Wheatheart Hydrostatic Portable and Truck-Mount Super Sweep User Manual

HYDROSTATIC SUPER SWEEP

PORTABLE & TRUCK MOUNT SUPERSWEEP

ASSEMBLY & OPERATION MANUAL

Read this manual before using product. Failure

to follow instructions and safety precautions can

result in serious inju ry, death, or property

damage. Keep manual fo r future reference.

Part Number: IM1 R3

Revised: Feb/10

This product has been designed and constructed according to general engineering

standardsa. Other local regulations may apply and must be followed by the operator.

We strongly recommend that all personnel associated with this equipment be trained

in the correct operational and safety procedures required for this product. Periodic

reviews of this manual with all employees should be standard practice. For your

convenience, we include this sign-off sheet so you can record your periodic reviews.

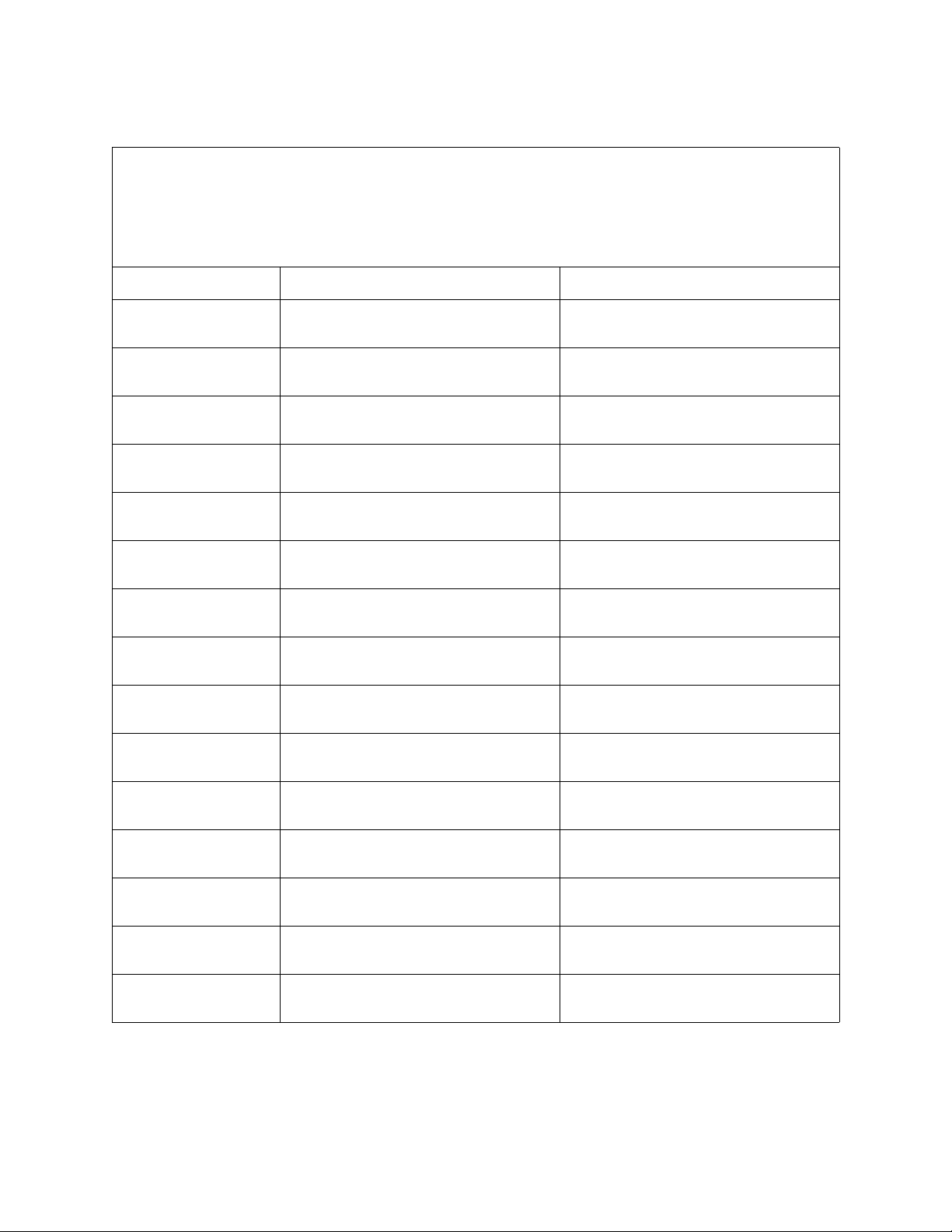

Date Employee Signature Employer Signature

a. Standards include organizations such as the American Society of Agricultural and Biological Engineers,

American National Standards Institute, Canadian Standards Association, International Organization for

Standardization, and/or others.

