Page 1

User Guide

6641-2211

Viper

008

Westermo Teleindustri AB

©

Unmanaged 8-port

Ethernet Switch

www.westermo.com

Page 2

Legal information

The contents of this document are provided “as is”. Except as required by applicable

law, no warranties of any kind, either express or implied, including, but not limited to,

the implied warranties of merchantability and fitness for a particular purpose, are made

in relation to the accuracy and reliability or contents of this document. Westermo

reserves the right to revise this document or withdraw it at any time without prior

notice.

Under no circumstances shall Westermo be responsible for any loss of data or income

or any special, incidental, and consequential or indirect damages howsoever caused.

More information about Westermo can be found at the following Internet address:

http://www.westermo.com

2

6641-2211

Page 3

Safety

!

!

Before installation:

Read this manual completely and gather all information on the unit. Make sure that

you understand it fully. Check that your application does not exceed the safe operating specifications for this unit.

This unit should only be installed by qualified personnel.

This unit should be built-in to an apparatus cabinet, or similar, where access is

restricted to service personnel only.

The power supply wiring must be sufficiently fused (e.g. Littlefuse 0461 1.25), and

if necessary it must be possible to disconnect manually from the power supply. If

fault contact is used, make sure that fault contact wiring is sufficiently fused.

This unit uses convection cooling. To avoid obstructing the airflow around the unit,

follow the spacing recommendations (see Cooling section).

Before mounting, using or removing this unit:

Prevent access to hazardous voltage by disconnecting the unit from power supply.

Warning! Do not open connected unit. Hazardous voltage may occur within this

unit when connected to power supply.

Care recommendations

Follow the care recommendations below to maintain full operation of unit and to fulfil

the warranty obligations.

This unit must not be operating with removed covers or lids.

Do not attempt to disassemble the unit. There are no user serviceable parts inside.

Do not drop, knock or shake the unit, rough handling above the specification may cause

damage to internal circuit boards.

Do not use harsh chemicals, cleaning solvents or strong detergents to clean the unit.

Do not paint the unit. Paint can clog the unit and prevent proper operation.

Do not expose the unit to any kind of liquids (rain, beverages, etc). The unit is not water-

proof. Keep the unit within the specified humidity levels.

Do not use or store the unit in dusty, dirty areas, connectors as well as other mechanical

part may be damaged.

If the unit is not working properly, contact the place of purchase, nearest Westermo dis-

tributor office or Westermo Tech support.

Do not cover or bring mechanical force to the ventilation membrane on the back of the

unit.

Maintenance

No maintenance is required, as long as the unit is used as intended within the specified

conditions.

6641-2211

3

Page 4

4

6641-2211

Agency approvals and standards compliance

Type Approval / Compliance

EMC EN 61000-6-1, Immunity residential environments

EN 61000-6-2, Immunity industrial environments

EN 55024, Immunity IT equipment

EN55022, Emission IT equipment

EN 61000-6-3, Emission residential environments

EN 61000-6-4, Emission industrial environments

EN 50155 Railway applications - Electronic equipment used on rolling stock

EN 50121-3-2, Railway applications - EMC: Rolling stock – Apparatus

FCC part 15 Class B

EN 50121-4, Railway signalling and telecommunications apparatus

IEC 62236-4, Railway signalling and telecommunications apparatus

Safety EN 60950-1, IT equipment

FCC Part 15.105 Notice:

This equipment has been tested and found to comply with the limits for a

Class B digital device, pursuant to Part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful interference

in a residential installation. This equipment generates, uses and can radiate

radio frequency energy and, if not installed and used in accordance with

the instructions, may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful interference to radio

or television reception, which can be determined by turning the equipment

off and on, the user is encouraged to try to correct the interference by

one or more of the following measures:

… Reorient or relocate the receiving antenna

… Increase the separation between the equipment and receiver

… Connect the equipment into an outlet on a circuit different from that to

which the receiver is connected

… Consult the dealer or an experienced radio/TV technician for help.

