West 6400 Operating Manual

1

-DIN

1 6

PROFILER/CONTROLLER

Product Manual

59129-2

HOW TO USE THIS MANUAL

This manual comprises two volumes:

PM077-V1

Volume I

(

iii

)

PM-0077

1

-DIN PROFILER/CONTROLLER

1 6

PRODUCT MANUAL

VOLUME I

OPERATING INSTRUCTIONS

In normal operation, the operator must not remove the

Profiler/Controller from its housing or have unrestricted access to the

rear terminals, as this would provide potential contact with hazardous

live parts.

Installation and configuration must be undertaken only by

technically-competent servicing personnel. This is covered in Volume II

of this manual.

CONTENTS

1 BASE MODE 1-1

1.1 DISPLAY SEQUENCE - NO PROGRAM RUNNING 1-1

1.2 STARTING A PROGRAM 1-2

1.3 PUTTING A PROGRAM IN HOLD 1-2

1.4 RELEASING A PROGRAM FROM HOLD 1-2

1.5 ABORTING A PROGRAM 1-2

1.6 DISPLAY SEQUENCE - PROGRAM RUNNING 1-3

1.7 RaPID CONTROL FEATURE 1-4

1.8 PRE-TUNE FEATURE 1-4

1.9 ENGAGING BOTH PRE-TUNE AND RaPID FEATURES 1-5

1.10 INDICATION OF PRE-TUNE AND RaPID STATUS 1-5

1.11 VIEWING THE HARDWARE DEFINITION CODE 1-6

1.12 MANUAL CONTROL 1-7

(iv)

Volume I

PM077-V1

PM-0077

2 PROGRAM DEFINITION MODE -

CREATING/EDITING A PROGRAM 2-1

2.1 ENTRY 2-1

2.2 CREATING A PROGRAM 2-2

2.3 DEFAULT VALUES AND ADJUSTMENT RANGES 2-9

2.4 EXIT FROM PROGRAM DEFINE MODE 2-9

3 CONTROLLER SET-UP MODE 3-1

3.1 PARAMETER DETAILS 3-3

3.2 EXIT FROM CONTROLLER SET-UP MODE 3-9

4 MODBUS COMMUNICATIONS 4-1

4.1 INTRODUCTION 4-1

4.2 MODBUS FUNCTIONS SUPPORTED 4-1

4.3 MESSAGE FORMATS 4-1

4.4 PARAMETER NUMBERS 4-7

4.5 PROFILER STATUS BYTE 4-11

4.6 PROFILER COMMANDS 4-11

O077-1

Volume I

1-1

PM-0077

1 BASE MODE

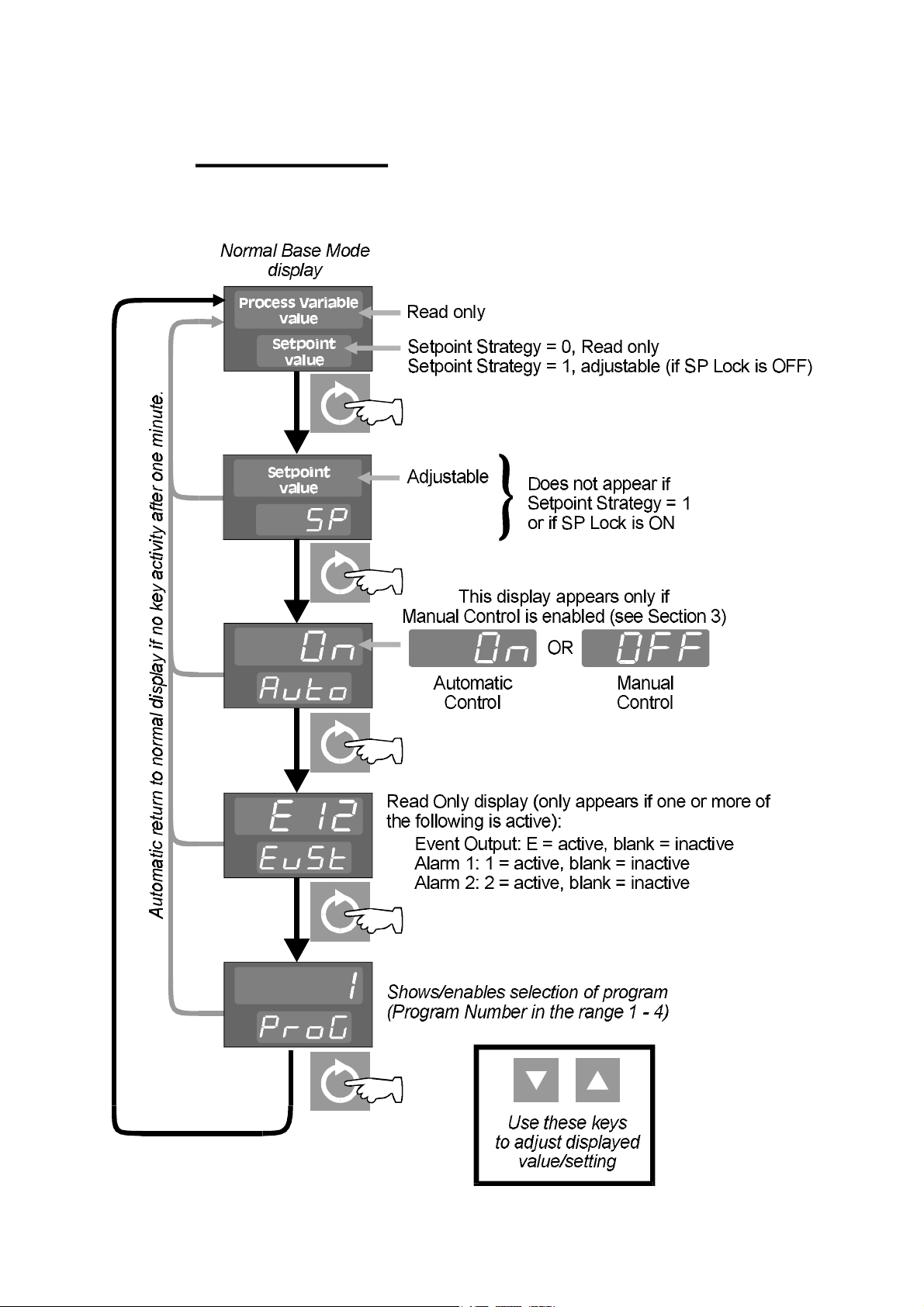

1.1 DIS P L A Y SEQUENCE - NO PROGRAM RUNNING

1.2 STARTING A PROGRAM

1-2

Volume I

O077-1

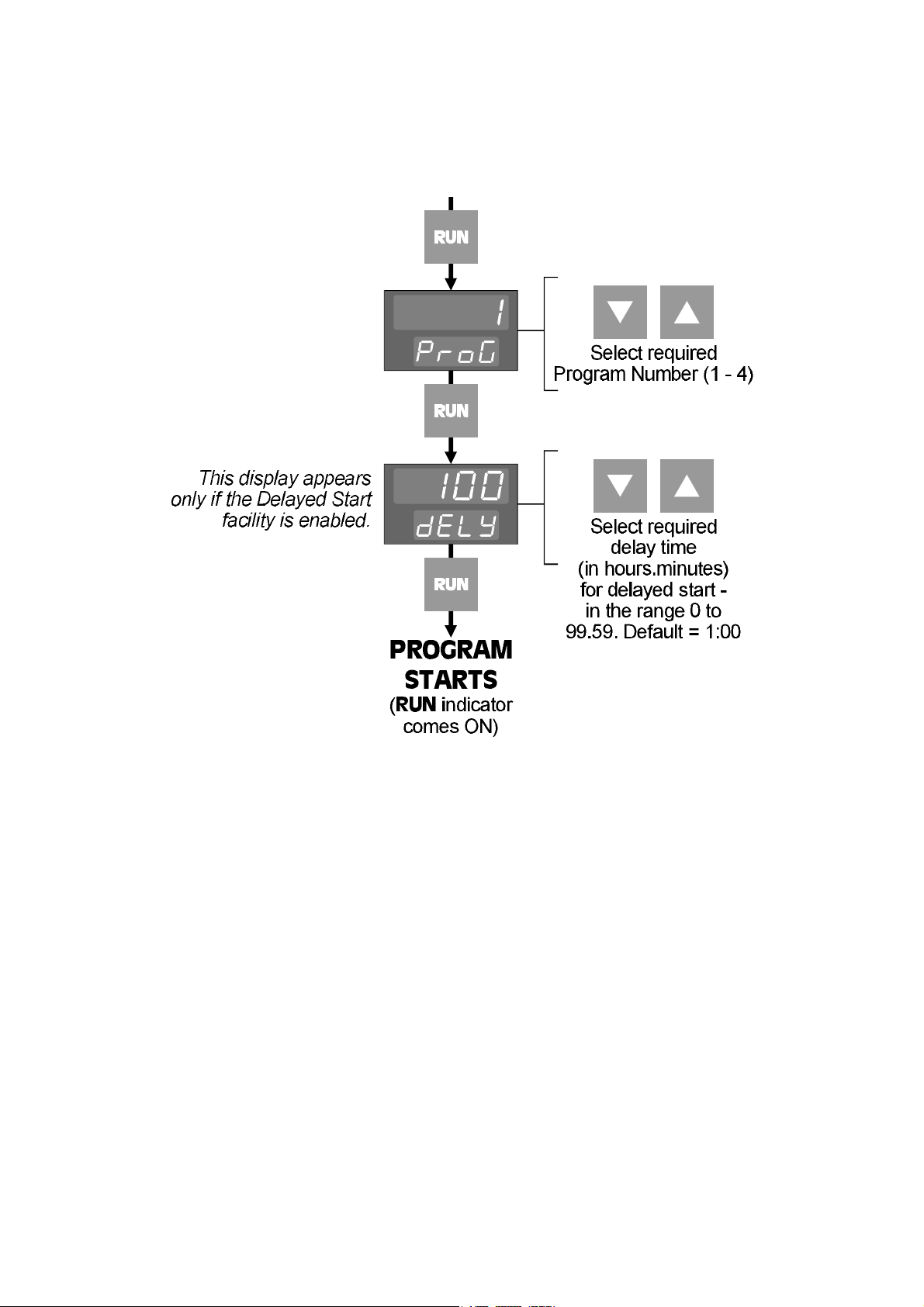

To start a program running:

PM-0077

1.3 PUTTING A PROGRAM IN HOLD

A program can be put in Hold (i.e. frozen) at any time whilst it is running. The

program setpoint will stay at its value at the instant the program entered Hold until

the program is released (see Subsection 1.4) or aborted (see Subsection 1.5). To

put a program in hold, momentarily press the RUN key. The RUN indicator will

flash whilst the program is in hold.

1.4 RELEASING A PROGRAM FROM HOLD

To release a program currently in Hold, momentarily press the RUN key. The

RUN indicator will then go ON continuously.

1.5 ABORTING A PROGRAM

To abort the current-running (or held) program, hold down the RUN key for 5

seconds. The program will be aborted, the RUN indicator will go OFF and the

normal Controller functions will be resumed.

