Wfly ET12 Instruction Manual

WFLY

Shenzhen WFLY Technology Development Co., LTD

INSTRUCTION MANUAL

ET12

(ET Series)12-channel Digital Proportional R/C System

001

V1.0 2

Thank you for using WFLY products!

● Please read this product manual carefully before using this product!

● Please use this product correctly!

The model is not a toy, for safety,please don't fly in crowded places!

——Shenzhen WFLY Technology Development Co., LTD

002

CATALOGUE

000

007

007

008

009

009

009

000

000

010

010

011

012

012

000

000

013

014-015

016

016

017

018

000

019

020

021

022

000

000

023

024-025

\Safety Precautions

Symbols Definition

Flying Precautions

Battery

Headphone Port

Trainer Port

USB Port

\Before Use

Basic Configuration

Product Features

Each Parts Name Of Transmitter

The Travel of Antenna Direction Adjustment

Switch Configuration and Model Types

\Basic Operation

Home Interface Introduction

Touch Screen Operation

Stick Adjustment

Indicator Light of Transmitter

Left and Right Hand Mode Replacement Method

Receiver Instructions

Receiver and servo connection example:

--Airplane

--Glider

--Helicopte

--Multicopter

\Basic Setting Sequence of Models

--Airplane and Glider

--Helicopter

003

CATALOGUE

000

026

027

028

029

030

031

032

033

034

035

036

037

038

039

040

000

000

041

042

043

044

045

046

047

048

049

050

051

052

000

000

053

054

055

056

057

058

059

060

061

062

063

064

065

066

\System Setting

Trainer

Display

User Name

Sound

Warning

Low Battery

Stick Mode

Calibration

Telemetry Voice

Back Colour

Language

Screen Cali(Calibration)

Data Reset

Information

Screen Lock Set

\Linkage Setting

Link

Telemetry

PPM/W.BUS

Receiver Output

Fail Safe

Relay Flight

Servo Frequency

BUS Servo Setting

Range Check

Telemetry Unit

180/270° Servo

\General Menu

Monitor

Model Select

Model Type

Function

Servo Reverse

Dual Rate

End Point

Timer

Trim Setting

Sub-Trim

Channel Delay

Program Mixes

Flight Mode

Doublel Engine

004

CATALOGUE

000

067

068

069

070

071

072

073

074

075

076

077

078

079

080-081

000

000

082

083

084

085

086

087

088

089

090

091

092

093

094

095

096

097

098

099

100

101

102

103

\Model Menu\Helicopter

Condition

Pitch Curve

Throttle Curve

Throttle Hold

Throttle Cut

Gyro

Swash Ring

Swash Mixing

Throttle Mixing

Idle Down

Governor

Pitch→Rudder

Fuel Mixes

Swash

\Model Menu\Airplane

Condition

AIL Differential

Throttle Curve

Throttle Cut

Throttle Hold

Idle Down

Aileron→Rudder

Rudder→Aileron

Rudder→ELE

Snap Roll

Flap Setting

Camber Mix

ElE to Camber

Camber Flap to Elevator

Aileron to Camber Flap

Airbrake

Gyro

Motor

Fuel Mix

Elevator

V-Tail

Winglet

005

CATALOGUE

000

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

000

000

124

125

126

127

128

129

\Model Menu\Glider

Condition

AIL Differential

Throttle Curve

Throttle Cut

Throttle Hold

Idle Down

Aileron→Rudder

Rudder→Aileron

Flap Setting

Camber Mix

Elevator to Camber

Flap to ELE

Aileron to Flap

Butterfly

Trim Mixing

Gyro

Motor

V-tail

Aileron Elevator

Winglet

\Model Menu\Multicopte

Condition

Throttle Curve

Throttle Cut

Throttle Hold

Stick Alarm

Gyro

006

Safety Precautions

WARNING

NOTICE

DANGER

WARNING

NOTICE

DANGER

Symbols Definition

Pay special attention to the safety information of the following symbols.

If without a proper operation,it may cause dangerous accident or seriously injury or

may even cause death.

If without a proper operation,it may cause dangerous accident or seriously injury or

may even cause death,and it may cause slight hurt or probability cause bodily injure!

If without a proper operation,it may cause less possibility to serious hurt,but it may

cause hurt or bodily injure.

Prohibitions

Flying Precautions

Disclaimer & Warning

User should be responsible for any consequences

caused by using the product. WFLY shall not be

liable for any directly or indirectly damage, injury

and any legal liability, User shall comply with all

guidelines including but not limited to this

document.

Please follow the local laws and regulations for

regular flight activities. Do not use this product to

carry out personal safety, property safety or other

bad flight behaviors.

To ensure the safety of yourself and others,

please observe the following precautions:

Charge the batteries! Check transmitter and

receiver battery levels and always recharge the

batteries before each flying session. A low battery

will soon die potentially, causing loss of control and

a crash. When you begin your flying session, reset

your ET12 built-in timer, and during the session pay

attention to the duration of usage.

Be careful when flying near electric wires, highrise buildings or communication facilities, as there

may be radio interference around.

Mandatory

Before flying, inspect the aircraft carefully,

inspect whether the aircraft and transceiver system

it's normal. When flying, make the transmitter

display to the initial interface, in case of mistaken

parameter change. After flight, turn off the receiver

power before turn off the transmitter power, in case

of any injury caused by fail safe works.

More debugging, more testing, less loss, less

damage!

Mandatory

Power on and off sequency of transmitter and

receiver

Power on:

Firstly turn on the transmitter (ensuring the

minimum throttle position), Secondly Turn on the

receiver

Power off:

Firstly turn off the receiver, Secondly turn off the

transmitter

Transmitter and receiver low voltage may cause

fail-safe danger!

Beginners should pay particular attention to the

following safety precautions! Please read carefully!

No fly when user is in poor health condition such as

fatigue and drunkenness.

No fly in bad weather day such as rain, strong wind

or at night, etc.

No fly near high voltage wires, communication base

stations, government secret zone or public places

where crowds gathered.

No fly in airports and other places where fly is

forbidden.

Mandatory

Note: The transmitter will display the warning

interface, please pay attention to the transmitter

prompt! Improperly operation may cause

accident injury to user.

007

Safety Precautions

DANGER

NOTICE

NOTICE

Battery

Lithium polymer battery(Short for LiFe

battery),please use the WFLY special charger

only.It is important to understand the operating

characteristics of Li-FE batteries.

IMPORTAN!

Long term storage (more than 3 months),storage

temperature≤45°C general storage voltage 3.7-

3.9v.Failure to follow the proceeding precautions

can quickly result in severe, permanent damage to

the batteries and possibly result in a fire!

1.Do not attempt to disassemble LiFe packs or

cells.

2.Do not allow LiFe cells to come in contact with

moisture or water at any time.

3.Always provide adequate ventilation around

LiFe batteries during charge, discharge, while in

use, and during storage.

4.Do not leave a LiFe battery unattended at any

time while being charged or discharged.

5.Do not attempt to charge LiFe batteries with a

charger that is NOT designed for LiFe batteries, as

permanent damage to the battery and charger could

result.

6.Always charge LiFe batteries in a fireproof

location. Do not charge or discharge LiFe batteries

on carpet, a cluttered workbench, near paper,

plastic, vinyl, leather or wood, or inside an R/C

model or full-sized automobile! Monitor the charge

area with a smoke or fire alarm.

7.Do not charge LiFe batteries at currents greater

than the “1C” rating of the battery (“C” equals the

rated capacity of the battery).

8.Do not allow LiFe cells to overheat at any time!

Cells which reach greater than 140 degrees

Fahrenheit (60°C) should be placed in a fireproof

location.

9.LiFe cells will not charge fully when too cold or

show full charge.

10.It is normal for the batteries to become warm

during charging, but if the charger or battery

becomes excessively hot disconnect the battery

from the charger immediately!! Always inspect a

battery which has previously overheated for

potential damage, and do not re-use if you suspect it

has been damaged in any way.

11.Do not use a LiFe battery if you suspect

physical damage has occurred to the pack.

Carefully inspect the battery for even the smallest of

dents, cracks, splits, punctures or damage to the

wiring and connectors.DO NOT allow the battery’s

internal electrolyte to get into eyes or on skin—wash

affected areas immediately if they come in contact

with the electrolyte. If in doubt, place the battery in a

fire-proof location for at least 30 minutes.

12.Do not store batteries near an open flame or

heater.

注意

13.Do not discharge LiFe batteries at currents

which exceed the discharge current rating of the

battery.

14.Always store LiFe cells/packs in a secure

location away from children.

Transmitter (ET12):

ET12 adopts the power supply mode of lithium

battery, and the working voltage adapts to the range

of 3.5V-13V. Using a power supply that exceeds the

operating voltage stroke may burn the machine!

The USB interface of the ET12 cannot be

charged. Please charge the battery with a

professional charger!

Receiver (RF209S):

The receiver's operating voltage adapts to the

range 3.5V-13V, with anti-reverse protection slot

(power input pole, positive and negative reverse

protection). With a power supply that exceeds the

operating voltage stroke, the receiver will burn out.

