Wen 3962 Instruction Manual

MODEL 3962

10-INCH BAND SAW

WITH STAND

Instruction Manual

NEED HELP? CONTACT US!

Have product questions? Need technical support? Please feel free to contact us:

TECHSUPPORT@WENPRODUCTS.COM1-800-232-1195 (M-F 8AM-5PM CST)

IMPORTANT: Your new tool has been engineered and manufactured to WEN’s highest standards for dependability,

ease of operation, and operator safety. When properly cared for, this product will supply you years of rugged,

trouble-free performance. Pay close attention to the rules for safe operation, warnings, and cautions. If you use

your tool properly and for its intended purpose, you will enjoy years of safe, reliable service.

For replacement parts and the most up-to-date instruction manuals, visit WENPRODUCTS.COM

CONTENTS

WELCOME 3

Introduction ......................................................................................................3

Specifications ................................................................................................... 3

SAFETY 4

General Safety Rules ........................................................................................ 4

Specific Rules for Your Band Saw .................................................................... 6

Electrical Information ....................................................................................... 8

BEFORE OPERATING 9

Unpacking & Transportation ............................................................................ 9

Know Your Band Saw ..................................................................................... 10

Assembly & Adjustments ............................................................................... 11

OPERATION & MAINTENANCE 16

Operation ....................................................................................................... 16

Maintenance ....................................................................................................18

Troubleshooting Guide ................................................................................... 19

Exploded View & Parts List ............................................................................ 21

Warranty Statement ....................................................................................... 25

To purchase accessories for your tool, visit WENPRODUCTS.COM

Replacement Blades - visit our website for our full line of 72-inch band saw blades

2

INTRODUCTION

Thanks for purchasing the WEN Band Saw. We know you are excited to put your tool to work, but first, please

take a moment to read through the manual. Safe operation of this tool requires that you read and understand this

operator’s manual and all the labels affixed to the tool. This manual provides information regarding potential safety

concerns, as well as helpful assembly and operating instructions for your tool.

SAFETY ALERT SYMBOL: Indicates danger, warning, or caution. The safety symbols and the explanations

with them deserve your careful attention and understanding. Always follow the safety precautions to reduce the

risk of fire, electric shock or personal injury. However, please note that these instructions and warnings are not

substitutes for proper accident prevention measures.

NOTE: The following safety information is not meant to cover all possible conditions and situations that may occur.

WEN reserves the right to change this product and specifications at any time without prior notice.

At WEN, we are continuously improving our products. If you find that your tool does not exactly match this manual,

please visit wenproducts.com for the most up-to-date manual or contact our customer service at 1-800-232-1195.

Keep this manual available to all users during the entire life of the tool and review it frequently to maximize

safety for both yourself and others.

SPECIFICATIONS

Model Number 3962

Motor 120V, 60 Hz, 3.5A

Throat 9-3/4 inches

Maximum Workpiece Thickness 6 inches

Blade Speed 1520 / 2620 FPM

Blade Length 72 inches

Blade Width 1/8 to 1/2 inch (3/8 inch blade included)

Work Table Bevel 0 to 45°

Work Table Dimensions 14-1/8 inches x 12-1/2 inches

Weight 73.5 pounds

Product Dimensions (w/ stand) 26.5 in. x 21 in. x 58.5 in.

3

GENERAL SAFETY RULES

WARNING! Read all safety warnings and all instructions. Failure to follow the warnings and instructions

may result in electric shock, fire and/or serious injury.

Safety is a combination of common sense, staying alert and knowing how your item works. The term “power tool”

in the warnings refers to your mains-operated (corded) power tool or battery-operated (cordless) power tool.

SAVE THESE SAFETY INSTRUCTIONS.

WORK AREA SAFETY

1. Keep work area clean and well lit. Cluttered or dark

areas invite accidents.

2. Do not operate power tools in explosive atmo-

spheres, such as in the presence of flammable liquids, gases or dust. Power tools create sparks which

may ignite the dust or fumes.

3. Keep children and bystanders away while operat-

ing a power tool. Distractions can cause you to lose

control.

ELECTRICAL SAFETY

1. Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any adapter

plugs with earthed (grounded) power tools. Unmodi-

fied plugs and matching outlets will reduce risk of electric shock.

