Page 1

Fieldbus Adapter

INSTALLATION MANUAL

6630-2212

www.westermo.com

FD-10

©

W estermo T eleindustri AB • 2003 • REV.A

Page 2

2 6630-2212

Contents

1. Safety .................................................................................................................................................................................. 4

2. Approvals ....................................................................................................................................................................... 4

2.1. Declaration of Conformity ..................................................................................................................... 5

3. Introduction ............................................................................................................................................................... 6

3.1 Device types ....................................................................................................................................................... 6

3.2 When are FD-10 devices useful? ........................................................................................................ 6

3.3 Field of application ................................................................................................................................. 7–8

4. Specifications .................................................................................................................................................. 9–10

4.1 Interfaces .............................................................................................................................................................. 9

4.2 Insulation between interfaces ........................................................................................................... 10

4.3 Climatic environment ............................................................................................................................. 10

4.4 Mechanics ......................................................................................................................................................... 10

5. Maintenance ........................................................................................................................................................... 11

6. Installation ....................................................................................................................................................... 11–17

6.1 Mounting /Removal ................................................................................................................................... 11

6.2 Connections .................................................................................................................................................... 12

6.2.2 Power ........................................................................................................................................................ 13

6.2.3 PROFIBUS DP ................................................................................................................................... 13

6.2.4 RS-232 (DTE) ..................................................................................................................................... 13

6.2.5 RS-485 ...................................................................................................................................................... 13

6.3 Indicators .......................................................................................................................................................... 14

6.3.1 LED indicators ................................................................................................................................... 14

6.4 Configuration ................................................................................................................................................. 14

6.4.1 DIP switch settings ............................................................................................................... 14–15

6.4.2 On-line configuration by FD-Tool ....................................................................................... 16

6.4.3 Off-line configuration by FD-Tool ....................................................................................... 17

6.4.4 Save,load and modify configuration files by FD-Tool ......................................... 17

Page 3

36630-2212

7. Functional description .................................................................................................................... 18–29

7.1 Point to point and Addressed, serial transfer slave,FD-10 P .................................... 19

7.1.1 Basic configuration ........................................................................................................................ 20

7.1.1.1 Expert configuration ......................................................................................................... 21

7.1.2 PROFIBUS DP I/O data ............................................................................................................. 22

7.2 Addressed,serial transfer master,FD-10 A ............................................................................ 22

7.2.1 Basic configuration ........................................................................................................................ 22

7.2.1.1 Expert configuration ......................................................................................................... 23

7.2.2 PROFIBUS DP I/O data ........................................................................................................... 23

7.2.2.1 Output data word ...................................................................................................... 23–24

7.2.2.2 Input data word ........................................................................................................... 24–25

7.2.2.3 PROFIBUS DP communication .............................................................................. 25

7.3 Network,serial sending, FD-10 N ......................................................................................... 25–26

7.3.1 Basic configuration ........................................................................................................................ 26

7.3.1.1 Expert configuration ......................................................................................................... 26

7.3.2 PROFIBUS DP I/O data ........................................................................................................... 26

7.3.2.1 Output data word ............................................................................................................... 27

7.3.2.2 Input data word ............................................................................................................ 27–28

7.3.2.3 PROFIBUS DP communication ............................................................................... 29

Page 4

4 6630-2212

1. Safety

General:

Before using this unit,read this manual completely and gather all information on

the unit.Make sure that you understand it fully. Check that your application does

not exceed the safe operating specifications for this unit.

Before installation,maintenance or modification work:

Prevent damage to internal electronics from electrostatic discharges (ESD)

by discharging your body to a grounding point (e.g. use of wrist strap).

Prevent access to hazardous voltages by disconnecting the unit from AC/DC

mains supply and all other electrical connections.

Installation:

This unit should only be installed by qualified personnel.

This unit should only be installed in a “restricted access area”,for example

a lockable cabinet where access is restricted to service personnel only.

This unit is intended for permanent connection to the AC/DC mains supply.

The power supply wiring must be sufficiently fused,and if necessar y it must be

possible to disconnect manually from the AC/DC mains supply.Ensure compliance

to national installation regulations.

Unit with the rated voltage exceeding 42.4 V peak or 60 VDC, is defined as class I

equipment with a protective earthing conductor terminal.

Unit with the rated voltage up to 42.4 V peak or 60 VDC, is defined as class III

equipment and shall be separated from hazardous voltage by double or reinforced

insulation.

This unit uses convection cooling.To avoid obstructing the air flow around the

unit,follow the spacing recommendations (see under chapter Installation).

2. Approvals

Conformity with the Directive 89/339/EEC (Electromagnetic compatibility)

has been assessed by application of standards EN 61000-6-2 (industrial immunity)

and EN 61000-6-4 (industrial emission).

!

!

!

Page 5

56630-2212

2.1. Declaration of Conformity

e

Westermo Teleindustri AB

Declaration of conformity

The manufacturer Westermo Teleindustri AB

SE-640 40 Stora Sundby, Sweden

herewith declares that the product(s)

Type of product Model Art no Installation manual

DIN-rail Fieldbus adapter FD-10 P

FD-10 A

FD-10 N

DIN-rail Fieldbus converter FD-40 3630-1400 6630-2242

is in conformity with the following EC directive(s).

No Title

89/336/EEG Electromagnetic Compatibility (EMC-directive)

3630-1100

3630-1101

3630-1102

6630-2212

References of standards applied for this EC declaration of conformity.

No Title Issue

EN 61000-6-2 Immunity for industrial environments 2 (2001)

EN 61000-6-4 Emission standard for industrial environments 1 (2001)

Hans Levin

Technical Manager

26th May 2003

Postadress/Postal address Tel. Telefax Postgiro Bankgiro Corp. identity number Registered office

S-640 40 Stora Sundby 016-61200 016-61180 52 72 79-4 5671-5550 556385-6367 Eskilstuna

Sweden Int+46 1661200 Int+46 1661180

Org.nr/ S‰t

Page 6

6 6630-2212

3. Introduction

The FD-10 is a PROFIBUS DP slave unit that is able to transfer PROFIBUS DP data via

leased lines,dialup modems or radio systems.The FD-10 is used to interface different

PROFIBUS DP networks.

All Westermo Fieldbus Adapters use the same protocol to communicate with each other

via serial interface.