O077-1

Volume I

1-3

PM-0077

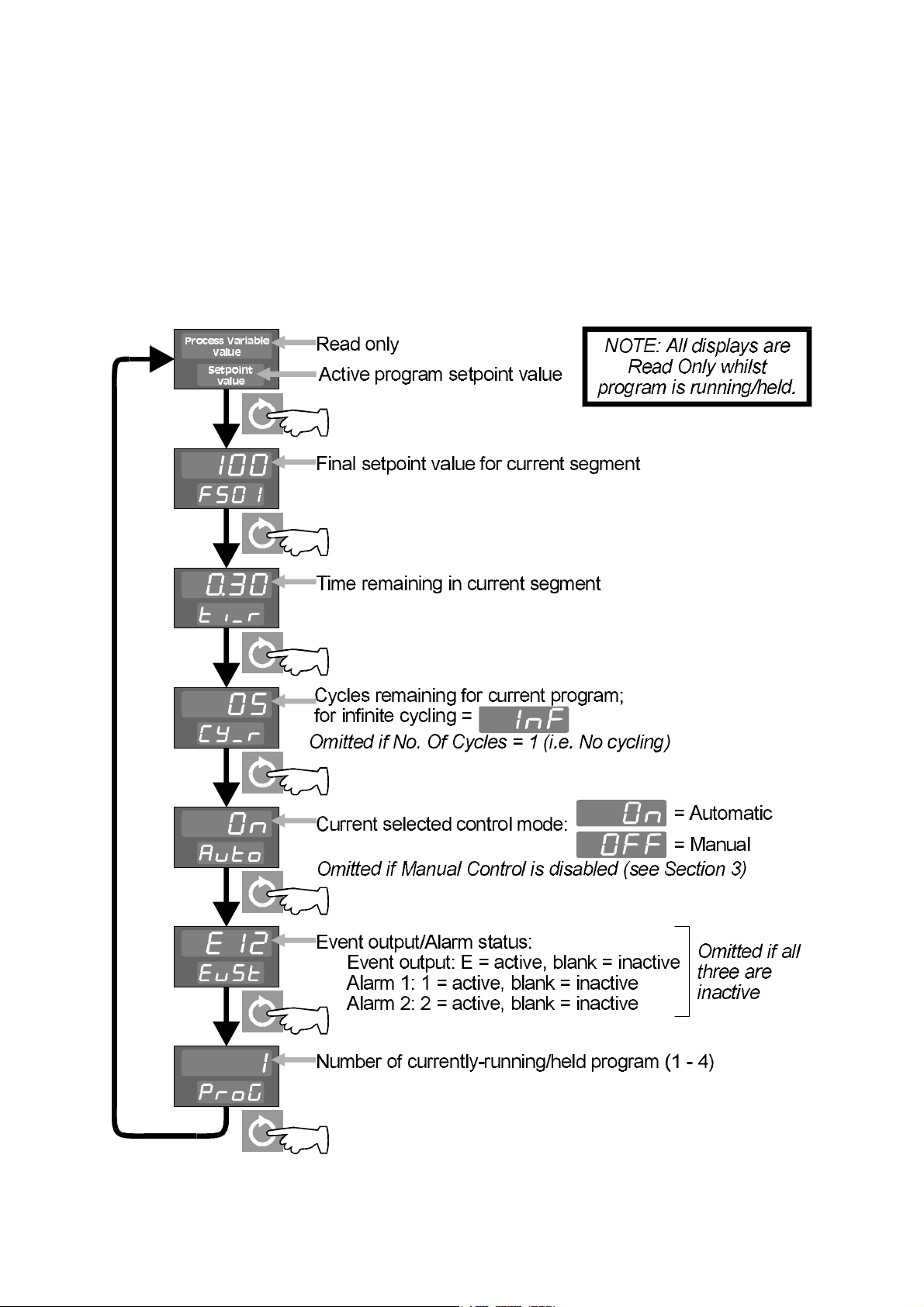

NOTE: When a program is aborted, the instrument returns to the Controller

Setpoint value. If a program is successfully completed, the Controller

Setpoint is automaticaly set to the final setpoint value of the program. If it is

desired to restore the initial Controller Setpoint value after the program is

completed, this value should be used as the program Final Setpoint value.

1.6 DISPLA Y SEQ U EN CE - PROGRAM RUNNING

1-4

Volume I

O077-1

PM-0077

1.7 RaPID CONTROL FEATURE

The RaPID control feature may be used when extra fast responses and minimum

overshoot are required. The RaPID feature works best when PID terms are

well-tuned; therefore, it is recommended that the Pre-Tune feature (see Subsection

1.8) is run before the RaPID feature is engaged.

To dis-engage RaPID control, use the same key actions. NOTE: The RaPID feature

cannot be engaged if Proportional Band 1 or Proportional Band 2 is set to 0.

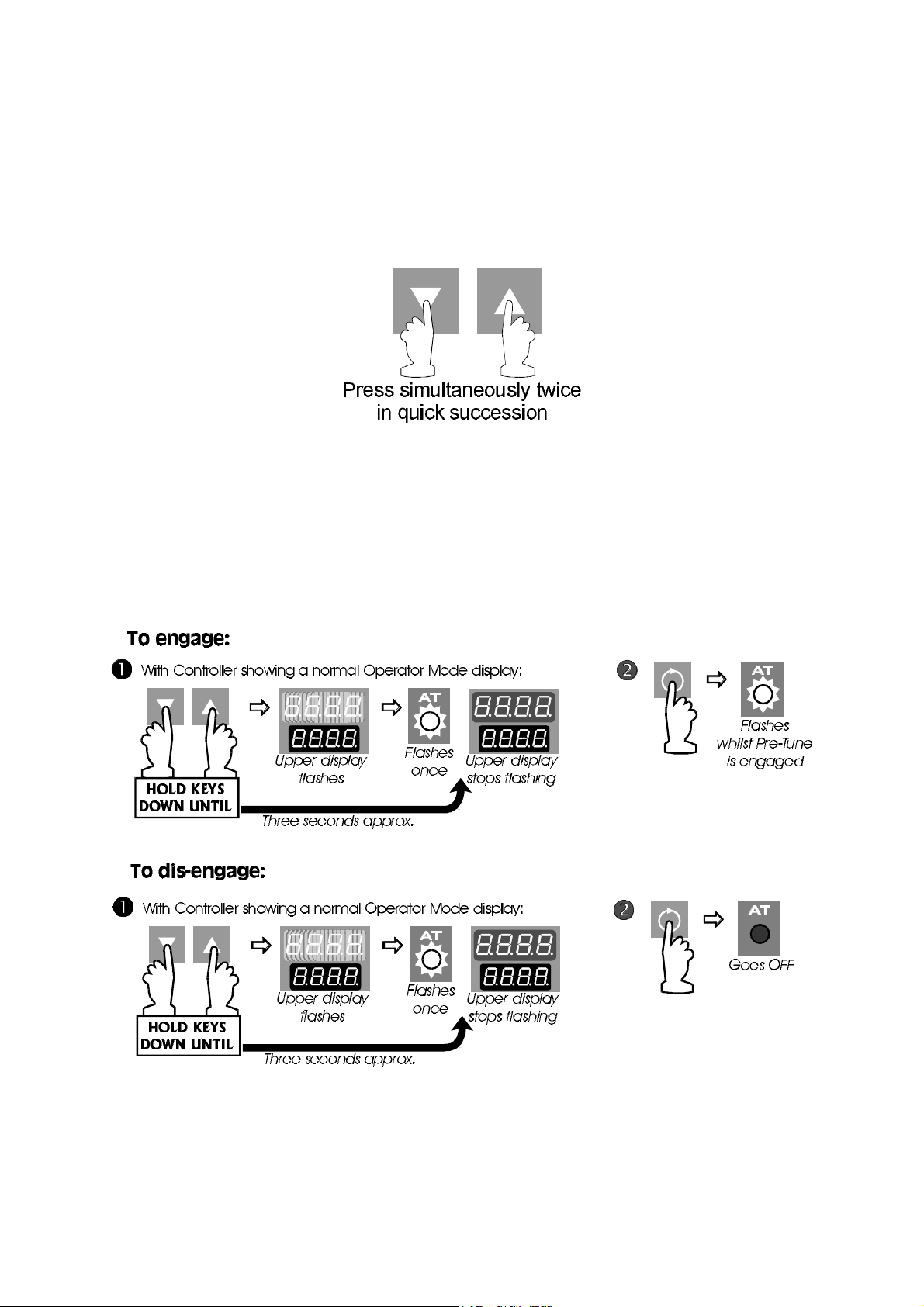

1.8 PRE-TUNE FEATURE

This facility may be used to provide initial tuning of the Controller’s PID parameters.

Pre-Tune may be engaged (and subsequently dis-engaged) as follows:

NOTE: The Pre-Tune facility will not engage if (a) a program is currently

running, (b) the process variable is within 5% of input span of the setpoint,

or (c) an erroneous key sequence is used. Pre-Tune is a single-shot process

which automatically dis-engages itself when completed.

O077-1

Volume I

1-5

PM-0077

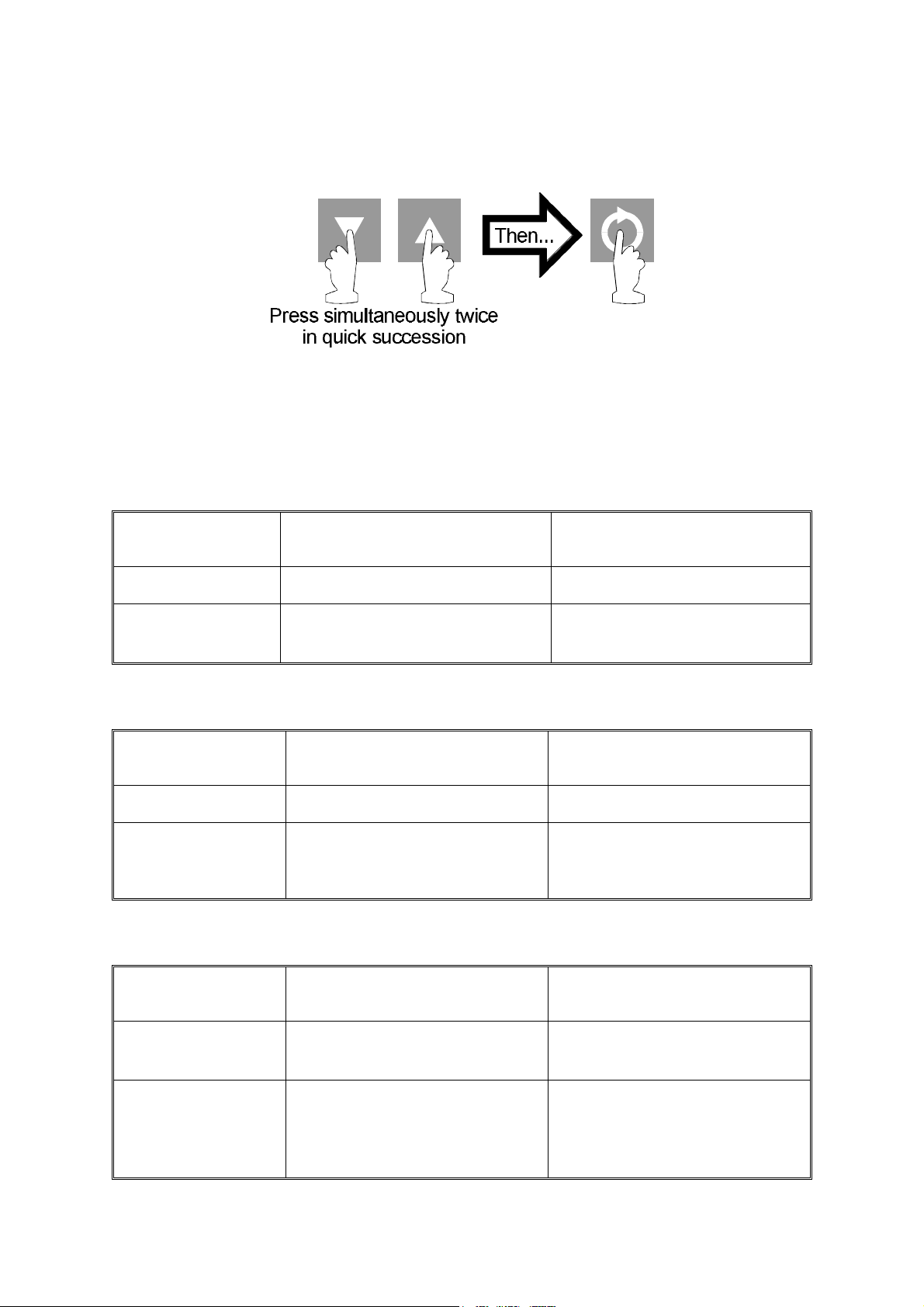

1.9 ENGAGING BOTH PRE-TUNE AND RaPID FEATURES

The Pre-Tune and RaPID features can be engaged in one key action sequence:

Pre-Tune will operate first. When it is completed it will dis-engage itself and the

RaPID feature will then operate automatically.

