Page 1

User Guide

6621-2214

DDW-120

Westermo Teleindustri AB

©

Industrial Ethernet

SHDSL Extender

www.westermo.com

Page 2

Software tools

Related software tools are available in the folder software tools under

technical support on the Westermo website.

Legal information

The contents of this document are provided “as is”. Except as required by applicable

law, no warranties of any kind, either express or implied, including, but not limited to,

the implied warranties of merchantability and fitness for a particular purpose, are made

in relation to the accuracy and reliability or contents of this document. Westermo

reserves the right to revise this document or withdraw it at any time without prior

notice.

Under no circumstances shall Westermo be responsible for any loss of data or income

or any special, incidental, and consequential or indirect damages howsoever caused.

More information about Westermo can be found at the following Internet address:

http://www.westermo.com

2

6621-2214

Page 3

Safety

WARNING:

To reduce the risk of fire, use only No. 26 AWG or larger telecommunication line cord.

For more information see General safety, art. no.100-5001.

Maintenance

No maintenance is required, as long as the unit is used as intended within the specified

conditions.

6621-2214

3

Page 4

ATEX Information (Applicable for DDW-120 EX only)

General

This unit is intended for use in Zone 2 hazardous location only.

Marking

II 3 G

Ex nA IIC T4 Gc

SPECIAL CONDITION

WARNING – DO NOT SEPARATE WHEN ENERGIZED

Indicate that this unit complies with relevant European standards that are

harmonised with the 94/9/EC Directive (ATEX).

II

3

G

Ex Indicates that this unit is in conformity with relevant European Ex standard(s).

nA

IIC Gas group, a typical gas i hydrogen.

T4

Gc

SPECIAL

CONDITION

Equipment group II.

This unit can be installed in all places with an explosive gas atmosphere other

than mines susceptible to firedamp

Equipment category 3.

A category is the classification according to the required level of protection.

This unit ensures the requisite level of protection during normal operation and

is intended for use in areas in which explosive atmosphere caused by gases,

vapours, mists, or dust mixtures are unlikely to occure or, if they do occure, are

likely to do so only infrequently and for a short periode only.

Indicates protection concerning explosive atmospheres caused by gases,

vapours or mists (G).

Type of protection used.

This unit is a non-sparking device "nA" which is constructed to minimize the

risk of occurence of arcs or sparks capable of creating an ignition hazard during

conditions of normal operation.

Temperature class T4 (T4 = 135°C).

This unit is classified in accordance with its maximum surface temperature

(external and internal).

Equipment protection level Gc (EPL Gc).

Equipment for explosive gas atmospheres, having a "enhanced" level of protection, which is not a source of ignition in normal operation and which may have

some additional protection to ensure that it remains inactive as an ignition

source in the case of regular expected occurences. EPL Gc are analogous to the

ATEX Categories (Category 3 G = EPL Gc).

This unit has a special condition of use.

The special condition for safe use contains safety related information that is

necesarry for the correct installation and safe use.