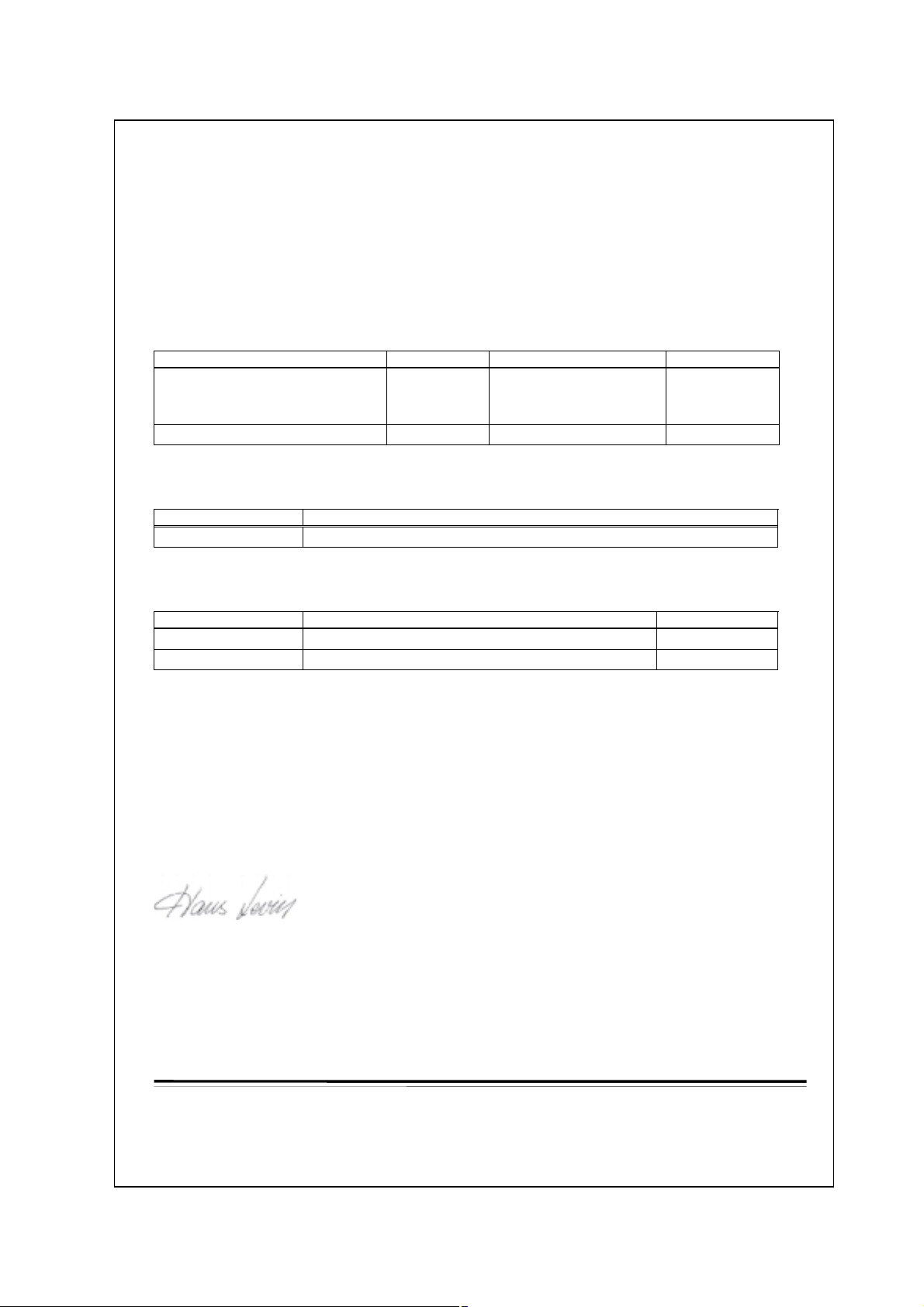

3.1 Device types

There are three different types of FD-10 devices described in this manual:

• FD-10 P Point to point and Addressed, serial transfer slave

• FD-10 A Addressed,serial transfer master

• FD-10 N Network, serial sending

All device types are based on the same hardware architecture, schematically shown

below.

3.2 When are FD-10 devices useful?

Where a PROFIBUS DP net require connection to one or some PROFIBUS DP units

which are so located,that they:

• can’t be included in the net due to the distance,or

• reduce PROFIBUS DP data rate below the rated required for the system,or

• disturbance in PROFIBUS DP line (transmission line)

FD-10 will,together with the transfer units (modem), act as a interconnecting line

between two or many PROFIBUS DP nets.The interconnection line protocol handle

retransmission due to disturbances (e.g.due to the use of radio network or moving

trolleys),without any limitations at the PROFIBUS DP net.From the PROFIBUS DP

master point of view the whole system will be seen as a single PROFIBUS DP net,while

the master has all PROFIBUS I/O data handling with FD-10.

