Read this manual before using product. Failure

IN-BIN SUPER SWEEP

ALL MODELS

ASSEMBLY & OPERATION MANUAL

to follow instructions and safety precautions can

result in serious injury, death, or property

damage. Keep manual for future reference.

Part Number: IM5-R1

Revised: 12/2/10

This product has been designed and constructed according to general engineering

standardsa. Other local regulations may apply and must be followed by the operator.

We strongly recommend that all personnel associated with this equipment be trained

in the correct operational and safety procedures required for this product. Periodic

reviews of this manual with all employees should be standard practice. For your

convenience, we include this sign-off sheet so you can record your periodic reviews.

Date Employee Signature Employer Signature

a. Standards include organizations such as the American Society of Agricultural and Biological Engineers,

American National Standards Institute, Canadian Standards Association, International Organization for

Standardization, and/or others.

WHEATHEART - IN-BIN SUPER SWEEP

ALL MODELS

TABLE OF CONTENTS

1. Assembly .............................................................................................................................. 5

1.1. Hydraulic Hose Installation....................................................................................... 5

1.2. Relief Valve Installation............................................................................................ 6

1.3. Assembly.................................................................................................................. 7

1.4. Wheel Move Option.................................................................................................. 8

2. Operation ............................................................................................................................ 11

3. Appendix............................................................................................................................. 13

Warranty Registration ............................................................................................................. 15

Limited Warranty..................................................................................................................... 17

IM5-R1 3

WHEATHEART - IN-BIN SUPER SWEEP

ALL MODELS

4 IM5-R1

WHEATHEART - IN-BIN SUPER SWEEP 1. ASSEMBLY

Warning: Before continuing, please reread the safety information relevant to this section at the

beginning of this manual. Failure to follow the safety instructions can result in serious injury,

death, or property damage.