WHEATHEART - HYDROSTATIC BIN SWEEP

STANDARD, PORTABLE, TRUCK MOUNT, & SUPER SWEEP

TABLE OF CONTENTS

1. Introduction .......................................................................................................................... 5

2. Safety First............................................................................................................................ 7

2.1. General Safety ......................................................................................................... 8

2.2. Assembly Safety....................................................................................................... 9

2.3. Operation Safety ...................................................................................................... 9

2.4. Maintenance Safety.................................................................................................. 9

2.5. Storage Safety........................................................................................................ 10

2.6. Hydraulic Safety ..................................................................................................... 10

2.7. Engine Safety ......................................................................................................... 10

2.8. Safety Decal Locations........................................................................................... 10

2.8.1. Decal Installation ...................................................................................... 11

2.8.2. Decal Locations ........................................................................................ 11

3. Assembly ............................................................................................................................ 13

3.1. Mounting The Spider .............................................................................................. 13

3.1.1. Wheatheart & Brandt / Any Four-Rod Cage Models ................................ 13

3.1.2. Sakundiak / Any Center Rod Cage Models .............................................. 13

3.2. Hydraulic Pump Kit Installation (Portable Model) ................................................... 14

3.2.1. Pump Guard Installation ........................................................................... 15

3.2.2. Oil Reservoir Installation........................................................................... 15

3.2.3. Hydraulic Hose Installation ....................................................................... 16

3.2.4. Relief Valve Installation ............................................................................ 20

3.3. Supersweep Assembly........................................................................................... 20

3.3.1. Flighting Kit............................................................................................... 20

3.3.2. Assembly .................................................................................................. 21

3.4. Supersweep Wheel Move Assembly (Optional) ..................................................... 22

4. Operation ............................................................................................................................ 23

4.1. Supersweep Operation........................................................................................... 23

4.1.1. Starting The Supersweep ......................................................................... 24

4.2. Operating The Portable / Truck Mount Supersweep .............................................. 25

5. Maintenance ....................................................................................................................... 27

5.1. General Maintenance ............................................................................................. 27

5.2. Adjusting Belt Tension............................................................................................ 27

6. Troubleshooting................................................................................................................. 29

7. Appendix............................................................................................................................. 31

7.1. Parts Lists............................................................................................................... 31

7.1.1. Hydraulic Motor Kit ................................................................................... 31

7.1.2. Hydraulic Pump Kit ................................................................................... 32

7.1.3. Wheel Move Option .................................................................................. 34

Warranty Registration ............................................................................................................. 37

IM1 R3 3

WHEATHEART - HYDROSTATIC BIN SWEEP

STANDARD, PORTABLE, TRUCK MOUNT, & SUPER SWEEP

TABLE OF CONTENTS

Limited Warranty ..................................................................................................................... 39

4 IM1 R3

WHEATHEART - HYDROSTATIC BIN SWEEP 1. INTRODUCTION

STANDARD, PORTABLE, TRUCK MOUNT, & SUPER SWEEP

1.Introduction

Congratulations on your purchase of a Wheatheart Portable or Truck Mount

Supersweep. This piece of equipment will complement your agricultural

operation by aiding in the safe and efficient movement of grain, pulse crops,

fertilizer, or any other granular materials.

The standard equipment provided with Wheatheart’s Supersweeps includes a

motor coupler, universal section with u-joint, two plain straight sections, and a

third straight section with a walking shoe to prevent the sweep from tipping over.

The Portable Supersweep is a completely self-contained bin sweep. The unique

upright design in a “wheeler” style provides easy movement over any terrain. The

unit comes complete with the standard equipment listed above, and an easystarting Honda engine that provides plenty of power.

The Truck Mount Supersweep attaches easily to your existing hydraulic system,

and the Self-Propelled Mover Kit Supersweep adds on to the existing mover kit;

both come with the standard equipment listed above.