In data

PROFIBUS DP

In buffer

15k

Serial transfer

PROFIBUS DP

Master control

Interface

Serial transfer

control

Out data

PROFIBUS DP

Out buffer

15k

Serial T ransfer

RS-232

RS-485

Power

DC

DC

PROFIBUS DP

Page 7

76630-2212

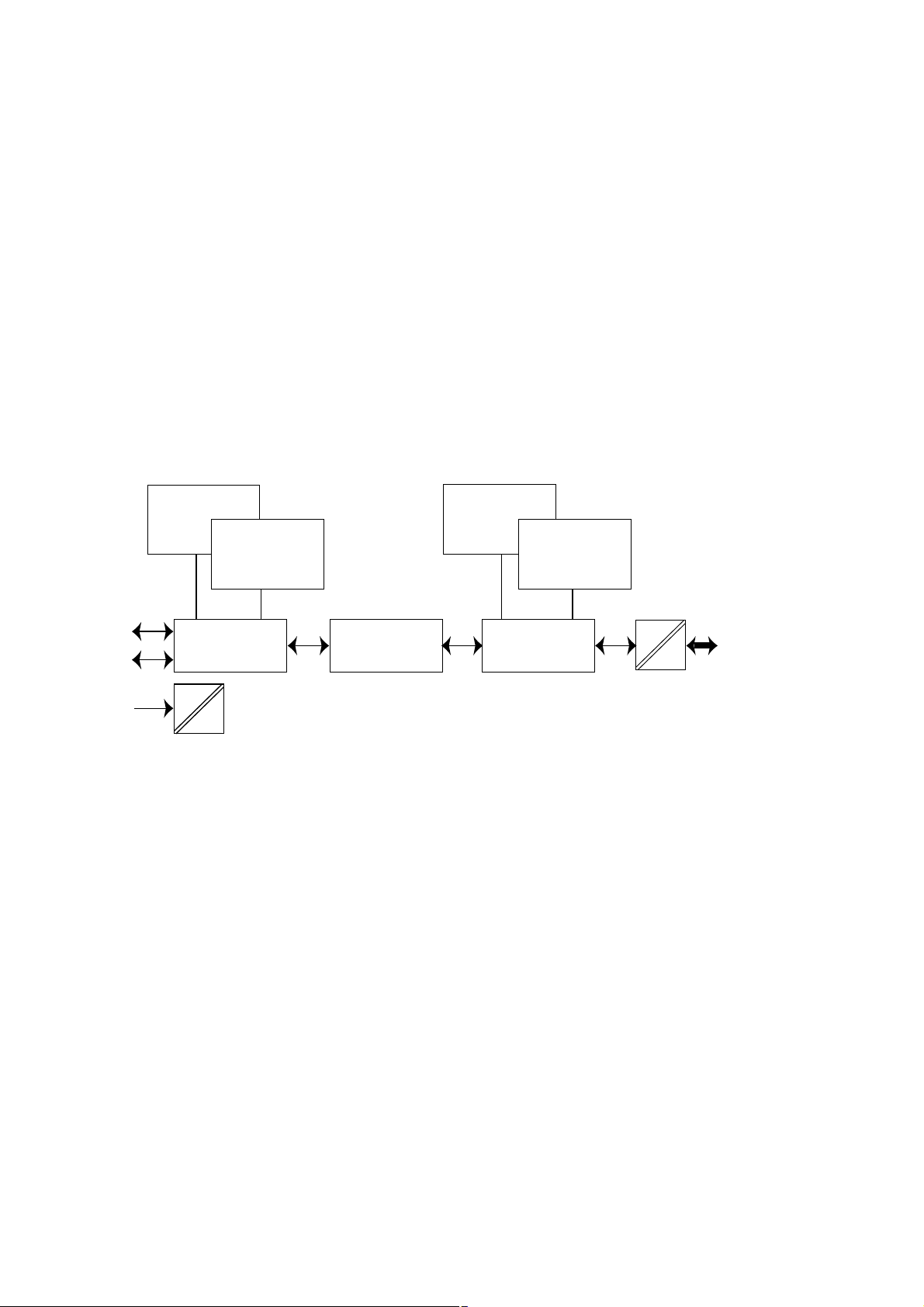

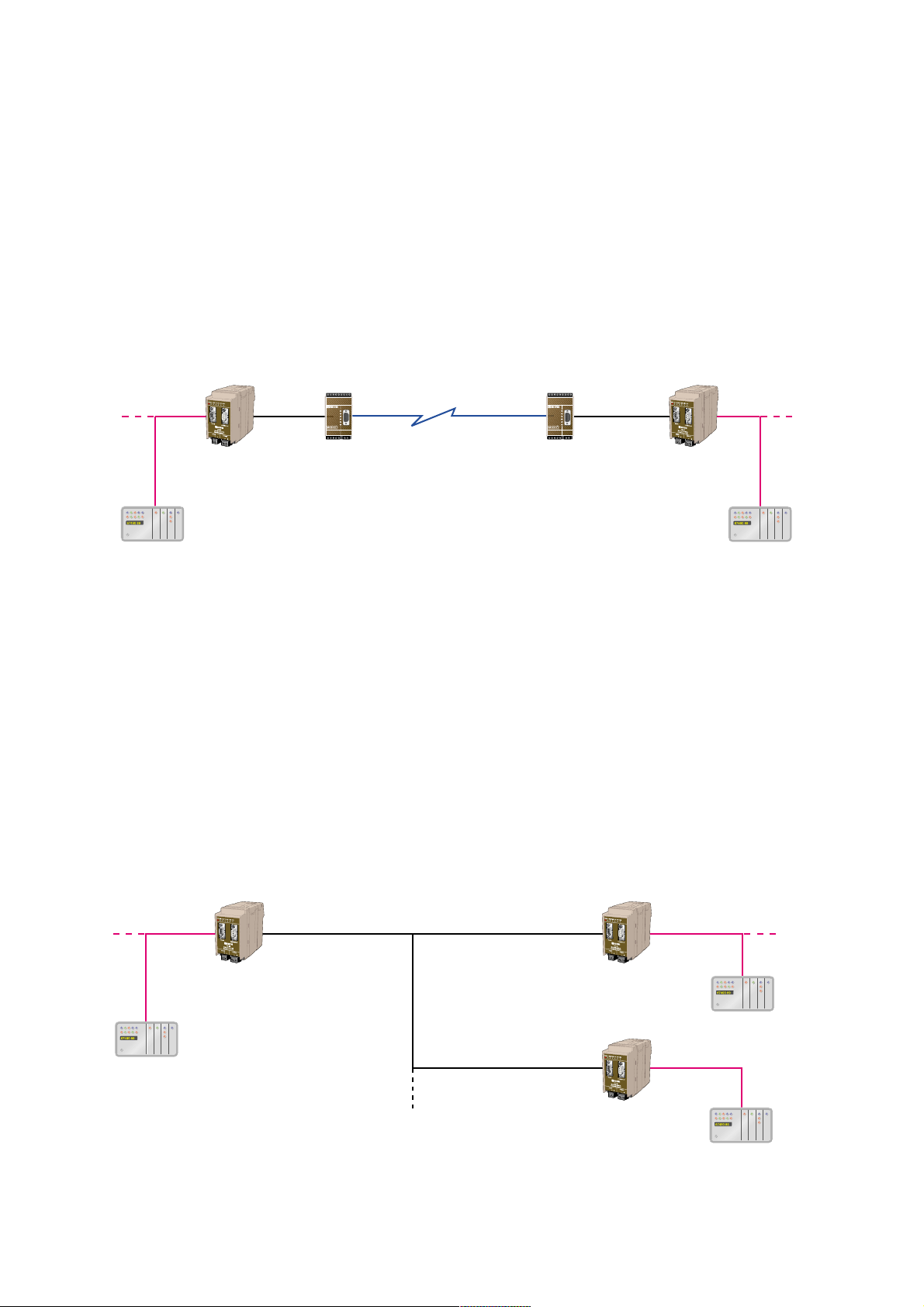

3.3 Field of application

Between Fieldbus adapters is PROFIBUS DP I/O data transferred over a transmission

line, divided in following type of applications:

• Point to point transfer

Continuous transfer of defined PROFIBUS I/O data modules between two FD-10’s.

This application is ideal when a high speed update of PROFIBUS DP data is required

and where no additional measures at installation is desired.

This application is realised by two FD-10 P (point to point mode) with an interconnecting line and modems,if required.

• Master controlled transfer (Addressed)

One transfer of defined PROFIBUS I/O data modules between two FD-10’s, on demand

from a PROFIBUS DP master. One FD-10 act as serial transfer master and can transfer

I/O data between various FD-10’s,selected by serial transfer address.This application is

ideal when a PROFIBUS DP master need connection to two,or more,independent

remote PROFIBUS DP systems.Radio system or RS-485 is typically used as transfer line.

Required additional measures,as serial transfer addressing.

This application is realised by one FD-10 A and one or many FD-10 P (addressed serial

transfer slave mode) with an interconnecting line and modems,if required.

FD-10 P

PROFIBUS DP

PROFIBUS DP

FD-10 P

Modem

(e.g PSTN*, Radio)

PROFIBUS DP

master

PROFIBUS DP

master

Modem

(e.g PSTN*, Radio)

FD-10 A FD-10 P

PROFIBUS DP

master

PROFIBUS DP

master

PROFIBUS DP

master

Serial

master

Serial

slave

Serial

slave

FD-10 P

PROFIBUS DP

PROFIBUS DP

PROFIBUS DP

* PSTN = Public Switch Telephone Transfer

123456789123456789

R+ R-T+ T- T+ T- R+ R-

CHANNEL 3

PWR

RD

TD

DCD2

DCD3

DCD4

CHANNEL 2 POWER

R+ R- T+ T12345

12-36V DC

- +

123456789123456789

R+ R-T+ T- T+ T- R+ R-

CHANNEL 3

PWR

RD

TD

DCD2

DCD3

DCD4

CHANNEL 2 POWER

R+ R- T+ T12345

12-36V DC

- +

Page 8

8 6630-2212

• Master controlled sending (Network)

Send defined PROFIBUS I/O data module once, from a FD-10 to an other.Sending data

on demand (event) from a PROFIBUS DP master.One of the included FD-10’s can send

I/O data to any other FD-10,selected by serial transfer address.This application is ideal

when data transfer between a number of PROFIBUS DP master systems is required.

Radio system or RS-485 is typically used as transfer line.Required additional measures,

as serial transfer addressing.

This application is realised by two or many FD-10 N with an interconnecting line and

modems,if required.

