Page 1

Installation and Assembly Vision•Point™ Articulating Wall Arm/

Model: MT25 ARM18

Patent Pending

Cabinet Side mount for LCD screens

Provides full swivel capability around the side of a cabinet for screens 10" to 15" wide.

Note: Read entire instruction sheet before you start installation and assembly . Max. Load Capacity:

25 lb (11.3 kg)

T o mount to met al studs, order metal stud accessory kit ACC 908.

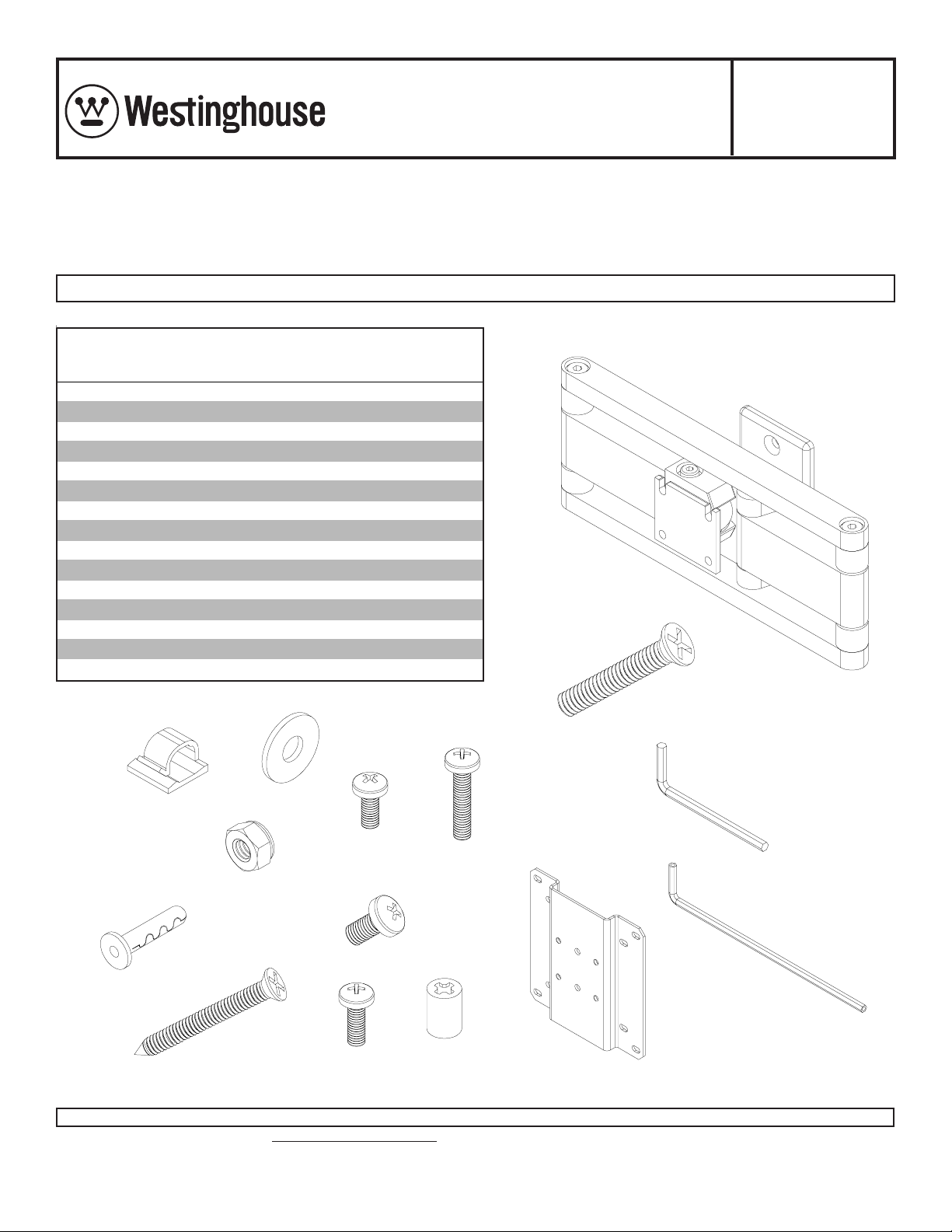

Parts List

Descri p tion Qty. Part #

wall arm as sembly 1 095-0188

A

cable c l i p 2 590-2155

B

1/4- 20 x 1.5 " fl at head s crew 2 520-2164

C

.25" ID x .75" OD washer 2 540-2015

D

1/4- 20 n ylock nu t 2 530-2002

E

M5 x .8 x 10 mm phil li ps sc rew 4 520-2005

F

3/16" all e n wrench 1 560-0071

G

All i gat or® concret e anc hor 2 590-0097

H

#14 x 2.5" fl at head wood s crew 2 520-2165

I

4 mm al l en wrench 1 560-9706

J

M4 x .7 x 12 mm phil li ps sc rew 4 504-2013

K

adapter brack et 1 095-4101

L

M4 x .7 x 10 mm phil li ps sc rew 4 520-2027

M

M4 x .7 x 20 mm phil li ps sc rew 4 504-2014

N

.198" x .313" x . 437" H retai ni ng s pac er 4 590-5003

O

C

A

D

B

M

N

G

E

F

H

J

I

K

Visit the Westinghouse Web Site at www.westinghousedigital.com For customer service call 1-866-287-5555.

