Page 1

Fieldbus adapter,

PROFIBUS DP Master

INSTALLATION MANUAL

6630-2220

www.westermo.com

FD-20

©

Westermo Teleindustri AB • 2004 • REV. C

Page 2

2 6630-2220

Contents

1. Safety .................................................................................................................................................................................. 3

2. Approvals ....................................................................................................................................................................... 3

2.1 Declaration of Conformity .......................................................................................................................... 4

3. Introduction ............................................................................................................................................................... 5

3.1 Field of application ....................................................................................................................................... 5–6

4. Specifications ..................................................................................................................................................... 7–8

5. Maintenance .............................................................................................................................................................. 8

6. Installation .......................................................................................................................................................... 9–26

6.1 Mounting/Removal ............................................................................................................................................. 9

6.2 Connections ......................................................................................................................................................... 10

6.2.1 Power ............................................................................................................................................................. 11

6.2.2 PROFIBUS DP ........................................................................................................................................ 11

6.2.3 RS-232 (DTE) ........................................................................................................................................... 11

6.2.4 RS-485 ........................................................................................................................................................... 11

6.3 Indicators ................................................................................................................................................................ 12

6.3.1 LEDindicators .......................................................................................................................................... 12

6.4 Configuration ...................................................................................................................................................... 13

6.4.1 DIP switch settings ..................................................................................................................... 13–15

6.4.2 On-line configuration using SyCon®,

a universal System Configurator

................................................................................................ 16

6.4.2.1 Initiate PROFIBUS DP Master Configuration ................................................... 16

6.4.2.1.1 The first run (no saved project),

Initiate communication

............................................................................................ 16

6.4.2.2 PROFIBUS DP Master configuration using SyCon

®

...................................... 17

6.4.2.2.1 Create a new configuration ................................................................................... 17

6.4.2.2.2 Open an existing project ......................................................................................... 17

6.4.2.2.3 GSD file ................................................................................................................................. 18

6.4.2.2.4 Insert PROFIBUS DP Master .............................................................................. 18

6.4.2.2.5 PROFIBUS DP Master configuration ............................................................ 19

6.4.2.2.6 Insert PROFIBUS DP Slave ................................................................................... 19

6.4.2.2.7 PROFIBUS DP Slave configuration ....................................................... 20–22

6.4.2.3 Load the configuration to the FD-20 ........................................................................ 22

6.4.2.4 Store configuration ................................................................................................................ 23

6.4.2.5 Diagnostics functions ............................................................................................................. 23

6.4.2.5.1 Live list, all devices ....................................................................................................... 23

6.4.2.5.2 Debug mode, PROFIBUS DP and Slave diagnostic ............................ 24

6.4.2.5.3 Global State Field ................................................................................................ 25–26

7. Functional description .................................................................................................................... 27–30

7.1 Halt state ................................................................................................................................................................ 28

7.2 Run state ................................................................................................................................................................. 28

7.3 LED error indication ............................................................................................................................ 29–30

Page 3

36630-2220

1. Safety

General:

Before using this unit, read this manual completely and gather all information on

the unit. Make sure that you understand it fully. Check that your application does

not exceed the safe operating specifications for this unit.

Before installation, maintenance or modification work:

Prevent damage to internal electronics from electrostatic discharges (ESD)

by discharging your body to a grounding point (e.g. use of wrist strap).

Prevent access to hazardous voltages by disconnecting the unit from AC/DC

mains supply and all other electrical connections.

Installation:

This unit should only be installed by qualified personnel.

This unit should only be installed in a “restricted access area”, for example

a lockable cabinet where access is restricted to service personnel only.

This unit is intended for permanent connection to the AC/DC mains supply.

The power supply wiring must be sufficiently fused, and if necessary it must be

possible to disconnect manually from the AC/DC mains supply. Ensure compliance

to national installation regulations.

Units with the rated voltage exceeding 42.4 V peak or 60 VDC, are defined as

class I equipment with a protective earthing conductor terminal.

Units with the rated voltage up to 42.4 V peak or 60 VDC, are defined as class III

equipment and shall be separated from hazardous voltage by double or reinforced

insulation.

This unit uses convection cooling.To avoid obstructing the air flow around the

unit, follow the spacing recommendations (see Installation section).

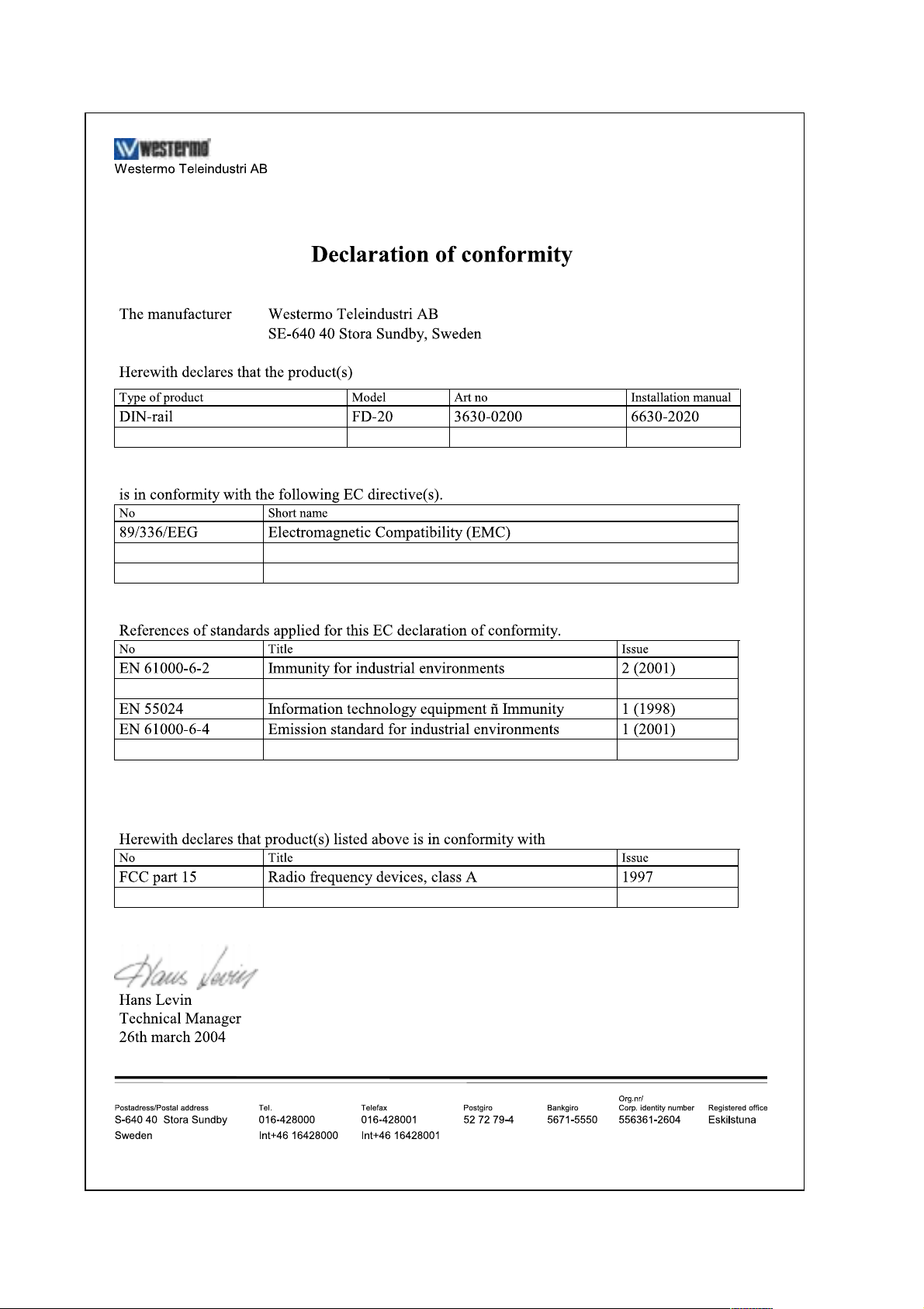

2. Approvals

Conformity with the Directive 89/336/EEC Electromagnetic Compatibility (EMC)

has been assessed by application of standards EN 61000-6-2 (industrial immunity) and

EN 61000-6-4 (industrial emission).

