Page 1

If any co mpo nents of this un it are broken, do not ope rat e properly, or f or pro duct returns,

Phone: 1-800-814-4895 (Outside the U.S. 440-638-3131)

Mail: 20365 Progress Drive, Strongsville, Ohio 44149

E-Mail: CustomerService@WestonProducts.com

All Trademarks and Registered Trademarks are property of the respective companies.

ATTENTION!

please co nta ct Weston Products LLC

Web Site: WestonProducts.com

5 LB (3 L)

SAVE THESE INSTRUCTIONS!

Refer to them often a nd use t hem to i nstruct others.

VERTICAL

SAUSAGE

STUFFER

MODEL NO. 73-0501-W

Due to constant factory improvements, the product pictured

might differ slightly from the product received.

REV052011

Page 2

Stuffer

Sides

Stuffer

Base

11

ASSEMBLED

5 LB (3 L)

VERTICAL

STUFFER

10

WESTON WARRANTY INFORMATION

SAVE THIS WARRANTY INFORMATION FOR YOUR RECORDS!

Weston Products LLC warrants to the ORIGINAL RETAIL PURCHASER of this product that if operated in

accordance with the printed instruction accompanying it, then for a period of 1 year from the date of purchase,

9

8

3

4

2

1

6

the product shall be free from defects in material and workmanship.

The Warranty Card, along with a copy of the original receipt, must be received by Weston Products LLC

within 30 days from purchase date for the warranty to apply. Failure to send the completely lled out Warranty

Card, along with a copy of the original receipt, will void the warranty.

The product must be delivered to or shipped freight prepaid to Weston Products LLC for warranty services,

in either its original packaging or similar packaging affording an equal degree of protection. Damage due to

shipping is not the responsibility of the company. Weston Products LLC charges a $35.00 per hour bench

charge. NOTE: No repairs will be started without the authorization of the customer. The return shipping cost

to the customer will be added to the repair invoice.

Weston Products LLC will repair (or at its discretion, replace) the product free of charge, if in the judgment

of the company, it has been proven to be defective as to seller’s labor and material, within the warranty period.

New or rebuilt replacements for factory defective parts will be supplied for one (1) year from the date of

purchase. Replacement parts are warranted for the remainder of the original warranty period.

For non-warranty repairs, contact Weston Products LLC’s Customer Service at 1-800-814-4895 M-F

8am-5pm EST (outside of the United States 440-638-3131) to obtain a Return Merchandise Authorization

Number (RMA Number). Weston Products LLC will refuse all returns that do not contain this number. DO

NOT RETURN THE UNIT WITHOUT PROPER AUTHORIZATION FROM WESTON PRODUCTS LLC.

LIMITATIONS: The warranty is void if the product is used for any purpose other than that for which it is

designed. The product must not have been previously altered, repaired, or serviced by anyone else other

than Weston Products LLC. If applicable, the serial number must not have been altered or removed. The

product must not have been subjected to accident in transit or while in the customer’s possession, misused,

abused, or operated contrary to the instructions contained in the instruction manual. This includes failure

caused by neglect of reasonable and necessary maintenance, improper line voltage and acts of nature. This

warranty is not transferable and applies only to U.S. and Canadian sales.

Except to the extent prohibited by applicable law, no other warranties whether expressed or implied,

including warranty merchantability and tness for a particular purpose, shall apply to this product. Under no

circumstances shall Weston Products LLC be liable for consequential damages sustained in connection with

said product and Weston Products LLC neither assumes nor authorizes any representative or other person to

assume for it any obligation or liability other than such as is expressly set forth herein. Any applicable implied

warranties are also limited to the one (1) year period of the limited warranty.

This warranty covers only the product and its specic parts, not the food or other products processed in it.

