secure.

LOCKOUT

1. Shut down and lock out power source.

2. For engines with a rope or crank start, remove the spark plug wire or the

spark plug. For engines with an electric start, remove the ignition key, the

spark plug wire, or the spark plug.

ELECTRIC MOTOR

DRIVE SYSTEM

Before starting the motor, ensure that:

1. The motor is properly grounded.

2. The belt release is disengaged so that belts are released from motor pulley.

3. Pulley shields are in place and secure.

LOCKOUT

1. The electric motor should be equipped with a main power disconnect switch

capable of being locked in the off position only. The switch should be in the

30758 R1 23

5. OPERATION WHEATHEART - R SERIES AUGERS

5.4. OPERATING PROCEDURES R8-36, R8-41, R8-46, R8-51, R10-36, R10-41, & R10-51

locked position during shutdown or whenever maintenance is performed on

the auger.

2. If reset is required, disconnect all power before resetting motor.

PTO DRIVELINE

DRIVE SYSTEM

1. Ensure that the PTO driveline is securely attached to the tractor and

jackshaft.

2. Do not use PTO driveline without a rotating shield in good working order.

3. Do not exceed the maximum operating angle of 15°

4. Be sure that the PTO-drive on the tractor is in the off position before starting

tractor.

5. Stay clear of the PTO hazard area.

LOCKOUT

1. Shut off engine.

2. Remove ignition key from tractor.

3. If step 2 is impossible, remove the PTO driveline from tractor.

5.4. OPERATING PROCEDURES

5.4.1. BREAK-IN PERIOD

Your auger does not require an elaborate break-in. However, following a few

simple tips during the first 1000 bu of operation can add to the reliability and life

of your machine.

If any unusual noises or vibrations are encountered, determine the source, shut

the auger off, lock out the power source, and adjust. If unsure of the problem, or

the procedure to fix it, contact your local Wheatheart dealer.

PRE OPERATION CHECKLIST:

• Read the power source operation manual.

• Inspect motor mounting bolts for tightness.

• Check oil level in the gear box by removing the filler plug. Make sure the

gear box is half full (center cross shaft) and free of foreign objects.

• Inspect all belts for alignment, tightness, and abnormal wear. Adjust or

replace as required.

• Inspect components for damage and abnormal wear. Replace as

required.

• Check that safety decals are installed and legible. Apply new decals if

required.

• Check the wheel bolt torque prior to transporting the unit. See Section

6.3.6. for recommended torque values.

• Check that tires are inflated to the manufacturer’s recommended pressure

prior to transporting the unit.

24 30758 R1

WHEATHEART - R SERIES AUGERS 5. OPERATION

R8-36, R8-41, R8-46, R8-51, R10-36, R10-41, & R10-51 5.4. OPERATING PROCEDURES

• Check the upper chain drive tension and alignment.

Please refer to the regular maintenance schedule given in Section 6.2. for

recommended service intervals after the break-in period.

5.4.2. OPERATION

The following items should be checked before operating the machine each time:

• Visually inspect the machine, check engine oil, and service the PTO driveline (if applicable).

• Check that the gas cap is in place (gas drives only).

• Ensure that all guards are in place, and secure.

• Check that drive belts are not frayed or damaged, and that they are properly adjusted and aligned.

• Ensure auger wheels are chocked.

• See that the discharge spout and intake area are free of obstructions.

• Ensure that operators are aware of safety precautions.

• Check that the cable is not frayed or damaged.

• Check that cable clamp(s) are secured.

NORMAL START-UP

NOTICE

Foreign objects can damage the auger. Remove any

obstructions from the intake and discharge areas before

operating the unit.

NOTICE

Engine must be idling before belts are engaged.

Engaging belts at high engine speed will result in premature

belt wear.

1. Disengage the belt engaging lever so the motor pulley is not under load.

2. Start the engine and then engage the belt engaging lever with engine at idle.

Note: The flighting rpm on auger equipped with electric motors is not adjustable.

DANGER

Rotating Flight Hazard: Keep away from

auger intake.