4

6621-2214

Page 5

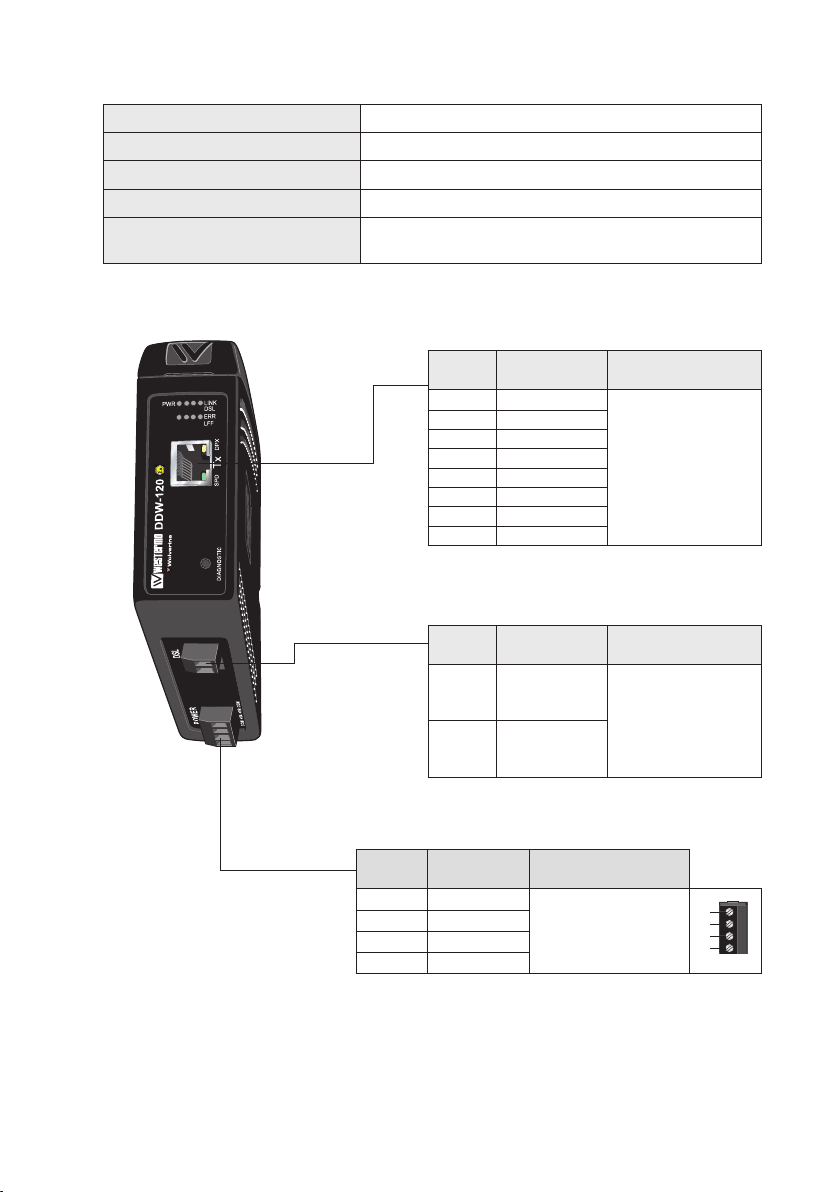

Safety Control Drawing and ratings

Power (12 – 48) VDC; 240 mA

Ambient temperature –40ºC to +70ºC

Maximum surface temperatur 135ºC (temperature class T4)

Degree of protection IP 21

Installation spacing Minimum 25 mm above / below

Direction relative this unit!

Minimum 10 mm left / right

Position

Direction*/

descripton

Input/Output values

1 In/Out / TD+

2 In/Out / TD–

3 In/Out / RD+

4 Not connected

5 Not connected

6 In/Out / RD–

U = ± 1 V (4μV/s)

I = ± 20 mA

Data rate:

10/100 Mbit/s

7 Not connected

8 Not connected

Galvanically isolated via signal transformers and

capacitively isolated to signal ground through a

250 V 3300 pF capacitor.

See user manual for proven transient protection.

Position

12

Direction*/

descripton

1 In/Out / SHDSL

Input/Output values

U = peak to peak: 15 V

I = ± 25 mA

1234

2 In/Out / SHDSL

Galvanically isolated via signal transformer and capacitively

isolated to signal ground through a 1,5kV 220pF capacitor.

See user manual for proven transient protection.

Position

See section Type tests and environmental conditions in this

user manual for proven transient protection.

Direction*/

descripton

1 In / Common

2 In / +Voltage A

3 In / +Voltage B

4 In / Common

Input values

Uin = (10 – 60) VDC

Iin = 295 mA @ 10 VDC

PIn = Max 3 W

Data rate up to

15,3 Mbit/s

1

2

3

4

6621-2214

5

Page 6

SPECIAL CONDITION FOR SAFE USE

Ambient temperature:

This unit is designed for use in extreme ambient temperature conditions as follows:

–40 ºC ≤ Ta ≤ +70 ºC

Installation in an apparatus cabinet:

This unit requires installation in an Ex certified apparatus cabinet suitable for the area of use and

providing a degree of protection of at least IP54.

Resistance to impact:

This unit requires installation in an apparatus cabinet where adequate resistance to impact is

provided by the apparatus cabinet. See "Installation in an apparatus cabinet" above for requirements

on the external apparatus cabinet.

Resistance to light:

This unit requires installation in an apparatus cabinet where it is protected from light

(for example daylight or light from luminaires).

See "Installation in an apparatus cabinet" above for requirements on the external apparatus cabinet.

Secureness of plugs:

When this unit is installed in an explosive atmospheres, all connectors must be mechanically secured

to prevent loosening.

Conductor temperature:

When this unit is installed in locations with high ambient temperature, special precautions shall be

taken upon the choice of external conductors and the temperature rating of the conductor(s).

Directive 94/9/EC alongside with other directives:

Directive 2004/108/EC (EMC) applies and to assure a safe performance of this unit under the scope

of Directive 94/9/EC, refer to the electromagnetic immunity level specified under "Type tests and

environmental conditions" in this manual.

Standards and date of compliance

EN 60079-0 and EN 60079-15

2010-11-05

Class 1, Division 2 Information (DDW-120 EX only)

Special Conditions of Use:

This unit shall be installed in compliance with the enclosure, mounting, spacing and segregation

requirements of the ultimate application, including a tool removable cover.

• Installations shall comply with the relevant requirements of the National Electrical Code®

(ANSI/NFPA 70) and the Canadian Electrical Code® (CEC, CAN/CSA-C22.1).

• Installations shall comply with the latest edition of the manufacturer’s instruction manual.

• Tampering and replacement with non-factory components may adversely affect the safe use

of the system.

• Insertion or withdrawal of removable electrical connectors or modules is to be accomplished

only when the area is known to be free of flammable vapors.