Meets EN 50170, Profibus-DP Specification.

FCC Part 15 Notice: This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules.These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment.

This equipment generates, uses, and can radiate radio frequency energy and, if not installed and

used in accordance with this installation manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his own

expense.

!

!

!

Page 4

4 6630-2220

2.1 Declaration of Conformity

Page 5

56630-2220

3. Introduction

The FD-20 is designed to provide a method of transferring PROFIBUS I/O data over

serial data links.

The FD-20 contains a PROFIBUS master that can control a network of PROFIBUS DP

Slaves connected to its fieldbus port.The unit can be easily configured within the limits set

by the serial data rate to transfer input and output data between PROFIBUS networks.

The unit is able to transfer PROFIBUS DP data over leased line, dial up modems,

Ethernet or radio systems.

The FD-20 can be used in conjunction with the FD-10

(which contains a PROFIBUS DP Slave)

All Westermo Fieldbus Adapters use the same protocol to communicate with each other

via the serial interface.

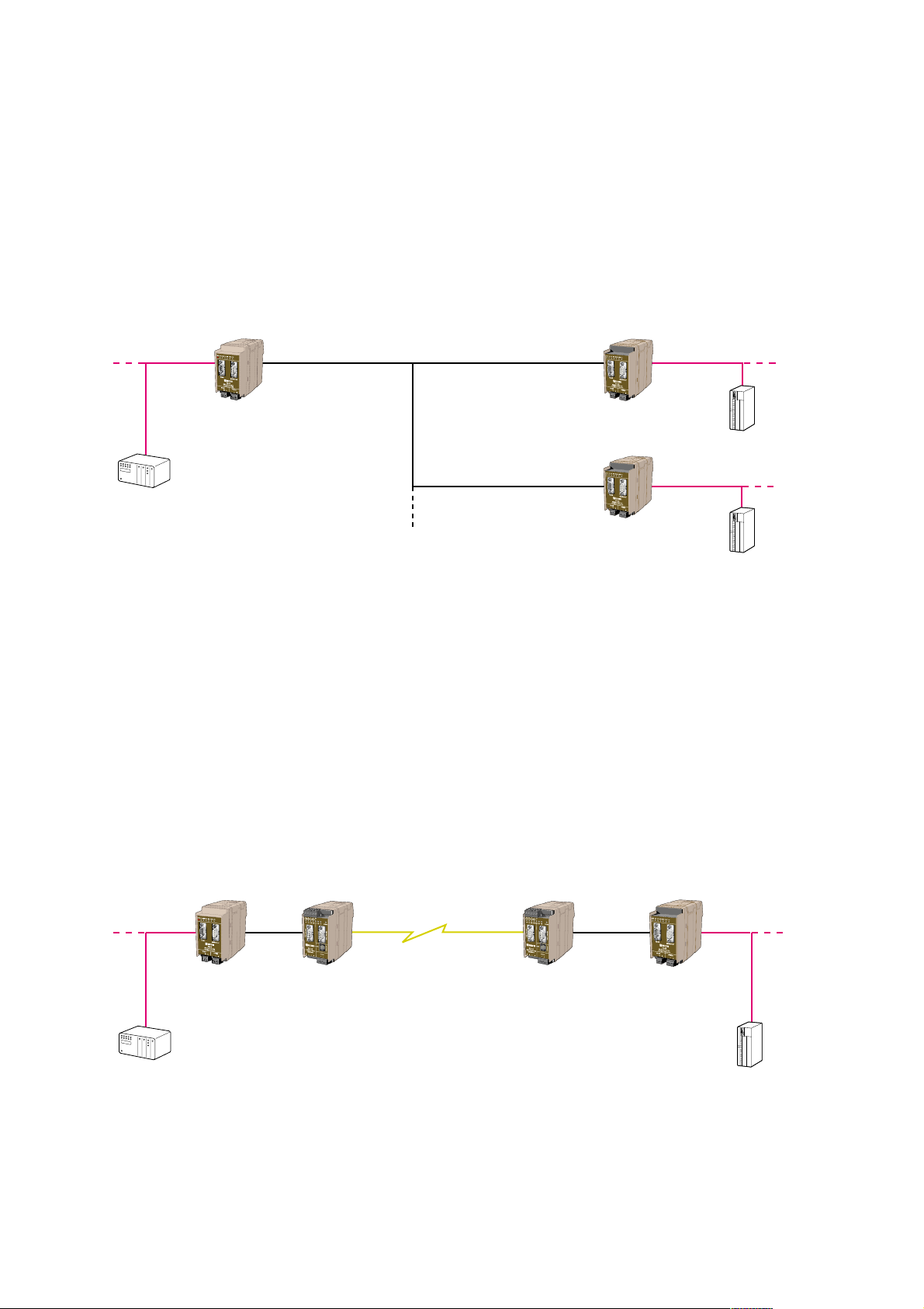

3.1 Field of application

Point to point transfer

The continuous transfer of defined PROFIBUS I/O data between one FD-10 P

(Fieldbus adapter PROFIBUS DP Slave) and one FD-20

(Fieldbus adapter PROFIBUS DP Master).

*PSTN= Public Switch Telephone Network

FD-10 P

PROFIBUS DP

PROFIBUS DP

FD-20

PROFIBUS DP Master

Modem

(e.g PSTN*, Radio)

PROFIBUS DP Master

PROFIBUS DP Slave

Modem

(e.g PSTN*, Radio)

