Page 1

U/R/T200 series Operator Manual

V4.5

www.westermo.com

U/R/T200 series

- 1 -

Page 2

V4.5

1

INTRODUCTION..................................................................................................................... - 4 -

1.1 T200......................................................................................................................................- 4 -

1.2 R200 .....................................................................................................................................- 4 -

1.3 U200.....................................................................................................................................- 4 -

2 ABOUT WESTERMO ONTIME ............................................................................................ - 5 -

2.1 COMPANY HISTORY ..............................................................................................................- 5 -

2.2 MISSION STATEMENT............................................................................................................- 5 -

2.3 CORE TECHNOLOGY ..............................................................................................................- 5 -

3 ETHERNET – INDUSTRIAL ETHERNET........................................................................... - 6 -

3.1 HISTORY OF ETHERNET.........................................................................................................- 6 -

3.2 INDUSTRIAL ETHERNET – WHAT ARE THE DIFFERENCES?....................................................- 6 -

3.3 SWITCHES VS. HUBS..............................................................................................................- 7 -

4 SWITCH OPERATION............................................................................................................- 9 -

4.1 INTRODUCTION......................................................................................................................- 9 -

4.2 ERROR DETECTION................................................................................................................- 9 -

4.3 FLOODING .............................................................................................................................- 9 -

4.4 MAC TABLE AND PACKET MEMORY ....................................................................................- 9 -

4.5 FULL WIRE SPEED...............................................................................................................- 10 -

4.6 TWISTED PAIR PORT SPECIFICATION ...................................................................................- 10 -

4.6.1 Introduction............................................................................................................... - 10 -

4.6.2 MDI/MDI-X............................................................................................................... - 10 -

4.6.3 Straight Connection –Switch-PLC, Hub-PLC, Switch-NIC etc................................. - 10 -

4.6.4 Crossed Connection – Switch-Switch, Hub-Hub, Switch-Hub...................................- 10 -

4.6.5 Auto MDI/MDI-X....................................................................................................... - 11 -

4.6.6 Electrical Isolation.................................................................................................... - 11 -

4.6.7 Auto-Negotiation ....................................................................................................... - 11 -

4.7 FIBRE OPTIC PORT SPECIFICATION......................................................................................- 11 -

4.7.1 Fibre Optic Communications..................................................................................... - 11 -

4.7.2 Fibre Optic Parameters............................................................................................. - 12 -

5 POWER SUPPLY CONNECTOR......................................................................................... - 13 -

5.1 REDUNDANT POWER INPUTS................................................................................................- 13 -

5.2 FAULT CONTACT.................................................................................................................- 13 -

5.3 POWER SUPPLY & FAULT CONTACT CONNECTION DIAGRAM .............................................- 14 -

6 DETERMINISTIC ETHERNET - QOS................................................................................- 17 -

6.1 PRINCIPLES OF DETERMINISTIC ETHERNET .........................................................................- 17 -

6.2 LAYER 2 PRIORITY...............................................................................................................- 17 -

6.3 LAYER 3 PRIORITY...............................................................................................................- 18 -

6.4 FLOW CONTROL...................................................................................................................- 18 -

6.5 HEAD OF LINE BLOCKING PREVENTION ..............................................................................- 18 -

7 FAST RE-CONFIGURATION OF NETWORK TOPOLOGY (FRNT)........................... - 19 -

7.1 INTRODUCTION....................................................................................................................- 19 -

7.2 FRNT VERSION 0 ................................................................................................................- 19 -

7.2.1 FRNT version 0 principles......................................................................................... - 19 -

7.2.2 FRNT version 0, configuration rules......................................................................... - 20 -

7.3 FRNT VERSION 1 ................................................................................................................- 20 -

7.3.1 FRNT version 1 principles......................................................................................... - 20 -

7.3.2 FRNT version 1, configuration rules......................................................................... - 21 -

www.westermo.com

U/R/T200 series

- 2 -

Page 3

8

RAPID SPANNING TREE PROTOCOL (RSTP)............................................................... - 22 -

V4.5

9 SIMPLE NETWORK MANAGEMENT PROTOCOL (SNMP)........................................ - 25 -

9.1 WESTERMO ONTIME PRIVATE MIB INFORMATION .............................................................- 26 -

9.2 SNMP TRAPS......................................................................................................................- 27 -

10 IGMP SNOOPING.............................................................................................................. - 28 -

10.1 IP MULTICAST FILTERING....................................................................................................- 28 -

10.2 ROUTERLESS OPERATION.....................................................................................................- 28 -

10.3 STOP FILTER OPTION............................................................................................................- 29 -

10.4 FAST MC FILTER SETUP.......................................................................................................- 29 -

10.5 FRNT INTEGRATION............................................................................................................- 29 -

11 VLAN.................................................................................................................................... - 30 -

11.1 STANDARD VS. ADDITIONAL VLANS..................................................................................- 31 -

11.2 VLAN EXAMPLE .................................................................................................................- 32 -

12 TIME SYNCHRONIZATION ........................................................................................... - 33 -

12.1 IEEE 1588 GRANDMASTER .................................................................................................- 35 -

12.2 IEEE1588 TRANSPARENT CLOCK .......................................................................................- 35 -

12.3 IEEE1588 TRANSPARENT CLOCK VERSION 1 AND 2............................................................- 37 -

12.4 SNTP/NTP TIME SERVER ....................................................................................................- 38 -

12.5 SNTP/NTP TIME CLIENT OR PTP SLAVE AND GPS EMULATION .........................................- 38 -

12.6 IRIG-B................................................................................................................................- 41 -

12.7 PULSE PER X SECONDS ON GPS INTERFACE ........................................................................- 42 -

12.8 X KHZ OUTPUT SIGNAL ON GPS INTERFACE .......................................................................- 42 -

12.9 EXTERNAL GPS...................................................................................................................- 42 -

12.10 TIME SYNCHRONIZATION REDUNDANCY.........................................................................- 43 -

13 SWITCH TECHNICAL SPECIFICATION..................................................................... - 46 -

13.1 INTERFACE SPECIFICATIONS................................................................................................- 46 -

13.2 FIBRE SPECIFICATIONS ........................................................................................................- 46 -

13.3 POWER SPECIFICATION........................................................................................................- 46 -

13.4 ENVIRONMENTAL SPECIFICATION .......................................................................................- 47 -

13.4.1 Climatic ..................................................................................................................... - 47 -

13.4.2 Mechanical ................................................................................................................ - 47 -

13.4.3 Electromagnetic Compatibility (EMC)...................................................................... - 47 -

13.4.4 Radiated Immunity..................................................................................................... - 47 -

13.4.5 Conducted Immunity.................................................................................................. - 47 -

13.4.6 Safety ......................................................................................................................... - 48 -

www.westermo.com

U/R/T200 series

- 3 -

Page 4

V4.5

1 Introduction

This Operator Manual describes the properties of the T200, R200 and U200 series.

1.1 T200

The T200 is the time synchronization switch series of Westermo. The T200 series has also

full management support including QoS, network redundancy either based on FRNT or

RSTP/STP, SNMP, IGMP snooping, VLAN and MAC security. The switches are approved for

industrial use.

All chapters in this document are relevant for the T200 series.

1.2 R200

The R200 series contains the same features as the R200 series except for time

synchronization.

All chapters in this document except chapter 12 are relevant for the R200 series.

1.3 U200

The U200 series is an unmanaged switch implementation with QoS support (layer 2 and 3).

The U200 switch series has the same approvals for industrial use as the R200 and T200

series.

All chapters in this document except chapters 7-12 are relevant for the U200 series.

www.westermo.com

U/R/T200 series

- 4 -

Page 5

V4.5

2 About Westermo OnTime

2.1 Company History

Westermo OnTime is dedicated to the implementation of industrial and deterministic Ethernet

infrastructure. Westermo OnTime is a privately held company based in Norway. We work

closely with a number of large automation companies; enhancing older proprietary networks

and working in partnership developing new network technology.

2.2 Mission Statement

Westermo OnTime's mission is to provide an extension of Ethernet to the factory floor,

outdoor installation and real time application by offering high end Ethernet products that

fulfilling industrial and real time requirements.

2.3 Core Technology

Westermo OnTime's Ethernet switches are based on a robust and reliable industrial design

for maximum life cycle and minimum life time costs. Real time properties are implemented in

order to achieve determinism for real time critical applications.

www.westermo.com

U/R/T200 series

- 5 -

Page 6

V4.5

3 Ethernet – Industrial Ethernet

3.1 History of Ethernet

In late 1972, Metcalfe and his Xerox PARC colleagues developed the first experimental

Ethernet system to interconnect the Xerox Alto, a personal workstation with a graphical user

interface. The experimental Ethernet network was used to link Altos to each other, and to

servers and laser printers.

The signal clock for the experimental Ethernet interface was derived from the Alto's system

clock, which resulted in a data transmission rate on the experimental Ethernet of 2.94 Mbps.

Robert Metcalfe's first experimental network was called the Alto Aloha Network.

In 1973, Robert Metcalfe changed the name to "Ethernet," to make it clear that the system

could support any type of computer; not just the Xerox Altos and to point out that his new

network mechanisms had evolved well beyond the Aloha system. He chose to base the name

on the word "ether" as a way of describing an essential feature of the system: the physical

medium (i.e., a cable) carries bits to all stations, much the same way that the old "luminiferous

ether" was once thought to propagate electromagnetic waves through space. Thus, Ethernet

was born.”

``The diagram ... was drawn by Dr. Robert M. Metcalfe in 1976 to present Ethernet ... to the

National Computer Conference in June of that year. On the drawing are the original terms for

describing Ethernet. Since then other terms have come into usage among Ethernet

enthusiasts.''

Figure 1

3.2 Industrial Ethernet – What Are The Differences?

Ethernet is moving into the Automation Industry. Manufacturers are exporting their legacy

protocols onto Ethernet, designing new IP based communication protocols and providing

embedded Web-Pages within PLCs to provide real-time information using simple tools like

Internet Explorer and Netscape.

www.westermo.com

U/R/T200 series

- 6 -

Page 7

However, the domain of Ethernet has always been controlled by the IT department who

configured office networks normally with an iron fist and dictated to the company how the

network would be designed with complex recovery protocols like spanning tree and SNMP to

help with fault finding and system analysis. If a network failure occurred the IT department

would casually look at repairing the equipment - there was no real rush as it was an office

network. However, with Industrial Ethernet you need very fast repair time, and, with an IT

department not present on the factory floor the maintenance personnel need to be made

aware of the fault, find the error and repair it - quickly.

