Page 1

USER'S GUIDE

WD 1003-RAH

WD 1003S-RAH

WD 1003-RA2

WD 1003A-RA2

Winchester

Disk Controllers

Important Information

Do not Discard

Page 2

Document Scope

This document describes the hardware and software installation of the following Western

Digital controllers:

WD 1003-RAH WD 1003-RA2

WD1003S-RAH WD 1003A-RA2

Two versions of the WD1003-RA2 are available:

Feature 000 (F000). Non-translation operation only

Feature 001 (F00l). Translation operation only.

The other controllers described in this document have one standard version.

These controllers are designed for use in IBM Personal Computer ATs or other AT-c ompatible

computers with a 16-bit data bus.

The use of the term controller refers to all boards described within this document. When a

reference is made to a particular board, the appropriate WD part number is used.

Page 3

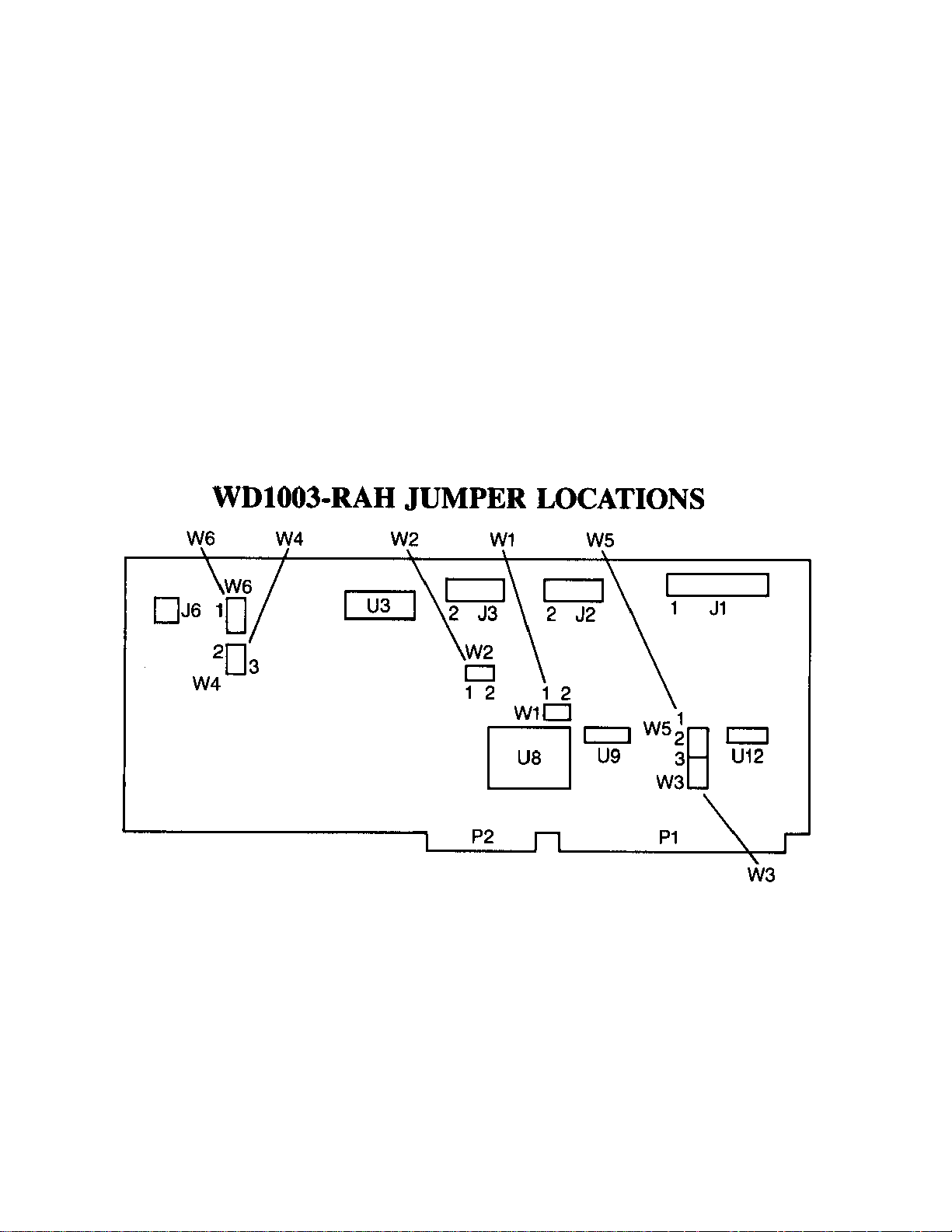

WDl003-RAH JUMPER SETTINGS

JUMPER PIN CONNECTS DESCRIPTION

W1 1-2 Standard factory setting. Status read is latched. Used for IBM

Personal Computer AT if Winchester activity LED is connected to

J6.

OPEN Status read is not latched. Activity LED turns on during drive

access. W5 must be jumpered 2 to 3. Used for Compaq hosts.

W2 OPEN Standard factory setting. Selects primary addresses, 1F0 through

1F7 and 3F0 through 3F7 hex. Do not modify the primary address

jumper unless your BIOS operating system is configured to accept

more than two hard disk drives.

1-2 Selects secondary addresses, 170 through 177 and 370 through

377 hex.

W3 OPEN

1-2

W4 2-3 Standard factory setting. No translation for drive 0.

1-2 Enables translation for drive 0. Translation is only available for

W5 2-3 Standard factory setting. WG and drive select lines only enabled

1-2 WG and drive select lines are disabled during power up reset and

W6 2-3 Standard factory setting. No translation for drive 1.

1-2 Enables translation for drive 1. Translation is only available for

This configuration used with WD11C00C-22 at board location US

or if W5 is jumpered 1 to 2. Required only on early units with

WD11C00-22 at board location U8 and W5 is jumpered 1 to 2. DO

NOT JUMPER WITH THE WDl1C00C-22 INSTALLED.