FD-10 N

PROFIBUS DP

master

PROFIBUS DP

PROFIBUS DP PROFIBUS DP

Modem

(e.g PSTN, Radio)

FD-10 N

PROFIBUS DP

master

Modem

(e.g PSTN, Radio)

FD-10 N

PROFIBUS DP

master

Modem

(e.g PSTN, Radio)

Page 9

96630-2212

4. Specifications

4.1 Interfaces

Power

Rated voltage 12–48 VDC

Operating voltage 9.6–57.6 VDC

Rated current 250 mA @ 12 V, 120 mA @ 24 V,60 mA @ 48 V

Rated frequency DC

Polarity Reverse polarity protected

Connection Screw terminal

Connector size 0.2–2.5 mm

2

(AWG 24–12)

Fuse To be externally fused

PROFIBUS DP

Electrical specification RS-485 / EN 50 170

Data rate 9.6, 19.2, 45.45, 93.75,187.5, 500,1 500, 3 000,6 000

and 12 000 kbit/s

Connection 9-position D-sub (female)

Termination External

Circuit type TNV-1

RS-485

Electrical specification RS-485/V.11

Data rate 1 200,2 400, 4 800,9 600, 14 400,19 200 and 38 400 bit/s

Connection 2-position screw terminal

Connector size 0.2 – 2.5 mm

2

(AWG 24-12)

Circuit type TNV-1

RS-232

Electrical specification RS-232/V.24

Data rate 1 200,2 400, 4 800,9 600, 14 400,19 200 and 38 400 bit/s

Connection 9-position D-sub,DTE

Circuit type SELV

Page 10

10 6630-2212

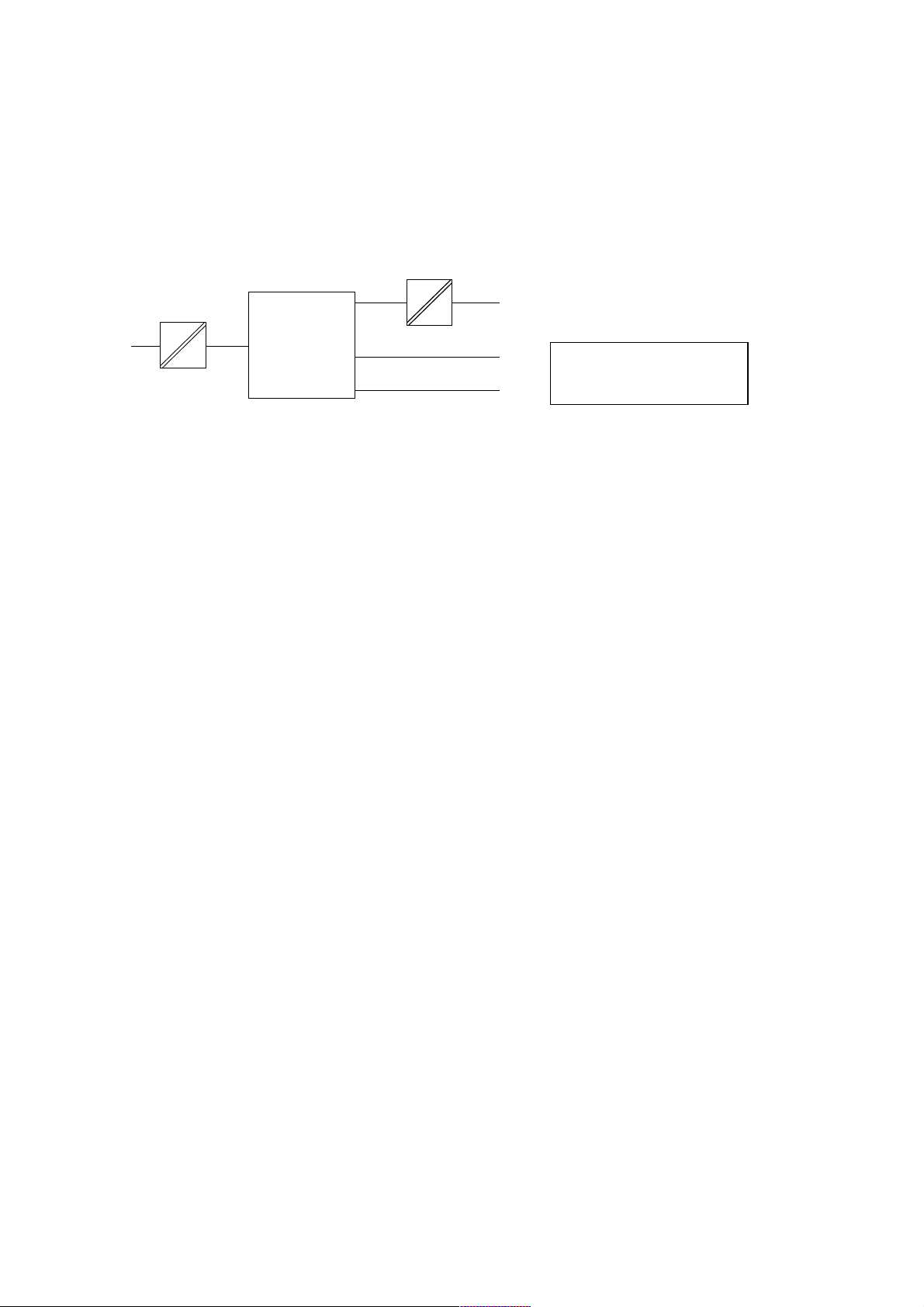

4.2 Insulation between interfaces

Power to all other 1.0 kV RMS @ 50Hz and 60 s duration

PROFIBUS DP to all other 1.0 kV RMS @ 50Hz and 60 s duration

Please note that there is no galvanic isolation between the RS-232 and the RS-485 ports so

they should not be connected simultaneously.

Internal

electronics

Power

PROFIBUS DP

RS-485

RS-232

NOTE:

Connect only one of RS-232

or RS-485 simultaneously

4.3 Climatic environment

Temperature, operating +5 to +55°C (optional industrial –25 to +70°C)

Temperature,

storage and transportation –25 to +70°C

Relative humidity,operating 5 to 95% (non-condensing)

Relative humidity,

storage and transportation 5 to 95% (condensation allowed outside packaging)

4.4 Mechanics

Dimension (W x H x D) 55 x 100 x 132 mm

Weight 0.3 kg

Mounting 35 mm DIN-rail

Degree of protection IP 20 (IEC 529)

Page 11

116630-2212

5. Maintenance

No maintenance is required, as long as the unit is used as intended within the specified

conditions.

6. Installation

6.1 Mounting /Removal

Before mounting or removing the unit:

Prevent damage to internal electronics from electrostatic discharges (ESD)

by discharging your body to a grounding point (e.g. use of wrist strap).

Prevent access to hazardous voltages by disconnecting the unit from AC/DC

mains supply and all other electrical connections.

Mounting

This unit should be mounted on 35 mm DIN-rail which is

horizontally mounted on a wall or cabinet backplate.

This unit uses convection cooling. To avoid obstructing the air

flow around the unit, use the following spacing rules.

Minimum spacing 25 mm (1.0 inch) above/below and 10 mm

(0.4 inches) left/right the unit.

Snap on mounting, see figure.

Removal

Press down the black support at the back of the unit

using a screwdriver, see figure.

Min

10 mm

25 mm

25 mm

!

CLICK!