ALL MODELS 1.1. HYDRAULIC HOSE INSTALLATION

1.Assembly

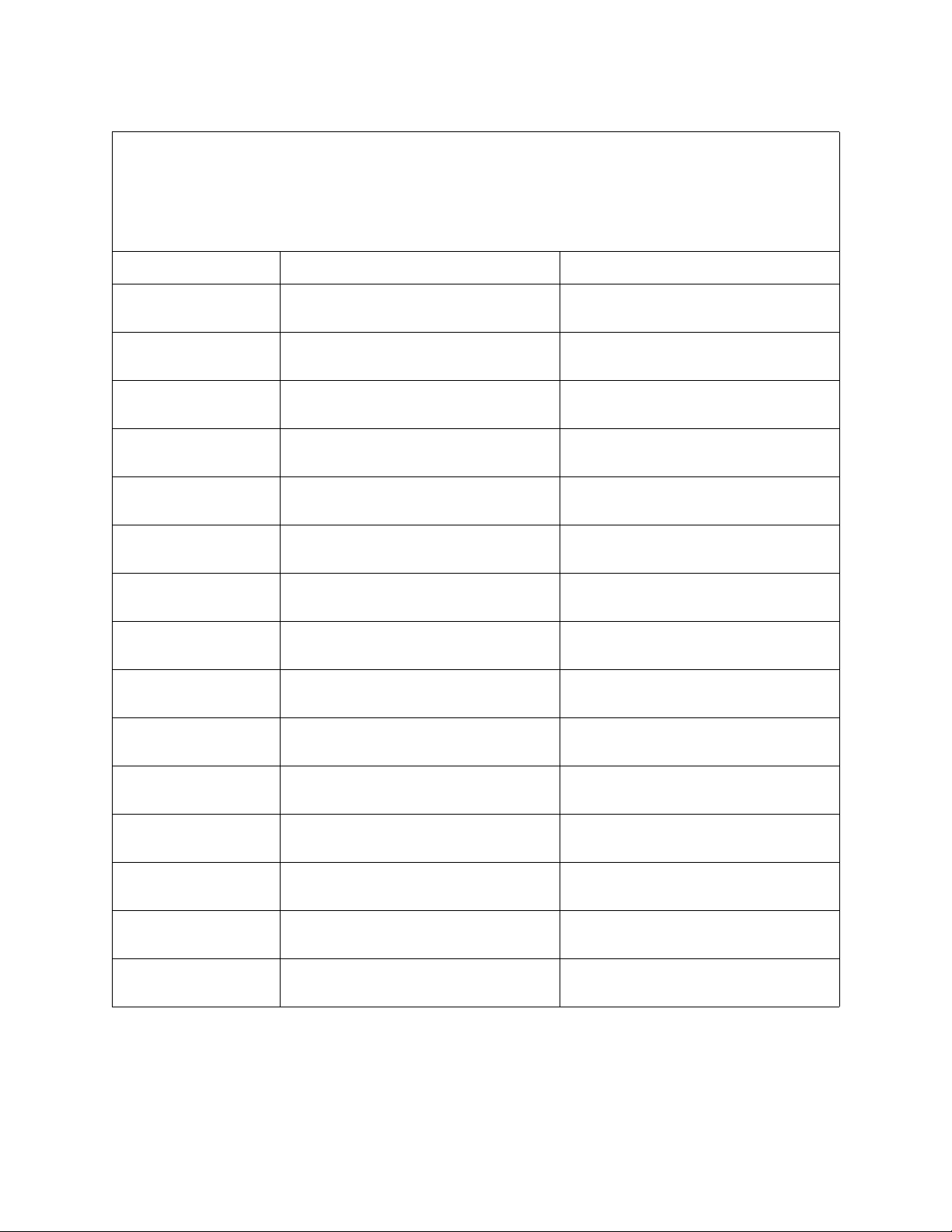

The In-Bin Sweep kit consists of (see Figure 1.1):

1. motor

2. motor coupler

3. relief valve

4. 2-16’ hoses

5. In-Bin pivot assembly

6. straight section with a walking shoe

7. three plain straight sections

8. 1-15” section

9. In–Bin Tower

Figure 1.1 In-Bin Super Sweep Kit (Total 11’3” Flighting in Kit)

