Page 1

OPERATOR’S MANUAL

16" Electric Chainsaw

Model # 4016

IMPORTANT:

Read this instruction manual carefully

before putting the chainsaw into operation

and strictly observe the safety regulations!

Keep this instruction manual for future reference!

Questions? Problems?

DO NOT RETURN TO STORE

Store personnel where the winch was purchased

are not trained to handle technical questions.

In order to answer questions in the most efcient and

speedy manner, contact Customer Service at:

(888) 315-3080 M-F 8-5 CST or

by email: partsandservice@greatlakestec.com

Page 2

TABLE OF CONTENTS

Package Contents . . . . . . . . . . . . . . . . . . . 2

Specications . . . . . . . . . . . . . . . . . . . . . . .3

Important Safety Information . . . . . . . . . . . 3

Before Operating Saw . . . . . . . . . . . . . 3

While Operating Saw. . . . . . . . . . . . . . 4

Kickback Safety Precaution. . . . . . . . . 5

Extension Cords . . . . . . . . . . . . . . . . . 7

Chainsaw Components . . . . . . . . . . . . . . .7

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Chain Lubricating Oil . . . . . . . . . . . . . . . . . 9

Chain Tension Adjustment . . . . . . . . . . . . . 9

Chain Lubrication Verication. . . . . . . . . . . 9

Chain Brake Operation. . . . . . . . . . . . . . . . 9

Cutting Instructions. . . . . . . . . . . . . . . . . . 10

Maintenance. . . . . . . . . . . . . . . . . . . . . . . 12

Guide Bar and oil Holes. . . . . . . . . . . 12

Sprocket . . . . . . . . . . . . . . . . . . . . . . 12

Saw Chain Sharpening . . . . . . . . . . . 12

Carbon Brushes. . . . . . . . . . . . . . . . . 12

Maintenance Chart . . . . . . . . . . . . . . . . . . 13

Exploded View & Parts List . . . . . . . . . . .14

Warranty. . . . . . . . . . . . . . . . . . . . . . . . . . 15

The WEN product you purchased has been factory pre-assembled for your convenience. Due to

packaging restrictions, guide bar and saw chain installation will be necessary. After opening the

carton, check for damage or missing parts. Use the content list below to check for missing parts.