1.10 INDICATION OF PRE-TUNE AND RaPID STATUS

The responses to the RaPID feature being engaged are:

Pre-Tune Status when

RaPID engaged

Not operational. RaPID activated.

Operational. Pre-Tune completes routine,

then RaPID activated.

The responses to the RaPID feature being dis-engaged are:

Pre-Tune Status when

RaPID dis-engaged

Not operational. RaPID de-activated.

Operational. Pre-Tune completes routine,

then RaPID de-activated return to normal control.

The responses to Pre-Tune being engaged are:

Response Indication

AT indicator goes ON.

AT indicator flashes at

double rate then comes ON.

Response Indication

AT indicator goes OFF.

AT indicator flashes at

double rate then goes OFF.

RaPID status when

Pre-Tune engaged

Not operational. Pre-Tune activated and

routine completed

Operational. RaPID interrupted, Pre-Tune

activated. Pre-Tune

completes routine, then

RaPID control resumed.

Response Indication

AT indicator flashes at

normal rate the goes OFF.

AT indicator flashes at

double rate then goes ON.

1-6

Volume I

O077-1

PM-0077

The responses to Pre-Tune being dis-engaged (manually or automatically) are:

RaPID Status when

Pre-Tune dis-engaged

Not operational. Pre-Tune dis-engaged,

Response Indication

AT indicator goes OFF.

normal control resumed.

Operational. Pre-Tune dis-engaged,

AT indicator goes ON.

RaPID control resumed.

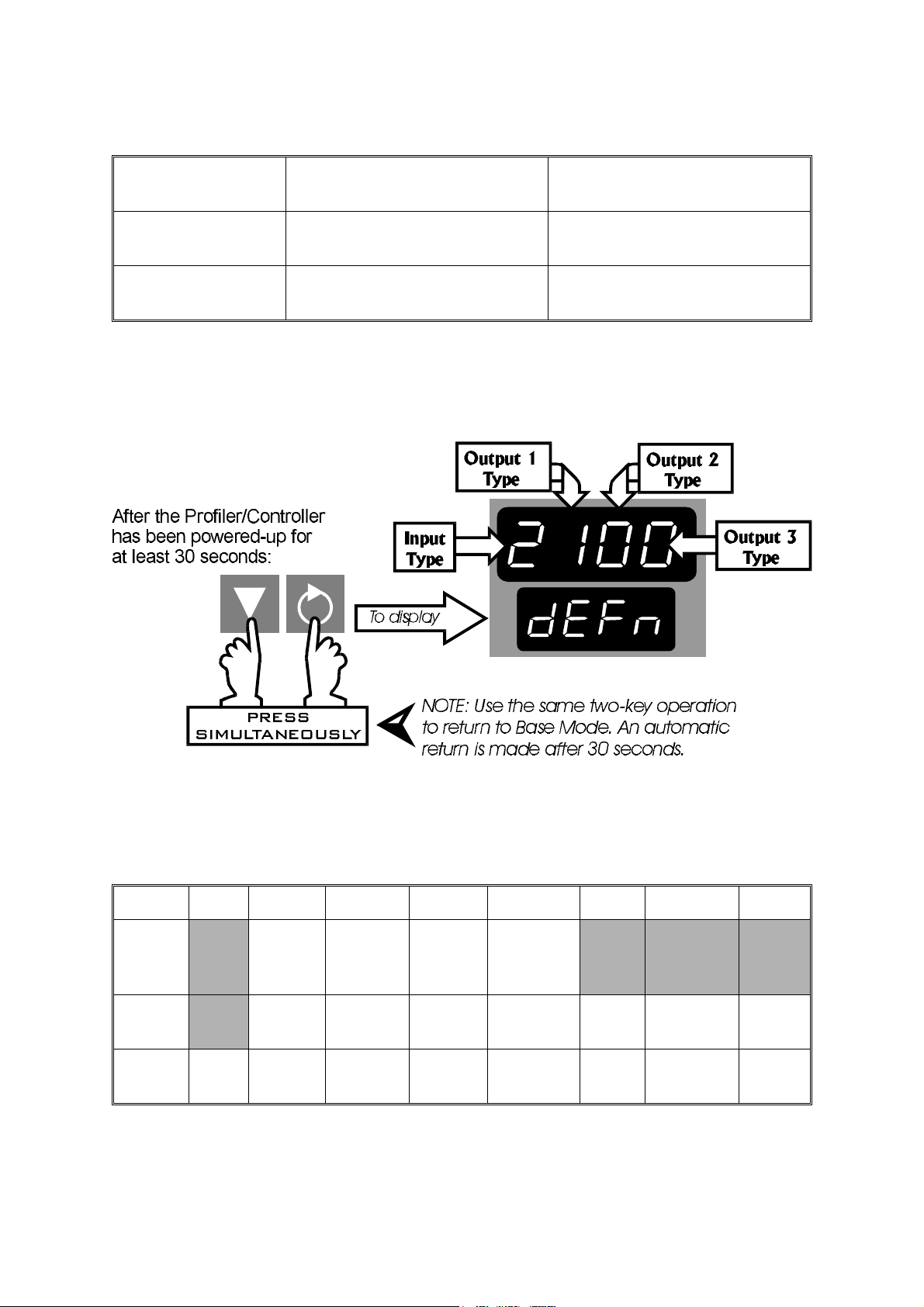

1.11 VIEWING THE HARDWARE DEFINITION CODE

NOTE: An automatic return is made to the normal Base Mode display after

30 seconds.

The Hardware Definition Code has the following significance:

Value 0 1 2 3 4 5 7 8

Input RTD/

Linear

Thermocouple

Linear

DC mA

Linear

DC V

DC mV

Output

1

Output

2/3

Not

fitted

Relay SSR

Drive

Relay SSR

Drive

DC

0 - 10VDC0 - 20mADC0 - 5VDC4 - 20mA

DC

0 - 10VDC0 - 20mADC0 - 5VDC4 - 20mA

* Output 2 only

Solid

State

Solid

State*

O077-1

Volume I

1-7

PM-0077

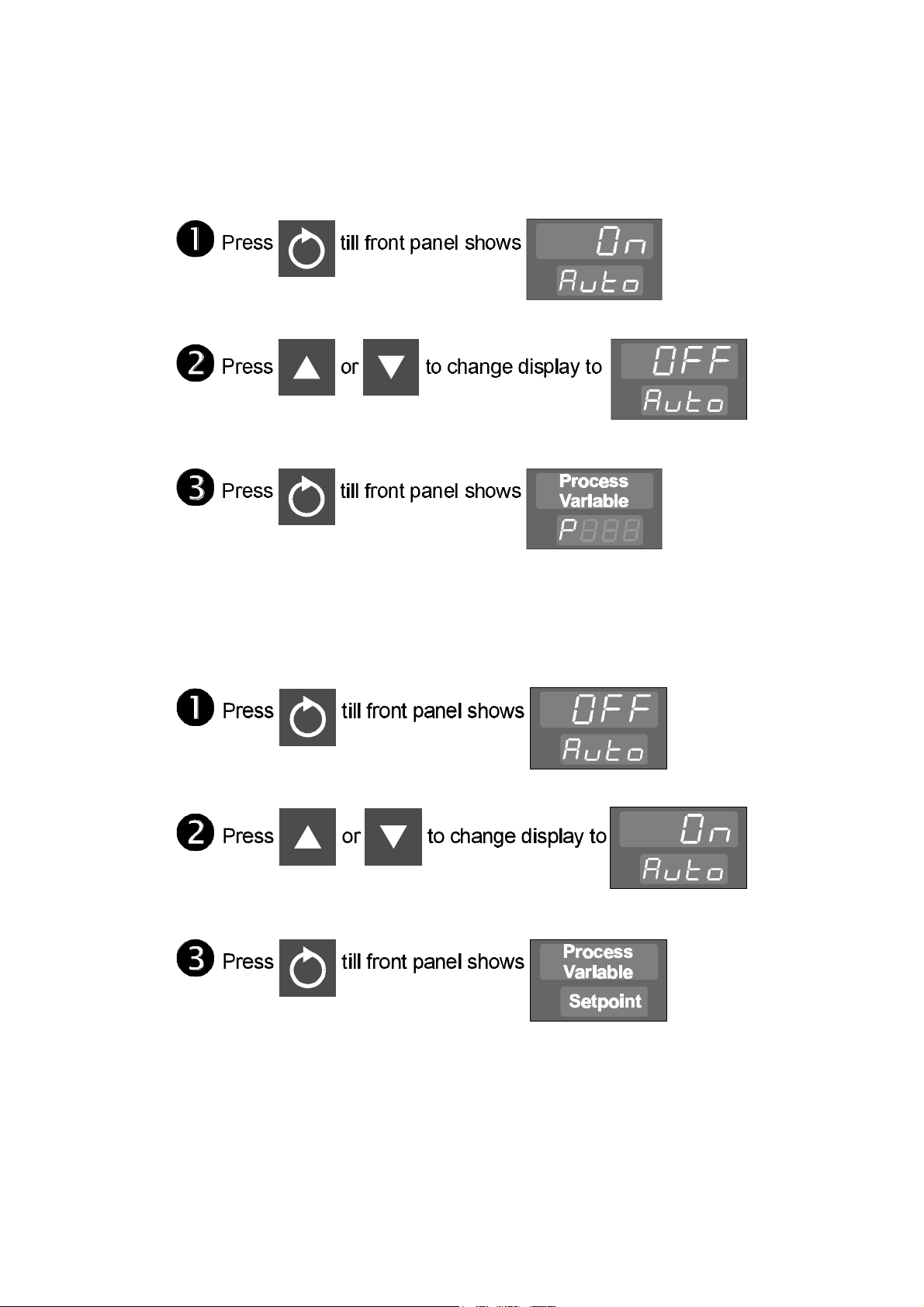

1.12 MANUAL CONTROL

In Base Mode, with no program running or held, Manual Control may be selected

as follows:

The lower display shows the output power in the form Pxxx (xxx is in the range

000% to 100% of maximum output power). This may be adjusted using the Up and

Down keys.