615 cylinders and four headed drives. In translation mode, the

controller translates the 26 physical sectors per track into 17

sectors. The extra sectors are "translated" into logical heads. To

use the translation mode, select through the Setup program a 615

cylinder and six head drive type. (This is drive type three for IBM

Personal Computer AT users. Not all AT-compatible systems use

the same drive tables as IBM.) This configuration must be used

when running an operating system or application program which

requires a 17 sector per track disk drive.

when drive is accessed. This configuration also provides power up

and down protection.

when + 5V power supply drops below approximately +4.1 5V.

615 cylinders and four headed drives. In translation mode, the

controller translates the 26 physical sectors per track into 17

sectors. The extra sectors are "translated" into logical heads. To

use the translation mode, select through the Setup program a 615

cylinder and six head drive type. (This is drive type three for IBM

Personal Computer AT users. Not all AT-compatible systems use

the same drive tables as IBM.) This configuration must be used

when running an operating system or application program which

requires a 17 sector per track disk drive.

Page 4

Hardware Installation

This section describes installation of your hardware. If the disk drive(s) is (are) installed

internally, it is best to locate the controller in the closest available expansion slot relative to the

drive.

CAUTION

Handle the controller board by the ends of the boar d. So me of t he chips are static sensitive

and damage may occur if the board is incorrectly handled.

Furthermore, do NOT under any circumstances connect an RLL controller to an MFM

drive. Refer to “If You Have a Problem” section for further information.

Page 5

WD10035-RAH JUMPER SETTINGS

JUMPER PIN CONNECTS DESCRIPTION

W1 1-2

OPEN

W2 OPEN

1-2

Standard factory setting. Status read is latched. Used for IBM Personal Computer AT

if Winchester activity LED is connected to J6.

Status read is not latched. Activity LED turns on during drive access. W5 must be

jumpered 2 to 3. Used for Compaq hosts.