PACKAGE CONTENTS

(1)-power head

(1)-guide bar

(1)-saw chain

(1)-scabbard

(2)-brushes

(1)-Wrench

(1)-owner’s manual

2

Page 3

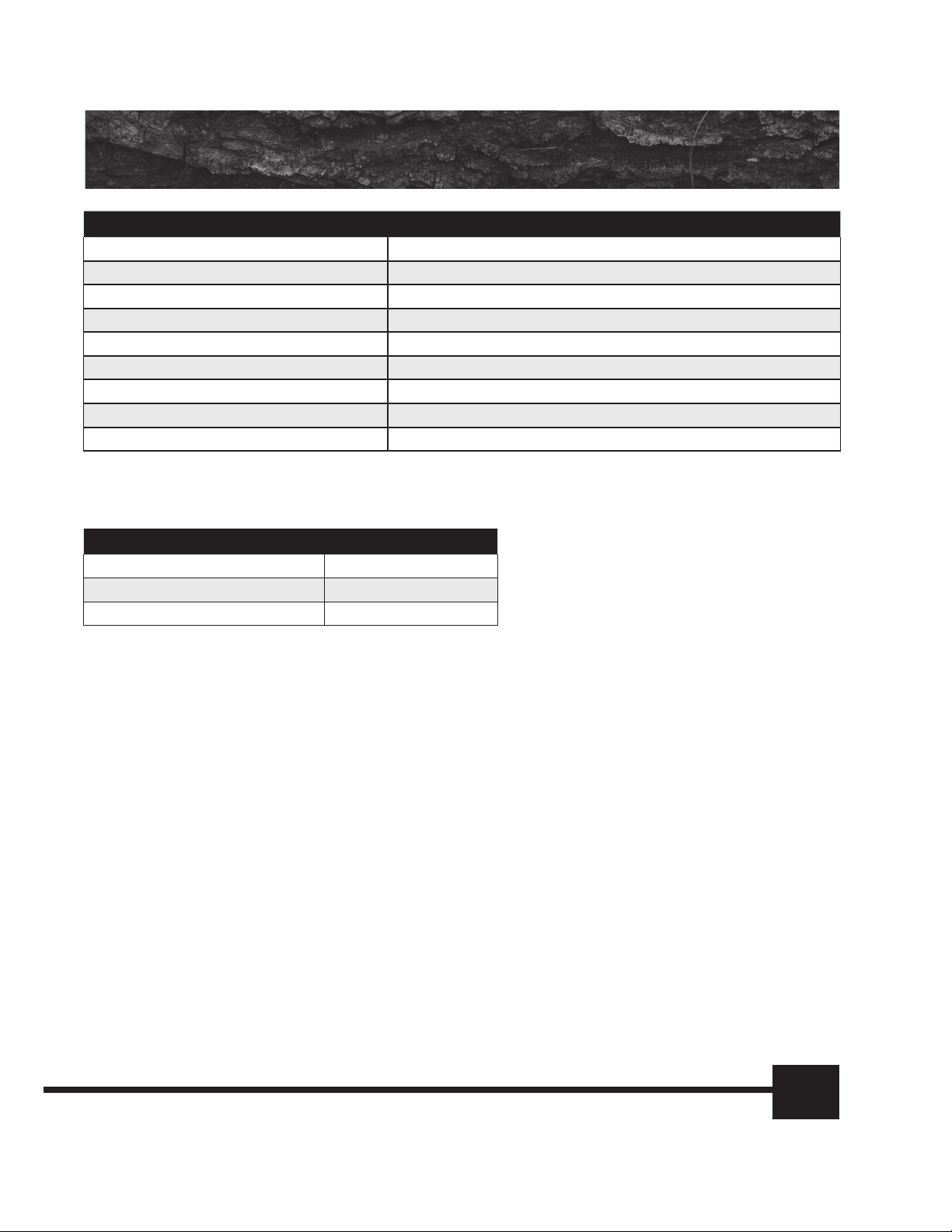

CHAINSAW SPECIFICATIONS

SPECIFICATIONS

Model 4016

Motor 120V, 60Hz, 13A

Saw Chain Oregon 91VG, 3/8” Pitch

Bar Length 16”

Chain Speed at No Load 11.5m/s

Lubrication of Chain Automatic Lubrication

Chain Oil Required Yes

Oil Tank Capacity 90 cc (3.17 uid ounces)

Weight 7 LB

BAR AND CHAIN

Chainsaw Size 16"

Oregon Bar/Chain Combo 509535

Oregon Chain S54

3

Page 4

IMPORTANT SAFETY INFORMATION

Warning – When using an electric chain saw, basic safety pre-

cautions should always be followed to reduce the risk of re,

electric shock, and injury to persons, including the following:

READ ALL INSTRUCTIONS.

Make sure you read and understand all instructions Important Safety Information on pages 2 through

4. Improper use of this chain saw can cause severe injury or death from re, electrical shock, and

body contact with moving chain, on falling wood.

BEFORE OPERATING SAW

1. Read and understand this owner’s manual before operating chain saw.

2. Watch what you are doing .Use common sense .Do not operate saw when you are tired.

3. Use chain saw for cutting wood only .Do not use chain saw for purpose not intended. Do not use for cutting

plastic, masonry, etc.

4. Only well-instructed adults should operate chain saw. Never allow children to operate chain saw.

5. Use only electrical voltage noted on model plate of chain saw.

6. Use only extension cords marked for outdoor use.

7. Do not operate chain saw

• While under the inuence of alcohol, medication, or drugs

• In rain or in damp or wet areas

• Where highly ammable liquids or gases are present

• If saw is damaged, adjusted wrong, or not fully and securely assembled

• If trigger does not turn saw on and off. Chain must stop moving when you release trigger. Have

faulty switch replaced by authorized service center.

• While in a hurry

• While in tree or on a ladder unless trained to do so

8. Wear snug-tting clothes when operating chain saw. Do not war loose clothing or jewelry. They can get

caught in moving saw chain.

9. Wear the following safety gear when operating chain saw.

• Heavy-duty gloves(wear rubber gloves when working outdoors)

• Steel-toed safety footwear with non-skid soles

• Eye protection such as safety glasses, goggles, or face screen

• Safe hard hat

• Ear mufers or ear plugs

• Hair covering to contain long hair

• Face or dust mask (if working in dusty areas)

4

Page 5

10. Before cutting, always provide the following:

Clear work area

Secure footing

Planned retreat path from falling tree

11. Inspect tree before cutting down. Make sure there are no dead limbs or branches that may fall on you.

12. To reduce the risk of electric shock, this saw has a polarized plug (one blade is wider than the other).This

plug will t in a polarized outlet only one way. If the plug does not t fully in the outlet of your extension

cord, reverse the plug. If it still does not t, a polarized extension cord will be necessary. Do not change

the plug in any way.

WHILE OPERATING SAW

1. Stay alert. Use common sense wile operating chain saw.

2. Keep work area clean. Cluttered areas invite injuries.

3. Be aware of extension cord while operating chain saw. Be careful not to trip over cord. Keep cord away

from chain and operator at all times.

4. Keep children, animals, and bystanders away from chain saw and extension cord. Only chain saw user

should be in work area.

5. Do not cut down a tree unless you are trained or have expert help.

6. If two or more persons perform bucking and felling operations at the same time, provide plenty of distance

between operations. Provide distance of at least twice the height of tree being felled.

7. Secure wood you are cutting by suing clamps or chocks.

8. Grip chain saw rmly with both hands. Never operate chain saw with one hand. Never use hand guard as

handle.

9. Keep nger off trigger until ready to make cut.

10. Before starting chain saw, make sure chain is not touching anything.

11. To guard against electrical shock, avoid body contact with grounded objects such as pipes, fences, and

metal posts.

12. Keep all parts of body away from chain when saw is running.

13. Do not force chain saw while cutting. Apply light pressure. It will do the job better and safer at he rate for

which it was intended.

14. Cut small brush and saplings with extreme care. Slender material may catch in chain and be whipped

toward you. This could also pull you off balance.

15. When cutting limb or tree trunk that is under tension, use extreme caution. Be alert for wood springing

back. When wood tension is released, limb could spring back and strike operator causing severe injury

or death.

