Page 1

Technical Documentation

PID-131-U

Standard PID-Controller

Page 2

W.E.ST.

Elektronik GmbH

CONTENTS

1 General Information.............................................................................................................................................. 4

1.1 Order number ............................................................................................................................................... 4

1.2 Scope of supply ............................................................................................................................................ 4

1.3 Accessories ................................ ................................................................ ................................ .................. 4

1.4 Symbols used ............................................................................................................................................... 5

1.5 Using this documentation ............................................................................................................................. 5

1.6 Legal notice ................................................................................................ ................................ .................. 5

1.7 Safety instructions ........................................................................................................................................ 6

2 Characteristics ..................................................................................................................................................... 7

2.1 Compatibility ................................................................................................................................................. 8

2.2 Device description ........................................................................................................................................ 9

3 Use and application ............................................................................................................................................ 10

3.1 Installation instructions ............................................................................................................................... 10

3.2 Typical system structure ............................................................................................................................. 11

3.3 Method of operation ................................................................................................................................... 11

3.4 Commissioning ........................................................................................................................................... 12

4 Technical description.......................................................................................................................................... 13

4.1 Input and output signals ............................................................................................................................. 13

4.2 LED definitions ........................................................................................................................................... 14

4.3 Circuit diagram ........................................................................................................................................... 15

4.4 Typical wiring.............................................................................................................................................. 16

4.5 Connection examples ................................................................................................................................. 16

4.6 Technical data ............................................................................................................................................ 17

5 Parameters ......................................................................................................................................................... 18

5.1 Parameter overview ................................................................................................................................... 18

5.2 Basic parameters ....................................................................................................................................... 20

LG (Changing the language) ............................................................................................................. 20

MODE (Switching between parameter groups) ................................................................................. 20

SENS (monitoring of the modul functions) ......................................................................................... 20

PIN5 (Function of PIN 5).................................................................................................................... 21

CDWIN (Size of the control deviation window) .................................................................................. 21

EOUT (Output signal if not ready) ..................................................................................................... 21

5.3 Input signal adaptation ............................................................................................................................... 22

SIGNAL (Type of input) ..................................................................................................................... 22

N_RANGE:X (Nominal range of the sensor)...................................................................................... 22

OFFSET:X (Sensor offset) ................................................................................................................. 22

Using the commands SIGNAL:X, N_RANGE:X and OFFSET:X ....................................................... 23

5.4 Ramp and PID control parameters ............................................................................................................. 23

RA (Command signal ramp times) ..................................................................................................... 23

C (PID Control Settings) .................................................................................................................... 24

5.5 Output signal adaptation ............................................................................................................................ 25

MIN (Deadband compensation) ................................ ................................................................ ......... 25

MAX (Output scaling) ........................................................................................................................ 25

TRIGGER (Deadband compensation trigger point) ........................................................................... 25

SIGNAL:U (Output type and polarity) ................................................................................................ 26

5.6 Special commands ..................................................................................................................................... 27

TS (Sample time) ............................................................................................................................... 27

AINMODE (Input scaling mode) ........................................................................................................ 27

AIN (Free analogue input scaling) ..................................................................................................... 28

5.7 PROCESS DATA (Monitoring) ................................................................................................................... 29

Page 2 of 32 PID-131-U-2030 30.12.2015

Page 3

W.E.ST.

6 Appendix ............................................................................................................................................................ 30

6.1 Failure monitoring ....................................................................................................................................... 30

6.2 Troubleshooting .......................................................................................................................................... 30

6.3 Description of the command structure ........................................................................................................ 31

7 Notes ................................................................................................................................................................. 32

Elektronik GmbH

Page 3 of 32 PID-131-U-2030 30.12.2015

Page 4

W.E.ST.

1

Elektronik GmbH

1 General Information

1.1 Order number

PID-131-U-20301 - with analogue ±10 V differential output or 4… 20 mA output and analogue sensor

interface

1.2 Scope of supply

To the scope of supply belongs the module including the terminal blocks which are part of the housing.

The Profibus plug, interface cables and further parts which may be required should be ordered separately.

This documentation can be downloaded as a PDF file from www.w-e-st.de.

1.3 Accessories

WPC-300 - Start-Up-Tool (downloadable from our homepage – products/software)

The number of the version consists of the hardware-version (first two digits) and the software-version (second two digits).

Because of the development of the products these numbers can vary. They are not strictly necessary for the order. We will

always deliver the newest version.

Page 4 of 32 PID-131-U-2030 30.12.2015

Page 5

W.E.ST.

Elektronik GmbH

1.4 Symbols used

General information

Safety-related information

1.5 Using this documentation

Structure of the documentation:

The standard product is described up to chapter 6. The extensions like POWER STAGE or SSI-INTERFACE

are described in the chapters ADDITIONAL INFORMATION.

1.6 Legal notice

W.E.St.

Gewerbering 31

D-41372 Niederkrüchten

Tel.: +49 (0)2163 577355-0

Fax.: +49 (0)2163 577355-11

Home page: www.w-e-st.de or www.west-electronics.com

EMAIL: info@w-e-st.de

Date: 30.12.2015

The data and characteristics described herein serve only to describe the product. The user is required to

evaluate this data and to check suitability for the particular application. General suitability cannot be inferred

from this document. We reserve the right to make technical modifications due to further development of the

product described in this manual. The technical information and dimensions are non-binding. No claims may be

made based on them.

This document is protected by copyright.

Elektronik GmbH

Page 5 of 32 PID-131-U-2030 30.12.2015

Page 6

W.E.ST.

Elektronik GmbH

1.7 Safety instructions

Please read this document and the safety instructions carefully. This document will help to define the product

area of application and to put it into operation. Additional documents (WPC-300 for the start-up software) and

knowledge of the application should be taken into account or be available.

General regulations and laws (depending on the country: e. g. accident prevention and environmental

protection) must be complied with.

