Page 1

1

Page 2

Table of Contents

Technical data…………………………………………………………… 2

General safety rules……………………………………………………… 3

Additional safety rules…………………………………………………... 5

Electrical requirements………………………………………………..…. 8

Know your table saw……………………………………………………. 10

Unpacking……………………………………………………………….. 11

Assembly and adjustments……………………………………………… 12

Operation………………………………………………………………... 20

Maintenance…………………………………………………………….. 24

Trouble shooting………………………………………………………… 25

Exploded view………………………………………………………….. 26

Parts list…………………………………………………………………. 27

Warranty statement……………………………………………………… 30

Technical Data

Model: 3710

Motor: 120V, 60Hz, 15A, 4800rpm

Blade: 10 inch carbide tipped blade

Arbor: 5/8"

Depth of Cut at 90º: 3"

Depth of Cut at 45º: 2-3/8"

Bevel Angle Range: Left, 90º-45º

Table Height (with stand): 36"

Table Dimensions: 20"x26"

Weight: 46 lbs

2

Page 3

General Safety Rules

The purpose of safety symbols is to attract your attention to possible dangers. The safety symbols, and

the explanations with them, deserve your careful attention and understanding. The safety warnings do

not by themselves eliminate any danger. The instructions or warnings they give are not substitutes for

proper accident prevention measures.

Symbol Meaning

Safety Alert Symbol:

Indicated danger, warning, or caution, may be used in conjunction with other symbols or

pictographs. Always follow the safety precautions to reduce the risk of fire, electric shock

and personal injury.

NOTE: advising you of information or instructions is vital to the operation or maintenance of the

equipment.

Important

Servicing requires extreme care and knowledge and should be performed only by a qualified service

technician. For service, we suggest you return the tool to WEN PRODUCTS a division of Great Lakes

Technologies, LLC for repair. When servicing, use only identical WEN® replacement parts.

WARNING - Do not attempt to operate this tool until you have read thoroughly and

understand completely all instructions, safety rules, etc…contained in this manual. Failure

to comply can result in accidents involving fire, electric shock, or serious personal injury. Save this

operator’s manual and review frequently for continuing safe operation and instructing others who may

use this tool.

Safe operation of this power tool requires that you read and understand this operator’s manual and all

labels affixed to the tool. Safety is a combination of common sense, staying alert, and knowing how

your tool works.

―READ ALL INSTRUCTIONS‖ Failure to follow the safety rules listed below and other basic safety

precautions may result in serious personal injury.

Work Area

KEEP CHILDREN AWAY

Do not let visitors contact tool or extension cord. All visitors should be kept away from work area.

KEEP WORK AREAS CLEAN

Cluttered areas and benches invite accidents.

MAKE WORKSHOP CHILD-PROOF

With padlocks, master switches.

AVOID DANGEROUS ENVIRONMENTS

Don’t use power tools in damp or wet locations. Keep work area well lit. Do not expose power tools to

rain. Do not use tool in presence of flammable liquids or gases.

AVOID ACCIDENTAL STARTING

Make sure the switch is in the ―OFF‖ position before plugging in tool.

3

Page 4

NEVER STAND ON TOOL OR ITS STAND

Serious injury could occur if the tool is tipped or if the cutting tool is accidentally contacted. Do not

store materials on or near the tool such that it is necessary to stand on the tool or its stand to reach

them.

CHECK DAMAGED PARTS

Before further use of the tool, a guard or other part that is damaged should be carefully checked to

ensure that it will operate properly and perform its intended function. Check for alignment of moving

parts, mounting and any other conditions that may affect its operation. A guard or other part that is

damaged should be properly replaced.

Personal Safety

KNOW YOUR POWER TOOL

Read and understand the owner’s manual and labels affixed to the tool. Learn its application and

limitations as well as th e specific potential hazards peculiar to this tool.

DON’T OVERREACH

Keep proper footing and balance at all times.

STAY ALERT

Watch what you are doing. Use common sense. Do not operate

operate while under medication or while using alcohol or other drug.

DRESS PROPERLY

Do not wear loose clothing or jewelry. They can get caught in moving parts. Rubber gloves and nonskid footwear are recommended when working outdoors. Wear protective hair covering to contain long

hair.

USE SAFETY GOGGLES

Also face or dust mask if cutting operation is dusty, and ear plugs during extended periods of operation.

GUARD AGAINST ELECTRIC SHOCK

Prevent body contact with grounded surfaces. For example:

Pipes, radiators, ranges, refrigerator enclosures

DISCONNECT TOOL FROM POWER SOURCE

When not in use, before servicing, when changing blades, bits, cutters, etc.

KEEP GUARDS IN PLACE

In working order, and in proper adjustment and alignment.

REMOVE ADJUSTING KEYS AND WRENCHES

When not in use, before servicing, when changing blades, bits, cutters, etc.

All repairs, electrical or mechanical, should be attempted only by trained repairmen.

Use only WEN replacement parts; any others may create a hazard.

Use only accessories that are recommended by the manufacturer for your model. Accessories that may

be suitable for one tool may become hazardous when used on another tool.

4

the tool when you are tired. Do not

Page 5

Additional Safety Rules

Tool Care

DO NOT ALTER OR MISUSE TOOL

These tools are precision built. Any alteration or modification not specified is misuse and may result in

dangerous conditions.

AVOID GASEOUS AREAS

Do not operate electric tools in gaseous or explosive at mospheres. Motors in these tools normally

spark, and may result in a dangerous condition.

MAINTAIN TOOLS WITH CARE

Keep tools sharp and clean for better and safer performance. Follow instructions for lubricating and

changing accessories. Inspect tool cords periodically and if damaged, have repaired by authorized

service facility. Inspect extension cords periodically and replace if damaged. Keep handles dry, clean

and free from oil and grease.

Before connecting the tool to a power source (receptacle, outlet, etc.), be sure voltage supplied is the

same as that specified on the nameplate of the tool. A power source with voltage greater than that

specified for the tool can result in serious injury to the user — as well as damage to the tool. If in

doubt, DO NOT PLUG IN THE TOOL. Using a power source with voltage less than the nameplate

rating is harmful to the motor.

