GRAIN AUGERS

4" GALVANIZED UTILITY

ASSEMBLY & OPERATION MANUAL

Read this manual before using product. Failure

to follow instructions and safety precautions can

result in serious injury, death, or property

damage. Keep manual for future reference.

Part Number: 30645 R0

Revised: 26/4/10

This product has been designed and constructed according to general engineering

standardsa. Other local regulations may apply and must be followed by the operator.

We strongly recommend that all personnel associated with this equipment be trained

in the correct operational and safety procedures required for this product. Periodic

reviews of this manual with all employees should be standard practice. For your

convenience, we include this sign-off sheet so you can record your periodic reviews.

Date Employee Signature Employer Signature

a. Standards include organizations such as the American Society of Agricultural and Biological Engineers,

American National Standards Institute, Canadian Standards Association, International Organization for

Standardization, and/or others.

WHEATHEART - GRAIN AUGERS

4" GALVANIZED UTILITY

TABLE OF CONTENTS

1. Introduction.......................................................................................................................... 5

2. Safety First............................................................................................................................ 7

2.1. General Safety ......................................................................................................... 8

2.2. Assembly Safety....................................................................................................... 9

2.3. Operation Safety ...................................................................................................... 9

2.4. Maintenance Safety.................................................................................................. 9

2.5. Safety Decal Locations........................................................................................... 10

2.5.1. Decal Installation...................................................................................... 10

2.5.2. Decal Locations........................................................................................ 10

3. Assembly ............................................................................................................................ 13

3.1. Tube / Flight Extensions......................................................................................... 13

3.2. Intake Assembly..................................................................................................... 13

3.3. Hopper Assembly (Optional).................................................................................. 14

3.4. Head Drive Assembly............................................................................................. 14

3.5. Feed Control Assembly (Optional)......................................................................... 15

3.6. Swivel Mount Assembly (Optional)......................................................................... 16

4. Operation ............................................................................................................................ 17

4.1. Pre-Operational Checklist ...................................................................................... 17

4.2. Auger Drive and Lockout Procedure ..................................................................... 17

4.3. Operating Procedure.............................................................................................. 17

4.3.1. Start-Up and Break-in............................................................................... 17

4.3.2. Operating With A Full Load ...................................................................... 18

4.3.3. Shutdown.................................................................................................. 19

4.4. Maintenance........................................................................................................... 20

4.4.1. General Maintenance Procedures............................................................ 20

5. T roubleshooting................................................................................................................. 21

Limited Warranty..................................................................................................................... 23

30645 R0 3

WHEATHEART - GRAIN AUGERS

4" GALVANIZED UTILITY

4 30645 R0

WHEATHEART - GRAIN AUGERS 1. INTRODUCTION

4" GALVANIZED UTILITY

1.Introduction

Congratulations. As the new owner of a grain auger, you will be working with

equipment designed to complement and improve your farming operation. Before

using this auger, please read this manual and all safety labels and familiarize

yourself with the various features of the machine and the necessary precautions

for efficient and safe operation.

In addition, anyone using this auger is required to comply with all safety precautions in this manual and in safety labels attached to the auger. A sign-off form is

supplied on the inside front cover to record your safety reviews.

Thank you.

Serial Number:

Serial number is located at the top of the tube.