Optional Supersweep add-ons:

• A larger 6.3 hp motor for added torque when adding extra sections.

• A u-joint backboard to help reduce the grain pile at the auger intake also

helps prevent the sweep from tipping over.

• A drive wheel that helps drive the sweep into the pile.

• A larger oil reservoir for heavy-duty service (used with the mover option).

Your new Wheatheart Supersweep will serve you well if you understand how it

operates, if you use it properly, and if you care for it properly. This manual is

intended to help you learn how to assemble, operate, and maintain your

equipment in a safe, efficient, and trouble-free manner. Please read this manual

all the way through before using your new equipment.

Should any information remain unclear after thoroughly reviewing this manual,

contact your Wheatheart Dealer for clarification.

IM1 R3 5

1. INTRODUCTION WHEATHEART - HYDROSTATIC BIN SWEEP

STANDARD, PORTABLE, TRUCK MOUNT, & SUPER SWEEP

6 IM1 R3

WHEATHEART - HYDROSTATIC BIN SWEEP 2. SAFETY FIRST

STANDARD, PORTABLE, TRUCK MOUNT, & SUPER SWEEP

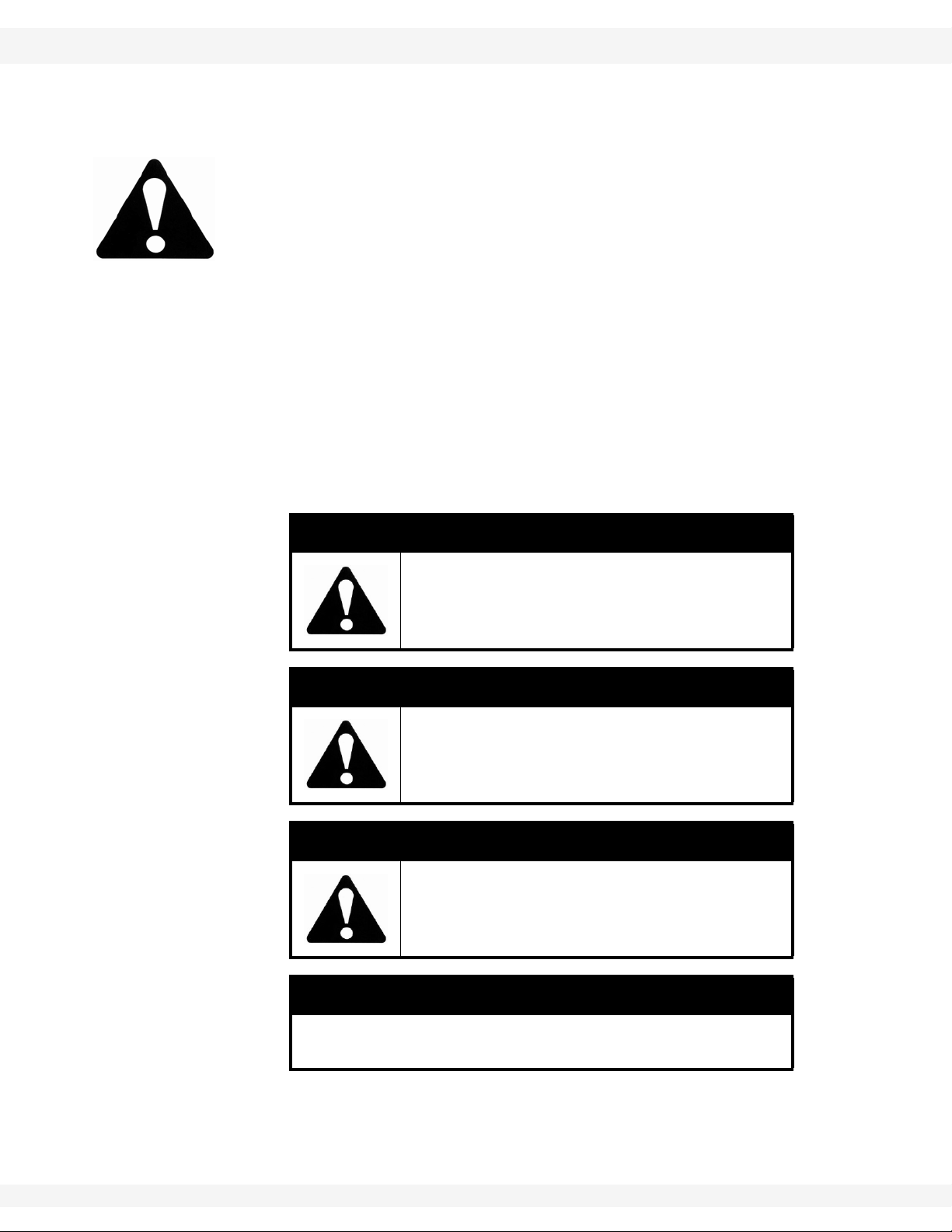

2.Safety First

The Safety Alert symbol to the left identifies important safety messages on the

product and in the manual. When you see this symbol, be alert to the possibil-

ity of personal injury or death. Follow the instructions in the safety messages.

Why is SAFETY important to you?

Three big reasons:

• Accidents disable and kill.

• Accidents cost.

• Accidents can be avoided.

SIGNAL WORDS

Note the use of the signal words DANGER, WARNING, CAUTION, and NOTICE

with the safety messages. The appropriate signal word for each message has

been selected using the definitions below as a guideline.

The Safety Alert symbol means ATTENTION, BE ALERT!, YOUR SAFETY IS

INVOLVED.

DANGER

Indicates an imminently hazardous situation

that, if not avoided, will result in serious injury

or death.

WARNING

Indicates a hazardous situation that, if not

avoided, could result in serious injury or

death.

CAUTION

Indicates a hazardous situation that, if not

avoided, may result in minor or moderate

injury.

NOTICE

Indicates a potentially hazardous situation that, if not

avoided, may result in property damage.

IM1 R3 7

2. SAFETY FIRST WHEATHEART - HYDROSTATIC BIN SWEEP

2.1. GENERAL SAFETY STANDARD, PORTABLE, TRUCK MOUNT, & SUPER SWEEP

2.1. GENERAL SAFETY

Important: The general safety section includes instructions that apply to all safety practices.

Any instructions specific to a certain safety practice (e.g., assembly safety), can

be found in the appropriate section. Always read the complete instructional