3. Increase the engine speed to achieve the desired augering speed.

4. If everything is operating normally, start running grain through the auger.

30758 R1 25

5. OPERATION WHEATHEART - R SERIES AUGERS

5.4. OPERATING PROCEDURES R8-36, R8-41, R8-46, R8-51, R10-36, R10-41, & R10-51

RESTARTING WITH A FULL TUBE

NOTICE

Always engage belts with engine idling. Engaging belts at

high engine speed will result in premature belt wear

The tube may be filled with material if the machine is shut down inadvertently or

for an emergency. It is recommended that you restart with the following

procedure:

1. With the power source locked out, remove as much of the grain as possible

from the tube and intake.

2. Start the engine and run it at half speed. Slowly engage the belt until the

auger is brought up to speed.

3. Once the auger has been started, increase the engine speed to achieve the

desired augering speed.

5.4.3. SHUTDOWN

NORMAL SHUTDOWN

1. Near the end of the load, reduce the feed of grain and decrease the auger

speed (if possible).

2. Run the auger until the tube is empty.

3. When auger is clear of grain, disengage the belt, and stop engine/motor, or

disengage the PTO.

4. Shut down, and lock out power source.

EMERGENCY STOP

Although it is recommended that the machine be emptied before stopping, in an

emergency situation:

1. Stop or shut down the power source immediately.

2. Stop the flow of material (if applicable).

3. Lock out power, and correct the emergency before resuming work.

NOTICE

Prolonged operation of an empty auger will cause

unnecessary wear.

26 30758 R1

WHEATHEART - R SERIES AUGERS 5. OPERATION

R8-36, R8-41, R8-46, R8-51, R10-36, R10-41, & R10-51 5.4. OPERATING PROCEDURES

WARNING

Lock out all power before attempting repairs /

removing obstructions.

5.4.4. CLEANOUT

1. Run the unit to clean out the majority of the grain.

2. Shut down and lock out the power source.

.

3. Clean grain from the auger and hopper, and dump it into a container.

30758 R1 27

5. OPERATION WHEATHEART - R SERIES AUGERS

5.4. OPERATING PROCEDURES R8-36, R8-41, R8-46, R8-51, R10-36, R10-41, & R10-51

28 30758 R1

WHEATHEART - R SERIES AUGERS 6. MAINTENANCE

Warning: Before continuing, ensure you have read and understand the relevant information

in the safety section. Safety information is provided to help prevent serious injury, death, or

property damage.

R8-36, R8-41, R8-46, R8-51, R10-36, R10-41, & R10-51 6.1. FLUIDS & LUBRICANTS

6.Maintenance

The Wheatheart Auger has been designed and manufactured to meet the

highest standards, while requiring minimal maintenance. Following a careful

service and maintenance program will provide many years of trouble-free

service.

When performing adjustments, service, or repa irs:

• Always take safety into consideation and note Section 2.5.

• Use extra caution when cleaning and servicing augers because flighting

edges can become sharp.

• Follow proper procedures when mounting a tire on a rim. If in doubt, have

a qualified tire repair service perform the required maintenance.

Do not modify the equipment.

Unauthorized modification may impair the function or safety

of the equipment, could affect the life of the equipment, and

will void your warranty.

6.1. FLUIDS & LUBRICANTS

ENGINE OIL

Refer to engine operation manual for recommended oil usage.

GEAR OIL

Use SAE approved 90W or equivalent gear oil.

GREASE

Use SAE multi-purpose high-temperature grease with extreme pressure (EP)

performance or SAE multi-purpose lithium based grease.

NOTICE

6.1.1. STORAGE & HANDLING

Always follow manufacturer’s guidelines for the safe and effective storage and

handling of lubricants.

Your machine can operate at top efficiency only if clean lubricants are used. Use

clean containers to handle all lubricants. Store them in an area protected from

dust, moisture, and other contaminants.

30758 R1 29

6. MAINTENANCE WHEATHEART - R SERIES AUGERS

6.2. MAINTENANCE INTERVALS R8-36, R8-41, R8-46, R8-51, R10-36, R10-41, & R10-51

6.2. MAINTENANCE INTERVALS

Refer to Section 6.3. for details of service.