Page 6

6 6630-2220

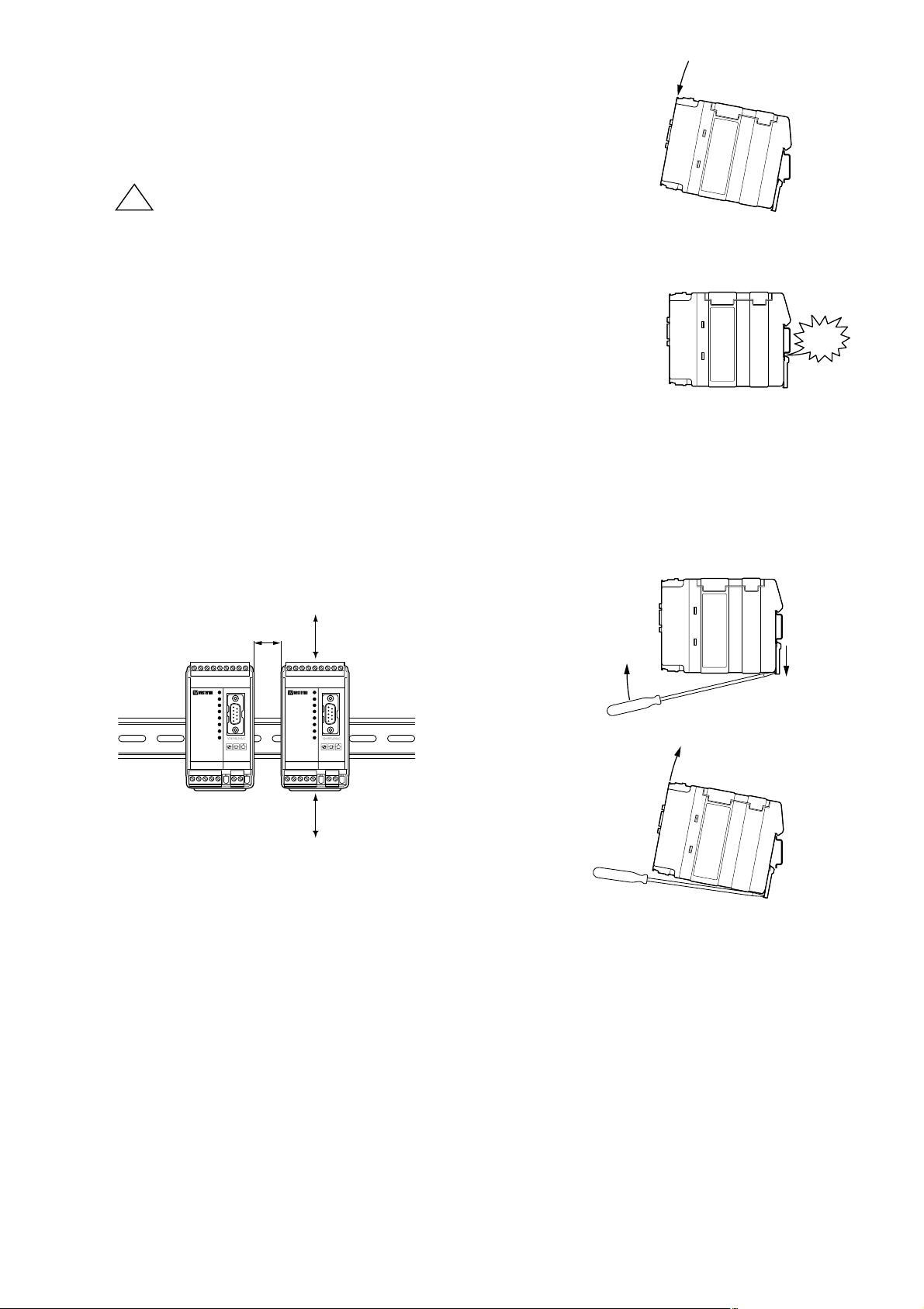

Point to point over Ethernet

The continuous transfer of defined PROFIBUS I/O data over Ethernet, between one

FD-10 P (fieldbus adapter PROFIBUS DP Slave) and one FD-20 (Fieldbus adapter

PROFIBUS DP Master).

This application is created by using one FD-10 P (point to point mode) and one

ED-10 UDP (Ethernet adapter) in the main PROIBUS DP network and one ED-10 UDP

and one FD-20 in the remote network.The FD-20 can support a number of

PROFIBUS DP Slaves

FD-10 P

PROFIBUS DP

PROFIBUS DP

FD-20

PROFIBUS DP Master

ED-10 UDP

Ethernet

PROFIBUS DP Master

PROFIBUS DP Slave

ED-10 UDP

Configure ED-10:

Data rate the same as

FD-10 serial port.

Local IP : i.e:10.0.0.11

Remote IP: i.e: 10.0.0.12

Configure ED-10:

Data rate the same as

FD-20 serial.port

Local IP: i.e:10.0.0.12

Remote IP: i.e: 10.0.0.11

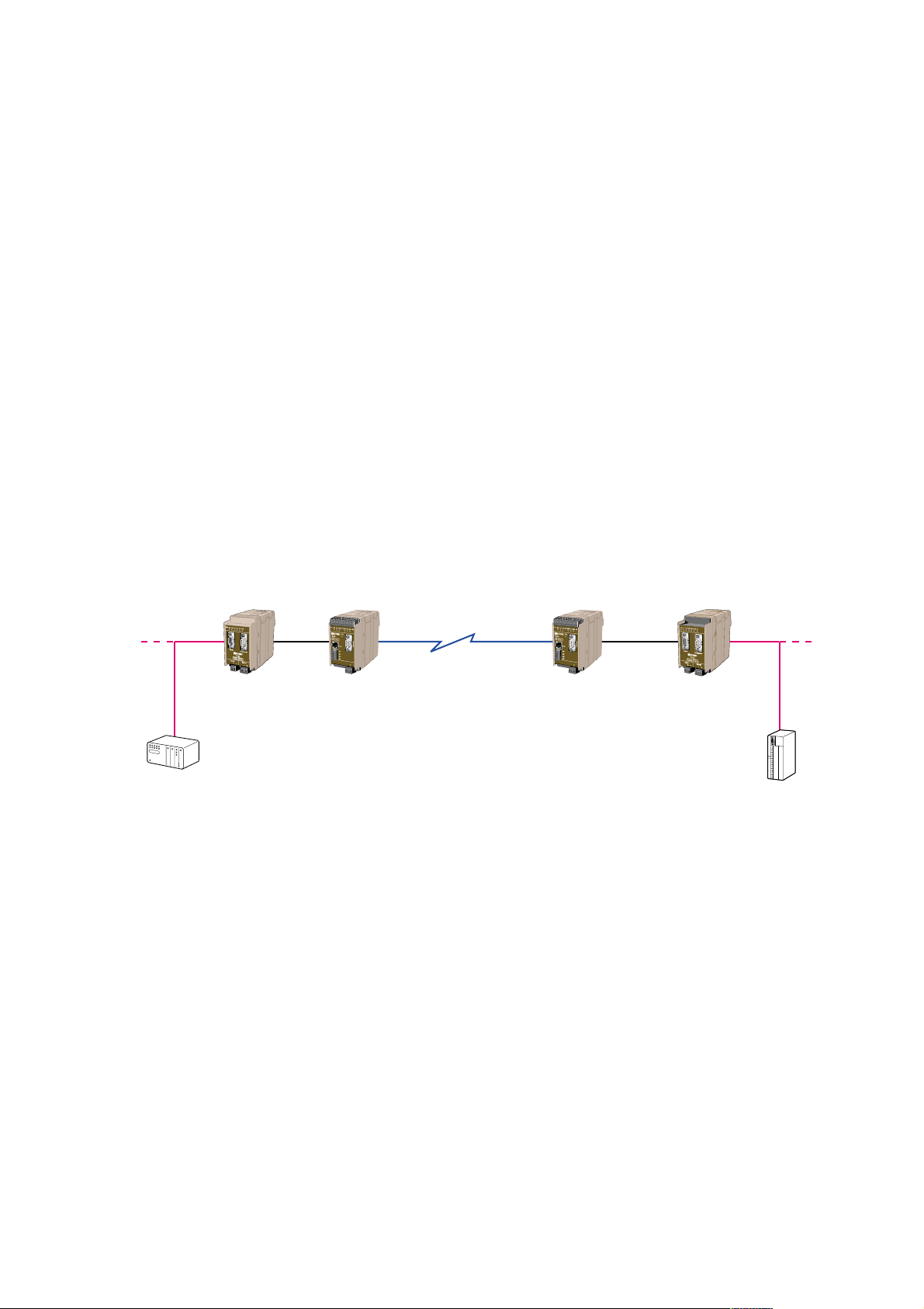

Master controlled transfer (Addressed)

The transfer of defined PROFIBUS I/O data between one FD-10 A controlled by a

PROFIBUS DP Master and several FD-20s.The FD-10 acts as serial transfer master

and can transfer I/O data between various addressed FD-20s.This solution is ideal

when a PROFIBUS DP Master needs to connect to two, or more, independent remote

PROFIBUS DP Slaves.A radio system, multi-drop modem or RS-485 bus is typically used

as the connecting medium.The serial data rate is independent of the PROFIBUS DP rate,

so each PROFIBUS DP network could run at different data rates to the serial backbone.