5

Page 6

16. Carry chain saw from one place to another

• With saw stopped and unplugged

• By holding front handle (never use hand guard as handle)

• With nger off trigger

• With guide bar and chain to rear

KICKBACK SAFETY PRECAUTIONS

Warning – Kickback may occur when the nose or tip of the

guide bar touches on object, or when the wood closes in the

cut. Tip contact in some cases may cause a lightning fast

reverse reaction, kicking the guide bar up and back towards

the operation. Pinching the saw chain along the top of the guide bar

may push the guide bar rapidly back towards the operator. Either

of these reactions may cause you to lose control of the saw which

could result in serious injury to user.

Kickback is the name given to a sudden, rapid upward movement of the saw cutting mechanism in an upward

arc towards the operator. Kickback occurs when the upper quadrant of the bar nose comes in contact with a

solid object or is pinched. The rotational force of the chainsaw can be reversed in the opposite direction of the

chain movement. This may ing the bar up and back in an arc towards the operator. Serious injury or even

death can result from contact between the moving saw chain and the operator.

The best protection against injury due to kickback is to avoid situations that can cause kickback:

- Hold the chainsaw rmly with both hands and maintain a secure grip.

- Be aware of the location of the bar nose at all times while cutting.

- Never bring the nose of the guide bar in contact with any object. Never cut limbs with the nose of the guide

bar. Be especially careful when cutting saplings, brush and small hard limbs that may easily pinch the cutting

chain.

- Don’t cut above shoulder height. Don’t overreach or use the chainsaw while standing on a ladder or tree.

- Never use the chainsaw one-handed.

- Begin and continue cutting at full throttle.

- Use extreme caution when entering a previous cut.

- Do not attempt plunge cuts if you are not familiar with this cutting technique.

- Stand to the side of the cutting path of the chainsaw.

- Cut with a correctly sharpened, properly tensioned chain at all times.

Save these instructions. It is your guide to safe and proper operation of this chain saw.

6

Page 7

EXTENSION CORDS

If you use an extension cord, be sure to use one heavy enough to carry the current your electric saw will

draw. An improper gauged extension cord will cause a drop in wire voltage resulting in loss of power and

overheating. Use only extension cords having an electric rating not less than the rating of the product.

The following table shows the correct size to use depending on cord length and machine ampere rating.

AMERICAN WIRE GAUGE RATING CHART

EXTENSION CORD

LENGTH (FEET)

AMPS

0 TO 10.0 18 18 16 16 14 14 12 12

10.1 TO 13.0 16 16 14 14 14 12 12 12

13.1 TO 15 14 12 12 12 12 12 12 --

15 TO 18 14 12 12 12 12 12 -- --

25 50 75 100 125 150 175 200

AWG

CHAINSAW COMPONENTS

1. SPROCKET COvER

2. LOCKING KNOB

3. OIL TANK CAP

4. SCREW

5. FRONT HANDLE

6. CHAIN BRAKE LEvER

7. GEAR BOX

8. OUTPUT OIL HOLE

9. CHAIN TENSION

ADjUSTABLE WHEEL

10. SPIKE BAR

11. SCREW

12. FASTENING STUD

13. SPROCKET

14. OIL TANK

15. GUIDE BAR

16. INPUT OIL HOLE

17 ADjUST BLOCK

7

Page 8

ASSEMBLY

WARNING - Check the chain tension before each use.

Always use protective gloves.