STABILITY OF SAW

Your table saw MUST BE BOLTED securely to a stand or workbench. In addition, if there is any

tendency for the table saw to tip over or move during certain operations such as cutting long, heavy

boards, use an auxiliary support.

LOCATION

Use the table saw in a well lit area and on a level surface, clean and smooth enough to reduce the risk

of trips and falls. Use it where neither the operator nor the casual observer is forced to stand in line

with the blade.

KICKBACK

Kickbacks can cause serious injury: A ―KICKBACK‖ occurs when a part of the workpiece binds

between the saw blade and the rip fence or other fixed object. Workpiece binding the blade due to

misalignment can also cause kickback. During kickback, workpiece rises from table and is thrown

toward the operator. Keep your face and body to one side of the saw blade, out of line with a possible

―KICKBACK‖.

KICKBACKS AND POSSIBLE INJURY CAN USUALLY BE AVOIDED BY:

a. Maintaining the rip fence parallel to the saw blade.

b. Keeping the saw blade sharp. Replacing or sharpening anti-kickback pawls when points become

dull.

c. Keeping saw blade guard, spreader and anti-kickback pawls in place and operating properly. The

spreader must be in alignment with the saw blade and the pawls must stop a kickback once it has

started. Check their action before ripping.

5

Page 6

d. NOT ripping workpiece that is twisted or warped or does not have a straight edge to guide along

the rip fence.

e. NOT releasing work until you have pushed it all the way past the saw blade.

f. Using a Push Stick for ripping widths of 2" to 6" and an auxiliary fence and Push Block for ripping

widths narrower than 2" (See ―Basic Saw Operation, Using the Rip Fence ―section.).

g. NOT confining the cut-off piece when ripping or cross -cutting.

h. When ripping, apply the feed force to the section of the workpiece between the sawblade and the

rip fence. Use

Push Stick or Push Block when appropriate (See item f. above).

PROTECTION: Eyes, hands, face, ears and body.

TO AVOID BEING PULLED INTO THE SPINNING TOOL,

DO NOT WEAR: Loose Fitting Gloves, Loose Clothing, Necktie, Jewelry

DO: TIE BACK LONG HAIR, ROLL LONG SLEEVES ABOVE ELBOWS

a. If any part of your saw is missing, malfunctioning, has been damaged or broken … such as the

motor switch, or other operating control, a safety device or the power cord … cease operating

immediately until the particular part is properly repaired or replaced.

b. Wear safety goggles and a face shield if operation is dusty. Wear ear plugs or muffs during

extended periods of operation. Small loose pieces of wood or other objects that contact the rear of

the revolving blade can be thrown back at the operator at excessive speed. This can usually be

avoided by keeping the guard and spreader in place for all ―THRU-SAWING‖ operations (sawing

entirely thru the work) AND by removing all loose pieces from the table with a long stick of wood

IMMEDIATELY after they are cut off.

c. Use extra caution when the guard assembly is removed for resawing, dadoing, rabbeting or

molding — replace the guard as soon as that operation is completed.

d. NEVER turn the saw ―ON‖ before clearing the table of all tools, wood scraps, etc., except the

workpiece and related feed or support devices for the operation planned.

e. NEVER place your face or body in line with the cutting tool.

• NEVER place your fingers and hands in the path of the saw blade or other cutting tool.

• NEVER reach in back of the cutting tool with either hand to hold down or support the

workpiece, remove wood scraps, or for any other reason. Avoid awkward operations and hand

positions where sudden slip could cause fingers or hand to move into a saw blade or other

cutting tool.

• DO NOT perform any operation ―FREEHAND‖ — always use either the rip fence or the miter

gauge to position and guide the work.

• NEVER use the rip fence when crosscutting or the miter gauge when ripping. DO NOT use the

rip fence as a length stop.

• NEVER hold onto or touch the ―free end‖ of the workpiece or a ―free piece‖ that is cut off,

while power is ―ON‖ and/or the saw blade is rotating.

• Shut ―OFF‖ the saw and disconnect the power cord when removing the table insert, changing

the cutting tool, removing or replacing the blade guard, or making adjustments.

• Provide adequate support to the rear and sides of the saw table for wider or long workpieces.

• Plastic and composition (like hardboard) materials may be cut on your saw. However, since

these are usually quite hard and slippery, the anti-kickback pawls may not stop a kickback.

Therefore, be especially attentive to following proper set-up and cutting procedures for ripping.

Do not stand, or permit anyone else to stand, in line with a potential kickback.

f. If you stall or jam the saw blade in the workpiece, turn saw ―OFF‖, remove the workpiece from the

saw blade, and check to see if the saw blade is parallel to the table slots or grooves and if the

6

Page 7

spreader is in proper alignment with the saw blade. If ripping at the time, check to see if rip fence

is parallel with the saw blade. Readjust as indicated.

g. NEVER gang crosscut — lining up more than one workpiece in front of the blade (stacked

vertically or horizontally outward on the table) and then pushing thru saw blade. The blade could

pick up one or more pieces and cause a binding or loss of control and possible injury.

h. DO NOT remove small pieces of cut-off material that may become trapped inside the blade guard

while the saw is running. This could endanger your hands or cause a kickback. Turn saw ―OFF‖

and wait until blade stops.

KNOW YOUR CUTTING TOOLS

Dull, gummy or improperly sharpened or set cutting tools can cause material to stick, jam, stall the

saw, or kickback at the operator. Minimize potential injury by proper cutting tool and machine

maintenance. NEVER ATTEMPT TO FREE A STALLED SAWBLADE WITHOUT FIRST

TURNING THE SAW OFF.

a. NEVER use grinding wheels, abrasive cut-off wheels, friction wheels (metal slitting blades) wire

wheels or buffing wheels.

b. USE ONLY RECOMMENDED ACCESSORIES.

c. Crosscutting operations are more conveniently worked and with greater safety if an auxiliary wood

facing is attached to the miter gauge.

d. Make sure the top of the cutting tool rotates toward you when standing in normal operating

position. Also make sure the cutting tool, arbor collars and arbor nut are installed properly. Keep

the cutting tool as low as possible for the operation being performed. Keep all guards in place

whenever possible.

e. Do not use any blade or other cutting tool marked for an operating speed less than 5000 R.P.M.