30645 R0 5

1. INTRODUCTION WHEATHEART - GRAIN AUGERS

4" GALVANIZED UTILITY

6 30645 R0

WHEATHEART - GRAIN AUGERS 2. SAFETY FIRST

4" GALVANIZED UTILITY

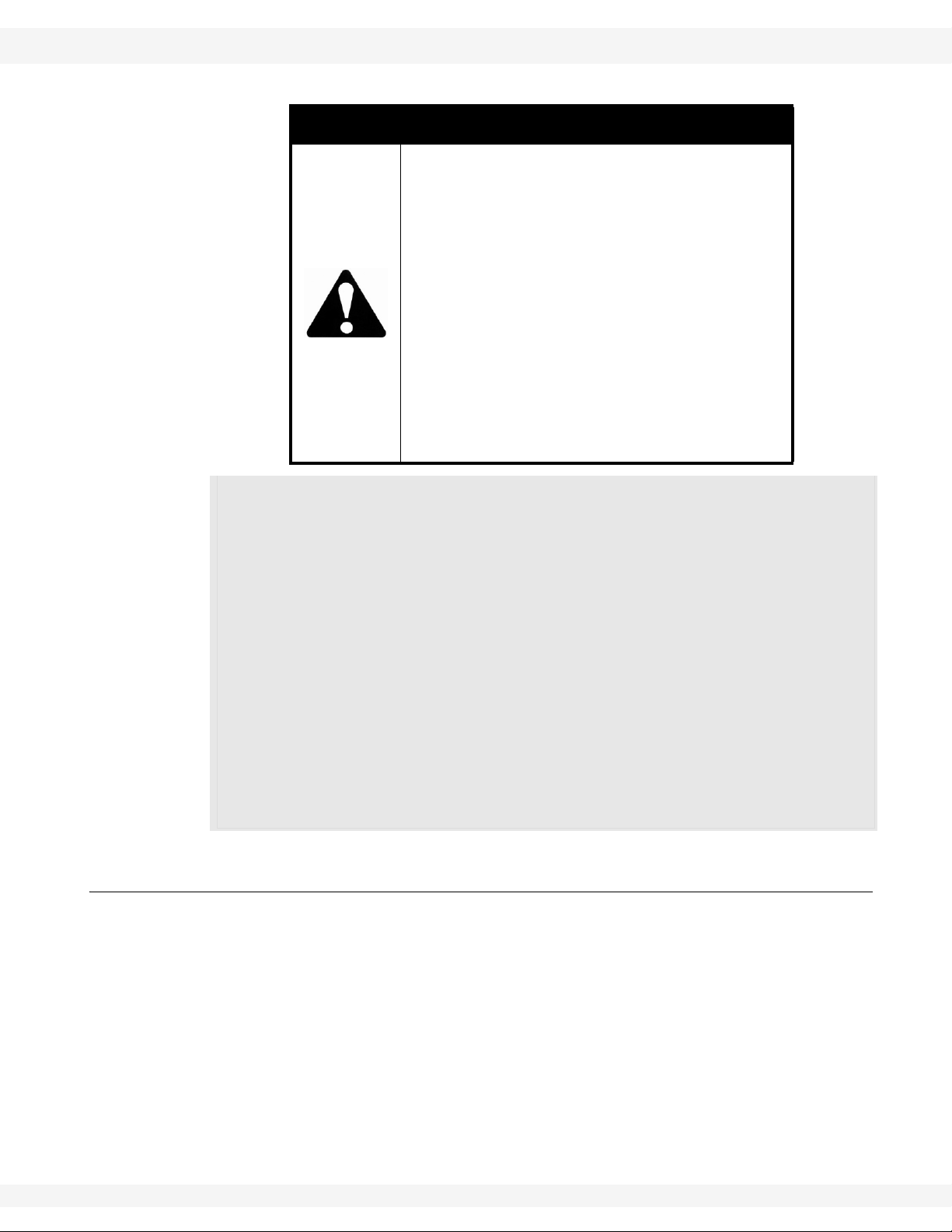

2.Safety First

The Safety Alert symbol to the left identifies important safety messages on the

product and in the manual. When you see this symbol, be alert to the possibility of personal injury or death. Follow the instructions in the safety messages.

Why is SAFETY important to you?

Three big reasons:

• Accidents disable and kill.

• Accidents cost.

• Accidents can be avoided.

SIGNAL WORDS

Note the use of the signal words DANGER, WARNING, CAUTION, and NOTICE

with the safety messages. The appropriate signal word for each message has

been selected using the definitions below as a guideline.

The Safety Alert symbol means ATTENTION, BE ALERT!, YOUR SAFETY IS

INVOLVED.

DANGER

Indicates an imminently hazardous situation

that, if not avoided, will result in serious injury

or death.

WARNING

Indicates a hazardous situation that, if not

avoided, could result in serious injury or

death.

CAUTION

Indicates a hazardous situation that, if not

avoided, may result in minor or moderate

injury.

NOTICE

Indicates a potentially hazardous situation that, if not

avoided, may result in property damage.