2. Avoid body contact with earthed or grounded sur-

faces such as pipes, radiators, ranges and refrigerators. There is an increased risk of electric shock if your

body is earthed or grounded.

3. Do not expose power tools to rain or wet condi-

tions. Water entering a power tool will increase the risk

of electric shock.

4. Do not abuse the cord. Never use the cord for carry-

ing, pulling or unplugging the power tool. Keep cord

away from heat, oil, sharp edges or moving parts.

Damaged or entangled cords increase the risk of electric shock.

6. If operating a power tool in a damp location is

unavoidable, use a ground fault circuit interrupter

(GFCI) protected supply. Use of a GFCI reduces the risk

of electric shock.

PERSONAL SAFETY

1. Stay alert, watch what you are doing and use common sense when operating a power tool. Do not use a

power tool while you are tired or under the influence

of drugs, alcohol or medication. A moment of inatten-

tion while operating power tools may result in serious

personal injury.

2. Use personal protective equipment. Always wear

eye protection. Protective equipment such as a respiratory mask, non-skid safety shoes and hearing protection used for appropriate conditions will reduce the risk

of personal injury.

3. Prevent unintentional starting. Ensure the switch is

in the off-position before connecting to power source

and/or battery pack, picking up or carrying the tool.

Carrying power tools with your finger on the switch or

energizing power tools that have the switch on invites

accidents.

4. Remove any adjusting key or wrench before turning

the power tool on. A wrench or a key left attached to a

rotating part of the power tool may result in personal

injury.

5. Do not overreach. Keep proper footing and balance

at all times. This enables better control of the power

tool in unexpected situations.

5. When operating a power tool outdoors, use an ex-

tension cord suitable for outdoor use. Use of a cord

suitable for outdoor use reduces the risk of electric

shock.

4 5

6. Dress properly. Do not wear loose clothing or jewelry. Keep your hair and clothing away from moving

parts. Loose clothes, jewelry or long hair can be caught

in moving parts.

GENERAL SAFETY RULES

WARNING! Read all safety warnings and all instructions. Failure to follow the warnings and instructions

may result in electric shock, fire and/or serious injury.

Safety is a combination of common sense, staying alert and knowing how your item works. The term “power tool”

in the warnings refers to your mains-operated (corded) power tool or battery-operated (cordless) power tool.

SAVE THESE SAFETY INSTRUCTIONS.

7. If devices are provided for the connection of dust

extraction and collection facilities, ensure these are

connected and properly used. Use of dust collection

can reduce dust-related hazards.

POWER TOOL USE AND CARE

1. Do not force the power tool. Use the correct power

tool for your application. The correct power tool will

do the job better and safer at the rate for which it was

designed.

2. Do not use the power tool if the switch does not turn

it on and off. Any power tool that cannot be controlled

with the switch is dangerous and must be repaired.

3. Disconnect the plug from the power source and/or

the battery pack from the power tool before making

any adjustments, changing accessories, or storing

power tools. Such preventive safety measures reduce

the risk of starting the power tool accidentally.

4. Store idle power tools out of the reach of children

and do not allow persons unfamiliar with the power

tool or these instructions to operate the power tool.

Power tools are dangerous in the hands of untrained

users.

5. Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and any

other condition that may affect the power tool’s operation. If damaged, have the power tool repaired before

use. Many accidents are caused by poorly maintained

power tools.

6. Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting edges are less

likely to bind and are easier to control.

7. Use the power tool, accessories and tool bits, etc.

in accordance with these instructions, taking into account the working conditions and the work to be performed. Use of the power tool for operations different

from those intended could result in a hazardous situation.

8. Use clamps to secure your workpiece to a stable

surface. Holding a workpiece by hand or using your

body to support it may lead to loss of control.

9. KEEP GUARDS IN PLACE and in working order.

SERVICE

1. Have your power tool serviced by a qualified repair

person using only identical replacement parts. This

will ensure that the safety of the power tool is maintained.

CALIFORNIA PROPOSITION 65 WARNING

Some dust created by power sanding, sawing, grinding,

drilling, and other construction activities may contain

chemicals, including lead, known to the State of California to cause cancer, birth defects, or other reproductive

harm. Wash hands after handling. Some examples of

these chemicals are:

• Lead from lead-based paints.