008

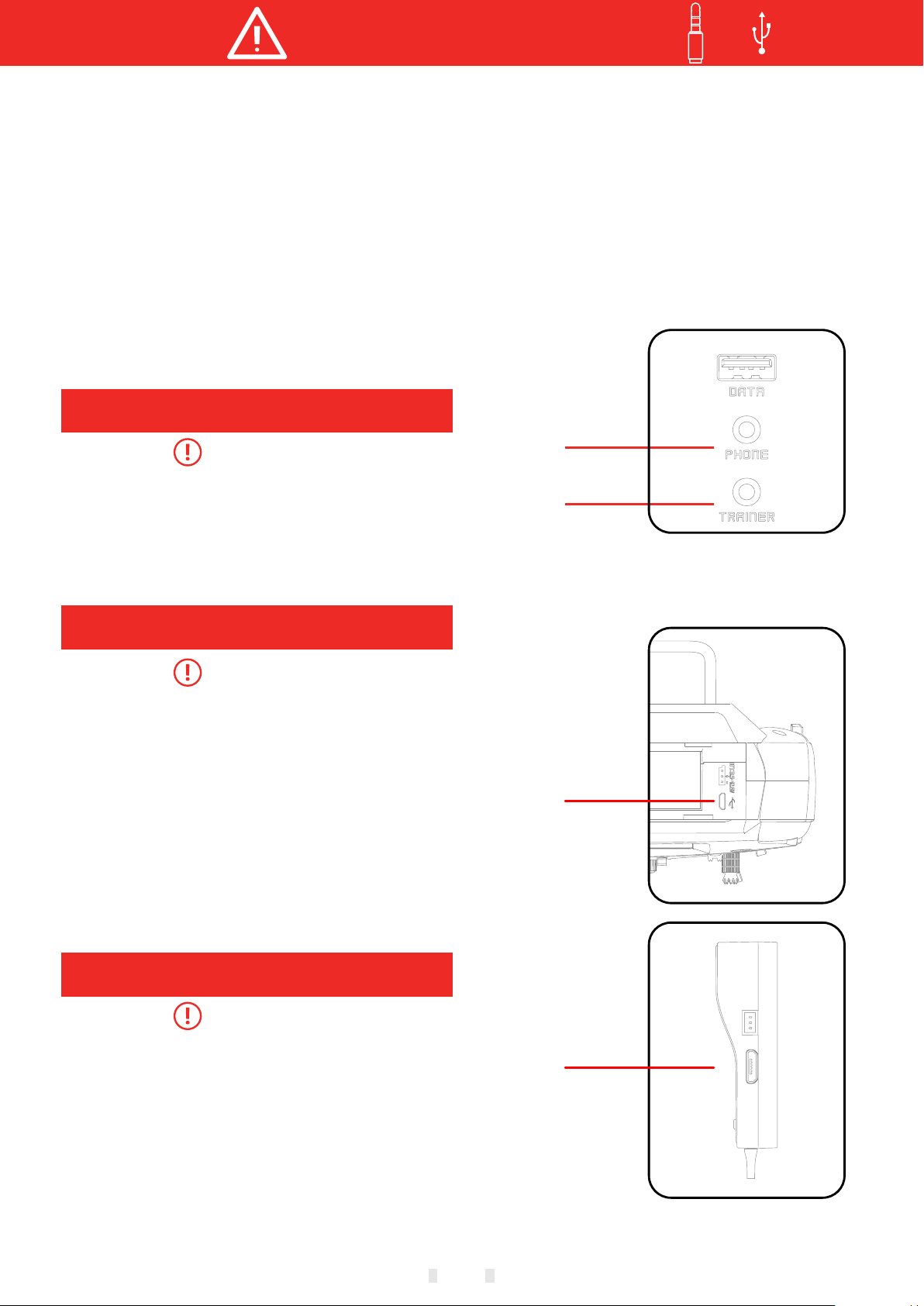

Safety Precautions

Headphone Port

Mandatory

Headphone port

Transmitter headphone port:

Only for voice output! Standard:3.5mm audio

port. Warning: This port is only used as a voice port.

Do not insert the charging (high voltage) terminal

into the port to avoid damage to the transmitter.

Trainer Port

Mandatory

Transmitter trainer port:

The trainer port is with 3.5mm audio port output

mode. This suite is without the trainer data line. If

you want to use the trainer function, you need to

purchase the trainer data line separately! Warning:

This port is only used for trainer data transmission.

It is forbidden to insert the power supply (high

voltage) terminal to the port to avoid damage for the

transmitter. Suggestion: You can consult the

purchase line at WFLY Technology Taobao Store or

other model online stores or physical stores.

Trainer port

USB port

USB Port

Mandatory

Transmitter USB port:

ET12 adopt standard USB port for upgrading

function! Warning: This port is only used as

upgrading data transmission, it is forbidden to insert

the power supply (high voltage) terminal to the USB

port to avoid damage for the transmitter.

Receiver USB port:

RF209S USB port is only used as upgrading data

port, it is forbidden to insert the power supply (high

voltage) terminal to the USB port to avoid damage

for the receiver.

USB port

009

Before Use

Product Features

Transmitter

Type: ET12

Channel: 12

Voltage: 3.5V-13V(1S-3SLithium battery)

Current: 260-400mA

Application: Helicopter, Airplane, Multi-rotors,

Vehicle, Ship.

Resolution: Full Channel 4096

Band: 2.4GHz (Bidirectional)

Storage: 30 models

Programming: 5 Groups Mixed Control

Language: Chinese, English

Upgrading:USB online upgrade

Display: 3.5inch touch, 480*320, color display

Voice: Support voice broadcast

Relay light: Available

180/270°Servo: Available

Wireless signal copy: model data

Receiver

Type: RF209S

Band: 2.4GHz

Voltage: 3.5V-13V

Current: 95mA

Application: Helicopter, Airplane, multicopter,

Vehicle, Ship, Robot.

Resolution: 4096

PWM: 9channels

W.BUS: Compatible

W.BUS2: Remote sensor input

Two-way transmission: Available

Lost-control protection: Available

Online upgrading: Available

Relay flight: Available

180/270°servo: Available

Receiver port setting: Available

External voltage detection: DC 0~96V

Dimension: 47x14x25mm

Weight: 12g

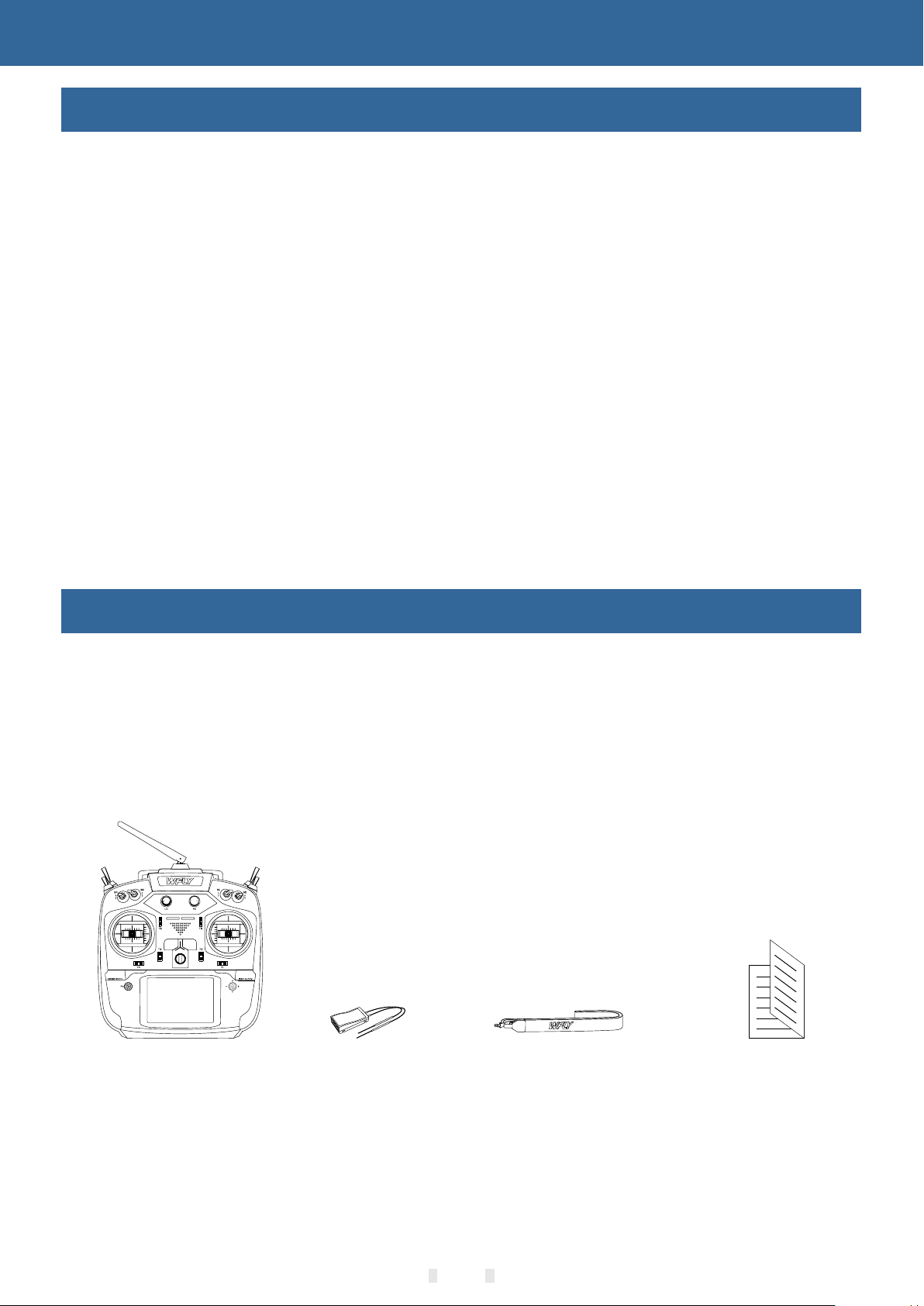

Basic Configuration

ET12 transmitter x1

RF209S receiver x1(include external power detection line x1)

Hanging strap x1

Summary manual x1

①

Transmitter

②

Receiver

010

③

Hanging Strap

④

Summary Manual

Carr y handle

Before Use

Each Parts Name Of Transmitter

Antenna

SF Switch Block

SE Switch Block

SB Switch Block

SA Switch Block

LD Rotary Knob

J3

J4

HOME/MON.

Fn Toggle Key

Fn Status LED

Power LED

Trim6

Stick

Power key

Trim3

Trim4

SH Switch Block

SG Switch Block

SC Switch Block

SD Switch Block

RD Rotary Knob

RF LED

Trim5

Speaker

Stick

Trim2

Trim1

EXIT/LOCK

5-way Button

Hook

J2

J1

Color LCD

VR Thumb Wheel

RS Slide Lever

Headphone Port

Trainer Port

Battery cover

VL Thumb Wheel

LS Slide Lever

Battery Interface

USB Port

011

Before Use

Switch configuration and model types

Power LED: Left, power indicator light, red

RF LED: Right, RF indicator light, blue.