FD-10 A

PROFIBUS DP Slave

PROFIBUS DP Slave

PROFIBUS DP Master

Serial

master

Serial

slave

Serial

slave

PROFIBUS DP

PROFIBUS DP

PROFIBUS DP

FD-20

PROFIBUS DP Master

FD-20

PROFIBUS DP Master

Page 7

76630-2220

4. Specifications

FD-20

Rated voltage 12 to 48 VDC

Operating voltage 9.6 to 57.6 VDC

Rated current 250 mA @ 12 VDC

120 mA @ 24 VDC

65 mA @ 48 VDC

Rated frequency DC

Polarity Reverse polarity protected

Connection Detachable screw terminal

Connector size 0.2 – 2.5 mm2(AWG 24-12)

Fuse To be externally fused

Power

PROFIBUS DP interface

Electrical specification RS-485 / EN 50 170

Data rate 9 600 bit/s, 19.2, 93.75, 187.5, 500, 1 500, 3 000, 6 000 and

12 000 kbit/s

Connection D-sub (female)

Circuit type TNV-1

Termination External

RS-485 interface

Electrical specification RS-485

Data rate 1 200, 2 400, 4 800, 9 600 bit/s, 14.4, 19.2, 38.4, 57.6

and 115.2 kbit/s

Connection Detachable screw terminal

Connector size 0.2 – 2.5 mm

2

(AWG 24-12)

Circuit type TNV-1

RS-232 interface

Electrical specification RS-232

Data rate 1 200, 2 400, 4 800, 9 600 bit/s, 14.4, 19.2, 38.4, 57.6

och 115.2 kbit/s

Connection D-sub, DTE

Circuit type SELV

Page 8

8 6630-2220

Environmental

Temperature, operating –25 to 70°C

Temperature, storage

and transportation –25 to 70°C

Relative humidity, operating 5 to 95 % (non-condensing)

Relative humidity, storage

and transportation 5 to 95 % (condensation allowed outside packaging)

Mechanical

Dimension (W x H x D) 55 x 100 x 132 mm (including connectors)

55 x 100 x 128 mm (enclosure)

Weight 0.3 kg

Mounting 35 mm DIN-rail

Degree of protection IP 20 (IEC 529)

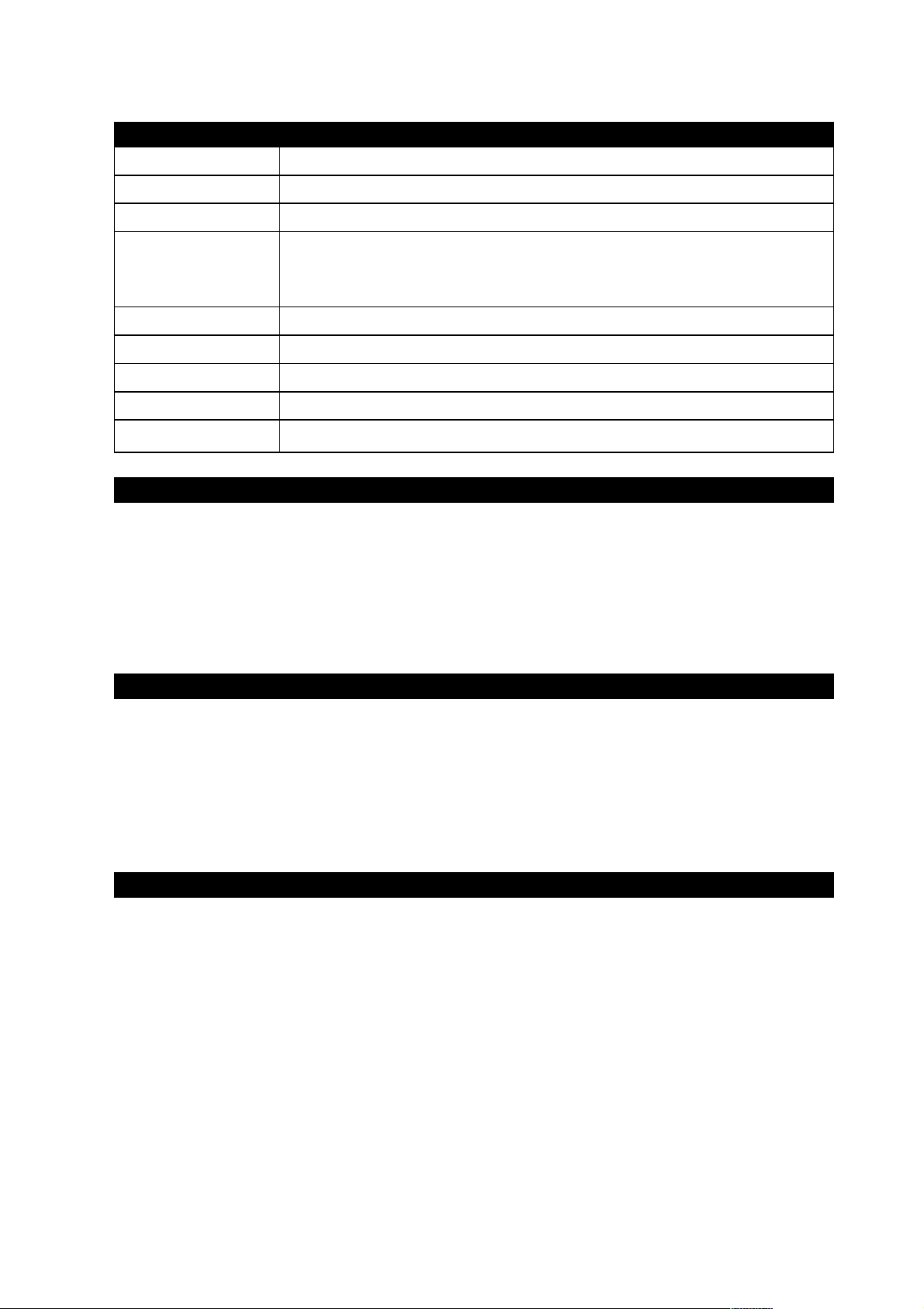

Isolation between interfaces

Power to all other 1.0 kV RMS @ 50 Hz and 60 s duration

PROFIBUS DP to all other 1.0 kV RMS @ 50 Hz and 60 s duration

Internal

electronics

Power

PROFIBUS DP

RS-485

RS-232

Only one of RS-232 or

RS-485 can be connected

simultaneoysly

5. Maintenance

No maintenance is required, as long as the unit is used as intended within the specified

conditions.