Table 6.1 Maintenance Intervals

Time Period

Daily (8000)BU

Maintenance Procedure

Visually Inspect the Unit 6.3.1. X

Check engine oil level 6.3.7. X

Service PTO Driveline 6.3.11. X

Check Air Filter 6.3.7. X

Service Upper Chain Drive 6.3.2. X

Service Belts 6.3.13. X

6.3.14.

Grease Machine 6.3.3. X

Check Gear Box Oil Level 6.3.8. X

Check Winch 6.3.12. X

Clean Machine 6.3.4. X

Service Engine 6.3.7. X

Repack Wheel Bearings 6.3.5. X

Tighten Wheel Bolts 6.3.6. X

Change Gear Box Oil 6.3.9. X

Service Truss Cables (R 851 only) 6.3.10. X

6.3. MAINTENANCE PROCEDURES

6.3.1. VISUAL INSPECTION

Periodically (40,000)BU

Annually (Before Storage)

Annually (After Storage)

Before beginning the visual inspection, chock auger wheels and ensure that all

operators are aware of safety precautions.

When inspecting look for possible defects, and the following:

• Ensure all guards are in place, and in good working order.

• Examine the auger for damage or unusual wear.

• Inspect the machine for evidence of oil leaks.

• Examine hydraulic hoses and fittings for leaks and cracks.

• Be sure all safety decals are in place and are legible.

• Check that drive belts are not frayed or damaged. Ensure they are properly adjusted and aligned.

30 30758 R1

WHEATHEART - R SERIES AUGERS 6. MAINTENANCE

Figure 6.1 Auger Bushing

Figure 6.2 Upper Chain Driver

R8-36, R8-41, R8-46, R8-51, R10-36, R10-41, & R10-51 6.3. MAINTENANCE PROCEDURES

• Check that PTO driveline is connected securely (where applicable).

• Check that the discharge spout and

intake area are free of obstructions.

• Ensure that intake housing fasteners

are properly secured.

• Examine all flighting for damage or

unusual wear.

• Examine tires for gashes, uneven

wear, or loss of air pressure.

• Inspect auger shaft bushing for unusual wear or discoloration.

• Inspect all truss cables for tension,

and possible failure points.

• Inspect winch cable for fraying, kinks, unwinding, or other possible damage.

6.3.2. SERVICING UPPER CHAIN DRIVE

1. Lock out power.

2. Remove cover plate from discharge end of

auger.

3. Check chain slack.

• Chain slack is checked at the midpoint

of the longest span. It should be no

more than 5/16” (8 mm).

Improper adjustment of chain will result in premature wear.

4. Adjust the chain slack.

• Remove the connecting link from the chain.

• Remove a link from the chain; if the chain will not fit with one link removed,

add a half link to the chain and replace.

5. Grease the chain with appropriate lubricant (Section 6.1.)

6. Reattach cover plate.

NOTICE

6.3.3. GREASING MACHINE

Important: Original equipment bearings used by Wheatheart are sealed units and will not

accept grease.

30758 R1 31

6. MAINTENANCE WHEATHEART - R SERIES AUGERS

6.3. MAINTENANCE PROCEDURES R8-36, R8-41, R8-46, R8-51, R10-36, R10-41, & R10-51

1. Lockout all power.

2. Grease points on the machine are shown in Figure 6.3.

Figure 6.3 Upper Chain Drive Zerk & Intake Zerk

3. Use grease recommended in Section 6.1.

4. Use only a hand-held grease gun.

5. Wipe grease fitting with a clean cloth before greasing to avoid injecting dirt

and grit.

6. If a fitting will not take grease, remove and clean thoroughly. Also clean

lubricant passageway. Replace fitting if necessary.

7. Replace and repair broken fittings immediately.

6.3.4. CLEANING MACHINE

1. Lockout all power.

2. Clean out excess grain from auger tube and intake.

3. Make sure nothing is obstructing the auger intake so water can run out.

4. Wash the tube with a water hose or pressure washer until all dirt, mud, debris,

or residue is washed from the auger.

5. Provide sufficient time for the water to drain from the auger.

6.3.5. REPACKING WHEEL BEARINGS

1. Block wheels and ensure unit is stable.

2. Remove the wheel bolts and the wheels.

3. Remove the wheel bearing and pack with grease. Refer to Section 6.1. for

recommended grease.