30645 R0 7

2. SAFETY FIRST WHEATHEART - GRAIN AUGERS

2.1. GENERAL SAFETY 4" GALVANIZED UTILITY

2.1. GENERAL SAFETY

Important: The general safety section includes instructions that apply to all safety practices.

Any instructions specific to a certain safety practice (e.g., assembly safety), can

be found in the appropriate section. Always read the complete instructional

sections and not just these safety summaries before doing anything with the

equipment.

YOU are responsible for the SAFE use and maintenance of your equipment.

YOU must ensure that you and anyone else who is going to work around the

equipment understands all procedures and related SAFETY information

contained in this manual.

Remember, YOU are the key to safety. Good safety practices not only protect

you, but also the people around you. Make these practices a working part of your

safety program.

• It is the equipment owner and the operator's responsibility to read and understand ALL safety instructions, safety decals, and manuals and follow them

before assembling, operating, or maintaining the equipment. All accidents

can be avoided.

• Equipment owners must give instructions and review the information initially

and anually with all personnel before allowing them to operate this product.

Untrained users/operators expose themselves and bystanders to possible

serious injury or death.

• Use this equipment for its intended purposes only.

• Do not modify the equipment in any way. Unauthorized modification may

impair the function and/or safety, and could affect the life of the equipment.

Any modification to the equipment voids the warranty.

• Do not allow children, spectators, or bystanders within the work area.

• Have a first-aid kit available for use should the need arise, and know how to

use it.

• Provide a fire extinguisher for use in case of an accident. Store in a highly visible place.

• Wear appropriate protective gear . This list includes, but

is not limited to:

• a hard hat

•gloves

• protective shoes with slip-resistant soles

• protective goggles

• hearing protection

• For Powered Equipment: before servicing, adjusting, or repairing powered

equipment, unplug, place all controls in neutral or off position, stop the engine

or motor , remove ignition key or lock out power source, and wait for all moving parts to stop.

8 30645 R0

WHEATHEART - GRAIN AUGERS 2. SAFETY FIRST

4" GALVANIZED UTILITY 2.2. ASSEMBLY SAFETY

• Follow good shop practices:

• keep service area clean and dry

• be sure electrical outlets and tools are properly

grounded

• use adequate light for the job at hand

• Think SAFETY! Work SAFELY!

2.2. ASSEMBLY SAFETY

• Read through the instructions to get to know the sub-assemblies and hardware that make up the equipment.

• Do not take chances with safety. The components are large, heavy, and can

be hard to handle. Always use the proper tools, stands, jacks, and hoists for

the job.

• Always have 2 or more people assembling the equipment. Because of the

weight, do not attempt assembly alone.

2.3. OPERATION SAFETY

• Have another person nearby who can shut down the auger in case of accident. Always work with a second person around augers.

• Do not operate with any of the safety guards removed.

• Keep body, hair, and clothing away from moving p art s. Stay away from intake

during operation.

• Augers are not insulated. Keep away from electrical lines. Electrocution can

occur without direct contact.

• Ensure that auger is empty before moving.

• Inspect auger supports on a daily basis.

• Support auger securely to prevent upending or upsetting.

2.4. MAINTENANCE SAFETY

• Shut down and lock out all power before attempting maintenance of any kind.

If applicable, disconnect PTO driveline from tractor or hydraulic hoses on

units with hydraulic drive hoppers.

• After maintenance is complete, replace and secure all safety guards and

safety devices, and if applicable, service doors and cleanout covers.

• Use only genuine Wheatheart replacement parts or equivalent. Replacement

parts such as intake guards, pulley guards, PTO driveline shields, winches,

and lift cables must meet ASAE standards or serious injury may result. Use of

unauthorized parts will void warranty. If in doubt, contact Wheatheart or your

Wheatheart dealer. Do not modify any auger components.

•

30645 R0 9

2. SAFETY FIRST WHEATHEART - GRAIN AUGERS

2.5. SAFETY DECAL LOCATIONS 4" GALVANIZED UTILITY

2.5. SAFETY DECAL LOCATIONS

• Keep safety decals clean and legible at all times.

• Replace safety decals that are missing or have become illegible. See decal

location figures below.