To return to automatic control:

2 PROGRAM DEFINITION MODE -

2-1

Volume I

O077-2

CREATING/EDITING A PROGRAM

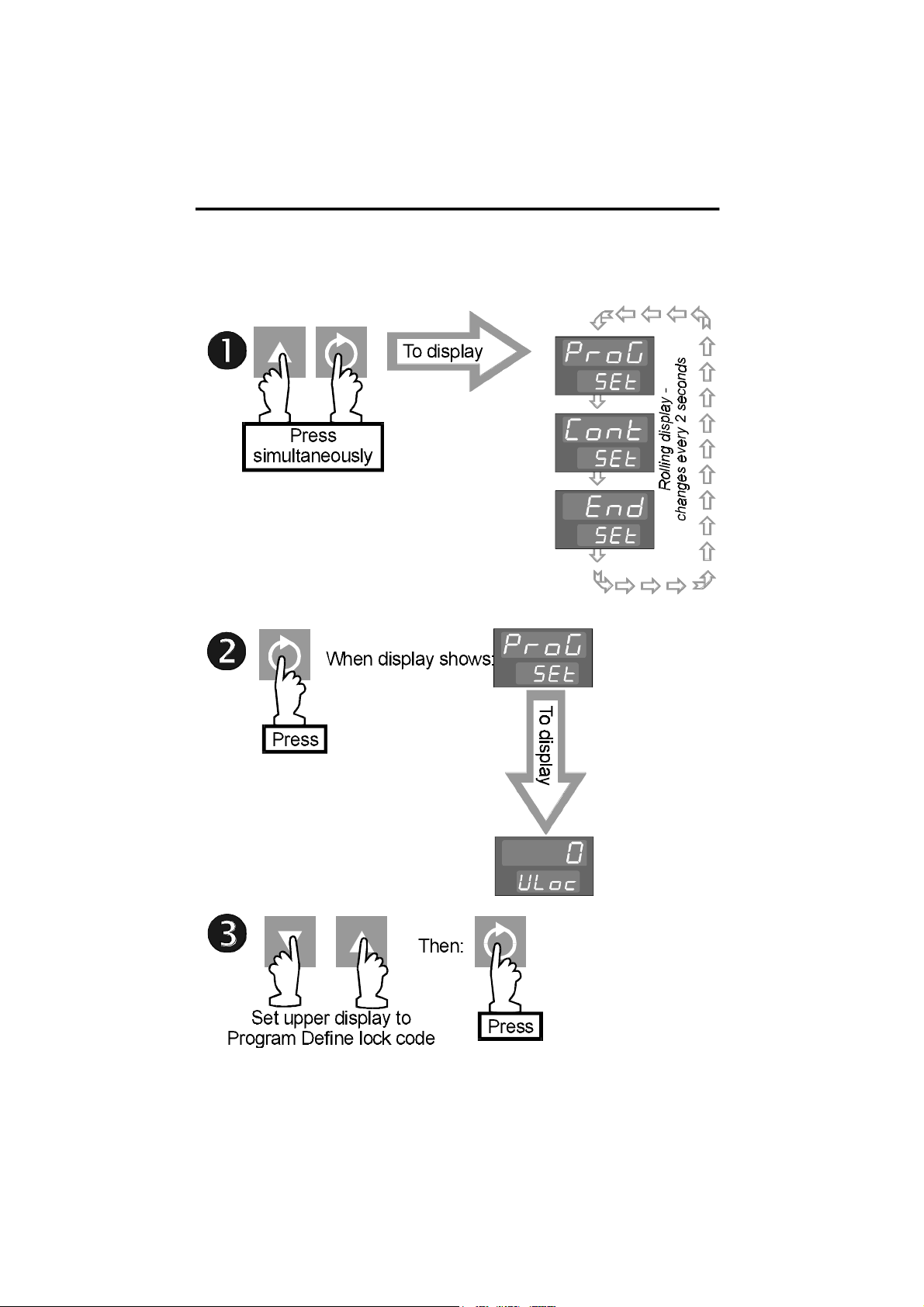

2.1 ENTRY

To enter Program Definition Mode:

PM-0077

NOTE: If the Program Define Mode lock code has been set to 0, pressing

the Scroll key in Step 2 will give direct access to Program Define Mode; no

entry of lock code is required.

Upon entry into Program Define Mode, the first Segment Definition parameter for

Segment 1 of Program 1 will be displayed.

O077-2

Volume I

2-2

PM-0077

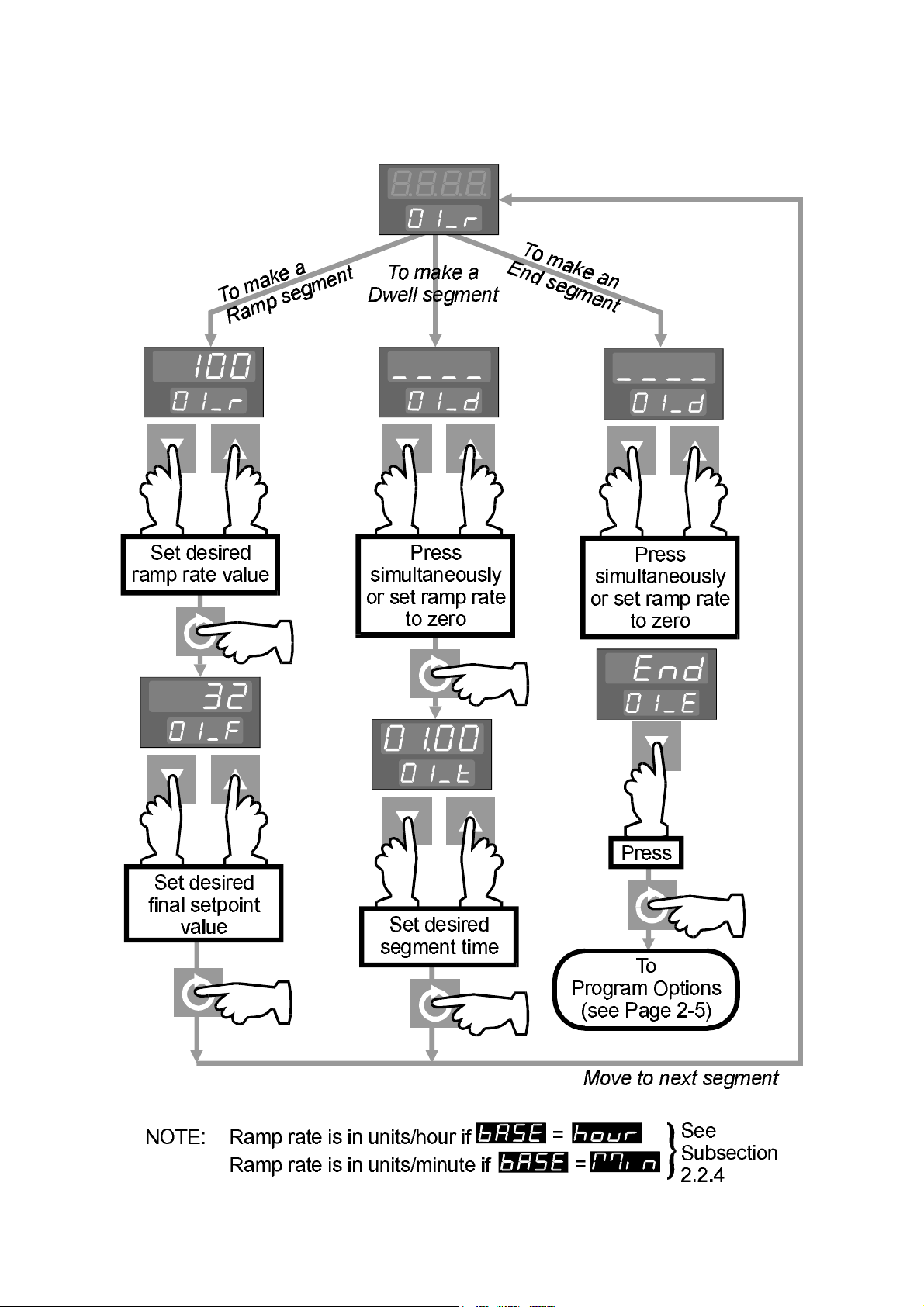

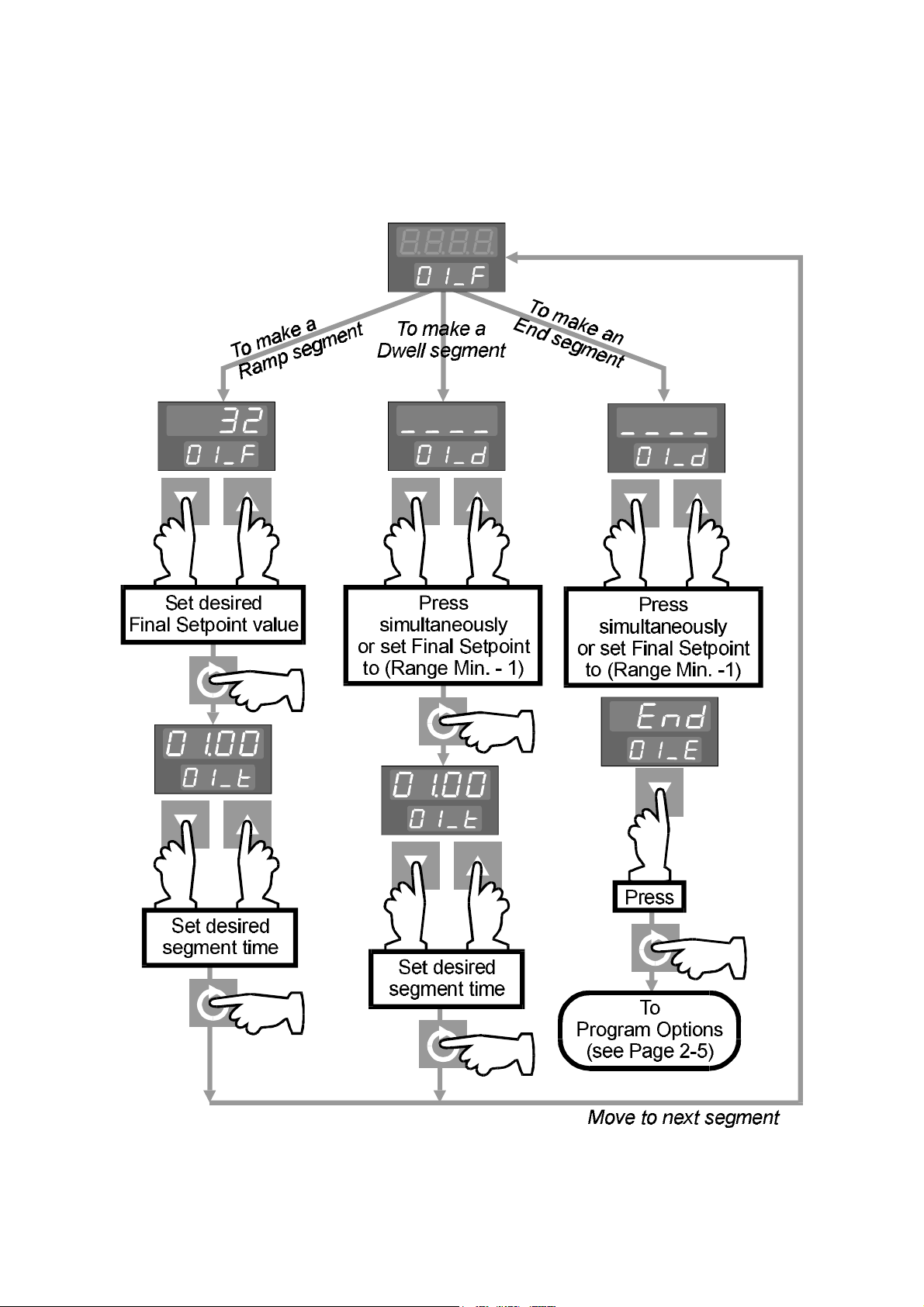

2.2 CREATING A PROGRAM

A program is created in two steps:

1. Define the segments of your program; the parameters used depend on

what Program Mode has been configured - Rate Mode (see Subsection

2.2.2) or Time Mode (see Subsection 2.2.3). The segment definitions

determine whether the selected segment is a Ramp Segment, a Dwell

(soak) Segment or an End Segment.