Page 9

96630-2220

6, Installation

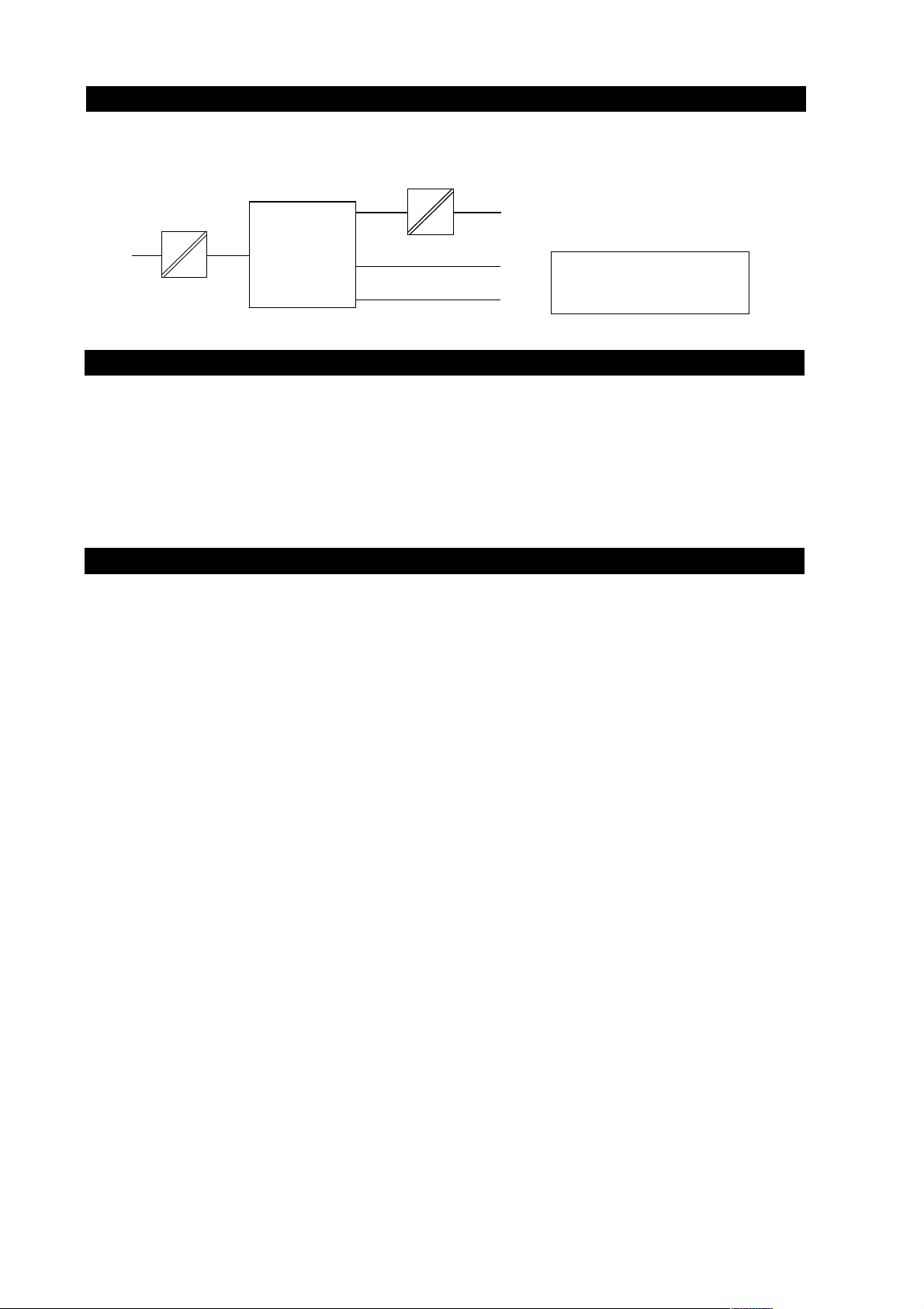

6.1 Mounting / Removal

Before mounting or removing the unit:

Prevent damage to internal electronics from electrostatic

discharges (ESD) by discharging your body to a grounding

point (e.g. use of wrist strap).

Prevent access to hazardous voltages by disconnecting the

unit from AC/DC mains supply and all other electrical

connections.

Mounting

This unit should be mounted on 35 mm DIN-rail which is horizontally mounted on a wall

or cabinet backplate.

This unit uses convection cooling.To avoid obstructing the airflow around the unit,

use the following spacing rules. Recommended spacing 25 mm (1.0 inch) above/below

and 10 mm (0.4 inches) left/right the unit.

Snap on mounting, see figure

Removal

Press down the black support at the back of the unit

using a screwdriver, see figure.

10 mm *

(0.4 inches)

25 mm

25 mm

* Spacing (left/right) recommended

for full operating temperature range

!

C

I

L

C

!

K

Page 10

10 6630-2220

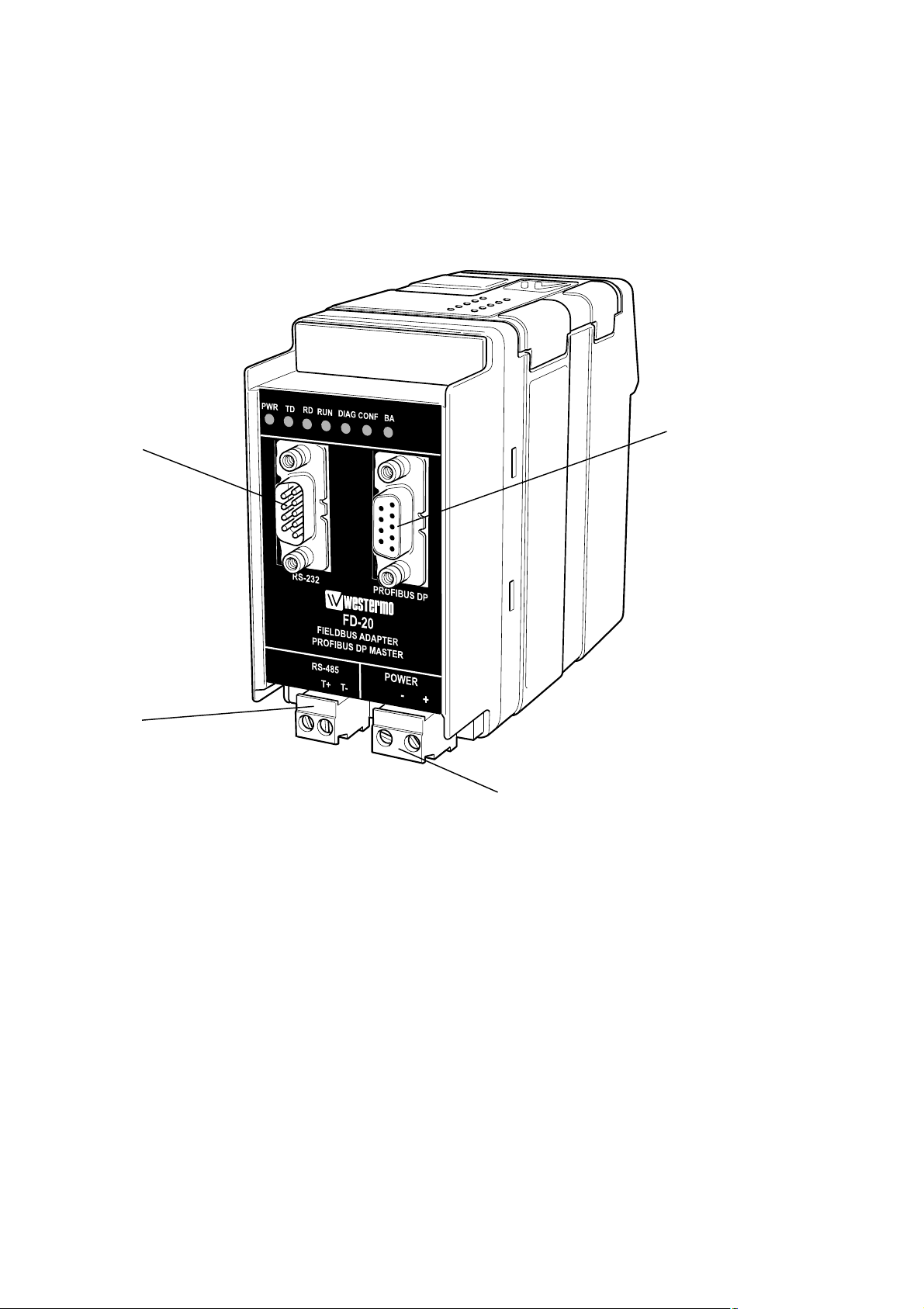

6.2 Connections

PROFIBUS DP

Power

RS-232

RS-485

Page 11

116630-2220

6.2.1 Power

2-pos screw terminal Direction Description

No. 1 In 0 VDC (–)

No. 2 In +12 to +48 VDC (+)

6.2.4 RS-485

2-pos Detachable screw terminal Direction Description

No. 1 In/Out Transmit/Receive T/R+ (T+)

No. 2 In/Out Transmit/Receive T/R– (T–)

6.2.2 PROFIBUS DP

9-pos D-sub Direction Description

No. 1 – –

No. 3 – –

No. 3 In/Out RxD/TxD-P

No. 4 Out CNTR-P

No. 5 – DGND

No. 6 Out VP

No. 7 – –

No. 8 In/Out RxD/TxD-N

No. 9 – DGND

6.2.3 RS-232 (DTE)

9-pos D-sub Direction Description

No. 1 – –

No. 2 In Receive Data (RD)

No. 3 Out Transmit Data (TD)

No. 4 Out Data Terminal Ready (DTR)

No. 5 – Signal ground (SG)

No. 6 – –

No. 7 Out Request To Send (RTS)

No. 8 In Clear To Send (CTS)

No. 9 – –

1

2

1

2

5

4

3

2

1

9

8

7

6

1

2

3

4

5

6

7

8

9

Female

Male

Page 12

12 6630-2220

6.3 Indicators

6.3.1 LED indicators

PWR On In service (power)

Off Out of service

TD On Transmit serial (RS-232/485) data

Off –

RD On Receive serial (RS-232/485) data

Off –

RUN On Running, PROFIBUS DP and serial (RS-232/485)

transfer in operation. Exchanging data with all slaves.