• Replaced parts must display the same decal(s) as the original part.

• Safety decals are available from your distributor, dealer, or factory.

2.5.1. DECAL INSTALLATION

1. Decal area must be clean and dry, with a temperature above 10°C (50°F).

2. Decide on the exact position before you remove the backing paper.

3. Align the decal over the specified area and carefully press the small portion

with the exposed sticky backing in place.

4. Slowly peel back the remaining paper and carefully smooth the remaining

portion of the decal in place.

5. Small air pockets can be pierced with a pin and smoothed out using the sign

backing paper.

2.5.2. DECAL LOCATIONS

Replicas of the safety decals that are attached to the equipment are shown in the

figure(s) that follow. Good safety requires that you familiarize yourself with the

various safety decals and the areas or particular functions that the decals apply

to as well as the safety precautions that must be taken to avoid serious, injury,

death, or damage.

10 30645 R0

WHEATHEART - GRAIN AUGERS 2. SAFETY FIRST

PLACED ON MACHINE

BEHIND GUARD

DECAL #17098

DECAL #17096

DECAL #17101

DECAL #27709

DECAL #17161

4" GALVANIZED UTILITY 2.5. SAFETY DECAL LOCATIONS

Figure 2.1 Safety Decals

* Wheatheart reserves the right to update safety decals without notice. Safety

decals may not be exactly as shown.

30645 R0 11

2. SAFETY FIRST WHEATHEART - GRAIN AUGERS

2.5. SAFETY DECAL LOCATIONS 4" GALVANIZED UTILITY

12 30645 R0

WHEATHEART - GRAIN AUGERS 3. ASSEMBLY

Warning: Before continuing, please reread the safety information relevant to this section at

the beginning of this manual. Failure to follow the safety instructions can result in serious

injury, death, or property damage.

Figure 3.1

Figure 3.3

4" GALVANIZED UTILITY 3.1. TUBE / FLIGHT EXTENSIONS

3.Assembly

Before starting assembly of your new auger, please read the following instructions carefully and familiarize yourself with all the sub-assemblies and hardware

making up the auger. Arrange all parts for easy access. Carry out assembly in a

large open area with a level surface.