Standard factory setting. Selects primary addresses, 1F0 through 1F7 and 3F0 through

3F7 hex. Do not modify the primary address jumper unless your BIOS operating

system is configured to accept more than two hard disk drives.

Selects secondary addresses, 170 through 177 and 370 through 377 hex.

W3

W4 1-2

2-3

W5 2-3

1-2

W6 1-2

2-3

W7 1-2

3-4

1-3

2-4

Applicable to the WD1003-RAH. Eliminated by design and artwork changes to the

WD1003S-RAH.

Standard factory setting. No translation for drive 0.

Enables translation for drive 0. Translation is only available for 615 cylinders and four

headed drives. In translation mode, the controller translates the 26 physical sectors per

track into 17 sectors. The extra sectors are "translated" into logical heads. To use the

translation mode, select through the Setup program a 615 cylinder and six head drive

type. (This is drive type three for IBM Personal Computer AT users. Not all ATcompatible systems use the same drive tables as IBM.) This configuration must be

used when running an operating system or application program which requires a 17

sector per track disk drive.

Standard factory setting. WG and drive select lines only enabled when drive is

accessed. This configuration also provides power up and down protection.

WG and drive select lines are disabled during power up reset and when + 5V power

supply drops below approximately +4.1 5V.

Standard factory setting. No translation for drive 1.

Enables translation for drive 1. Translation is only available for 615 cylinders and four

headed drives. In translation mode, the controller translates the 26 physical sectors per

track into 17 sectors. The extra sectors are "translated" into logical heads. To use the

translation mode, select through the Setup program a 615 cylinder and six head drive

type. (This is drive type three for IBM Personal Computer AT users. Not all ATcompatible systems use the same drive tables as IBM.) This configuration must be

used when running an operating system or application program which requires a 17

sector per track disk drive.

Standard factory setting. Controller operates with daisy-chained drive(s). Both can be

daisy-chained from J1 or drive 0 can be connected to J1 and drive 1 can be connected

to J5. For daisy-chained operation, set the drive select jumpers on the first drive for

drive 0 and on the second drive for drive 1.

Controller operates with parallel connected drives. Attach drive 1 control connector to

J1.

Attach drive 0 control connector to J5. For parallel operation, set the drive select

jumpers on both drives for drive 0.

W8 1-2

2-3

Standard factory configuration. Ties input high

Enables seek to landing zone (cylinder 663) on any seek to a cylinder greater than

615. Used only for 615 cylinder drives. This jumper also changes step rate 0 (24 µsec)

to step rate 15 (11 µsec).

.

Page 6

Only verify the jumper settings in step 1. Modification of the standard factory jumper settings

on the controller is rarely necessary. Modify jumpers only under the direction of a qualified

individual, i.e. your dealer.

1.Verify controller jumper settings. Refer to pages 1 through 9 for jumper setting

information.

2. Verify terminat ion on last drive. Verify proper setting of drive select switches on drive,

i.e. set the drive select switches for drive select 1 or 2. Refer to your drive owner's

manual for information about proper drive termination and select switches.

3. Remove the bla nk expansion slot bracke t. Put the bracke t away and save it for possible

future use. The screw will be used to hold the new controller board in place.

NOTE

Verify that the cable c onnectors mate properly with the board connectors. This is easily

done by checking that pin 1 on the cable mates with pin 1 on the connector. Pin 1 is clearly

marked on the board's connectors. Pin 1 on the cables is usually on the color coded side.

4. WD1003-RAH: Attach 34-pin control connector to J1

WD10035-RAH: Attach 34-pin control connector to J 1 if W7 is set for daisy-chained

operation.

NOTE

Normally, daisy-chaining implies that two drives connect to the same connector. That is

still true with the WDl0035-RAH. However, it i s possible to connect the second drive to J5.

Regardless of the connection, one drive must be configured as drive 0 and the other drive

must be configured as drive 1.