WARNING:

• SUBSTITUTION OF COMPONENTS MAY IMPAIR SUITABILITY FOR DIVISION 2

• DO NOT OPEN WHEN ENERGIZED

• DO NOT DISCONNECT EQUIPMENT UNLESS AREA IS KNOWN TO BE NONHAZARDOUS

AVERTISSEMENT

• RISQUE D'EXPLOSION. NE PAS DÉBRANCHER TANT QUE LE CIRCUIT EST SOUS TENSION,

À MOINS QU'IL NE S'AGISSE D'UN EMPLACEMENT NON DANGEREUX

6

6621-2214

Page 7

Agency approvals and standards compliance

Type

EMC

Safety W-mo

SHDSL NEMKO ITU-T G.991.2, G.SHDSL and G.SHDSL.bis standard

Ex**

Environmental Tektronix*

* Applicable for DDW-120 only

** Applicable for DDW-120 Ex only

FCC Part 15.105 Notice: This equipment has been tested and found to comply with the

Approved

Agency/ W-mo

W-mo EN 61000-6-1, Immunity residential environments

W-mo EN 61000-6-2, Immunity industrial environments

W-mo EN 55024, Immunity IT equipment

W-mo EN 61000-6-3, Emission residential environments

W-mo FCC part 15 Class B

W-mo EN 50121-4, Railway signalling and telecommunications apparatus

FM Approvals Class I, Division 2

W-mo EN 60079-0 and EN 60079-15

Approval / Compliance

UL/CSA/IEC/EN 60950-1, IT equipment*

EN 60950-1, IT equipment**

NEMA TS 2-2003 version 02.06

Traffic Controller Assemblies with NTCIP Requirements

limits for a Class B digital device, pursuant to Part 15 of the

FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a residential installation.

This equip ment generates, uses and can radiate radio frequency

energy and, if not installed and used in accordance with the

instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference will not

occur in a particular installation. If this equipment does cause

harmful interference to radio or television reception, which can

be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of

the following measures:

… Reorient or relocate the receiving antenna

… Increase the separation between the equipment and receiver

… Connect the equipment into an outlet on a circuit different

from that to which the receiver is connected

… Consult the dealer or an experienced radio/TV technician

for help.

6621-2214

7

Page 8

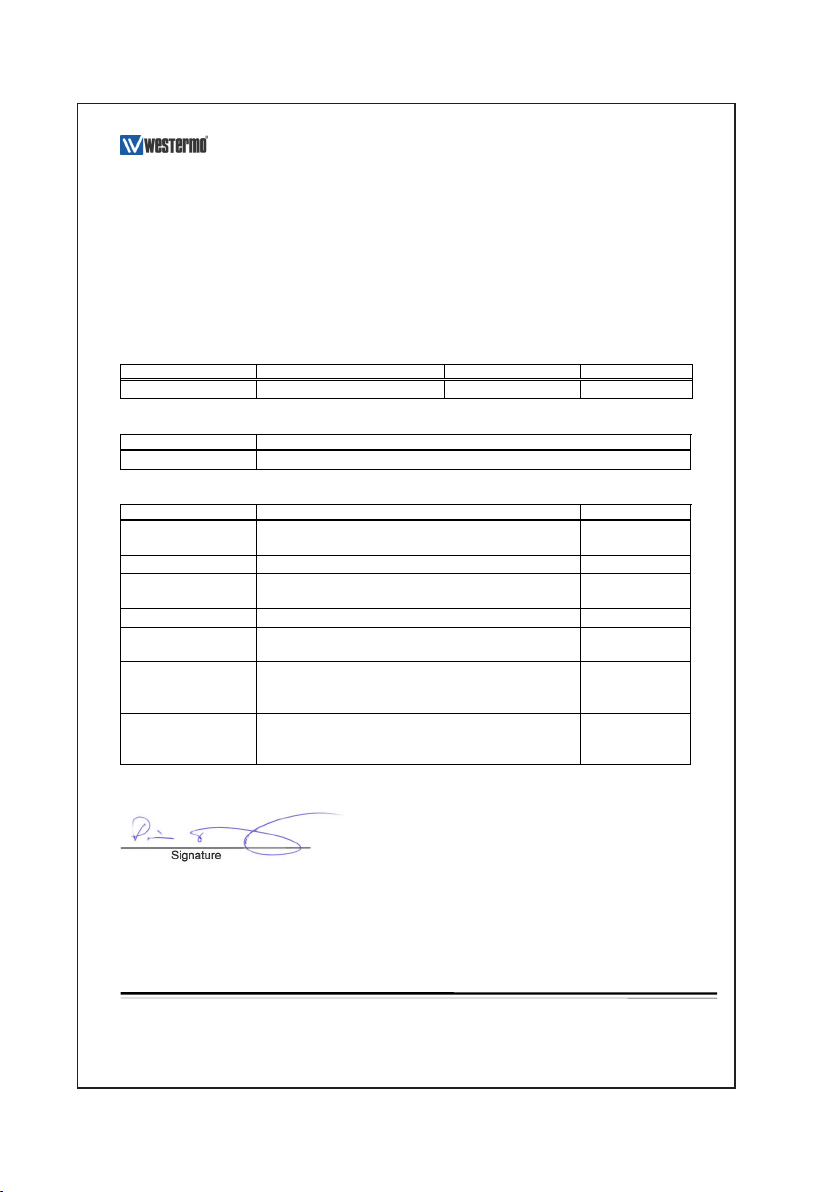

Org.nr/

Declaration of Conformity, DDW-120

Westermo Teleindustri AB

Declaration of conformity

The manufacturer Westermo Teleindustri AB

Herewith declares that the product(s)

Type of product Model Art no From serial no.