Industrial rated Switches are intended to be installed in harsh conditions and electrical

environments with the added benefit of fast recovery of a network failure. The switches are

an excellent example of how such Switches should be designed – very high operating

temperatures, fast repair of redundant ring, layer 2 and layer 3 priority switching, time

synchronization capability, etc. Without doubt, Westermo OnTime switches are technically

superior to many similar models available on the market.

V4.5

3.3 Switches vs. Hubs

A hub consists of a number of ports normally with either RJ-45 (copper) sockets and / or fibre

optic ports that have a number of different styles of fibre optic sockets. Usually a ‘patch cable’

is connected to the hub; the other end is normally connected to a device (PC, Printer etc).

A hub has no intelligence and therefore is unable to identify addresses or any information

contained within the Header frame of an Ethernet packet. This means that it is not capable of

determining which port to send the frame to. Therefore, every frame is sent to every port.

A network of repeaters and hubs is called a ‘Shared Ethernet’ or ‘Collision Domain’. Various

systems will all compete with each other using ‘Carrier Sense Multiple Access / Collision

Detect’ (CSMA/CD) protocol. This means that only one system is allowed to proceed with

a transmission of a frame within a Collision Domain at any one time. This is a major

disadvantage when using Hubs and Repeaters within a network.

If a hub sees a collision on a cable segment, it is detected and a ‘jam’ signal is generated.

The ‘jam’ signal is sent to all connected devices. This ensures that every device is aware of

the collision and they do not attempt to transmit during the collision.

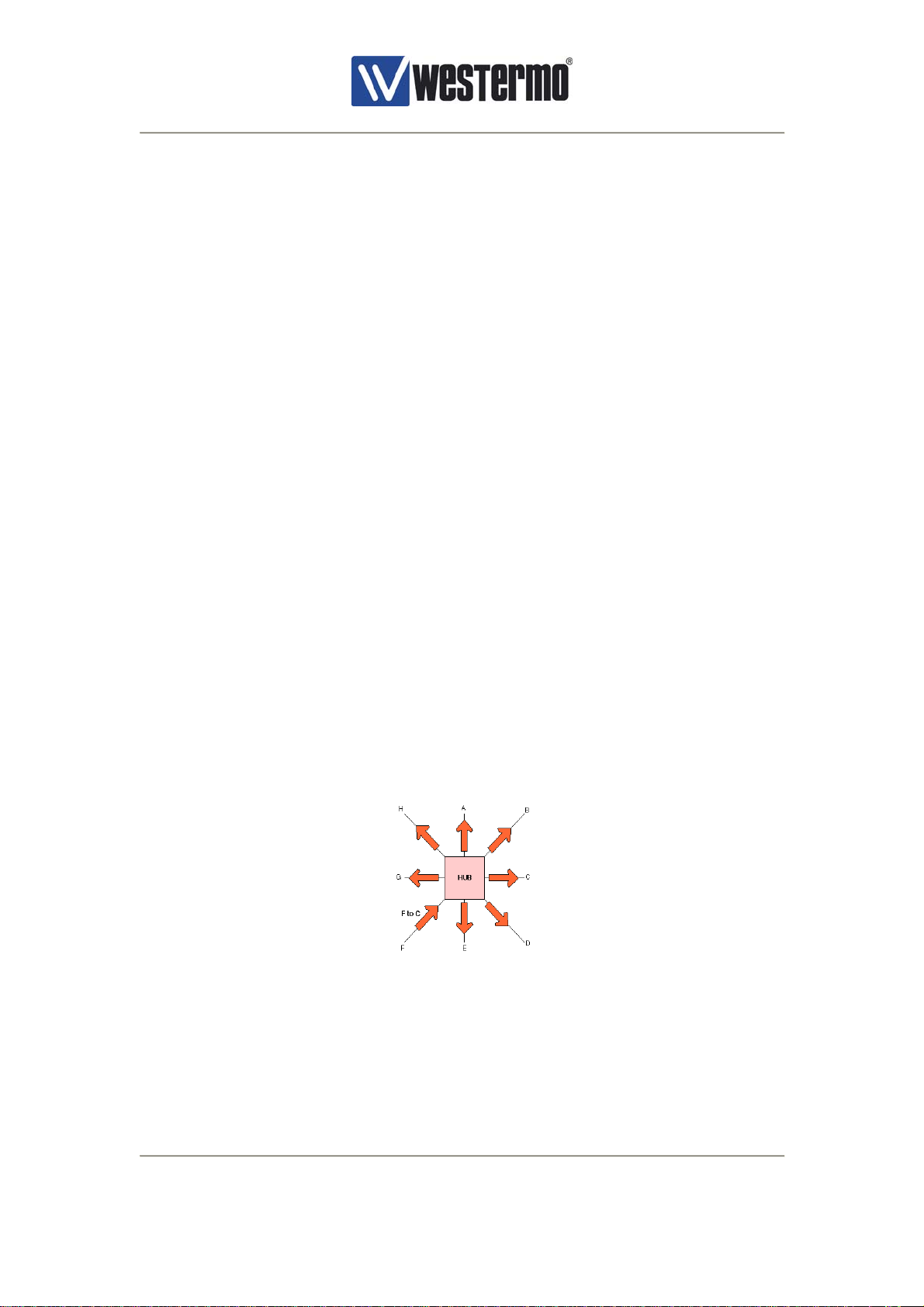

All Ports Receive the Same Ethernet Frame

Figure 2, hub

To summarise, hubs operate with the following limitations:

• Only a single speed of operation – no ability to automatically change between 10M or

100M.

www.westermo.com

U/R/T200 series

- 7 -

Page 8

V4.5

• Only one system is allowed to proceed with a transmission of a frame within a

Collision Domain at any one time.

• Hubs require special ‘crossed’ cables to enables links from Hub to Hub (If no up-link

port with twisted wiring is present).

www.westermo.com

U/R/T200 series

- 8 -

Page 9

V4.5

4 Switch Operation

4.1 Introduction

A switch has to forward and receive packets from one LAN or device to another. The switch

could forward all packets, but if this was the case it would have similar behavior to a hub.

It would be more intelligent if the switch only forwarded packets which need to travel from one

LAN or device to another. To do this, the switch must learn which devices or LANs are

connected to each port. In simplistic terms; it needs to learn the destination and source ports

of each and every packet received on each individual Switch port. Once learnt, any identically

addressed packet will be automatically be forwarded.

4.2 Error Detection

The switch stores every incoming packet and scans this for errors, usually by checking the

frame CRC (cyclic redundancy check sum). If any errors are found or detected the packet is

discarded. In addition each frame is checked for size. Undersized packets (less than 64

Bytes) and oversized packets (more than 1518 bytes (*)) are also discarded.

Once these basic checks have been carried out the switch can then start learning packet

source and destination information.

(*) When implementing Ethernet MAC tagging maximum Ethernet packet length is increased

to 1522 bytes.

4.3 Flooding

The switch needs to make a decision regarding which port(s) the packet is to be forwarded to.

This decision is based upon the MAC tables that are maintained and updated automatically

by the Switch. The process is known as Layer 2 Switching.

When first powered on the MAC tables within the Switch are empty. When a packet is

received on a port the Switch does not know where the destination MAC address is located.

The Switch learns the address by ‘flooding’ the packet out to all ports. Eventually, the

destination node responds, the address is located and the Switch remembers the destination

port. In simplistic terms; when a Switch receives a packet on a port it stores the source MAC

address in the MAC table that corresponds to that Port. The flooding technique is always

used with Broadcast and Multicast packets. If the switch is equipped with multicast

management then multicast packets will not be flooded.

4.4 MAC Table and Packet Memory

.

The MAC table can hold up to 8 K entries with a MAC aging interval of five minutes. MAC

aging means that a MAC address learned on a given port will be removed from the MAC table

if no packets with this MAC address as the source MAC address are received on the port for

five minutes.

The total packet memory is 1Mbyte. This means that 657 (maximum packet length - 1522

bytes) to 15625 (minimum packet length - 64 bytes) packets. The packet memory is used to

handle short high load/overload situations. Exceeding the packet memory means that the

www.westermo.com

U/R/T200 series

- 9 -

Page 10

switch engine will drop packets. Packet re-transmission is then required and must be handled

by the end nodes (e.g. TCP).

A MAC table of 8 K entries and a packet memory of 1Mbyte is adequate for large networks.

V4.5

4.5 Full Wire Speed

The Switch supports full wire speed. This equates to 100Mbit/s full duplex on every port.

100Mbit/s in each direction on all ports equals 200Mbit/s per port.

4.6 Twisted Pair Port Specification

4.6.1 Introduction

The T/R/U200 series is available with up to eight copper ports. The copper ports support the

long cable specification that enables standard CAT5e copper cables to run up to 150 Meters

when used with devices that also support this specification. This highlights the enhanced

design specification the switch employs when used in noisy electrical environments. In

industrial networks long cables should be avoided but equipment specified according to long

cable specification gives more margins for disturbances.

Port configuration is available via the IP configuration tool or the push buttons on the front

panel of the Switch. See the Installation Guide for details.

4.6.2 MDI/MDI-X

There are two types of copper Ethernet ports available; MDI (Medium Dependant Interface)

and MDIX (Medium Dependant Interface Crossover). The MDI port types are associated with

copper interfaces available on NICs (Network Interface Cards), PLCs, VSDs and DCSs etc.

The latter type of interface (MDI-X) is found on Hubs or Switches.

In addition there are two types of Ethernet cable available. These are referred to as a ‘straight

through cable’ or ‘crossed cable’.