• Crystalline silica from bricks, cement, and other

masonry products.

• Arsenic and chromium from chemically treated

lumber.

Your risk from these exposures varies depending on

how often you do this type of work. To reduce your exposure to these chemicals, work in a well-ventilated area

with approved safety equipment such as dust masks

specially designed to filter out microscopic particles.

SPECIFIC RULES FOR YOUR BAND SAW

WARNING! Do not operate the power tool until you have read and understood the following instructions

and the warning labels.

SAW BLADE SAFETY

1. Always wear protective gloves when handling saw

blades.

2. Only use blades with correct size and type for both

your band saw and your workpiece.

• See the blade specifications on page 3.

• Make sure the blade is installed in the proper direction.

3. Never use damaged or deformed saw blades. Only

use sharp blades.

4. Install the saw blade in the correct orientation indi-

cated in the instructions (see “Changing the Saw Blade”,

page 16).

5. Keep hands out of path of saw blade. Never use your

hands to remove sawdust or scrap wood. Use a brush

at all times.

4. Wear work gloves when handling saw blades. DO

NOT wear gloves, neckties, jewelry, or loose clothing

while operating the saw.

5. Saw dust is harmful to your health. Use NIOSH-approved dust masks or other respiratory protection during operation and cleaning.

6. Always turn off and unplug the band saw before making any adjustments or repair tasks. Never adjust the

band saw or the workpiece while the saw is running.

7. Only use the band saw to cut wood.

PREPARING THE BAND SAW

1. When transporting the band saw, never carry the device by its guards or its accessories.

2. Examine the band saw for any damaged or missing

parts. Replace or repair damaged parts before operation. Periodically check that all nuts, bolts and other fasteners are properly tightened.

6. Never reach around saw blade or reach in back of the

saw blade.

7. The use of accessories or attachments not recommended by the manufacturer may result in a risk of personal injury.

PERSONAL SAFETY

1. Operate in a well ventilated area. Keep the floor area

around the band saw level and free of slippery substances or other tripping hazards.

2. Wear ANSI Z87.1-approved safety goggles to protect

your eyes from saw dust. Use hearing protection to protect yourself from hearing loss.

3. People with pacemakers should consult their

physician(s) before use. Electromagnetic fields in close

proximity to pacemakers could cause pacemaker interference or pacemaker failure.

SECURE YOUR WORKPIECE

1. To avoid blade binding or loss of control, always secure the workpiece to a stable platform, ensuring that

body exposure is minimized.

2. Ensure that work is correctly supported. Supports

must be placed under the workpiece on both sides,

close to the line of cut and near the edge of the workpiece.

3. For accuracy of cut, and to avoid blade binding, always use a rip fence or straight edge guide.

4. Use extra caution with very large, very small, or awkwardly-shaped workpieces. Small pieces should be secured with clamps. Do not hold small pieces with your

hand because your fingers might go under the blade

guard.

6

SPECIFIC RULES FOR YOUR BAND SAW

WARNING! Do not operate the power tool until you have read and understood the following instructions

and the warning labels.

5. Never hand-hold a workpiece that is too small to be

clamped, as it can be launched away and cause injury. Use proper support and guides to secure the small

workpiece.

6. Support round work properly (use a V block or press

it against the miter gauge) to prevent it from rolling and

the blade from biting.

7. Plan intricate or small work carefully to avoid pinching the blade. Avoid awkward operations and hand positions to prevent accidental contact with the blade.

DURING CUTTING OPERATIONS

1. Always stand to one side when operating the saw.

Never have any part of the body in line with the path of

the saw. Never hold a workpiece in your hand or across

your legs while cutting.

2. Ensure hands are away from the cutting area and

blade.

3. Feed work into the blade against the direction of rotation of the blade only.

4. If you are interrupted when operating the saw, complete the process and switch the saw off before looking

up.

5. Power tools must always be held by the insulated

gripping surfaces when performing an operation, ensuring protection if the cutting tool makes contact with

its own cord or hidden wiring. Contact with a ‘live’ wire

will make exposed metal parts of the power tool ‘live’

and shock the operator if the insulated gripping surfaces are not used.