6.3.6. TIGHTENING WHEEL BOLTS

1. Clean wheel and hub mounting surfaces to ensure there is no rust or debris.

2. Install the wheel and “finger tighten” the wheel bolts. Inspect to make sure the

wheel is sitting flush with the hub.

3. Tighten the wheel bolts with a torque wrench to 80 ft-lb (±10 ft-lb) of torque.

Note: Tighten the wheel bolts in a diagonal pattern as in Figure 6.4.

32 30758 R1

WHEATHEART - R SERIES AUGERS 6. MAINTENANCE

R8-36, R8-41, R8-46, R8-51, R10-36, R10-41, & R10-51 6.3. MAINTENANCE PROCEDURES

Figure 6.4 Diagonal Pattern

6.3.7. SERVICE ENGINE

1. See engine operation manual for service requirements.

6.3.8. CHECKING GEAR BOX OIL LEVELS

1. Lock out all power.

2. Remove oil filler plug.

3. Make sure the gearbox is half full (center of cross shaft) and free of foreign

objects. Gearbox should be level when checking gears.

6.3.9. CHANGING GEARBOX OIL

1. Remove guards and gearbox from auger.

2. Place a pan under the drain plug.

3. Use a wrench and remove the drain plug.

4. Loosen the filler plug so air can enter the gearbox and the oil will drain freely.

5. Allow the oil to drain completely.

6. Replace the drain plug.

7. Add oil until the gearbox is half full (center of cross shaft) and replace filler

plug. Gearbox should be level when checking or refilling. Do not overfill.

8. Reinstall gearbox and guards.

30758 R1 33

6. MAINTENANCE WHEATHEART - R SERIES AUGERS

6.3. MAINTENANCE PROCEDURES R8-36, R8-41, R8-46, R8-51, R10-36, R10-41, & R10-51

Figure 6.5 Gearbox

6.3.10. TRUSS CABLE SERVICE (R-851 & R-1051 AUGER ONLY)

1. Locate the eyebolt anchors for the cable. Refer to Figure 6.6.

Figure 6.6 Cable Adjustment

2. Tighten the nut on the eyebolt until there is enough tension in the cable as to

keep the tube straight.

3. If the proper cable tension cannot be obtained before the eyebolt runs out of

adjustment:

• Support auger tube.

• Loosen the eyebolts but do not remove the nut.

• Loosen the clamps on the cable on both sides.

• Shorten the cable until there is tension on the cable and tighten the

clamps.

• Return to step 2.

WARNING

Before doing anything to the trussing, ensure

auger tube is properly supported by overhead

crane or other proper lifting device.

34 30758 R1

WHEATHEART - R SERIES AUGERS 6. MAINTENANCE

R8-36, R8-41, R8-46, R8-51, R10-36, R10-41, & R10-51 6.3. MAINTENANCE PROCEDURES

6.3.11. PTO DRIVELINE

1. Lock out all power.

2. Check shield and replace if damaged.

3. Use grease recommended in Section 6.1.

4. Lubricate both universal joints after every 8 hours of operation. Lubricate the

center portion of the driveline (grease fitting is beneath shield) on a yearly

basis (where applicable).

6.3.12. WINCH (R8-41, R8-46, R8-51, R10-41, & R10-51 AUGERS ONLY)

1. Service winch with auger in fully lowered position and cable slack.

2. Check to make sure cable clamps are secure.

3. Keep a film of grease on gears. Occasionally oil the bushings, drumshaft and

ratchet. Take care not to get oil or grease on brake discs.

4. Inspect brake discs, replace if less than 1/16” (2mm) thick.

Figure 6.7 Cable Pulley

6.3.13. REPLACING BELTS

1. Lock out all power.

2. Make sure that the belt engaging lever is disengaged.

3. On motor drive: Remove pulley shield at motor if necessary (belts may slip

past pulley without removing shield). If belts do not come off easily, the

engine mounting bolts will have to be loosened and the engine pushed

toward the intake end of the auger.

On PTO drive: The PTO driveline and shield will need to be removed before

the belts can be taken off the pulley.