DIN-rail Wolverine DDW-120 3621-0110 1000

is in conformity with the following EC directive(s).

No Short name

2004/108/EC Electromagnetic Compatibility (EMC)

References of standards applied for this EC declaration of conformity.

No Title Issue

EN 61000-6-1 Immunity for residential, commercial and light-

EN 61000-6-2 Immunity for industrial environments 2005

EN 61000-6-3 Emission standard for residential, commercial and

EN 61000-6-4 Emission standard for industrial environments 2007

EN 55022

EN 55022 A1

EN 50121-4 Railway applications – Electromagnetic compatibility

EN 55024

EN 55024 A1

EN 55024 A2

The last two digits of the year in which the CE marking was affixed: 10

SE-640 40 Stora Sundby, Sweden

industrial environments

light-industrial environments

Information technology equipment. Radio disturbance

characteristics. Limits and methods of measurement.

– Emission and Immunity of the signalling and

telecommunications apparatus

Information technology equipment – Immunity

2007

2007

2006

2007

2006

1998

2001

2003

Pierre Öberg

R&D Manager

11th January 2010

Postadress/Postal address

S-640 40 Stora Sundby 016-428000 016-428001 52 72 79-4 5671-5550 556361-2604 Eskilstuna

Sweden Int+46 16428000 Int+46 16428001

Tel.

Telefax

Postgiro

Bankgiro Corp. identity number Registered office

8

6621-2214

Page 9

Declaration of Conformity, DDW-120 EX

Org.nr/

Westermo Teleindustri AB

Declaration of conformity

The manufacturer Westermo Teleindustri AB

SE-640 40 Stora Sundby, Sweden

Herewith declares that the product(s)

Type of product Model Art no

Industrial Ethernet SHDSL Extender DDW-120 EX 3621-5110

is in conformity with the following EC directive(s).

No Short name

2004/108/EC Electromagnetic Compatibility (EMC)

94/9/EC Equipment Explosive Atmospheres (ATEX)

References of standards applied for this EC declaration of conformity.

No Title Issue

EN 61000-6-1 Electromagnetic compatibility – Immunity for residential environments 2007

EN 61000-6-2 Electromagnetic compatibility – Immunity for industrial environments 2005

EN 61000-6-3 Electromagnetic compatibility – Emission for residential environments 2007

EN 61000-6-4 Electromagnetic compatibility – Emission for industrial environments 2007

EN 55022 Information technology equipment – Radio disturbance characteristics –

EN 50121-4 Railway applications – Electromagnetic compatibility – Emission and

EN 55024 Information technology equipment – Immunity characteristics

EN 60079-0

EN 60079-15

Limits and methods of measurement

immunity of the signalling and telecommunications apparatus

Limits and methods of measurement

Explosive atmospheres

Equipment – General requirements

Electrical apparatus for explosive gas atmospheres –

Construction, test and marking of type of protection “n” electrical

apparatus

The last two digits of the year in which the CE marking was affixed: 10

2006

+A1:2007

2006

1998

+A1:2001

+A2:2003

2009

2005

Pierre Öberg

Technical Manager

15th November 2010

Postadress/Postal address

S-640 40 Stora Sundby 016-428000 016-428001 52 72 79-4 5671-5550 556361-2604 Eskilstuna

Sweden Int+46 16428000 Int+46 16428001

Tel.