O

L

ISSUED: 04-22-04 SHEET #: 095-9195-11 of 8

Page 2

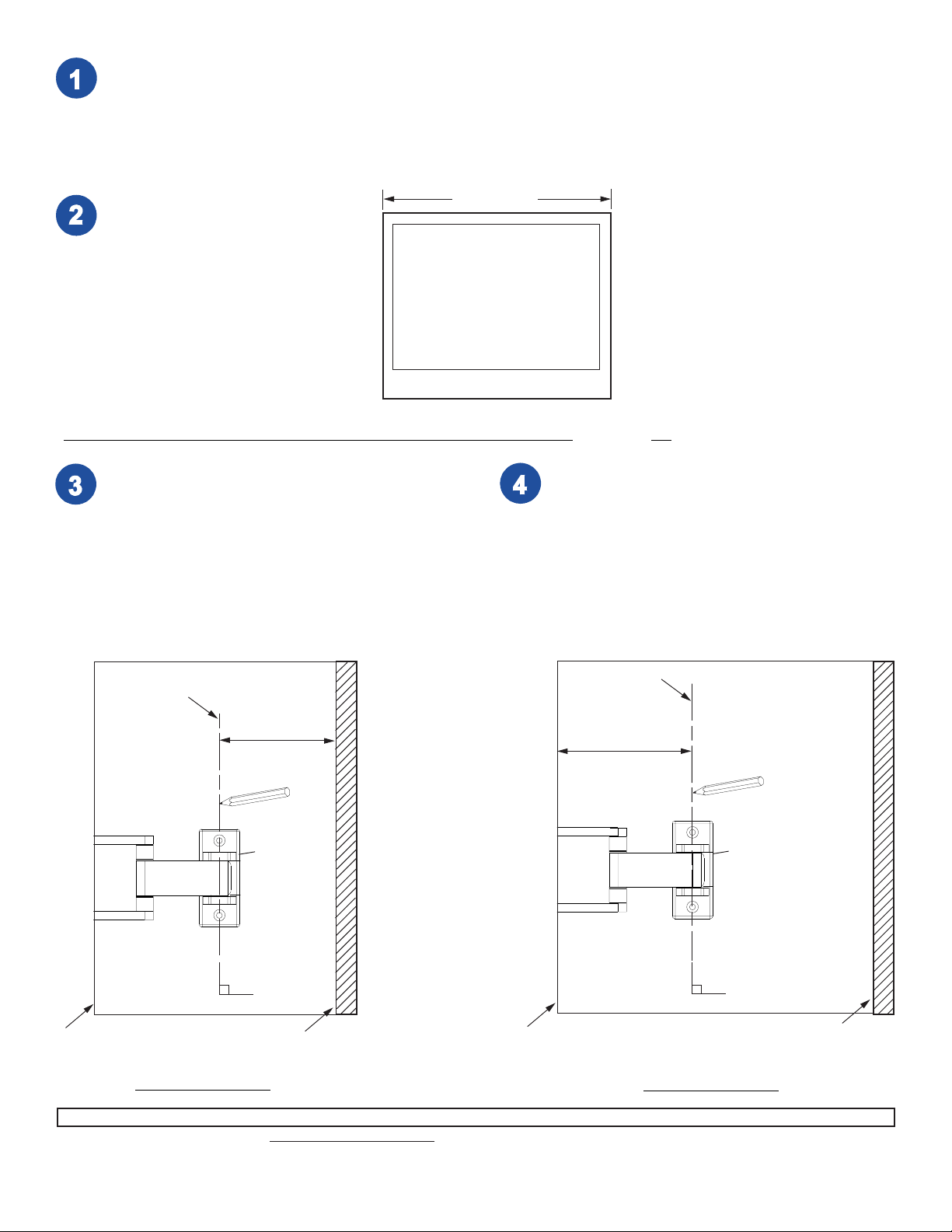

For mounting to side of cabinet start with step 2. For mounting to wall start with step 7.

WIDTH OF

Measure the width of your screen.

SCREEN

Note: The dimension of half the

width will be used for steps 3 and 4.

For mounting to the side of a kitchen or bathroom cabinet – follow all steps below:

T o ensure the screen does not hit the wall when

the arm is in the closed position and mounted to

the side of your cabinet, do the following:

Measure 1/2 the width of your screen and

subtract 3/4". This dimension is the minimum

space you need between the back wall and the

wall plate mounting holes. This is shown by line

"A" in the illustration below. Draw line "A" on

your cabinet using a pencil.

LINE "A"

HALF WIDTH - 3/4"

WALL PLATE

Note: Make both

lines "A" & "B" at a

90° angle with the

cabinet.

If you would like your screen to swivel the full 180°

over the outer edge of your cabinet, do the

following:

Measure 1/2 the width of your screen and add 1 3/8".

This is the maximum space you need between

the outer edge of your cabinet and the wall plate

mounting holes. This is shown with line "B" in the

illustration below. Draw line "B" on your cabinet

using a pencil.

LINE "B"

HALF WIDTH + 1 3/8"

WALL PLATE

90°

OUTER EDGE

OF CABINET

BACK WALL

Side of Cabinet

Visit the Westinghouse Web Site at www.westinghousedigital.com For customer service call 1-866-287-5555.

OUTER EDGE

OF CABINET

Side of Cabinet

ISSUED: 04-22-04 SHEET #: 095-9195-12 of 8

90°

BACK WALL

Page 3

The depth of the cabinet and the size of your screen will determine which line "A" or "B" is closer to the outer

edge of the cabinet. Use the line closer to outer edge of your cabinet as your centerline. This will ensure 180°

of swivel around the side of your cabinet and that your screen will not hit the back wall in the closed position.

Use wall plate as template to mark center of holes onto side of

cabinet along centerline.

Make sure wall plate is level, then drill two 9/32" (7 mm) holes

where marked.