Never use a cutting tool larger in diameter than the diameter for which the saw was designed. For

greatest safety and efficiency when ripping, use the maximum diameter blade for which the saw is

designed, since under these conditions the spreader is nearest the blade.

f. Make sure the table insert is flush or slightly below the table surface on all sides except for rear

side. NEVER operate the saw unless the proper insert is installed.

THINK SAFETY

SAFETY IS A COMBINATION OF OPERATOR COMMON SENSE AND ALERTNESS AT ALL

TIMES WHEN THE TABLE SAW IS BEING USED.

Do not allow familiarity (gained from frequent use of your table saw) to become common place.

Always remember that a careless fraction of a second is sufficient to inflict severe injury.

The operation of any power tool can result in foreign objects being thrown into the eyes, which can

result in severe eye damage. Always wear safety goggles that comply with ANSI Z87.1 (shown on

package) before commencing power tool operation.

Some dust created by power sanding, sawing, grinding, drilling, and other construction activities

contains chemicals known to cause cancer, birth defects or other reproductive harm. Some

examples of these chemicals are:

• Lead from lead-based paints,

• Crystalline silica from bricks and cement and other masonry products, and

• Arsenic and chromium from chemically treated lumber.

Your risk from these exposures varies, depending on how often you do this type of work. To reduce

your exposure to these chemicals: work in a well ventilated area, and work with approved safety

equipment, such as those dust masks that are specially designed to filter out microscopic particles.

7

Page 8

Electrical Requirements

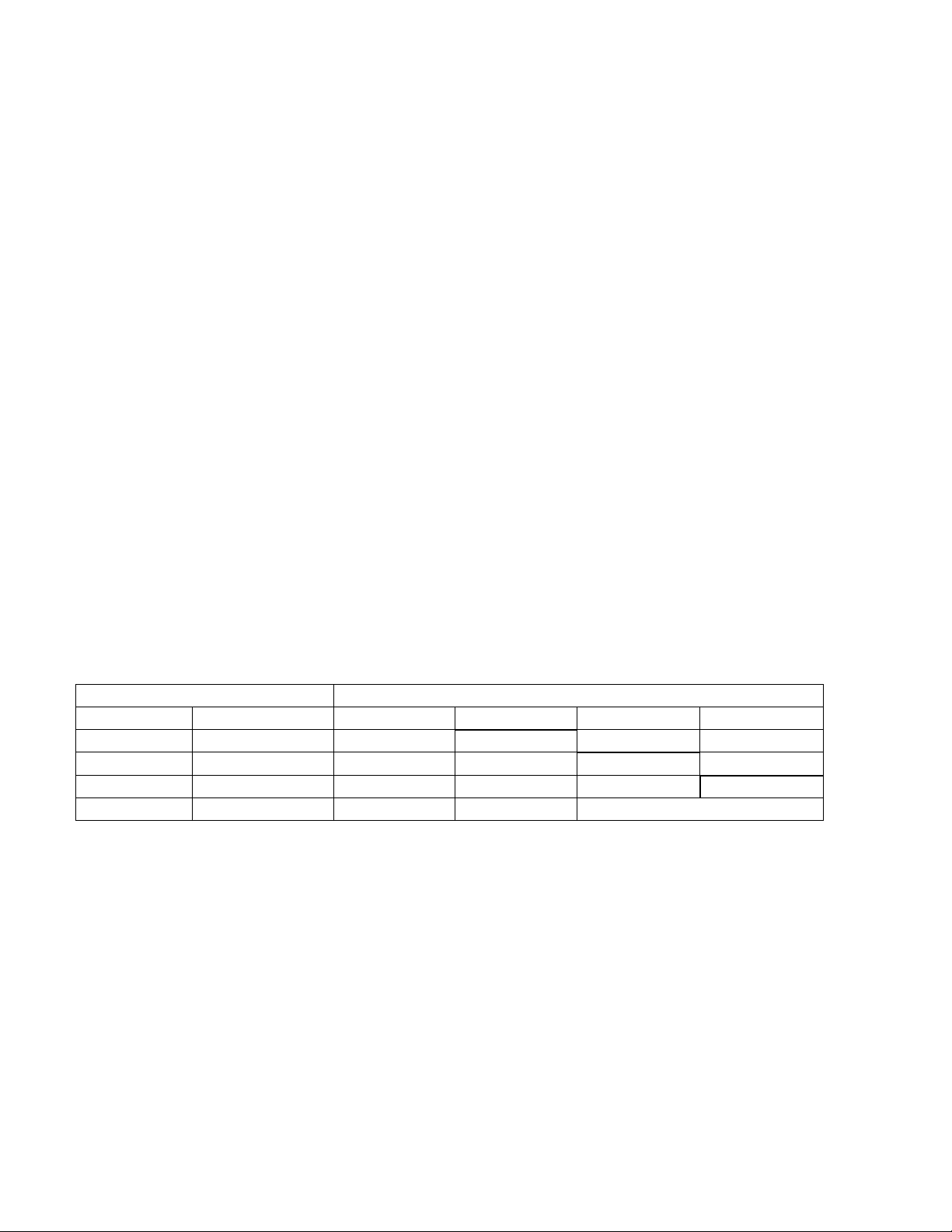

Ampere Rating

Total Length of Cord in feet

More Than

Not More Than

25

50

100

150 0 6

18

16

16

14 6 10

18

16

14

12

10

12

16

16

14

12

12

16

14

12

Not Recommended

Double Insulated Tools

Double Insulation is a design concept used in electric power tools which eliminates the need for the

three wire grounded power cord and grounded power supply system. It is a recognized and approved

system by Underwriter’s Laboratories, CSA and Federal OSHA authorities.

IMPORTANT: Servicing of a tool with double insulation requires care and knowledge of the system

and should be performed only by a qualified service technician.