CUT ALONG THE DOTTED LINE AND SEND THE WARRANTY CARD ALONG WITH A COPY OF YOUR ORIGINAL

PURCHASE RECEIPT TO:

Weston Products LLC - WARRANTY DEPARTMENT

20365 Progress Drive, Strongsville, OH 44149

7

WESTON WARRANTY CARD

SEND T HIS CARD AL ONG WITH A CO PY OF YOUR ORIGINAL P URCHASE R ECEIPT TO:

5

WESTON PRODUCTS LLC-WARRANTY DEPT. , 20365 P ROGRESS D RIVE, STR ONGSVILLE , OH 44149

Customer Name: _________________________________

Address: _______________________________________

City/State/Zip: ___________________________________

Telephone Number: (_________) ____________________

40 mm 20 mm

30 mm 13 mm

E-Mail Address: _________________________________

Original Date of Purchase: ______/________/________

Product Model #: _________________________________

Serial # (if applicable): ______________________

-2- -11-

Page 3

people think that a smoked sausage will last much longer without spoilage, but this is not

true. Smoked sausages should be treated the same as fresh sausage in terms of storage.

Dried sausages require the longest processing time, as they are air dried over a long

period of time. Some types of dry sausages are pepperoni, prosciutto and a variety of

ham products, just to name a few. The conditions under which the meat is dried are very

exacting; temperature, time and humidity must all be carefully monitored for a safe and

delicious product.

STORAGE

It is important to remember that sausage will lose its avor the longer that it is stored. It is

recommended that you only make as much sausage as you will need for 4-6 weeks. Even

frozen sausage will begin to lose avor noticeably after 6 weeks. Frozen sausage should

be thawed slowly in the refrigerator before cooking or serving. Quick thawing of the product

will degrade the taste as well.

RECIPES

VENISON SAUSAGE

6 lbs venison 6 lbs lean pork ½ tsp sage

½ tsp cayenne pepper 2 tsp salt ½ cup honey

2 tsp pepper Sausage casings

.

Grind the venison and pork through a coarse grinder plate.

.

Add all the ingredients to the meat and mix well.

.

Regrind the mixed meat through a ne grinding plate.

.

Stuff the sausage into casings or shape into patties.

FRESH ITALIAN SAUSAGE - MILD/HOT

5 tsp salt 1 tsp sugar 2 tsp caraway seeds

3 tsp crushed hot peppers 1 tsp cracked fennel seed (omit if making mild sausage)

2 tsp coarse ground black pepper 1 tsp coriander 1 pint cold water

10 lbs boneless pork butts Sausage casings

.

Grind the pork butts through a grinder plate.

.

Add all the ingredients to the meat and mix well.

.

Stuff the sausage into casings to make 4” (10 cm) links.

BRATWURST

2 ½ lbs lean veal 2 ½ lbs lean pork 1 ½ cup water

2 tsp dried sage 1 tsp ground white pepper 3 tsp salt

1 cup ne bread crumbs soaked in ½ cup milk

.

Grind the veal and pork through a coarse grinder plate.

.

Add the sage, pepper and salt to the meat and mix well.

.

Regrind the mixed meat through a ne grinding plate.

.

Using your hands, mix the meat with the bread crumbs.

.

Add the water, then beat the mixture with a wooden spoon until it is light and uffy.

.

Stuff the sausage into casings to make 4” (10 cm) links.