Page 5

5

6641-2211

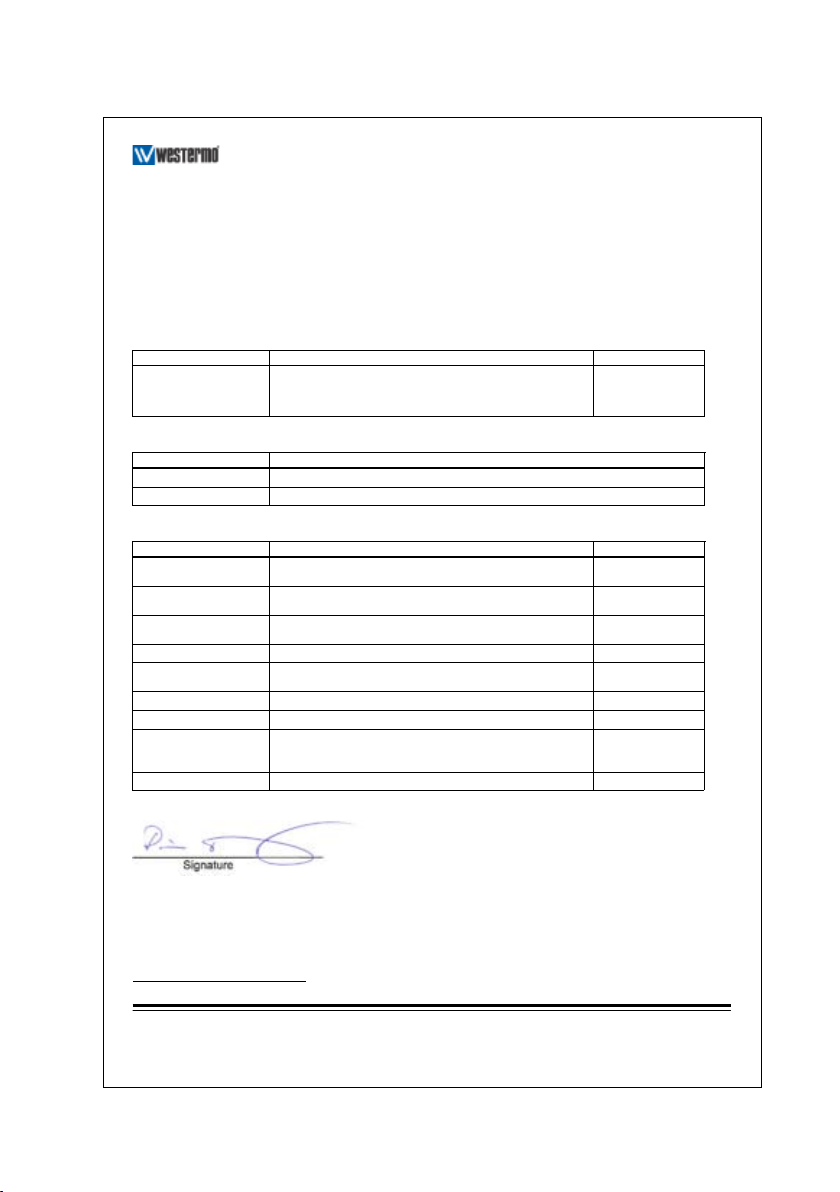

Declaration of Conformity

Westerm o Teleindustri AB

Declaration of conformity

Org.nr/

Postadress/Postal address

Tel.

Telefax

Postgiro

Bankgiro Corp. identity number Registered office

S-640 40 Stora Sundby 016-428000 016-428001 52 72 79-4 5671-5550 556361-2604 Eskilstuna

Sweden Int+46 16428000 Int+46 16428001

The manufacturer

Westermo Teleindustri AB

SE-640 40 Stora Sundby, Sweden

Type of product Model Art no

Ethernet switch Viper switch 3641-0360,

3641-0350,

3641-0340

is in conformity with the following EC directive(s).

No Short name

2004/108/EC Electromagnetic Compatibility (EMC)

2006/95/EC Low Voltage Directive - LVD

References of standards applied for this EC declaration of conformity.

No Title Issue

EN 55022 Information technology equipment – Radio disturbance

characteristics - Limits and methods of measurement

2006

+A1:2007

EN 55024 Information technology equipment - Immunity characteristics -

Limits and methods of measurement

1998

+A1:2001 +A2:2003

EN 61000-6-1 Immunity for residential, commercial and light-ind ustrial

environments

2007

EN 61000-6-2 Immunity for industrial environments 2005

EN 61000-6-3 Emission standard for residential, commercial and light-industrial

environments

2007

EN 61000-6-4 Emission standard for industrial environments 2007

EN 50121-3-2 Railway applications - Electromagnetic compatibility 2006

EN 50121-4 Railway applications - Electromagnetic compatibility - Part 4:

Emission and immunity of the signaling and telecommunications

apparatus

2006

EN 60950-1♣

Safety of information technology equipment 2006

The last two digits of the year in which the CE marking was affixed: 09

Pierre Öberg

Technical Manager

28th October 2009

♣

Note: Manual and safety instructions are only in English

Page 6

6

6641-2211

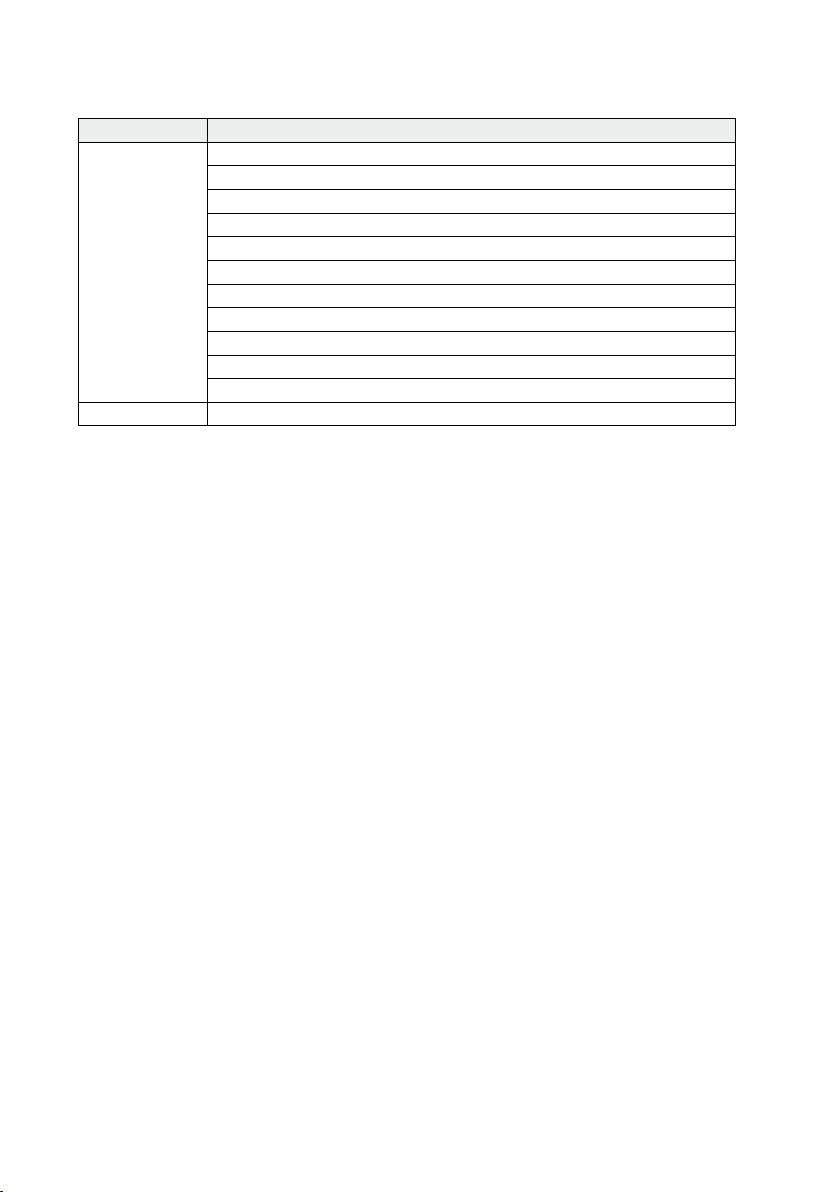

Type tests and environmental conditions

Phenomena Test Description Test levels

ESD EN 61000-4-2 Enclosure contact ± 6 kV (crit A)

RF field AM modulated IEC 61000-4-3 Enclosure 20 V/m 80% AM (1 kHz),

Fast transient EN 61000-4-4 Ethernet ports ± 2 kV (crit A)

Surge EN 61000-4-5 Fault port ± 2 kV line to earth (crit A)

RF conducted EN 61000-4-6 Ethernet ports 10 V 80% AM (1 kHz), 0.15 – 80 MHz

Power frequency magnetic

field

EN 61000-4-8 Enclosure 1000 A/m 50 Hz

Pulse magnetic field EN 61000-4-9 Enclosure 300 A/m (crit A)

Voltage dips and interruption EN 50155 DC power ports 10 ms, interruption (crit A)

Radiated emission EN 55022 Enclosure Class B

FCC part 15 Class B

Conducted emission EN 55022 DC power port &

FCC part 15 DC power port Class B

Dielectric strength EN 50155 Ethernet ports to other

Temperature Operating –40 to +70ºC

Humidity Operating 5 to 95% relative humidity

Altitude Operating 2000 m / 70 kPa

Reliability prediction (MTBF) MIL-C217F2 Operating Ground Benign:

Service life Operating 10 year

Vibration, random simulated

long life

Vibration, random functional IEC 60068-2-64,

IEC 60068-2-64,

Cat. 1 class B

(EN 61373)

Cat. 1 class B

(EN 61373)

Enclosure air ± 8 kV (crit A)

80 – 2500 MHz (crit A)

Power port ± 2 kV (crit A)

Earth port ± 2 kV (crit A)

Ethernet ports ± 2 kV line to earth (crit A)

Power port ± 2 kV line to earth, ± 2 kV line to line

(crit A)

(crit A)

Power port 10 V 80% AM (1 kHz), 0.15 – 80 MHz

(crit A)

300 A/m 16.7 Hz, 60 Hz, DC (crit A)

100 ms +- 40 % above/below

rated voltage (crit A)

Ethernet ports

isolated ports

Power & Fault port to

other isolated ports 2121 VDC 1 min

Class B

707 VDC 1 min

Storage & Transport –40 to +70ºC

Storage & Transport 5 to 95% relative humidity

150 years @ 20 ºC

147 years @ 40 ºC

135 years @ 60 ºC

Ground Mobile:

9,87 years @ 20 ºC

9,85 years @ 40 ºC

9,79 years @ 60 ºC

Ground Fix:

28,54 years @ 20 ºC

28,43 years @ 40 ºC

27,95 years @ 60 ºC

Not Operating

Operating

Vertical: 7.9 m/s

Transverse: 7.9 m/s

Longitudinal: 7.9 m/s

3 x 5 h

Vertical: 1.0 m/s

Transverse: 1.0 m/s

Longitudinal: 1.0 m/s

3 x 10 min

2

2

2

2

2

2

Page 7

7

6641-2211

Phenomena Test Description Test levels

Shock, half sine pulses IEC 60068-2-27,

Shock, sawtooth IEC 60068-2-27,

Cat. 1 class B

(EN 61373)

Cat. 1 class B

(IEEE1478-2001)

Operating

Operating

Vertical: 50 m/s

Transverse: 50 m/s

Longitudinal: 50 m/s

30 ms, 3 x 6 shocks

Vertical: 100 m/s

Transverse: 100 m/s

Longitudinal: 100 m/s

11 ms, 3 x 6 shocks

2

2

2

2

2

2

Enclosure UL 94 Nickel coated zinc Flammability class V-1

Dimension W x H x D 175 x 100 x 53,4 mm

Weight 1 kg

Degree of protection IEC 529 Enclosure IP 65 when all ports are protected/

connected else IP 40

Cooling Convection

Mounting DIN Rail or wall mounted

Page 8

8

6641-2211

Description

Functional description

Viper 008 is a unmanaged switch developed for rail and industrial applications. To meet

the environmental requirements from rail and harsh industrial applications the switch

has rugged M12 Ethernet connectors and full metal housing. The IP65 sealed metal case

make it robust and allows for the surrounding air temperature to be between –40 to

+70°C. There are no sensitive or fragile components, hardening the product against shock

and vibration making these units suitable for rolling stock usage. The power supply operates over a wide input range from 24 to 110 VDC.

Page 9

9

6641-2211

Interface specifications

Power and fault relay port PWR

Rated voltage 24 to 110 VDC

Operating voltage 24 to 110 VDC ±40%

Rated current 30 mA @ 110 VDC

90 mA @ 24 VDC

Rated frequency DC

2

Inrush current, I

Polarity Reverse polarity protected

Redundant power input No

Isolation to Connections X1 – X8 and to ground, 1500 VAC.

Connection 4 pin male M12 connector with A-code

Connector size M12, recommended cable area 0.5 mm

Shielded cable Not required, twisted pair is recommended

Fault relay resistance < 10 Ω

Operating voltage Up to 110 VDC

t Max 0.02 A2s @ 24 – 110 VDC

Fault relay belongs to the same isolation group as the power

supply lines (fault relay signals are also contained within

PWR).

2

(minimum 0.25 mm

), cable dimensions depend on choice of

M12 connector

Position Direction Description

1 U+ Positive supply voltage

2

recommended

M12 A-Coded

Power

Connector

2 Out Alarm relay (status) +

3 0 V Negative supply voltage

4 Out Alarm relay (status) –

Housing Shield Chassis of product (ground)

Page 10

10

6641-2211

Fault Contact

The Viper switch is equipped with a potential free normally closed fault contact.