BACK WALL

OUTER EDGE

OF CABINET

CENTERLINE

Side of Cabinet

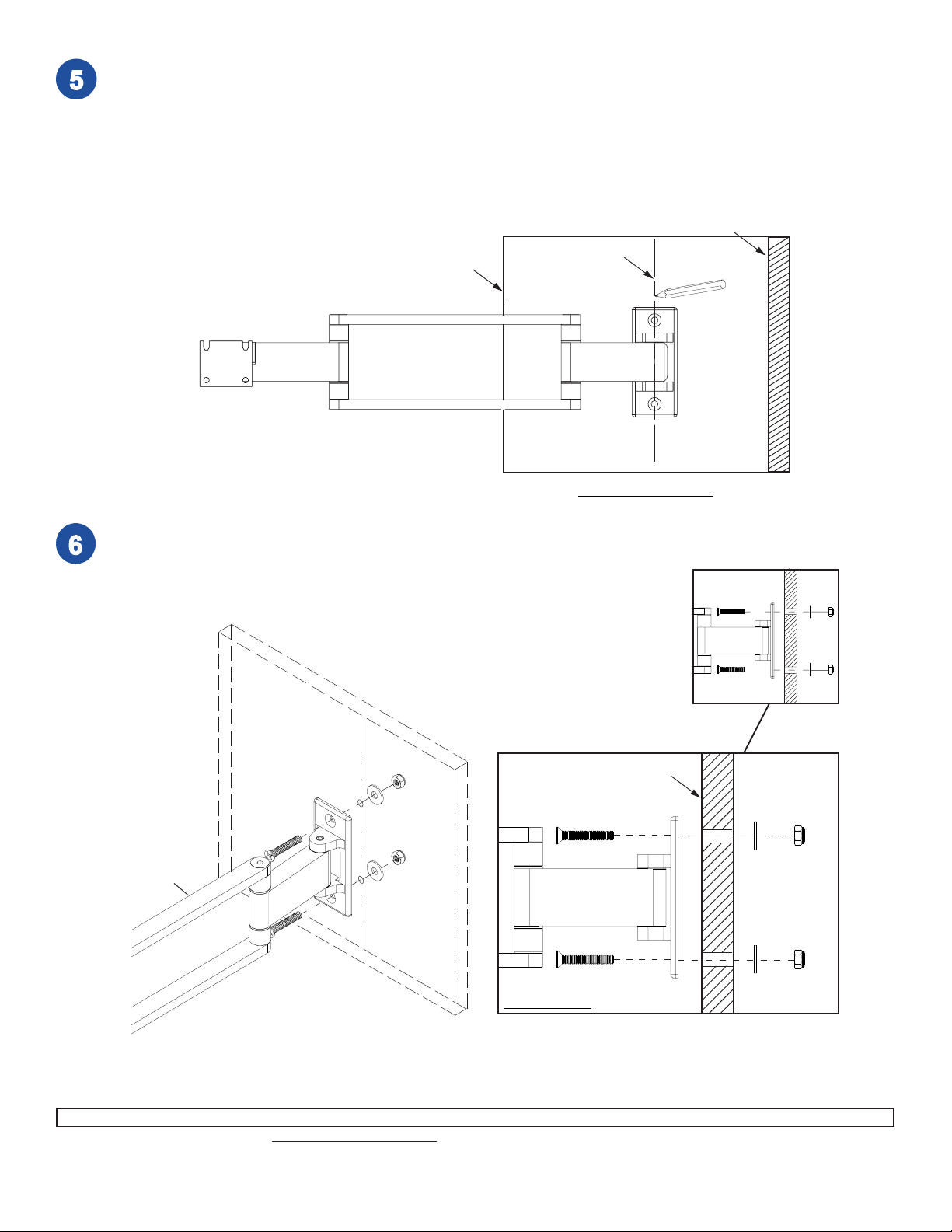

Fasten wall arm assembly (A) to side of cabinet using two 1/4-20 flat head screws (C),

washers (D), and 1/4-20 nylock nuts (E) as shown below .

Skip to step 9.

CABINET

A

C

D

E

A

Side View

ISSUED: 04-22-04 SHEET #: 095-9195-13 of 8

Visit the Westinghouse Web Site at www.westinghousedigital.com For customer service call 1-866-287-5555.

Page 4

WARNING

• When installing wall mounts on cinder block, verify that you have a minimum of 1-3/8" of actual concrete surface in

the hole to be used for the concrete anchors. Do not drill into mortar joints! Be sure to mount in a solid part of the

block, generally 1" minimum from the side of the block. Cinder block must meet ASTM C-90 specifications. It is

suggested that a standard electric drill on slow setting is used to drill the hole instead of a hammer drill to avoid

breaking out the back of the hole when entering a void or cavity .

• Concrete must be 2000 psi density minimum. Lighter density concrete may not hold concrete anchor .

• Make sure that the wall will safely support four times the combined load of the equipment and all attached hardware and components.

For Cinder Block and Concrete Walls, drill one 1/4"

(6 mm) dia. hole to a minimum depth of 2" (51 mm).