Attach drive 1 's 34-pin connector to J 1 and drive 0's 34-pin connector to J5 if W7 is set

for parallel connection. (Refer to Tabl e 2 for further information.) Set the drive select

jumpers on both drives to drive 0 if W7 configures the controller for parallel connection.

WDl003-RA2: Attach 34-pin control connector J5.

WDl003A-RA2: Attach 34-pin control connector to J4.

5. Connect control cable(s) to drive(s).

6. WD1003-RAH WDl003S-RAH: Attach drive 0's 20-pin data connector to J2.

Page 7

WD1003-RA2: Attach drive 0's 20-pin data connector to J4.

WD1003A-RA2: Attach drive 0's 20-pin data connector to J3.

7. WD1003-RAH

WD1003S-RAH

WD1003-RA2: Attach drive 1's data connector to J3.

WD1003A-RA2: Attach drive l's data connector to J2.

8. Connect data cables to drives.

9. WD1003-RA2: Attach 34-pin floppy cable connector to J1.

WD1003A-RA2: Attach 34-pin floppy cable connector to J5.

10. WD1003-RAH

WD1003S-RAH

WD1003-RA2: Attach Winchester activity LED connector to J6.

WD1003A-RA2: Attach Winchester activity LED to Jl.

11. Install the controller board into the expansion slot. Make sure that the board is seated

properly by pressing down on both ends of the board. Secure the boa rd wit h the bra cket

screw.

12. Remove or disable any other floppy controller in your system if you are installing a

WD1003RA2 or WDl003A-RA2. It is NOT possible to disabl e the floppy cont roller on

the WD1003-RA2 or WD 1003A-RA2.

Page 8

NOTE (For WD1003-RA2 only)

Translation

translation program converts the drive's 26 physical sectors per track to 17 sectors per track. The extra sectors are

"translated" into logical heads. To use the translation mode, select through the Setup program a 615 cylinder and six

head drive type. (This is drive type three for IBM Personal Computer AT users. Not all AT-compatible systems use the

same drive tables as IBM.) This configuration must be used when running an operating system, application program, or

system BIOS that requires a 17 sector per track disk drive.

only available with F001 controllers. F000 controllers operate in non-translation mode only. F001's

is

WD1003-RA2 JUMPER SETTINGS

JUMPER PIN CONNECTS DESCRIPTION

E1

E2

E3

E4

E5

E6

E7

E8

E9

E2-E3 Standard factory setting. Selects primary addresses, 1F0 through

for the hard disk controller. Do not modify the primary address jumper

unless your operating system is configured to accept more than two hard

disk drives. Also verify that ES and E6 are connected if E2 and E3 are

jumpered.

El-E2 Selects secondary addresses, 170 through 177 hex, for the hard disk

controller. Also verify that E4 and ES are connected if El and E2 are

jumpered.

E5-E6 Standard factory setting. Selects primary addresses, 3F0 through 3F7 hex,

for the floppy disk controller. Do not modify the primary address jumper

unless your operating system is configured to accept more than two hard

disk drives. Also verify that E2 and E3 are connected if ES and E6 are

jumpered.

E4-E5 Selects secondary addresses, 370 through 377 hex, for the floppy disk

controller. Also verify that El and E2 are connected if E4 and ES are

jumpered.

E7-E8

E8-E9

Standard factory setting. Supports 300 or 360

Selects dual speed spindle floppy disk drives.

floppy disk drives.

RPM

1F7

hex,

Page 9

Page 10

WD1003A-RA2 JUMPER SETTINGS

JUMPER PIN CONNECTS DESCRIPTION

W1 1-2

2-3

W2 1-2 Standard factory setting. No translation for drive 0.

OPEN

1-2

CLOSED

W2 3-4 Standard factory setting. No translation for drive 1.

OPEN

CLOSED Enables translation for drive 1.

This configuration used with a WDllC00C-22 at board location Ul6.

Required only on early units with WDl lC00-22 at board location U8 and

W5 is jumpered 1 to 2. DO NOT JUMPER WITH WDllC00C-22

INSTALLED.