4.6.3 Straight Connection –Switch-PLC, Hub-PLC, Switch-NIC etc.

Connector A Connector B

Pair 1 pin 4 <-------> Pin 4

pin 5 <-------> Pin 5

Pair 2 RD + pin 3 <-------> Pin 3 RD +

RD - pin 6 <-------> Pin 6 RD -

Pair 3 TD + pin 1 <-------> Pin 1 TD +

TD - pin 2 <-------> Pin 2 TD -

Pair 4 pin 7 <-------> Pin 7

pin 8 <-------> Pin 8

4.6.4 Crossed Connection – Switch-Switch, Hub-Hub, Switch-Hub

Connector A Connector B

Pair 1 pin 4 <-------> Pin 7

pin 5 <-------> Pin 8

www.westermo.com

U/R/T200 series

- 10 -

Page 11

Pair 2 RD + pin 3 <-------> Pin 1 TD +

RD - pin 6 <-------> Pin 2 TD -

Pair 3 TD + pin 1 <-------> Pin 3 RD +

TD - pin 2 <-------> Pin 6 RD -

Pair 4 pin 7 <-------> Pin 4

pin 8 <-------> Pin 5

V4.5

4.6.5 Auto MDI/MDI-X

The complete range of Westermo OnTime switches automatically detects the transmit and

receive copper pairs used in a patch cable. This eliminates the need to source the two types

of patch cable (crossed and straight through) highlighted above and therefore reduces the

cost of carrying two types of spares.

4.6.6 Electrical Isolation

The copper (TX) ports incorporate high electrical isolation between the signal lines and the

internal electronics. In addition, the switch can also withstand over 500 Amps through the

shield for short periods of time (20-30mS) without effecting the operation and communication

of the Switch. However, this is not advisable. Fibre optical cables should be used in such

environments. Each TX port is isolated to chassis and other ports. Isolation is rated 1500Vrms

(1 minute).

4.6.7 Auto-Negotiation

Auto-Negotiation is a protocol that controls the speed and duplex of a copper cable when a

connection is established between two Ethernet devices. Auto-Negotiation detects the various

modes that exist in the device on the other end of the cable and highlights its own abilities to

automatically configure itself. Therefore, it will automatically operate at the highest

performance in relation to speed and duplex. This allows simple and automatic connection of

devices that support a variety of modes from a variety of manufacturers. The auto-negotiation

protocol only functions on copper ports.

As standard the range of Westermo OnTime switches are shipped with the Auto-Negotiation

feature enabled.

4.7 Fibre Optic Port Specification

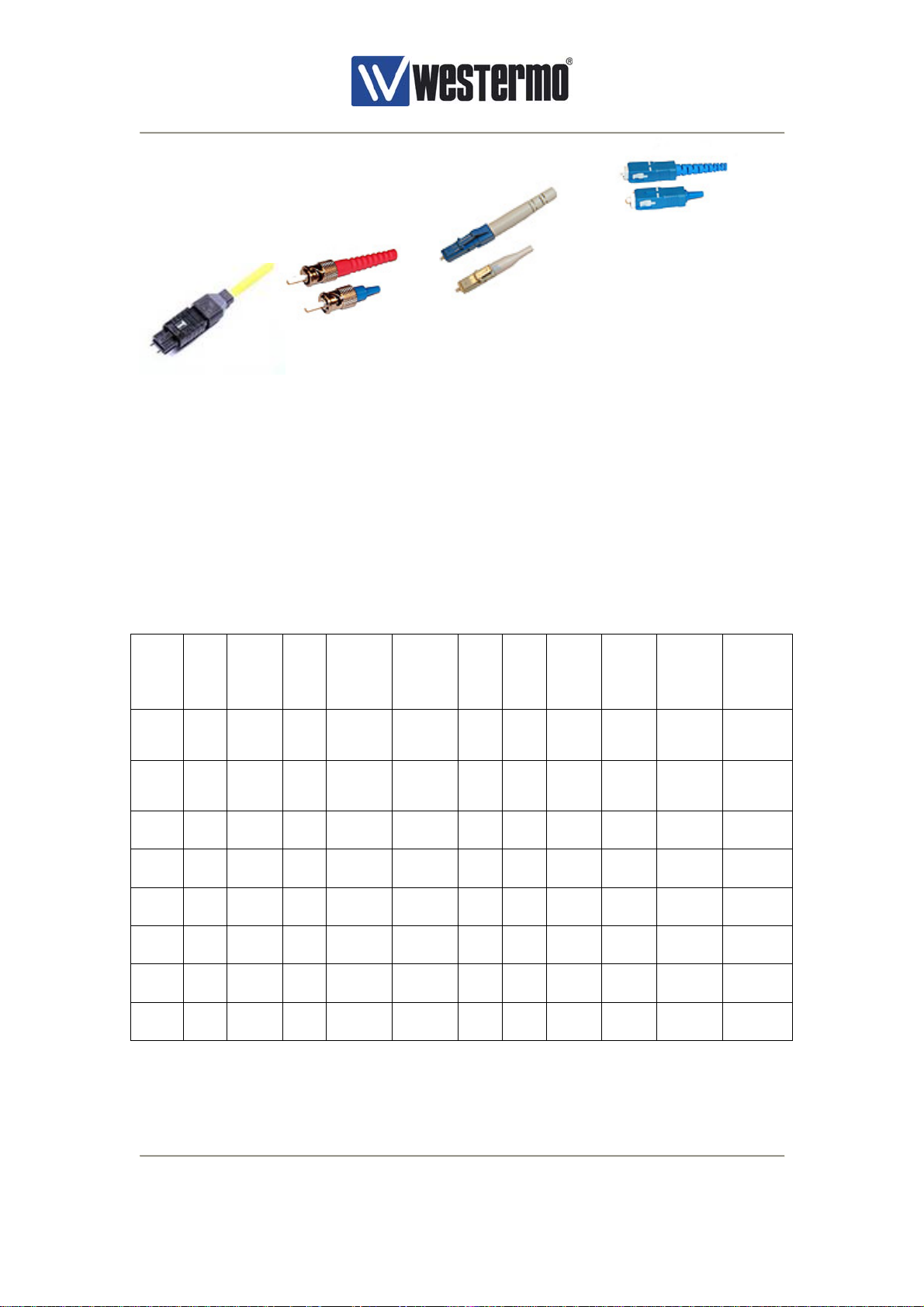

4.7.1 Fibre Optic Communications

The fibre optic (FX) ports are available with either multi-mode or single mode fibre

transceivers. Multi-mode transceivers are available with MTRJ, SC or ST style connectors.

Single mode transceivers are only available with LC or SC style connectors.

Available fibre connector types are shown below:

www.westermo.com

U/R/T200 series

- 11 -

Page 12

V4.5

SC: SM

LC: SM-small form factor

ST: MM

MTRJ: MM-small form factor

Figure 3, FX connector types

4.7.2 Fibre Optic Parameters

Parameters that have relevance for fibre power budget calculations for relevant fibre

transceivers are given below:

Link

type

Multi

mode

Multi

mode

Single

mode

Single

mode

Single

mode

Multi

mode

Multi

mode

Single

mode

Note: Fibre Ports are always configured for 100 Mbit/s and full duplex.

Link

distance

[km]

Con-

nector

2 MTRJ Yes -19dBm

2 MTRJ Yes -22,5dBm

15 LC Yes -15dBm

40 LC No -5dBm

85 LC No -5dBm

2 SC Yes -20dBm

2 ST Yes -20dBm

15 MTRJ Yes -20dBm

Zero

cable

len.

Output

power min.

(62,5/

125µm

MMF)

(50/

125µm

MMF)

(9µm

SMF)

(9µm

SMF)

(9µm

SMF)

(62,5/125

µm MMF)

(62,5/125

µm MMF)

(9µm

SMF)

Output

power

typical

-15,7dBm

(62,5/

125µm

MMF)

-20,3dBm

(50/

125µm

MMF)

-8dBm

(9µm

SMF)

-0dBm

(9µm

SMF)

-0dBm

(9µm

SMF)

TBD -31 -35,2 -14

TBD -31 -35,2 -14

TBD -31 TBD -8

Rec-

Rec-

eiver

sensi-

[dBm]

eiver

sensi-

tivity

tivity

min.

max.

[dBm]

-31 -34,5 -14

-31 -34,5 -14

-31 -38 -8

-34 -38 -8

-34 TBD -10

Receiver

satura-

tion

power

[dBm]

(min)

(min)

(min)

(min)

(min)

(min)

(min)

(min)

Link

budget

[dBm]

Center

Wave-

min.

length

[nm]

11 1270-

7,5 1270-

16 1261-

29 1280-

29 1480-

11 1270-

11 1270-

11 1261-

1380

1380

1360

1335

1580

1380

1380

1360

Aging

during

lifetime

1dBm

included in

budget

1dBm

included in

budget

included in

budget

included in

budget

included in

budget

1dBm

included in

budget

1dBm

included in

budget

included in

budget

www.westermo.com

U/R/T200 series

- 12 -

Page 13

V4.5

5 Power Supply Connector

5.1 Redundant power inputs

The switch is designed to operate permanently over a very wide range of power (19 V DC to

60 VDC). Two redundant inputs are provided to provide enhanced redundancy if either supply

fails.

The power supply draws power from the input that has the highest potential difference when

compared to the alternate supply.

This enables use of e.g. a 48V source as primary supply with a 24VDC battery as back up.

Power supply inputs have reverse polarity protection.

Large transient protection devices are present on both power inputs. During transients,

transient currents of up to more than thousand Ampere may pass thru cabling infrastructure.

The switch is delivered with a power connector (Wieland 25.621.3553.0) that is suitable for

wires between AWG 20 and AWG 22 (0,34-0,5 mm

2

).

Figure 4, Power contact

5.2 Fault Contact

The switch is incorporated with a user configurable fault contact (STAT pin) that enables

network and switch faults to be highlighted, see the Installation Guide.

The user configurable fault contact is a solid state component and therefore requires power to

control the device. The fault relay is equipped with transient protection.

As standard the fault contact will always highlight the following:

• Internal switch watchdog failure.

• Link / Port 7 Failure (if FRNT 0 is activated)

• Link / Port 8 Failure (if FRNT 0 is activated)

• Power Supply Failure

• Focal Point / Redundancy Mode activated.