These modules are designed for hydraulic applications in open or closed-loop control circuits.

Uncontrolled movements can be caused by device defects (in the hydraulic module or the

components), application errors and electrical faults. Work on the drive or the electronics must

only be carried out whilst the equipment is switched off and not under pressure.

This handbook describes the functions and the electrical connections for this electronic

assembly. All technical documents which pertain to the system must be complied with when

commissioning.

This device may only be connected and put into operation by trained specialist staff. The

instruction manual must be read with care. The installation instructions and the commissioning

instructions must be followed. Guarantee and liability claims are invalid if the instructions are not

complied with and/or in case of incorrect installation or inappropriate use.

CAUTION!

All electronic modules are manufactured to a high quality. Malfunctions due to the failure of

components cannot, however, be excluded. Despite extensive testing the same also applies for

the software. If these devices are deployed in safety-relevant applications, suitable external

measures must be taken to guarantee the necessary safety. The same applies for faults which

affect safety. No liability can be assumed for possible damage.

Further instructions

The module may only be operated in compliance with the national EMC regulations. It is the

user’s responsibility to adhere to these regulations.

The device is only intended for use in the commercial sector.

When not in use the module must be protected from the effects of the weather,

contamination and mechanical damage.

The module may not be used in an explosive environment.

To ensure adequate cooling the ventilation slots must not be covered.

The device must be disposed of in accordance with national statutory provisions.

Page 6 of 32 PID-131-U-2030 30.12.2015

Page 7

W.E.ST.

Elektronik GmbH

2 Characteristics

This module was developed for general controlling of dynamic systems. The controller structure is designed as

a classic PID compensator with a short cycle time of 1ms.

It is possible to choose from different sensor and command signal types and polarities as 4… 20 mA, 0… 10 V

or 10… 0V. More special input signals can be freely adapted via a mathematical scaling function.

The output signal is available as an active difference signal for the direct connection of valves with integrated

electronics. Alternatively also single ended ones can be used.

The user may choose between two parameter sets by the use of Input S0 (pin 6)

Because of the easy handling a very short training period is guaranteed. A remote control function allows con-

trolling the system without a higher level controller via the serial interface, e.g. for commissioning

The setup via USB is simple and easy to understand. A standard terminal program or our special windows appli-

cation software (WPC-300, download from our homepage) can be used.

Typical applications: dynamic PID compensator for force, pressure and speed control.

Features

Analogue command and feedback values (0… 10 V or 4… 20 mA)

Ramp function on the command value

Universal controller structure

Feedback value depending activation of the integrator by pre-set threshold value (automatically

switching of the control structure)

Application orientated parameter settings

Universal output signal for control elements

0...10V, ± 10 V, 4… 20 mA or 4… 20mA with a virtual zero at 12mA

REMOTE CONTROL mode via serial interface

Failure monitoring

Adjustments via USB interface

Page 7 of 32 PID-131-U-2030 30.12.2015

Page 8

W.E.ST.

Elektronik GmbH

2.1 Compatibility

As a result of further developments some smaller changes have to be taken in consideration.

Functionality:

1. Downward compatible to the older modules.

2. 100 % wiring compatible.

3. Baud rate: The default baud rate has changed from 9600 baud to 57600 baud. This is adaptable in

WPC-300: OPTIONS/SETTINGS/INTERFACE.

FIXBAUDRATE = 57600 and/or AUTO BAUDRATE DETECTION = 57600

4. Technical enhancements:

- Programmable analogue output: only one version (U instead A and I) is necessary

Parameterization:

1. Standardizing of parameter names

2. Simplified and intuitive parameterization of the analogue inputs and sensors

3. Compatibility mode of the input scaling (AINMODE), if necessary

4. Adaptation of the output signal (current or voltages) and the polarity with the command SIGNAL:U (the

POL commando is removed)