7. Blade guide, supports, bearings, and blade tension

must be properly adjusted to avoid accidental blade

contact and to minimize blade breakage. To maximize

blade support, always adjust the upper blade guide and

blade guard so that it barely clears the workpiece.

8. Turn on the band saw and let it reach full speed, then

slowly slide the workpiece into the blade. This will help

produce safer and cleaner cuts.

9. Never cut more than one piece at a time. Do not stack

workpieces together. Do not attempt to cut material

thicker than specified on page 3 of this manual. Adjust

the upper blade guide to suit the thickness of the workpiece.

10. If a cut does not extend to the edge of the workpiece, or if the blade binds in the cut, allow the blade

to come to a complete stop and lift the workpiece away

from the blade.

11. Turn off tool and wait for saw blade to stop before

moving workpiece or changing settings. Do not slow

or stop a blade with a piece of wood or by hand. Let

the blade come to rest naturally. Do not attempt to free

a jammed blade while the machine is still running and

connected to power.

12. Always adjust the upper blade guide to cover the

blade after use.

6. Do not use the band saw unless all guards are in

place. Do not operate with any guard disabled, damaged, or removed. Moving guards must move freely and

close instantly.

7

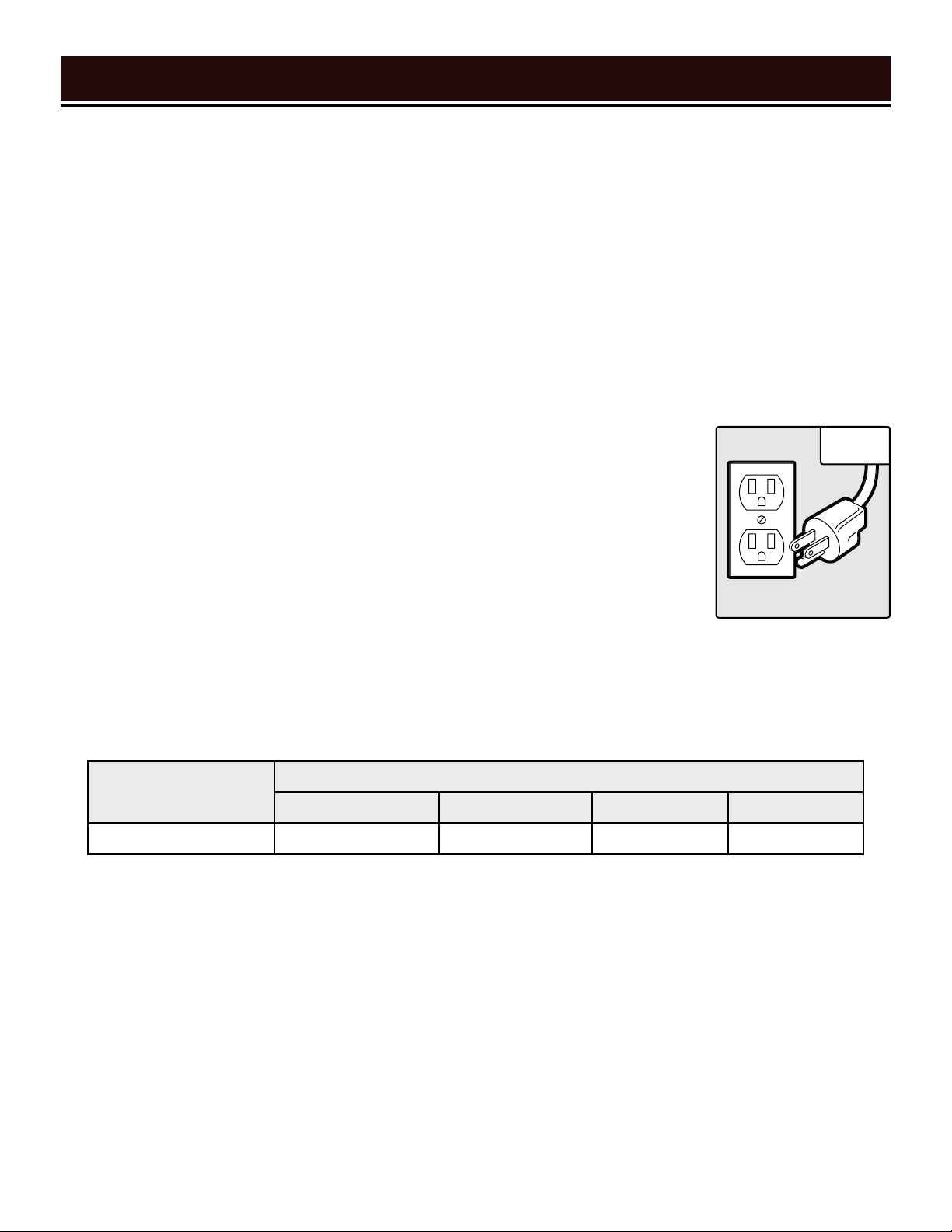

ELECTRICAL INFORMATION

GROUNDING INSTRUCTIONS

In the event of a malfunction or breakdown

current and reduces the risk of electric shock. This tool is equipped with an electric cord that has an

equipment grounding conductor and a grounding plug. The plug MUST be plugged into a matching outlet

that is properly installed and grounded in accordance with ALL local codes and ordinances.

, grounding provides the path of least resistance for an electric

1. Do not modify the plug provided.

electrician.

2. Improper connection

with the green insulation (with or without yellow stripes) is the equipment grounding conductor. If repair or

replacement of the electric cord or plug is necessary, DO NOT connect the equipment grounding conductor

to a live terminal.

3. Check

understand the grounding instructions or whether the tool is properly grounded.

4. Use only three-wire extension cords

that accept the tool’s plug (INSERT CR). Repair or replace a damaged or worn

cord immediately.

CAUTION!

you are not sure, have a licensed electrician check the outlet.