4. The new auger belts can now be put in place. Make sure to route the belt over

the idler pulley.

5. Follow the procedure in Section 6.3.14. for the proper belt tension.

6. Re-attach shield and PTO driveline (where applicable).

30758 R1 35

6. MAINTENANCE WHEATHEART - R SERIES AUGERS

6.3. MAINTENANCE PROCEDURES R8-36, R8-41, R8-46, R8-51, R10-36, R10-41, & R10-51

6.3.14. TIGHTENING BELTS

1. Lock out all power.

2. Engage the belt engaging lever.

3. Loosen the bolts on the engine mount shown in Figure 6.8.

Figure 6.8 Engine Mount Bolts

7. Slide the engine back (towards the spout) until there is adequate tension on

the belt. If the alignment of the pulleys needs adjustment, slide the engine left

or right until the pulleys line up.

8. Re-tighten the engine mount bolts and torque as shown in the tables in

Section 9.

9. Minor tension adjustments can be made by sliding the idler up or down. Idler

shown in Figure 6.9.

Figure 6.9 Belt Idler

36 30758 R1

WHEATHEART - R SERIES AUGERS 7. STORAGE

Warning: Before continuing, ensure you have read and understand the relevant information

in the safety section. Safety information is provided to help prevent serious injury, death, or

property damage.

R8-36, R8-41, R8-46, R8-51, R10-36, R10-41, & R10-51

7.Storage

WARNING

To reduce the risk of injury or death to

persons using this equipment, follow basic

safety precautions.

When storing:

• Store in an area away from human

activity.

To ensure a long, trouble-free life, the following procedure should be followed

when preparing the unit for storage after the season’s use:

• Lock out all power.

• Check tire pressure and inflate to 24psi (165kPa).

• Store the machine on a level surface, free of debris, and in an area away

from human activity. Store in a dry place, or use a tightly secured tarp to

protect the equipment from the weather.

• Ensure that the unit is in transport position.

• Remove all residual material and clean the machine thoroughly.

• Inspect the unit at stress points for cracks.

• Repair or replace any worn or damaged components to prevent any

unnecessary downtime at the start of the next season.

• Touch up paint nicks and scratches to prevent rusting.

• Check hydraulic fittings, hoses, lines, couplers, and valves. Tighten any

loose fittings. Replace any hose that is badly cut, nicked, abraded, or is

separating from the crimped end of the fitting. Secure the hoses to the

machine.

• Inspect and tighten all fasteners; replace fasteners if required.

• Lower auger fully, with slight tension on the cable.

• Inspect the engine for any abnormal leaks, check the air filter and clean or

replace as necessary. Drain the gas from the carburetor and gas tank.

Check to see if there is sufficient oil in the crankcase.

• Support intake on blocks to eliminate prolonged contact with the ground.

• Lubricate all grease fittings.

• Cover motor/engine to protect from weather.

• Chock wheels.

• Remove battery (where applicable) and store in a cool, dry place.

30758 R1 37

7. STORAGE WHEATHEART - R SERIES AUGERS

R8-36, R8-41, R8-46, R8-51, R10-36, R10-41, & R10-51

WARNING

To reduce the risk of injury or death to

persons using this equipment, follow basic

safety precautions.

When handling batteries:

Exercise caution; batteries contain acid which

can eat through clothing, burn skin, and cause

blindness.

38 30758 R1

WHEATHEART - R SERIES AUGERS 8. TROUBLESHOOTING

R8-36, R8-41, R8-46, R8-51, R10-36, R10-41, & R10-51

8.Troubleshooting

The following table lists the causes and solutions to some potential problems you

may encounter in operating your R Series Auger.

Table 8.1

PROBLEM CAUSED BY SOLUTION

auger is plugged or obstructed identify and remove obstruction

drive belt is slipping

The auger does not

turn.

The bottom auger

will not turn.

Auger is noisy.

The auger will not

raise or lower.

Low material augering rate.

Auger will not hold

in elevated position.