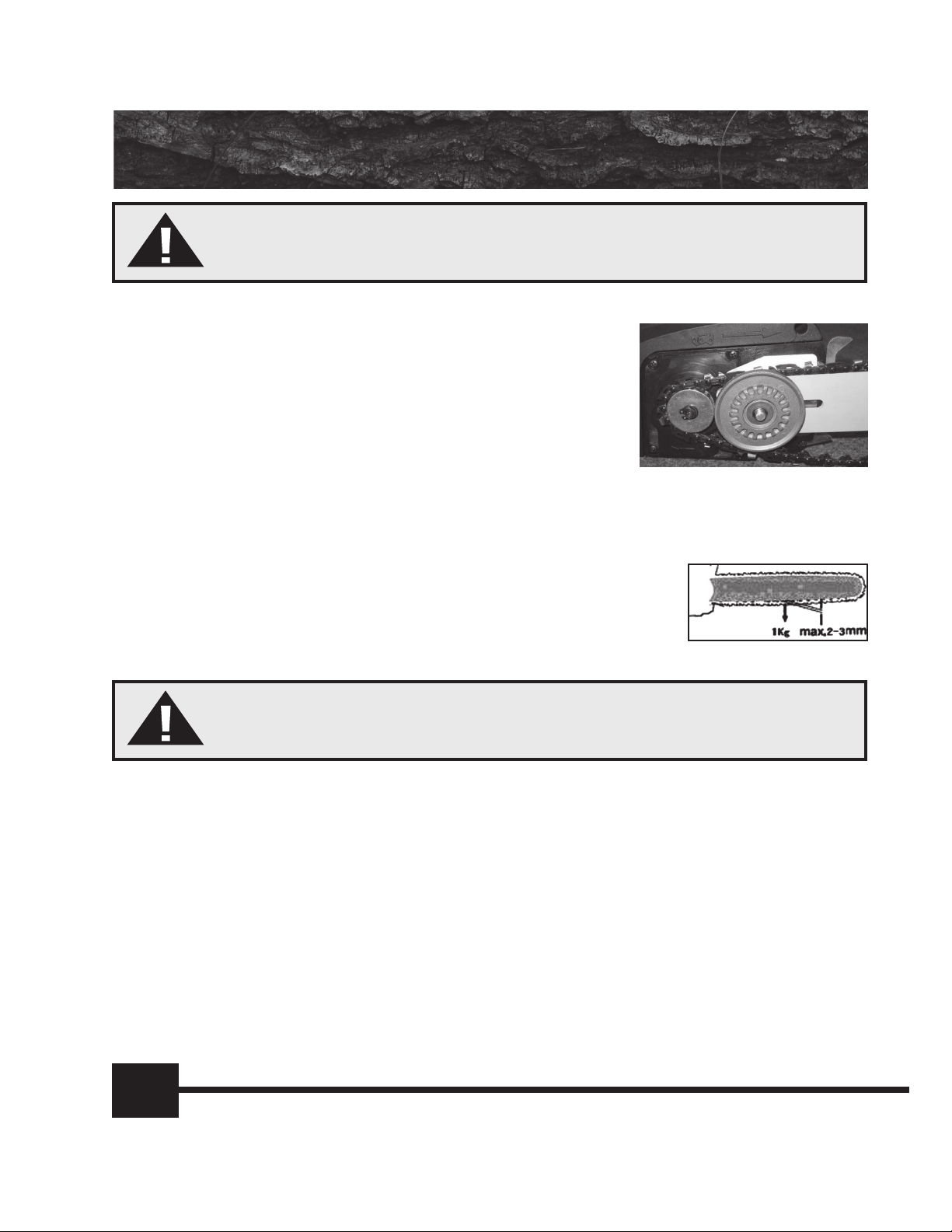

INSTALLING THE GUIDE BAR AND SAW CHAIN

1. Loosen the locking knob counter clockwise and remove the

sprocket cover

2. The adjust block should already be attached to the guide bar. Make sure

the adjust block is turned all the way counter-clockwise and then put the

saw chain on the guide bar.

3. Place the guide bar onto the bar studs and the chain around the sprocket.

Make sure the chain cutters on top of the guide bar face in the direction

that the chain runs. See below picture.

4. Install the sprocket cover by turning the locking knob clockwise. Don’t tighten it before adjusting

chain tension.

5. Adjust the chain tension by turning the tension wheel clockwise. The chain is

correctly tensioned when it is still possible to raise it by 2-3 mm in the middle of

the guide bar.

6. Tighten the sprocket cover by turning the locking knob clockwise.

WARNING - Never try to run the chainsaw without sprocket

cover securely tightened.

Caution: Proper saw chain tension is extremely important. If saw chain is too tight, the guide

bar and saw chain will be quickly damaged. If the saw chain is too loose, it may get out of

the guide bar groove and cause an injury.

Note: A new chain will stretch so adjust the tension after a few cuts. Watch saw chain tension

carefully for the rst half hour of cutting.

8

Page 9

CHAIN LUBRICATING OIL

Use high quality chain lubricating oil to minimize wear between the saw chain and guide bar while in use.

We recommend using SAE No. 30 in the summer and SAE No. 10 in the winter or when cutting resinous

wood. Check the oil level prior to each use.

Oil tank capacity: 90 cc (3.1 uid ounces)

WARNING - Never use waste or reclaimed oil. This results in

damage to the oil pump, saw chain and guide bar.

CHAIN TENSION ADjUSTMENT

WARNING - Always loosen locking knob before turning tension wheel otherwise sprocket cover and tension wheel will be

damaged. Do not over-tighten locking knob.

1. Loosen the locking knob.

2. Using gloved hand, hold the guide bar nose up and turn the tension wheel clockwise. The chain is correctly

tensioned when it is still possible to raise it by 2-3 mm in the middle of the guide bar.

3. Tighten the sprocket cover by turning the locking knob clockwise.

WARNING - Never touch the chain while chainsaw is running.

Unplug chainsaw from power source before adjusting the saw

chain tension. Not doing so may cause severe personal injury

or death.

CHAIN LUBRICATION vERIFICATION

To test if chain lubricating oil is adequately dispensed onto the guide bar, hold the guide bar above a dry

surface and run the chainsaw for 30 seconds. A thin line of “thrown” oil should be seen on the dry surface.

Never operate the saw without chain lubrication. Even running the saw without lubrication can cause irreparable harm to the entire cutting attachment.

CHAIN BREAK OPERATION

The chain brake stops the rotation of the chain during kickback. The chain brake does not prevent kickback.

An efcient chain brake stops the chain in 1/10th of a second or less by pushing the front handle guard forward. The chain brake is designed to only stop the chain, if activated, during certain kickback situations. The

system must be properly maintained and in good working order for the chain brake to stop the rotation of the

chain.

To release the chain brake, pull the hand guard back towards the operator until a noticeable click is heard.

9

Page 10

CUTTING INSTRUCTIONS

Before use: Check that the chain brake works properly and is not damaged. Visually inspect

the entire saw to ensure all components are free from damage and work properly. Check the

chain tension and adjust if necessary.