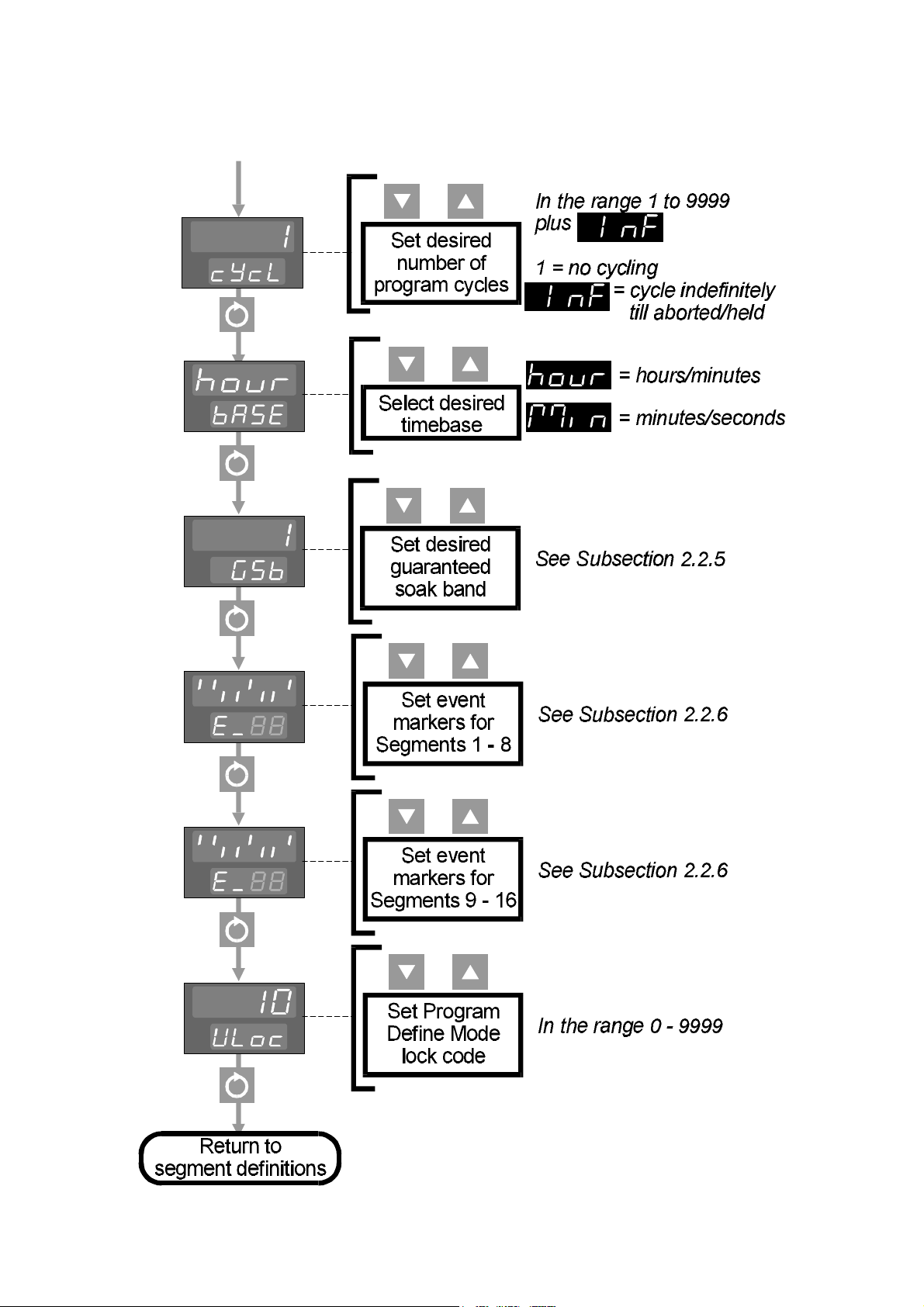

2. Set the required Program Options (see Subsection 2.2.4). These

determine:

(i) The number of cycles performed by the program,

(Ii) The timebase to be used (hours/minutes or minutes/seconds)

(Iii) The width of the Guaranteed Soak Band (if enabled),

(Iv) The state of the event indicator for each segment in the

program,

(v) The lock code to be used for subsequent entries into Program

Define Mode.

2.2.1 Basic Guidelines

1. The Profiler/Controller may contain up to four programs.

2. Each program may comprise up to 16 segments.

3. Each segment may be:

(a) a Ramp Segment (setpoint changing at a defined rate or

between the initial value and a pre-determined final value over a

defined time),

(b) a Dwell Segment (setpoint constant for a defined time,) or

(c) an End Segment (marking the end of the program).

4. A program may contain only one End Segment (the last segment in the

program).

5. If the program comprises 16 segments, Segment 16 is automatically an

End Segment.

2.2.2 Defining Segm ents - Rate Mode

2-3

Volume I

O077-2

PM-0077

O077-2

Volume I

2-4

PM-0077

2.2.3 Defining Segments - Time Mode

2.2.4 Prog ram O ptions

2-5

Volume I

O077-2

PM-0077

O077-2

Volume I

2-6

PM-0077

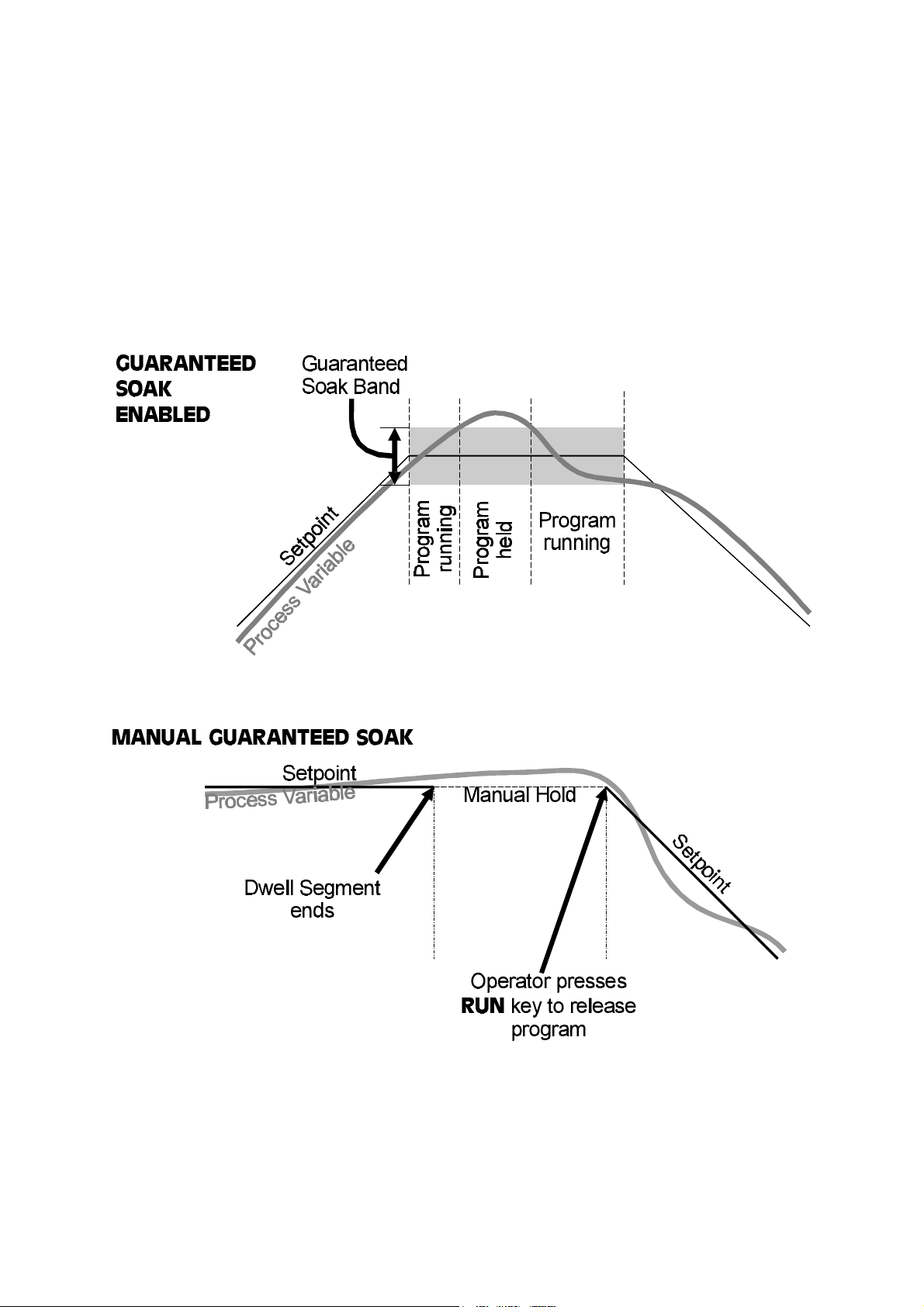

2.2.5 Guaran teed Soak Band

The Guaranteed Soak Band is applicable to Dwell segments only and operates as

follows (depending on whether Guaranteed Soak has been enabled or Manual

Guaranteed Soak has been configured):