Insert anchor (H) in hole flush with wall as shown in fig

1.1 on next page. Place wall plate over anchor (H) and

secure with wood screw (I) as shown in figure 1.2. Make

sure wall plate is level, mark other hole and repeat steps

with other fasteners. Tighten all fasteners. See figure

1.3.

Skip to step 9.

WARNING

• Tighten concrete anchor bolts firmly, but do not

overtighten. Overtightening can damage the bolts,

greatly reducing their holding power.

• Never tighten in excess of 80 in • lb (9 N.M.).

WARNING

• Concrete anchors are not intended for attachment to

concrete wall covered with a layer of plaster, drywall,

or other finishing material. If mounting to concrete wall

covered with plaster/drywall is unavoidable, plaster/

drywall (up to 5/8" thick) must be counterbored as

shown below. If plaster/drywall is thicker than 5/8",

custom fasteners must be supplied by installer .

fig 1.1

CONCRETE

WALL

H

Drill hole and insert anchor (H).

fig 1.2

WALL PLATE

I

H

Place wall plate over anchor (H) and secure with screw (I).

fig 1.3

After repeating figure 1.1, tighten all fasteners.

I

H

CUT AW A Y VIEW

WALL

PLA TE

ISSUED: 04-22-04 SHEET #: 095-9195-14 of 8

Visit the Westinghouse Web Site at www.westinghousedigital.com For customer service call 1-866-287-5555.

Page 5

For Wood Stud Walls, use a stud finder to locate

center of stud. Make sure wall plate is level, drill two

3/16" (5 mm) dia. holes to a minimum depth of 2"

(51 mm). Attach wall plate to center of wood stud

using two #14 wood screws (I).

WOOD

STUD

WALL

WARNING

WALL

PLA TE

• Tighten wood screws so that wall plate is firmly

attached, but do not overtighten. Overtightening can

damage the screws, greatly reducing their holding

power.

• Never tighten in excess of 80 in • lb (9 N.M.).

I

• Make sure that mounting screws are anchored into the

center of the studs. The use of an "edge to edge" stud

finder is highly recommended.

Note: This product is designed to accommodate screens with VESA® compliant hole pattern. For safe

mounting, please make sure that mounting screws turn at least three complete turns in the screen inserts.

FOR VESA 75 MOUNTING PATTERN:

1) Choose hole pattern indicated below. 2) Attach

adapter bracket (L) to back of screen using four

10 mm screws (M) as indicated below. 3) If hole

pattern is in a pocket, attach adapter bracket (L)

to back of screen using four 20 mm screws (N)

and four retaining spacers (O) as indicated below.

FOR VESA 100 MOUNTING PATTERN:

1) Choose hole pattern indicated below. 2) Attach adapter

bracket (L) to back of screen using four M4 x 10 mm

screws (M) as indicated below.

Note: If you don't get three complete turns in the screen

inserts, use four M4 x 12 mm screws (K) instead of four

M4 x 10 mm screws (M).

For screens with a hole

L

Visit the Westinghouse Web Site at www.westinghousedigital.com For customer service call 1-866-287-5555.

pattern in a pocket,

spacers (O) go between

adapter bracket (L) and

screen.

Note: LCD screen may

appear slightly different

than illustrated.

L

ISSUED: 04-22-04 SHEET #: 095-9195-15 of 8

Page 6

Note: If the balljoint feels loose or

too easy to adjust, slightly tighten

cap socket screw until balljoint feels

firmly in place.

Insert two M5 x 10 mm screws (F)

into top two holes of adapter bracket

(L) leaving approximately 1/4" of

exposed thread. With slots facing

upward, hook screws onto wall arm

balljoint as shown in figure 2.1.

Insert two M5 screws (F) through

bottom holes of wall arm balljoint

into adapter bracket (L) as shown in

figure 2.2.

Tighten all screws (F).

T o obt ain full range of motion and enough tension to hold the screen in any position, simply tighten or loosen cap

socket screw a few turns using 4 mm allen wrench (J).

fig 2.1

F

WALL ARM

BALL JOINT

fig 2.2

L

L

1/4"

F

CAP SOCKET

SCREW

CAUTION

• Do not remove screw or loosen screw until it is no

longer engaged with the mount. Doing so may cause

the screen to fall.