Page 8 of 32 PID-131-U-2030 30.12.2015

Page 9

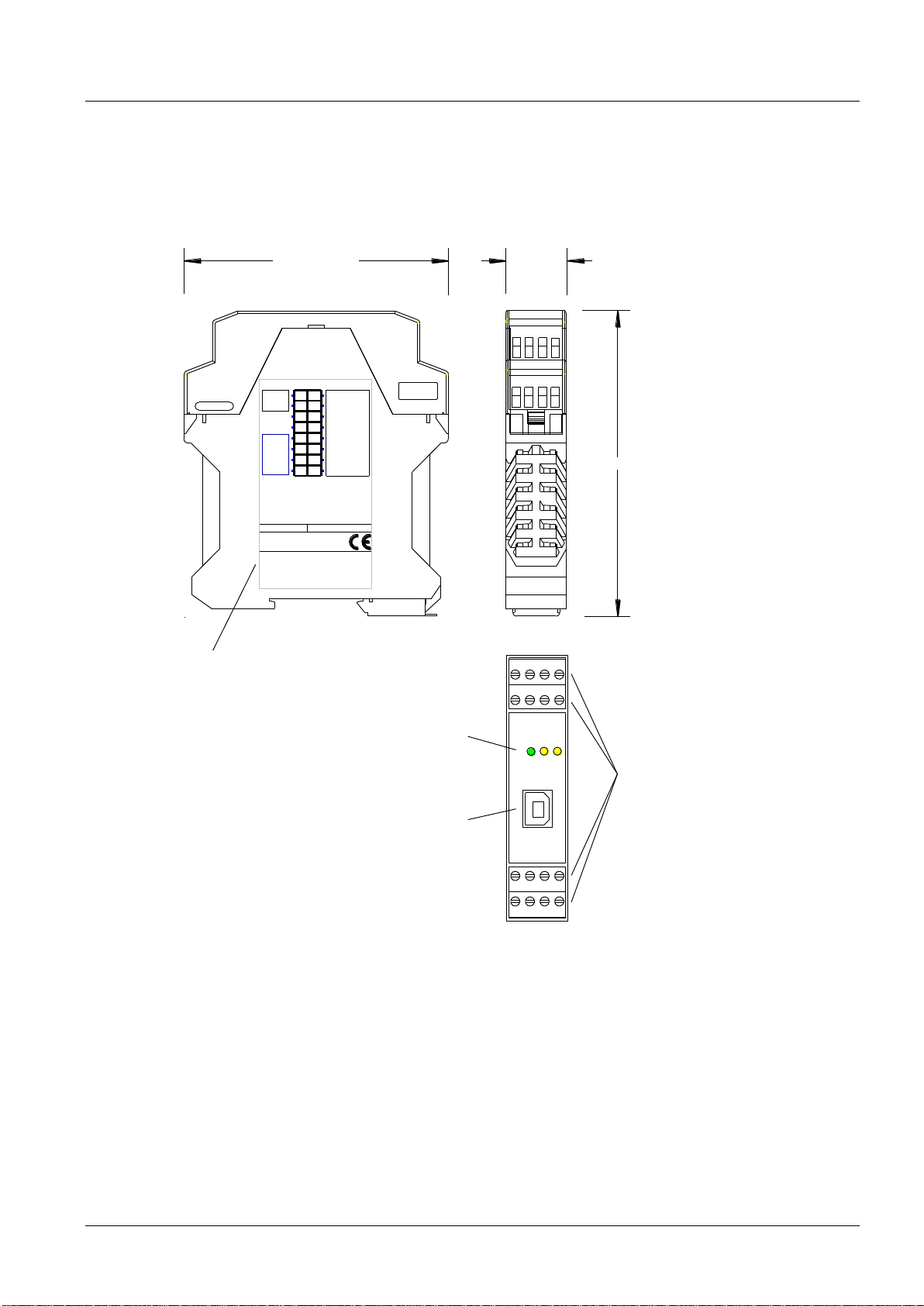

V:

ID:

Add.:Date:

Made in Germany

W.E.ST.

Ready

1 2 3 4

5 6 7 8

9 10 11 12

14 15 1613

D-41372 Niederkrüchten

Homepage: http://www.w-e-st.de

W.E.ST.

Elektronik

131415

9

10

11

12

16

A B

Klemmblöcke (steckbar)

Terminals (removable)

LEDs

USB

Interface

Typenschild und Anschlussbelegung

Type plate and terminal pin assignment

23,0000 mm99,0000 mm

114,0000 mm

2.2 Device description

W.E.ST.

Elektronik GmbH

Page 9 of 32 PID-131-U-2030 30.12.2015

Page 10

W.E.ST.

Elektronik GmbH

3 Use and application

3.1 Installation instructions

This module is designed for installation in a shielded EMC housing (control cabinet). All cables which

lead outside must be screened; complete screening is required. It is also necessary to avoid strong

electro-magnetic interference sources being installed nearby when using our open and closed loop

control modules.

Typical installation location: 24 V control signal area (close to PLC)

The devices must be arranged in the control cabinet so that the power section and the signal section

are separate from each other.

Experience shows that the installation place close to the PLC (24 V area) is most suitable. All digital and

analogue inputs and outputs are fitted with filters and surge absorbers in the device.

The module should be installed and wired in accordance with the documentation bearing in mind EMC

principles. If other consumers are operated with the same power supply, a star-shaped ground wiring

scheme is recommended. The following points must be observed when wiring:

The signal cables must be laid separately from power cables.

Analogue signal cables must be screened.

All other cables must be screened if there are powerful interference sources (frequency

converters, power contactors) and cable lengths > 3 m. Inexpensive SMD ferrites can be

used with high-frequency radiation.

The screening should be connected to PE (PE terminal) as close to the module as possible.

The local requirements for screening must be taken into account in all cases. The screening

should be connected to at both ends. Equipotential bonding must be provided where there

are differences between the connected electrical components.

If having longer lengths of cable (> 10 m) the diameters and screening measures should be

checked by specialists (e. g. for possible interference, noise sources and voltage drop).

Special care is required if using cables of over 40 m in length, and if necessary the

manufacturer should be consulted if necessary.

A low-resistance connection between PE and the mounting rail should be provided. Transient

interference is transmitted from the module directly to the mounting rail and from there to the local earth.

Power should be supplied by a regulated power supply unit (typically a PELV system complying with

IEC364-4-4, secure low voltage). The low internal resistance of regulated power supplies gives better

interference voltage dissipation, which improves the signal quality of high-resolution sensors in

particular. Switched inductances (relays and valve coils) which are connected to the same power supply

must always be provided with appropriate overvoltage protection directly at the coil.

Page 10 of 32 PID-131-U-2030 30.12.2015

Page 11

W.E.ST.

MINMAX

Input w

Input x

PID

Application interface

u

PLC

Sensor (position, pressure, velocity)

*4

*1

*2

*3

*5

Elektronik GmbH

3.2 Typical system structure

This minimal system consists of the following components:

(*1) Proportional valve (or control valve) with integrated electronics

(*2) Hydraulic cylinder

(*3) Sensor for the regulation of positions, pressures or speeds

(*4) Electronic module PID-131

(*5) Interface to PLC with analogue and digital signals

3.3 Method of operation

This control module can be used in a wide variety of applications, as powe , pressure and speed or velocity

control. The output signal suites any valves (with integrated electronics or external power amplifiers and power

plugs).

Due to the high stability of the PID controller, the use is particularly recommended where open loop control

would lead to poor reproducibility.

Typical use cases are pressure controlling fixed displacement pumps or remotely adjustable control pumps as

well as force/torque controls for cylinders and motors.

ENABLE: This digital input signal initializes the application. Error messages are deleted, the output is switched

on and the READY signal gets activated.

If the ENABLE input is deactivated the output gets switched off. Attention: Take care of the EOUT command.

Activating the RUN input starts the PID controller. Command and feedback input are evaluated now. The S0

input provides using an alternative second set of parameters if activated.