POWER: Click one power key only for 3 seconds to open/shut down; Click 2 pow er k ey s at t he s am e ti me

to flash shutdown.

SA: Short lever 3 positions (user-defined)

SB: Long lever 3 positions (user-defined)

SC: Long lever 3 positions (user-defi ne d)

SD: Short lever 3 positions (user-defined)

SE: Short lever 3 positions (user-defined)

SF: Short lever 3 positions (user-defined)

SG: Short lever 3 positions (use

SH: Long lever momentary (user-define d)

LS/RS: Slide lever (user-defined)

VL/VR: Thumb wheel (user-defined)

T1-T6: Trim (user-defined)

5-way button: Move the cursor button up and down or left and right, middle button for confirmation(Long

press for momentary)

Fn switch key: Click to switch for 5-way button working mode. Fn status LED lighting-o ff, 5-w ay b ut to n

works for interface operation setting and parame ters inp ut w he n to uc h sc re en i s ou t of w or k( PS : 5- wa y

button and touch panel could be used at the sa me tim e) . Fn s ta tu s LE D is o n, 5 -w ay b ut to n wo rk s as c

switch, click button or trimming.

r-defined)

ontrol

PHONE: Earphone plug in the earphone tra ns mi tt er s pe ak er, m ea nw hi le e arphone output the voice.

TRAINER: Trainer port.

HOME/MON.: Home/Monitor key, short click home, long click monitor.

EXIT/LOCK: Exit/Lock key, short click to exist, long click to lock the screen.

The Travel Of Antenna Direction Adjustment

The antenna activity of the transmitter is limited by the stroke. If the activity is exceede d, t he a nt en na w il l

be damaged. The active travel indication of the antenna is as following:

Mandatory

Up and down 90°

Rotate 180° on the front

012

Basic Operation

WFLY

Home Interface Introduction

18

17

1

2

3

Home Interface 1

4

5

6

7

Introduction and Operation

1.Transmitter model

2.LOGO, Click to enter main menu

3.Timer 1

4.Return data(receiver voltage)

5.Return data(External battery)

6.Model active time,switch model,long press,

reset shutdown.

7.Trim monitor,display active trimming

status(Right side diagram)

8."HPME2" key,click to enter home Interface 2

9.Model name: Click to enter models select

interface

10.Model Type:Click to enter current model type

Interface

11.Timer 2

12.User name,click into user defined name

13.Indicate trim status,display the current trim

position

14.Transmitter battery voltage

15.Receiver signal strength

16.Flight condition,current flight mode

17.Trainer mode(Trainer/Simulator/Student)

18.Lock(Click and hold EXIT/LOCK buttom for 2s

ET12

00:00.0

Receiver

00:00.0

-500 -500

5.0V

12.0VExternal

16

T5

T6

+25

0 +1000

HOME2

8

to enter lock status)

15

T6

T3

14

13

12

11

10

9

T5

T2

T1

12.9V

T2 T1

T4

+1000

RXCondition1SIM

T3

User name

00:00.0

Model 1

T4

19."HOME1 interface1",click into home interface

20.Return data(Receiver voltage)

21.Timer 1

22.Timer 2

23.Return data(Ext battery voltage)

Home Interface 2

19

20

21

22

HOME1

Receiver

5.0

SIM

Condition1

RX

External

V

12.0

00:00.0

00:00.0

013

12.9V

23

V

Basic Operation

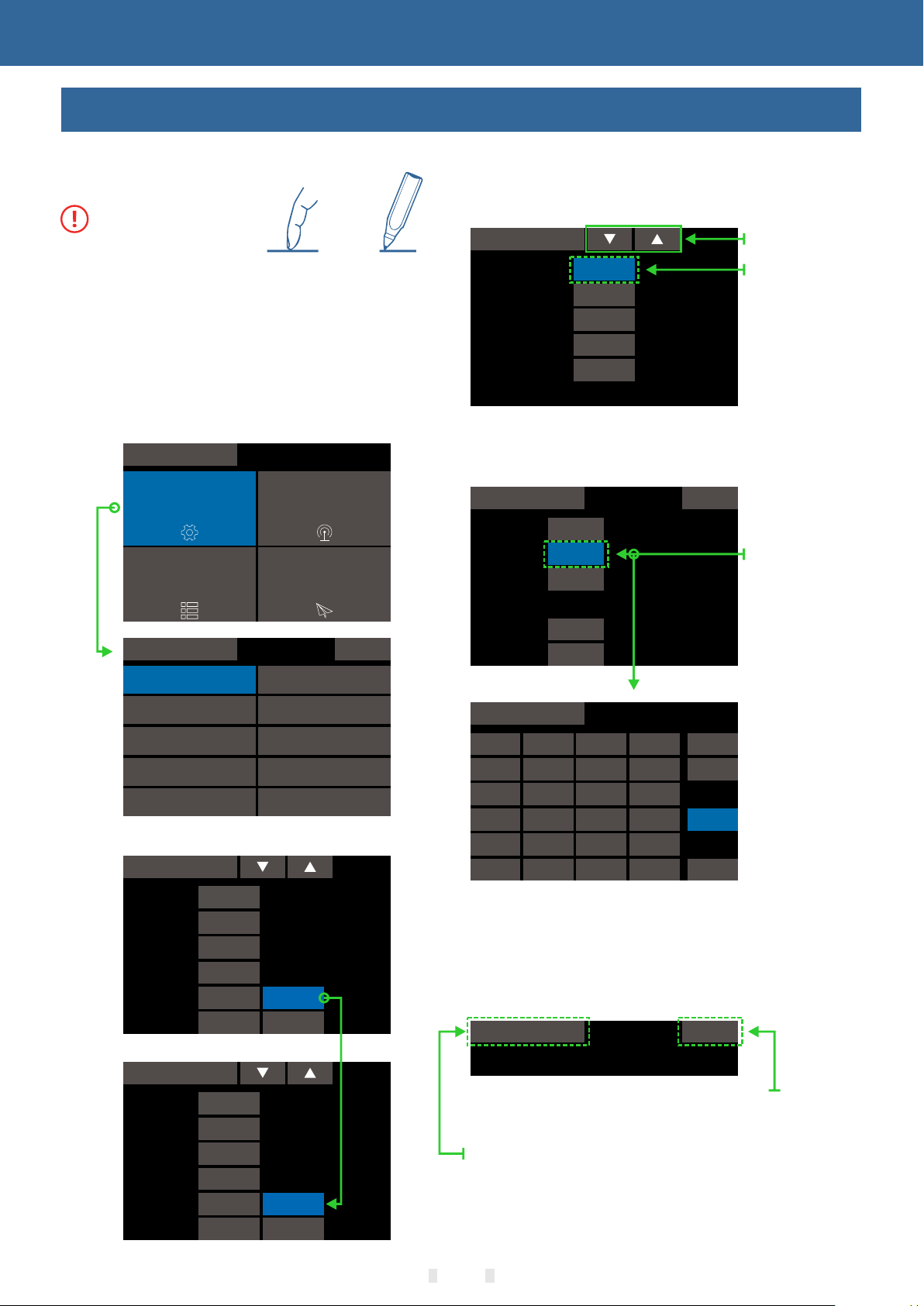

Touch Screen Operation

ET12 uses 3.5 inches resistive touch screen,

which makes ET12 operation more flexible and

efficient.

Mandatory

Touch softly the Touch Screen with the stylus pen

or your fingertips.Plastic film is attached to the touch

screen. Please be careful so that you don't scratch

the touch screen with anything hard such as a metal

object. Don't push the touch screen with excessive

force or drop anything on the panel.

Operate Demonstration

Menu Operation:Click enter into the relative

interface

Menu

System setting

General menu

System setting

Tra iner

Linkage setting

Model menu

1/2

Low battery

Parameters Setting

1 Data setting:Click and pop up the upper right

setup key,press long for rapid add and

subtract.Long Press the number button to reset the

default value.

Telemetry voice

Status

Switch

Speed interval

Alarm repeat

Alarm duration

ON

--

30 Sec

1

10 Sec

Setting Button

Long Press to

reset the

default value

2 Switch Selection:Click switches selecting

button,choose the required switch from the switches

selecting interface

Tra iner

Mode

Teach SW

CH mode

CH

Aileron

1

Rudder

2

Tra iner

--

12CH

Status

ON

ON

1/2

Jump to the

interface of

the distribution

switch button

Display

User name

Sound

Warn ing

Stick mode

Calibration

Telemetry voice

Back colour

Status Switch: Click into switch status

Sound

Warn ing

Telemetry

Button

Other

Tri m

Tim er

Sound

Warn ing

Telemetry

Button

Other

Tri m

Tim er

50

50

50

50

50 Voice

50 Voice

50

50

50

50

50 Voice

50 Voice

Tra iner

J1

J2

J3

J4

LD

RD

SA

SB

SC

SD

LS

RS

SE

SF

SG

SH

VL

VR

T1

T2

T3

T4

T5

T6

C L/R

C U/D

--

Diagram

Return,Paging Operation

Return:Click pages button to switch interface

Paging:Click paging button to switch

interface,when multiple page,the upper right of

interface indicates A/B style (A,current page;B page

numbers)

Tra iner

1/2

This shows the first page interface,

a total of two pages.

Click to return to the previous interface

014

Basic Operation

Touch Screen Operation

Popup prompt:

When the operation changes important

parameters, the selection box will pop up for

secondary confirmation. The default "No" is

selected.

Example:Model selection, interface replication

model operation!

After clicking the "Copy" button, the prompt

selection box pops up, select "Yes", then complete

the operation of copying the parameter of "Model 1"

to "Model 2".

Model Select

Source

Model 1

Model Select

Sure?