Flashing (2 Hz) PROFIBUS DP error,

e.g. missed data exchange with a slave

Off –

DIAG On Stat_Diag (static diagnostics) set

Off –

CONF On Configuration mode

Flashing (2 Hz) Missed or invalid configuration

Flashing (once) The received serial (RS-232/485) data length ≠

slaves output data length (as defined by configuration)

Off –

BA On PROFIBUS DP in operation

Flashing (2 Hz) Failed PROFIBUS DP master initiation

Off –

Page 13

136630-2220

6.4 Configuration

Configuration is divided into two parts:

… Serial transfer configuration, by DIP-switch settings in the FD-20.

… PROFIBUS DP Master configuration, using SyCon

®

a PC based universal system

configurator

6.4.1 DIP switch settings

DIP-switches are accessable under the lid on top of the unit. DIP-switches are

used to configure the unit.

Warning!

Prevent damage to internal electronics from electrostatic discharges (ESD) by

discharging your body to a grounding point (e.g. use of wrist strap), before the

lid on top of the unit is removed.

Warning! Do not open connected equipment.

Prevent access to hazardous voltages by disconnecting the unit from AC/DC

mains supply and all other electrical connections.

!

!

Page 14

14 6630-2220

S3:1–8 S2:1–8 S1:1–8

Switch 1

ON

12345678

S1

No termination (RS-485)

ON

12345678

S1

Termination with fail-safe

(RS-485)

ON

12345678

S1

Data control

ON

12345678

S1

RTS/CTS control

ON

12345678

S1

RS-232 as serial

transfer port

ON

12345678

S1

RS-485 as serial

transfer port

ON

12345678

S1

2 ms turning time

Factory setting

ON

12345678

S1

No termination (RS-485)

Data control

RS-232 as serial transfer port

No turning time

5 s timeout allowed between received frames

No serial transfer at Stat_Diag (static diagnostics)

Reset slaves output data at running interrupt (RUN-LED off)

ON

12345678

S2

Default transfer setting

9 600 bit/s, 8 data bits,

no parity, 1 stop bit

ON

12345678

S3

Configuration mode, SyCon

®

* When this switch is selected, the slaves output remain at serial transfer interruption. To ensure that

the slaves output remain even at PROFIBUS DP interruption as well as power supply interruption or

restart of FD-20, select this switch together with selecting Controlled release of communication by the

application program in DP Master settings window (accessible from the Master Configuration window)

during the SyCon

®

configuration.

ON

12345678

S1

100 ms turning time

ON

12345678

S1

Timeout, 5 s allowed

between received frames

ON

12345678

S1

Timeout, 40 s allowed

between received frames

ON

12345678

S1

No serial transfer at

Stat_Diag (static diagnostics)

ON

12345678

S1

Serial transfer even

at Stat_Diag

(static diagnostics)

ON

12345678

S1

Stop the data exchange

with slaves at serial

transfer timeout

ON

12345678

S1

Continue the data exchange

with slaves at serial transfer

timeout*

NOTE

DIP-switch alterations are only

effective after a power on.

Page 15

38.4 kbit/s

156630-2220

Switch 2

ON

12345678

S2

9 600 bit/s, 8 data bits,

no parity, 1 stop bit

ON

12345678

S2

1 200 bit/s

ON

12345678

S2

2 400 bit/s

ON

12345678

S2

4 800 bit/s

ON

12345678

S2

9 600 bit/s

ON

12345678

S2

14.4 kbit/s

ON

12345678

S2

19.2 kbit/s

ON

12345678

S2

57.6 kbit/s

ON

12345678

S2

115.2 kbit/s

Switch 3

ON

12345678

S3

Serial transfer mode,

point to point

ON

12345678

S3

Configuration mode,

SyCon

®

ON

12345678

S3

Serial transfer mode,

addressed with address range

1–254

(binary 1000 0000 – 0111 1111)

E.G.

Addr. 1 = 1000 0000

Addr. 254 = 0111 1111)

ON

12345678

S2

8 data bits, No parity

ON

12345678

S2

8 data bits, Even parity

ON

12345678

S2

8 data bits, Odd parity

ON

12345678

S2

1 stop bit

ON

12345678

S2

2 stop bits

S2:7 används ej

ON

12345678

S2

Page 16

16 6630-2220

6.4.2 On-line configuration using SyCon®, a universal System

Configurator

This part of the installation guide describes the usage of the SyCon®(universal SYstem

CONfigurator) software to perform an on-line configuration of the PROFIBUS DP

Master within the FD-20. For software installation details and general SyCon

®

operation,

please see the “SyCon

®

Installation manual” on the CD, supplied with the FD-20.

Required items

… PC with installed System Configurator SyCon

®

.

… FD-20 with power supply.

… DTE-DTE RS-232 serial cable (crossover/null modem cable).

… PROFIBUS DP network with connected slaves.

Not necessary, but makes correct configuration easier.

6.4.2.1 Initiate PROFIBUS DP Master Configuration

… Set the FD-20 to configuration mode by setting DIP-switch S1 to S3 to factory default

setting (all positions on S1 and S2 to off and all positions on S3 to on).

… Connect a DTE-DTE RS-232 serial cable (crossover/null modem) to the serial port of

the PC and RS-232 port of the FD-20.

… Power on the FD-20 and wait for the CONF LED to activate.

… Start SyCon

®

on the PC.

6.4.2.1.1 The first run (no saved project), Initiate communication

… Initiate communication with the FD-20 by selecting Online > Start communica-

tion and assign the Communication Interface (CIF) Serial Driver. This serial driver is

used by the FD-20.

Figure 1: CIF driver selection

Page 17

176630-2220

… Press Connect COM X to establish a connection (X is the PC serial port).

The system configurator sends a request to the corresponding COM port

interface and polls the firmware of the FD-20. Name,Type etc. will indicate

when a device is connected. Select the COM port tick box and press OK.

6.4.2.2 PROFIBUS DP Master configuration using SyCon

®

Below we have described the most essential parts of a FD-20 Master configuration. For

more details, use the SyCon

®

help facilities by selecting Help > Help Topics....

6.4.2.2.1 Create a new configuration

Select File > New, choose PROFIBUS and press OK.The PROFIBUS configuration

window will open after about 10s, a vertical line to the left of the window.

… The name of your configuration file can be assigned now or when the configuration is

completed by selecting File > Save as, choose a project name and store under the

folder Project.

6.4.2.2.2 Open an existing project

Select File > Open, choose project (*.pb) and press Open.

Figure 3: Fieldbus selection

Figure 2: CIF serial driver assignment

Note: The ”Connect COM X” will not be activ if a projekt window allready are open.

Page 18

18 6630-2220

6.4.2.2.3 GSD file

When SyCon®is started, the System Configurator automatically loads all the GSD files

stored in the GSD directory.The device names are placed into an internal list. During

configuration, device-specific data is loaded directly from the GSD files.

If a DP Slave device does not appear in the selection list, then a corresponding GSD file

must be copied into the GSD directory by:

… Select File > Copy GSD, or

… Copy the GSD file into the SyCon

®

GSD directory with Internet Windows Explorer

and then retrieve the GSD files into the GSD directory with Settings > Path

and OK

6.4.2.2.4 Insert PROFIBUS DP Master

… Click on the symbol in figure 5 or choose the Insert > Master menu and the insert

master pointer will be displayed, a left arrow and letter M.

Click on the position where the Master is to be inserted.The dialog box, from which a

master can be chosen, then opens.

Select CIF30-DPM / CIF104-DPM /-R as the master for the FD-20, by clicking on it in

the list of available masters and then click the Add button to put this master in the

selected masters list. Press OK to confirm the selection.

Figure 4: GSD files and bitmaps location

Figure 5:The insert master button

Figure 6: Master selection dialog box

The insert master pointer

Page 19

196630-2220

6.4.2.2.6 Insert PROFIBUS DP Slave

… Click on the symbol or choose the Insert > Slave menu to get the Insert slave

pointer, a left arrow and letter S.