Telefax

Postgiro

Bankgiro Corp. identity number Registered office

6621-2214

9

Page 10

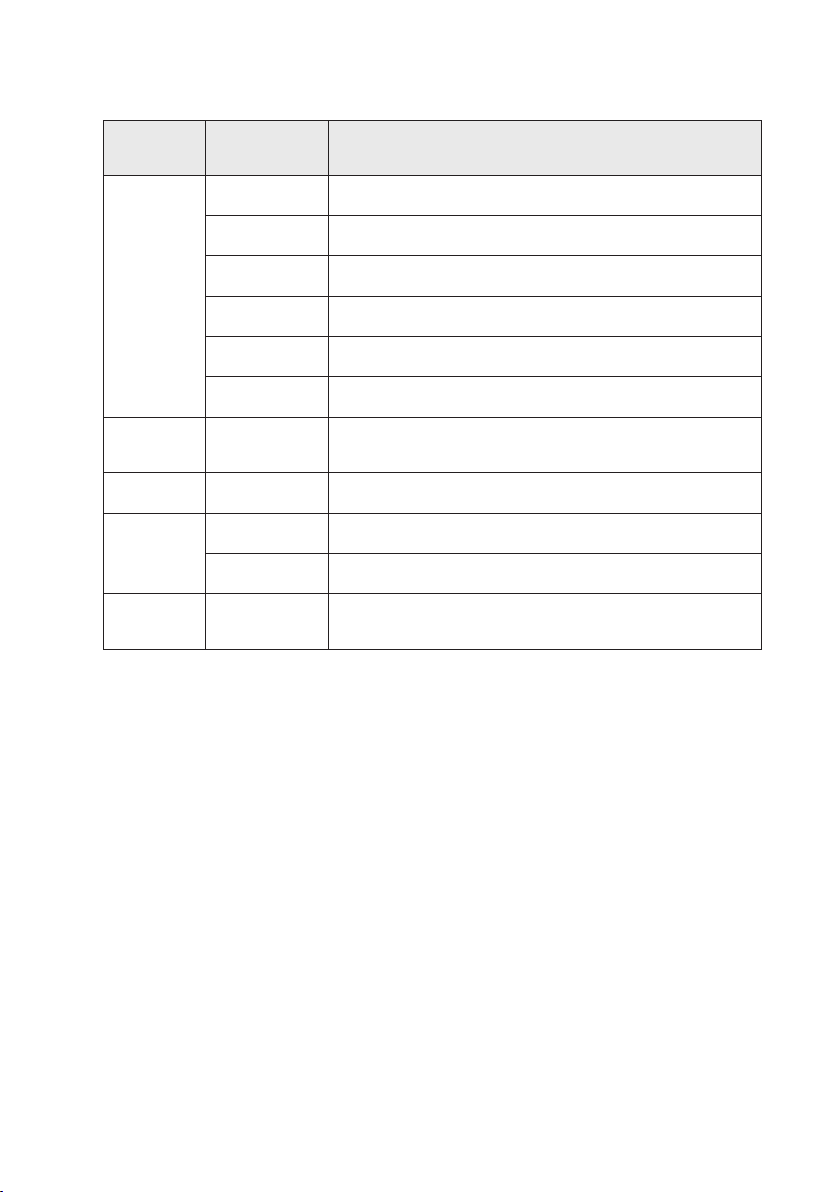

Type tests and environmental conditions

Phenomena Test Description Test levels

ESD EN 61000-4-2 Enclosure contact ± 6 kV

RF field AM modulated IEC 61000-4-3 Enclosure 10 V/m 80% AM (1 kHz), 80 – 1 000 MHz

RF field 900 MHz ENV 50204 Enclosure 20 V/m pulse modulated 200 Hz, 900 ± 5 MHz

Fast transient EN 61000-4-4 Signal ports ± 2 kV

Surge EN 61000-4-5 Signal ports unbalanced ± 2 kV line to earth, ± 2 kV line to line

RF conducted EN 61000-4-6 Signal ports 10 V 80% AM (1 kHz), 0.15 – 80 MHz

Power frequency

magnetic field

Pulse magnetic field EN 61000-4-9 Enclosure 300 A/m, 6.4 / 16 μs pulse

Voltage dips and

interruption

Mains freq. 50 Hz EN 61000-4-16 Signal ports 100 V 50 Hz line to earth

Mains freq. 50 Hz SS 436 15 03 Signal ports 250 V 50 Hz line to earth

Voltage dips and inter-

ruption

Radiated emission EN 55022 Enclosure Class B

Conducted emission EN 55022 AC power ports Class B

Dielectric strength EN 60950 Signal port to other

Temperature Operating –40 to +70ºC

Humidity Operating 5 to 95% relative humidity

Altitude Operating 2 000 m / 70 kPa

Reliability prediction

(MTBF)

Service life Operating 10 year

Vibration IEC 60068-2-6 Operating 7.5 mm, 5 – 8 Hz

Shock IEC 60068-2-27 Operating 15 g, 11 ms

Enclosure, DDW-120 UL 94 PC / ABS Flammability class V-1

Enclosure, DDW-120 Ex Cabelec 6141

Dimension W x H x D 35 x 121 x 119 mm

Weight 0.2 kg

Degree of protection IEC 529 Enclosure IP 21

Cooling Convection

Mounting Horizontal on 35 mm DIN-rail

EN 61000-4-8 Enclosure 100 A/m, 50 Hz, 16.7 Hz & 0 Hz

EN 61000-4-11 AC power ports 10 & 5 000 ms, interruption

EN 61000-4-29 DC power ports 10 & 100 ms, interruption

FCC part 15 Class B

FCC part 15 AC power ports Class B

EN 55022 DC power ports Class B

MIL-HDBK- 217F Operating 1 180 000 hours

Enclosure air ± 8 kV

20 V/m 80% AM (1 kHz), 80 – 2 000 MHz

Power ports ± 2 kV

Signal ports balanced ± 2 kV line to earth, ± 1 kV line to line

Power ports ± 2 kV line to earth, ± 2 kV line to line

Power ports 10 V 80% AM (1 kHz), 0.15 – 80 MHz

10 & 500 ms, 30% reduction

100 & 1 000 ms, 60% reduction

10 ms, 30% reduction

10 ms, 60% reduction

+20% above & –20% below rated voltage

isolated ports

Power port to other

isolated ports

Maximum surface

temperature

Storage & Transport –40 to +70ºC

Storage & Transport 5 to 95% relative humidity

2 kVrms 50 Hz 1 min

3 kVrms 50 Hz 1 min

2 kVrms 50 Hz 1 min (@ rated power <60 V)

135°C (temperature class T4)

2 g, 8 – 500 Hz

10

6621-2214

Page 11

Description

Functional description

The DDW-120 Ethernet Extender is the ideal solution for extending your Ethernet

network over copper cables where in the past the only option would have been fibre.