Source

Model 1

Copy

Yes

Object

Model 2

Object

Model 2

No

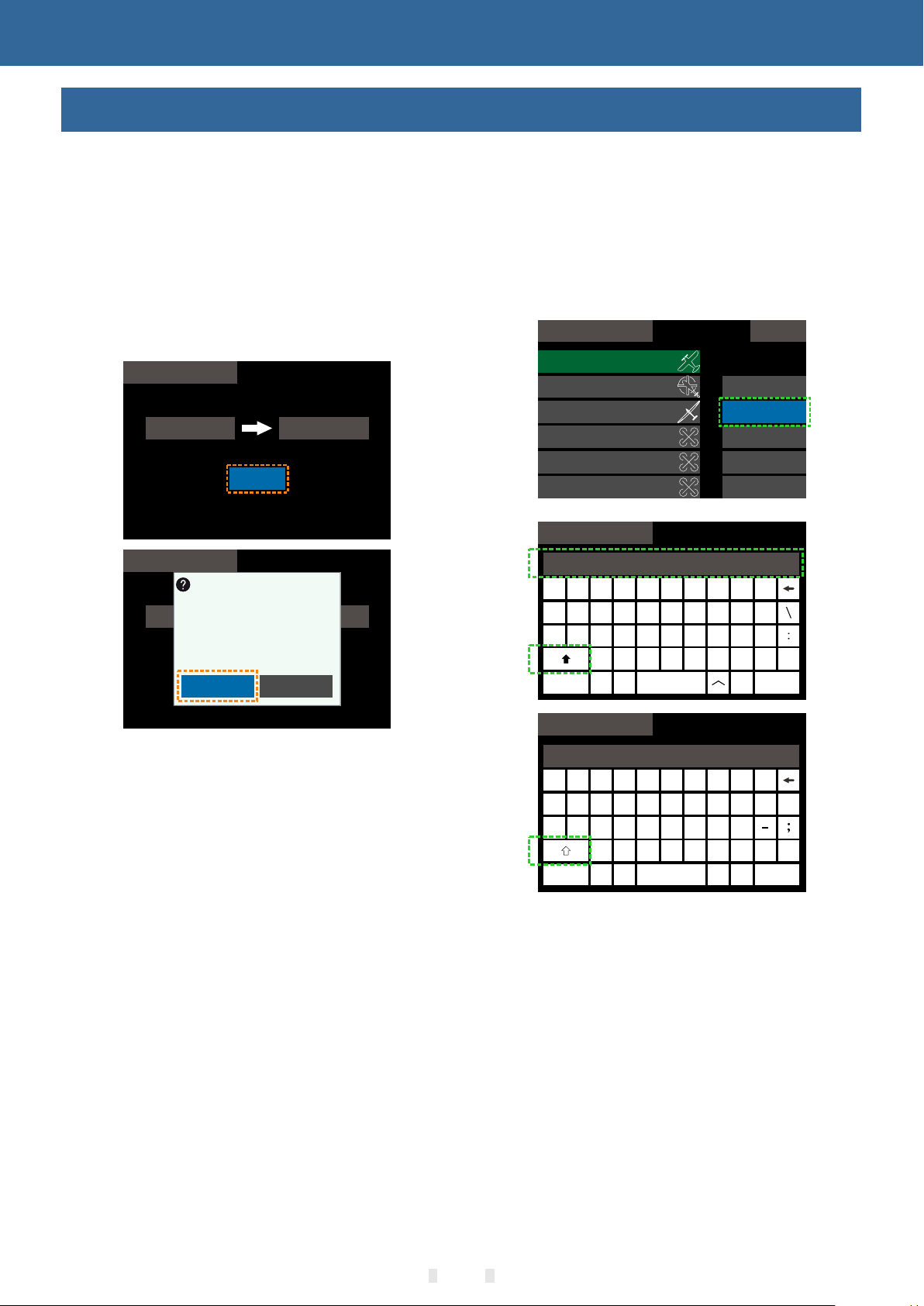

Keyboard

The keyboard is only used for naming function,

such as model renaming,

Flight condition naming, username setting.

The input keyboard is case sensitive and has

multiple symbols to choose from.

The input content above the interface could be

checked when naming.

1/7Model Select

Model 1

8

I

K

N

Select

Rename

Copy

Send

Receive

0

9

O

P

-

L

!

M

@

OK

"

Capital

Key

Model 2

Model 3

Model 4

Model 5

Model 6

Model Select

Model 12

2

Exit

W

S

3

E

D

Z

(

1

Q

A

7

6

4

5

R

F

X

Y

U

T

J

H

G

B

C

V

)

Warning popup

Starting up machine model function warning:

Turn the corresponding function switch to the

off position and enter into the system after the

warning disappeared.

Starting up machine low voltage alarm: select

"Yes" to continue the power on; select "No" to

shut down.

Receiver not connected alarm: Select "Back"

to close the alarm interface. (Some functions

need to enable the “Telemetry” function to be

used normally. After “ Telemetry” is turned on

and connected normally, the warning will not be

displayed.)

Stick calibration warning: Select "Back" to

close the alarm interface. (The receiver needs to

be disconnected during calibration!)

Shutdown alarm: Select "Back" to close the

warning interface and shutdown alarm.

Capital

Key

Model Select

Model 12

Exit

3

w

e

s

d

<

1 2

q

a

5

4

r

t

g

f

cx>z

7

6

y

h

v

8

9 0

u

j

k

b

p

o

i

mn

.

%

l

*

#

,

OK

015

LED

Status

Power

LED

Light on

Power on

Light off

Power off

Light flash

Power on alarm(Low voltage,power on/off warning)

RF

LED

Light off

Power Off/Student/Simulator/Mode

Light on

Normal communication,Trainer or normal mode

Light flash

Linking status

Basic Operation

Indicator Light of Transmitter

Power LED

Red

RF LED

Blue

Stick Adjustment

Stick head height adjustment:

1. Loosen the upper section head counterclockwise

2. Then twist the lower head to adjust the height

3. Twist the upper head clockwise to lock it

Stick feel and function adjustment

ET12 uses the newly developed four-bearing assembly to trim the feel!

Uncover the silicone sheet on the back and adjust the feel directly.

Note: Do not use excessive force or over twist the number of turns when adjusting the screw. Otherwise,

the structure assembly would be twisted off and the screw may fall off, resulting in irreversible damage.

Tooth adjustment

Smooth adjustment

Upper and lower elastic

adjustment position

Left and right elastic

adjustment position

Tooth adjustment

Smooth adjustment

Left and right elastic

adjustment position

Upper and lower elastic

adjustment position

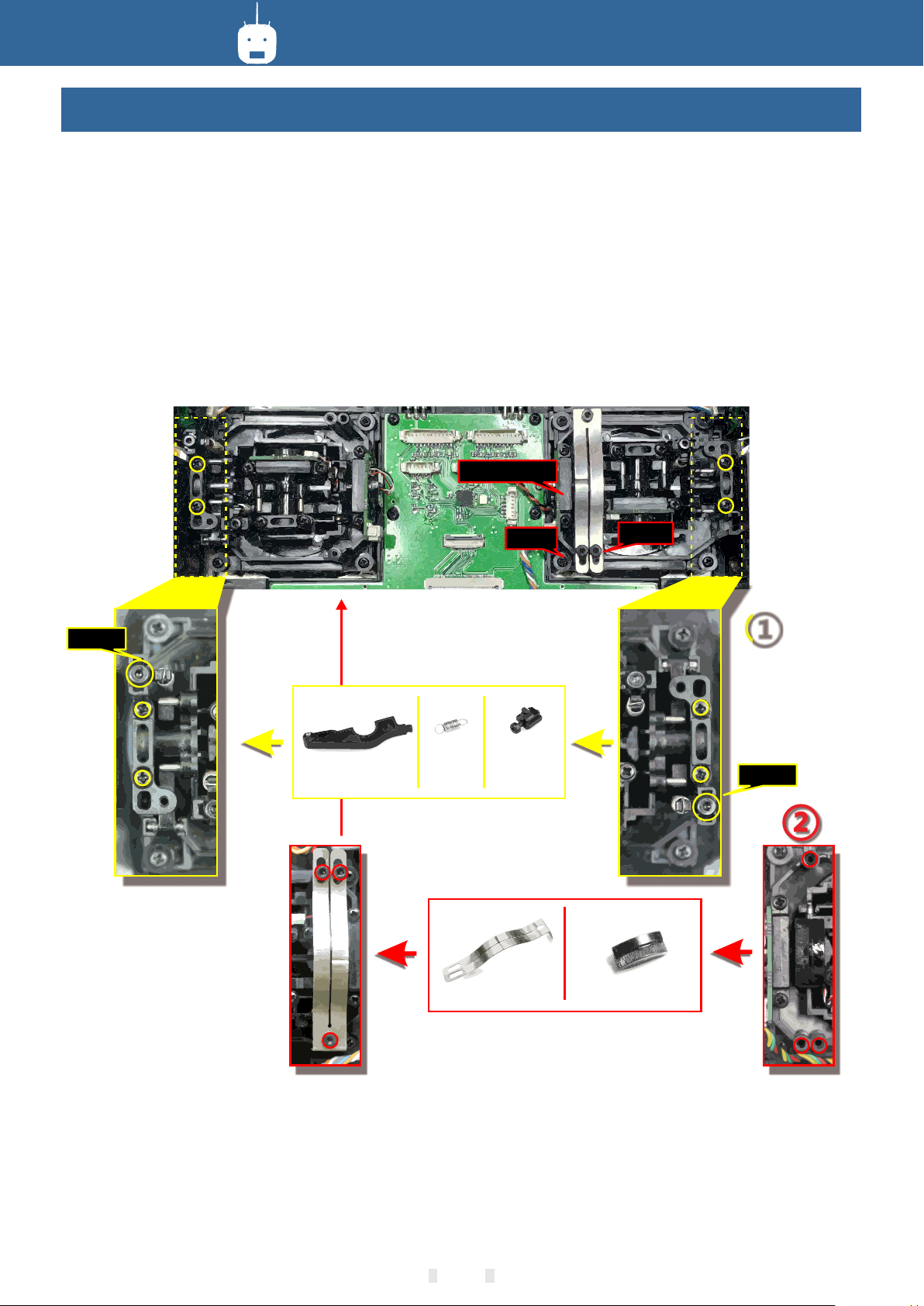

016

①

Basic Operation

Left and right stick mode replacement method

It is not recommended to replace the left and right sticks by yourself, otherwise the transmitter may be

damaged.