with a licensed electrician or service personnel if you do not completely

In all cases, make certain the outlet in question is properly grounded. If

of the equipment grounding conductor can result in electric shock. The conductor

If it will not fit the outlet, have the proper outlet installed by a licensed

Fig. 1

that have three-pronged plugs and outlets

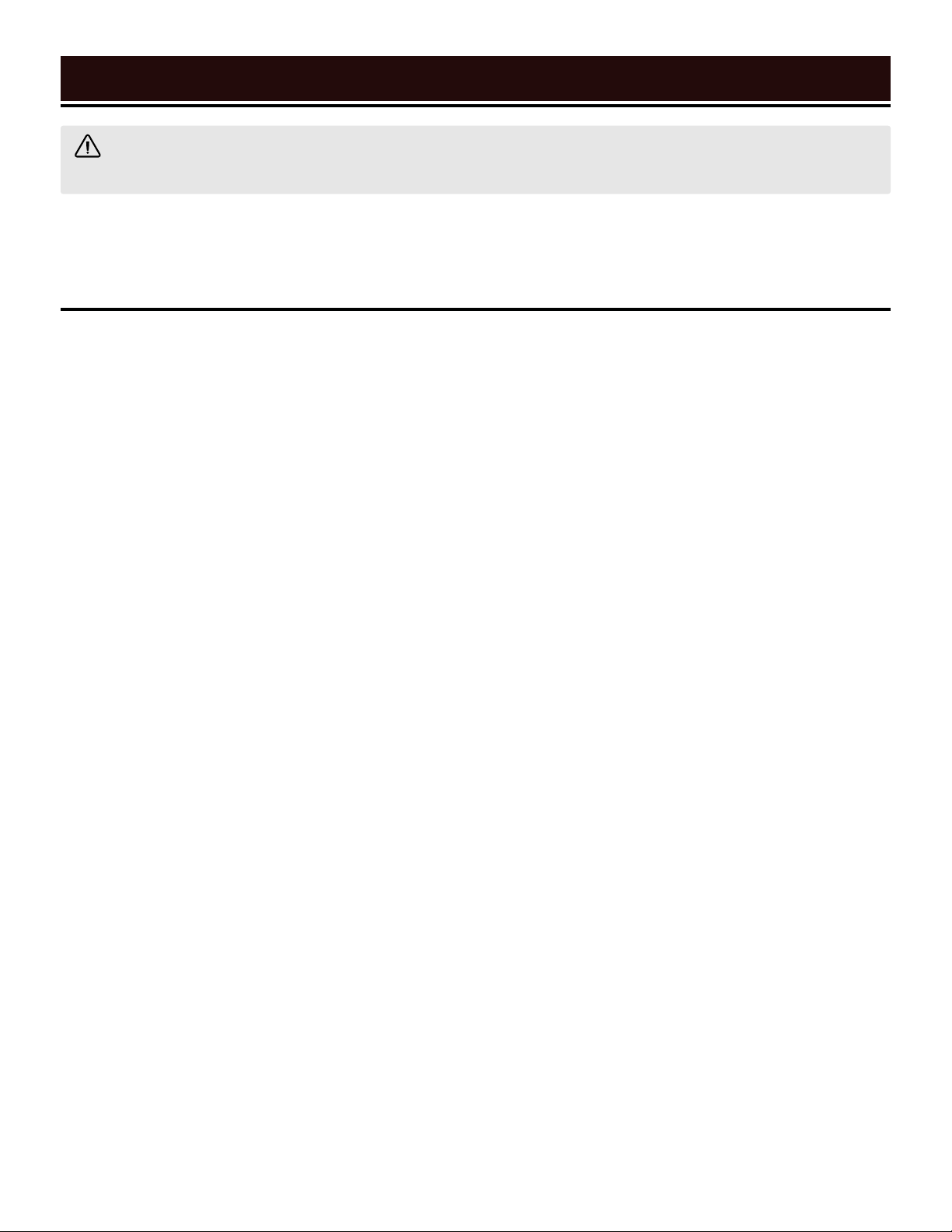

GUIDELINES AND RECOMMENDATIONS FOR EXTENSION CORDS

When using an extension cord, be sure to use one heavy enough to carry the current your product will draw. An

undersized cord will cause a drop in line voltage resulting in loss of power and overheating. The table below shows

the correct size to be used according to cord length and ampere rating. When in doubt, use a heavier cord. The

smaller the gauge number, the heavier the cord.

AMPERAGE

25 ft. 50 ft. 100 ft. 150 ft.

3.5A 18 gauge 16 gauge 16 gauge 14 gauge

1. Examine extension cord before use. Make sure your extension cord is properly wired and in good condition.

Always replace a damaged extension cord or have it repaired by a qualified person before using it.

2. Do not abuse extension cord. Do not pull on cord to disconnect from receptacle; always disconnect by pulling

on plug. Disconnect the extension cord from the receptacle before disconnecting the product from the extension

cord. Protect your extension cords from sharp objects, excessive heat and damp/wet areas.

3. Use a separate electrical circuit for your tool. This circuit must not be less than a 12-gauge wire and should

be protected with a 15A time-delayed fuse. Before connecting the motor to the power line, make sure the switch

is in the OFF position and the electric current is rated the same as the current stamped on the motor nameplate.

Running at a lower voltage will damage the motor.

8

REQUIRED GAUGE FOR EXTENSION CORDS

UNPACKING & TRANSPORTATION

WARNING! Do not plug in or turn on the tool until it is fully assembled according to the instructions. Failure

to follow the safety instructions may result in serious personal injury.

UNPACKING

With the help of a friend or trustworthy foe, carefully remove the band saw from the packaging. Make sure to take

out all contents and accessories. Do not discard the packaging until everything is removed. Check the packing list

below to make sure you have all of the parts and accessories. If any part is missing or broken, please contact our

customer service at 1-800-232-1195 (M-F 8-5 CST), or email techsupport@wenproducts.com.