Page 12

12 6630-2212

6.2 Connections

RS-232

PROFIBUS DP

RS-485

Power

Page 13

136630-2212

2-pos screw terminal Direction Description

No.1 – 0 V DC (–)

No.2 + +12 to +48 VDC (+)

6.2.2 Power

9-pos D-sub Direction Description

No.1 ––

No.2 ––

No.3 In/Out RxD/TxD-P

No.4 Out CNTR-P

No.5 – DGND

No.6 Out VP

No.7 ––

No.8 In/Out RxD/TxD-N

No.9 – DGND

6.2.3 PROFIBUS DP

9-pos D-sub Direction Description

No.1 ––

No.2 In Receive Data (RD)

No.3 Out Transmit Data (TD)

No.4 Out Data Terminal Ready (DTR)

No.5 – Signal ground (SG)

No.6 ––

No.7 Out Request To Send (RTS)

No.8 In Clear To Send (CTS)

No.9 ––

6.2.4 RS-232 (DTE)

1

2

2-pos screw terminal Direction Description

No.1 In/out T ransmit/Receiv e T/R+ (T+)

No.2 In/out T ransmit/Receiv e T/R– (T–)

6.2.5 RS-485

1

2

5

4

3

2

1

9

8

7

6

1

2

3

4

5

6

7

8

9

Female

Male

Page 14

14 6630-2212

6.3 Indicators

6.3.1 LED indicators

6.4 Configuration

Most of the FD-10 settings have to be carried out by Westermo FD-Tool, a PC based

configuration software,either on-line or off-line. Only RS-232 or RS-485 transfer settings

will be set by DIP switches.

6.4.1 DIP switch settings

DIP-switches are accessible under the lid on top of the unit.

Warning! Prevent damage to internal electronics from electrostatic discharges

(ESD)

by discharging your body to a grounding point (e.g. use of wrist

strap),before the lid on top of the modem is removed.

Warning! Do not open connected equipment.

Prevent access to hazardous voltages by disconnecting the unit from

AC/DC mains supply and all other electrical connections.

NOTE The change of DIP switch settings are valid only after a power on.

PWR LED on In service

LED off Out of service

BA LED on PROFIBUS DP active

LED off PROFIBUS DP inactive

CONF LED on Configuration mode

LED off Normal operation mode

TD LED on Transmit serial (RS-232/485) data

LED off –

RD LED on Receive serial (RS-232/485) data

LED off –

RTS LED on Request To Send (RTS) set

LED off –

CTS LED on Clear To Send (CTS) received active

LED off –

!

!

Page 15

156630-2212

Switch block 1

Serial transfer setting

Factory setting

S2:1-8

ON

1234

No RS-485 termination

ON

1234

RS-485 terminated by

120 Ω, with fail-safe

ON

1234

RS-232 selected as serial

transfer port, data control

ON

1234

RS-232 selected as serial

transfer port, RTS/CTS control

ON

1234

S1

RS-232 selected as serial

transfer port, data control.

No RS-485 termination

ON

1234

RS-485 selected as serial

transfer port

Note 1: Configuration by FD-Tool require factory setting (all S1 switches off).

Note 2: Switch 2 is not used.

S1:1-4

Page 16

16 6630-2212

6.4.2 On-line configuration by FD-Tool

This part will only describe the usage of FD-Tool to perform an on-line configuration.

For FD-Tool installation and general FD-Tool handling, see “FD-Tool installation manual”

on theCD,FD-Tool.

The FD-10 goes into configuration mode, a connection with FD-Tool,immediately after a

power on.The serial interface is set as follows, and should not be changed.

RS-232 9 600 bit/s no parity 8 data bits 1 stop bit data control

Initiate an on-line configuration

• Start the FD-Tool.

• Connect a DTE-DTE serial cable (zero-modem) to the serial port of the PC and the

RS-232 port of the FD-10.

• Initiate communication between the FD-Tool and the FD-10 by selecting Connect >

RS-232.The FD-Tool will attempt to get communication until a successful connection

or a manual cancel.

• Power the connected FD-10.The CONF LED of FD-10 will be active and remain so as

long as the FD-10 is in configuration mode. After some seconds, the connection will

established and the Status (to left in lower border of FD-Tool window) will be changed

from Disconnected to Connected.If the CONF LED will be inactive (after about

3 seconds),the initiation of on-line configuration is failed. If failed,check the serial

cable and that all S2 switches are set to off.Power on the device again.

• The FD-Tool shows the device type of this FD-10,present configuration, or the default

configuration whether the FD-10 is used for the first time.

Modify configuration

Configurations are defined per device type,see “Functional description”,chapter 7.

FD-10 P Point to point and Addressed, serial transfer slave

FD-10 A Addressed,serial transfer master

FD-10 N Network,serial sending

Load configuration to FD-10

• The present configuration,shown by FD-Tool, will be loaded to the FD-10 by selecting

File > Configuration > Load to device.

• This loaded configuration will be running in normal operation after a new power on

and when the CONF LED has been set to inactive.

Page 17

176630-2212

6.4.3 Off-line configuration by FD-Tool

This part will only describe the usage of FD-Tool to perform an off-line configuration.

For FD-Tool installation and general FD-Tool handling, see “FD-Tool installation manual.”

Initiate a new off-line configuration

• Start the FD-Tool.

• Select the device type by selecting File > Configuration > New (default / device)

and Select Group in Device Selection window. The selected group has to be the same

as the FD-10 device,for which the configuration will be used.

• FD-Tool will show the device type of this FD-10 for which all configuration parameters

have to be set.

Modify configuration

Configurations are defined per device type,see “Functional description”,chapter 7.

FD-10 P Point to point and Addressed, serial transfer slave

FD-10 A Addressed,serial transfer master

FD-10 N Network,serial sending

Load configuration to FD-10

• See “On-line configuration by FD-Tool”,chapter 6.4.2.

6.4.4 Save, load and modify configuration files by FD-Tool

Save configuration to disk

• The present configuration can be saved to disk as a file, to be used for future configurations of the same device type,by selecting File > Configuration > Save to disk

• An arbitrary file name can be used, saved as a *.cnf file.

Load and modify a disk stored configuration

• Load configuration from disk by selecting Configuration > Load from disk

and open the wanted configuration file (*.cnf).

• FD-Tool shows the device type of this FD-10 with the present configuration.

Page 18

18 6630-2212

Point to point Addressed Network

Device type FD-10 P FD-10 A FD-10 N

GSD-file FD-10.GSD FD-10.GSD FD-10.GSD

Device type Slave Slave Slave

Address range 0 to 126 0 to 126 0 to 126

Number Up to 8 Up to 8 2

of modules

Input data Up to 65 word/ Up to 65 word 16 word

130 byte

Output data Up to 65 word/ Up to 65 word 16 word

130 byte

Data control – One word for One word for

programming serial transfer serial transfer

control control

7. Functional description

Technical data

PROFIBUS DP data

Device

Serial transfer

Transfer type Slave Master Master

Transfer check 16 bit CRC 16 bit CRC 16 bit CRC

Transfer mode Point to Addressed Addressed Addressed

point transfer transfer sending

Serial address – 0 to 254 – 0 to 63

Connection Stat_Diag, Stat_Diag, Receive timeout, Receive

control number of timeout 1 500 ms timeout,

faild frames without 0 to 65 535 ms

1 to 255 frames

1 to 255 s

Page 19

196630-2212

7.1 Point to point and Addressed, serial transfer slave, FD-10 P

Point to point transfer

Continuous transfer of defined PROFIBUS I/O data modules from this FD-10 to an

other FD-10.

All by FD-Tool defined PROFIBUS I/O modules will be mirrored between the two

FD-10’s.Input modules of FD-10 at one side will be sent to output modules of FD-10

at the other side, and vice versa. However,note that there will be a time delay which

depends on the serial transfer time.

FD-10 continuously transfer I/O data,or try to initiate continuously transfer in the

initially stage, when the unit is in normal operation mode and the PROFIBUS DP is active,

LED CONF inactive and BA active.