Required tools: 3 mm cross screwdriver, 1 .5 mm he x dr iv er

First open the transmitter housing and then follow the instructions show n be lo w:

1 Loosen the bearing housing s cr ew s (t he s cr ew s do n ot n ee d to b e fu ll y re tr ac te d) , th en r em ove th e

spring, bracket 7 and bracket 5 and tighten the scre ws ; th en r em ov e th e re mo ve d sp ring, bracket 7 and

bracket 5 in another assembly corres po nd in g po si ti on ( re move the bearing housing screw before

assembly),The tightness of the st

2 Remove the screw of the throttle reed, the throttle reed and the throttle sleeve, and install them in the

corresponding position o f th e othe r as se mb ly. According to your own habits, select the type of throttle

sliding (toothed and smooth) and adjust the screw (screw 1 o r The height of the screw 2) makes the

damping of the throttle conform to your own habits.

ick can be changed by adjusting the height of screw 3.

Throttle sleeve

Screw3

Screw 2

Bracket 5 Bracket 7

Spring

Screw 1

①

Screw3

Throttle reed Throttle sleeve

After the throttle structure is modified, turn on the machine, enter system setting → stick mode, select the

corresponding operatio n mo de , an d th en a dj us t th e st ic k af te r re pl ac in g th e left a nd r ig ht m od es! If you n eed

components such as bracket 5 (such as the pa rts need ed f or a ss em bl in g do ub le circuit structure!), you can

e-mail to WFLY overseas seller to order the spare parts at sales@wflysz.com

017

Mode

LED

Action

Status

Work

Purple

On

PWM normal work mode

Green

On

W.BUS normal work mode

Blue

On

PPM normal work mode

Red

On

No signal

Red

Slow flash

Low voltage

Orange

Slow flash

Linking

SET

Green

Slow flash

W.BUS mode

Blue

Slow flash

PPM mode

Purple

Slow flash

PWM mode

Ext.voltage

Basic Operation

Receiver Instructions

Receiver LED STATUS LIST

Link: Charge the receiver then press and hold

'SET' button for 3 seconds,wait for the link

instruction after the orange light slowly flashes.

PPM/W.BUS/PWM port modes select: Click and

hold the “SET” to charge, then enter into model

setting, slightly click the switcher mode, press and

hold to confirm.

USB port

External voltage detection port

Antenna

Keep straight

90°

Receiver mode switching: The receiver works in

"mode A" by default, and the receiver interface

output data according to the sticker serial number.

Switching the "mode" to the code will change the

interface output mode. You can use multiple

receivers to output more channels. More details,

please check [Linkage Settings - Link]

Receiver connection and installation

The working voltage of the receiver is 3.7-13V.

Each port can be used as the power input terminal.

Notice: pay attention to the positive and negative

polarity when connecting the power supply. Do not

use the power supply that exceeds the working

voltage of the receiver. Otherwise, the receiver will

be damaged!

The RF209S is the newest series of high

performance receiver with 9 PWM channels, 1

PPM/W.BUS channel (User defined), and 1 W.BUS2

channel (User defined).

In order to obtain optimal signal retrieval

performance, the two antennas are preferably

processed 90° to each other when installed, as

shown in the right diagram.

Mandatory

1Ω

W.BUS/PPM/PWM

W.BUS2/W.BUS/

PPM/PWM

The resistance is

connected to the negative pole

The red is

connected to the positive pole

External voltage detection port

Port polarity mark

PPM/PWM

8 7 6 543 2 1

Signal

Positive

9

Negative

1.If there is a metal conductor around the receiver antenna,the signal performance would be affected.

In this case, the antenna should be bypassed by the conductor, placed on both sides of the fuselage, and

it is better to make the antenna leak outside the model casing ! In this way, good signal reception can be

maintained regardless of the flight attitude.

2. When the antenna is installed. The unshielded end of the antenna should be as far away as possible

from the conductor materials such as metal and carbon fiber. The antenna cable avoids bending at large

angles. And the end core should be as straight as possible.

3. If the model body is covered with a conductive material such as carbon fiber or metal, the antenna

portion must be extended beyond the body. At the same time, do not stick too close to the conductive body

after the antenna is extended. In addition, the antenna should also be kept away from the fuel tank.

The receiver has an external battery detection interface, which can be used to view voltage information

such as ESC, battery, etc., and the transmitter can separately set alarm voltages for the receiver voltage

and external voltage. Pay attention to the positive and negative polarity when using the detection wire!

