West ProVU 4 Specifications

TECHNICAL DATA SHEET

ProVU 4 Advanced Temperature Controller

• ¼ DIN Format

• Graphical / text LCD Display (red/green)

• Profiling option

• Datalogging option (data, alarms & events)

• 5 language

• Configurable user-menu structure

• Modbus RS485 and Modbus TCP Ethernet supported

• USB option

• Standards CE, UL and cUL

Features

HMI Display

- Graphic display - Easy to read backlit LCD display.

(160 x 80 pixels)

- Dual colour screen (green / red).

Colour can be set to change on alarm.

- Multi-language option

(English, French, German, Italian, Spanish)

- Custom splash-screen on startup (bitmap file)

- Alarm status view

- On screen trend view

- LEDs to indicate heat, cool, autotuning and alarm

User operation and control

- Easy setup wizard for quick configuration.

(inputs, alarms, outputs, comms & real-time clock)

- Universal input for thermocouple, RTDs and linear DC

process signals (mA, mV or V)

- Flexible output options, relay, ssd driver, triac &

Linear DC (9 max). Select to precisely match the

process.

- Digital input (2 max) for setpoint selection, profile control,

datalogging start/stop, control output enable/disable or

auto/manual control

- Configurable menus (via BlueControl software)

- USB port for local upload/download of configuration files

& download logged data

- Password protected supervisor and configuration mode

- Pre-tune and self-tune function

- Master-slave configuration for multi-zone applications

Profiling function (option)

- 255 segments to allocate freely in up to 64 programs

- Ramp, dwell, hold, loop or jump to other profile

- User defined text profile names

- Delayed or real-time day/time profile start

- Up to 5 event outputs

(English, French, German, Italian, Spanish)

West Instruments is a division of Danaher UK Industries (2006) Ltd. A member of the Danaher Corporation.

Registered in England No 06020956 VAT No GB 788620583

Registered Office: Unit 4 Holmewood Bus. Park, Chesterfield Road, Holmewood, Chesterfield, Derbyshire, S42 5US

Datalogging Function (option)

- Historic process data for analysis or reporting

- Export data files via front USB or comms

- Log process values, setpoints or alarms

(including min, max & ave)

- Run-then-stop or FIFO (first in – first out) buffer recording

- Logging intervals from 1s to 30m

Description

ProVU with graphic/text LCD display is an affordable

temperature and process controller with advanced

functionality including profiling and datalogging options.

Designed to improve user efficiency many features are

integrated to reduce commissioning time, simplify

operation and minimise maintenance downtime.

The LCD screen on ProVU displays real-text messages,

removing ambiguity that can be caused by mnemonic

codes on LED displays used in many products.

Information is displayed in a logical format to be easily

understood, hence reducing the risk of errors. User

screens are only displayed as each function is enabled,

creating an optimised menu structure that is simpler to

navigate. Access to specific settings and parameters can

also be restricted by assigning them to password

protected supervisor and configuration parameter access

levels.

The process of configuring ProVU is simplified as a setup

wizard runs on first power-up. The user is guided step-bystep through the common parameter settings to quickly

program the unit. These settings can be saved on a

memory stick via the USB port and can be used for

reconfiguration or to program other ProVU units.

BlueControl software can be used for on and off-line

configuration.

Flexible input and output option boards mean that the

controller can be selected to precisely match an

application. Universal process input (Thermocouple,

PT100 & linear DC), digital inputs, remote setpoint

TECHNICAL DATA SHEET

inputs, RS485 and Ethernet (Modbus TCP) comms and

up to nine outputs (relay, SSR driver, triac, linear DC and

24V transmitter PSU) are all available .

The optional profiling function supports 255 segments for

use in up to 64 profiles, segments supported are ramp,

dwell, hold, loop, jump to profile. Profile control is

possible from the controller, remote input or timed via the

integral real time clock.

There is an increasing requirement to log process data

for quality control purposes. The optional datalogging

feature is a low cost method of recording historical data

for exporting to a .CSV file.