WHEN SERVICING, USE ONLY IDENTICAL REPLACEMENT PARTS.

Extension Cords

In the event of a malfunction or breakdown, grounding provides a path of least resistance for electric

current and reduces the risk of electrical shock. Tools equipped with an electrical cord having an

equipment-grounding conductor must be plugged into a matching outlet that is properly installed and

grounded in accordance with all local codes and ordinances.

Do not modify the plug provided in any way. If the plug does not fit the outlet, have the proper outlet

installed by a qualified electrician.

The use of any extension cord will cause some loss of power. To keep this to a minimum and to

prevent overheating and motor burned-out; use the table below to determine the minimum wire size

(A .W .G.) of extension cord.

Use only three (3) wire extension cords that have three (3) prong grounding plugs, and three (3) pole

receptacles that accept the tool’s plug.

Minimum Gauge for Extension Cords (AWG)

(When using 120 V only)

Grounding Instructions

IN THE EVENT OF A MALFUNCTION OR BREAKDOWN, grounding provides the path of least

resistance for electric current and reduces the risk of electric shock. This tool is equipped with an

electric cord that has an equipment grounding conductor and a grounding plug. The plug MUST be

plugged into a matching outlet that is properly installed and grounded in accordance with ALL local

codes and ordinances.

DO NOT MODIFY THE PLUG PROVIDED. If it will not fit the outlet, have the proper outlet

installed by an electrician.

8

Page 9

IMPROPER CONNECTION of the equipment grounding conductor can result in electric shock. The

conductor with the green insulation (with or without yellow stripes) is the equipment grounding

conductor. If repair or replacement of the electric cord or plug is necessary, DO NOT connect the

equipment grounding conductor to a live terminal.

CHECK with a licensed electrician or service personnel if you do not completely understand the

grounding instructions, or if you are not sure if the tool is properly grounded.

USE ONLY THREE-WIRE EXTENSION CORDS that have 3-pronged plugs and outlets that accept

the tool's plug as shown in Fig. A. Repair or replace a damaged or worn cord immediately.

CAUTION: In all cases, make certain the outlet in question is properly grounded. If you are not sure

if it is, have a licensed electrician check the outlet.

9

Page 10

Know Your Table Saw

A

Miter Gauge

G Hand Wheel

B

Blade Guard

H Leg Stand

C

Table

I ON/OFF Switch with Safety Key

D

Rip Fence Scale

J Blade Bevel Scale

E

Rip Fence Storage

K Miter Gauge Storage

F

Blade Bevel Locking Lever

10

Page 11

Unpacking

Item

Description

Qty

Item

Description

Qty

1

Table Saw

1 9

Push Stick

1 2 Miter gauge

1 10

Long Top Plate

2 3 Rip Fence

1 11

Short Top Plate

2 4 Wheel Handle

1 12

Long Support Plate

2 5 Blade Guard

1 13

Short Support Plate

2 6 Blade Wrench

2 14

Leg 4 7

Anti-kickback Device

1 15

Rubber Foot

4 8 Table Insert

2

Hardware Bag (not shown)

1

WARNING - to prevent accidental starting that could cause possible serious personal injury;

assemble all parts to your saw before connecting it to power supply. Saw should never be

connected to power supply when you are assembling parts, making adjustments, installing or

removing blades, or when not in use.

WARNING - if any parts are missing, do not operate this tool until the missing parts are

replaced. Failure to do so could result in possible serious personal injury.

Do not discard the packing materials until you have carefully inspected the saw, identified all parts,

and satisfactorily operated your new saw.

NOTE: if any parts are damaged or missing, do not attempt to plug in the power cord and turn the

switch on until the damaged or missing parts are obtained and are installed correctly.

11

Page 12

Assembly and Adjustments

WARNING! Prior to performing any assembly procedures, make sure the 10" table saw is

disconnected from its electrical power source.

Assembling the Leg Stand (Figure 1)

Warning: The stamped rails may have sharp edges. Be careful in handling the rails to

prevent being cut.

NOTE: Use the screws, washers, and lock nuts supplied in the

hardware bag to attach the pieces of the leg stand together. Do

not tighten the hardware completely until the leg stand is

completely assembled.

1. Attach the long top plates (10, Figure 1) to the legs (14,

Figure 1).

2. Attach the long support plates (12, Figure 1) to the legs (14,

Figure 1).

3. Place the front and rear short top plates (11, Figure 1) over

the side top plates (10, Figure 1). And attach to the legs (14,

Figure 1).

4. Attach the front and rear short support plates (13, Figure 1)

to the legs (14, Figure 1).

5. Tap the four rubber feet (15, Figure 1) onto the bottom of the legs (14, Figure 1).

Mounting the Table Saw to the Leg Stand (Figure 2)

NOTE: Mount the table saw to the leg stand using the

hardware supplied in the hardware bag.

1. Place the table saw onto the assembled leg stand so that the

four (4) mounting holes (1, Figure 2) in the base of the saw

are over the four (4) mounting holes in the front and rear

top plates (2, Figure 2).

2. Secure the table saw to the leg stand using four (4) bolts (3,

Figure 2), washers (4, Figure 2), and lock nuts (5, Figure 2).

IMPORTANT! When mounting the table saw to the leg stand,

DO NOT overtighten the mounting hardware.

Warning! Before operating table saw, securely fasten table saw to stand and entire unit must

be placed on solid, level surface.

Warning! Do not stand on table saw sand or use as ladder or scaffolding.

Warning! Do not use table saw if stand tips, slides, or moves in any way.

12

Page 13

Mounting Table Saw to Workbench (Figure 3 & 4)

If table saw is to be used in a permanent location, it should be fastened securely to a firm supporting

surface such as a stand or workbench, using the four mounting holes, 1 (Figure 3) two of which are

shown.

When mounting table saw to a workbench or plywood, holes should be drilled through the supporting

surface of the workbench or plywood and a opening MUST be made the same size as the opening in

the bottom of the saw using the dimensions illustrated (Figure 4), so the saw dust can drop through.