018

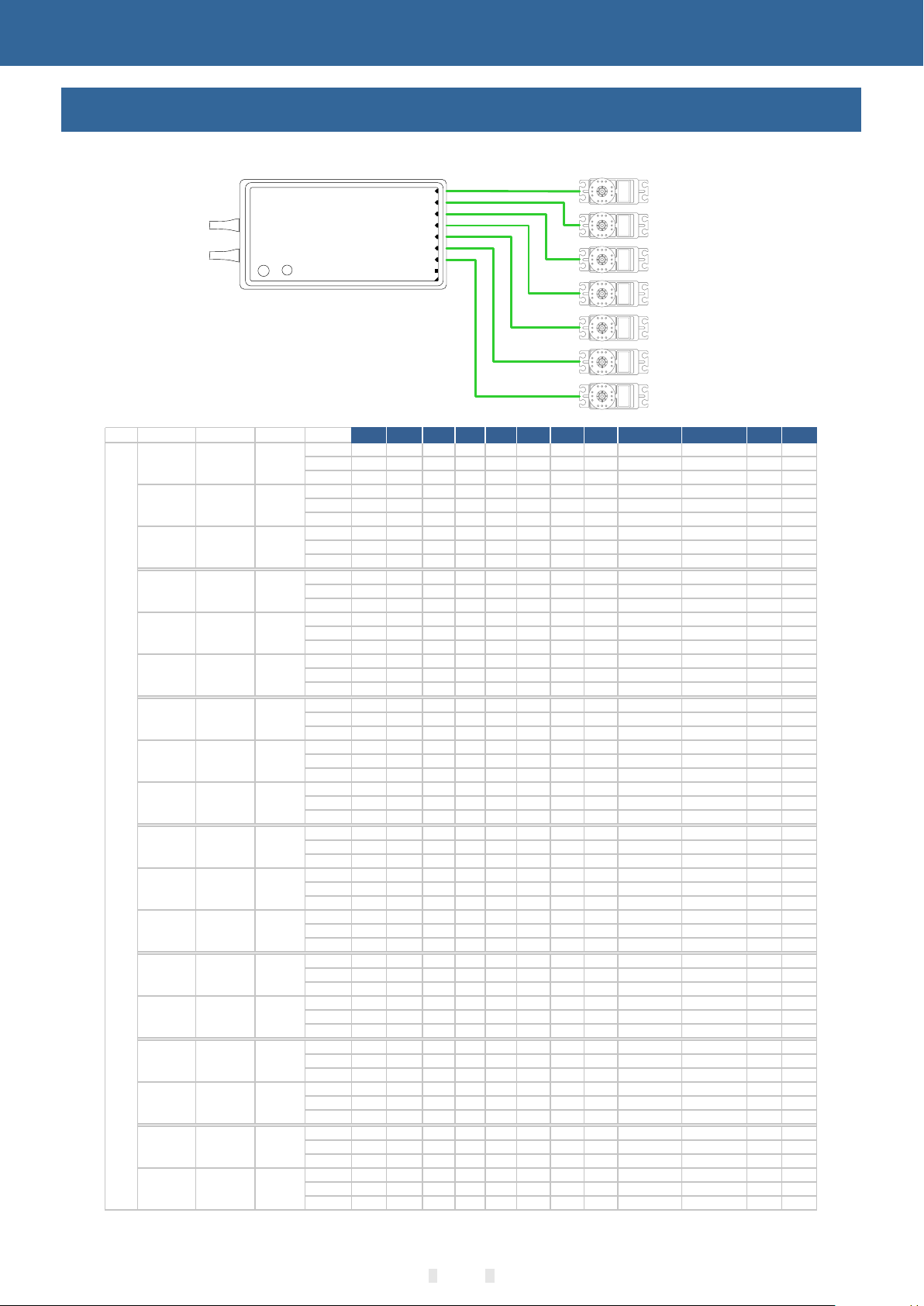

Basic Operation

Type Wing Flying wing Tail

1 AIL Normal

Channel AIL ELE THR RUD Gear Aux6 Aux6 Aux5 Aux4 Aux3 Aux2 Aux1

Control J1 J3 J2 J4 SG

Trim T1 T3 T2 T4

1 AIL V-Tail

Channel AIL ELE THR RUD Gear Aux6 Aux6 Aux5 Aux4 Aux3 Aux2 Aux1

Control J1 J3 J2 J4 SG

Trim T1 T3 T2 T4

1 AIL Ailevator

Channel AIL ELE THR RUD Gear Aux6 ELE2 Aux5 A ux4 Aux3 Aux2 Aux1

Control J1 J3 J2 J4 SG

Trim T1 T3 T2 T4

2 AIL Normal

Channel AIL ELE THR RUD Gear AIL2 Aux6 Aux5 Camber mix Aux3 Aux2 Aux1

Control J1 J3 J2 J4 SG LS

Trim T1 T3 T2 T4

2 AIL V-Tail

Channel AIL ELE THR RUD Gear AIL2 Aux6 Aux5 Camber mix Aux3 Aux2 Aux1

Control J1 J3 J2 J4 SG LS

Trim T1 T3 T2 T4

2 AIL Ailevator

Channel AIL ELE THR RUD Gear AIL2 ELE2 Aux5 Camber mix Aux3 Aux2 Aux1

Control J1 J3 J2 J4 SG LS

Trim T1 T3 T2 T4

2AIL+1FLP Normal

Channel AIL ELE THR RUD Gear FLP AIL2 A ux5 Camber mix A ux3 Aux2 Aux1

Control J1 J3 J2 J4 SG LD LS

Trim T1 T3 T2 T4

2AIL+1FLP V-Tail

Channel A IL ELE T HR RUD Ge ar FLP A IL2 Aux5 Camber mix Aux3 Aux2 Aux1

Control J1 J3 J2 J4 SG LD LS

Trim T1 T3 T2 T4

2AIL+1FLP Ailevator

Channel A IL ELE T HR RUD Ge ar FLP A IL2 ELE2 Camber mix Aux3 Aux2 Aux1

Control J1 J3 J2 J4 SG LD LS

Trim T1 T3 T2 T4

2AIL+2FLP Normal

Channel A IL ELE T HR RUD Ge ar AIL2 FLP FLP2 Camber mix Aux3 Aux2 Aux1

Control J1 J3 J2 J4 SG LD LS

Trim T1 T3 T2 T4

2AIL+2FLP V-Tail

Channel A IL ELE T HR RUD Ge ar AIL2 FLP FLP2 Camber mix Aux3 Aux2 Aux1

Control J1 J3 J2 J4 SG LD LS

Trim T1 T3 T2 T4

2AIL+2FLP Ailevator

Channel A IL ELE T HR RUD ELE2 AIL2 FLP FLP2 Camber mix Gear Aux2 Aux1

Control J1 J3 J2 J4 LD LS SG

Trim T1 T3 T2 T4

2AIL Normal

Channel A IL AIL2 THR RUD Gear Aux6 Aux5 Aux4 ELE Camber mix Aux2 Aux1

Control J1 J2 J4 SG J3 LS

Trim T1 T2 T4 T3

2AIL Winglet

Channel A IL AIL2 THR RUD Gear RUD2 Aux6 Aux5 ELE Camber mix Aux2 Aux1

Control J1 J2 J4 SG J3 LS

Trim T1 T2 T4 T3

2AIL+1FLP Norm al

Channel A IL AIL2 THR RUD Gear FLP AIL6 Aux5 ELE Camber mix Aux2 Aux1

Control J1 J2 J4 SG LD J3 LS

Trim T1 T2 T4 T3

2AIL+1FLP Winglet

Channel A IL AIL2 THR RUD Gear FLP RUD2 Aux5 ELE Camber mix Aux2 Aux1

Control J1 J2 J4 SG LD J3 LS

Trim T1 T2 T4 T3

2AIL+2FLP Norm al

Channel A IL AIL2 THR RUD Gear FLP Aux6 FLP2 ELE Camber mix Aux2 Aux1

Control J1 J2 J4 SG LD J3 LS

Trim T1 T2 T4 T3

2AIL+2FLP Winglet

Channel A IL AIL2 THR RUD Gear FLP RUD2 FLP2 ELE Camber mix Aux2 Aux1

Control J1 J2 J4 SG LD J3 LS

Trim T1 T2 T4 T3

CH1 CH2 CH3 CH4 CH5 CH6 CH7 CH8 CH9 CH10 CH11 CH12

Receiver and servo connection example - Airplane

The figure below shows an example of airplane connection. Please use the actual wing type and

tail type for servo connection.

1 2 3 4 5 6 7 8 9

Servo connection position (Airplane)

The table below shows examples of the servo

connection positions for the different wing types

and tail types(system default settings).

CH1/Aileron

CH2/Elevator

CH3/Throttle

CH4/Rudder

CH5/Gear

CH6/FLP

CH7/Aileron2/Aux1

019

Basic Operation

Type Wing Flying wing Tail

1 AIL Normal

Channel AIL ELE Motor RU D Aux6 Aux6 Aux6 Aux5 Aux4 Aux3 Aux2 Aux1

Control J1 J3 SG J4

Trim T1 T3 T4

1 AIL V-Tail

Channel AIL ELE Motor RU D Aux6 Aux6 Aux6 Aux5 Aux4 Aux3 Aux2 Aux1

Control J1 J3 SG J4

Trim T1 T3 T4

1 AIL Ailevator

Channel AIL ELE Motor RU D Aux6 Aux6 ELE2 Aux5 Aux4 Aux3 Aux2 Aux1

Control J1 J3 SG J4

Trim T1 T3 T4

2AIL Normal

Channel AIL ELE Motor RU D Aux6 AIL2 Aux6 Aux5 Camber mix Butterfly Aux2 Aux1

Control J1 J3 SG J4 LS J2

Trim T1 T3 T4

2AIL V-Tail

Channel AIL ELE Motor RU D Aux6 AIL2 Aux6 Aux5 Camber mix Butterfly Aux2 Aux1

Control J1 J3 SG J4 LS J2

Trim T1 T3 T4

2AIL Ailevator

Channel AIL ELE Motor RU D Aux6 AIL2 ELE2 Aux5 Camber mix Butterfly Aux2 Aux1

Control J1 J3 SG J4 LS J2

Trim T1 T3 T4

2AIL+1FLP Normal

Channel AIL ELE Motor RU D Aux6 FLP AIL2 Aux5 Camber mix Butterfly Aux2 Aux1

Control J1 J3 SG J4 LS J2

Trim T1 T3 T4

2AIL+1FLP V-Tail

Channel AIL ELE Motor RU D Aux6 FLP AIL2 Aux5 Camber mix Butterfly Aux2 Aux1

Control J1 J3 SG J4 LS J2

Trim T1 T3 T4

2AIL+1FLP Ailevator

Channel AIL ELE Motor RU D Aux6 FLP AIL2 ELE2 Camber mix Butterfly Aux2 Aux1

Control J1 J3 SG J4 LS J2

Trim T1 T3 T4

2AIL+2FLP Normal

Channel AIL ELE Motor RU D Aux6 AIL2 FLP FLP2 Camber mix Butterfly Aux2 Aux1

Control J1 J3 SG J4 LS J2

Trim T1 T3 T4

2AIL+2FLP V-Tail

Channel AIL ELE Motor RU D Aux6 AIL2 FLP FLP2 Camber mix Butterfly Aux2 Aux1

Control J1 J3 SG J4 LS J2

Trim T1 T3 T4

2AIL+2FLP Ailevator

Channel AIL ELE Motor RU D ELE2 AIL2 FLP FLP2 Camber mix Butterfly Aux2 Aux1

Control J1 J3 SG J4 LS J2

Trim T1 T3 T4

2AIL Normal

Channel AIL AIL2 M otor R UD Aux5 Aux6 Aux4 Aux3 ELE Camber mix Aux2 Aux1

Control J1 SG J4 J3 LS

Trim T1 T4 T 3

2AIL Winglet

Channel AIL AIL2 M otor R UD Aux5 RUD2 Aux4 Aux3 ELE C amber mix Aux2 Aux1

Control J1 SG J4 J3 LS

Trim T1 T4 T 3

2AIL+1FLP Normal

Channel AIL AIL2 M otor R UD Aux5 FLP Aux6 Aux3 ELE Camber mix Butterfly Aux1

Control J1 SG J4 J3 LS J2

Trim T1 T4 T 3

2AIL+1FLP Winglet

Channel AIL AIL2 M otor R UD Aux5 FLP RUD2 Aux3 ELE Camber mix Butterfly Aux1

Control J1 SG J4 J3 LS J2

Trim T1 T4 T 3

2AIL+2FLP Normal

Channel AIL AIL2 M otor R UD Aux5 FLP Aux6 FLP2 ELE Camber mix Butterfly Aux1

Control J1 SG J4 J3 LS J2

Trim T1 T4 T 3

2AIL+2FLP Winglet

Channel AIL AIL2 M otor R UD Aux5 FLP RUD2 FLP2 ELE Camber mix Butterfly Aux1

Control J1 SG J4 J3 LS J2

Trim T1 T4 T 3

CH1 C H2 CH3 CH4 CH5 CH6 CH7 CH8 CH 9 CH10 CH11 CH12

Receiver and servo connection example - Glider

The figure below shows an example of glider connection. Please use the actual wing type and tail type for

servo connection.

1 2 3 4 5 6 7 8 9

CH1/Aileron

CH2/Elevator

CH3/Throttle

CH4/Rudder

Servo connection position (Glider)

The table below shows examples of the servo

connection positions for the different wing types

and tail types.

CH5/Gear

CH6/FLP

CH7/Aileron2/Aux1

020

Basic Operation

T yp e S wash

H

e

l

i

c

o

p

t

e

r

H-1

Ch anne l A IL EL E T HR R UD G yro P IT G overn or N e e dl e G yro2 G yro3 A u x2 A u x1

Co ntro l J1 J3 J2 J4 J2 LS

T rim T1 T 3 T 2 T 4

HR3

Ch anne l A IL EL E T HR R UD G yro P IT G overn or N e e dl e G yro2 G yro3 A u x2 A u x1

Co ntro l J1 J3 J2 J4 J2 LS

T rim T1 T 3 T 2 T 4

H-3

Ch anne l A IL EL E T HR R UD G yro P IT G overn or N e e dl e G yro2 G yro3 A u x2 A u x1

Co ntro l J1 J3 J2 J4 J2 LS

T rim T1 T 3 T 2 T 4

HE3

Ch anne l A IL EL E T HR R UD G yro P IT G overn or N e e dl e G yro2 G yro3 A u x2 A u x1

Co ntro l J1 J3 J2 J4 J2 LS

T rim T1 T 3 T 2 T 4

HN 3

Ch anne l A IL EL E T HR R UD G yro P IT G overn or N e e dl e G yro2 G yro3 A u x2 A u x1

Co ntro l J1 J3 J2 J4 J2 LS

T rim T1 T 3 T 2 T 4

H4X

Ch anne l A IL EL E T HR R UD G yro P IT G overn or ELE2 Gyro 2 G yro 3 A u x2 A ux 1

Co ntro l J1 J3 J2 J4 J2

T rim T1 T 3 T 2 T 4

H-4

Ch anne l A IL EL E T HR R UD G yro P IT G overn or ELE2 Gyro 2 G yro 3 A u x2 A ux 1

Co ntro l J1 J3 J2 J4 J2

T rim T1 T 3 T 2 T 4

CH 1 C H2 C H3 CH 4 CH 5 C H6 CH 7 CH 8 CH 9 CH1 0 CH 11 CH 12

Receiver and servo connection example - Helicopter

The figure below shows an example of helicopter connection. Please use the actual wing type and tail

type for servo connection.