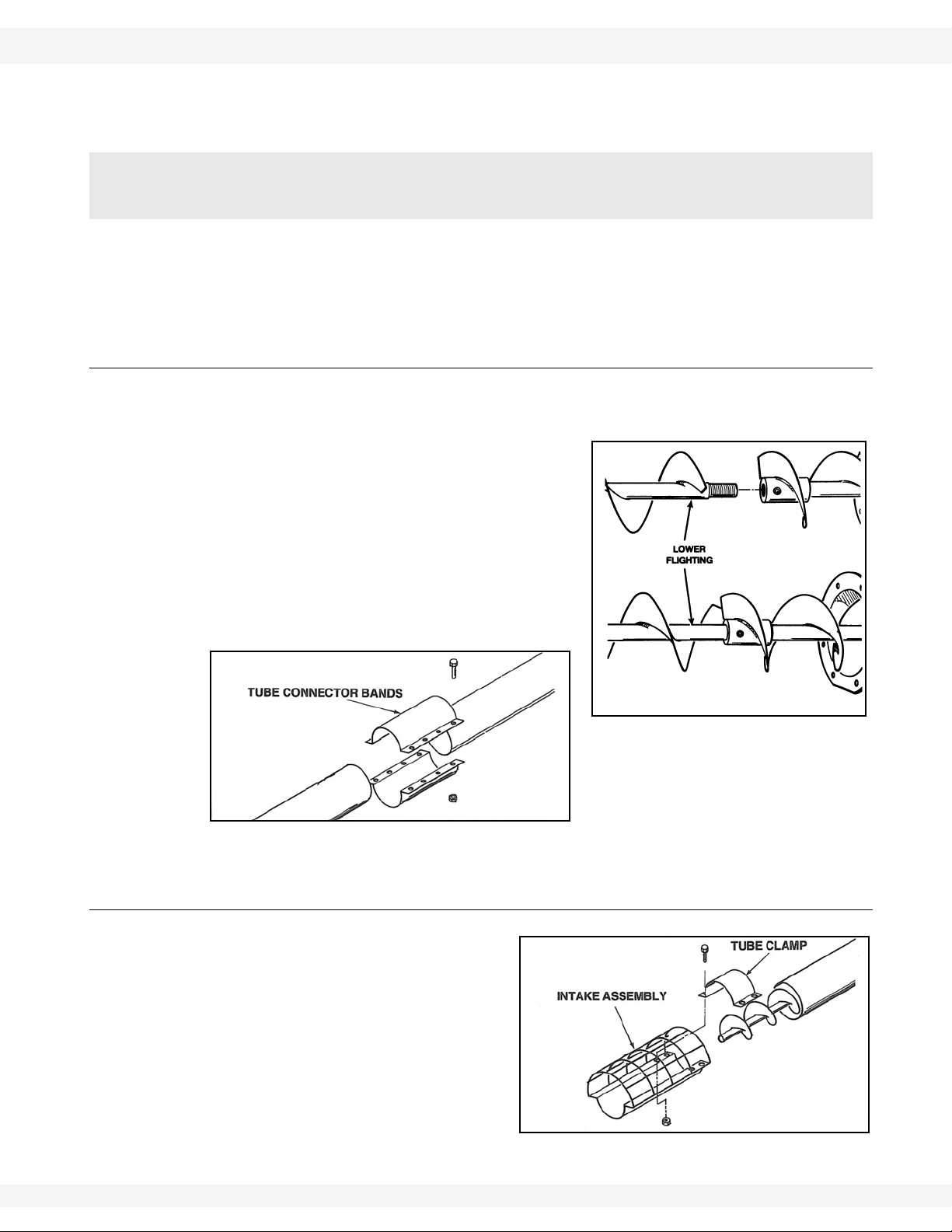

3.1. TUBE / FLIGHT EXTENSIONS

1. When extending the basic upper section, align upper and lower tube sections

on a flat surface.

2. Connect the flighting by screwing the

lower flight into the threaded pipe on

upper flight until flight ends butt together

and flighting spiral matches up (Figure

3.1).

3. Slide tube sections together and connect

with 2 half-tube connector bands. Secure

with 5/16”x 3/4” bolts and washerlocknuts (Figure 3.2.).

Figure 3.2

3.2. INTAKE ASSEMBLY

Attach the guarded intake assembly

to lower end of auger tube with tube

clamp and four 5/16” x 3/4” bolts

and washer-locknuts.

30645 R0 13

3. ASSEMBLY WHEATHEART - GRAIN AUGERS

Figure 3.4

Figure 3.5

3.3. HOPPER ASSEMBLY (OPTIONAL)4" GALVANIZED UTILITY

3.3. HOPPER ASSEMBLY (OPTIONAL)

See Figure 3.4.

1. Screw the stub shaft into

threaded pipe on lower

end of auger flight.

2. Slide hopper over lower

flighting and secure to

auger tube with four

5/16” x 3/4” bolts and

washer locknuts.

3.4. HEAD DRIVE ASSEMBLY

See Figure 3.5.

1. Remove dirt from upper end of flight shaft and insert Woodruff key.

2. Slide pulley onto flight shaft with hub facing the auger. Washer should

already be in place. Tighten set screws.

3. Place motor mount over top end of auger and secure with four 5/16” x 3/4”

bolts and washer locknuts.

4. Place pulley guard over pulley and secure with two 5/8” self-tapping screws.

5. After mounting the motor,

align the two pulleys with a

straight edge and adjust the

tension.

• The correct operating tension is the lowest tension

at which the belts will not

slip under peak load conditions.

• Recommended pulley

size for a 1750 rpm motor

is 2”.

14 30645 R0

WHEATHEART - GRAIN AUGERS 3. ASSEMBLY

When using an electric motor:

• The motor and controls should be installed by a qualified electrician in

accordance with all local and national codes.

• Incorporate a magnetic starter to protect the motor.

• The motor must have a manual reset button.

• Locate reset and starter controls so that the operator has full view of the

entire operation.

• Locate main power disconnect switch within reach from ground level to

permit ready access in case of an emergency.

• A main power disconnect switch capable of being locked (in the off position only) must be provided.