The function of input PIN5 depends on the parameterization. Either the ramp generator or the integrator can be

switched on and off with this input.

Page 11 of 32 PID-131-U-2030 30.12.2015

Page 12

Step

Task

Installation

Install the device in accordance with the circuit diagram. Ensure it is wired

correctly and that the signals are well shielded. The device must be installed in a

protective housing (control cabinet or similar).

Switching on for the first

time

Ensure that no unwanted movement is possible in the drive (e. g. switch off the

hydraulics). Connect an ammeter and check the current consumed by the device.

If it is higher than specified there is an error in the wiring. Switch the device off

immediately and check the wiring.

Setting up communication

Once the power input is correct the PC (notebook) should be connected to the

serial interface. Please see the WPC-300 program documentation for how to set

up communication.

Further commissioning and diagnosis are supported by the operating software.

Pre-parameterization

Now set up the following parameters (with reference to the system design and

circuit diagrams):

SENSOR SETTINGS and OUTPUT SIGNAL.

Parameterize specific settings for the control element (MIN, MAX and dither).

Pre-parameterization is necessary to minimize the risk of uncontrolled

movements.

Control signal

Check the control signal with a voltmeter. The control signal (PIN 15 to PIN16) is

in the range of ±10 V. In the current state it should show 0 V. Alternatively, if using

current signals, approximately 0 mA (PIN 15 to PIN 11) should flow.

Switching on the

hydraulics

The hydraulics can now be switched on. The module is not yet generating a

signal. Drives should be at a standstill or drift slightly (leave its position at a slow

speed).

Activating ENABLE

The module is set in operating state. If no error occures the operating state is

confirmed by the activated READY output and glowing green READY LED.

With the feedforward value the drive can be moved.

Activating START

Attention! Drives can now leave their position with maximum speed.

Take safety measures to prevent personal injury and damage. The control can

now be driven by the anlogue inputs.

Optimize controller

Now optimize the controller parameters according to your application and your

requirements.

3.4 Commissioning

W.E.ST.

Elektronik GmbH

Page 12 of 32 PID-131-U-2030 30.12.2015

Page 13

W.E.ST.

Connection

Supply

PIN 3

Power supply (see technical data)

PIN 4

0 V (GND) connection.

Connection

Analogue signals

PIN 11

GND

PIN 12

10 V Referenzspannungsausgang

PIN 13

Demand value (W), signal range 0… 10 V or 4… 20 mA, scalable

PIN 14

Actual value (X), signal range 0… 10 V or 4… 20 mA, scalable

PIN 15 / 16

Output control signal to the valve. Signal range +/- 10V, 0… 10V or 4… 20mA. Signal type and polarity are set with the parameter SIGNAL:U.

Connection

Digital inputs and outputs

PIN 8

Enable input:

General enabling of the application.

PIN 7

START (RUN) input:

Activates the controler and sets control signal.

PIN 6

S0 input:

Switching over between the parameter sets.

S0 = OFF : parameter set 1 is active

S0 = ON : parameter set 2 is active

PIN 5

RAMP/INTEG input:

Activates the ramp- or the integrator function. Function is chosen with the

parameter PIN5.

PIN 1

READY output:

ON: The module is enabled; there are no known errors.

OFF: Enable (PIN 8) is disabled or an error (current input or internal error) has

been detected.

PIN 2

STATUS output:

Monitoring of the control deviation depending on the CDWIN parameter, the status

output will be deactivated, if the control deviation is higher than the adjusted permitted range.

ON: control deviation is within the permitted range.

OFF: control deviation is out of the permitted range.

4 Technical description

4.1 Input and output signals

Elektronik GmbH

Page 13 of 32 PID-131-U-2030 30.12.2015

Page 14

LEDs

Description of the LED function

GREEN

Identical to the READY output.

OFF: No power supply or ENABLE is not activated

ON: System is ready for operation

Flashing: Error discovered

Only active when SENS = ON

YELLOW A

Identical to the STATUS output.

OFF: Control deviation is higher than CDWIN value.

ON: Control deviation is lower than CDWIN value.

GREEN +

YELLOW A+B

1. Chasing light (over all LEDs): The boot loader is active. No normal functions are

possible.

2. All LEDs flash shortly every 6 s: An internal data error was detected and corrected

automatically! The module still works regularly. To acknowledge the error the module

has to be cycle powered.

YELLOW A +

YELLOW B

Both yellow LEDs flash oppositely every 1 s: The non-volatile stored parameters are

inconsistent! To acknowledge the error, data has to be saved with the SAVE command or

the corresponding button in the WPC

4.2 LED definitions

W.E.ST.

Elektronik GmbH

Page 14 of 32 PID-131-U-2030 30.12.2015

Page 15

Commands:

SIGNAL:W

AIN:W

Input Scaling

PE via DIN-RAIL

15

16

11

1

2

Output: A

Output: B

8

5

Ready

Status

Enable

Run

24 V output

24 V output

USB Type B

Differential

Input

PID-131-U

7

13

14

0 V

0..10V

0 V

11

11

Feedback

4..20mA

Output Adaptation

Ramp / Integ

24 V input

24 V input

24 V input

U

Internal Power

3

4

0 V

Control program

24 V input

6

S0

Input Scaling

Commands:

SIGNAL:X

R_SENS:X

OFFSET:X

AIN:X

0..10V

4..20mA

0 V

Command

0 V

PID control

Commands:

- MIN:A and :B

- MAX:A and :B

- TRIGGER

- SIGNAL:U

DC

DC

24 V

0 V

PELV

Commands:

- LG (Language)

- MODE (Expert or Standard)

- TS

- SENS

- AINMODE

- PIN:5

- CDWIN

- EOUT (Error Mode)

Ramp Generator

X

WA

W

E

-

S0

C2:PIDD_T1FFI_LIM

I_ACT

PT1_P

PT1_T1

C1:PIDD_T1FFI_LIM

I_ACT

PT1_P

PT1_T1

RA1:UPDOWN

RA2:UPDOWN

Commands:

USB

Serial

56700 Bd

8N1

Commands:

4... 20 mA OUTPUT

PIN 15 = +

PIN 11 = GND

12

Reference voltage

output

4.3 Circuit diagram

W.E.ST.