CAP SOCKET SCREW

ISSUED: 04-22-04 SHEET #: 095-9195-16 of 8

Visit the Westinghouse Web Site at www.westinghousedigital.com For customer service call 1-866-287-5555.

Page 7

If more or less tension is desired in the arm pivot points, do the following:

• To increase tension, turn socket screw clockwise with 3/16" allen wrench (G).

• To reduce tension, turn socket screw counterclockwise with allen wrench (G). Do not turn more than half a

turn.

SOCKET SCREWS

Place cable clips (B) as needed, to better manage cords, making sure that one clip is

close enough to the hinge area to prevent cord from bunching up.

Note: Make sure cords have enough slack to allow full movement of the arm.

B

ISSUED: 04-22-04 SHEET #: 095-9195-17 of 8

Visit the Westinghouse Web Site at www.westinghousedigital.com For customer service call 1-866-287-5555.

Page 8

Limited Five-Year Warranty

Westinghouse Digital Electronics warrants to original end-users of this Westinghouse television mounting product (the

“Product”) that the Product will be free from defects in material and workmanship, under normal use, for a period of five (5)

years from the date of purchase by the original end-user, subject to the following terms and conditions:

REP AIR OR REPLACEMENT – For a period of five (5) years from the original date of purchase, W estinghouse Digit al

Electronics will repair any defect in material or workmanship in the Product, or , at its option, replace a defective Product.

Replacement parts and products will be warranted for either the remainder of the original warranty period or ninety (90)

days from the date of delivery to the end-user, whichever occurs last.

OBT AINING WARRANTY SER VICE – To obt ain warranty services, you must either personally deliver or ship the Product

to Westinghouse Digital Electronics, freight prepaid. Please call Westinghouse Digital Electronics at (866) 287-5555 to

obtain a Return Merchandise Authorization (“RMA”) and for other instructions regarding return and replacement or repair of

the Product. Westinghouse Digital Electronics will not accept Products delivered to it without an RMA.

EXCLUSIONS TO W ARRANTY – This warranty does not cover damage caused by (a) service or repairs by anyone other

than personnel authorized by Westinghouse Digital Electronics, (b) the failure to utilize proper packing when returning the

product, (c) improper installation or the failure to follow Product instructions or warnings, or (d) misuse or accident, in

transit or otherwise.

PROOF OR ORIGINAL PURCHASE – A sales receipt, invoice, or other proof of purchase specifying the original date of

purchase within the five (5) year warranty period must be presented to obtain warranty service. This warranty extends to

the original purchaser and is not transferable.

EITHER REP AIR OR REPLACEMENT IS YOUR EXCLUSIVE REMEDY UNDER THIS WARRANTY. EXCEPT TO THE

EXTENT PROHIBITED BY LAW, WESTINGHOUSE DIGITAL SHALL NOT BE LIABLE FOR ANY INCIDENTAL OR

CONSEQUENTIAL DAMAGES CLAIMED T O ARISE FROM BREACH OF ANY EXPRESS OR IMPLIED W ARRANTY ON

THIS PRODUCT . ANY IMPLIED WARRANTY OF MERCHANT ABILITY OR FITNESS FOR A P ARTICULAR PURPOSE

ON THIS PRODUCT IS LIMITED IN DURA TION AND SCOPE TO THE TERMS OF THIS W ARRANTY .

Some States do not allow the exclusion or limit ation of incidental or consequential damages, or allow limitations on how

long an implied warranty lasts, so the above limitation may not apply to you. This warranty gives specific legal rights, and

you may also have other rights which vary from S tate to S tate.

Westinghouse Digital Electronics, LLC

16257 East Gale A ve.

City of Industry , California 91745

T el: (626) 333-9677.

ISSUED: 04-22-04 SHEET #: 095-9195-18 of 8

Visit the Westinghouse Web Site at www.westinghousedigital.com For customer service call 1-866-287-5555.

and Westinghouse are trademarks of Westinghouse Electric Corporation and are used under license.

Loading...

Loading...