Figure 3.6

4" GALVANIZED UTILITY 3.5. FEED CONTROL ASSEMBLY (OPTIONAL)

3.5. FEED CONTROL ASSEMBLY (OPTIONAL)

See Figure 3.6.

1. Loosely attach tube clamp to auger

tube with two 5/16” x 3/4” bolts and

washer-locknuts. Do not tighten at this

time.

2. Thread the control handle through tube

clamp as shown, then place feed

control slide beneath the intake guard.

3. Seat tube clamp against stop on

control handle and lock into place with

the t -bolt on the clamp.

4. Slide feed control assembly down until

lower end is 1/2” past lower end of

auger tube. Tighten the tube clamp.

30645 R0 15

3. ASSEMBLY WHEATHEART - GRAIN AUGERS

Figure 3.7

3.6. SWIVEL MOUNT ASSEMBLY (OPTIONAL)4" GALVANIZED UTILITY

3.6. SWIVEL MOUNT ASSEMBLY (OPTIONAL)

See Figure 3.7.

1. Attach the half tube

clamps with two 5/16” x

3/4” bolts and washerlocknuts.

2. Attach the swivel bracket

to bottom tube clamp

with one 5/16” x 3/4” bolt

and locknut.

3. Screw the t-bolt into box

clamp, then attach box

clamp to swivel bracket

with one 5/16” x 3/4” bolt

and locknut.

16 30645 R0

WHEATHEART - GRAIN AUGERS 4. OPERATION

Warning: Before continuing, please reread the safety information relevant to this section at

the beginning of this manual. Failure to follow the safety instructions can result in serious

injury, death, or property damage.

4" GALVANIZED UTILITY 4.1. PRE-OPERATIONAL CHECKLIST

4.Operation

Operators must observe safety procedures at all times and follow the pre-operational checklist before each start-up.

4.1. PRE-OPERATIONAL CHECKLIST

Before operating auger each time, the operator must confirm the following:

• All fasteners are secure as per assembly instructions.

• Drive belt(s) are not frayed or damaged.

• Drive belt(s) are properly adjusted and aligned.

• Tube alignment is reasonably straight.

• Intake area and discharge spout are free of obstructions.

• Proper maintenance has been performed.

• Inspect auger supports frequently.

4.2. AUGER DRIVE AND LOCKOUT PROCEDURE

Drive Type Before Operation Lockout

The electric motor should be equipped with a

main power disconnect switch capable of

being locked in the off-position only. The

switch should be in the locked position during

shutdown or whenever maintenance is

performed on the auger.

• If reset is required, disconnect all power

before resetting motor.

Electric Motor

Before starting motor, ensure

• motor is properly

grounded

• pulley shields are in

place and secure

4.3. OPERATING PROCEDURE

4.3.1. START-UP AND BREAK-IN

BREAK IN

1. Complete the checklist at the beginning of this chapter. If everything is

satisfactory, prepare for a 30-minute operation at half speed.

2. Correctly position the portable grain hopper secure it to auger with both

straps (where applicable).

30645 R0 17

4. OPERATION WHEATHEART - GRAIN AUGERS

4.3. OPERATING PROCEDURE 4" GALVANIZED UTILITY

CAUTION

Maintain a hazard zone of 20’ around the work

site. Do not start auger until area is clear of all

untrained personnel.

3. Start electric motor, then feed grain to auger.

Important: When starting auger for the first time, be prepared for an emergency shutdown in

case of excessive vibration or noise. Note that auger may run rough until tube is

polished.

4. Upon completion of initial run, decrease grain input until auger is empty, then

stop.

5. Lock out motor and conduct a complete inspection of auger following the

checklist at the beginning of this chapter.

After the initial start-up and inspection, the auger should be shut down and

inspected at least three times during the first 10 hours of operation.

Keep operation of empty auger to a minimum, as this results in excessive wear.

Once auger is broken in, the checklist should be a part of the daily routine before

operating auger.

4.3.2. OPERATING WITH A FULL LOAD

1. When operating the auger , always work with a second person in a position to

monitor the operation and initiate a shutdown in case of emergency.