Master controlled transfer (Addressed)

Wait for a received serial transfer frame including this unit’s serial transfer address.

After a correct received frame, an I/O data frame will be sent back once .

All by FD-Tool defined PROFIBUS I/O modules will be mirrored between this FD-10

and the FD-10 at the other side. Input modules of FD-10 will be sent to output modules

of FD-10 at the other side, and vice versa. Note that command and status data (including

this unit’s serial transfer address) will not be included in PROFIBUS I/O data of this

FD-10.

FD-10 can receive frames when the unit is in normal operation mode and the PROFIBUS

DP is active,LED CONF inactive and BA active.

Page 20

20 6630-2212

7.1.1 Basic configuration

Serial transfer > Transfer mode

Point – point Select Transfer slave point to point mode,with serial con-

nection to one Fieldbus Adapter. FD-10 will initiate and

begin continuous transfer of data with the other Fieldbus

Adapter.

Addressed slave Select Transfer slave addressed mode, with serial connec-

tion to one Fieldbus Adapter acting as transfer master.

FD-10 will wait for received data (including serial

address) from the Fieldbus Adapter master and send back

data once.

Address 0–254 Set this FD-10 Transfer slave address.Only needed when

Addressed slave has been selected.

Serial transfer > Serial interface

Select the desired parameters of the Serial interface.

PROFIBUS-DP > PROFIBUS DP parameters

PROFIBUS DP Address Set this FD-10 PROFIBUS DP address.

Number of I/O Modules Set the number of I/O modules used by this FD-10.

Module 1 and up to selected “Number of I/O Modules”

will be used by FD-10.

I/O module 1–4 > I/O module 1

Data type Select data type for I/O module 1.

Module type Select module type for I/O module 1.

Data length Set data length of I/O module 1.Note that data length is

related to selected data type,byte or word.Byte has a

length of 8 bit and word 16 bits.

Identifier [hex] Show the resulting identifier in hex.

The same content for all I/O modules,1 to 8. Module 1 and up to selected “Number of

I/O Modules” will be used by FD-10.

7.1.1.1 Expert configuration

Serial transfer > Expert parameters

Delay to send first byte Set the delay time before switching from send to receive,

in frame [ms] or vice versa.Default is 0. Used when serial transfer line

requires a turning time.

Max time between bytes Set the maximum allowed time between bytes in a serial

in frame [ms] frame. Default is 100. Useful when a frame will be divided

by transferring units (modem) which can cause a gap in

parts of the frame. Shall be less than “Min random delay

at initiation”.

Page 21

216630-2212

Min/max random delay Create a random delay until sending the initial frame at

at initiation [ms] point to point mode, to avoid collisions after start up or

at disturbed communication.Default is min 200 and max

500.For radio communications these times normally

need to be increased,min 500 and max 800 is recommended.

Fixed frame length Fixed 25 byte frame length.Should not be used.

20 data bytes Only when used together with old system.

Fixed frame length Fixed 37 byte frame length.Should not be used.

32 data bytes Only when used together with old system.

Variable frame length Should be selected for all Westermo Fieldbus Adapters.

1..249 data bytes

PROFIBUS-DP > Expert parameters

Enable/Disable Stat Diag When set to enable, the setting of the PROFIBUS DP

diagnostic information Stat_Diag (static diagnostics)

flag is enabled.Disable may be used when the PROFIBUS

DP master don’t handle Stat_Diag.Default is Enable.

Failed frames until set Only for Point to point transfer.

Stat Diag Set maximum number of consecutive sent frames without

any correct acknowledge.When exceeded will the

Stat_Diag flag be set.Default is 3. Can be increased if

transmission line is disturbed and that is acceptable.

Timeout until set Only for Addressed transfer.

Stat Diag Set maximum time in seconds since last received frame,

or time since device set in normal operation (power on),

without any new correct received frame. When time is

exceeded will the Stat_Diag flag be set.Default is 3. Can

be increased if it is long time between transfer of data

with this device and/or the transmission line is disturbed.

ID number Show the ID number of FD-10.Can’t be changed.

7.1.2 PROFIBUS DP I/O data

Ordinary PROFIBUS DP input and output data are used by FD-10.No additional

programming of the PROFIBUS DP master is needed for I/O data transfer.

Page 22

22 6630-2212

7.2 Addressed,serial transfer master,FD-10 A

Transfer defined PROFIBUS I/O data modules between two FD-10’s,each time on

demand by a PROFIBUS DP master.FD-10 A is the serial transfer master that transfer

I/O data between various FD-10’s,selected by serial transfer address.This serial address-

ing enable access to up to 255 independent remote PROFIBUS DP nets by only one

serial transmission line (e.g. radio system or RS-485).

By FD-Tool defined PROFIBUS I/O modules will be mirrored between FD-10 A and the

serial addressed FD-10 P at the other side.Input modules of FD-10 will be sent to output modules of FD-10 at the other side, and vice versa. Note that one data word command output and one data word status input has to be included in PROFIBUS I/O data

of FD-10 A.The command control the serial transfer and the status return information

about the transfer.

FD-10 can transfer frames when the unit is in normal operation mode and the

PROFIBUS DP is active,LED CONF inactive and BA active.

7.2.1 Basic configuration

Serial transfer > Serial interface

Select the desired parameters of the Serial interface.

PROFIBUS-DP > PROFIBUS DP parameters

PROFIBUS DP Address Set this FD-10 PROFIBUS DP address.

Number of I/O Modules Set the number of I/O modules used by this FD-10.

Module 1 and up to selected “Number of I/O Modules”

will be used by FD-10.

I/O module 1–4 > I/O module 1

Data type Select data type for I/O module 1.

Module type Select module type for I/O module 1.

Data length Set data length of I/O module 1.Note that data length is

related to selected data type,byte or word.Byte has a

length of 8 bit and word 16 bits.

Identifier [hex] Show the resulting identifier in hex.

The same content for all I/O modules,1 to 8. Module 1 and up to selected

“Number of I/O Modules” will be used by FD-10.

Page 23

236630-2212

7.2.1.1 Expert configuration

Serial transfer > Expert parameters

Max time between bytes Set the maximum allowed time between bytes in a serial

in frame [ms] frame. Default is 100. Useful when a frame will be divided

by transferring units (modem) which can cause a gap in

parts of the frame.

Fixed frame length Fixed 25 byte frame length.Should not be used.

20 data bytes Only when used together with old system.

Fixed frame length Fixed 37 byte frame length.Should not be used.

32 data bytes Only when used together with old system.

Variable frame length Should be selected for all Westermo Fieldbus Adapters.

1..249 data bytes

PROFIBUS-DP > Expert parameters

ID number Show the ID number of FD-10.Can’t be changed.

CPU type Hardware information.For service purpose only.

Can’t be changed.

7.2.2 PROFIBUS DP I/O data

Ordinary PROFIBUS DP I/O data are used by FD-10 A, including one data word in and

one out for the serial transfer control. Additional programming of the PROFIBUS DP

master to control I/O data transfer is needed,as defined below.

7.2.2.1 Output data word

Data transmitted from PROFIBUS DP master to FD-10 A.The first word is the serial

transfer command word and the remaining 2 to 65 words are ordinary output data

sent to addressed remote Fieldbus Adapter.

Out word 1 high byte (bit 15..8) is the serial transfer command byte,

with following content:

EN ENable FD-10 (bit15).