Enables translation for drive 0. Translation is only available for 615

cylinders and four headed drives. In translation mode, the controller

translates the 26 physical sectors per track into 17 sectors. The extra

sectors are "translated" into logical heads. To use the translation mode,

select through the Setup program a 615 cylinder and six head drive type.

(This is drive type three for IBM Personal Computer AT users. Not all

AT-compatible systems use the same drive tables as IBM.) This

configuration must be used when running an operating system or application program which requires a 17 sector per track disk drive.

W3 3-4

1-2

W4 3-5 Standard factory setting. Selects primary addresses, 1F0 through 1F7 hex,

4-6 Standard factory setting. Selects primary addresses, 3F0 through 3F7 hex,

1-3 Selects secondary addresses, 170 through 177 hex, for the hard disk

2-4 Selects secondary addresses, 370 through 377 hex, for the floppy disk

W5 1-2 Standard factory setting. Closed by etch on the solder side of the board.

2-3 Carefully cut etch and jumper to operate the controller with hard disk

W6 Removed from final release.

W7 2-3

1-2

Standard factory setting. DO NOT OPEN.

Standard factory setting. DO NOT OPEN.

for the hard disk controller. Do not modify the primary address jumper

unless your operating system is configured to accept more than two hard

disk drives. Also verify that W4 positions 4 and 6 are connected if 3 and

5 are jumpered.

for the floppy disk controller. Do not modify the primary address jumper

unless your operating system is configured to accept more than two hard

disk drives. Also verify that W4 3 and 5 are connected if 4 and 6 are

jumpered.

controller. Also verify that W4 2 and 4 are connected if 1 and 3 are

jumpered.

controller. Also verify that W4 1 and 3 are connected if W4 2 and 4 are

jumpered.

Configures the board to control drives with a maximum of eight heads or

Reduced Write Current (RWC).

drives having a maximum of 16 heads.

Standard factory setting. Supports 300 or 360

Supports dual speed spindle floppy drives.

floppy disk drives.

RPM

Page 11

Software Installation Instructions

This section contains instructions for preparing (low level format) the drive to be recognized by

the operating system. Formatting the drive uses one of several software programs, the Advanced

Diagnostics (or equivalent in AT compatibles), Disk Manager from Ontra ck Comput er Systems,

or Speedstor 4.02 from Storage Dimensions. Use of the programs depends on the controller

configuration. Configuring the controller to use the translation feature requires running the

Advanced Diagnostics program, Setup. Setup defines the drive type for the system and low level

formats the drive. Without translation, Advanced Diagnostics can low level format the drive if

the system BIOS recognizes the 26 sector RLL format. (Storage Dimensions' Speedstor 286

BIOS is a replacement set of BIOS ROMs for the AT system board.) Run the DOS programs,

FORMAT and FDISK, after performing the low level format, regardless of the controller

configuration.

Software Installation Instructions for Non-Translation Mode

NOTE

Formatting disk media with this operational mode requires a host system with a 26 sector

BIOS. If the system does not contain a 26 sector BIOS, O ntrack and Storage Dimensions

produc e pro grams t o support t he 26 se ctor RLL dri ves. F or fur ther i nfor mation on these

programs, contact:

Ontrack Computer Systems

6222 Bury Drive

Eden Prairie, Minnesota 55344

(612) 937-1107

Storage Dimensions

14127 Capri Drive, Suite 1

Los Gatos, California 95030

(408) 370-3304

The Disk Manager and Speedstor products are the only products that have been tested by

Western Digital at this publication date. Both work well, providing full usage of the RLL

capacities. However, these are not the only alternatives for removing system limitations.

Contact your dealer for further information.

1. Boot the system with the Advanced Diagnostics. Define the drive type(s)

through the Setup option. After defining the drive types, run System

Checkout. Enter 0 after the "Select the action desired" prompt.