… Click on the position where the slave is to be inserted.The dialog box, from which

one or more slaves can be selected, will open.

… Select a Slave by clicking on it in the list Available slaves and then click the Add>>

button to put this slave into the Selected slaves list. Several different slaves can be

selected, as well as the same slave several times. Once you have selected the required

slaves press OK.

6.4.2.2.5 PROFIBUS DP Master configuration

Double click on the master symbol or set the focus on to the master (left mouse click)

and then select Settings > Master Configuration, to open the master configuration

window. The description and the station address can be set in this window.

Set the Auto addressing check box. Note: automatic addressing is recommended for

the DP Master.The addresses are allocated from 0 and incremented in accordance with

the entry sequence of the Slaves before downloading and can be viewed and checked in

the View > Address Table. Click OK

Figure 7: Master configuration

Figure 8:The insert slave button The insert slave pointer

Page 20

20 6630-2220

The Available slaves list on the left displays all the slave devices whose GSD files have

been loaded into the GSD directory.A filter can be used to limit the selection list to

slave type and vendor (manufacturer).The slave can be added to the right-hand list with a

double mouse click or with the Add button. All devices in the right-hand list are assigned

to the master shown in the window above the list. If the slaves are selected individually,

then each slave can be allocated a Station address as well as a name in the Description

field. For every slave entered in the right-hand list, the station address count is automatically incremented by one but can be overwritten by the user in the Station address field.

6.4.2.2.7 PROFIBUS DP Slave configuration

Double click the PROFIBUS DP slave device symbol or click the symbol with the left

mouse button and then choose the Settings > Slave Configuration, to open the

slave configuration window.The slave-specific configuration is carried out in this window.

Here, the modules and their addresses are allocated into the process data memory

of the master.

Note 1: The offset addresses refer to the addressing of the data in the Master!

The address information does not refer to the addressing of the data in

the Slave! The Slave organises its own data addressing.

The selection list (upper list) shows all the possible slave modules. In the case of a simple

slave, one module is shown and this is automatically copied into the configuration list

(lower list). In the case of a modular slave, the user must select the required modules and

transfer these by means of a double click or transfer it using the Append Module

button into the configuration list (lower list).

For configuration of slave modules (selection of modules), proceed as follows:

… Transfer all the required modules from the selection list (upper list) into the

configuration list (lower list) by a double click or using the Append Module button.

Click on OK when configuration of this slave is complete.

Figure 9: Insert slave

Page 21

216630-2220

Note 2: The sequence of the modules in the configuration list (lower list) is important

and must be identical to the actual slave.Typically, the sequence follows the

actual physical sequence. There are slaves to which this rule does not apply.

For instance analogue modules must be entered before digital modules.

Note 3: The DP slaves utilize the Watchdog Control setting in order to detect

communication errors to the assigned DP Master.When the DP slave detects

a break in an established connection, defined by a watchdog timeout, the slave

carries out an independent reset and puts all the outputs into a secure condition.

Caution:When the Watchdog Control has been deactivated, it is possible

that the outputs are not securely reset by the slave if the connection is lost.

Note 4: Activate Device in actual configuration must be selected. If not, no data

exchange will occur from the bus to this slave.

Figure 10: Slave configuration

Page 22

22 6630-2220

PROFIBUS DP data rate

PROFIBUS DP data rate can be set in the Settings > Bus Parameters menu.

… After a successful configuration the FD-20 must be powered off and the DIP-switches

set to the desired operational mode, before it is powered on again.

Note 1: Before the download is carried out, the configuration is tested by the

Configurator.The most common cause of error is overlapping of addresses in

the process data image.This will not occur if addresses in the process data

image are assigned automatically, by having the Auto addressing button

checked in the Master Configuration window.

Note 2: The configuration is transferred into the FD-20s PROFIBUS DP Master and

stored in non-volatile memory (FLASH).

Note 3: After the download, the master carries out an internal restart and starts the

communications providing the Automatic Release of Communication by

the Device setting has been made in the DP Master Settings.

6.4.2.3 Load the configuration to the FD-20

… When master and slaves has been inserted, click on the master symbol with the left

mouse.

… In order to release the configuration and network access, a transfer (Load) to the

FD-20 must be carried out on the Online > Download menu.A warning will appear

that communications on the PROFIBUS will be interrupted.This warning must be con-

firmed.

Note: If “Driver select” menu pops up, see “The first initiation (no saved project),

Initiate communication” section.

Figure 11: PROFIBUS DP data rate setting

Figure 12: Configuration download to FD-20

Page 23

236630-2220

6.4.2.4 Store configuration

… A configuration file can be assigned now or when the configuration is complete by

selecting File > Save as, choose a project name and store in the Project folder.

… If this configuration has not previous been saved with the project file, the File > Save

As menu must be used to store the configuration, else the File > Save menu can be

used.

6.4.2.5 Diagnostics functions

The most important diagnostic functions are described below, for further diagnostic

information use the Help > Help Topics.. menu.

Note: The FD-20 must be in configuration mode to get access to the diagnostics

functions. See “Initiate PROFIBUS DP Master Configuration” section.

6.4.2.5.1 Live list, all devices

Click on the master symbol with the left mouse button.Then select the Online > Live

List menu and obtain an overview of all active devices on the PROFIBUS network.

Figure 13: Live list

A green highlighted number shows a master and blue number a slave, where the number

indicates the station address.The meaning of the other colours is given in the list above

the table.

Page 24

24 6630-2220

6.4.2.5.2 Debug mode, PROFIBUS DP and Slave diagnostic

Click on the master symbol with the left mouse button.Then select the Online > Start

Debug Mode menu.After starting the debugger SyCon

®

cyclically interrogates the status of the PROFIBUS DP network and the individual conditions of the attached devices. If

there is an error on a device the bus line to this slave is drawn in red otherwise the line

will be is green.

To end Debug Mode select the menu Online > Stop Debug Mode.

If diagnostic information is available for a specific device while running debug mode, the

text Diag appears in red next to the device icon.To get further device specific diagnostic

information then double click on the device itself or set the focus on the device and

select Online > Device Diagnostic.

To check that the I/O modules are correctly configured, click on Compare

Configuration.The SyCon

®

configuration and the actual configuration (I/O modules)

must be identical.

To get detailed information about the slave diagnostics, see Help > Help Topics..

and search for “PROFIBUS DP Device Diagnostics” under the index.

Figure 14: Debug mode

Figure 15: Slave diagnostic

Page 25

256630-2220

6.4.2.5.3 Global State Field

Click on the master symbol with the left mouse button.Then select the Online >

Global State Field menu. A display window opens in which the cyclic statuses of the

bus condition and the connected devices are shown.

Figure 16: Global state

The first row shows the main state of the master.This can have the condition

OPERATE or STOP. The next row shows individual bus errors.A current error

is shown in a red field.The meanings of the individual abbreviations are shown below.

TOUT Timeout error, the device has detected an expired supervision timeout caused

by rejected PROFIBUS telegrams.

NRDY Host not ready notification, indicates if the host program has set its state to

operative or not. If this bit is set the host program is not ready to communicate.

EVE Event error, the device has detected bus short circuits.The number of detected

events is stored in the bus statistic information variable.The bit will be set when

the first event is detected and will not be cleared.

FAT Fatal error, because of a serious bus error, no further bus communication is

possible.

NEXC Non exchange error, at least one slave has not reached the data exchange state

and no process data can be exchanged.

Page 26

26 6630-2220

ACLR Auto clear error, the device stopped communication to all slaves and reached

the auto-clear end state.

CTRL Control error, parameterisation error.

The device specific status bits, Parameterised Devices,Activated Devices and

Devices with Diagnostic are shown if you click on the respective buttons.

The activated addresses are shown as coloured numbers.This application updates

online the status in the global state field.You can see the diagnostics by double clicking

on a highlighted device station address.