Using the Switch configuration software (relevant for switches in the R200 and T200 series),

the fault contact can highlight the following addition failures:

• Link / Port 1 to Port 8 Failure; relevant for the R/T200 series.

• A minute pulse that is used for time synchronization can be enabled for switches in

the T200 series. This is a special function that disables all other fault indication.

www.westermo.com

U/R/T200 series

- 13 -

Page 14

V4.5

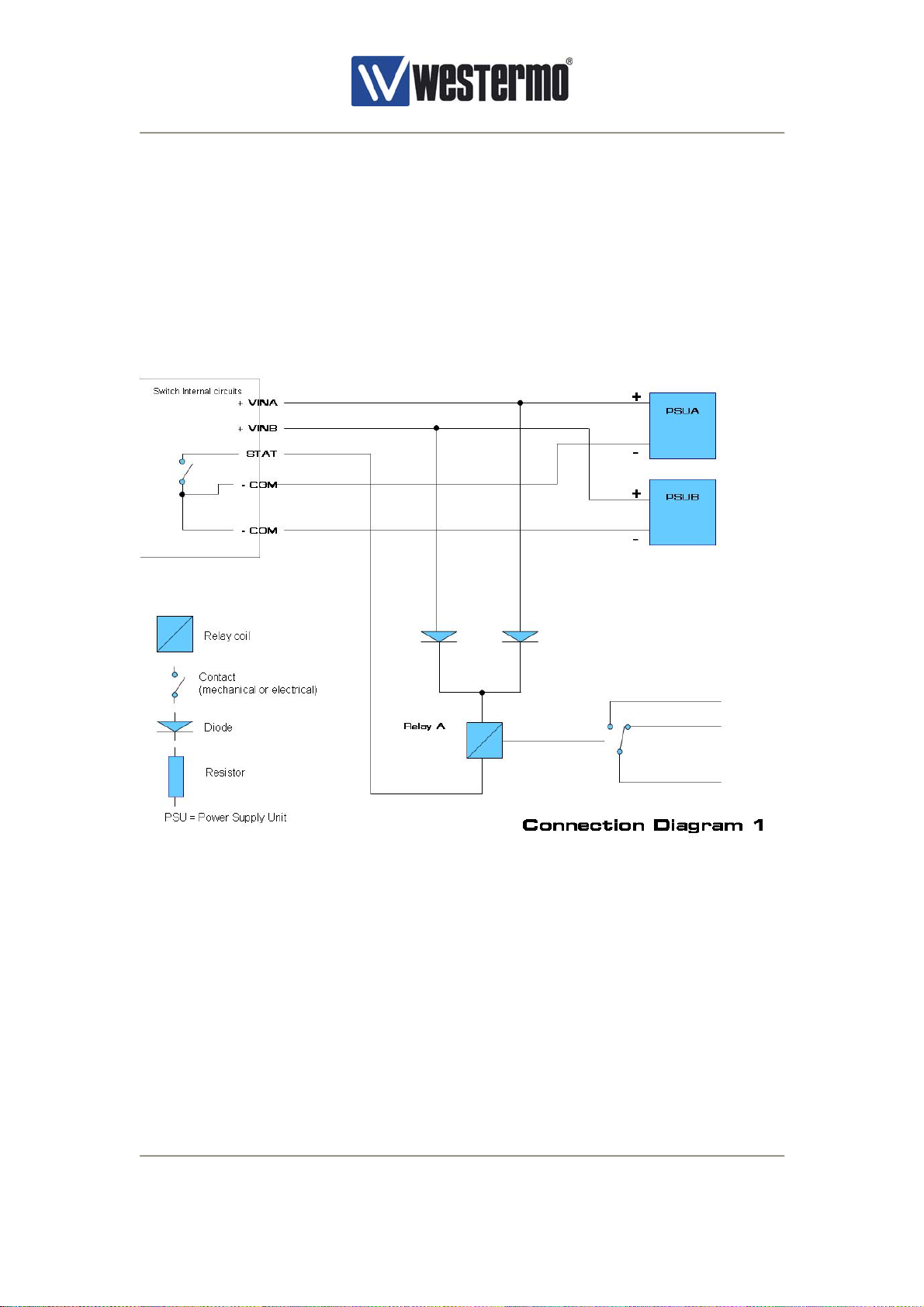

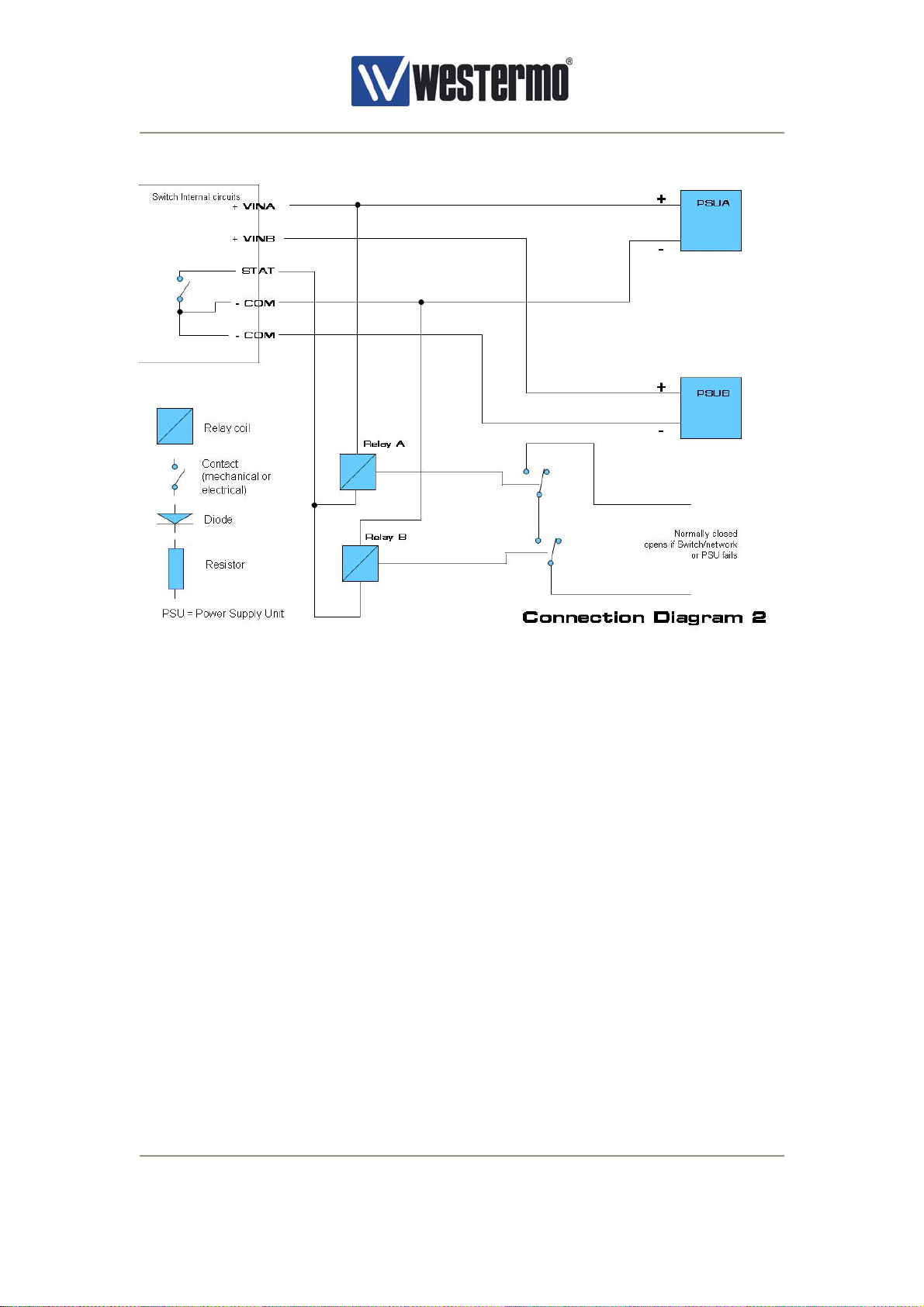

5.3 Power Supply & Fault Contact Connection Diagram

Power supply connection terminals +VinA and +VinB are not interconnected internally within

the Switch. -COM terminals on the other hand are internally connected to each other. –COM,

+Vin and STAT terminals have an isolation barrier to internal logic and chassis ground that

withstand 1500Vrms.

In some cases polarity needs to be reversed or current increased on the fault contact, in such

cases an external relay may be used. Dual relays may be used if monitoring of individual

power supplies is required. Two example circuit diagrams are presented as a guideline, see

Figure 5 and Figure 6.

Figure 5, Power and fault contact – connection diagram 1

The diodes can be omitted if only one power supply is used. The diode can be any general

purpose diode capable of carrying the current through the relay winding. The function of the

circuit is that the current through the relay winding goes from the positive terminal of the

power supply via diodes and into the STAT connection. The STAT pin is normally connected

to the –COM terminal during normal operation resulting in a magnetised relay in normal

mode. The STAT pin will float when an error occurs and the relay will be de-energised.

www.westermo.com

U/R/T200 series

- 14 -

Page 15

V4.5

Figure 6, Power and fault contact – connection diagram 2

Example circuit 1, see Figure 5, will not indicate if one of the external power supplies fails,

while example circuit 2 will if this is required, see Figure 6. The only difference between the

two examples (except that two relays are used) is that each relay is powered from only one of

the power supplies. The result of this is that if a power supply is failing the corresponding

relay will be de-energised.

Example circuit 3, see Figure 7 shows how to connect the fault contact (status connection) to

a PLC. The reason for connecting the fault contact to a local PLC can be that the PLC needs

to know the status of the network in order to decide operational mode or to summarize alarms

if SNMP and SNMP traps are not used, see chapter 9. Connection of status output of the two

PSUs can be done in the same way. The fault contact in the switch is an electronic relay with

an internal resistance of approx. 8Ω. When calculating the pullup resistor R the threshold

voltage of the digital input on the PLC needs to be taken into account. Also the maximum

power dissipated in the resistor R as well as the maximum current thru the fault contact. If

+24V supply is used to pullup the resistor (+5V may also be used) as in connection diagram

3, a suitable resistor is 2,2kΩ 0,5W.

www.westermo.com

U/R/T200 series

- 15 -

Page 16

V4.5

Figure 7, Power and fault contact – connection diagram 3

www.westermo.com

U/R/T200 series

- 16 -

Page 17

V4.5

6 Deterministic Ethernet - QoS

6.1 Principles of Deterministic Ethernet

Westermo OnTime switches can operate in full duplex mode. This ensures that an Ethernet

controller will never see any collisions occurring when operated in such a manner. The core

section of the Network; the redundant ring topology always runs full duplex and at 100Mbit/s;

this cannot be altered.