2-7

Volume I

O077-2

PM-0077

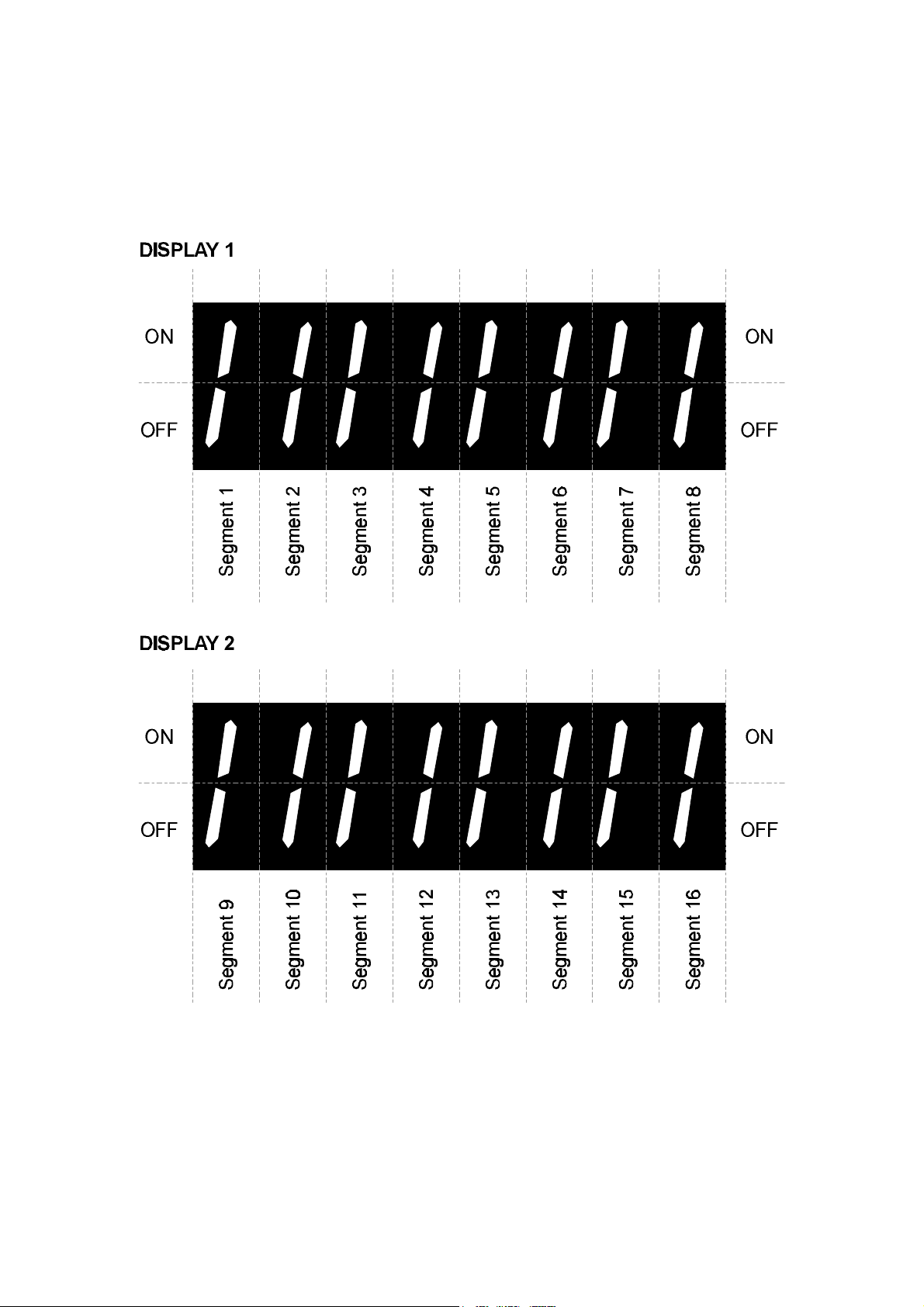

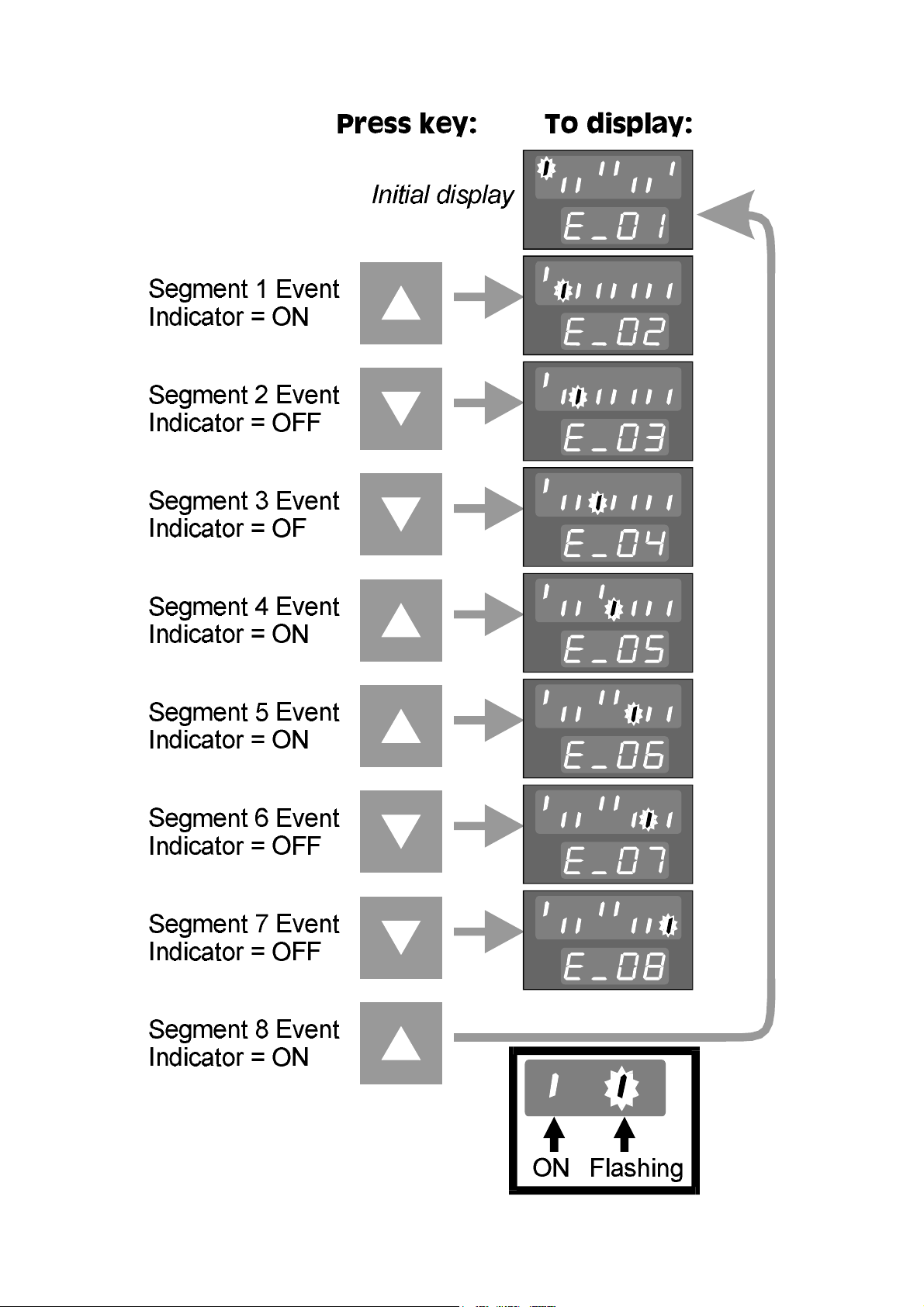

2.2.6 Segment Event Status

For every segment in a program there is an event indicator. This may be set ON or

OFF for that segment. The status for the segments in the currently-selected

program appears in the following form in the upper display:

The first display shows the current event status for Segments 1 - 8 and the second

display shows the current event status for Segments 9 - 16. Each event marker

may be set ON (Up key) or OFF (Down key) in order of segment number. Only the

event indicators for the segments in the program are displayed. If the program

has less than 16 segments (including the End Segment), the non-applicable

display positions are blank; if the program has eight segments or less, the second

display is not included.. The lower display shows the current segment number.

Thus, the key sequence to define the event markers for Segments 1 - 8 could be:

O077-2

Volume I

2-8

PM-0077

2-9

Volume I

O077-2

PM-0077

Pressing the Scroll key would then display the event markers for Segments 9 - 16

(as applicable), which could be defined in a similar manner.

2.3 DEFAULT VALUES AND ADJUSTMENT RANGES

Parameter Range Minimum Range Maximum Default

Ramp Rate 0 = Dwell segment

9999, then INF 100

-1 = End segment

Final (End of

Range Minimum Range Maximum Range Minimum

Ramp) Setpoint

Segment Time 00:00 99:59 01:00

Number of Cycles 1 9999 then INF 1

Guaranteed Soak

1 Span plus OFF OFF

Band

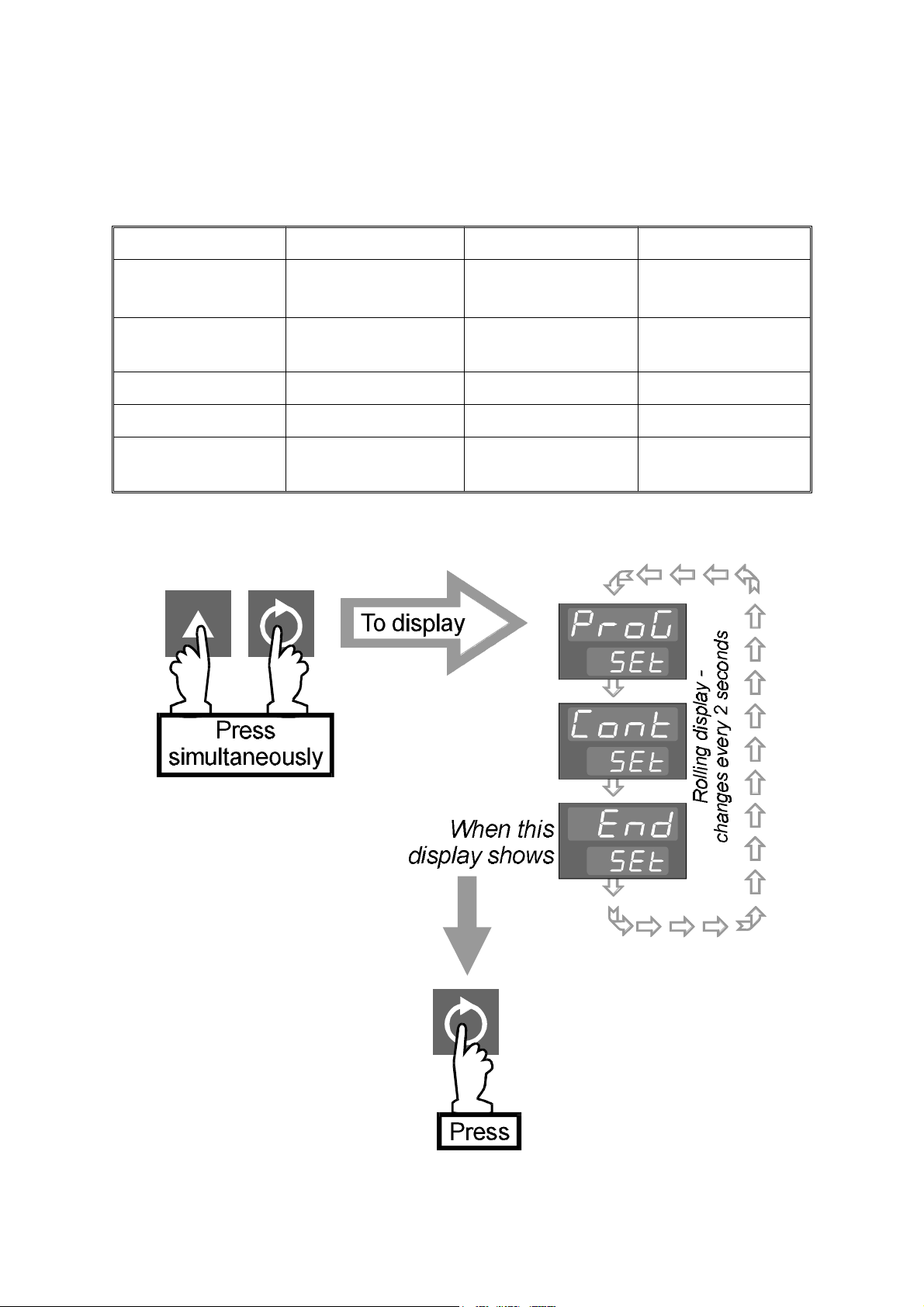

2.4 EXIT FROM PROGRAM DEFINE MODE

A return is then made to the normal Base Mode display.

O077-3

Volume I

3-1

PM-0077

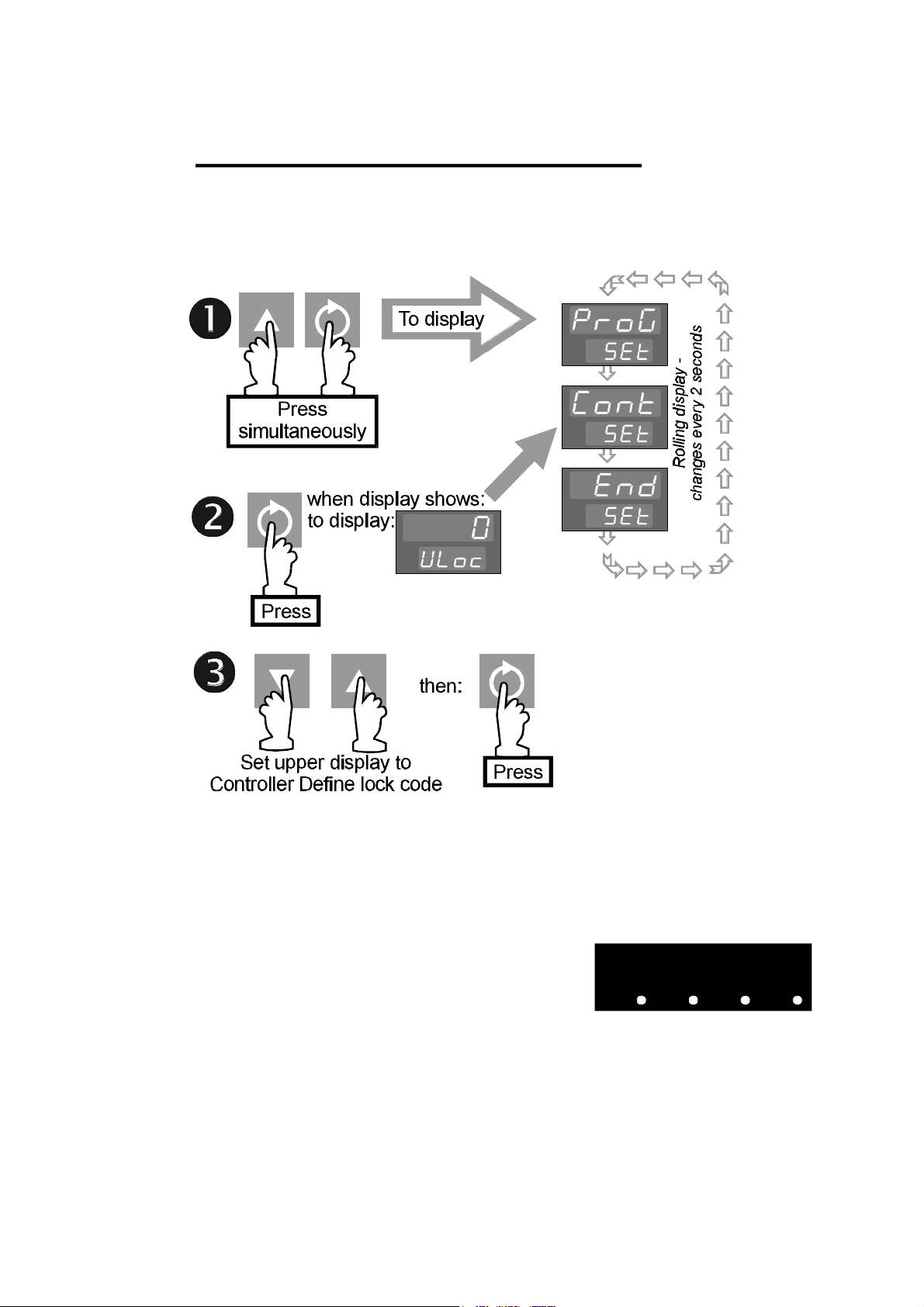

3 CONTROLLER SET-UP MODE

In this mode, the parameters which define the operation of the controller are

defined. Controller Set-Up Mode can be entered (whether or not there is a

program currently running) as follows:

NOTES:

1. If the Controller Set-Up Mode lock code has been set to 0, pressing the

Scroll key in Step 2 will give direct access to Controller Set-Up Mode; no

entry of lock code is required.