At shorter range the transfer rate will be as fast as 15.3 Mbit/s in both directions.

Depending on the quality of the cables distances up to 15 km are possible.

DDW-120 is transparent for multicast addressing, VLAN packets, VPN pass-through for

IPSec and for protocols like MODBUS/tcp and Profinet. The Link Fault Forward (LFF)

functionality in DDW-120 forwards information about the Ethernet link status, this is

sent over the SHDSL link between two DDW-120 units. In many applications it is a

requirement to disconnect the link on the other side of the SHDSL link if the primary

Ethernet link goes down.

The units will auto negotiate the transmission speed but can also be forced to choose a

slower (more reliable) or faster (less reliable) data rate.

Communication speed and distance depends on the cable characteristics, communication

reach with different cables can be calculated with DDW-tool

DDW-120 can be used in point-to-point applications or as start and termination unit

together with DDW-22x in a daisy-chain application.

Description of used nomenclature:

Noise margin:

The margin between signal and noise (dB)

CO/CPE:

CO (Central Office) answering central unit, the CO configures the CPE when establishing a connection. CPE (Customer Premises Equipment) is the unit that initiates the connection.

6621-2214

11

Page 12

Getting started

The DDW-120 is easy to use and install, the units work in pairs, one as has to be configured as CO (Central Office) and one as CPE (Customer Premises Equipment). This configuration is made with DIP-switches situated under the lid of the DDW-120.

Connect the SHDSL Line

1) Connect the twisted pair to DSL screw terminal 1 and 2 (polarity independent)

situated at the base of the DDW-120.

Connect the Ethernet Line

Connect Ethernet to the TX port on the front of the DDW-120.

The factory settings for the DDW-120 is plug and play mode where TX port

is enabled for:

… Ethernet Auto-negotiation enabled.

… Auto MDI/MDI-X.

… Auto-polarity enabled.

The DDW-120 will automatically sense the data rate of the connected unit and cable

type.

Settings in the units

The units operate in pairs, one as CO (Central Office) and one as CPE

(Customer Premises Equipment). Factory setting in the DDW-120 is as CPE.

Note! Before connection and installation one of the connecting units have to be

reconfigured as a CO, see DIP-switch S1:4.

Depending on the quality of the line and the distance there is possibility to select autobaud function.

This is done via DIP switches in the unit configured as CO.

Factory default is autobaud, reliable mode.

Note!

If the DSL link is not established, the speed might be set to high for the distance.

12

6621-2214

Page 13

Diagnostic information

The DDW-120 can display diagnostic information on two way:

1) Using the Westermo diagnostic tool DDWtool.exe.

2) Using a terminal program.

1211-2027

Using DDW-tool

1) Connect the standard cable 1211-2027 to the diagnostic port, located under the lid of

DDW-120.

2) Choose the corresponding Com port in the drop list of the tool. The tool will try to

find the port used by the debug cable.

3) Click the button connect, if the correct com port is selected DDW-tool will be

updated with actual status online information.

Information from diagnostic tool

• Software release

• Serial number

• DIP switch settings

• If the unit is configured as CO or CPE

• Ethernet link status

• Ethernet data rate

• Ethernet duplex

• System uptime

• DSL uptime

• DSL negotiations

• LFF status

• DSL link state

• DSL data rate

• DSL noise margin (information is sampled and continually displayed)

6621-2214

13

Page 14

Using a terminal program

If a customer supervision system is used the DDW-120 can provide with diagnostic

status.

The DDW-120 support

Data rate: 115.2 kbit/s

Data bits: 8

Stop bits: 1

Parity: None

Flow control: None

The unit is responing to two commandon

1) DIAG

2) RUNDIAG

Information from DIAG command

• Software release

• DIP switch settings

• If the unit is configured as CO or CPE

• If the unit is configured for Annex A or Annex B

• DSL link state

• DSL data rate (bit/s)

• DSL noise margin (dB)

• Ethetnet data rate

• Ethernet duplex

Information from RUNDIAG command

• DSL link state

• DSL Data rate (bit/s)

• DSL Noise margin (dB)

The DDW-120 is ready for commando then prompt “DDW” is transmitted to

supervisor system.

The commando RUNDIAG will continuously send the information. Approx update with

1s base. Commando is aborted by sending “any key to abort”.