Tube is flexing. loose truss cables tighten cables as required

a bearing is seized identify the bearing and replace

a chain is broken identify the chain and repair or replace

gearbox is seized fix or replace the gearbox

gearbox coupler bolt is broken or

missing

center coupler bolt is broken or

missing

obstruction in the auger identify and remove obstruction

auger shaft bolts are loose or damaged

auger shaft is bent repair or replace auger

flighting is damaged repair or replace auger

worn bearing repair or replace bearing

low gear oil level

upper chain drive loose tighten the chain as required

auger is already at its maximum or

minimum height

broken cable replace cable

obstruction in the slide clear the obstruction

winch is seized consult your local Wheatheart dealer

the bottom or top of auger is

obstructed

engine speed is too slow increase rpm of the engine

inadequate material flow from truck

or hopper

flow into the auger intake is

restricted

material too wet or heavy unloading rates are for dry grain

flighting is worn repair or replace as required

belt slipping identify the belt, adjust or replace as required

malfunctioning or damaged winch

mechanism

adjust the tension of the belt

fully engage the belt release

replace the bolt

replace the bolt

tighten or replace bolts

inspect the gearbox, replace if damaged or

add oil if not damaged

if at maximum height, lower the auger

if at minimum height, raise the auger

clear the obstruction

increase flow of material

clear grating of obstructions

consult your local Wheatheart dealer

30758 R1 39

8. TROUBLESHOOTING WHEATHEART - R SERIES AUGERS

R8-36, R8-41, R8-46, R8-51, R10-36, R10-41, & R10-51

40 30758 R1

WHEATHEART - R SERIES AUGERS 9. APPENDIX

R8-36, R8-41, R8-46, R8-51, R10-36, R10-41, & R10-51 9.1. SPECIFICATIONS

9.Appendix

9.1. SPECIFICATIONS

Important: Wheatheart Manufacturing reserves the right to change specifications without

notice.

Table 9.1

Auger Model R8-36 R8-41 R8-46 R8-51 R10-36 R10-41

Tube Size 8” (203mm) 8” (203mm) 8” (203mm) 8” (203mm) 10” (254mm) 10” (254mm)

CAPACITIES

Up to

Unloading Rate

Length 36’5”(11.1m) 41’5”(12.6m) 46’4”(14.1m) 51’3”(15.6m) 36’11”(11.2m) 42’(12.8m)

Transport

Discharge

Clearance

Inflation Pressure 20 – 24 PSI (137-165kPa)

Hitch Tongue Weight

(no engine)

Total Weight 1188lb (539kg) 1285lb (583kg) 1397 lb (634kg) 1540lb (699kg) 1250lb (567kg) 1351lb (617kg)

Gas Engine

Electric Motor

PTO Drive 540 rpm

Gas Tank Capacity 5 Imp Gal (22 L)

Gearbox Oil

Capacity

Belt Size B210 B240 B270 B300 B210 B240

Width 8’ (2.44m) 8’ (2.44m) 8’ (2.44m) 8’ (2.44m) 8’ (2.44m) 8’ (2.44m)

Height 11’(3.35m) 10’ 9”(3.28m) 11’10”(3.6m) 12’10”(3.91m) 11’2”(3.39m) 11’6”(3.39m)

Min 9’ 7”(2.92m) 9’ 6”(2.9m) 10’ 6”(3.2m) 11’ 6”(3.5m) 9’2”(2.78m) 9’5”(2.86m)

Max 21’ 6”(6.55m) 24’ 8”(7.52m) 27’ 6”(8.38m) 30’ 8”(9.35m) 20’7”(6.25m) 23’7”(7.17m)

Type 15” Radial

3000 Bu/Hr

(106m3/Hr) (106m3/Hr) (106m3/Hr) (106m3/Hr) (212m3/Hr) (212m3/Hr)

66lb (30kg) 68lb (31kg) 72lb (33kg) 70lb (32kg) 70lb (32kg) 90lb (41kg)

15-18 HP

(11-13.5KW)

5 - 7-1/2 HP

(3.75-5.6KW)

Up to

3000 Bu/Hr

POWER REQUIREMENTS

18-20 HP

(13.5-15KW)

5 - 7-1/2 HP

(3.75-5.6KW)

PART SPECIFICATIONS

3000 Bu/Hr

DIMENSIONS

TIRES

WEIGHT

(16.5-18.8KW)