sections and not just these safety summaries before doing anything with the

equipment.

YOU are responsible for the SAFE use and maintenance of your equipment.

YOU must ensure that you and anyone else who is going to work around the

equipment understands all procedures and related SAFETY information

contained in this manual.

Remember, YOU are the key to safety. Good safety practices not only protect

you, but also the people around you. Make these practices a working part of your

safety program.

• It is the equipment owner and the operator's responsibility to read and under-

stand ALL safety instructions, safety decals, and manuals and follow them

before assembling, operating, or maintaining the equipment. All accidents

can be avoided.

• Equipment owners must give instructions and review the information initially

and anually with all personnel before allowing them to operate this product.

Untrained users/operators expose themselves and bystanders to possible

serious injury or death.

• Use this equipment for its intended purposes only.

• Do not modify the equipment in any way. Unauthorized modification may

impair the function and/or safety, and could affect the life of the equipment.

Any modification to the equipment voids the warranty.

• Do not allow children, spectators, or bystanders within the work area.

• Have a first-aid kit available for use should the need arise, and know how to

use it.

• Provide a fire extinguisher for use in case of an accident. Store in a highly visible place.

• Wear appropriate protective gear. This list includes, but

is not limited to:

• a hard hat

•gloves

• protective shoes with slip-resistant soles

• protective goggles

• hearing protection

• For Powered Equipment: before servicing, adjusting, or repairing powered

equipment, unplug, place all controls in neutral or off position, stop the engine

or motor, remove ignition key or lock out power source, and wait for all moving parts to stop.

8 IM1 R3

WHEATHEART - HYDROSTATIC BIN SWEEP 2. SAFETY FIRST

STANDARD, PORTABLE, TRUCK MOUNT, & SUPER SWEEP 2.2. ASSEMBLY SAFETY

• Follow good shop practices:

• keep service area clean and dry

• be sure electrical outlets and tools are properly

grounded

• use adequate light for the job at hand

• Think SAFETY! Work SAFELY!

2.2. ASSEMBLY SAFETY

• Read the instructions and familiarize yourself with the subassemblies and

hardware making up the equipment.

• The components are large, heavy, and can be hard to handle. Be sure to use

the proper tools, stands, jacks, and hoists for the job.

• Have 2 people handle the heavy bulky components.