In addition a very fast switching core is provided to ensure that the switch can handle full wire

speed on each port. Finally, a large buffer is available to store packets destined for a busy

port. However, it is very unlikely that the buffers are used during normal network operation.

It should be noted that if buffers are used in such a network then it is not viable to state that a

network is Deterministic. In practice, the only time such buffers maybe used is in 10M / 100M,

half duplex devices. Where such devices are in use, a feature called Head of Line Blocking

Prevention is automatically implemented to ensure critical data is received at the destination

node, see 6.5 for details.

The switch contains two priority queues. A packet that is identified as a high priority packet is

put in the high priority queue. The switch alternates between the two queues by using strict

priority. I.e. packets from the low priority queue are only sent if the high priority queue is

empty. A packet is identified as a high priority packet based on priority tagging according to

IEEE 802.1p (layer 2 priority) or IP Type of Service (ToS -layer 3 priority).

6.2 Layer 2 priority

The IEEE 802.1p and IEEE802.1q standards specify an extra field for the Ethernet MAC

header. This field is called Tag Control Info (TCI) field, and is inserted between the source

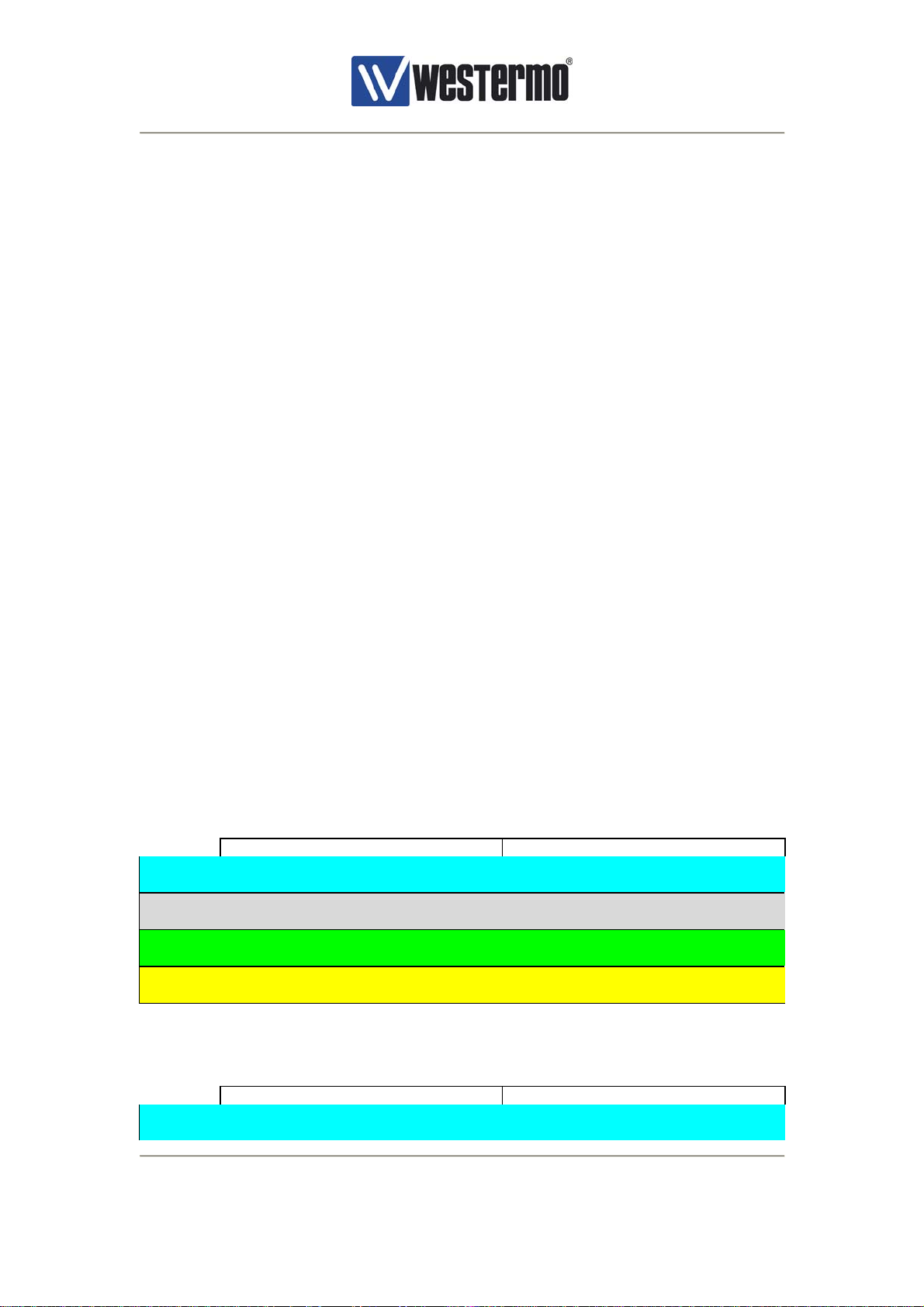

MAC address and the MAC Type/Length field of an Ethernet packet, see figure below.

Figure 8, MAC header with tag

This field contains a 3 bit priority field that is used for priority handling. The switch will put a

tagged packet with the priority field set to four or higher in the high priority queue, while all

other packets will be put in the low priority queue.

www.westermo.com

U/R/T200 series

- 17 -

Page 18

V4.5

6.3 Layer 3 priority

Each IPv4 header contains a ToS field, see figure below. The switch is configured to put IP

packets with the following ToS values in the high priority queue:

- 0x04 (IPTOS_RELIABILITY)

- 0x08 (IPTOS_THROUGHPUT)

- 0x10 (IPTOS_LOWDELAY)

- 0xF8

- 0xFC

High priority setting of the IP ToS field of real time critical packets must be set in the IP

protocol of the sending station. This can be done on TCP/UDP socket level by a setsockopt( )

command both on the client and server socket side in most Operating Systems (OS). E.g.:

tos = 0xFC;

setsockopt( .., IP_TOS, &tos,...)

Figure 9, IP header

6.4 Flow control

By default the switch is disabled for flow control (IEEE 803.3x), since flow control is a not a

good real time property.

6.5 Head of Line Blocking Prevention

The switch supports head of line blocking prevention for low priority packets only. This means

that low priority packets received on any port will not be forwarded to ports that are

congested. This will reduce the amount of packets in the output buffer. This function is

particular useful when high amounts of multicast, unknown unicast and broadcast traffic are

available in large networks where both 10BASE and 100BASE ports are available. High

priority packets will always be forwarded.

www.westermo.com

U/R/T200 series

- 18 -

Page 19

V4.5

7 Fast Re-configuration of Network Topology (FRNT)

7.1 Introduction

The Westermo OnTime 200 series is available with redundant ring technology. This

eliminates network failure caused by fibre or copper failures on the trunk ports (ring ports).

The speed of ring recovery is an essential part of designing your network. The Westermo

OnTime ring solution can recover from a failure in only 30mS if such a failure does occur.

When used in conjunction with redundant power supplies a very reliable system can be

designed.

Standard Ethernet networks would collapse and fail if normal office based Ethernet Switches

were formed into a complete ring. This failure is commonly referred to as a ‘broadcast storm’

as Ethernet Packets have multiple routes on a network to communicate to devices. Usually,

an incorrect type of packet broadcasts (or floods) over a network and causes hosts to

respond all at once, typically with wrong responses. This starts the process over and over

again; hence your network crashes.

7.2 FRNT version 0

7.2.1 FRNT version 0 principles

The FRNT version 0 protocol is similar to the IEEE Spanning Tree Protocol (STP) except for

the following:

Each switch in a ring topology has knowledge of the network topology, see figure below. I.e.

not only its neighbouring switches as is the case for STP. A FRNT topology change event

packet will be sent directly to the focal point switch in case of a topology change (e.g. a link

loss or a link establishment), while a STP implementation will only send STP control packets

one network hop. The focal point switch will, based on the received topology change event

packet, generate a topology change command. This packet is sent to each member switch in

the ring. The time it takes from the occurrence of a topology change until the corresponding

topology change event packet is received on the focal point is typical a fraction of millisecond

(ms) or a few milliseconds (ms) at the most, even though there is 50 switches on the path

between the topology change detecting switch and the focal point and the network load on the

links are high (e.g. 50 % of full wire speed). Thus, the switch latency in the no load scenario

is 15 microseconds (µs), while a conservative estimate in case of 50 % load is 70

microseconds (µs). The most time consuming part in case of a topology change is MAC table

update procedure. The MAC tables on each switch must be updated in case of a topology

change. This operation takes approx. 20 milliseconds (ms) and is independent on the

number of switches in the ring.

Note:

Similar proprietary network redundant protocols are often based on polling instead of event

controlled handling of a topology change. This will introduce a slower establishment of a new

topology. Another aspect is link re-training. A proprietary network redundant protocols that

are based on link re-training will suffer from a delay of 300 milliseconds (mS) or more.

www.westermo.com

U/R/T200 series

- 19 -

Page 20

V4.5

Figure 10, FRNT version 0, single ring topology

7.2.2 FRNT version 0, configuration rules

The rules are as follows:

• Port 7 and 8 are FRNT version 0 ports

• Always connect port 8 to 7, 8 to 7, .. 8 to 7 through the ring

• Never 7 to 7 or 8 to 8!

• One switch as the network focal point (root)

7.3 FRNT version 1

7.3.1 FRNT version 1 principles

The Fast Re-configuration of Network Topology (FRNT) protocol version 1 is used together

with FRNT version 0 rings, when redundancy between FRNT version 0 rings also is required,

see figure below.