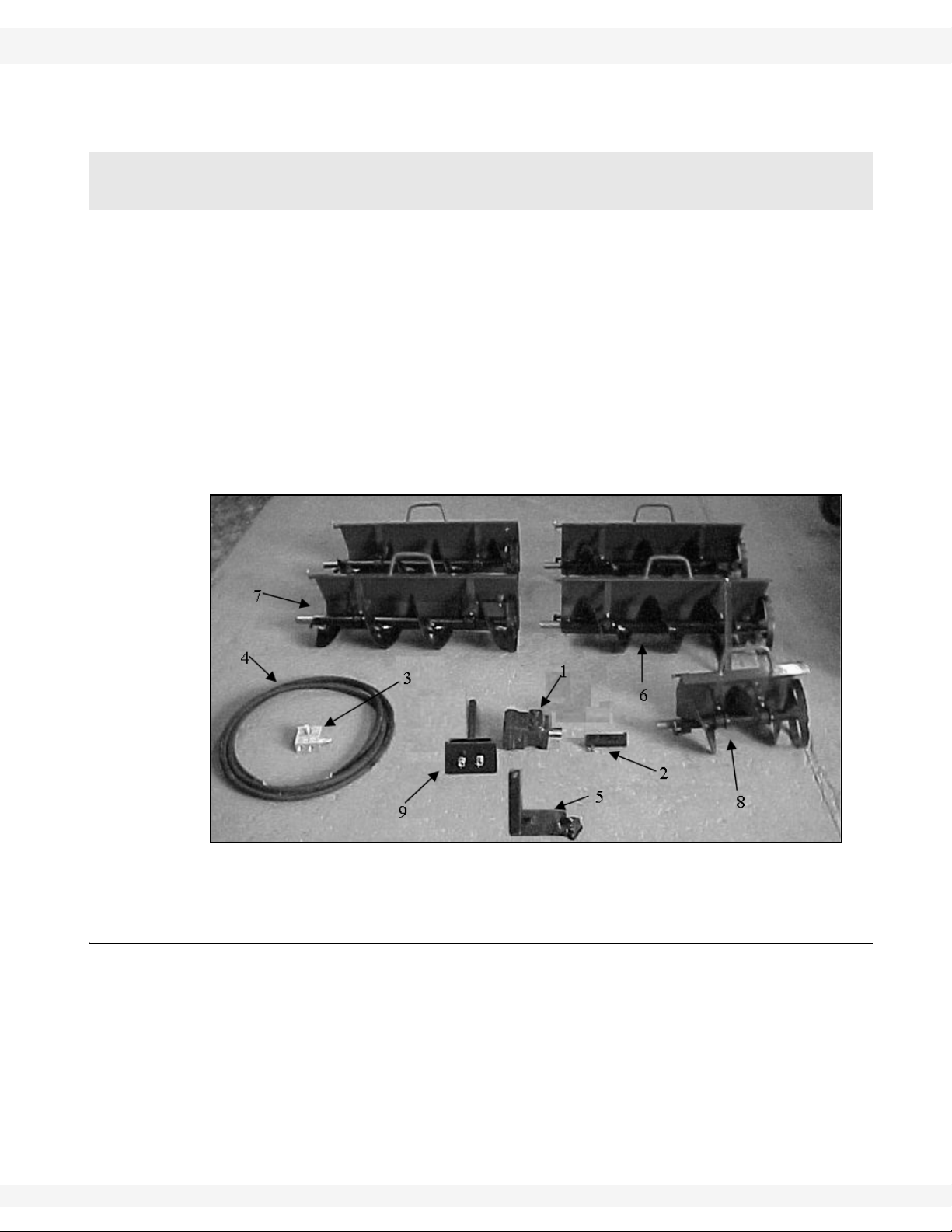

1.1. HYDRAULIC HOSE INSTALLATION

1. Connect hydraulic hoses between orbit motor and relief valve.

2. Quick couplers may be used on pressure “P” and return (“T” for tank) fittings

of the relief valve.

Note: System requires a minimum hydraulic source of 8 gpm at 1200 psi (see Figure

1.2 and 1.3).

IM5-R1 5

1. ASSEMBLY WHEATHEART - IN-BIN SUPER SWEEP

1.2. RELIEF VALVE INSTALLATION ALL MODELS

Figure 1.2 Schematic Drawing

Figure 1.3 Relief Valve

1.2. RELIEF VALVE INSTALLATION

1. The “P” on the relief valve must be connected to the “out” side of the pump

(see Figure 1.2 and 1.3) or directly to the “Pressure” source if using a remote

hydraulic source.

2. The “T” return or “tank” must be connected to the t ank or reservoir of the Bin

Sweep.

DANGER

Ensure that the return is connected to the tank

or reservoir of the Bin Sweep.

If it is not, the relief valve will not kick out and

serious injury or death can occur to the

operator.

3. If the motor turns the wrong way, first verify that the pressure and tank are

right, then try again. If motor still turns the wrong way, cross hydraulic lines

between valve and motor.

6 IM5-R1

WHEATHEART - IN-BIN SUPER SWEEP 1. ASSEMBLY

ALL MODELS 1.3. ASSEMBLY

1.3. ASSEMBLY

1. Mount tower over opening in floor and in the center of the bin.

2. Remove hairpin and slide pivot assembly down pivot shaft until it rests on the

collar. Mount motor to pivot assembly with 3/8” bolts.

3. Attach special motor coupler to hydraulic motor and then a straight bin sweep

section pinning in place. Add on extra straight sections as needed with the

last long section having the walking shoe. Add the 15” section to the end,

space permitting.

4. Make sure all sections are fully interlocked. The pins on the backboards fit

into the hole of the next section and the flighting sections line up to form one

continuous auger when twisted into place. (The welded finger on the end of

one section of flighting wraps around the spoke on the stationary wheel of the

next section.) (See Figure 1.4 and 1.5.)

Figure 1.4 In-Bin Tower and Pivot Assembly

IM5-R1 7

1. ASSEMBLY WHEATHEART - IN-BIN SUPER SWEEP

1.4. WHEEL MOVE OPTION ALL MODELS

Figure 1.5 Flighting and Backboard Assembly

5. Adjust collar until pivot assembly holds the first sweep section of flighting

about 1/8” off the floor (this is level).

6. The pivot assembly can be adjusted up to 10” horizontally in four different

positions by means of the two welded pegs and the welded cross pipes,

which can be swiveled 180°.

Note: In severe cases, extra walking shoes can be added to outer sections to prevent

tipping.