1. Each of the four mounting holes should be bolted securely using 5/16" hex nuts (not included).

Screw lengths should be 2-1/2" longer than the thickness of the bench top.

2. Locate and mark where the saw is to be mounted.

3. Drill four (4) 3/8" diameter holes through workbench.

4. Place table saw on workbench aligning holes in base with holes drilled in workbench.

5. Insert four (4) 5/16" screws and tighten.

13

Page 14

Mounting to Plywood (Figure 5)

An alternative method of securing your table saw is to fasten the saw base to a mounting board 24" x

24" minimum size to prevent saw from tipping while in use. Any good grade of plywood with a 3/4"

minimum thickness is recommended.

1. Follow instructions for mounting to workbench,

substituting a plywood board 24" x 24" minimum size

and using 5/16" flat head machine screws, flat washers,

and hex nuts (not included). Screw length must be at

least 2-1/2" more than the thickness of the mounting

board. Insert screws up through mounting board and

through base holes. Place flat washers on stud and

secure with hex nuts.

NOTE: For proper stability, holes must be counter sunk

on bottom side of plywood so screw heads are flush with

the bottom surface of the supporting board.

2. Securely clamp board (2, Figure 5) to workbench (3, Figure 5) using two or more ―C‖ clamps (4,

Figure5, not include).

Supporting surface where saw is to be mounted should be examined carefully after mounting to insure

that no movement can occur during use. If any tipping or walking is noted, secure the workbench or

stand before operating the table saw.

14

Page 15

90° and 45° Positive Stops Adjustment (Figure 6, 7 & 8)

Warning: To prevent personal injury, always disconnect the plug from power source before

making any adjustments.

The saw has positive stops that will quickly position the saw blade at 90° or 45° to the table. Make the

following adjustments only if necessary.

NOTE: 90° and 45° blade adjustment screws require a 5 mm Allen wrench (not supplied) and a 10

mm wrench or socket (not supplied) for adjustment. To access the 10 mm jam nut attached to the 90°

and 45° adjustment screws, turn the saw on its left side.

Make sure the saw is secure.

Adjusting the 90° Stop:

1. Raise the blade to the maximum height by turning the hand wheel

(1, Figure 6) counterclockwise.

2. Loosen the blade bevel locking knob (2, Figure 6). Push in the

blade elevation/tilting hand wheel (1, Figure 6) and rotate

clockwise as far as possible.

3. Place a combination square on the table and against the blade to

determine if the blade is at a 90° angle to the table (Figure 7).

4. If the blade is not at a 90° angle to the table, loosen the jam nut

(underneath table) and turn the 90° adjusting socket head screw (3, Figure 8) left to reduce the

angle or right to increase the angle.

Adjusting the 45° Stop:

1. Raise the blade to the maximum height by turning the

control wheel (1, Figure 6) counterclockwise.

2. Loosen the blade lock lever (2, Figure 6). Push in the blade

elevation/tilting control wheel (1, Figure 6) and rotate

counterclockwise as far as possible.

3. Place a combination square on the table and against the

blade to determine if the blade is at a 45° angle to the table

(Figure 7).

4. If the blade is not at a 45° angle to the table, loosen the jam nut (underneath table) turn the 45°

adjusting socket head screw (4, Figure 8) left to reduce the angle or right to increase the angle.

Adjusting the Blade Tilt Indicator:

1. When the blade is positioned at 90°, adjust the blade tilt

pointer to read 0° on the scale.

2. Loosen the holding screw, position pointer over 0° and tighten

the screw.

NOTE: Always make a trial cut on scrap wood when making

critical cuts. Measure for cut precision.

15

Page 16

Blade Parallel to Miter Gauge Groove Adjustment (Figure 9, 10 & 11)

Warning: To prevent personal injury, always disconnect the plug from power source before

making any adjustments.

Warning: If the blade is misaligned by more than 1/8", do not attempt to align or operate the

saw. Have a qualified service technician perform blade alignment.

1. Move the blade guard out of the way.

2. Raise the blade to the maximum height by turning the hand

wheel (1, Figure 9) counterclockwise. Push in the hand wheel

(1, Figure 9) and tilt the blade to 0°, then lock in place with

the bevel locking lever (3, Figure 9).

3. Select a tooth with a ―right set‖ on the end of the blade

closest to you. Mark it with a marker.

4. Place a combination square base (4, Figure 10) against the

left side of the right miter gauge groove (5, Figure 10).

5. Adjust the rule so it touches the front marked tooth. Lock the

ruler so it holds its position in the square assembly.

6. Rotate the blade bringing the marked tooth to the rear and

about 1/2" (13 mm) above the table.

7. Carefully, slide the combination square to the rear until the

ruler touches the marked tooth.

8. If the ruler touches the marked tooth at the front and rear

positions, no adjustment is necessary.

If the front and rear measurements are not the same, blade is not

parallel to the miter slot. Proceed to steps 9 –19 to perform the

adjustment.

9. Remove the combination square and stand the saw on its left

side so you can access the six adjustment nuts (6 & 7 Figure

11) that secure the axis rod to the table. Make sure the table

is secure.

Warning: Place folded pieces of cardboard over the blade

to protect your hands.

10. Us a 10 mm wrench to loosen all eight adjustment nuts

about 1/2 turn each.

11. Place the saw in the upright position.

12. Carefully move the blade to the left or right until it is

aligned properly.

13. Check the alignment with the combination square

(repeat steps 4 – 7).

14. Tighten the two front adjustment nuts (6, Figure 11).

Reach under the front and rear of the table with a

wrench to access these nuts.

15. Re-check the alignment. If additional adjustment is required, loosen only the two front adjustment

nuts (6, Figure 11) and repeat steps 4 & 5 until the blade is parallel to the miter slot. Tighten the

two front adjustment nuts (6, Figure 11).

16

Page 17

16. Stand the saw on its left side and tighten the four center adjustment nuts (7, Figure 11).

17. Place the saw upright and re-check the alignment to make sure the blade is parallel to the miter slot.

Removal and Installation of the Blade (Figure 12, 13 & 14)

Warning: Disconnect plug from power source before performing any assembly, adjustment

or repair to avoid possible injury.