Two FRNT version 0 rings are linked together via a primary and a backup link, where these

two links are originating from two different switches in the same FRNT version 0 ring. These

two switches are both enabled for FRNT version 1 operation. The two links are connected to

two different switches in the second FRNT version 0 ring. These two switches in the second

ring are NOT enabled for FRNT version 1 operation.

Link health packets are sent on both primary and the backup link in order to verify that the

links are ok or not. The primary link is default in packet forwarding state and the backup link

is default in packet blocking state (only link health packets get through). The backup link will

be put in packet forwarding state if the backup link is ok and the:

- primary link is not ok, or

- there is no communication between the primary switch and backup switch

www.westermo.com

U/R/T200 series

- 20 -

Page 21

The communication media between the two FRNT version 0 rings may not be under direct

control of the switches at either end. Thus any type of commutation technologies can be used

on the primary and a backup links.

Failure of the either the primary or the backup links will cause the primary or backup switch to

raise an alarm via SNMP, activate the fault contact and start switch LED blinking.

A FRNT version 1 topology change (link loss or link establishment on the primary and a

backup link) will also trig a MAC table on some or all switches in the FRNT 0 rings. The reconfiguration time in case of is FRNT version 1 topology change is comparable to the FRNT

version 0 re-configuration time.

V4.5

Figure 11, FRNT version 1, multiple ring topology

7.3.2 FRNT version 1, configuration rules

The rules are as follows:

• Only two switches in a FRNT version 0 ring can be configured for FRNT version 1,

one as primary

• Only one port can be enabled for FRNT version 1

www.westermo.com

U/R/T200 series

- 21 -

Page 22

V4.5

8 Rapid Spanning Tree Protocol (RSTP)

The R/T200 switch series supports the Rapid Spanning Tree Protocol (RSTP) according to

IEEE802.1w with fall-back to the Spanning Tree Protocol (STP - IEEE802.1D). The STP

fallback feature means that the R/T200 switches can be used together with switches that only

have support for STP.

RSTP/STP is a Layer 2 link management protocol that provides path redundancy while

preventing loops in the network. For a Layer 2 Ethernet network to function properly, only one

active path can exist between any two stations. Multiple active paths among end stations

cause loops in the network. If a loop exists in the network, end stations might receive

duplicate messages with broadcast storm and an unstable network as result.

The STP uses a spanning-tree algorithm to select one switch of a redundantly connected

network as the root (focal point) of the spanning tree. The algorithm calculates the best loopfree path through a switched Layer 2 network by assigning a role to each port based on the

role of the port in the active topology:

• Root - a forwarding port elected for the spanning-tree topology

• Designated - a forwarding port elected for every switched LAN segment

• Alternate - a blocked port providing an alternate path to the root port in the spanning

tree

Switches that have ports with these assigned roles are called root or designated switches.

Spanning tree forces redundant data paths into a standby (blocked) state. If a network

segment in the spanning tree fails and a redundant path exists, the spanning-tree algorithm

recalculates the spanning-tree topology and activates the standby path. Switches send and

receive spanning-tree frames, called bridge protocol data units (BPDUs), at regular intervals.

The switches do not forward these frames, but use them to construct a loop-free path. BPDUs

contain information about the sending switch and its ports, including switch and MAC

addresses, switch priority, port priority, and path cost. Spanning tree uses this information to

elect the root switch and root port for the switched network and the root port and designated

port for each switched segment. When two ports on a switch are part of a loop, the spanningtree port priority and path cost settings determine which port is put in the forwarding state and

which is put in the blocking state. The spanning-tree port priority value represents the location

of a port in the network topology and how well it is located to pass traffic. The path cost value

represents the media speed.

The stable, active spanning-tree topology of a switched network is determined by these

elements:

• The unique bridge ID (switch priority and MAC address) associated with each VLAN

on each switch

• The spanning-tree path cost to the root switch

• The port identifier (port priority and MAC address) associated with each port

When the switches in a network are powered up, each switch functions as if is the root switch.

Each switch sends a configuration BPDU through all of its ports. The BPDUs communicate

and compute the spanning-tree topology. Each configuration BPDU contains this information:

• The unique bridge ID of the switch that the sending switch identifies as the root switch

• The spanning-tree path cost to the root

• The bridge ID of the sending switch

• Message age

• The identifier of the sending port

• Values for the hello, forward-delay, and max-age protocol timers

When a switch receives a configuration BPDU that contains superior information (lower bridge

ID, lower path cost, and so forth), it stores the information for that port. If this BPDU is

www.westermo.com

U/R/T200 series

- 22 -

Page 23

V4.5

received on the root port of the switch, the switch also forwards it with an updated message to

all attached LANs for which it is the designated switch.

If a switch receives a configuration BPDU that contains inferior information to that currently

stored for that port, it discards the BPDU. If the switch is a designated switch for the LAN from

which the inferior BPDU was received, it sends that LAN a BPDU containing the up-to-date

information stored for that port. In this way, inferior information is discarded, and superior

information is propagated on the network.

A BPDU exchange results in these actions:

• One switch in the network is elected as the root switch (the logical centre of the

spanning-tree topology in a switched network).

• For each VLAN, the switch with the highest switch priority (the lowest numerical

priority value) is elected as the root switch. If all switches are configured with the

default priority (0x8000), the switch with the lowest MAC address in the VLAN

becomes the root switch.

• A root port is selected for each switch (except the root switch). This port provides the

best path (lowest cost) when the switch forwards packets to the root switch.

• The shortest distance to the root switch is calculated for each switch based on the

path cost.

• A designated switch for each LAN segment is selected. The designated switch incurs

the lowest path cost when forwarding packets from that LAN to the root switch. The

port through which the designated switch is attached to the LAN is called the

designated port.

• Ports included in the spanning-tree instance are selected. Root ports and designated

ports are put in the forwarding state.

• All paths that are not needed to reach the root switch from anywhere in the switched

network are placed in the spanning-tree blocking mode.

The user can easily set the root of the network by configuring one of the switches in the

network as the RSTP focal point (see Installation manual). This will result in a lower priority

value for this switch than for the other switches in the network.

Propagation delays can occur when protocol information passes through a switched LAN. As

a result, topology changes can take place at different times and at different places in a

switched network. When a port transitions directly from nonparticipation in the spanning-tree

topology to the forwarding state, it can create temporary data loops. Ports must wait for new

topology information to propagate through the switched LAN before starting to forward

frames. They must allow the frame lifetime to expire for forwarded frames that have used the

old topology.

Each port on a switch using spanning tree exists in one of these states:

• Blocking - the port does not participate in frame forwarding.

• Listening - the first transitional state after the blocking state when the spanning tree

determines that the port should participate in frame forwarding.

• Learning - the port prepares to participate in frame forwarding.

• Forwarding – the port forwards frames.

• Disabled – the port is not participating in spanning tree because of a shutdown port,

no link on the port, or no spanning-tree instance running on the port.

A port moves through these states:

• From initialization to blocking

• From blocking to listening or to disabled

• From listening to learning or to disabled

• From learning to forwarding or to disabled

From forwarding to disabled

•

www.westermo.com

U/R/T200 series

- 23 -

Page 24

V4.5

The typical time it takes to enter forwarding state from blocking state or vica versa (i.e. the

network re-configuration time) in case of a RSTP enabled network is approx. <40 seconds,

while the re-configuration time in case of a STP based network network is approx. 40

seconds.

www.westermo.com

U/R/T200 series

- 24 -

Page 25

V4.5

9 Simple Network Management Protocol (SNMP)

The Westermo OnTime R/T200 switch supports Simple Network Management Protocol

version 2c (SNMPv2c).

SNMP is an Internet standard protocol (IP) developed to manage IP nodes (servers,

workstations, routers, switches and hubs etc.) on an Ethernet network. SNMP enables

network administrators and controls engineers to manage network performance, find and

solve network problems, and plan for network growth.

Devices or Ethernet Switches that support SNMP are usually referred to as Managed

Switches. There are currently three different versions of SNMP available; SNMPv1, SNMPv2

and SNMPv3. Any node on a network that must is managed incorporates an agent module

that is responsible for the following:

• Collecting and maintaining information about the local environment and network.

• Providing that information to a SNMP Master, either responding to a request or in an

unsolicited fashion, or, when an event the managed device has been configured to

monitor occurs.

• Responding to manager commands to alter the local configuration or operating

parameters.

Each agent on the network maintains a unique Management Information Base (MIB) that is

specific to the SNMP agent. This is the case with the Westermo OnTime switches. SNMP is

based on a standard that covers all type of devices. Some of the information is common

regardless of Switch manufacturer (Port Health , Port Status etc) while other information is

specific to the Switch Manufacturer (Switch temperature, No. of Satellites available etc).

The R/T200 MIB is divided into groups allowing the SNMP manager to poll the SNMP agents

for information. The following MIB groups are implemented:

• MIB-2 System Group, RFC1213-MIB, OID: 1.3.6.1.2.1.1. Contains generic

configuration information such as system description (switch type, software version),

location, hostname, etc on the switch CPU.

• MIB-2 Interface Group, RFC1213-MIB, OID: 1.3.6.1.2.1.2. Contains generic

information on the entities at the interface layer. This means port speed, switch MAC

address, and packets statistics (number of packets sent and received, number of

unicast and multicast, packet sizes, over- and undersized packets, CRC errors,

collisions, etc) per port on the switch.

• MIB-2 Internet Protocol Group (IP), RFC1213-MIB, OID: 1.3.6.1.2.1.4. Contains

information used to keep track of the IP layer on the switch CPU.

• MIB-2 Internet Control Message Protocol Group (ICMP), RFC1213-MIB, OID:

1.3.6.1.2.1.5. Contains 26 counters, counting how many times this message type was

generated by the local IP entity and how many times this message type was received

by the local IP entity. It also counts the total number of ICMP messages received,

sent, received in error, or not sent due to error on the switch CPU.

www.westermo.com

U/R/T200 series

- 25 -

Page 26

• MIB-2 Transmission Control Protocol Group (TCP) , RFC1213-MIB, OID:

1.3.6.1.2.1.6. Contains information used to keep track of the application entities using

TCP on the switch CPU.