2. If the upper display initially shows all decimal

points illuminated (see right), one or more

configuration parameters have been altered and,

as a consequence, all ControllerSet Up Mode

parameters have been automatically set to their

default values/settings. To clear this display, simply alter the value/setting of

any Controller Set Up Mode parameter.

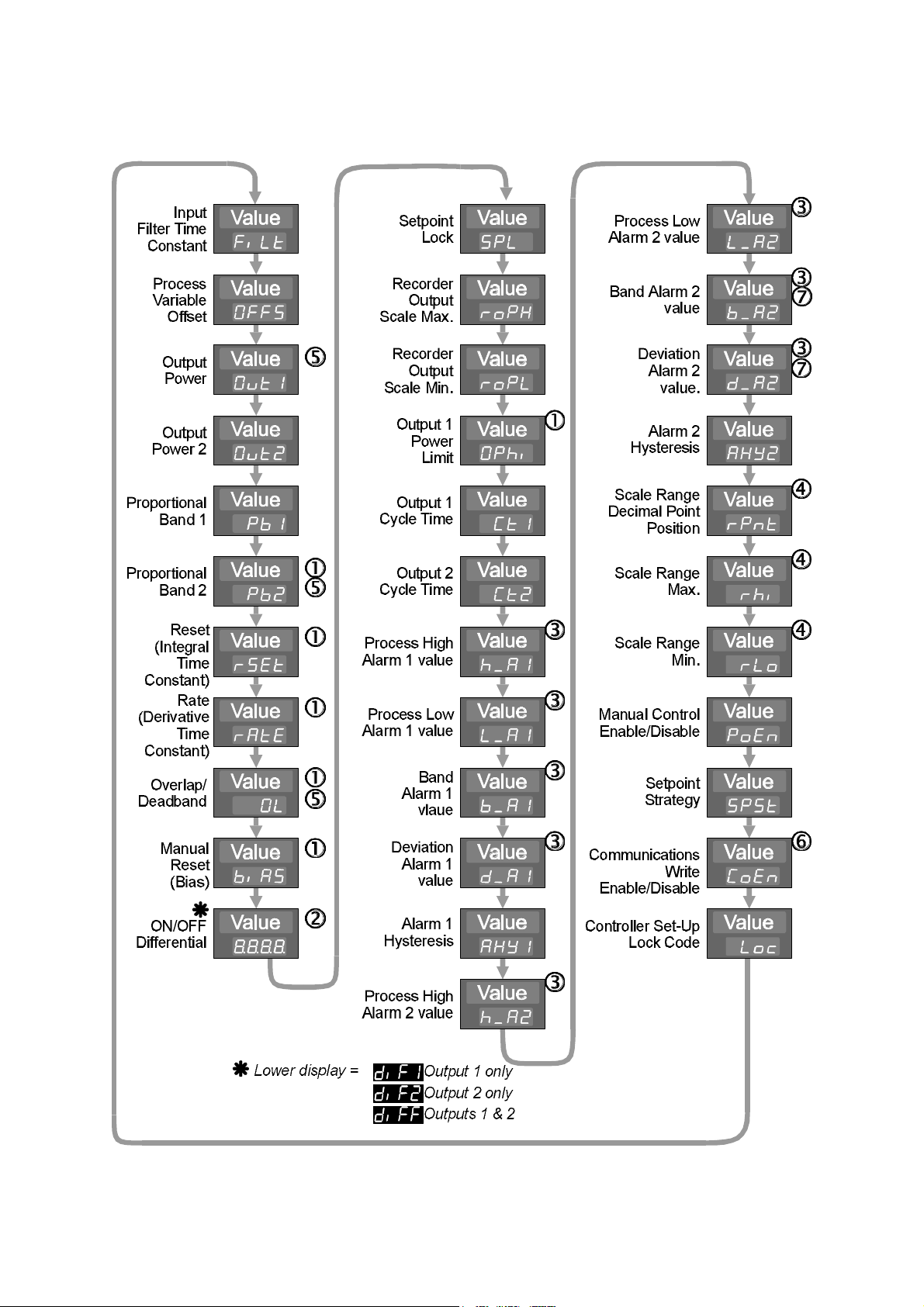

Upon entry into Controller Set-Up Mode, the first in a sequence of controller

parameters will be displayed. The operator may then step through the parameter

sequence using the Scroll key, adjusting the setting/value of each displayed

parameter using the Up/Down keys. The parameter sequence is as follows:

3-2

Volume I

O077-3

PM-0077

O077-3

Volume I

3-3

PM-0077

NOTES

1. Not operative if Proportional Band = 0.

2. Switching differential for ON/OFF control output.

3. Optional; only one legend will appear for each alarm.

4. Only applicable if a DC linear input is fitted.

5. Only applicable if Output 2 is fitted as a secondary control

(COOL) output.

6. Applicable only if the Communications Option is fitted.

7. When a program is running, respective to program setpoint.

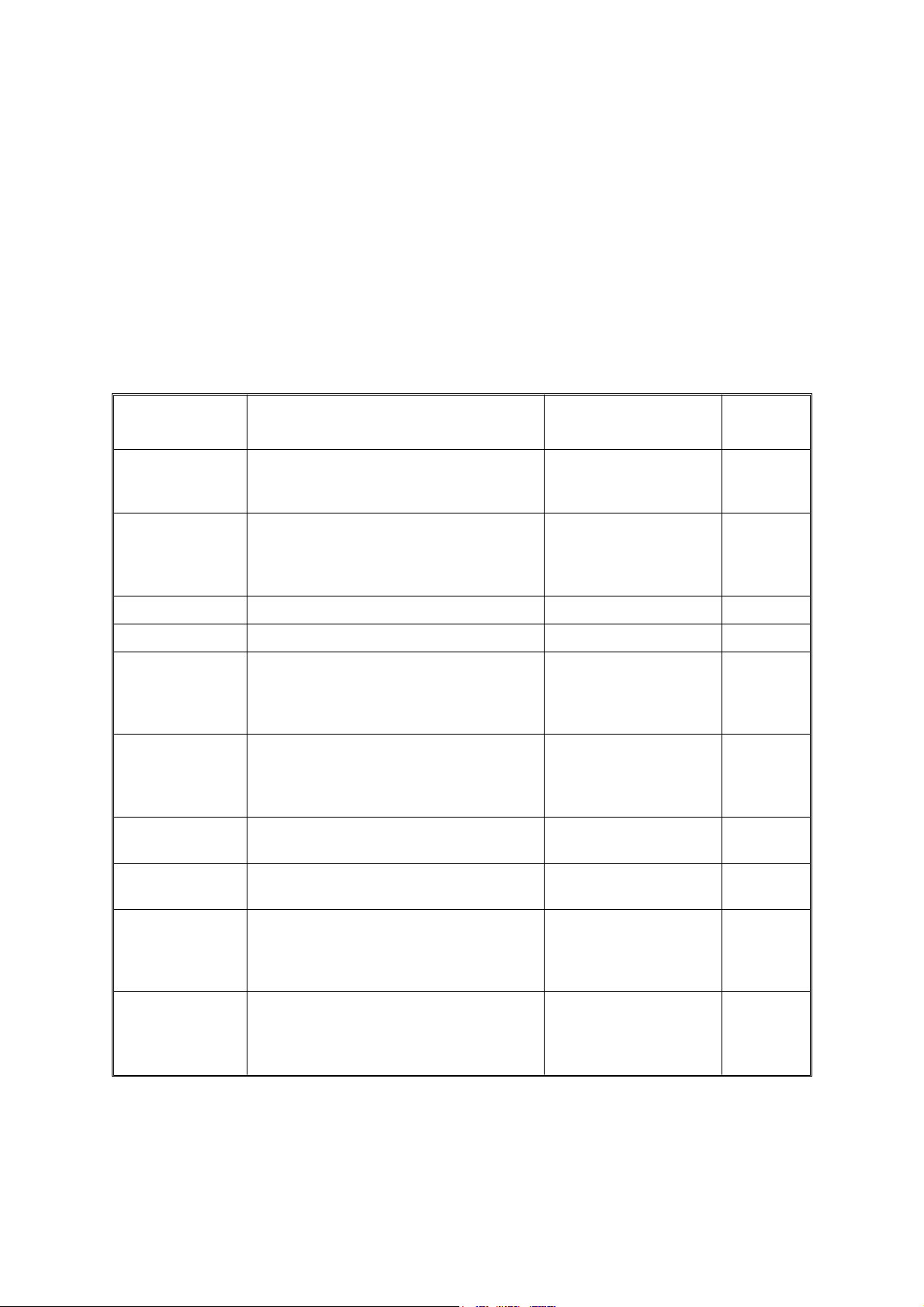

3.1 PARAMETER DETAILS

Parameter Function Adjustment Range

Input Filter Time

Constant

P rocess Variable

Offset

Output Power 1 Current Output 1 power level 0 to 100% Read only

Output Power 2 Current Output 2 power level 0 to 100% Read only

Proportional

Band 1 (PB1)

Proportional

Band 2 (PB2)

Reset (Integral

Time Constant)

Filter removes extraneous impulses from

the process variable input

Modifies actual process variable (PV)

value:

Offset PV + actual PV

= PV value used

Portion of input span in which Output 1

power level is proportional to the

(offset) process variable value (see

Figure 3-1).

Portion of input span in which Output 2

power level is proportional to the

(offset) process variable value (see

Figure 3-1).

Integral time constant 1sec. to 99min. 59

OFF, 0.5 to 100.0

seconds in 0.5 second

increments

±input span of

Controller

0.0 to 999.9% of input

span

0.0 to 999.9% of input

span

secs. and OFF

Default

value

2.0

seconds

0

10.0%

10.0%

5 mins. 00

secs.

Rate (Derivative

Time Constant)

Overlap/

Deadband

Manual Reset

(Bias)

Derivative time constant 00 secs. to 99 mins. 59

secs.

Portion of proportional band (PB1 +

PB2) in which both outputs are active

(overlap) or neither output is active

(deadband) - see Figure 3-1).

Bias applied to output power,

expressed as a percentage of output

power.

− 20% to +20% of

(Proportional Band 1 +

Proportional Band 2)

0% to 100% (Output 1

only);

−100% to +100%

(Output 1 & Output 2)

1 min. 15

secs.