1 2 3 4 5 6 7 8 9

CH1/Aileron

CH2/Elevator

CH3/Throttle

CH4/Rudder

GRO

CH5/Gyro

CH6/Pitch

CH7/Aux/Governor

Servo connection position (Helicopter)

The table below shows examples of the servo connection positions for different swashes.

Swash Types

PIT

Normal

H-1

AIL

HN3(120°)

ELE

PIT

PIT

H-4

AIL

ELE

ELE

AIL

ELE 2

ELE

PIT

HE3H-3

H-4X

ELE

ELE 2

021

PITAIL

AIL

PIT

HR3(120°)

AIL

ELE

Basic Operation

Type

M ultic opter

C hannel A IL ELE T HR R UD Fl ig ht mode 1 P&T PITC H P&T Around C amera r ecor d Aux4 Aux3 Aux2 A ux1

C ontrol J1 J2 J3 J4 VL VR SH

Tr im T1 T 2 T3 T4

C H1 C H2 C H3 C H4 CH 5 CH 6 C H7 C H8 C H9 C H10 C H11 C H12

Receiver and servo connection example - Multicopter

The figure below shows the four-rotor multicopter. Please refer to the model manual for specific

applications. Motor,electronic speed controller, flight controller, battery, etc. are sold separately.

Use 5CH-9CH when using accessories such

as camera shutters. Use a W.BUS interface or

dual receiver when the channel is insufficient.

1 2 3 4 5 6 7 8 9

Ch1 Ailero n

Ch2 Elev ato r

Ch3 Thro ttle

Ch4 Rudd er

Ch5

Multic opt er

fli ght c ont roll er

Battery

This figure is for illustrative purposes only. Link amplification also changes depending on the

multicopter collective and the flight controller. Please connect according to the instruction

manual of the multicopter kit to be used.

Servo connection position (Multicopter)

022

Basic Operation

Basic setting sequence of airplane and glider

1. Call of the model

The ET12 transmitter has 30 built-in models from

the factory, and you can use the [Model Selection]

under [General Menu] to call up the existing model.

The Rename feature makes it easy to make a

selection call to a model whose name has already

been set.

The name of the model currently in use is

displayed on the home page. Before flying and

changing the parameter settings, be sure to

determine if the correct model is selected.

When a new model is added, please select [Type

Selecting] under [General Menu] according to the

model used. If a new receiver is used, the receiver's

code operation is also required ([Linkage Setting][Link]

2. Model type selection

Use the [Type Selecting] function under [General

Menu] to select the model type, wing type, and tail

type that match the model airplane.

For example, the left and right azimuth servos

can be selected from the main wing type by

selecting "2 ailerons" and adjusting the two servos

in [Sub-Trim] and [End Point] respectively.

3. The fuselage control part connect

Install the ailerons, elevators, throttles, rudders,

etc. as required by the model aircraft product

specification. For the connection method, refer to

the "Receiver and Servo Connection Example Airplane" (P19) and the "Receiver and Servo

Connection Example - Glider" (P20) section.

Note: ET12 transmitters have different channel

assignments depending on the model type, so

please pay special attention (in the [General Menu]

option under General Menu], you can check the

allocation of each channel).

● If the direction of the actual connection is

opposite to the direction you want, you can use

[Reverse Setting] under [General Menu] to adjust

the direction.

● Install the throttle section to ensure that the

carburetor/electronic governor can be fully open or

fully closed.

● Use the [End Point] under [Function] to adjust

the end point and rotation angle of each rudder

surface, and use the [Sub-trim] function and the

[End Point] function to make fine adjustments. In

order to protect the connecting rod, the stroke limit

position can be set in the [Rudder Angle Setting]

function item. [End Point] function item can adjust

the up and down or left and right movement amount

of each rudder surface And limit.

4. Throttle Cut Setting (Airplane)

The [Throttle Cut] function allows us to turn off the

engine by only one switch without affecting the

throttle trim position (after idle adjustment).

* When the [Throttle Cut] function is activated,

the engine flame out position will be fixed. If the

throttle cut switch is not required, use the [ Idle

Down] setting function below.

Please use the [Throttle Cut] function option

under [Model Menu] to set. After the flame out

function is activated and the corresponding switch

is selected, the throttle position will be adjusted

until the carburetor is fully closed. For safety

reasons, the activation position of the throttle lever

position corresponding to the throttle stop function

can be set separately.

5. Idle Down setting (Airplane)

The [Idle Down] function option is located under

[Model Menu]. * When the [Throttle Cut] function is

operated, the [Idle Down] function will not be

activated. Without changing the throttle trim

position, using a switch can reduce the idle speed of

the airplane.

After activating this function and selecting a

switch, you can adjust the desired number of idling

revolutions. For safety reasons, this function is only

activated when the throttle lever is in the lower

position (approximately 1 / 3 of the total stroke).

6. Dual Rate Settings

[Dual Rate] function is to match the feeling of

control and adjust the rudder angle, which makes

the control more convenient. The basic operating

range of the steering gear is set in the [End Point]

function under [General Menu], and the steering

feel is adjusted by the [Dual Rate] ratio function of

the [General Menu]. In addition, after setting the

rudder angle ratio, it can also be switched by the

switch or flight condition, and the flight action can be

used to call up the set rudder angle.

7. Air brake

[Air Brake] function is used when landing, etc.,

when the sliding angle is large but the speed is no

need to be increased. This function can only be

used on models with [General Menu] - [Model

Selecting] and "2 Ailerons" on the wing. * Normally,

the left and right ailerons are simultaneously set to

the upward movement, and the pitch of the nose can

be corrected by the elevator mixing when the

function is started.

8. Flight conditions

The factory default setting assigns only one flight

condition per model. Only one flight condition can

support basic flight without barriers, but if you are in

a competitive situation such as a game, you need

more detailed settings. Through the [Flight

Condition] function in [Model Menu], you can select

the required flight conditions more effectively. It can

also be set for the switch of the condition switch and

the name of the condition. After the flight condition

setting is completed, the switch needs to be

operated, and the condition name displayed on the

interface is confirmed.

023

Basic Operation

Basic setting sequence of the helicopter

1. Model addition and invocation

Please refer to the first part of the previous

section "Basic Operation - Basic Settings of Fixed

Wings and Gliders".

2. Model type and swash plate type selection

If you have already set up a model, use the

[Model Type] selection interface to select the

helicopter in [Model Function], and then select the

swash type according to the model.

3. Flight conditions setting

The default setting contains the common mode

(default naming) conditions.

There are 5 conditions that have been set.

● Normal

● Idle 1 (SE)

● Idle 2 (SE)

● Idle 3 (SF)

● Hold

*This switch is not set in the default settings

Examples of common flight conditions settings:

● Normal: (for default settings, switch off) usually

starting, hanging

Use when stopped.

● Idle 1: (Starting when the SE switch is in the

middle position) is usually used to lose

Speed reverse, muscles and other Idles.

● Idle 2: (Starting when the SE switch is forward)

is usually used for roll.

●Lock: (usually set to start when the SG switch is

forward) Usually in self

Used in the spin state.

The priority of these operating conditions is

1,Hold(Throttle Hold)

2,Idle 2

3,Idle 1

4,Normal

5,The lock mode has the highest priority

4. Body control connecting rod installation

Install the throttle, tail rotor, aileron, elevator,

pitch, etc. as required by the model helicopter

product specification. The connection method can

be referred to the "Receiver and Servo Link

Example - Helicopter" (P21) section.* In the

[Function] option under [General Menu], you can

check the allocation of each channel.

● If the direction of the actual connection is

opposite to the direction you want, you can use

[Servo Reverse] under [General Menu] to adjust the

direction. In addition to the H-1 mode, you can also

change the direction using the [Swash] function.

● Set the direction of the gyroscope (this is the

"Gyro" function)

● The throttle section should be installed to

ensure that the carburetor can be completely closed

when Trim is fully closed.

● Use the [End Point] under [General Menu] to

adjust the ravel amount and rotation angle of each

rudder surface, and use the [Sub-trim] function and

the [End Point] function to make fine adjustments. In

order to protect the connecting rod, the travel limit

position can be set in the [End Point] function item.

The [End Point] function item can adjust the up and

down or left and right movement amount and limit of

each rudder surface.

The swash calibration (except H-1 mode) can

calibrate the swash motion by the correction mixing

control of the [swash] function. This function is

required when the pitch, aileron,and elevator

operations cause the swash to deviate from the

correct elbow. In addition,the pitch of the link at the

low point and the high point can also be calibrated,

which is used to ensure the horizontal state of the

swash in the full stroke range.

5.Throttle Curve,Pitch Curve setting

Bring up [Throttle Curve] or [Pitch Curve] from the

[Model Menu] and set the curve for various flight

conditions.

+1 5 0

+1 0 0

+5 0

-5 0

-1 0 0

-1 5 0

+0 %

PO S

0

RA T E

+0 %

<Setting example>

Use the flight condition selection switch to bring

up the throttle curve for each flight condition.

Throttle curve setting example is as follows:

● Throttle curve (General)

The normal curve uses a normal line type, and the

basic pitch curve is set near the hover point (50% of

the stick). This curve is usually adjusted with the

pitch to ensure that the engine speed is uniform and

the up/down action is easy to handle.