WARNING - Always follow safety procedures. Use the chainsaw only for cutting wood and not other types of materials.

Do not use the chainsaw as a lever for lifting, moving or

splitting objects. Never cut in high wind, bad weather, poor visibility conditions, or in extreme temperatures. Always check for dead

branches which may fall during cutting operations.

In all circumstances, the operation of a chainsaw is a one man job. Keep all

other people away from the cutting area. It is difcult enough to take care of

your own safety without assuming responsibility for the safety of others.

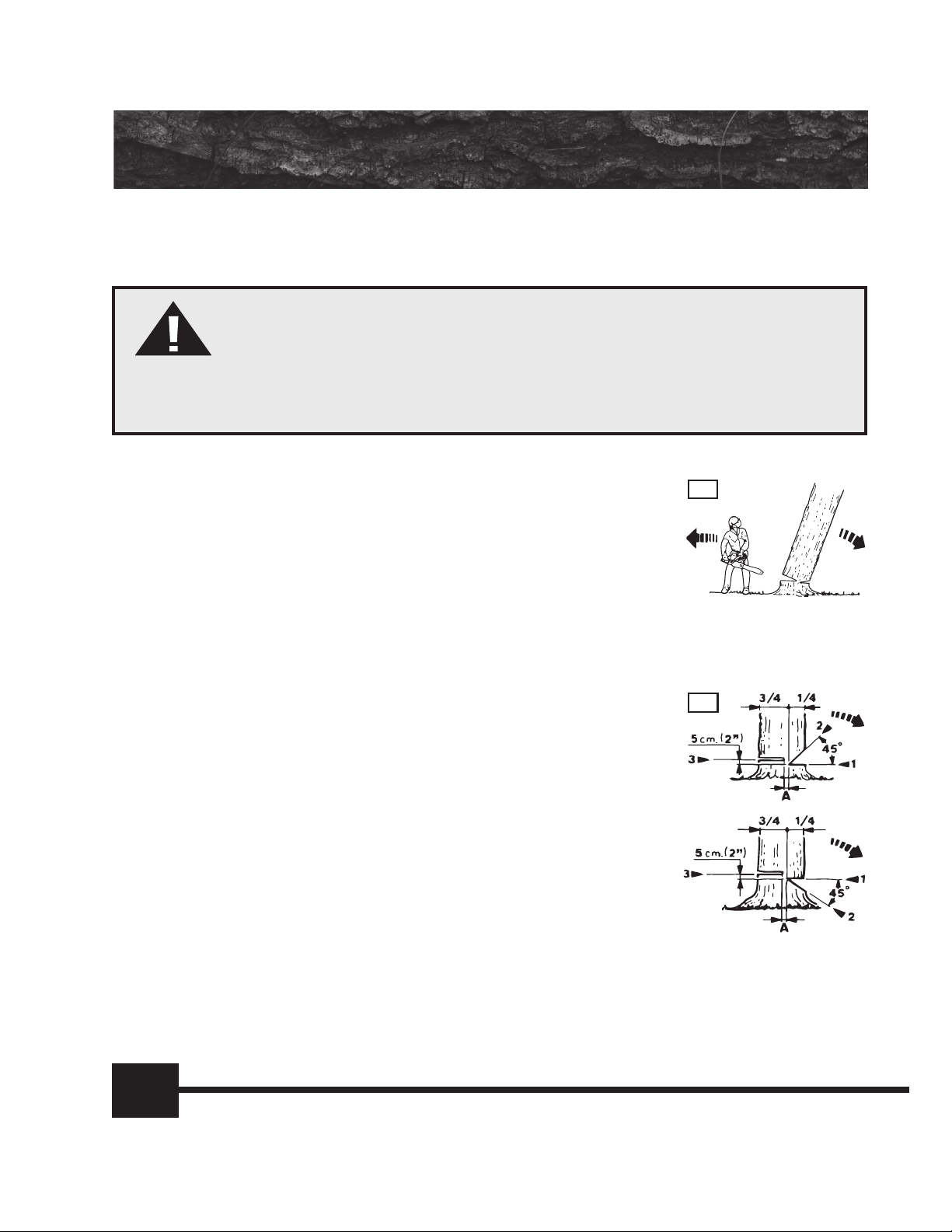

- Before felling a tree, study the surrounding area to determine where you

want the tree to fall. Select a retreat path. The path should be at a 45 degree

angle from the tree fall line. (Fig.14)

- Clear the work area before beginning the cutting process. Remove the

undergrowth from the base of the tree and check the area for obstacles so a

clear retreat path exists.

14

- Start by cutting off any branches up to shoulder height. Do not cut above

shoulder height and always use two hands in gripping the saw.

Never use the saw one-handed.

- Begin the cut on the side to which the tree is to fall. Cut a notch about 1/3rd

of the way into the tree. The position of the notch is important since the tree

will try to “fall” into the notch. (Fig.15)

- The felling cut is made on the opposite side of the notch at about 2” above

the center of the notch. Do not cut through to the notch with the felling cut.

The wood between the notch cut and the felling cut will act as a hinge when

the tree falls, guiding it in the desired falling direction. (Fig.15)

- When the tree starts to fall, turn off ignition switch, place the chainsaw on the

ground and retreat to a safe position at least 10’ from the trunk.