-10-

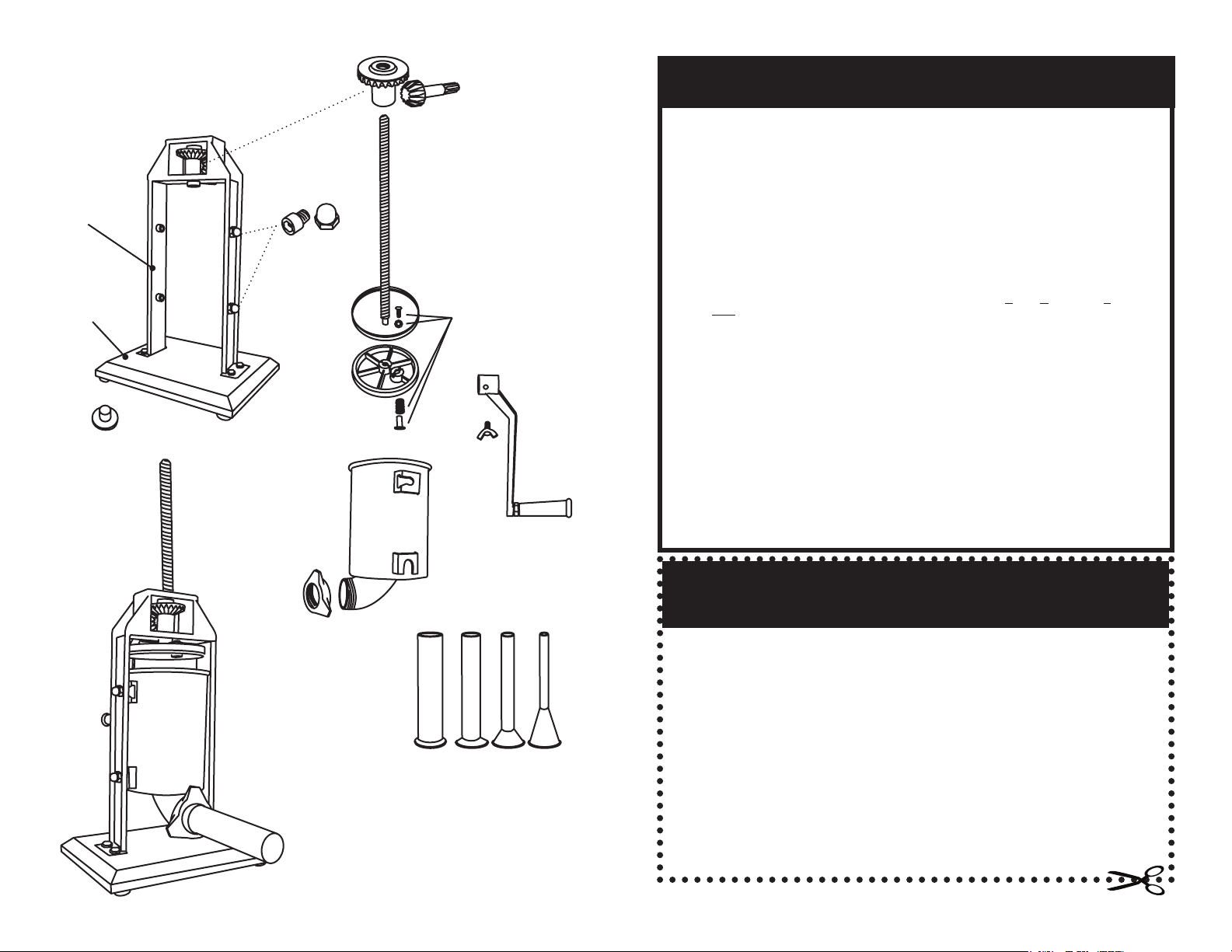

COMPONENT LIST

DIAGRAM PART PART

NUMBER DESCRIPTION NUMBER

1 Handle with Wingnut (Wingnut only 73-0511) 73-0510

2 Plunger 73-0514

3 Plunger Seal 73-0516

4 Pressure Release Valve (4 Piece Set) 73-0515

5 Plastic Funnel Set (4 Funnels) 73-0520

6 Stainless Steel Canister 73-0519

7 Front Ring Nut 73-0521

8 Canister Mounting Hardware Kit (4 Sets) 73-0522

9 Plunger Shaft 73-0512

10 Gear Set (2) 73-0513

11 Rubber Foot (4 Piece Set) 73-0517

If any c omponents o f this unit are broken or the uni t does not operate

properly , call West on Products LLC Toll Free at

Monday thru Friday 8:00am-5:00pm EST. Outside the U.S. call 440-638-3131

1-800-814-4895

E-Mail: CustomerService@WestonProducts.com

ADDITIONAL ACCESSORIES AVAILABLE

ACCESSORY DESCRIPTION PART #

Food-Grade Silicone Spray 03-0101-W

Hog Ring Pliers 47-1401

500 Count Hog Rings 47-1452

19 mm Processed-Type Collagen Casing 19-0101-W

33 mm Processed-Type Collagen Casing 19-0102-W

38 mm Processed-Type Collagen Casing 19-0103-W

1 1/2” x 12” Mahogany Casings 19-0201-W

2 1/2” x 20” Mahogany Casings 19-0102-W

These products and many more products can be ordered by visitin g

Monday thru Friday 8:00am-5:00pm EST. Outside the U.S. call 440-638-3131

W e s t o n P r o d u c t s . c o m or by calling

Weston Products LLC Toll Free at 1-800-81 4-4895

E-Mail: CustomerService@WestonProducts.com

-3-

Page 4

GENERAL SAFETY RULES

READ AND FULLY UNDERSTAND ALL

INSTRUCTIONS AND WARNINGS PRIOR TO

USING THIS STUFFER. YOUR SAFETY IS

MOST IMPORTANT: FAILURE TO COMPLY

WARNING!