This bit must always be set high (1) for normal operation. When set, FD-10

indicates data set ready by the EN bit being set in the Input status word.EN

bit set to low (0) disable FD-10.

SDO Send actual Data Once , toggle bit (bit 14).

When this toggle bit change state, all out words are taken from DP output

data words and transmitted directly over the serial transfer interface of FD-10.

Word 15 High byte 8 7 Low byte 0

1 EN SDO – CNF RES – – – Transfer slave address, in range 0–254

2 Out data word 1, high byte Out data word 1, low byte

…… …

…… …

65 Out data word 64, high byte Out data word 64, low byte

Page 24

24 6630-2212

CNF CoNFiguration mode (bit 12).

For testing purpose only.

This bit is set low (0) during the normal operating mode of the FD-10. This bit

is set high (1) in order to switch the FD-10 over from normal operating mode

to configuration mode via PROFIBUS DP.

RES RESet read back status,toggle bit (bit 11).

When this toggle bit change state, it will reset read back status of ACK, TO

and all data input words.

Out word 1 low byte (bit 7..0) is the serial transfer address,with following content:

Transfer slave address of the Fieldbus Adapter to which this frame shall be

sent.Serial transfer slave address,in range 0 to 254.

Out word 2 to 65 is the output data,with following content:

Word 2 High: Output byte 1 Low: Output byte 2

Word 3 High: Output byte 3 Low: Output byte 4

......... ........ ......

Word 65 High:Output byte 127 Low: Output byte 128.

7.2.2.2 Input data word

Data is transmitted from the FD-10 A to the PROFIBUS DP master.The first word is the

added status word and the remaining 2 to 65 words are ordinary input data received

from the output word addressed remote Fieldbus Adapter.

Input word 1 high byte (bit 15..8) is the serial transfer status byte, with following content:

ST Status of serial transfer command FD-10 (bit15).

Set high (1) when the received command has been accepted by the FD-10.Set

low (0) if the received command has not been accepted.

DV Data Valid (bit 13).

For testing purpose only.

Acknowledgement of the command CNF.

ACK ACKnowledgement of serial transfer (bit 11).

Set high (1) when serial transfer sent output data to a remote FD-10 has

resulted in a received frame with input data from the remote FD-10.

TO Time Out received serial transfer (bit 10).

Set high (1) when the last serial transfer of output data to a remote FD-10 has

not resulted in any received frame within 1500 ms.

In word 1 low byte (bit 7..0) is not used.

In word 2 to 65 is the input data,with following content:

Word 15 High byte 8 7 Low byte 0

1 ST – DV – ACK TO – – – – – – – – – –

2 In data word 1, high byte In data word 1, low byte

…… …

…… …

65 In data word 64, high byte In data word 64, low byte

Page 25

256630-2212

Word 2 High:Input byte 1 Low:Input byte 2

Word 3 High: Input byte 3 Low: Input byte 4

......... ........ ......

Word 65 High:Input byte 127 Low: Input byte 128.

7.2.2.3 PROFIBUS DP communication

Required PROFIBUS DP communication sequence,from a PROFIBUS DP master unit to

FD-10 A,to get access and data exchange with remote Fieldbus Adapters.

Preparing for data exchange:

1. Enable normal operation access with FD-10 by command EN

Out word 1,bit 15 set high (1).

2. Verify accepted EN command by checking status ST.

In word 1,bit 15 shall be high (1).

Data exchange with a remote Fieldbus Adapter:

1. Set the Transfer slave address.

Out word 1,low byte to current serial transfer address.

2. Set Out data (up to 64 words) to this Transfer slave.

Out word 2 ...65.

3. Reset last received Input data and status by the command RES.

Out word 1,change state of toggle bit 11.

4. Transmit output data over serial transfer line by the command SDO.

Out word 1,change state of toggle bit 14.

5. Verify correct sent and received data by checking status ACK.

In word 1,bit 11 shall be high (1).

• Or,incorrect sent and received data,has not been received

within 1500 ms by checking status TO.

In word 1,bit 10 is set to high (1) in case of time out.

6. If correct received data will ACK be high (1) and TO low (0).

Read In data (up to 64 word) from addressed Fieldbus Adapter.

In word 2 ...65.

Page 26

7.3 Network,serial sending, FD-10 N

Send PROFIBUS in data from one FD-10 to an other FD-10 to be set as PROFIBUS out

data,on demand (event) by the PROFIBUS DP master in the sending PROFIBUS DP net.

One of the included FD-10’s can send I/O data to any other FD-10,selected by serial

transfer address.Note that the first data word,command output and one data word status input has to be included in PROFIBUS I/O data of FD-10.

Arbitrary FD-10 can send a frame to an other FD-10 at any time.This serial addressing

enable access to up to 64 independent remote PROFIBUS DP nets by only one serial

transmission line (e.g. radio system or RS-485).To reduce collisions on the transmission

line, the frequency or time between events resulting in sending has to be limited.

The degree of limitation depend on the number of FD-10’s and data rate of the serial

transfer.

FD-10 can send frames when the unit is in normal operation mode and the PROFIBUS

DP is active,LED CONF inactive and BA active.

7.3.1 Basic configuration

Serial transfer > Transfer mode

Network Address 0–64 Set this Transfer address of this FD-10.

Serial transfer > Serial interface

Select the desired parameters of the Serial interface.

PROFIBUS-DP > PROFIBUS DP parameters

PROFIBUS DP Address Set this FD-10 PROFIBUS DP address.

7.3.1.1 Expert configuration

Serial transfer > Expert parameters

Acknowledge timeout [ms] Set the maximum allowed time from sending a serial

transfer frame until received acknowledge.

The status TO will be set high (1) when this time has

been exceeded without any received acknowledge.

Default is 500.

Max time between bytes in Set the maximum allowed time between bytes in a serial

frame [ms] frame. Default is 100.Useful when a frame will be divided

by transferring units which can cause a gap in parts of the

frame.

PROFIBUS-DP > Expert parameters

ID number Show the ID number of FD-10.Can’t be changed.

I/O module 1–2 > I/O module 1

Identifier [hex] Show the 16 word input Identifier in hex.

Can’t be changed.

26 6630-2212

Page 27

276630-2212

I/O module 1–2 > I/O module 2

Identifier [hex] Show the 16 word output Identifier in hex.

Can’t be changed.

7.3.2 PROFIBUS DP I/O data

Ordinary 16 word PROFIBUS DP I/O data are used by FD-10 N,including one data word

in and one out for the serial transfer control. Additional programming of the PROFIBUS

DP master to control I/O data transfer is needed,as defined below.

7.3.2.1 Output data word

Data transmitted from PROFIBUS DP master to FD-10 N. The first word is the serial

transfer command word and the remaining 2 to 15 words are ordinary output data

sent to addressed remote Fieldbus Adapter.

Output word 1 high byte (bit 15..8) is the serial transfer command byte,

with following content:

EN ENable FD-10 (bit15).

This bit must always be set high (1) for normal operation.

When set the FD-10 indicates data set ready by the EN bit being set in the

Input status word.EN bit set to low (0) disable FD-10.

SDO Send actual Data Once , toggle bit (bit 14).

When this toggle bit change state, the data words are taken from the DP data

words and transmitted directly over the serial transfer interface of FD-10.

GTL Get TeLegram,toggle bit (bit 13).

When this toggle bit change state, the received serial transfer frame will be set

in the PROFIBUS DP input data.