Page 27

PROFIBUS DP

GSD-file HIL_7505.GSD

Device type DP Master (Class 1)

Address range 0 to 125 (Default address=0)

Serial transfer

Transfer type Point to point Addressed

Seriell adress – 1 to 254

Transfer initiation Passive. FD-20 reply after a correct received frame

Transfer check 16 bit CRC

Allowed timeout between Up to 5 or 40 s, set by DIP-switch (S1:6)

correct received frames

Allowed timeout between Up to 100 ms

correct received frames

Turning time 2 or 100 ms, set by DIP-switch (S1:5)

Serial transfer of PROFIBUS DP data

Number of modules Unlimited (depend on remote Fieldbus adapter)

Length of input data Up to 249 bytes

Length of output data Up to 249 bytes

Data location Slaves: In increased address order

Modules: In order as defined by configuration tool

Running, PROFIBUS DP • Correct received frame with correct data length, and

and serial (RS-232/485) • All slaves exchanging PROFIBUS DP data, and

transfer in operation, if: • No Stat_Diag (static diagnostics), or

• Ignored Stat_Diag (static diagnostics), set by DIP-switch

(S1:7)

Serial transfer timeout • Stop the data exchange with slaves

(SW 1:8 set to OFF), or

• Continue the data exchange with slaves

(SW 1:8 set to ON)

276630-2220

7. Functional description

The FD-20 acts as a stand-alone master that can control all PROFIBUS DP traffic with

connected slaves on that bus.The master can be configured, within the limits set by the

serial transfer of the input and output data.The serial link has higher priority than the

PROFIBUS DP network.

If the stop PROFIBUS data exchange on serial transfer timeout (SW 1:8 set to OFF) is

selected, PROFIBUS communication with the slaves is stopped.This eliminates the risk of

a slaves output being lost whilst the link is down.

Alternatively the PROFIBUS DP network can be run whether the serial link is operational or not, by selecting the continue data exchange with slaves at serial transfer timeout (SW 1:8 set to ON).The PROFIBUS DP traffic will be active as long as no failure

occurs on the PROFIBUS DP network.

Page 28

28 6630-2220

To ensure that the slaves output remain even at PROFIBUS DP interruption as well as

power supply interruption or restart of FD-20, select the continue data exchange with

slaves at serial transfer timeout (SW1:8) together with selecting “Controlled release of

communication by the application program” in DP Master settings window (accessible

from Master Configuration window), during the SyCon

®

configuration

A fully operational PROFIBUS DP network communicating with all slaves (not necessarily

exchanging data) is indicated by an active BA LED. Stat_Diag (static diagnostics) will be

indicated by an active DIAG LED.

As long as the FD-20 is in a run state, the data from the PROFIBUS DP slaves will be

exchanged with a remote fieldbus adapter via the serial transfer line.

Received serial data frames are indicated by the RD LED, even if there are errors.

Transmitted serial data frames are indicated by the TD LED.Transmission will occur after

receiving a correct frame and if the BA and RUN LED are active and the DIAG LED is

inactive, or if Stat_Diag (static diagnostics) is ignored.

7.1 Halt state

The FD-20 is in a halt state if the serial connection with the remote fieldbus adapter has

not been established.The RUN LED will be inactive.

The FD-20 will wait to receive a correct serial frame from a remote fieldbus adapter.

The FD-20 goes into a run state if a correct frame is received and the received data

length complies with the output data length (defined by configuration) and when the FD20 is exchanging data with all the PROFIBUS DP slaves.

Note: When the FD-20 receives a correct serial frame the PROFIBUS DP network will

be initiated (SW 1:8 set to OFF).The time to start the data exchange with all

slaves will be dependent on the number of slaves, the slave’s complexity and

PROFIBUS DP data rate. If the start time is so long that a new serial frame is

received, this new frame must be correctly received before the FD-20 goes to a

run state. Only the last received frame will be replied.

7.2 Run state

The FD-20 is in a run state if the serial connection with another fieldbus adapter has

been established, data is exchanging via the serial line and this data is exchanging with

all connected PROFIBUS DP slaves.The BA and RUN LEDs will be active.

If an error free serial frame is received, a reply will be sent after the turning time. (S1:5)

The FD-20 will go into a halt state if the time exceeds the allowed timeout since the last

correctly received frame (S1:6).

Note: If the allowed timeout between received frames is exceeded, this is indicated by

an inactive RUN LED and if “Stop the data exchange with slaves at serial transfer

timeout” (SW 1:8 set to OFF) is selected, the data exchange with all slaves is

stopped.

Page 29

296630-2220

7.3 LED error indication

PWR

Off

On

On

On

On – –

Flashing

(2 Hz)

–––

On –

On

while

receive

frame

Off – – Off

–––––

Flashing

(2 Hz)

Off

On

while

receive

frame

––

Flash

after a

received

frame

–

––––

Flashing

(2 Hz)

–

––––––

TD RD RUN DIAG CONF BA Error / Action(s)

No power supply or internal

failure / Connect power

supply

Failed PROFIBUS DP

initiation / Return product

to manufacturer

PROFIBUS DP error, such as

a bus short circuit or interrupt of bus or supply to any

slave /

• Check the bus cables,

supply of the slaves etc.

• Set to configuration mode

and use the SyCon

®

diagnostics functions to

find the error

Incorrect data received, or

PROFIBUS DP error /

• Incorrect serial data setting

or address (if addressed

mode)

• Check bus cables, power

supply of slaves etc.

• Set to configuration mode

and use the SyCon

®

diagnostics functions to

find the error

• No stored configuration

• Configuration exceed max

allowed data length /

New Master configuration

by SyCon

®

The received serial data

length ≠slaves output data

length (defined by configuration tool) / Modify remote

fieldbus adapter

configuration, or

Modify FD-20 configuration

Page 30

No slave found at

PROFIBUS DP initiation.

Check bus cables, power

supply of slaves, etc.

30 6630-2220

PWR

On –

On

while

receive

frame

Off – – On

TD RD RUN DIAG CONF BA Error / Action(s)

PROFIBUS DP operating but

incorrect data received /

Incorrect serial data setting

or address

(if addressed mode)

On – – – On – On

Stat_Diag (static diagnostics)

set by any slave / Set to

configuration mode and use

the SyCon

®

diagnostics functions to find slave and diagnostics.

–––

Flashing

(2 Hz)

Flashing

(2 Hz)

Flashing

(2 Hz)

Flashing

(2 Hz)

Page 31

Page 32

T04-0227 • 6630-2220 04.08 Mälartryck AB, Eskilstuna, Sweden

Westermo Teleindustri AB • SE-640 40 Stora Sundby, Sweden

Phone +46 16 42 80 00 Fax +46 16 42 80 01

E-mail: info@westermo.se

Westermo Web site: www.westermo.com

Westermo Teleindustri AB have distributors in several

countries, contact us for further information.

Westermo Data Communications Ltd

Unit 14 Talisman Business Centre • Duncan Road

Park Gate, Southampton • SO31 7GA

Phone: +44(0)1489 580 585 • Fax.:+44(0)1489 580586

E-Mail: sales@westermo.co.uk

Westermo Data Communications GmbH

Goethestraße 67, 68753 Waghäusel

Tel.: +49(0)7254-95400-0 • Fax.:+49(0)7254-95400-9

E-Mail: info@westermo.de

Westermo Data Communications S.A.R.L.

9 Chemin de Chilly 91160 CHAMPLAN

Tél : +33 1 69 10 21 00 • Fax : +33 1 69 10 21 01

E-mail : infos@westermo.fr

Subsidiaries

Application example

PSTN/GSM/Ethernet/leased line/

dedicated line

Serial data

Data rate

up to 115.2 kbit/s

Serial data

Data rate

up to 38.4 kbit/s

FD-20

PROFIBUS DP Master

PROFIBUS DP Slave

PROFIBUS DP Slave

PROFIBUS DP Slave

PROFIBUS DP Slave

PROFIBUS DP Slave

PROFIBUS DP Slave

PROFIBUS DP Master

FD-10

PROFIBUS DP Slave

Loading...

Loading...