- To fell bigger trees with diameters exceeding twice the bar length requires

specialized skills and should not be attempted without proper training.

10

15

Page 11

WARNING - A majority of kickback accidents occur

during limbing.

WARNING - Never attempt to cut logs while they are in a

pile or when a couple of logs are lying together. Such at-

tempts drastically increase the risk of kickback which can

result in serious or fatal injury. When bucking, do not stand on the

log. Make sure the log will not roll downhill. If bucking on a slope,

stand uphill of the log.

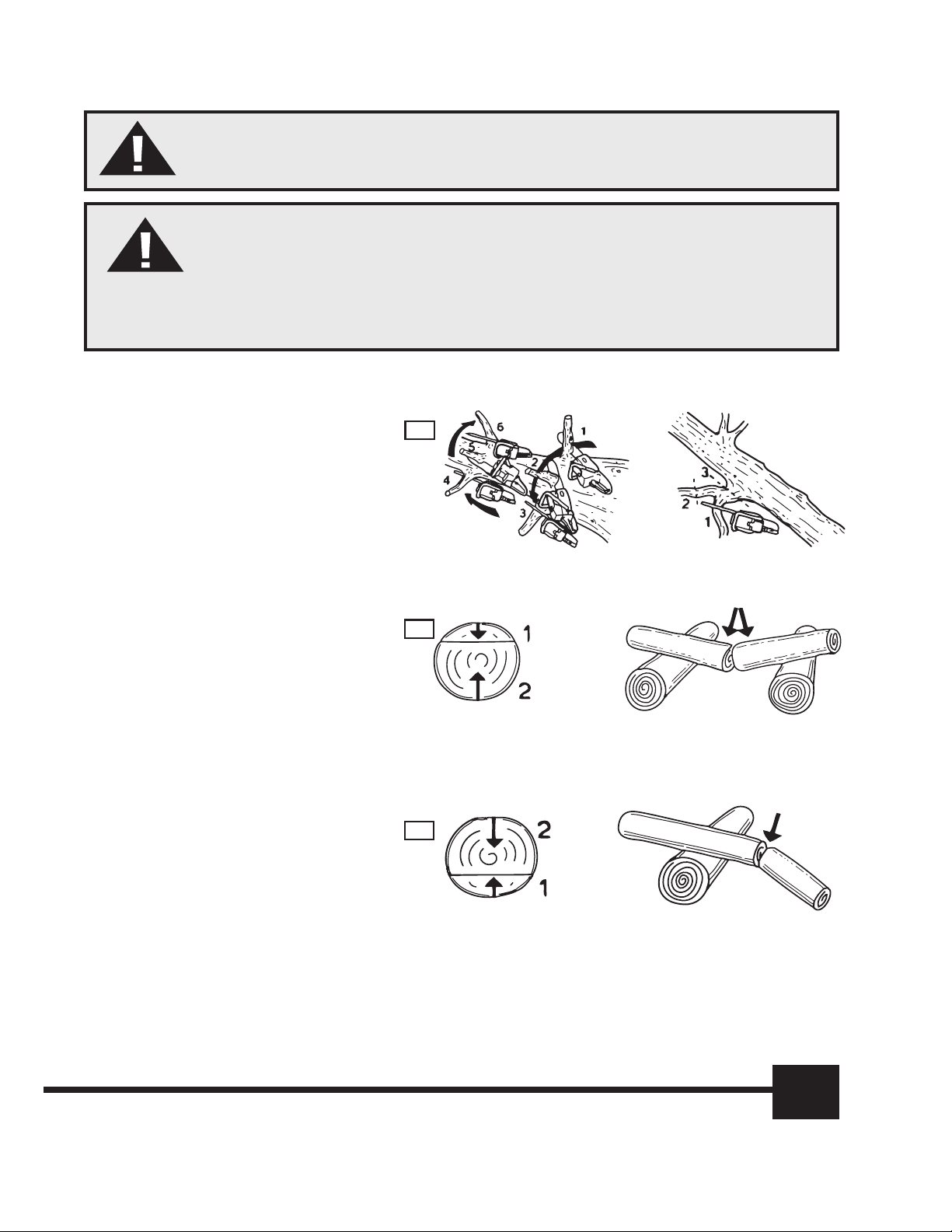

LIMBING – THE REMOvAL OF

BRANCHES FROM A FELLED

TREE. (FIG.16)

Do not use the nose of the guide bar.

Be careful and cautious and avoid

contacting the log, other limbs or

objects with the nose of the guide bar.

Be extremely cautious of limbs under

tension.

These limbs can spring back towards

the operator and cause loss of control

resulting in injury. Always stand to the

left of the trunk and maintain a secure

footing. Always use both hands when

cutting.

16

17

BUCKING

The sawing of a log or fallen tree into

smaller pieces. (Fig. 17-18)

When bucking up a log, check to see

where the log is supported and determine

which way the two halves will fall when

cut. If the log is under tension, always

start with a relieving cut (1) at compression side. Then make a bucking cut (2) at

tension side. If the saw pinches, stop the

engine and remove the saw from the log.

18

11

Page 12

MAINTENANCE

GUIDE BAR AND OIL HOLES

Clean guide bar before use. Follow instructions for removing and installing guide

bar and saw chain. Remove guide bar and clean groove of the guide bar with a

small screwdriver. Clean oil holes with a wire (see below). Check the sprocket

and the clutch and clean the bar mount area before installing the bar. Guide bar

with sprocket nose should be lubricated with grease using a lubricating syringe.