CNF CoNFiguration mode (bit 12).

For testing purposes only.

This bit is set low (0) during normal operating mode of FD-10.

This bit is set high (1) in order to switch the FD-10 over from

normal operating mode to configuration mode.

RES RESet read back status,toggle bit (bit 11).

When this toggle bit change state, it will reset read back status ACK,NAK and

TO also in all data in words.

Word 15 High byte 8 7 Low byte 0

1 EN SDO GTL CNF RES – – – Transfer slave address in range 0–63

2 Out data word 1

…… …

…… …

16 Out data word 15

Page 28

28 6630-2212

Output word 1 low byte (bit 7..0) is the serial transfer address,with following content:

Transfer slave address of the Fieldbus Adapter to which this frame will be sent.

Serial transfer slave address,is in the range 0 to 64.

Output word 2 to 16 is the output data,with following content:

Word 2 Output data word 1

Word 3 Output data word 2

......... ........

Word 16 Output data word 15.

7.3.2.2 Input data word

Data is transmitted from the FD-10 N to the PROFIBUS DP master.The first word is the

added status word and the remaining 2 to 15 words are ordinary input data received

from the input word transfer slave addressed Fieldbus Adapter.

Input word 1 high byte (bit 15..8) is the serial transfer status byte, with following content:

ST STatus of serial transfer command FD-10 (bit15).

Set to high (1) when the received command has been accepted by the FD-10.

Set to low (0) if the received command has not been accepted.

DEX Data EXist (bit 14).

Set to high (1) when correct data is located in PROFIBUS DP

input data.

DV Data Valid toggle bit (bit 13).

This toggle bit change state, when the received serial transfer

frame data has been set in the PROFIBUS DP input data.

NAK No AcKnowledge (bit 12).

Set to high (1) when last transmitted serial transfer frame to a remote

FD-10 resulted in a received no acknowledge (NAK).

ACK ACKnowledge of serial transfer (bit 11).

Set to high (1) when last transmitted serial transfer frame to a remote

FD-10 resulted in a received acknowledge (ACK).

TO Time Out of serial transfer (bit 10).

Set to high (1) when last transmitted serial transfer frame to a remote

FD-10 has not resulted in any received ACK or NAK

within “Max time to acknowledge frame”.

Input word 1 low byte is the serial transfer address,with following content:

Transfer slave address of the Fieldbus Adapter from which this received

frame has been transmitted,only valid when DEX is

high (1).Serial transfer slave address,in the range 0 to 64.

Word 15 High byte 8 7 Low byte 0

1 ST DEX DV NAK ACK TO – – Transfer slave address in range 0–63

2 In word 1

……

……

16 In word 15

Page 29

296630-2212

Input word 2 to 16 is the input data,with following content:

Word 2 Input word 1

Word 3 Input word 2

......... ........

Word 16 Input word 15.

7.3.2.3 PROFIBUS DP communication

This describes the required PROFIBUS DP communication sequence from a PROFIBUS

DP master to an FD-10 N,to get access and data exchange with a remote FD-10 N.

Preparing for data exchange:

1. Enable normal operation access with FD-10 by command EN

Out word 1,bit 15 set high (1).

2. Verify accepted EN command by checking status ST

In word 1,bit 15 shall be high (1).

Send PROFIBUS DP data from local FD-10 N to remote FD-10 N:

1. Set the Transfer slave address.

Out word 1,low byte.

2. Set Out data to this Transfer slave.

Out word 2 ...16.

3. Reset Input word status by the command RES.

Out word 1,change state of toggle bit 11.

Transmit output data over serial transfer line by the command SDO.

Out word 1,change state of toggle bit 14.

4. Verify correct transmitted serial transfer frame by checking status ACK.

In word 1,bit 11 shall be high (1).

• Or incorrect transmitted,resulting in no acknowledge by checking status NAK.

In word 1,bit 12 is set to high (1) in case of no acknowledge.

• Or,incorrect transmitted,resulting in exceeding “Max time to acknowledge frame”

by checking status TO.

In word 1,bit 10 is set to high (1) in case of time out.

Receive PROFIBUS DP data from remote FD-10 N via local FD-10 N:

1. Wait for received frame by checking status DEX.

In word 1,bit 14 shall be high (1).

2. Set the received serial transfer frame in the PROFIBUS DP input data by the command GTL.

Out word 1,change state of toggle bit 13.

3. Wait until serial transfer frame data has been set in the PROFIBUS DP input data,by

checking whether the status bit DV has changed.

In word 1,toggle bit 13 shall change state.

4. Read the Transfer slave address of the Fieldbus Adapter from which this received

frame has been transmitted.

In word 1,low byte.

5. Read input data of PROFIBUS DP.

In word 2 ...16.

Page 30

30 6630-2212

OWN COMMENTS

.....................................................................................................................................................................................................................

.....................................................................................................................................................................................................................

.....................................................................................................................................................................................................................

.....................................................................................................................................................................................................................

.....................................................................................................................................................................................................................

.....................................................................................................................................................................................................................

.....................................................................................................................................................................................................................

.....................................................................................................................................................................................................................

.....................................................................................................................................................................................................................

.....................................................................................................................................................................................................................

.....................................................................................................................................................................................................................

.....................................................................................................................................................................................................................

.....................................................................................................................................................................................................................

.....................................................................................................................................................................................................................

.....................................................................................................................................................................................................................

Page 31

Page 32

T03-0261 • 6630-2212 03.05 Mälartryck AB, Eskilstuna, Sweden

Application examples

Westermo Teleindustri AB • SE-640 40 Stora Sundby,Sweden

Phone +46 16 42 80 00 Fax +46 16 42 80 01

E-mail:info@westermo.se

W estermo W eb site: www.westermo .com

Westermo Teleindustri AB have distributors in several

countries, contact us for further information.

Westermo Data Communications Ltd

Unit 14 Talisman Business Centre • Duncan Road

Park Gate, Southampton • SO31 7GA

Phone:+44(0)1489 580 585 • Fax.:+44(0)1489 580586

E-Mail:sales@westermo.co.uk

Westermo Data Communications GmbH

Goethestraße 67,68753 Waghäusel

Tel.: +49(0)7254-95400-0 • Fax.:+49(0)7254-95400-9

E-Mail:info@westermo.de

Westermo Data Communications S.A.R.L.

9 Chemin de Chilly 91160 CHAMPLAN

Tél :+33 1 69 10 21 00 • Fax :+33 1 69 10 21 01

E-mail :infos@westermo.fr

Subsidiaries

Modem

(e.g PSTN*, Radio,

Ethernet, GSM)

Modem

(e.g PSTN*, Radio,

Ethernet, GSM)

123456789123456789

PROFIBUS DP

master

I/O

FD-10 P

PROFIBUS DP

PROFIBUS DP

FD-10 P

PROFIBUS DP

master

I/O

Leased Line

PSTN*, Radio,

Ethernet, GSM

* PSTN = Public Switch Telephone Transfer

R+ R- T+ T- T+ T- R+ R-

CHANNEL 3

PWR

RD

TD

DCD2

DCD3

DCD4

CHANNEL 2 POWER

12-36V DC

R+ R- T+ T12345

- +

123456789123456789

R+ R- T+ T- T+ T- R+ R-

CHANNEL 3

PWR

RD

TD

DCD2

DCD3

DCD4

CHANNEL 2 POWER

12-36V DC

R+ R- T+ T12345

- +

Loading...

Loading...