• MIB-2 User Datagram Protocol Group (UDP), RFC1213-MIB, OID: 1.3.6.1.2.1.7.

Contains information used to keep track of the application entities using UDP on the

switch CPU.

• MIB-2 SNMP Group, RFC1213-MIB, OID: 1.3.6.1.2.1.11. Contains information used

to keep track of SNMP application entities. It provides statistical information about the

SNMP protocol entity and tracks the amount of management traffic that the switch

CPU responds to.

• BRIDGE-MIB dot1dBridge dot1dStp Group, RFC1493, OID: 1.3.6.1.2.1.17.2. This

MIB holds Spanning Tree Protocol information on per port basis.

• ifMIB ifMIBObjects ifxTable Group, RFC2863, OID: 1.3.6.1.2.1.31.1.1. Contains

network load on per port basis and represents an extension to the MIB2-Interface

group.

• ifMIB ifRcvAddressTable Group, RFC2863, OID: 1.3.6.1.2.1.31.1.4. Contains

network MAC table on the switch CPU.

V4.5

Originally, SNMP was designed for networks designed using Hubs. Network bandwidth

allocated for SNMP had to be kept to a minimum and hence the Simple Network Management

Protocol was designed to be simple. Therefore, an SNMP manager can carry out the

following simple commands:

• Query SNMP agents

• Get responses from agents

• Set variables in agents

• Acknowledge asynchronous events from agents

9.1 Westermo OnTime private MIB Information

The Westermo OnTime Management Information Base (MIB) is a collection of variables or

data that determines the properties of the managed device. The MIB is unique to the

Westermo OnTime device and has therefore been compiled to take this into account.

There are various tools available that enable the MIB data to be displayed in a software

package or via OPC so that the MIB information can be displayed onto a SCADA.

The Westermo OnTime MIB is available on the documentation / software CD that is included

with every Westermo OnTime switch

The Westermo OnTime private MIB contains the following:

• General

• FRNT 0 status

• Status information

• Time synchronization configuration parameters and status information

• Multicast configuration

www.westermo.com

U/R/T200 series

- 26 -

Page 27

• Temperature alarm configuration

• SNMP host addresses

V4.5

9.2 SNMP Traps

One feature of SNMP is that the SNMP agent (in this case an Westermo OnTime switch) can

send SNMP traps to one or more SNMP Hosts. SNMP traps means system alarms such as a

port link loss or a port enabled for port alarms or the switch temperature exceeding a

predefined threshold.

www.westermo.com

U/R/T200 series

- 27 -

Page 28

V4.5

10 IGMP snooping

10.1 IP Multicast filtering

Several applications are based on multicast communication. Data is only sent once even

though the data is meant for more than one receiver. However, the multicast packets will be

sent on every drop link in the network unless the Ethernet switches support multicast filtering.

The R/T200 series support IP multicast filtering. This means that IP multicast "join" and

"leave" requests will be trapped by the switches, and the multicast filters will be set based on

which drop links where these requests are received.

10.2 Routerless operation

IGMP "Join" and "leave" request are forwarded to one or more IGMP servers (routers)

present in the network. This is one of the main properties of IGMP. The Westermo OnTime

IGMP snooping implementation does not depend on the availability of an IGMP Querier

(IGMP server) in the network. This is important from robustness or a performance point of

view. Thus, the multicast filtering feature will work even though the network connection to a

standalone IGMP Querier is lost or not, and the drop link to such standalone IGMP Querier

will not become a bandwidth bottleneck in the network, because the switch can also act as an

IGMP Querier. The IGMP Querier operation of the switch is controlled by the “Auto mode”

and “Querier” parameters. The following combinations of these two parameters are possible:

- “Auto mode” enabled + Querier enabled: the switch is able to act as an IGMP Querier

(IGMP server) and the IGMP Querier in the network is selected automatically. The

switch (with Querier support) in the network with the lowest IP address will be chosen as

the network Querier (i.e. IGMP focal point). Only one Querier will exist in the network if

all IGMP enabled switches and routers in the network have this configuration. This is

the default IGMP settings.

- “Auto mode” enabled + Querier disabled: same operation as above, but the switch

cannot act as an IGMP Querier.

- “Auto mode” disabled + Querier enabled: the switch will always act as an IGMP Querier.

Each switch/router will act as IGMP Querier if this configuration is used on each

switch/router in the network.

A switch with “Auto mode” enabled, which is not acting as the IGMP Querier, will forward

IGMP Queries received from the IGMP Querier on all ports except the port where the IGMP

Queries are received. The port where IGMP Queries are received is referred to as the

“Router port”. This port is part of every active multicast filter. The use of “Router port” is not

relevant in case “Auto mode” is disabled since the switch in this mode always is acting as a

Querier (IGMP focal point). A switch in this mode will not forward IGMP queries received.

IGMP Measurement reports for each active multicast filter on the switch will be sent back for

each IGMP Query received. This is valid for both “Auto mode” being enabled and disabled.

The interval between two IGMP query packets can also be set in the IP configuration tool.

Four intervals are possible: [12, 30, 70, 150] seconds.

The IGMP snooping implementation will also forward IGMP information (join, leave,

measurements reports) on the switch trunk ports. A trunk ports is automatically detected in

case a network redundancy protocol such as if FRNT or STP are running, but the user may

also configure manually ports as trunk ports. Manually trunk port configuration might be

relevant in case no network redundancy protocol is running on a port connected to another

IGMP snooping enabled switch. This feature is required in case the multicast producers (i.e.

Ethernet end nodes sending IP multicast packets) make no IGMP join or IGMP

www.westermo.com

U/R/T200 series

- 28 -

Page 29

measurements reports according to IGMP v2. IP multicast producers are not required to

make an IGMP join during start up or answer with IGMP measurement reports on received

IGMP query packets (ref. RFC 2236).

V4.5

10.3 Stop filter option

A stop filter will be set if a multicast packet is received prior to a "join" to an IP multicast group

where the received multicast address belong if the "Multicast stop filter" option is enabled.

This means that IP multicasting based on IGMP is required in order to get multicast through

the network. Multicast filters will be properly set only for IP multicast packets if this option is

disabled. That means that multicast packets not based on IP will be forwarded in the same

way as broadcast packets. This is acceptable if the non IP based multicast network load is

reasonable low.

10.4 Fast MC filter setup

Version 3.65 and newer versions have the following property:

- All trunk ports (i.e. RSTP or FRNT trunk ports), manually defined layer IGMP trunk ports

and the query port(s) are by default member of all MC filters.

- MC data generated by MC producers that do not generate IGMP measurement Reports

will be forwarded on all trunk ports (i.e. RSTP or FRNT trunk ports), manually defined

layer IGMP trunk ports and the query port(s).

These the two new IGMP snooping properties can be enabled or disabled in SNMP in the

private MIB:

includeIgmpL2TrunkPortsOnAllMcfilters (1.3.6.1.4.1.16177.1.1.7.7).

10.5 FRNT integration

The IP multicast filter implementation is integrated with the Fast Re-configuration of Network

Topology (FRNT) protocol. This means that the multicast filters will be updated as fast the

FRNT implementation handles a topology change, i.e. approx. 30 ms.

www.westermo.com

U/R/T200 series

- 29 -

Page 30

V4.5

11 VLAN

A physical Ethernet network can be divided into several overlapping Virtual LANs (VLAN)

without having IEEE802.1q tagging or GVRP (Generic VLAN Registration Protocol) support

on the Ethernet end nodes. All Ethernet trunk ports are member of all of the seven “Standard

VLANs” and the four “Additional VLANs”. A trunk port means a switch port connected to

another switch; where a network redundancy protocol is running (e.g. FRNT). This means

that the VLAN tables on each switch are dynamically updated during a network topology

change. Thus, no VLAN user configuration is required on the trunk ports.

Figure 12, VLAN setup dialog

www.westermo.com

U/R/T200 series

- 30 -

Page 31

Figure 12 shows the VLAN dialog setup of the IP configuration tool.

The VLAN implementation is meant for both Ethernet end nodes that support tagging and for

those that do not. An Ethernet end node that are not able to send tagged packets can,

however, only participate in one of the “Standard VLANs”, i.e. the default VLAN id for the port

is used as the VLAN for such an end node. A default VLAN id for a given port will be

associated to each untagged packet received on the switch (or tagged packet with VLAN id

equal to 0). This VLAN id will be added to packet as an IEEE802.1Q tag. This tag can be

removed at the output port(s) if the port(s) is configured for tag removal.

Seven different “Standard VLANs” are available:

- White, VLAN id = 1, priority = 7 [high]

- Red, default VLAN id = 2, default priority = 0 [low]

- Blue, default VLAN id = 3, default priority = 0 [low]

- Green, default VLAN id = 4, default priority = 0 [low]

- Yellow, default VLAN id = 5, default priority = 0 [low]

- Brown, default VLAN id = 6, default priority = 0 [low]

- Pink, default VLAN id = 7, default priority = 0 [low]

The VLAN that is selected as the default VLAN for a given port will appear as an

unchangeable VLAN, while other VLANs selected for the same port has only relevance in

case the end node connected to the same port is able to send and receive packets with these

VLAN ids.

All ports on a switch are by default members of the white VLAN, i.e. the switch management

VLAN. The administrator can remove non-trunk ports from the white VLAN. That means that

such ports cannot be used for switch management. All trunk ports are part of the white VLAN.

This is automatically configured on run-time.

Port 1 has the white VLAN id as the ports default VLAN id, and this cannot be changed. An

end node that is used for network management (SNMP or IP configuration) must always use

the white VLAN in order to communicate with the switch CPUs. Thus, the switch CPUs can

always be accessed via port 1 with untagged packets, since port 1 has the white VLAN as the

default VLAN.

The tag is not removed on packets sent on a trunk port, and each trunk port is member of all

the seven “Standard VLANs” and the four “Additional VLANs”. This means that the user does

not need to set any VLAN parameters on the trunk ports, and that any network topology

change will be handled automatically.

The layer 2 priority of a given VLAN can also be set. I.e.:

- Priority 0 ..3: low priority

- Priority 4 ..7: high priority

This priority will be added to the tag. See Figure 8 for the MAC header with tag.