1.4. WHEEL MOVE OPTION

1. Assemble on flat surface.

2. Slide the outermost Supersweep backboard over the drivewheel alignment

pin and driveshaft.

3. Insert the hairpin to prevent the backboard from sliding back.

4. Place the backboard locking bracket against backboard and over the

backboard mount bracket.

5. Mark and drill the hole locations for bolting or welding the locking bracket to

the backboard.

8 IM5-R1

WHEATHEART - IN-BIN SUPER SWEEP 1. ASSEMBLY

ALL MODELS 1.4. WHEEL MOVE OPTION

Figure 1.6 Wheel Move Assembly

IM5-R1 9

1. ASSEMBLY WHEATHEART - IN-BIN SUPER SWEEP

1.4. WHEEL MOVE OPTION ALL MODELS

10 IM5-R1

WHEATHEART - IN-BIN SUPER SWEEP 2. OPERATION

Warning: Before continuing, please reread the safety information relevant to this section at the

beginning of this manual. Failure to follow the safety instructions can result in serious injury,

death, or property damage.

ALL MODELS

2.Operation

Important: The Super Sweep is an aggressive bin sweep, and when starting the sweep in

an in-bin situation, you must slowly lower the flighting down to the floor manually

with the backboard handle or the sweep will bury itself down into the grain,

kicking out the relief valve and shutting itself off. If this should occur, you will

have to dig the unit out by shovel.

NOTICE

Pulling the bin sweep out of buried grain by force could

damage flighting or alignment.

• The collar may have to be adjusted so the Super Sweep runs level. Too high

or too low will slow down the Super Sweep (see Figure 1.4).

• The rubber kicker on each section’s stationary wheel is adjustable – the further out, the more it drives the sweep forward into the pile. The kicker is

adjusted by placing or removing washers between the plate and the kicker

(see Figure 2.1).

Note: Do not adjust the kicker too far out as it will cause excessive wear on the kicker

and rough sweep operation.

In case of drag on bin sweep sections, check for build up of material around

bushings (ice, mud, etc.) or misalignment of welded bushing strut.

Some operators prefer to let the bin sweep run twice to reduce the center pile for

easier cleanup.

Figure 2.1 Rubber Kicker

IM5-R1 11

2. OPERATION WHEATHEART - IN-BIN SUPER SWEEP

ALL MODELS

12 IM5-R1

WHEATHEART - IN-BIN SUPER SWEEP 3. APPENDIX

ALL MODELS

3.Appendix

Figure 3.1 Wheel Move Components

IM5-R1 13

3. APPENDIX WHEATHEART - IN-BIN SUPER SWEEP

ALL MODELS

Parts List

No. Qty Description

1 1 Bin Sweep Wheel Drive

2 1 Top Wheel Driveshaft

3 1 Bottom Wheel Driveshaft

4 4 1/4” x 1” Woodruff Key

5 1 #40 Chain with Connector

6 1 Wheel Drive Axle

7 1 Sprocket Motor

8 7 1” Rim Washer

9 1 Small Drive Shield

10 1 Large Drive Shield

11 6 SMS, #14 x 5/8” With Washerhead

12 2 Bolt, 7/16” x 1” UNC GR5 PLD

13 1 5/16” x 1-1/2” Roll Pin

14 2 Nylon Chain Roller

15 2 Bolt, 5/16” x 2-1/2” UNC GR5 PLD

16 1 Bin Sweep Drive Wheel

17 1 Roller Chain, #40, 39”

18 1 Roller Chain, #40, Half Link

19 1 Roller Chain, #40, Single Link

20 1 Sprocket, with Hub, #40 54T, 1, Key

21 1 Sprocket, with Hub, #40 30T, 1, Key

22 1 Sprocket, with Hub, #40 13T, 1, Key

23 1 Driveshaft

24 2 Nut Nylock, 5/16” UNC GR5 PLT

25 2 Nut Hex, 5/16” UNC GR5 PLT

26 2 Nut Nylock, 7/16” UNC GR5 PLT

27 1 Shaft Spacer

14 IM5-R1

WARRANTY REGISTRATION

Wheatheart congratulates you on your new equipment purchase.