Up to

22-25 HP

7-1/2 HP

(5.6KW)

1/2 Imp Gal (2.3 L)

Up to

3000 Bu/Hr

25-27 HP

(18.8-20.3KW)

7-1/2 - 10 HP

(5.6-7.5KW)

Up to

6000 Bu/Hr

27-35 HP

(20.3-26.3KW)

10 HP

(7.5 KW)

Up to

6000 Bu/Hr

30-35HP

(22.5-26.3KW)

10 - 15 HP

(7.5-11.3KW)

30758 R1 41

9. APPENDIX WHEATHEART - R SERIES AUGERS

9.2. BOLT TORQUE VALUES R8-36, R8-41, R8-46, R8-51, R10-36, R10-41, & R10-51

9.2. BOLT TORQUE VALUES

The tables shown below give correct torque values for various bolts and

capscrews. Tighten all bolts to the torque specified in the chart unless otherwise

noted. Check tightness of bolts periodically, using bolt torque chart as your guide.

Replace hardware with the same strength bolt.

Table 9.2 Imperial Bolt Torque

BOLT

DIAMETER

1/4" 8 6 12 9 17 12

5/16" 13 10 25 19 36 27

3/8" 27 20 45 33 63 45

7/16" 41 30 72 53 100 75

1/2" 61 45 110 80 155 115

9/16" 95 60 155 115 220 165

5/8" 128 95 215 160 305 220

3/4" 225 165 390 290 540 400

7/8" 230 170 570 420 880 650

1" 345 225 850 630 1320 970

(Nm) (lb-ft) (Nm) (lb-ft) (Nm) (lb-ft)

Figure 9.1 Pattern for Tightening Wheel Bolts

Torque figures indicated above are valid for non-greased or non-oiled threads

and head unless otherwise specified. Therefore, do not grease or oil bolts or

capscrews unless otherwise specified in this manual. When using locking

elements, increase torque values by 5%.

42 30758 R1

WHEATHEART - R SERIES AUGERS 9. APPENDIX

R8-36, R8-41, R8-46, R8-51, R10-36, R10-41, & R10-51 9.3. TIGHTENING FLARE TYPE TUBE FITTINGS

Table 9.3 Metric Bolt Torque

BOLT DIAMETER

M3 0.5 0.4 1.8 1.3

M4 3 2.2 4.5 3.3

M5 6 4 9 7

M6 10 7 15 11

M8 25 18 35 26

M10 50 37 70 52

M12 90 66 125 92

M14 140 103 200 148

M16 225 166 310 229

M20 435 321 610 450

M24 750 553 1050 774

(Nm) (lb-ft) (Nm) (lb-ft)

M30 1495 1103 2100 1550

M36 2600 1917 3675 2710

9.3. TIGHTENING FLARE TYPE TUBE FITTINGS

1. Check flare and flare seat for defects that might cause leakage.

2. Align tube with fitting before tightening.

3. Lubricate connection and hand tighten swivel until snug.

4. To prevent twisting the tube(s), use two wrenches. Place one wrench on the

connector body and with the second tighten the swivel nut to the torque

shown.

Table 9.4 Flare Type Tube Fittings

Tube Size OD

(in.)

Nut Size

Across Flats

(in.)

3/16 7/16 8 6 1 1/6

1/4 9/16 12 9 1 1/6

5/16 5/8 16 12 1 1/6

3/8 11 / 16 24 18 1 1/6

1/2 7/8 46 34 1 1/6

5/8 1 62 46 1 1/6

3/4 1 1/4 102 75 3/4 1

7/8 1 3/8 122 90 3/4 1

a. * The torque values shown are based on lubricated connections as in reassemble.

Torque

Values(N-m)

T orque Values

a

(lb-ft)

# of Turns to

a

Tighten (Flats)

(After Finger

Tightening)

(Turn)

9.4. TIGHTENING O-RING FITTINGS

1. Inspect o-ring and seat for dirt or obvious defects.

30758 R1 43

9. APPENDIX WHEATHEART - R SERIES AUGERS

9.4. TIGHTENING O-RING FITTINGS R8-36, R8-41, R8-46, R8-51, R10-36, R10-41, & R10-51

2. On the angle fittings, back the lock nut off until washer bottoms out at top of

groove.