1. Read this owners manual before

attempting to assemble or operate the

Vertical Stuffer.

2. NEVER use any accessories

or parts from other manufacturers.

Doing so will void your warranty.

3. NEVER store or leave the

machine at a temperature lower than

32oF (0oC).

4. Thoroughly clean all parts that

will come in contact with food before

and after using the appliance. Wash

all parts by hand and thoroughly dry.

5. Before using the Stuffer, always

apply a food-grade lubricant to the

inside of the Canister to decrease

the friction.

WITH PROCEDURES AND SAFE GUARDS MAY

RESULT IN SERIOUS INJURY OR PROPERTY

DAMAGE. REMEMBER: YOUR PERSONAL

SAFETY IS YOUR RESPONSIBILITY!

6. KEEP CHILDREN AWAY! Never

leave the stuffer unattended. The

Stuffer is not a toy.

7. Be sure the Stuffer is on a stable

work area. Be sure all of the Stuffer

Feet are level.

8. WEAR EYE PROTECTION!

Everyday eye glasses are not safety

glasses. Safety glasses conform

to ANSI Z87.1 requirements. Note:

approved safety glasses have Z87

printed or stamped on them.

9. DO NOT use the Stuffer while

under the inuence of drugs or

alcohol.

SAVE THESE INSTRUCTIONS!

Refer to them often and use them to instruct others.

SAUSAGE INFORMATION

MEAT SELECTION FOR SAUSAGE MAKING

Sausage making has evolved over many years and generations, and as a result there are

countless types of sausage you can make using the basic ingredients of meat, fat and a

few carefully blended spices. Following are a few simple guidelines that will help you make

the best tasting sausage possible.

Any type of meat can be used for making sausage: pork, beef, bison, moose and caribou,

even antelope make great sausage. It is important when preparing venison or other red

game meats to trim all the fat from the meat, as red game tallow will turn rancid in as few as

ve days. Replace the fat with either pork or beef fat, depending on the type of product you

are making, at a ratio of 1 pound (0.5 kg) of fat for every 4 pounds (1.8 kg) of game meat.

The fat content of your sausage will affect the taste, texture, cooking characteristics and

shelf life of your product. Most commercially made sausage has a fat content of about

20%. Using less than 12% fat will result in a very dry tasting sausage, while using more than

20% may result in a sticky avorless sausage that will be difcult to cook.

CURING

It is important to properly cure meats to preserve meat and poultry, and to destroy undesirable

microorganisms on the meat surfaces that cause spoilage and food born illnesses. There

are many steps that help in this process, including smoking, cooking, drying, chilling and

the addition of cure ingredients. The oldest means of accomplishing this is by introducing

salt into the meat. The resistance of bacteria to salt varies widely among different types of

bacteria. The growth of some bacteria is inhibited by salt concentrations as low as 3%, e.g.,

Salmonella, whereas other types are able to survive in much higher salt concentrations,

e.g., Staphylococcus. Fortunately, the growth of many undesirable organisms normally

found in cured meat and poultry products is inhibited at low concentrations of salt.

Modern curing is based on Nitrates and is very scientic. The best way to ensure proper

curing is to purchase one of the many commercially available curing agents from either

a grocery store or your local butcher. A very common cure is Prague Powder, which is

available in two types (#1 and #2).

CASING

There are many different types of casings available, the right choice depends on personal

preference as well as the type of sausage you wish to make. For most sausages, your

choices are natural or collagen. Don’t let the names fool you; collagen casings are not a

synthetic product . They are made from beef skin and other tissues. Collagen casings

are uniform in size and texture and require almost no preparation. “Natural” casings are

the intestines of lamb, sheep, hogs or beef. They are less uniform in size and require

substantial preparation. For those reasons, more than 75% of commercially made sausage

in the U.S. is made with collagen casing. There are also brous non-edible casings that are

used for some varieties of smoked sausages and bolognas.

-4-

TYPES OF SAUSAGE

Most sausages fall into one of four categories: Fresh, Smoked, Cooked or Dried. All

sausages, except dried, require refrigerated storage. There is also a sub-category of

uncooked smoked sausages.