14

6621-2214

Page 15

Interface specifications

Power

Rated voltage 12 to 48 VDC

Operating voltage 10 to 60 VDC

Rated current 240 mA @ 12 VDC

Rated frequency DC

Inrush current, I2t 0.23 A2s

Startup current* 0.65 A

Polarity Reverse polarity protected

Redundant power input Ye s

Isolation to All other

Connection Detachable screw terminal

Connector size 0.2 – 2.5 mm2 (AWG 24 – 12)

Shielded cable Not required

* If external power supply is used it must meet specified start up current

Service port

Electrical specification TTL-level

Data rate 115.2 kbit/s

Data format 8 data bits, none parity, 1 stop bits, no flow control

Circuit type SELV

Transmission range 15 m

Isolation to All other

Galvanic connection to None

Connection 2.5 mm jack, use Westermo cable 1211-2027

110 mA @ 24 VDC

60 mA @ 48 VDC

peak

6621-2214

15

Page 16

DSL

Electrical specification IEEE G.991.2 Annex B

Data rate 192 kbit/s to 15304 kbit/s

Protocol EFM according to IEEE 802.3-2004

Transmission range According to ITU-T G.991.2 depending on the line quality

Protection Overcurrent / overvoltage protection circuit and varistor

Isolation to All other

Connection Detachable screw terminal

Connector size 0.2 – 2.5 mm2 (AWG 24 - 12)

Shielded cable Not required

Ethernet TX

Electrical specification IEEE std 802.3. 2000 Edition

Data rate 10 Mbit/s, 100 Mbit/s, manual or auto

Duplex Full or half, manual or auto

Circuit type SELV

Transmission range 100 m

Isolation to All other

Connection RJ-45 MDI or auto MDI/MDI-X

Shielded cable Not required, except when installed in Railway applications as

Conductive housing Isolated to all other circuits

Miscellaneous If Auto-Neg. is disabled then this interface will be set MDI

Number of ports 1

signalling and telecommunications apparatus and located close

to rails*

* To minimise the risk of interference, a shielded cable is recommended when the cable is located

inside 3 m boundary to the rails and connected to this port.

The cable shield should be properly connected (360°) to an earthing point within 1 m from this

port. This earthing point should have a low impedance connection to the conductive enclosure

of the apparatus cabinet, or similar, where the unit is built-in. This conductive enclosure should

be connected to the earthing system of an installation and may be directly connected to the

protective earth.

16

6621-2214

Page 17

Connections

Ethernet TX connection

(RJ-45 connector) 1 – 4**

Position

1 In/Out TD+

2 In/Out TD–

3 In/Out RD+

4 – Not Connected

5 – Not Connected

6 In/Out RD–

7 – Not Connected

8 – Not Connected

CAT 5 cable is recommended.

Unshielded (UTP) or shielded (STP) connectors

can be used.

Direction* Description

12

1234

DSL screw connector 1 & 2

Position Direction Description

1 In/Out 2-wire Receive/ Transmit SHDSL

2 In/Out 2-wire Receive/ Transmit SHDSL

Power connection

Position Direction* Description

1 In Common

2 In + Voltage A

3 In + Voltage B

4 In Common

* Direction relative this unit

** To minimise the risk of interference, a shielded cable is recommended when the cable is located inside 3 m

boundary to the rails and connected to this port. The cable shield should be properly connected (360°) to an

earthing point within 1 m from this port. This earthing point should have a low impedance connection to the conductive enclosure of the apparatus cabinet, or similar, where the unit is built-in. This conductive enclosure should

be connected to the earthing system of an installation and may be directly connected to the protective earth.

6621-2214

17

Page 18

LED indicators

LED Status Description

PWR

(green)

LFF

(green)

ERR

(red)

DSL OFF No DSL link

LINK OFF No Ethernet link

SPD OFF Ethernet speed, 10 Mbit/s

DPX OFF Ethernet duplex, half

OFF No internal power

ON Internal power ok / boot ok

OFF LFF disabled

ON LFF enabled

OFF LFF not active

ON LFF active, link fault on this unit

Flash LFF active, link fault on opposite unit

ON DSL link established

Flash DSL link negotiating

ON Ethernet link established

Flash Ethernet traffic indication

ON Ethernet speed, 100 Mbit/s

ON Ethernet duplex, full

18

6621-2214

Page 19

DIP-switch settings

S2S1

Before DIP-switch settings:

!

Prevent damage to internal electronics from electrostatic discharges (ESD)

by discharging your body to a grounding point (e.g. use of wrist strap).

NOTE DIP-switch alterations are only effective after a power on.

S1 DIP-switch

ON

1 2 3 4 5 6 7 8

Standard speed

ON

1 2 3 4 5 6 7 8

CPE,

Customer Premises Equipment

ON

1 2 3 4 5 6 7 8

ON

1 2 3 4 5 6 7 8

ON

1 2 3 4 5 6 7 8

ON

1 2 3 4 5 6 7 8

ON

1 2 3 4 5 6 7 8

Turbo speed

Manual speed locked

according to S2:4-8*

Autobaud, normal mode**

(Standard speed 192 kbit/s – 5.7 Mbit/s)

(Turbo speed 192 kbit/s – 15.3 Mbit/s)

Autobaud, high speed mode**

(Standard speed 192 kbit/s – 5.7 Mbit/s)

(Turbo speed 192 kbit/s – 15.3 Mbit/s)

Autobaud, reliable mode**

(Standard speed 192 kbit/s – 5.7 Mbit/s)

(Turbo speed 192 kbit/s – 15.3 Mbit/s)

ON

1 2 3 4 5 6 7 8

ON

1 2 3 4 5 6 7 8

ON

1 2 3 4 5 6 7 8

CO,

Central Office

LFF disabled

LFF enabled

S1: 6, 7 and 8 not used

* Autobaud is recommended. When using manual locked speed user must make sure a correct noise margin

is achieved. Westermo recommends at least 3 dB noise margin for reliable operation.