● Throttle curve (Idle 1)

This setting is to maintain stick rotate when the

throttle lever is in the low position.

● Throttle curve (Idle 2)

This setting maintains rotation when the throttle

lever is in the low position and there is no pitch.

●Setting when the condition is locked

Note: The throttle lock curve is used for the spin

landing action. Please confirm the ratio of the

lowest position of throttle control stick is 0% (this is

the initial setting).

Examples of pitch curve settings are as

follows:

The pitch curve can be called up under each

condition using the flight condition selection switch.

●Pitch curve (General)

In the pitch curve, the hover pitch is usually set to

approximately +5° ~ +6°. Under normal

circumstances, the throttle stick is hovered at 50%

position as the standard.* Stable hovering is also

related to throttle curve setting. It is easier to

achieve stable hover by using throttle curve

adjustment and pitch curve adjustment.

●Pitch curve (Idle 1)The pitch curve of the effect 1

is usually used for air flight, and is generally set to 7°~+9°.

●Pitch curve (Idle 2)The setting of the high point

bit 1 is slightly lower, and the value is set to about

+8°.

●Pitch curve (HOLD)In the throttle lock and spin

drop conditions, the pitch should be set to the

024

17%

Basic Operation

Basic setting sequence of the helicopter

maximum in both the positive and negative pitch

directions. For example, from -7 to +12°

6. Throttle Hold Setting

In the model menu, call the [Throttle Hold]

function setting interface, and use the [Fly

Condition] switch to switch to the throttle lock

condition interface.

Lock position setting: This function is used to

set the working position (extinguish or idle

position) of the servo under the throttle lock state.

Throttle hold

Status

Switch

Hold pos.

Speed

INH

--

0

7. The Swash Mixing Controls the

Interaction of the Ailerons, Elevators and

Paddles

Through the [Swash Mixing] under [Model

Menu], the mixing ratio of each operation of the

aileron, elevator, and pitch can be adjusted to

ensure that the swash is corrected under each

condition.

10. Throttle Setting

At the end of the flight, there is no need to

change the position of the throttle trim, just turn

off the engine by simply turning a flameout switch.

Set in the [Throttle Cut] function of [Model

Menu]. Set the throttle lever to idle speed and

adjust the rotation position of the flameextinguishing servo until the damper can be

closed and the movement is unimpeded.

*The throttle trigger position can be set

separately.

Throttle cut

Status

Switch

Cut pos.

Throttle

INH

--

17%

17%

8. Throttle Mixing Setting

The swash aileron and elevator action will

cause the engine speed to decrease. This

phenomenon can be compensated by [Throttle

Mixing] under [Model Menu]. In addition, the

clockwise and counterclockwise torque changes

can be compensated for when the body rotates.

9. Gyro Sensitivity Adjustment and Mode

Switching

In the [Gyro] mixing function under

[ModelMenu], you can adjust the gyro sensitivity

or mode switching for each condition or switch

position.

● Normal (hover flight): The gyroscope is the

most sensitive.

● Idle 1 / Idle 2 / Throttle Hold: Gyro sensitivity

is minimal.

Gyro

Gyro

Mode

Position

Status

Type

Gyro1

Condition

Condition1

INH

AVCS

1/2

Gyro

Rate

Tun ing

AVCS100%

--

0%

2/2

0%

025

System Setting

Trainer

Interface Path: WFLY → [System Setting] → [Trainer]

Trainers can assist students in learning flight skills and improving flight levels based on their flight

experience and operational level. A special trainer line (sold separately) is required between the trainer

and the trainer to connect. The trainer must turn on the trainer mode before the trainer can be operated.

When the trainer switch is turned off, it will return to the trainer transmitter to control the flight. When the

student machine flight is dangerous or the deviation is too large,the trainer can be switched immediately to

ensure safety.

When using the WFT08/09 as a trainer, please purchase a universal analog patch cord, 3.5mm male to

male audio cable. (The coaching line and audio cable need to be purchased separately. Two cores and

three cores are available.)

Tra iner

Mode

Teach SW

CHmode

CH

Aileron

1

Elevator

2

*The following trainer functions take the same model as an example.

Tra iner

--

12CH

Status

ON

ON

1/2

Mode: Normal, Trainer, Simulator, Student

- Normal: Default mode (non-"Trainer", "Student" mode

using trainer function may cause malfunctions! )

- Trainer: Control transmitter;

- Simulator: When the flight is practiced through the

computer-side simulator, the RF is turned off, reducing

power consumption.To extend the working hours of the

transmitter;

-Students: Turn off RF transmission,only the trainer turn on

theTeach switch can trainer channel could be controlled!

(Example: The trainer model has only three channels:

aileron, direction and gyro, so the student can only control

these three channels when the coach turn on the trainer

switch. )

Trainer Switch: Default [--]

Channel Mode: default is "12 channel" setting; "8 channel

mode" is compatible with WFLY training function of the

"WFT" series products. The trainer ’s two ET12s need to be

set up to the same mode.

Status: Each channel status switch of trainer. Turn on,

students can be controlled; off, students Uncontrollable

Trainer Setting:

Trainer switch → Trainer, channel mode → 12

channels, channel status → Turn on with demand

(status is the same as the student machine).

* The channel defaults to full on, and the visual

model and actual application are adjusted.

Be sure to check that all channels of the

trainer and the student can be operated

NOTICE

normally before flying. Be sure to insert

the interface of the trainer line to avoid

loosening.

Student Setting:

Trainer switch → student, channel mode → 12

channels, channel status → Turn on with demand

(status is the same as the trainer).

* The channel defaults to full on, and the visual

model and actual application are adjusted.

026

System Setting

Display

Interface Path: WFLY → [System Setting] → [Display]

Adjust the brightness of the display backlight, the shutdown time, and the lock screen time to

adapt to different environments and energy saving.

Display

Backlight max

Backlight min

Tim e

Auto off time

Auto lock

Parameter Value Setting(taking the maximum backlight as an example):

Click the “Backlight max” value box and click the parameter adjustment buttons [▼], [▲] according to the

visual effect.

The maximum backlight, the default is 10, the range: 1~20, the setting value can't be lower than the

minimum backlight setting value.

The minimum backlight, the default is 10, the range: 1~20, the setting value can't be higher than the

maximum backlight setting value.

Backlight time, default 30 seconds, 15 seconds, 30 seconds, 1 minute, 2 minutes, 5 minutes, 10 minutes,

always bright.

Auto power off time, default off, 30 minutes, 40, 50, 60 minutes, off.

Automatic lock screen time, default off, 15 seconds, 30 seconds, 1 minute, 2 minutes, 5 minutes, 10

minutes, off.

10

10

30Sec

Never

Never

The backlight switches to the "Backlight max" value!

The darkest brightness value of normal standby.

It means that no button and touch screen operation time is

detected after setting value.

The transmitter is turned off after no operation.

Lock screen after when the touch screen has no operation.

WARNING

High brightness display will increase

the energy consumption of the

transmitter, which will affect the

working time of the transmitter. Please

pay attention to setting the transmitter

voltage alarm. Pay attention to the

battery level and avoid low battry

operation of the transmitter.

027

Q

W

E

R

T

Y

U

I

O

P

1

2

3

4

5

6

7

8

9

0

OK

@

Exit

-

"

!

M

N

B

V

C

X

)

Z

(

A

S

D

FGH

J

K

L

q

w

e

r

t

y

u

i

o

p

1

2

3

4

5

6

7

8

9

0

OK

,

.

Exit

;

-

*

#

m

n

b

v

c

x

>

z

<

a

s

d

f

g

h

j

k

l

System Setting

User Name

Interface path: WFLY → [System Setting] → [User Name]

The user defied name is composed of up to 9 characters and supports English character input, which can

be displayed on the standby interface.

SIM

ET12

00:00.0

Receiver

00:00.0

-50 0

User Name

5.0V

12.0VExternal

Condition1

T5

T6

+25

0 +100 0

Home2

T4

+10 00

00:00.0

12.9V

RX

T3

T2 T1

User name

Model 1

-50 0

User Name

User N a me

User Name

*The keyboard can only be operated by touch screen.

*The naming needs to be confirmed before the modification can be saved.

Model select

Model 12

Model select

Model 12

Case switch key

%

Confirmation key

(Save key)

Turn off keyboard

Unname

028

System Setting

Sound

Interface path: WFLY → [System Setting] → [Sound]

The sound helps the flight process to notice various anomalies or planned audible prompts.

The sound is associated with the model, and the prompt tone can be set according to the requirements of

each model.

Sound

Warn in

Telemetry

Button

Other

Tri m

timer

WARNING

80

80

50

50

80 Voice

80 Voice

Volume

To ensure safe operation, be sure to

turn on the Sound!

Voice

029

System Setting

Warning

Interface path: WFLY → [System Setting] → [Warning]

After the function is turned on,there will a corresponding detection reminder when the power-

on detection .

Under setting conditions,there will be an interface, sound, and vibration prompts when the

transmitter detection is in effect. Vibration tips can be set individually.

Warn ing

飞行条件

Condition

THR cut

Idle down

THR posi.

Airbrake

Alarm Vibrator

ACT

ACT

ACT

ACT

ACT

INH

INH

INH

INH

INH

Parameters Setting (Enable the "Flight Condition" alarm with vibration function as an example):

Click the “Alarm button” on the right side of “Flight Condition” and the function will switch to “ACT”; click

the “Vibraor button” on the far right to switch to “ACT”.

*Vibrator function may affect the focus of individual user operations,so the default status is inhibit.

Different models will have different warning content

Helicopter: flight condition, throttle cut,idle down, throttle position, throttle hold.

Airplane: flight condition, throttle cut,idle down, throttle position,air brake, motor, throttle hold.

Glider: flight condition, throttle cut,idle down, throttle position,motor, throttle hold.

Multicopter: flight condition, throttle cut, throttle position, throttle hold.

030

Loading...

Loading...