NOTE: Clean blade of any excess oil before installation.

1. Remove the table insert (1, Figure 12).

2. Raise the blade (2, Figure 12) to the maximum height by

turning the hand wheel (3, Figure 12) counterclockwise,

3. Remove the arbor nut (4, Figure 13) and flange (5, Figure

13).

4. Clean any sawdust from both blade collars before

installing the blade. Install a 10" (25.4 cm) blade. Install

the saw blade onto the arbor with the blade teeth pointing

toward the front of the saw.

To avoid injury, do not use a blade larger or smaller than 10"

diameter and 5/8" arbor.

5. Install the flange 5 against the blade (2, Figure 13) and

thread the arbor nut (4, Figure 13) as far as possible by

hand. Ensure that the blade is flush against the inner blade

flange (6, Figure 13).

6. To tighten the arbor nut (4, Figure 14), use the open-end

wrench (7, Figure 14) and align the wrench jaws on the

flats of the flange to keep the arbor from turning. Place the

box-end wrench (8, Figure 14) on the arbor nut (4, Figure

14) and turn clockwise (to the rear of the saw table).

7. Install the table insert (1, Figure 12) in the table recess.

To avoid injury from a thrown workpiece, blade part, or blade

contact, never operate the saw without the proper insert in

place. Use the table insert when sawing. Use the dado insert

when using a dado blade.

Using Carbide-Tipped Blades

Handle carbide-tipped blades carefully. Carbide is very

brittle and can be easily damaged. Use caution when you

install, use or store the blades. Do not use a carbide-tipped

blade that is bent or has bent teeth, or if the blade has cracks,

is broken, or has missing/loose carbide tips. Do not operate

a carbide-tipped blade faster than its recommended speed.

17

Page 18

Installing the blade guard system

Warning: To prevent personal injury, always disconnect plug from power source before

installing or removing the blade guard.

POSITIONING THE RIVING KNIFE (Figure 15 & 16)

1. Remove table insert using finger hole.

2. Raise the blade as high as it will go and set it

perpendicular to table (0° on bevel scale) (Figure 15).

3. Rotate the riving knife release lever clockwise, so that

it points upward (Figure 15).

4. Pull riving knife towards release lever to disengage it

from the pins.

5. Slide the riving knife up to its highest position, so that

it is directly over the center of the blade (Figure 16).

6. Align holes in riving knife with pins and lock the

release lever by rotating it counterclockwise.

Push/pull riving knife to verify that it is locked in

place (Figure 16).

7. Replace table insert.

Installing the blade guard (Figure 17)

1. With one hand, hold the front of the barrier guard

assembly by the metal ―fork‖. With the other hand,

hold the guard release lever up (Figure 17).

2. Lower the rear of guard assembly and slip the cross

bar into the rear notch on top of the riving knife (Fig.

21).

3. Lower the front of the guard assembly until the metal

―fork‖ is parallel with the table (Fig. 22).

4. Press down on the guard release lever until you feel

and hear it snap into the locking position. Check that

the guard assembly is securely connected (Fig. 22).

18

Page 19

Installing the anti-kickback device (Figure 18)

While pulling out the attachment pin, attach the

Anti-Kickback Device into the flat recessed area A

of the riving knife (Figure 18).

Slide the Anti-Kickback Device down until it drops

into the recessed area – then release the attachment

pin such that the Anti-Kickback Device locks onto

the riving knife immediately behind the guard

assembly. Check that the attachment pin is securely

connected into locking hole.

Carefully raise and lower the pawls – when letting

go, the spring-loaded pawls must come down and

contact the table insert (Figure 18).

Note: The two installing are independent of each other, so the Anti-Kickback Device can be attached

before the Blade Guard.

19

Page 20

Operation

Warning: For your own safety, always observe the following safety precautions.

• Never make these cuts freehand (without using the miter gauge or other auxiliary devices)

because the blade could bind in the cut and cause a KICKBACK or cause your fingers or hand

to slip into the blade.

• Always tighten the miter gauge handle securely when in use.

• Remove rip fence from table during any operations which utilize the miter gauge.

• When cross cutting and the blade set at 90º to the table, the miter gauge can be used in either

slot on the table. When cross cutting and the blade is tilted, use slot on right side of table where

the blade is tilted away from your hands and miter gauge.

• Make sure blade guard is installed for all ―thru-sawing‖ operations (when sawblade cuts

entirely thru the thickness of the workpiece).

• Replace guard IMMEDIATELY after com pletion of dadoing, molding or rabbeting cuts.

• Have blade extend approximately 1/8" above top of work piece. Additional blade exposure

would increase the hazard potential.

• Do not stand directly in front of the blade in case of a THROWBACK (small cut-off piece

caught by the back of the blade and thrown toward the operator). Stand to either side of the

blade.

• Keep your hands clear of the blade and out of the path of the blade.

• If blade stalls or stops while cutting. TURN SWITCH OFF before attempting to free the blade.

• Do not reach over or behind the blade to pull the work piece through the cut … to support long

or heavy workpieces … to remove cut-off pieces of material or FOR ANY OTHER REASON.

• Do not pick up small pieces of cut-off material from the table. REMOVE them by pushing

them OFF the table with a long stick. Otherwise they could be thrown back at you by the rear

of the blade.

• Do not remove small pieces of cut-off material that may become TRAPPED inside the blade

guard while the saw is RUNNING. THIS COULD ENDANGER YOUR HANDS or cause a

KICKBACK. Turn the saw OFF. After the blade has stopped turning, lift the guard and remove

the piece.

• If workpiece is warped, place the CONCAVE side DOWN. This will prevent it from rocking

while it is being cut.