The legal VLAN id range is [1 .. 4096]. A few VLAN ids in this range are reserved for other

use. These ids can not be set in the IP configuration tool.

The network should only be based on switches enabled for VLAN or not. A mix of switches

with and without VLAN support will not provide the user with the capability of tag removal on

all parts of the network.

V4.5

11.1 Standard vs. Additional VLANs

www.westermo.com

U/R/T200 series

- 31 -

Page 32

- A trunk port will be member of all "Standard VLANs" and " Additional VLANs "

(i.e. no difference between " Standard VLANs" and " Additional VLANs ")

- The user can define the vlan that a non-trunk port shall be member of. The vlan set can

be any vlan among the " Standard VLANs " and " Additional VLANs " (i.e. no difference

between " Standard VLANs " and "Additional VLANs")

- The user can define the default vlan for a non-trunk port. The default vlan for a given

port can only be taken from the "Standard VLANs ".

V4.5

11.2 VLAN example

The figure below shows an example of a VLAN setup with three VLANs (red, blue and green

VLAN) in a network with ring topology.

Figure 13, VLAN example

www.westermo.com

U/R/T200 series

- 32 -

Page 33

V4.5

12 Time synchronization

Variable latencies through the protocol stacks and the Ethernet switches will degrade the

timing accuracy that can be achieved when time synchronization is performed via a switched

Ethernet infrastructure. Time stamping of incoming and outgoing time packets shall

preferably be done as low as possible in the protocol stack. The Ethernet switch latency

depends on the network load and the switch architecture. This problem is solved by

integrating state of the art time synchronization properties on the T200 switches from

Westermo OnTime. The main building blocks of the Westermo OnTime time server

(SNTP/NTP)/PTP (IEEE1588 v1) implementation (T200) is shown below:

RS422/RS232

CPU

Switch core

GPS

PPS

FPGA

MII/RMII/SMI

Ethernet PHY

Oscillator

Figure 14, T200 building blocks

Incoming and outgoing time packets are time stamped in hardware at the Media Independent

Interface (MII) between the switch core and the Ethernet PHY. An incoming time packet is

time stamped before it is forwarded through the Ethernet switch core and an outgoing time

packet is time stamped after the packet has been sent through the switch core. This means

that variable latency through the switch core has no impact on the time synchronization

accuracy. Thus, the T200 is network load independent. The time stamping is performed in

an FPGA (Field Programmable Gate Array). The FPGA also generates the local clock of the

PTP clock implementation based on either an external Pulse Per Second (PPS) input from

e.g. a GPS receiver, or only based on a local oscillator (e.g. the switch core oscillator). The

drift and offset of the local oscillator is adjusted based on the PPS signal in case an external

time base is used.

www.westermo.com

U/R/T200 series

- 33 -

Page 34

V4.5

The CPU handles the time sync protocol, T200 configuration via e.g. SNMP, serial interface

versus an external clock source (if this available) and the interface versus the FPGA. The

NMEA protocol over RS232 or RS422 versus an external GPS is often relevant in order to

have reference to absolute time. RS422 is the preferred interface for both serial data and the

PPS signal in order to meet various installation requirements (distance between GPS receiver

and PTP clock).

NMEA 0183 is an interface protocol created by the National Marine Electronics Association.

NMEA is a simple, yet comprehensive ASCII protocol which defines both the communication

interface and the data format. For those applications requiring output only from the GPS

receiver, NMEA is in most cases the preferred choice. The GGA and ZDA are the two NMEA

reports used by the T200. The format of these two reports is as follows:

$GPGGA,<UTC time>,<Latitude>,<N/S>,<Longitude>,<E/W>,<GPS quality>,

<Nr of satellites>,<Horizontal precision>,<Antenna height>,

M,<Geoidal height>,M,<Diff. GPS data age>,<Diff. ref. station ID><CR>,<LF>

UTC time hhmmss format

Latitude ddmm.mmmmm format

Latitude N/S Latitude hemisphere North or South

Longitude dddmm.mmmmm format

Longitude E/W Longitude hemisphere East or West

GPS quality 0=fix not available,

1=Non-diff GPS available,

2=diff. GPS fix available

Nr of satellites in use 00 to 12 satellites

Horizontal dilution precision 0.5 to 99.5

Antenna height above/below mean -9999.9 to 99999.9 meters

Geoidal height -999.9 to 9999.9 meters

Diff. GPS data age nr of seconds since last valid RTCM transmission

Diff. ref. station ID 0000 to 1023.

GPZDA - Time and Date

$GPZDA,<hhmmss.s>,dd,mm,yyyy,,*hh<CR>,<LF>

UTC hhmmss.s

Day dd (01 to 31)

Month mm (01 to 12)

Year yyyy

Unused Unused -

The most relevant time synchronization protocols are based on SNTP/NTP

(RFC2030/RFC1305) or P1588 (IEEE Std 1588™-2002). These protocols are all based on

UDP/IP.

Timing accuracies in the order of one millisecond (ms) can be achieved on a time client by

using the built-in SNTP client software available on newer versions of Windows or other

operating systems when time updates are performed versus the T200 time server. 5-25

microseconds (µs) timing accuracies is possible by performing time stamping of incoming an

outgoing time packets on the client interrupt service routine. 1 µs accuracy or better can be

www.westermo.com

U/R/T200 series

- 34 -

Page 35

achieved if time stamping on the client is performed in hardware. Westermo OnTime networks

provide intellectual property as part of design in projects together with customers that need

highest possible accuracy. Such an implementation is shown below. This is the preferred

configuration.

V4.5

Figure 15, OSI model of time server and time client

12.1 IEEE 1588 Grandmaster

The IEEE 1588 Grandmaster will periodically send SYNC and FOLLOW_UP multicast

packets with an interval of two seconds, when the switch is enabled for IEEE 1588

Grandmaster functionality, version 1. The SYNC packet contains no accurate time stamp in

the fraction part of the SYNC transmit time stamp, originTimestamp (nanoseconds), while the

corresponding FOLLOW_UP packet contains this time stamp of the SYNC packet in its

preciseOriginTimestamp (nanoseconds), i.e. the T3 time stamp (see figure above). The

sequenceId of the SYNC packet and the associatedSequenceId parameter of the

FOLLOW_UP packet are used for pairing the SYNC and the corresponding FOLLOW_UP

packet at the IEEE 1588 Slave implementation connected to the T200. The IEEE 1588

Grandmaster will also respond with a DELAY_RESP packet when a DELAY_REQ packet is

received from an IEEE 1588 Slave. The requestingSourceSequenceId parameter of the

DELAY_RESP packet and the sequenceId parameter of the DELAY_REQ packet is used for

pairing the two packets. The delayReceiptTimestampSec and delayReceiptTimestampFrac

parameters of the DELAY_RESP packet contains the receive time stamp of the DELAY_REQ

packet , i.e. the T2 time stamp (see figure above).

12.2 IEEE1588 Transparent Clock

One of the main properties of the IEEE1588 standard is related to the handling of variable

network latency between the Grand Master clock and the Slave clocks. Thus, the network

www.westermo.com

U/R/T200 series

- 35 -

Page 36

V4.5

load dependable latency through off-the-shelf Ethernet switches without any time sync

support will depredate the time sync accuracy that can be achieved on the IEEE1588 Slaves.

This degradation is proportional with the number of off-the-shelf switches between the IEEE

1588 Grand Master and the IEEE 1588 Slave.

This problem is solved if T200 switches with IEEE 1588 Transparent Clock functionality are

used on all network paths between the Grand Masters and Slaves in the network.

The IEEE 1588 Transparent Clock for IEEE1588 version 1 principles are as follows:

SYNC and FOLLOW_UP packets are sent from the Master to the Slaves. Both packets are

sent to the CPU of the Ethernet switch with Transparent Clock support before the packets are

forwarded on all ports except the port where the two packets were received. A receive time

stamp is generated on PHY level when the SYNC packet was received, and transmit time

stamps are generated on PHY level for each output port where the SYNC packets are

forwarded. The time difference between the transmit time stamps and the receive time

stamp, ∆Tsync(N-1) (,where N is the number of ports on the Ethernet switch), of the SYNC

packet is calculated and stored for each output port. The sequenceId of the SYNC packet is

also stored and compared with the assoiciatedSequenceId of the corresponding

FOLLOW_UP packet received on the same input port as the SYNC packet. These two

sequence ids must match. The preciseOriginTimestamp of each of the FOLLOW_UP packets

that are forwarded on the N-1 output ports are modified with ∆Tsync(i) for each output port.

The FOLLOW_UP packets are then forwarded on the output ports. See Figure 16 for the

handling of the SYNC/FOLLOW_UP packets at the switch with IEEE1588 Transparent Clock.

Figure 16, IEEE1588 SYNC/FOLLOW-UP Transparent Clock functionality

DEL_REQ packets are sent from the Slave to the Master in order to calculate the propagation

delay between Slave and the Master. This means the wire propagation delay in traditional

IEEE1588 context. The delay through an Ethernet switch with Transparent Clock support will

add network load depended switch delay to a DEL_REQ packet (i.e. store-and-forward and

queuing delays of the Ethernet switch). This delay must be removed. The delay is measured

when the DEL_REQ packet passes the switch and the delayReceiptTimestamp parameter of

www.westermo.com

U/R/T200 series

- 36 -

Page 37

the corresponding DELAY_RESP packet is then modified with this measured delay. The

sequenceId is used for pairing the DEL_REQ packet the corresponding DEL_RESP packet.

See Figure 17 for the handling of the DEL_REQ/DEL_RESP packets at the switch with

IEEE1588 Transparent Clock functionality.

A switch with IEEE1588 Transparent Clock support maintains a list of ports, where SYNC and

FOLLOW-UP packets are received. Any DEL_REQ packets received are only forwarded on

these ports.

V4.5

Figure 17, IEEE1588 DEL_REQ/DEL_RESP Transparent Clock functionality

A network of switches with IEEE1588 Transparent Clock support can in fact be considered as

one big LAN segment as if all the Ethernet switches were Ethernet hubs with the difference

that full duplex connectivity and bandwidth scalability of Ethernet switches are maintained.

12.3 IEEE1588 Transparent Clock version 1 and 2