2. Monitor the auger during operation for abnormal noises or vibrations.

3. Shut off all power before making adjustments, servicing, or clearing the

machine.

18 30645 R0

WHEATHEART - GRAIN AUGERS 4. OPERATION

USE OF GRAIN SPREADERS: Many grain spreaders cannot handle the large

capacity of some augers. Some augers plug, causing damage to the flighting

and other drive components. This type of damage is not covered by warranty.

Hints on how to avoid this...

• Get a larger spreader, if available.

• Remove the spreader.

• Make sure spreader is turned on and operating.

• When using a flex down spout, center auger spout above spreader and

do not lower auger spout into spreader.

• Suspend the spreader lower from bin ceiling leaving extra room for

excess grain to flow over the spreader.

BIN LEVEL INDICATORS: These augers are fast and bins fill up quickly. A full

bin will cause auger to plug, which can damage the flighting and other drive

components. Installing quality grain-level indicators on your bins will allow you to

monitor bin filling and help prevent damage to your auger.

4" GALVANIZED UTILITY 4.3. OPERATING PROCEDURE

DANGER

Rotating Flighting Hazard!

To prevent death or serious injury:

• Keep away from rotating auger flighting.

• Do not remove or modify auger flighting

guards, doors, or covers. Keep in good

working order. Have replaced if damaged.

• Do not operate the auger without all

guards, doors, and covers in place.

• Never touch the auger flighting. Use a

stick or other tool to remove an obstruction or clean out.

• Shut off and lock out power to adjust,

service, or clean.

4.3.3. SHUTDOWN

30645 R0 19

Note: Remember that the flighting rpm on augers equipped with electric motors is not

NORMAL SHUTDOWN:

1. Near the end of a load, decrease the flow of grain until auger is clear.

2. Once auger is clear, stop motor and lockout power (Section 4.2.).

adjustable except with a change of pulley size.

EMERGENCY RESTART:

1. If the auger is shut down for an emergency, lock out motor before correcting

problem.

4. OPERATION WHEATHEART - GRAIN AUGERS

4.4. MAINTENANCE 4" GALVANIZED UTILITY

• If the problem is plugging, clear as much of the grain as possible using a

piece of wood, vacuum cleaner or other tool (not your hands) before

restarting auger. Do not reach in and use your hands.See “Auger Drive

and Lockout Procedure” on page 17.

NOTICE

Starting the auger under full load may result in damage to

unit. Be sure there is no blockage.

4.4. MAINTENANCE

Proper maintenance on the auger mean a longer life for the machine, better

efficiency and safer operation. Please follow the guidelines below.

4.4.1. GENERAL MAINTENANCE PROCEDURES

Area Maintenance Procedure Frequency

General

General

Drive Belt

Auger Supports

Motor Cover Protect motor from weather by covering.

Important: Use only genuine Wheatheart replacement parts or equivalent. Replacement

parts such as intake guards, pulley guards, PTO driveline shields, winches, and

lift cables must meet ASAE standards or serious injury may result. Use of

unauthorized parts will void warranty. If in doubt, contact Wheatheart or your

Wheatheart dealer. Do not modify any auger components.

While auger is in use, observe the operation checklist

on page 17.

If for any reason a part becomes damaged, replace it

immediately. If possible, lower auger to replace parts.

Check and replace if frayed or damaged.

Ensure tension is correct under load (correct tension is

the lowest at which the belts will not slip under peak

load conditions)

Inspect (cracked welds, proper configuration of

supports, bent/damaged pieces, etc.)

Daily

Regularly

Frequently

Frequently

During off sea-

son or when not

in use.

20 30645 R0

WHEATHEART - GRAIN AUGERS 5. TROUBLESHOOTING

4" GALVANIZED UTILITY

5.Troubleshooting

.

Problem Possible Cause Remedy

Excessive

noise or vibration.

*Remember to

follow proper

break-in procedures—auger

may run rough

until tube is polished. If noise

is extreme from

outset or continuous after

several loads of

grade are fed,

continue with

troubleshooting below

Drive belts

jumping off

pulleys.

Premature

wear on auger

tubes.

Truss cables incorrectly

adjusted.

Flighting peeled back due to

plugging.

Bent flighting sections.