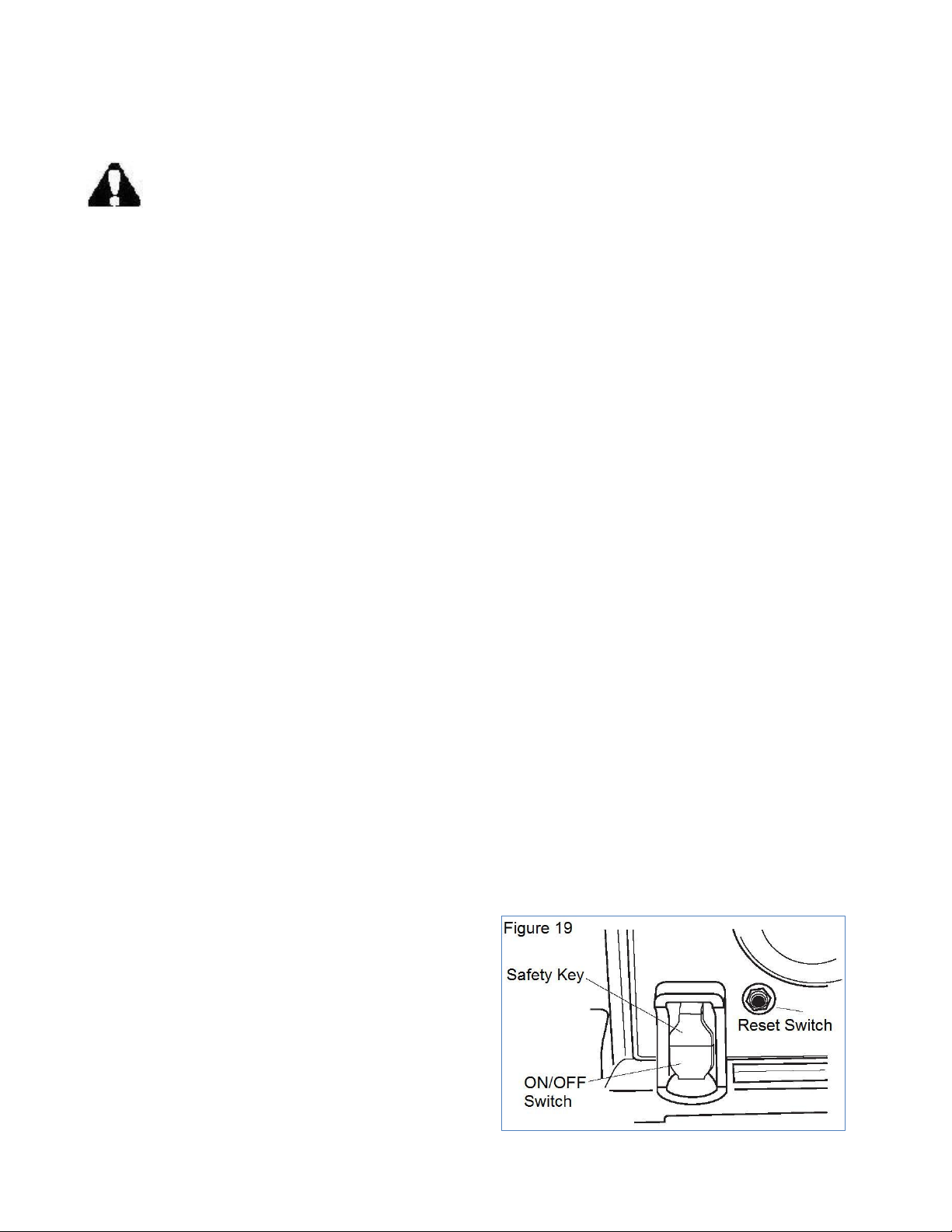

ON/OFF Switch (Figure 19)

The ON/OFF switch has a removable safety key to

protect against unauthorized use.

1. To turn the saw ON, insert the safety key into the

switch (Figure 19). Move the switch upward to the

ON position.

2. To turn the saw OFF, move the switch downward

to the OFF position.

3. To lock the switch in the OFF position, grasp the

safety key and pull it out of the switch. With the

20

Page 21

safety key removed, the switch will not operate.

NOTE: If the safety key is removed while the saw is running, the saw can be turned OFF, but cannot

be restarted without inserting the safety key.

Overload Reset Switch (Figure 19)

To prevent accidental startup if the overload reset switch is pushed, the ON/OFF switch should be in

the OFF position, and the plug should be removed from the power source while cool down takes place.

Overheating may be caused by misaligned parts or a dull blade. Inspect your saw for proper setup

before using it again.

This saw has an overload reset switch (Figure 19) that will allow the motor to be restarted after it shuts

off due to overloading or low voltage. If the motor stops during operation, perform the following:

1. Turn the ON/OFF switch to the OFF position.

2. Wait about five minutes for the motor to cool.

3. Push in the overload reset switch.

4. Turn the ON/OFF switch to the ON position.

Crosscutting (Figure 20)

Crosscutting is known as cutting wood across the grain, at 90°, or square with both the edge and the

flat side of the wood. This is done with the miter gauge set at 90° (Figure 20).

The graduations on the miter gauge provide accuracy for average

woodworking. In some cases where extreme ac curacy is

required, when making angle cuts, for example, make a trial cut

and then recheck it with an accurate square or protractor.

If necessary, the miter gauge head can be swiveled slightly to

compensate for any inaccuracy.

NOTE: The space between the miter gauge bar and the groove in

the table is held to a minimum during manufacturing.

For maximum accuracy when using the miter gauge, always ―favor‖ one side of the groove in the table.

In other words, don’t move the miter gauge from side to side while cutting but keep one side of the bar

riding against one side of the groove.

The miter gauge may be used in either of the grooves in the table. Make sure miter gauge bar is

engaged under table retainer tabs. Make sure lock handle is tightened securely to maintain angle.

When using the miter gauge in the LEFT hand groove, hold the workpiece firmly against gauge head

with your left hand, and grip the lock handle with your right hand.

When using the RIGHT hand groove, hold the workpiece with your right hand and the lock handle

with your left hand.

When cutting long workpieces, make sure the end is supported from the floor.

21

Page 22

Repetitive Cutting (Figure 21)

REPETITIVE CUTTING is known as cutting a quantity

of pieces the same length without having to mark each

piece (Figure 21).