3. Hand-tighten fitting until back up washer or washer face (if straight fitting)

bottoms on face and o-ring is seated.

4. Position angle fittings by unscrewing no more than one turn.

5. Tighten straight fittings to torque shown.

6. Tighten while holding body of fitting with a wrench.

Table 9.5 “O” Ring Fittings

Tube Size

OD (in.)

Nut Size Across

Flats (in.)

Torque

Values

a

(Nm)

3/8 1/2 8 6 2 1/3

7/16 9/16 12 9 2 1/3

1/2 5/8 16 12 2 1/3

9/16 11 /16 24 18 2 1/3

3/4 7/8 46 34 2 1/3

7/8 1 62 46 1-1/2 1/4

1-1/16 1-1/4 102 75 1 1/6

1-3/16 1-3/8 122 90 1 1/6

1-5/16 1-1/2 142 105 3/4 1/8

1-5/8 1-7/8 190 140 3/4 1/8

7/8 2-1/8 217 160 1/2 1/12

a. The torque values shown are based on lubricated connections as in reassemble.

Torque

Values

a

(Lb-ft)

# of Turns to

Tighten (Flats)

(After Finger

Tightening) (Turn)

44 30758 R1

LIMITED WARRANTY

Wheatheart warrants to the buyer that the new machinery is free from defects in material and workmanship.

This warranty is only effective for any new machinery that has not been altered, changed, repaired, or

treated since its delivery to the buyer, other than by Wheatheart or its authorized dealers or employees, and does not apply to accessories, attachments, tools, or parts sold or operated with the new

machinery if they have not been manufactured by Wheatheart.

Wheatheart shall only be liable for defects in the material or workmanship attributed to faulty material

or bad workmanship that can be proved by the buyer, and specifically excludes liability for repairs arising as a result of normal wear and tear of the new machinery or in any other manner whatsoever, and

without limiting the generality of the foregoing, excludes application or installation of parts not completed in accordance with Wheatheart operation manual, specifications, or printed instructions.

A Warranty Registration Form and Inspection Report must be completed at the time of delivery and

returned to Wheatheart Manufacturing within thirty (30) days.

Warranty Period

Private Farm Use One (1) year from date of purchase.

Commercial, Custom, or Rental Use Ninety (90) days from date of purchase.

Replacement Parts Ninety (90) days from date of replacement

Defective parts are subject to inspection by a Wheatheart representative prior to approval of a warranty claim. All returned parts must be sent to the factory, freight pre-paid, in order to qualify for warranty replacement. Repaired or replaced parts will be returned freight collect.

If these conditions are fulfilled, Wheatheart shall at its own cost and its own option either repair or

replace any defective parts provided that the buyer shall be responsible for all expenses incurred as a

result of repairs, labor, parts, transportation, or any other work, unless Wheatheart has authorized such

expenses in advance. Normal wear and service items such as belts, hoses, flashing, etc. are excluded

from warranty.

The warranty shall not extend to any repairs, changes, alterations, or replacements made to the new

equipment other than by Wheatheart or its authorized dealers or employees.

This warranty extends only to the original owner of the new equipment.

This warranty is limited to the terms stated herein and is in lieu of any other warranties whether

expressed or implied, and without limiting the generality of the foregoing, excluded all warranties,

expressed or implied, or conditions whether statutory or otherwise as to quality and fitness for any purpose of the new equipment, Wheatheart disclaims all liability for incidental or consequential damages.

This machine is subject to design changes and Wheatheart shall not be required to retro-fit or

exchange items on previously sold units except at its own option.

WARRANTY VOID IF NOT REGISTERED

Wheatheart

Part of the Ag Growth International Inc. Group

P.O. Box 39

Rosenort, Manitoba, Canada R0G 1W0

Phone: (866) 467- 7207 (Canada & USA)

Fax: (866) 768-4852

website: www.wheatheart.com

email: sales@wheatheart.com

© Ag Growth International Inc. 2013

Printed In Canada

Loading...

Loading...