Elektronik GmbH

Page 15 of 32 PID-131-U-2030 30.12.2015

Page 16

4.4 Typical wiring

+In PIN 13 or 14

PIN 11 (GND)

SPS / PLC 0... 10 V command input signal

+In PIN 13

-In PIN 11

AIN:W 2000 1600 2000 C ( für 0... 100%)

SPS / PLC 0... 10 V feedback input signal

+In PIN 14

In PIN 11 (GND)

PLC or sensor with 4... 20 mA (two wire connection)

z. B. 24 V

+In PIN 13 or 14

PIN 11 (GND)

AIN:W 2000 1600 2000 C ( für 0... 100%)

PLC or sensor with 4... 20 mA (three wire connection)

z. B. 24 V

Ventile (6 + PE Stecker) mit integrierter Elektronik

A : 24 V Versorgung

B : 0 V Versorgung

C : GND oder Enable

D : + Differenzeingang

E : - Differenzeingang

F : Diagnosesignal

PE -

PIN 15

PIN 16

PIN 12

8765

16151413

1211109

Shield

Analoger command

(0..10V or 4..20mA)

Power supply

tor

PLC

24V

0V

Ready

from

PLC

4321

Shield

Analoger feedback

(0..10V or 4..20mA)

0V

10 V Reference

voltage output

PE

PE

Enable

Run

S0

Ramp

CDWIN

To power amplifier /

valve +/- 10V.

Use differential input.

Using 4... 20mA PIN 15 to PIN 11.

0..10V or 4..20mA

0..10V

W.E.ST.

Elektronik GmbH

4.5 Connection examples

Page 16 of 32 PID-131-U-2030 30.12.2015

Page 17

Supply voltage (Ub)

Current requirement

External protection

[VDC]

[mA]

[A]

12… 30 (incl. ripple)

<100

1 medium time lag

Digital inputs

Input resistance

[V]

[V]

[kOhm]

logic 0: <2

logic 1: >10

25

Digital outputs

Maximum output current

[V]

[V]

[mA]

logic 0: <2

logic 1: max. Ub

50

Analogue inputs

Signal resolution

[V]

[mA]

[%]

0… 10; min. 25 kOhm

4… 20; 240 Ohm

0,003 incl. Oversampling

Analogue outputs

Voltage

Signal resolution

Current

Signal resolution

[V]

[mA]

[%]

[mA]

[%]

2 x 0… 10; differential output

5 (max. load)

0,006

4… 20; 390 Ohm maximum load

0,006

Controller sample time

[ms]

1 (variable from 0,5 … 3)

Serial interface

USB in RS 232C Emulation

(9600… 57600 Baud, 1 Stop bit,

no parity, Echo Mode)

Housing

Snap-on module to EN 50022

PA 6.6 polyamide

Flammability class V0 (UL94)

Weight

[kg]

0,170

Protection class

Temperature range

Storage temperature

Humidity

[°C]

[°C]

[%]

IP20

-20… 60

-20… 70

< 95 (non-condensing)

Connections

USB-B

4 x 4-pole terminal blocks

PE: via the DIN mounting rail

EMC

EN 61000-6-2: 8/2005

EN 61000-6-4: 6/2007 ; A1:2011

4.6 Technical data

W.E.ST.

Elektronik GmbH

Page 17 of 32 PID-131-U-2030 30.12.2015

Page 18

Group

Command

Default

Unit

Description

Basic parameters

LG

EN

-

Changing language help texts

MODE

STD

-

Parameter view

SENS

AUTO

-

Malfunction monitor

PIN:5

RAMP

-

Function of pin 5

CDWIN

200

0,01%

Size of the control deviation window

EOUT

0

0,01 %

Output signal if not ready

Input signal adaptation

Sensor scaling

SIGNAL:X

U0-10

Type of input

N_RANGE:X

100

%

Range of sensor in relation to working range

OFFSET:X

0

0,01%

Sensor offset

Command Input scaling

SIGNAL:W

U0-10

-

Type of input.

Ramp and PID control parameters

Parameter set 1

RA1:UP

RA1:DOWN

100

100

ms

ms

Command signal ramp times

C1:P

C1:I

C1:D

C1:D_T1

C1:FF

C1:I_LIM

C1:I_ACT

C1:PT1_P

C1:PT1_T1

50

4000

0

500

0

2500

2500

0

50

0,01 %

0,1 ms

0,1 ms

0,1 ms

0,01 %

0,01 %

0,01 %

0,01 %

0,1 ms

P gain

I gain

D gain

D gain filter

Feed forward

Integrator limitation

Integrator activation threshold

PT1 gain

PT1 time constant

Parameter set 2

RA2:UP

RA2:DOWN

100

100

ms

ms

Command signal ramp time

C2:P

C2:I

C2:D

C2:D_T1

C2:FF

C2:I_LIM

C2:I_ACT

C2:PT1_P

C2:PT1_T1

50

4000

0

500

0

2500

2500

0

50

0,01 %

0,1 ms

0,1 ms

0,1 ms

0,01 %

0,01 %

0,01 %

0,01 %

0,1 ms

P gain

I gain

D gain

D gain filter

Feed forward

Integrator limitation

Integrator activation threshold

PT1 gain

PT1 time constant

5 Parameters

5.1 Parameter overview

W.E.ST.

Elektronik GmbH

Page 18 of 32 PID-131-U-2030 30.12.2015

Page 19

W.E.ST.