The fault contact is a solid state component (relay) that requires power to work and it

is transient protected. Additionally, the fault contact is opened when any of the following

conditions is met:

No voltage on the power supply pin, a voltage level outside the legal voltage range •

or current limitation on the voltage source is applied on the power input.

Description of how connection to the fault contact could be done is shown below.

The relay is closed when the unit is OK and open at failure. The relay is of semiconductor type (no moving parts). It is specified for max current 250 mA continuous,

500 mA peak (10 ms), operational voltage up to 110 V, protected by a 150 VDC-varistor,

ON-resistance less than 10 Ohm, and leakage current max 1 µA.

External relay

Viper

+24/48 VDC

2 2

4 4

0V

To logic input

Viper

+

1 kΩ

Input on PLC

Service port

The Service Port should not be used by non other than the Westermo Technical Support

team. Do not connect any device or cable to the Service Port.

Page 11

11

6641-2211

Ethernet TX port X1 to X8

Electrical specification IEEE std 802.3. 2005 Edition

Data rate 10 Mbit/s or 100 Mbit/s

Duplex Full or half

Circuit type TNV-1

Transmission range 100 m

Isolation to Other Ethernet ports, 500 VAC

Galvanic connection to None, except for shielded contact to housing

Connection 4-pole M12 female with D-code

Shielded cable Not required, twisted pair is recommended

Conductive housing Nickel plated zinc, metal housings of X1-X8 also connected

Number of ports 8 Ethernet (X1-X8)

PWR, 1500 VAC

to the housing

Position Direction Description

1 Out Transmit Data +

2 In Receive Data +

3 Out Transmit Data –

4 In Receive Data –

Housing Shield Chassis of product (ground)

Page 12

12

6641-2211

Location of Interface ports, LED's

X1

X2

X6

X3

X7

PWR

SERVICE

X4

X8

X5

LED indicators

LED Status Description

PWR GREEN Unit indicates no fault

RED Unit indicated fault

X1 to X8 OFF No Link

GREEN Link is up

GREEN

FLASH

Data is transmitted

Page 13

13

6641-2211

Mounting, DIN-rail

This unit can be mounted on 35 mm DIN-rail, which is horizontally mounted inside an

apparatus cabinet or similar. Snap on mounting, see figure.

Removal

Press down the support at the back of the unit using a screwdriver. See figure.

Page 14

14

6641-2211

Wall mounting

X1

X2

X6

X3

X7

PWR

SERVICE

X4

X8

X5

There are four 6 mm bore holes intended for mounting the unit. The unit can be mounted vertical or horizontal. Use four M6 screws with 12 mm washer on a flat and stable

surface.

Removal

Disconnect all cables and unscrew the unit from the wall.

Cooling

This unit uses convection cooling. Avoid obstructing the airflow around the unit. Spacing

is recommended for the use of unit in full operating temperature range and service life.

Page 15

15

6641-2211

Dimensions

Measurements are stated in millimeters.

Page 16

Westermo Teleindustri AB • SE-640 40 Stora Sundby, Sweden

Phone +46 16 42 80 00 Fax +46 16 42 80 01

E-mail: info@westermo.se

Westermo Web site: www.westermo.com

Subsidiaries

Westermo Data Communications AB

Svalgången 1

SE-724 81 Västerås

Phone: +46 (0)21 548 08 00 • Fax: +46 (0)21 35 18 50

info.sverige@westermo.se

Westermo Data Communications Ltd

Talisman Business Centre • Duncan Road

Park Gate, Southampton • SO31 7GA

Phone: +44(0)1489 580-585 • Fax.:+44(0)1489 580586

E-Mail: sales@westermo.co.uk

Westermo Data Communications GmbH

Goethestraße 67, 68753 Waghäusel

Tel.: +49(0)7254-95400-0 • Fax.:+49(0)7254-95400-9

E-Mail: info@westermo.de

Westermo Data Communications S.A.R.L.

9 Chemin de Chilly 91160 CHAMPLAN

Tél : +33 1 69 10 21 00 • Fax : +33 1 69 10 21 01

E-mail : infos@westermo.fr

Westermo Data Communications Pte Ltd

2 Soon Wing Road #08-05

Soon Wing Industrial Building

Singapore 347893

Phone +65 6743 9801 • Fax +65 6745 0670

sales@westermo.com.sg

Westermo Teleindustri AB have distributors in several countries, contact us for further information.

REV.A 6641-2211 2009.10 Westermo Teleindustri AB, Sweden

Loading...

Loading...