0%

25%

3-4

Volume I

O077-3

PM-0077

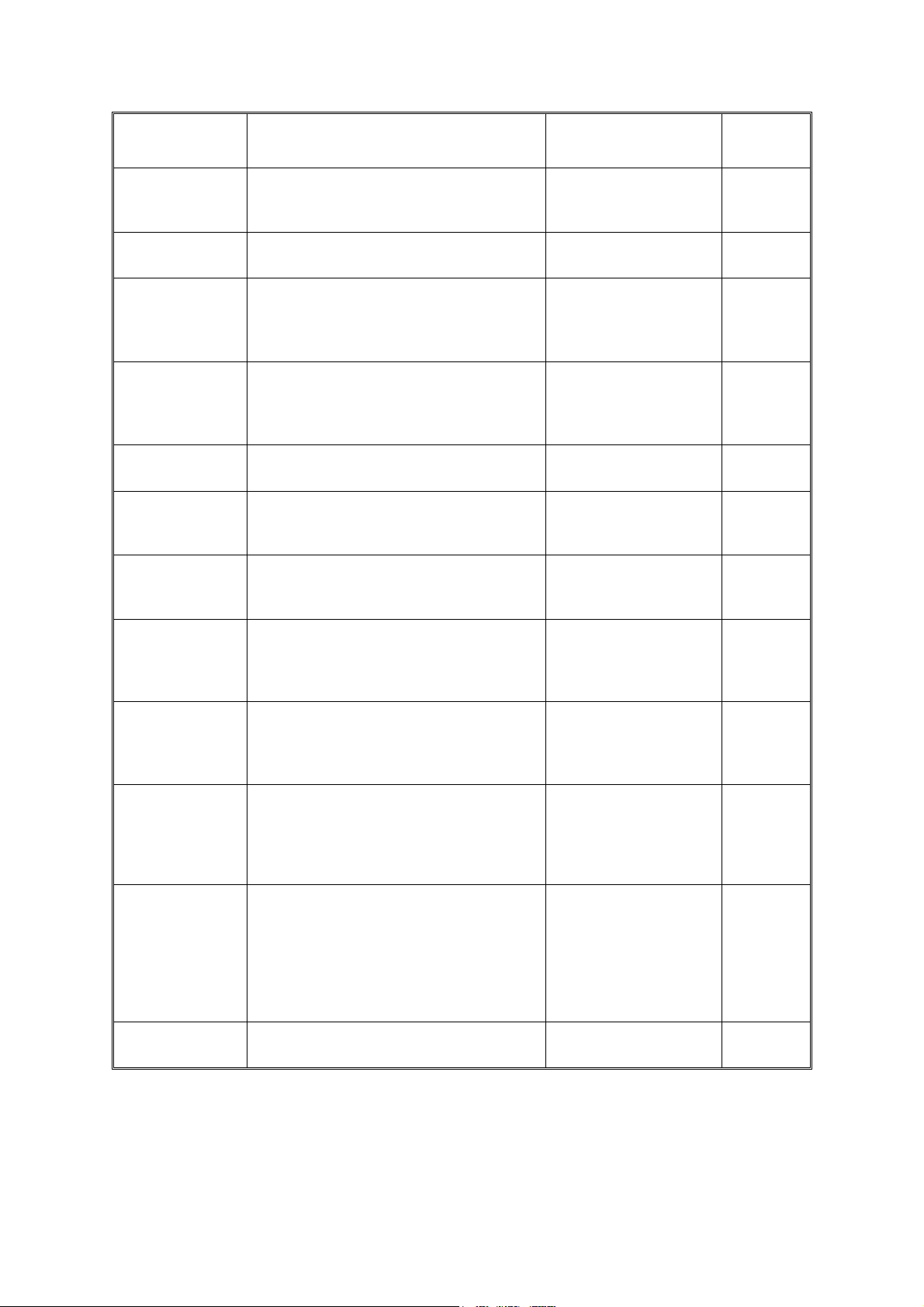

Parameter Function Adjustment Range

ON/OFF

Differential

Setpoint Lock Enables/disables setpoint (SP)

Recorder Output

Scale Maximum

Recorder Output

Scale Minimum

Output 1 Power

Limit

Output 1 Cycle

Time

Output 2 Cycle

Time

Switching differential for one output or

both outputs set to ON/OFF control (PB1,

PB2 or both = 0) - see Figure 3-1.

adjustment in Base Mode.

Process variable or setpoint value (as

applicable) for which the recorder

output is a maximum

Process variable or setpoint value (as

applicable) for which the recorder

output is a minimum

Limits Output 1 power level (to protect

the process)

Limits the frequency of operation of

output relay to maximise relay life

Limits the frequency of operation of

output relay to maximise relay life

0.1% to 10.0% of

input span

OFF - SP adjustable

ON - SP not adjustable

−1999 to 9999

(decimal point

position as for input

range)

−1999 to 9999

(decimal point

position as for input

range)

0% to 100% of full

power

0.5, 1, 2, 4, 8, 16, 32,

64, 128, 256 or 512

secs.

0.5, 1, 2, 4, 8, 16, 32,

64, 128, 256 or 512

secs.

Default

value

0.5%

OFF

Input

Range

Maximum

Input

Range

Minimum

100%

32 secs.

32 secs.

Process High

Alarm 1

Process Low

Alarm 1

Band Alarm 1 If Alarm 1 is a Band Alarm, the band of

Deviation

Alarm 1

Alarm 1

Hysteresis

If Alarm 1 is a Process High Alarm, the

value of the process variable at or

above which Alarm 1 will be active (see

Figure 3-2)

If Alarm 1 is a Process Low Alarm, the

value of the process variable at or

below which Alarm 1 will be active (see

Figure 3-2)

process variable values, centred on the

(program) setpoint, outside which the

process variable will cause this alarm to

be active (see Figure 3-2)

If Alarm 1 is a Deviation Alarm, gives a

value above (positive value) or below

(negative value) the (program) setpoint.

If the process variable deviates from

the setpoint by a marging greater than

this value, the alarm becomes active

(see Figure 3-2)

Defines a hysteresis band on the “safe”

side of the Alarm 1 value

Input Range Minimum

to Input Range

Maximum

Input Range Minimum

to Input Range

Maximum

0 to input span from

(program) setpoint

± input span from

(program) setpoint

1 to 250 units 1 unit

Input

Range

Maximum

Input

Range

Minimum

5 units

5 units

O077-3

Volume I

3-5

PM-0077

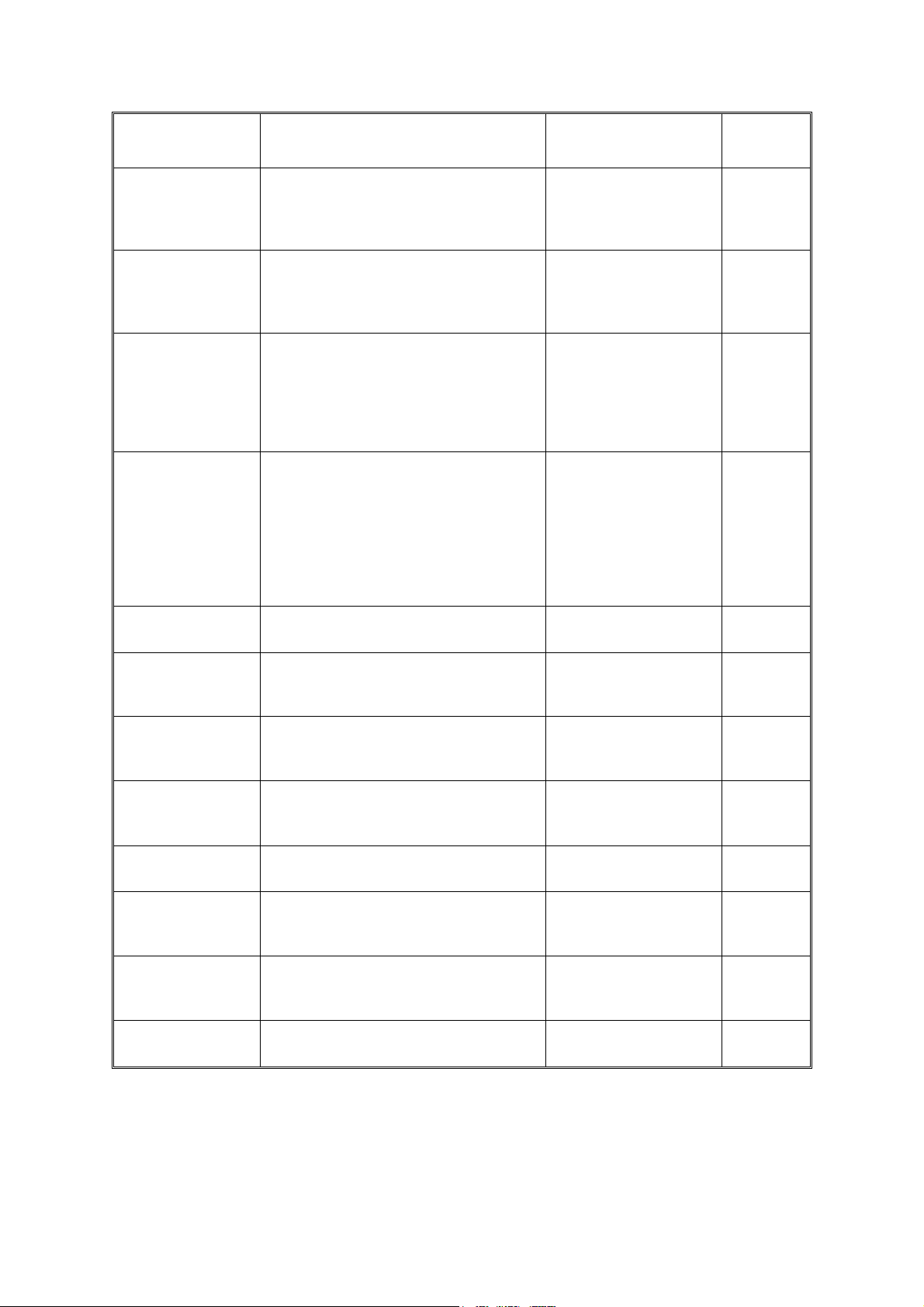

Parameter Function Adjustment Range

Process High

Alarm 2

Process Low

Alarm 2

Band Alarm 2 If Alarm 2 is a Band Alarm, the band

Deviation

Alarm 2

If Alarm 2 is a Process High Alarm, the

value of the process variable at or

above which Alarm 2 will be active

(see Figure 3-2)

If Alarm 2 is a Process Low Alarm, the

value of the process variable at or

below which Alarm 2 will be active

(see Figure 3-2)

of process variable values, centred

on the (program) setpoint, outside

which the process variable will cause

this alarm to be active (see Figure

3-2)

If Alarm 2 is a Deviation Alarm, gives

a value above (positive value) or

below (negative value) the (program)

setpoint. If the process variable

deviates from the setpoint by a

marging greater than this value, the

alarm becomes active (see Figure

3-2)

Input Range Minimum

to Input Range

Maximum

Input Range Minimum

to Input Range

Maximum

0 to input span from

(program) setpoint

±input span from

(program) setpoint

Default

value

Input

Range

Maximum

Input

Range

Minimum

5 units

5 units

Alarm 2 Hysteresis Defines a hysteresis band on the

“safe” side of the Alarm 2 value

Scale Range

Decimal Point

Position

Scale Range

Maximum

Scale Range

Minimum

Manual Control

Enable/Disable

Setpoint Strategy Determines whether or not the

Communications

Enable/Disable

Controller Set-Up

Mode Lock Code

For linear inputs only, defines the

decimal point position

For linear inputs only, defines the

scaled input value when the process

variable input is at its maximum value

For linear inputs only, defines the

scaled input value when the process

variable input is at its minimum value

setpoint is adjustable in the normal

Base Mode display

Enables/disables changing of

parameter values via the

communications link

Defines the four-digit code required

to enter the Controller Set-Up Mode

1 to 250 units 1 unit

0 (xxxx), 1 (xxx.x), 2

(xx.xx) or 3 (x.xxx)

−1999 to 9999

−1999 to 9999

0 (Disabled) or

1 (Enabled)

0 = not adjustable,

1 = adjustable

0 (disabled) or

1 (Enabled)

0 to 9999 10

1 (xxx.x)

1000

0000

0

(Disabled)

1

1

(Enabled)

Loading...

Loading...