** Negotiation of speed may take up to 3 minutes to complete.

6621-2214

19

Page 20

S2 DIP-switch

ON

1 2 3 4 5 6 7 8

Ethernet auto-negotiation disabled

ON

1 2 3 4 5 6 7 8

DSL-speed 2048kbit/s*

DSL-speed 9272kbit/s**

ON

1 2 3 4 5 6 7 8

ON

1 2 3 4 5 6 7 8

ON

1 2 3 4 5 6 7 8

ON

1 2 3 4 5 6 7 8

ON

1 2 3 4 5 6 7 8

ON

1 2 3 4 5 6 7 8

ON

1 2 3 4 5 6 7 8

ON

1 2 3 4 5 6 7 8

ON

1 2 3 4 5 6 7 8

Ethernet auto-negotiation enabled

Ethernet speed 10 Mbit/s

(if auto-neg. disabled)

Ethernet speed 100 Mbit/s

(if auto-neg. disabled)

Ethernet half duplex

(if auto-neg. disabled)

Ethernet full duplex

(if auto-neg. disabled)

DSL-speed 192 kbit/s*

DSL-speed 6200 kbit/s**

DSL-speed 384 kbit/s*

DSL-speed 6712 kbit/s**

DSL-speed 512 kbit/s*

DSL-speed 7224 kbit/s**

DSL-speed 768 kbit/s*

DSL-speed 7736 kbit/s**

ON

1 2 3 4 5 6 7 8

ON

1 2 3 4 5 6 7 8

ON

1 2 3 4 5 6 7 8

ON

1 2 3 4 5 6 7 8

ON

1 2 3 4 5 6 7 8

ON

1 2 3 4 5 6 7 8

ON

1 2 3 4 5 6 7 8

ON

1 2 3 4 5 6 7 8

ON

1 2 3 4 5 6 7 8

DSL-speed 2304kbit/s*

DSL-speed 9784kbit/s**

DSL-speed 2688kbit/s*

DSL-speed 10296kbit/s**

DSL-speed, 3072 kbit/s*

DSL-speed 10808kbit/s**

DSL-speed, 3456 kbit/s*

DSL-speed 11320kbit/s**

DSL-speed, 3840 kbit/s*

DSL-speed 11832kbit/s**

DSL-speed, 4224 kbit/s*

DSL-speed 12344kbit/s**

DSL-speed, 4608 kbit/s*

DSL-speed 13112kbit/s**

DSL-speed, 4992 kbit/s*

DSL-speed 13880kbit/s**

DSL-speed, 5376 kbit/s*

DSL-speed 14648kbit/s**

ON

1 2 3 4 5 6 7 8

ON

1 2 3 4 5 6 7 8

DSL-speed 1024 kbit/s*

DSL-speed 8248 kbit/s**

DSL-speed 1280 kbit/s*

DSL-speed 8760 kbit/s**

* Standard speed S1:1 OFF

** Turbo speed S1:1 ON

Factory settings

ON

S1

1 2 3 4 5 6 7 8

20

ON

1 2 3 4 5 6 7 8

ON

S2

1 2 3 4 5 6 7 8

DSL-speed 5696kbit/s*

DSL-speed 15304kbit/s**

6621-2214

Page 21

Mounting

CLICK!

This unit should be mounted on 35 mm DIN-rail, which is

horizontally mounted inside an apparatus cabinet, or similar.

Snap on mounting, see figure.

Cooling

This unit uses convection cooling. To avoid obstructing the airflow around the unit, use the following spacing rules. Minimum

spacing 25 mm (1.0 inch) above /below and 10 mm (0.4 inches)

left /right the unit. Spacing is recommended for the use of unit

in full operating temperature range and service life.

10 mm *

(0.4 inches)

25 mm

* Spacing (left/right) recommended for

full operating temperature range

Removal

Press down the black support at the top of the unit. See figure.

6621-2214

25 mm

21

Page 22

Page 23

Page 24

Westermo • SE-640 40 Stora Sundby, Sweden

Tel +46 16 42 80 00 Fax +46 16 42 80 01

Sales Units

Westermo Data Communications

E-mail: info@westermo.com

www.westermo.com

China

sales.cn@westermo.com

www.cn.westermo.com

France

infos@westermo.fr

www.westermo.fr

Germany

info@westermo.de

www.westermo.de

For complete contact information, please visit our website at www.westermo.com/contact or scan the QR code

REV.F 6621-2214 2015-02 Westermo Teleindustri AB, Sweden – A Beijer Electronics Group Company

North America

info@westermo.com

www.westermo.com

Singapore

sales@westermo.com.sg

www.westermo.com

Sweden

info.sverige@westermo.se

www.westermo.se

United Kingdom

sales@westermo.co.uk

www.westermo.co.uk

Other Offices

Loading...

Loading...