Invert the symmetrically shaped guide bar every 8 working hours or each time

the chain is removed to ensure uniform wear. Check the bar rails frequently for

wear and remove burs and square up the rails using a at le. Clean the Oiler

port on the saw every time the saw chain and guide bar are removed.

SPROCKET

A damaged drive sprocket will cause premature wear or damage of the chainsaw.

Check the sprocket when installing a new chain. When outer diameter of sprocket is worn 0.5mm (0.020”) or

more, replace it. Always clean sprocket, clutch and bar mount area before installing guide bar.

SAW CHAIN SHARPENING

It is advisable to have professional shops sharpen saw chains. It is beyond the expertise of the typical home

owner to sharpen saw chains. An improperly sharpened saw chain will not cut effectively, require more physical effort, and cause high vibrations and a higher rate of wear.

CARBON BRUSHES

Before accessing the carbon brushes, be sure that the

chainsaw is disconnected from the power source.

1. Check the condition of the carbon brushes after 50 hours of use of your new chainsaw. If the brushes are

worn to 1/8 inch in length, replace them.

2. Remove the motor cove to inspect the brushes.

3. Replace them if necessary.

REPLACING THE GUIDE BAR

1. To replace the guide bar, remove the adjust block by loosening the screw holding the adjust block to

guide bar.

2. Use the replacement bar recommended by manufacturer. Attach the adjust block to new guide bar by

tightening the screw.

3. Refer to "Installing Guide Bar and Chainsaw" section in manual (p. 8)

12

Page 13

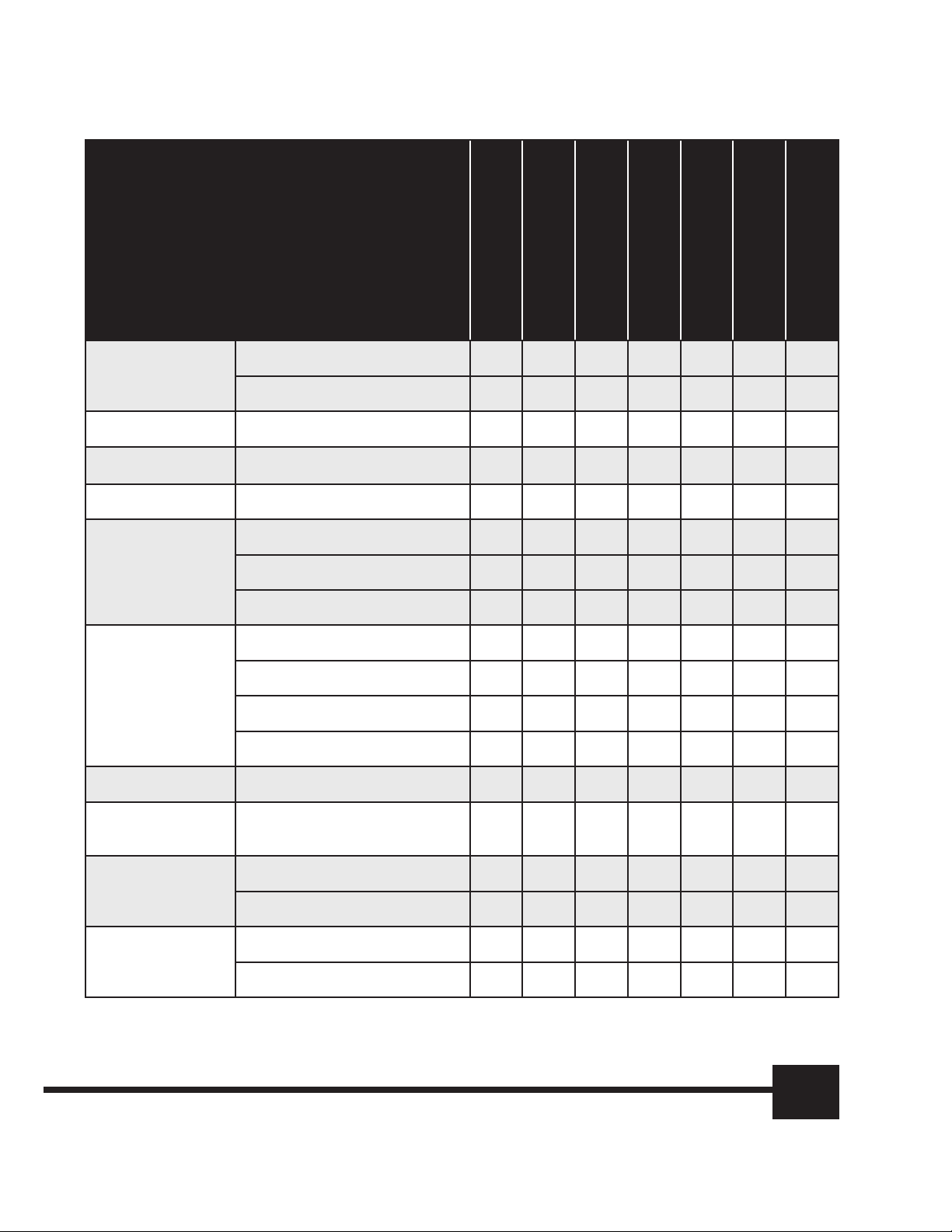

MAINTENANCE CHART

After nishing work or daily

Before starting work

Please note that the following maintenance intervals

apply for normal operating conditions only. If you daily

working time is longer than normal or cutting conditions

are different, shorten the specied intervals accordingly.