Group

Command

Default

Unit

Description

Output signal adaptation

MIN:A

MIN:B

0

0

0,01 %

0,01 %

Dead band compensation

MAX:A

MAX:B

10000

10000

0,01 %

0,01 %

Output scaling

TRIGGER

200

0,01 %

Dead band compensation trigger point

SIGNAL:U

U+-10

-

Type of output signal and polarity

Special commands

Sample time

TS

10

0,1 ms

Sample time of the control loop

Scaling mode

AINMODE

EASY

-

Input scaling mode

AIN:X

AIN:W

A: 1000

B: 1000

C: 0

X: V

-

-

0,01 %

-

Free scaling of the analogue inputs. Gets activated when

AINMODE is switched over to MATH.

Elektronik GmbH

Page 19 of 32 PID-131-U-2030 30.12.2015

Page 20

W.E.ST.

Command

Parameters

Unit

Group

LG x

x= DE|EN

-

STD

Command

Parameters

Unit

Group

MODE x

x= STD|EXP

-

STD

Command

Parameters

Unit

Group

SENS x

x= ON|OFF|AUTO

-

STD

Elektronik GmbH

5.2 Basic parameters

LG (Changing the language)

Either German or English can be selected for the help texts.

CAUTION: After changing the language settings the ID button (SPEED BUTTON) in the menu bar

(WPC-300) must be pressed (module identification).

MODE (Switching between parameter groups)

This command changes the operating mode. Various commands (defined via STD/EXP) are blanked out in

Standard Mode. The commands in Expert Mode have a more significant influence on system behavior and

should accordingly be changed with care.

SENS (monitoring of the modul functions)

This command is used to activate/deactivate the monitoring functions (4… 20 mA inputs and internal failures) of

the module.

ON: All monitoring functions are active. Detected failures can be reset by deactivating the ENABLE input.

OFF: No monitoring function is active.

AUTO: Auto reset mode. All monitoring functions are active. If the failure does not exist anymore, the mod-

ule automatically resumes to work.

Normally the monitoring functions are always active because otherwise no errors are detectable via

the READY output. Deactivating is possible mainly for troubleshooting.

Page 20 of 32 PID-131-U-2030 30.12.2015

Page 21

W.E.ST.

Command

Parameters

Unit

Group

PIN5 x

x= RAMP|INTEG

-

STD

Command

Parameters

Unit

Group

CDWIN x

x= 0… 2000

0,01 %

STD

Command

Parameters

Unit

Group

EOUT x

x= -10000… 10000

0,01 %

EXP

2

Elektronik GmbH

PIN5 (Function of PIN 5)

With this command the function of PIN 5 can be defined.

RAMP: With input PIN 5 the ramp can be (de-)activated.

INTEG: With input PIN 5 the integrator can be (de-)activated. Ramp generator is active.

CDWIN (Size of the control deviation window)

This parameter is entered in 0.01 % of the setpoint .

The CDWIN command defines a monitoring rangewindow for which the CDWIN message is generated. The

monitoring window monitors the deviation between the setpoint and the actual feedback value. if the deviation is

within the CDWIN window, this is signaled via the status output and the CDWIN LED. The control process is not

influenced by this signal.

EOUT (Output signal if not ready)

Output value in case of a detected error or a missing ENABLE signal. A value (degree of valve opening) for use

in the event of a sensor error (or the module is disabled) can be defined here. This function can be used if, for

example, the drive shall move to one of the two end positions (at the specified speed) in case of a sensor error.

|EOUT| = 0 The output is switched off in the event of an error. This is normal behavior.

CAUTION! If the output signal is 4… 20 mA, the output is switched off when |EOUT| = 0. If a null

value = 4 mA is to be output in the event of an error, EOUT must be set to 12.

The output value defined here is stored permanently (independently of the parameter set). The

effects should be analyzed by the user for each application from the point of view of safety.

This is necessary if using valves without error detection for signals lower than 4 mA. If the valve has an error detection it

goes into a defined position after switching of the output.

Page 21 of 32 PID-131-U-2030 30.12.2015

Page 22

W.E.ST.

Command

Parameter

Unit

Group

SIGNAL:i x

i= W|X

x= OFF|U0-10|I4-20|

U10-0|I20-4

V|mA

EASY

Command

Parameter

Unit

Group

N_RANGE:X x

x= 1… 10000

%

EASY

Command

Parameter

Unit

Group

OFFSET:X x

x=-10000… 10000

0,01%

EASY

3

Elektronik GmbH

5.3 Input signal adaptation

SIGNAL (Type of input)

This command can be used to change the type of input signal (voltage or current) and to define the direction of

the signal. This command is available for all analogue inputs (W, X).

OFF= Deactivation of the input3.

N_RANGE:X (Nominal range of the sensor)

With this command, the measurement range of the sensor is defined. The format is a percentage figure in relation to the operating range of the system. Since this is a general PID controller, the working range of the system

is defined as 100%. Incorrect specifications lead to a corrupted system and the dependent parameters cannot

be calculated correctly.

N_RANGE normally should not be less than 100 %

OFFSET:X (Sensor offset)

With this command, the zero point of the sensor is set. The format is a percentage figure in relation to the operating range of the system. Since this is a general PID controller, the working range of the system is defined as

100%

The deactivation can be used to deactivate the velocity (speed) input PIN_9/10 (the VELO value is active).

Page 22 of 32 PID-131-U-2030 30.12.2015

Page 23

W.E.ST.

Command

Parameters

Unit

Group

RAp:i x

p= 1|2(Parameter set)

i= UP|DOWN

x= 1… 600000

ms

STD

t

Ausgang/Output A

A:UP

A:DOWN

Elektronik GmbH

Using the commands SIGNAL:X, N_RANGE:X and OFFSET:X

With these commands, the feedback sensor is scaled. Suppose you have a pressure control with the following

characteristics:

The system pressure is 350 bar

The pressure sensor has a 4-20mA current output

The nominal pressure of the sensor is 600bar (20mA at 600bar)

The sensor has an offset of 3bar (at 0bar real pressure 3bar are displayed)

To scale this sensor correctly the following settings should be made:

SIGNAL:X I4-20

N_RANGE:X 171% (for 600bar are 171% of 350bar )

OFFSET:X -85 ( because 3bar is representing 0.85 % of 350bar )

5.4 Ramp and PID control parameters

RA (Command signal ramp times)

Ramp function for the 1st and 2nd quadrant.