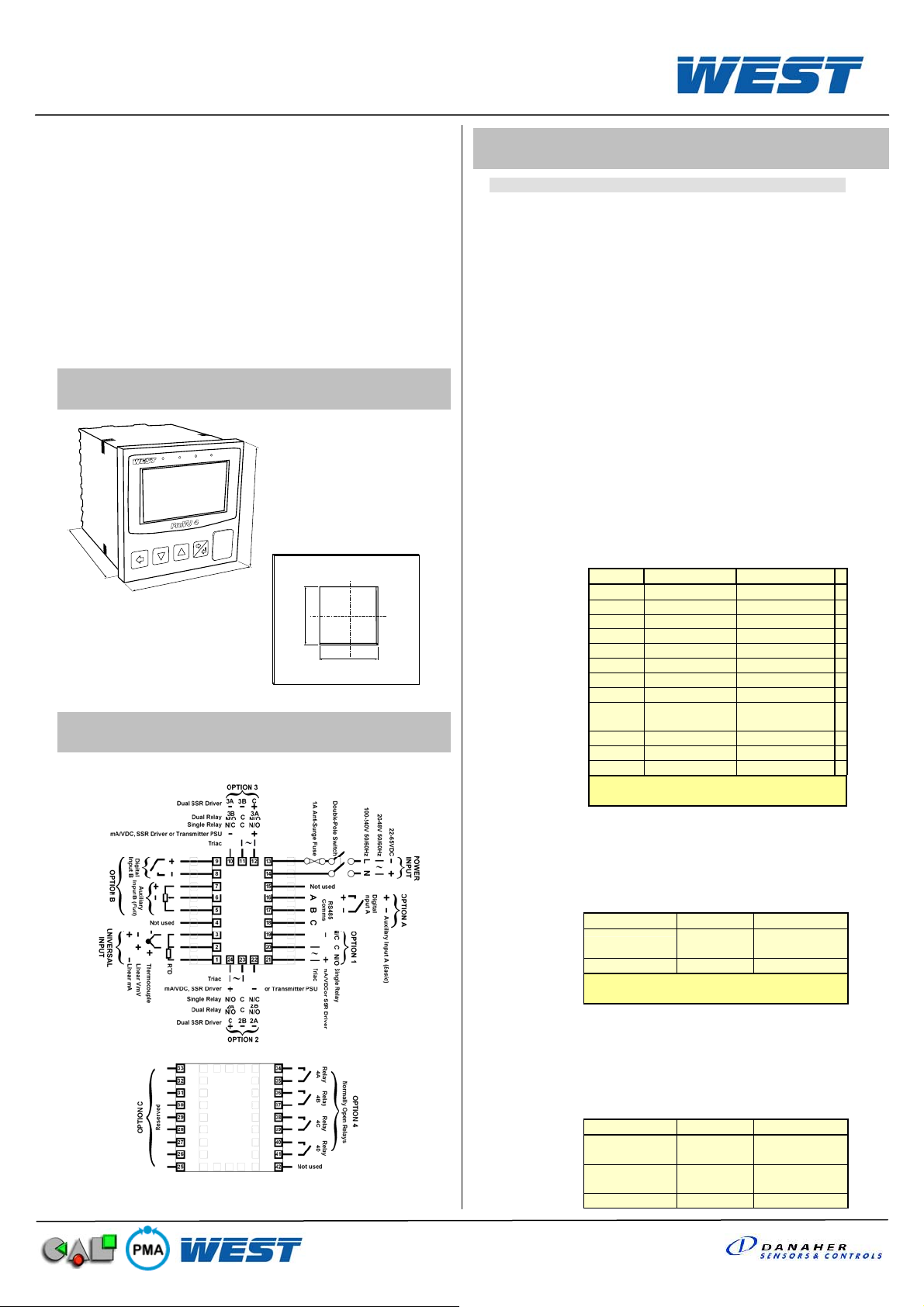

Dimensions and Installation

96mm

117mm

96mm

Weight 0.45kg

Panel Cut-out

92mm

92mm

Cut- out t ol eran ce +0 .5mm , -0.0m m

Maximum panel thickness 6.0 mm

Connections

West Instruments is a division of Danaher UK Industries (2006) Ltd. A member of the Danaher Corporation.

Registered in England No 06020956 VAT No GB 788620583

Registered Office: Unit 4 Holmewood Bus. Park, Chesterfield Road, Holmewood, Chesterfield, Derbyshire, S42 5US

Specification

PROCESS INPUT

Sampling Rate: 10 per second.

Resolution: 16 bits. Always four times better than display

Impedance:

Temperature

stability:

Supply Variation: Supply voltage influence negligible within

Humidity

Influence:

Process Display: Displays up to 5% over and 5% under span

Process Variable

Input Offset:

Sensor Break

Detection:

Isolation: Isolated from all outputs (except SSR driver)

Supported

Thermocouple

Types & Ranges:

Thermocouple

Calibration:

Supported RTD

Types &

Ranges:

RTD Calibration:

RTD Excitation:

Lead

Resistance:

Supported

Linear Types &

Ranges:

resolution.

>10MΩ resistive, except DC mA (5Ω) and V

(47kΩ ).

Error <0.01% of span per °C change in

ambient temperature.

supply limits.

Negligible if non-condensing.

limits.

Reading adjustable ± Controller Span. +ve

values added to Process Variable, -ve values

subtracted from Process Variable

Thermocouple & RTD - Control goes to pre-

set power value. High & Sensor Break alarms

activate.

Linear (4 to 20mA, 2 to 10V and 1 to 5V only)

- Control goes to pre-set power value. Low &

Sensor Break alarms activate.

at 240V AC.

Type Range °C Range °F

B +100 to 1824°C +211 to 3315°F

C 0 to 2320°C 32 to 4208°F

D 0 to 2315°C 0 to 4199°F

E -240 to 1000°C -400 to 1832°F

J -200 to 1200°C -328 to 2192°F *

K -240 to 1373°C -400 to 2503°F *

L 0 to 762°C 32 to 1402°F *

N 0 to 1399°C 32 to 2551°F *

PtRh

20%:40%

R 0 to 1759°C 32 to 3198°F

S 0 to 1762°C 32 to 3204°F

T -240 to 400°C -400 to 752°F *

Optional decimal place can be displayed up to

±0.1% of full range, ±1LSD (±1°C for internal

CJC if enabled).

Linearization better than better ±0.2°C (±0.05

typical) on ranges marked * in the table

above. Linearization for other ranges is better

than better than ±0.5°C.

BS4937, NBS125 & IEC584

Type Range °C Range °F

3-Wire PT100

NI120 -80 to 240°C -112 to 464°F

Optional decimal place can be displayed up to

0.1% of full range, ±1LSD.

Linearization better than ±0.2°C (±0.05 typical).

PT100 input to BS1904 & DIN43760

(0.00385

Sensor current 150μA ±10%.

<0.5% of span error for max 50Ω per lead,

balanced.

Type Range Offset Range

mA DC 0 to 20mA

mV DC 0 to 50mV

V DC 0 to 5V DC 1 to 5V DC

0 to 1850°C 32 to 3362°F

999.9°C/F

Ω/Ω

-199 to

800°C

999.9°C/F

/°C).

DC

DC

-328 to 1472°F

4 to 20mA DC

10 to 50mV DC

Loading...

Loading...