Among the fresh and uncooked smoked sausages, you will nd such avors as kielbasa

or Polish sausage, Italian sausage, breakfast sausage and many others. Both fresh and

uncooked smoked sausages require cooking before eating and also require refrigerated

storage.

Smoked and cooked sausages include salami, bologna, the ever-popular hot dogs and

many others. Proper smoking requires a smokehouse or smoker. These can be simple

home-built structures made from metal drums or even old refrigerators or they can be

elaborate manufactured units. Most smoked sausages are warmed before serving. Many

-9-

Page 5

FOOD SAFETY

There are basic rules to follow when handling food.

They are COOK, SEPARATE, CLEAN, and CHILL.

COOK

It’s crucial to cook food to a safe internal temperature to destroy bacteria that is present.

The safety of hamburgers and other foods made with ground meat has been receiving a

lot of attention lately, and with good reason. When meat is ground, the bacteria present on

the surface is mixed throughout the ground mixture. If this ground meat is not cooked to

at least 160oF to 165oF (71oC to 74oC), bacteria will not be destroyed and there’s a good

chance you will get sick.

Solid pieces of meat like steaks and chops don’t have dangerous bacteria like E. coli on the

inside, so they can be served more rare. Still, any beef cut should be cooked to an internal

temperature of at least 145oF (63oC) (medium rare). The safe temperature for poultry is

180oF (82oC) and solid cuts of pork should be cooked to 160oF (71oC). Eggs should be

thoroughly cooked too. If you are making a meringue or other recipe that uses uncooked

eggs, buy specially pasteurized eggs or use prepared meringue powder.

SEPARATE

Foods that will be eaten uncooked and foods that will be cooked before eating MUST

ALWAYS be separated. Cross-contamination occurs when raw meats or eggs come in

contact with foods that will be eaten uncooked. This is a major source of food poisoning.

Always double-wrap raw meats and place them on the lowest shelf in the refrigerator so

there is no way juices can drip onto fresh produce. Then use the raw meats within 1-2 days

of purchase, or freeze for longer storage. Defrost frozen meats in the refrigerator, not on

the counter.

When grilling or cooking raw meats or sh, make sure to place the cooked meat on a

clean platter. Don’t use the same platter you used to carry the food out to the grill. Wash

the utensils used in grilling after the food is turned for the last time on the grill, as well as

spatulas and spoons used for stir-frying or turning meat as it cooks.

Make sure to wash your hands after handling raw meats or raw eggs. Washing hands with

soap and water, or using a pre-moistened antibacterial towelette is absolutely necessary

after you have touched raw meat or raw eggs. Not washing hands and surfaces while

cooking is a major cause of cross-contamination.

CLEAN

Wash your hands and work surfaces frequently when you are cooking. Washing with soap

and warm water for at least 15 seconds, then dry with a paper towel.

CHILL

Chilling food is very important. The danger zone where bacteria multiply is between

40oF and 140oF (4oC and 6oC). Your refrigerator should be set to 40oF (4oC) or below;

your freezer should be 0oF (-17oC) or below. Simple rule: serve hot foods hot, cold foods

cold. Use chang dishes or hot plates to keep food hot while serving. Use ice water

baths to keep cold foods cold. Never let any food sit at room temperature for more than

2 hours - 1 hour if the ambient temperature is 90oF (32oC) or above. When packing

for a picnic, make sure the foods are already chilled when they go into the insulated

hamper. The hamper won’t chill food - it just keeps food cold when properly packed

with ice. Hot cooked foods should be placed in shallow containers and immediately

refrigerated so they cool rapidly. Make sure to cover foods after they are cool.

NOTE: Special considerations must be made when using venison or other wild game,

since it can become heavily contaminated during eld dressing. Venison is often held

at temperatures that could potentially allow bacteria to grow, such as when it is being

transported. Refer to the USDA Meat and Poultry Department for further questions or

information on meat and food safety.

PLUNGER ASSEMBLY

1. Slide the Plunger Seal

onto the Plunger (gure 1).

2. Assemble the Pressure

Release Valve Kit onto the

Plunger. From the top of the

Plunger, place the Washer

onto the Valve Hole, then

insert the Screw through the

Washer and into the Valve

Hole. From the underside of

the Plunger, place the Spring

onto the end of the Screw,

then place the Valve Cap onto

the end of the Screw and twist

to secure.