2. Select fixed disk option 17.

3. Select the Format Menu from the Fixed Disk Diagnostic Menu.

4. Unconditionally format the drive with the Format Selection Menu.

5. Enter bad block in the Defect Entry table.

Page 12

6. Formatting begins. After formatting the drive, press "ENTER". Boot and

operate the system normally.

If you require further information or other technical support, please contact your authorized

dealer.

Software Installation Instructions for Translation Mode

1. Insert your system diagnostic diskette (or equivalent) in drive A.

2. Turn on the system power.

3. Boot diagnostic and select Setup option.

CAUTION

Avoid system damage by consulting your Te c hnic al Re ference Manual to ensure that your

drive type is supported by your host BIOS ROM drive tables. Not all AT-compatibles share

the same drive tables as IBM.

4. Set up the system for the proper configuration of diskette and fixed drives (drive

type 3 for IBM), base memory size, expansion memory size, and display.

CAUTION

The following step requires execution of low level formatting. Formatting a dri ve destroys

any data on the drive. If your drive contains useful data, backup the dr iv e be fo re e xe cut io n

of the low level format. Use of Advanced Diagnostics (or similar program) is necessary

since the controllers contain no on-board BIOS ROM.

5. After performing Setup, execute a low level format using the Advanced Diagnostics

diskette. Follow the menu and reference manual instructions.

6. Load and execute the FDISK and FORMAT programs. Follow the menu and

reference manual instructions.

Page 13

If You Have a Problem. . .

Eliminate the obvious fault causing problems; i.e., reversed cables, improper drive selection or

termi nation, etc. This section lists some of the common problems and possible solutions

encountered when installing a drive controller.

PROBLEM: 1790 Disk 0 Error.

CAUSE: No lo w l e ve l format on hard disk. Wrong drive type selected. Not enough

drive power. Bad cables. Improper drive selection or termination.

PROBLEM: Drive does not partition.

CAUSE: Check drive types. Note that drive t ypes for the AT and AT-compatibles

differ.

PROBLEM: "Error Reading Fixed Disk" appears when booting from hard drive.

CAUSE: DOS partition not active.

PROBLEM: Winchester activity LED continuously lit.

CAUSE: No problem! Drive LED selected for latched mode.

PROBLEM: For systems with two drives, both Winchester activity LEDs light at the

same time.

CAUSE: Improper drive selection or termination. Inspect the drive cables. If the

data cables are straight, then set drive C's drive select switches for drive

select 1 and drive D's drive select switches for drive select 2. If the data

cables have a twist, set both drives' select switches for drive select 2.

Consult your drive manuals or dealer for drive switch settings. Finally,

under no circ umstanc e, use twiste d floppy ca bles for the W inche ster drive .

Floppy and Winchester drive interface connections differ significantly.

PROBLEM: Slow and inefficient operation.

CAUSE: The biggest culprit for this problem is an incorrect interleave factor.

Therefore, some experimentation with the interleave factor may be

necessary. (Refe r to the format instructions for setting interleave factor.)

Interleave factors are very dependent on the host operating system and

application.

Page 14

PROBLEM: Controller does not format a Seagate ST225 to 30 MB.

CAUSE: The ST225 is a 20 MB MFM drive. The ST238 is a 30 MB RLL drive . This

is a good time to point out the differences between RLL and Modified

Frequency Modulation (MFM) disk drives and controllers. First, RLL

equipment is able to record 50% more data on the drive. Second, RLL

drives must be physically formatted with 26 sectors because of the greater

data density. This leads to an important point:

DO NOT UNDER ANY CIRCUMSTANCES CONNECT A RLL

CONTROLLER TO AN MFM DRIVE!

RLL controllers physically format any attach drive into 26 sectors.

Therefore, the RLL controller squishes 26 sectors onto a drive designed for

17 sectors. Squishing the RLL data onto an MFM drive re sul ts i n c orrupte d

data, to say the least. Finally, the chip sets on RLL and MFM cont rollers

significantly differ as a result of the first and second points.

Loading...

Loading...