The warranty registration form must be filled out within thirty (30) days from delivery date and sent to:

Wheatheart Manufacturing

3455 Idylwyld Dr. N., Saskatoon, Saskatchewan S7L 6B5

CUSTOMER COPY

(Retain this card for warranty and record purposes.)

PRODUCT: DEALER’S NAME:

SERIAL #:

DELIVERY DATE:

OWNER’S NAME: PHONE #:

ADDRESS:

PHONE #:

DEALER COPY

(Retain this card for warranty and record purposes.)

PRODUCT: DEALER’S NAME:

SERIAL #:

DELIVERY DATE:

OWNER’S NAME: PHONE #:

ADDRESS:

PHONE #:

ADDRESS:

SIGNATURE:

INVOICE #:

(Please refer to invoice # when filing claim)

ADDRESS:

SIGNATURE:

INVOICE #:

(Please refer to invoice # when filing claim)

WARRANTY REGISTRATION

(Must be filled out and returned to Wheatheart within 30 days of delivery.)

OWNER’S NAME: DEALER’S NAME:

ADDRESS:

PHONE #: PHONE #:

SIGNATURE:

(I acknowledge the product to be whole and in

proper working order.)

PRODUCT: SERIAL #:

INVOICE #:

ADDRESS:

SIGNATURE:

(I acknowledge the product to be whole and in

proper working order. The owner has been given

an operation manual and has been informed on

proper operation and maintenance.)

DELIVERY DATE:

GAS MOTOR SERIAL #:

LIMITED WARRANTY

Wheatheart warrants to the buyer that the new machinery is free from defects in material and

workmanship.

This warranty is only effective for any new machinery that has not been altered, changed,

repaired, or treated since its delivery to the buyer, other than by Wheatheart or its authorized

dealers or employees, and does not apply to accessories, attachments, tools, or parts sold or

operated with the new machinery if they have not been manufactured by Wheatheart.

Wheatheart shall only be liable for defects in the material or workmanship attributed to faulty

material or bad workmanship that can be proved by the buyer, and specifically excludes liability

for repairs arising as a result of normal wear and tear of the new machinery or in any other manner whatsoever, and without limiting the generality of the foregoing, excludes application or

installation of parts not completed in accordance with Wheatheart operation manual, specifications, or printed instructions.

A Warranty Registration Form and Inspection Report must be completed at the time of delivery

and returned to Wheatheart Manufacturing within thirty (30) days.

Warranty Period

Private Farm Use One (1) year from date of purchase.

Commercial, Custom, or Rental Use Ninety (90) days from date of purchase.

Replacement Parts Ninety (90) days from date of replacement

Defective parts are subject to inspection by a Wheatheart representative prior to approval of a

warranty claim. All returned parts must be sent to the factory, freight pre-paid, in order to qualify

for warranty replacement. Repaired or replaced parts will be returned freight collect.

If these conditions are fulfilled, Wheatheart shall at its own cost and its own option either repair

or replace any defective parts provided that the buyer shall be responsible for all expenses

incurred as a result of repairs, labor , part s, transporta tion, or any other work, unless Wheatheart

has authorized such expenses in advance. Normal wear and service items such as belts,

hoses, flashing, etc. are excluded from warranty.

The warranty shall not extend to any repairs, changes, alterations, or replacements made to the

new equipment other than by Wheatheart or its authorized dealers or employees.

This warranty extends only to the original owner of the new equipment.

This warranty is limited to the terms stated herein and is in lieu of any other warranties whether

expressed or implied, and without limiting the generality of the foregoing, excluded all warranties, expressed or implied, or conditions whether statutory or otherwise as to quality and fitness

for any purpose of the new equipment, Wheatheart disclaims all liability for incidental or consequential damages.

This machine is subject to design changes and Wheatheart shall not be required to retro-fit or

exchange items on previously sold units except at its own option.

WARRANTY VOID IF NOT REGISTERED

Wheatheart

Part of the Ag Growth International Inc. Group

3455 Idylwyld Drive North

Saskatoon, Saskatchewan, Canada

Phone: (306) 934-0611

Fax: (306) 934-6020

Toll Free: (877) 934-0649 (Canada & USA)

website: www.wheatheart.com

email: sales@wheatheart.com

© Ag Growth International Inc. 2013

Printed in Canada

Loading...

Loading...