3. Place the assembled

Plunger onto the end of the

Plunger Shaft (gure 2).

STUFFER ASSEMBLY

4. Attach the Handle by

sliding it onto the Gear Shaft

and placing the Wingnut into

the hole in the Handle. Twist

to tighten (gure 3).

5. Crank the Handle counterclockwise to bring the Plunger

to the top of the Stuffer.

6. Rest the Canister’s

Bottom Brackets onto the

Canister Mounts inside the

Housing of the Stuffer. Pivot

the bottom of the Canister into

the Stuffer Housing. Pivot

the Canister fully into the

Stuffer Housing, snapping

the Top Brackets into the

Canister Mounts (gure 4).

ASSEMBLY

gure 1

Plunger

Seal

Plunger

Valve Hole

gure 3

Gear Shaft

Wingnut

-5--8-

Pressure

Release

Valve Kit

Screw

Washer

Spring

Valve Cap

Handle

Outside view of

Canister Mounts

gure 2

gure 4

Top Brackets

Bottom Brackets

Page 6

7. Insert the Stufng Funnel of your

choice through the Front Ring Nut.

Screw the Front Ring Nut and Stufng

Funnel onto the mouth of the Canister

until snug. DO NOT OVERTIGHTEN

the Front Ring Nut, as it may damage

the Funnel (gure 5).

8. Thoroughly coat the inside of the

Canister with a food-grade lubricant

prior to use (gure 6).

DISASSEMBLY &

CLEANING

1. Remove the Stufng Funnel by

unscrewing the Front Ring Nut, and

pulling the Funnel out.

2. Turn the Handle counter-clockwise

until the Plunger comes out of the

Canister.

Front

Ring Nut

Mouth of the

gure 6

Canister

Funnel

gure 5

STUFFING INSTRUCTIONS

CAUTION! Any time you complete stufng or

raise the Plunger out of the Canister, RELEASE THE

HANDLE SLOWLY! Pressure or gravity could cause

CAUTION!

NOTE: Apply a food-grade lubricant to the inside of the

Canister before lling with the meat mixture.

1. Tilt out the Canister.

2. Fill the Canister with your meat and seasoning

mixture (gure 7).

3. Press the mixture down into the Canister rmly to

release any trapped air.

4. Pivot the Canister back into the upright position and

snap the Top Brackets into the Canister Mounts.

5. Turn the Handle clockwise, until the Plunger

comes in contact with the meat and the mixture is

ready to extrude out the end of the Stufng Funnel.

6. Slip the casing on the end of the Stufng Funnel

until the entire casing has slid onto the Stufng

Funnel (gure 8).

the Handle to spin back slightly causing injury!

gure 7

Canister

3. Pivot the Canister outward and

then pull the Canister up to remove the

Canister from the Stuffer Housing.

4. Unscrew the Plunger from the

Plunger Shaft. Disassemble the

Pressure-Release Valve from the

Plunger. Remove the Plunger Seal from

the Plunger.

5. Wash all parts that have come in

contact with meat in hot soapy water. BE

SURE TO CLEAN THEM IMMEDIATELY

AFTER USE. Rinse and thoroughly dry

all parts IMMEDIATELY. Sterilize as

needed.

6. Fully lubricate the Shaft, Canister,

Pressure Release Valve Components

and the Front Ring Nut with a food-grade

lubricant before and after each use.

-6- -7-

7. Tie, twist or hog ring the end of the casing to seal it.

8. Turn the Handle clockwise to extrude the mixture

into the casing. For best results, apply pressure

around the casing, close to the end of the Stufng

Funnel. This will hold the casing tight and will cause

the mixture to pack rmly into the casing.

9. When the end of the casing has been reached,

twist, tie or hog ring the casing to seal the contents

inside.

STUFFING TIPS: The following are

suggestions to help reduce resistance when

stufng with the 13 mm Stufng Funnel.

A. Add water to your meat mixture – up to

1-1/2 cups (0.4 L) of water per every 5 lb (2.3

kg) of seasoned meat.

B. Add 1/4 cup (60 ml) of vegetable or olive oil

to the meat mixture for better ow.

gure 8

Loading...

Loading...