The ramp time is adjusted separately for rising and falling input signals.

Page 23 of 32 PID-131-U-2030 30.12.2015

Page 24

W.E.ST.

Command

Parameters

Unit

Group

Cp:i x

p= 1|2 (parameter set)

i= P|I|D|D_T1|FF|I_LIM|I_ACT|PT1_P|PT1_T1

:P x= 0… 10000

:I x= 0… 30000

:D x= 0… 1200

:D_T1 x= 0… 1000

:FF x= 0… 10000

:I_LIM x= 0… 10000

:I_ACT x= 0… 10000

:PT1_P x= 0… 10000

:PT1_T1 x= 5… 1000

0,01 %

0,1 ms

0,1 ms

0,1 ms

0,01 %

0,01 %

0,01 %

0,01 %

0,1 ms

STD

w Sollwertskalierung

Rampenfunktion

x Istwertskalierung

-

0.. 10 V

4.. 20 mA

C:PT1_P

C:PT1_T1

Druckregler

C:P P-Verstärkung

C:I I-Anteil

C:D D-Anteil

C:T1 D-Anteil Filter

C:FF Vorsteuerung

LIM:I Integratorbegrenzung

LIM:S Integratoraktivierungsschwelle

C:PT1_P PT1 Verstärkung

C:PT1_T1 PT1 Zeitkostante

0.. 10 V

4.. 20 mA

C:P

C:I LIM:ILIM:S

w

x

C:D

C:T1

-

C:SC

Elektronik GmbH

C (PID Control Settings)

The control function will be parameterized via these commands.

The P, I and D gain are similar to a standard PID controller. The D_T1 factor is a filter for the D-gain in order to

suppress high-frequency noise.

Via the FF value the command value is lead directly to the output. Because of that the controller only has to

compensate the control deviation. This causes a solid type of control and a dynamic triggering.

I_ACT controls the integrator function. To reduce pressure overshoots, an activation point for the integrator can

be programmed via the LIM:S value. The integrator is activated if the actual pressure is higher than the programmed threshold.

I_LIM limits the working range of the integrator, so that the controller can quickly react to the process without

any major overshoots. If the value is too small, it may have the effect that the non-linearity of the valve cannot

be fully compensated.

The commands PT1_P and PT1_T1 set up an additional PT1 controller component parallel to the P component.

The low pass filtered P component can often be operated at higher gains than the direct P component. The sta-

bility is improved by the T1 value.

Page 24 of 32 PID-131-U-2030 30.12.2015

Page 25

W.E.ST.

Command

Parameters

Unit

Group

MIN:I x

MAX:I x

TRIGGER x

i= A|B

x= 0… 6000

x= 3000… 10000

x= 0… 4000

-

0,01 %

0,01 %

0,01 %

STD

MAX:A

MIN:A

MIN:B

MAX:B

Input

Output

TRIGGER

Elektronik GmbH

5.5 Output signal adaptation

MIN (Deadband compensation)

MAX (Output scaling)

TRIGGER (Deadband compensation trigger point)

With this command, the output signal is adjusted to the valve characteristics. With the MAX value the output signal (the maximum valve current) will be defined. With the MIN value the overlap (dead band of the valve) will be

compensated. Via the TRIGGER the activation point of the MIN function is set and so a non-sensitive range

around the zero-point can be specified.

ATTENTION: If the MIN value is set too high, it influences the minimal pressure, which cannot

be adjusted any longer. In extreme case, this causes to an oscillating at small input values.

Page 25 of 32 PID-131-U-2030 30.12.2015

Page 26

W.E.ST.

Command

Parameters

Unit

Group

SIGNAL:U x

x= U+-10|I4-12-20|

U-+10|I20-12-4|

U0-10|I4-20|

U10-0|I20-4

V|mA

STD

Elektronik GmbH

SIGNAL:U (Output type and polarity)

This command defines the type of the output signal (current / voltage) and its polarity.

You can also choose between differential and unipolar output types.

With differential outputs, the output voltage lies between terminals 15 and 16, single ended Output lies on termi-

nal 15 with reference to terminal 11.

Differential voltage

o +-10V

o -+10V

Single ended voltage

o 0-10V

o 10-0V

Single ended current with zero point at 12mA

o 4-12-20mA

o 20-12-4mA

Single ended current with zero point at 4mA

o 4-20mA

o 20-4mA

An output current of less than 4 mA indicates that an error occurred or the module is not enabled.

It is important to ensure that the connected valve closes at currents below 4mA. (If this is not the

case, the EOUT command should be used to generate a defined output signal)

Page 26 of 32 PID-131-U-2030 30.12.2015

Page 27

W.E.ST.

Command

Parameters

Unit

Group

TS x

x= 5… 30

0,1 ms

TERMINAL

Command

Parameters

Unit

Group

AINMODE x

x= EASY|MATH

-

TERMINAL

Elektronik GmbH

5.6 Special commands

TS (Sample time)

The control dynamics can be influenced with the sample time. Changes should only be made by persons who

have sufficient knowledge of the dynamic system behavior.

CAUTION! After changing this value all time-dependent parameters must be checked and reset if

necessary.

AINMODE (Input scaling mode)

The command AINMODE is used to choose the input scaling method.

In the EASY mode (the default mode) the user may choose via the SIGNAL command from a variety of stand-

ard input signal types and polarities. The MATH mode, which is compatible to our older modules may be used to

freely scale inputs with the AIN command.