Obstruction in tube.

Motor misaligned.

Belts mismatched.

Belt tension inadequate.

Using a lower horsepower motor

than recommended.

Auger being run at low capacity

or empty for extended period of

time.

Bent flighting.

Flighting allowed to wear

beyond normal point of replacement.

Support end of auger and adjust cables so

auger is flat or curves slightly upwards.

Inspect spout end of auger for flight condition.

Remove and replace flight sections as necessary.

Support auger and remove all flight sections.

Check for straightness of flight stubs by rolling

across flat concrete section. Straighten stub or

replace as necessary. Take care not to bend

flighting when reinstalling.

Visually inspect for cloth or trash wrapped

around flighting, or buildup of gum from oily

crops such as flax or canola.

Ensure drive and driven pulleys are correctly

aligned.

Check Assembly Section for correct belt sizes

and only replace in pairs.

Maintain correct tension as per assembly section.

See Assembly Section for recommended motor

sizes.

Frequently occurs on farms using grain wagons.

Auger should not be left unattended when filling

bins.

When flighting becomes razor-thin at intake,

replacement is critical. Since flight material is

double thickness at welded lap joints, high spot s

on flight occur and can accelerate spot tube

wear.

30645 R0 21

5. TROUBLESHOOTING WHEATHEART - GRAIN AUGERS

4" GALVANIZED UTILITY

22 30645 R0

LIMITED WARRANTY

Wheatheart warrants to the buyer that the new machinery is free from defects in material and

workmanship.

This warranty is only effective for any new machinery that has not been altered, changed,

repaired, or treated since its delivery to the buyer, other than by Wheatheart or its authorized

dealers or employees, and does not apply to accessories, attachments, tools, or parts sold or

operated with the new machinery if they have not been manufactured by Wheatheart.

Wheatheart shall only be liable for defects in the material or workmanship attributed to faulty

material or bad workmanship that can be proved by the buyer, and specifically excludes liability

for repairs arising as a result of normal wear and tear of the new machinery or in any other manner whatsoever, and without limiting the generality of the foregoing, excludes application or

installation of parts not completed in accordance with Wheatheart operation manual, specifications, or printed instructions.

A Warranty Registration Form and Inspection Report must be completed at the time of delivery

and returned to Wheatheart Manufacturing within thirty (30) days.

Warranty Period

Private Farm Use One (1) year from date of purchase.

Commercial, Custom, or Rental Use Ninety (90) days from date of purchase.

Replacement Parts Ninety (90) days from date of replacement

Defective parts are subject to inspection by a Wheatheart representative prior to approval of a

warranty claim. All returned parts must be sent to the factory, freight pre-paid, in order to qualify

for warranty replacement. Repaired or replaced parts will be returned freight collect.

If these conditions are fulfilled, Wheatheart shall at its own cost and its own option either repair

or replace any defective parts provided that the buyer shall be responsible for all expenses

incurred as a result of repairs, labor , part s, transporta tion, or any other work, unless Wheatheart

has authorized such expenses in advance. Normal wear and service items such as belts,

hoses, flashing, etc. are excluded from warranty.

The warranty shall not extend to any repairs, changes, alterations, or replacements made to the

new equipment other than by Wheatheart or its authorized dealers or employees.

This warranty extends only to the original owner of the new equipment.

This warranty is limited to the terms stated herein and is in lieu of any other warranties whether

expressed or implied, and without limiting the generality of the foregoing, excluded all warranties, expressed or implied, or conditions whether statutory or otherwise as to quality and fitness

for any purpose of the new equipment, Wheatheart disclaims all liability for incidental or consequential damages.

This machine is subject to design changes and Wheatheart shall not be required to retro-fit or

exchange items on previously sold units except at its own option.

WARRANTY VOID IF NOT REGISTERED

Wheatheart

Part of the Ag Growth International Inc. Group

P.O. Box 39

Rosenort, Manitoba, Canada R0G 1W0

Phone: (866) 467-7207 (Canada & USA)

Fax: (866) 768-4852

website: www.wheatheart.com

email: sales@wheatheart.ca

© Ag Growth International Inc. 2013

Printed In Canada

Loading...

Loading...