Visual inspection x

Complete machine

Clean x

Switch Check operation x

Oil tank Clean x

Chain lubrication Check x

Inspect, also check the sharpness x

Saw chain

Check chain tension x

Sharpen x

Check (wear, damage) x

Weekly

Monthly

If faulty

If damaged

As required

Clean and turn over x x

Guide bar

Deburr x

Replace x x

Chain sprocket Check x

All accessible screws

and nuts

Chain catcher on

sprocket cover

Power cord

Retighten x

Check x

Replace sprocket cover x

Check x

Replace x

13

Page 14

EXPLODED VIEW & PARTS LIST

14

Page 15

EXPLODED VIEW & PARTS LIST

ITEM# DESCRIPTION QTY

1 SCREW ST4.2X16 18

2 LABEL 1

3 RIGHT HANDLE 1

4 O-RING 1

5 OIL CAP 1

6 POWER CORD 1

7 CORD SLEEVE 1

8 CORD BRACKET 1

9 BREAK SPRING 1

10 CAPACITOR 1

11 SWITCH 1

12 SWITCH LOCK BUTTON 1

13 WIRE POLE 1

14 WIRE CLIP 1

15 HANDLE GRIP 1

16 LEFT HANDLE 1

17 PLASTIC RING 1

18 BEARING 6001 1

19 FAN 1

20 ARMATURE 1

21 SHIELD RING 1

22 BEARING 608 1

23 LABEL 1

24 WIND SHIELD 1

25 SCREW ST4.8X50 2

26 STATOR 1

27 HOUSING 1

28 CARBON BRUSH 2

ITEM# DESCRIPTION QTY

29 BRUSH HOLDER 2

30 SPRING 2

31 LABEL 1

32 MOTOR COVER 1

33 NEEDLE BEARING HK0810 1

34 RED PAPER PAD 1

35 SHIELD RING 2

36 WASHER 1

37 HELICAL GEAR 1

38 NEEDLE BEARING HK1010 2

39 TORSION 1

40 SPINDLE 1

41 OIL OUTPUT MOUTH 1

42 OIL OUTPUT PIPE 1

43 GEAR BOX 1

44 SPIKE BAR 1

45 OIL PUMP 1

46 CAM 1

47 GEAR BOX COVER 1

48 SHIELD RING 1

49 WASHER 1

50 SPROCKET WASHER 2

51 SPROCKET 1

52 OIL RESISTANCE PLATE 1

53 OIL INJECTION PIPE 1

54 SPRING 1

55 OIL INPUT MOUTH 1

56 OIL TANK 1

ITEM# DESCRIPTION QTY

57 SWITCH BUTTON 1

58 ROLL WHEEL 1

59 LINK BLOCK 1

60 SWITCH 1

61 SCREW ST4.2X10 2

62 WASHER 2

63 BRAKE GUARD 1

64 SCREW ST4.2X42 9

65 FRONT HANDLE GUARD 1

66 FRONT HANDLE 1

67 BRAKE LINK ROD 1

68 BRAKE ROD 1

69 SPRING 1

70 SCREW M4X6 1

71 GUIDE BAR 1

72 BIG RIVET 1

73 DRIVER BLOCK 1

74 ADJUST BLOCK 1

75 WASHER 1

76 SAW CHAIN 1

77 SCABBARD 1

78 STEEL RING Ø55X2 1

79 SPROCKET COVER 1

80 STEEL RING Ø10X1 1

81 TENSION WHEEL 1

82 LABEL 1

83 LOCKING KNOB 1

15

Page 16

LIMITED WARRANTY

WEN Products warrants its power tools to be free of defects in materials and from workmanship for a period of one (1) year from date of original purchase. We will repair or replace, at our option, any tool covered by this warranty that after inspection is found to be

defective in materials or workmanship during the warranty period. If the product is used for

commercial, professional or income producing purposes, the limited warranty period is 90

days. If used for rental purposes, the limited warranty period is 30 days.

This limited warranty applies only to the original owner and is not transferable to subse-

quent owners. The limited warranty begins on the date of purchase by the original owner

and extends for the fore-mentioned time periods. This limited warranty does not apply to

normal wear and tear, misused, abused, and altered tools. Repairs by unauthorized personnel will void the warranty.

For warranty service, please contact us at 1-888-315-3080 or write to us at WEN Products,

PO Box 1110, Dundee, IL 60118. To acquire service, you will have to provide proof of pur-

chase and may be asked to ship the tool back to us freight prepaid.

Under no circumstances shall WEN Products be liable for any indirect, incidental or conse-

quential damages from the sale or use of this product. Some states do not allow the exclusion or limitation of incidental or consequential damages. Some states do not allow limitations on the length of an implied warranty. This warranty provides you with specic legal

rights and you may have other rights that vary from state to state.

16

Page 17

NOTES

17

Page 18

Loading...

Loading...