Attention: This command does not show up in the parameter list in WPC. It has to be entered manually in the terminal window. After any change of AINMODE, module default data should be applied

(by pressing the corresponding button in WPC300)

Page 27 of 32 PID-131-U-2030 30.12.2015

Page 28

W.E.ST.

Command

Parameters

Unit

Group

AIN:i

a

b

c

x

i= W|X

a= -10000… 10000

b= -10000… 10000

c= -500… 10000

x= V|C

-

-

0.01%

-

MATH

)( cInput

b

a

Output

Command

Input

signal

Description

AIN:x 1000 1000 0 V

0… 10 V

Range: 0… 100 %

AIN:x 10 8 1000 V OR

AIN:x 1000 800 1000 V

1… 9 V

Range: 0… 100 %; 1 V = 1000 used for the offset and

gained by 10 / 8 (10 V divided by 8 V (9 V -1 V))

AIN:x 10 4 500 V OR

AIN:x 1000 400 500 V

0,5… 4,5 V

Range: 0… 100 %; 0,5 V = 500 used for the offset and

gained by 10 / 4 (10 V divided by 4 V (4,5 V -0,5 V))

AIN:x 20 16 2000 C OR

AIN:x 2000 1600 2000 C OR

AIN:x 1250 1000 2000 C

4… 20 mA

Range: 0… 100 %

The offset will be compensated on 20 % (4 mA) and the

signal (16 mA = 20 mA – 4 mA) will be gained to 100 %

(20 mA).

Each of this parameterization for 4… 20 mA is setting the

range to 0… 100 %.

Elektronik GmbH

AIN (Free analogue input scaling)

This command offers a method to individualy scale an input. The following linear equation is used for the

scaling.

The “C” value is the offset (e.g. to compensate the 4 mA in case of a 4… 20 mA input signal).

The variables A and B are defining the gain factor with which the signal range is scaled up to 100 % (e.g. 1.25 if

using 4… 20mA input signal, defined in default current settings by A = 1250 and B = 1000). The internal shunt

for the current measuring is activated with switching the X value.

The gain factor is calculated by setting the usable range (A) in relation to the real used range (B) of the input

signal. Usable are 0… 20mA, means (A) has the value 20. Really used are 4… 20mA, means (B) has a value of

16 (20-4). Not used are 0… 4mA. In a range of 20mA this is an offset of 20%, means a value of 2000 for (C).

Last but not least (X) has to be set to C choosing current signal.

In this case AIN command would look like this:

AIN:I 20 16 2000 C or AIN:I 1250 1000 2000 C

Typical settings (examples):

Page 28 of 32 PID-131-U-2030 30.12.2015

Page 29

W.E.ST.

Command

Parameters

Unit

W

WA

X

E

C

U

Command input signal

Command value

Actual value

Control deviation

Controler output

Output control signal

%

%

%

%

%

%

Elektronik GmbH

5.7 PROCESS DATA (Monitoring)

The process data are the variables which can be observed continuously on the monitor or on the oscilloscope.

Page 29 of 32 PID-131-U-2030 30.12.2015

Page 30

W.E.ST.

Source

Fault

Characteristic

Command signal PIN 13

4... 20 mA

Out of range.

The output will be switched off.

Feedback signal PIN 14

4… 20 mA

Out of range.

The output will be switched off.

EEPROM

(at switching on)

Data error

The output is deactivated.

The module can be activated by

saving parameters again.

FAULT

CAUSE / SOLUTION

ENABLE is active, the

module does not

respond, and the

READY LED is off.

There is presumably no power supply or the ENABLE signal (PIN 8) is not present.

If there is no power supply there is also no communication via our operating

program. If a connection has been made to the WPC-300, then a power supply is

also available.

ENABLE is active, the

READY LED is flashing.

The flashing READY LED signals that a fault is been detected by the module. The

fault could be:

A broken cable or no signal at the input (PIN 13 oder 14), if 4…20 mA signals are

parameterized.

Internal data error: press the command/SAVE button to delete the data error. The

system reloads the DEFAULT data.

With the WPC-300 operating program the fault can be localized directly via the

monitor.

ENABLE and RUN are

active; the READY LED

is on, the system moves

to an end position.

The control circuit polarity is incorrect. The polarity can be changed with the

SIGNAL:U command or by reversing the connections to PIN 15 and PIN 16.

Elektronik GmbH

6 Appendix

6.1 Failure monitoring

Following possible error sources are monitored continuously when SENS = ON / AUTO:

CAUTION: Take care of the EOUT command. Changes will influense the behaviour.

6.2 Troubleshooting

It is assumed that the device is in an operable state and there is communication between the module and the

WPC-300. Furthermore, the valve control parameterization has been set with the assistance of the valve data

sheets. The RC in monitor mode can be used to analyze faults.

CAUTION: All safety aspects must be thoroughly checked when working with the RC (Remote

Control) mode. In this mode the module is controlled directly and the machine control cannot

influence the module.

Page 30 of 32 PID-131-U-2030 30.12.2015

Page 31

W.E.ST.

Elektronik GmbH

6.3 Description of the command structure

The command structure:

[nnnn:i x] or

[nnnn x]

Meaning:

nnnn - used for an arbitrary command name

nnnn: - used for an arbitrary command name, expandable by an index.

Indexed commands are indicated by the sign “:”

i or I - a dummy is for the index. E. g. an index can be „A“ or „B“, depending on the direction.

x - parameter value, in case of special commands more than one parameter are possible.

Examples:

MIN:A 2000 nnnn = “MIN”, i = “A” and x = “2000”

OFFSET 50 nnnn = „OFFSET“ and x = „50“

C:IC 2000 nnnn = “C”, i = “IC” and x = “2000”

Page 31 of 32 PID-131-U-2030 30.12.2015

Page 32

7 Notes

W.E.ST.

Elektronik GmbH

Page 32 of 32 PID-131-U-2030 30.12.2015

Loading...

Loading...