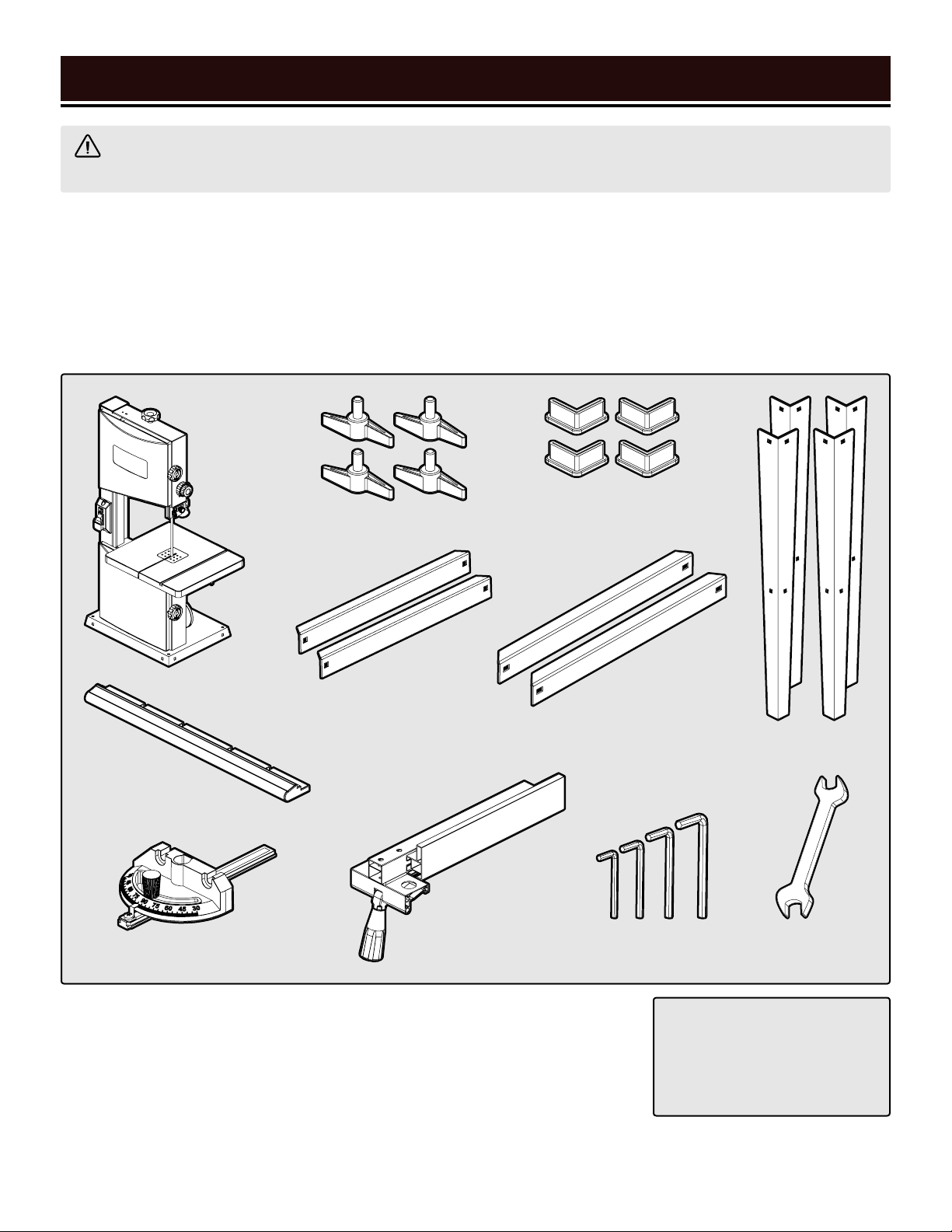

PACKING LIST (NOTE: A hardware bag is included but not shown below.)

Guide

Rail (1)

Miter Gauge

(1)

Band Saw &

Table (1)

Knob (4)

Short

Brace (2)

Rip

Fence (1)

Foot (4)

Hex Wrench

Long

Brace (2)

(4)

Legs (4)

10/13mm

Wrench (1)

ASSEMBLY/ADJUSTMENT TOOLS (NOT INCLUDED)

The tools listed below are required for either assembly or adjustment:

• 14mm Open-End Wrench (2)

• Phillips-Head Screwdriver (1)

• Combination Square (1)

• Bubble Level (1)

Hardware Bag Contents

• Carriage Bolts, M8 x 16 (16)

• Flat Washers, 8mm (16)

• Hex Nut, M8 (16)

• Hex Bolts, M6 x 10 (4 - with table)

• Flat Washers, 6mm (4 - with table)

TRANSPORTING

When transporting your band saw, never carry the saw by its guards or its accessories.

9

Loading...

Loading...