• Place safety stands or large blocks under the machine or components before

going beneath the component for assembly.

• Stay away from overhead power lines and obstructions when lifting the

machine during assembly. Electrocution can occur without direct contact.

Contact with obstructions can damage components or cause them to fail.

• Tighten all fasteners to their specified torque before using the machine.

2.3. OPERATION SAFETY

• Have another person nearby who can shut down the equipment in case of

accident.

• Do not operate with any of the safety guards removed.

• Keep body, hair, and clothing away from moving parts. Stay away from intake

during operation.

2.4. MAINTENANCE SAFETY

• Before applying pressure to a hydraulic system, make sure all components

are tight and that hoses and couplings are in good condition.

• Relieve pressure from hydraulic circuit before servicing or disconnecting from

tractor.

• Place stands or blocks under the frame before working beneath the machine.

• After maintenance is complete, replace and secure all safety guards and

safety devices, and if applicable, service doors and cleanout covers.

• Remove all tools and unused parts from machine before operation.

• Remove buildup of grease, oil, and debris.

• Inspect all parts. Ensure parts are in good condition and installed properly.

Use only genuine Wheatheart replacement parts or equivalent. Replacement

parts must meet ASAE standards or serious injury may result. Use of

unauthorized parts will void the warranty. If in doubt, contact Wheatheart or your

Wheatheart dealer.

IM1 R3 9

2. SAFETY FIRST WHEATHEART - HYDROSTATIC BIN SWEEP

2.5. STORAGE SAFETY STANDARD, PORTABLE, TRUCK MOUNT, & SUPER SWEEP

2.5. STORAGE SAFETY

• Store in an area away from human activity.

• Do not permit children to play on or around the stored machine.

2.6. HYDRAULIC SAFETY

• Always place all hydraulic controls in neutral and relieve system pressure

before disconnecting or working on hydraulic system.

• Keep all components in the hydraulic system tightly secured and in good condition and clean.

• Replace any worn, cut, abraded, flattened, or crimped hoses.

• Do not attempt any makeshift repairs to the hydraulic fittings or hoses with

tape, clamps, or concrete. The hydraulic system operates under extremely

high pressure; such repairs will fail suddenly and create a hazardous and

unsafe condition.

• Before moving a hydraulic cylinder, ensure that the attached component is

safely secured.

WARNING

Hydraulic fluid can cause serious injury if it

penetrates the skin. If it does, see a doctor

immediately.

• Relieve pressure before disconnecting

hydraulic line.

• Wear proper hand and eye protection and

use wood or cardboard, not hands, when

searching for leaks.

2.7. ENGINE SAFETY

• Be sure to stop engine and remove key or lock out power before inspecting or

servicing engine

• Refer to engine operation manual for further details.

2.8. SAFETY DECAL LOCATIONS

• Keep safety decals clean and legible at all times.

• Replace safety decals that are missing or have become illegible. See decal

location figures below.

• Replaced parts must display the same decal(s) as the original part.

• Safety decals are available from your distributor, dealer, or factory.

10 IM1 R3

WHEATHEART - HYDROSTATIC BIN SWEEP 2. SAFETY FIRST

STANDARD, PORTABLE, TRUCK MOUNT, & SUPER SWEEP 2.8. SAFETY DECAL LOCATIONS

2.8.1. DECAL INSTALLATION

1. Decal area must be clean and dry, with a temperature above 10°C (50°F).

2. Decide on the exact position before you remove the backing paper.

3. Align the decal over the specified area and carefully press the small portion

with the exposed sticky backing in place.

4. Slowly peel back the remaining paper and carefully smooth the remaining

portion of the decal in place.

5. Small air pockets can be pierced with a pin and smoothed out using the sign

backing paper.

2.8.2. DECAL LOCATIONS

Replicas of the safety decals that are attached to the equipment are shown

below. Good safety requires that you familiarize yourself with the various safety

decals and the areas or particular functions that the decals apply to as well as

the safety precautions that must be taken to avoid serious, injury, death, or

damage.

Figure 2.1

IM1 R3 11

2. SAFETY FIRST WHEATHEART - HYDROSTATIC BIN SWEEP

2.8. SAFETY DECAL LOCATIONS STANDARD, PORTABLE, TRUCK MOUNT, & SUPER SWEEP

12 IM1 R3

Loading...

Loading...