When making repetitive cuts from a long work piece,

make sure it is supported.

Warning: Never use the rip fence as a length

stop because the cutoff piece could bind

between the fence and the blade causing a

kickback.

When making repetitive cuts, clamp a block of wood 3" long to the table at desired length to act as a

length stop.

Warning: When clamping the block, make sure that the end of the block is well in front of

the saw blade. Be sure it is clamped securely.

Slide the work piece along the miter gauge until it touches the block … hold it securely.

Make the cut … pull the work piece back … push the cut-off piece off the table with a long Push

Stick … DO NOT ATTEMPT TO PICK IT UP AS THIS COULD ENDANGER YOUR HANDS.

Miter Cutting (Figure 22)

MITER CUTTING is known as cutting wood at an angle

other than 90° with the edge of the wood. Follow the same

procedure as you would for crosscutting (Figure 22).

Adjust the miter gauge to the desired angle, and tighten

lock handle.

The miter gauge may be used in either of the grooves in the

table.

When using the miter gauge in the LEFT hand groove, hold

the workpiece firmly against the miter gauge head with your left hand, and grip the lock handle with

your right hand.

When using the RIGHT hand groove, hold the workpiece with your right hand and the lock handle

with your left hand.

Before cutting, always make sure you securely tighten the lock handle to maintain the desired angle.

22

Page 23

Bevel Crosscutting (Figure 23)

BEVEL CROSSCUTTING is the same as crosscutting

except that the wood is also cut at an angle … other than

90° with the flat side of the wood (Figure 23).

Adjust the blade to the desired angle and lock it.

Use the Miter Gauge in the groove to the RIGHT of the

blade. It cannot be used in the groove to the LEFT

because the blade guard will interfere.

Hold the workpiece with your right hand and the lock

knob with your left hand.

Compound Miter Cutting

COMPOUND MITER CUTTING is a combination of miter cutting and bevel crosscutting. The cut is

made at an angle other than 90° to both the edge and the flat side of the wood.

Adjust the miter gauge and the blade to the desired angle. Make sure miter gauge is locked.

23

Page 24

Maintenance

For your own safety, turn switch ―OFF‖ and remove plug from power source outlet before

maintaining or lubricating your saw.

Do not allow sawdust to accumulate inside the saw. Frequently blow out any dust that may accumulate

inside the saw cabinet and the motor. Clean your cutting tools with a Gum and Pitch Remover.

The cord and the tool should be wiped with a dry clean cloth to prevent deterioration from oil and

grease.

Warning: Certain cleaning agents and solvents can damage plastic parts. Some of these are:

gasoline, carbon tetrachloride, chlorinated cleaning solvents, ammonia and household

detergents which contain ammonia. Avoiding use of these and other types of cleaning agents

will minimize the possibility of damage.

A coat of automobile-type wax applied to the table will help to keep the surface clean and allow

workpieces to slide more freely.

If the power cord is worn or cut, or damaged in any way, have it replaced immediately.

Make sure the teeth of the ANTI-KICKBACK pawls are always

sharp. To sharpen:

1. Remove blade guard.

2. Rotate pawl toward rear of spreader so that teeth are above

top of spreader.

3. Hold spreader with left hand and place pawl over corner of

workbench (Figure 24).

4. Using a small round file (Smooth Cut) sharpen the teeth.

Warning: All repairs, electrical or mechanical, should

be attempted only by trained repairmen. Contact the

Service Center or Authorized Service Station. Use only

identical replacement parts, any other may create a hazard.

Lubrication

All motor bearings are permanently lubricated at the factory and require no additional lubrication.

Lubricate all mechanical parts where a pivot or threaded rod is present, with graphite or silicone.

These dry lubricants will not hold sawdust.

Care of Blades

Blades become dull even from cutting regular lumber. If you find yourself forcing the saw forward to

cut instead of just guiding it through the cut, chances are the blade is dull or coated with wood pitch.

24

Page 25

Trouble shooting

PROBLEM

CAUSE

SOLUTION

Saw will not start.

1. Saw not plugged in.

1. Plug in the saw.

2. Fuse blown or circuit breaker tripped.

2. Replace fuse or reset circuit breaker.

3. Cord damaged.

3. Have cord replaced by an authorized

service center.

Does not make accurate 45°

and 90° rip cuts.

1. Positive stop not adjusted correctly.

1. Check blade with square and adjust

positive stop.

2. Tilt angle pointer not set correctly.

2. Check blade with square and adjust

pointer to zero.

Material pinches blade when

ripping.

1. Rip fence not aligned with blade.

1. Check and adjust rip fence.

2. Warped wood, edge against fence is

not straight.

2. Select another piece of wood.

Material binds on splitter.

Splitter not aligned correctly with blade.

Check and align splitter with blade.

Saw makes unsatisfactory

cuts.

1. Dull blade.

1. Replace blade.

2. Blade mounted backwards.

2. Turn blade around.

3. Gum or pitch on blade.

3. Remove blade and clean with

turpentine and coarse steel wool.

4. Incorrect blade for work.

4. Change the blade.

5. Gum or pitch on table causing erratic

feed.

5. Clean table with turpentine and steel

wool.

Material kicked back from

blade.

1. Rip fence out of alignment.

1. Align rip fence with miter gauge.

2. Splitter not aligned with blade.

2. Align splitter with blade.

3. Feeding stock without rip fence.

3. Install and use rip fence.

4. Splitter not in place.

4. Install and use splitter (with guard).

5. Dull blade.

5. Replace blade.

6. The operator letting go of material

before it is past the saw blade.

6. Push material all the way past blade

before releasing work.

7. Miter angle lock knob is not tight.

7. Tighten knob.

Blade does not raise or tilt

freely.

Sawdust and dirt in elevation and tilting

mechanisms.

Brush or blow out loose dust and dirt.

Blade does not reach full

speed.

1. Extension cord too tight or too long.

1. Replace with adequate size cord.

2. Low house voltage.

2. Contact your electric company.

Machine vibrates

excessively.

1. Saw not mounted securely to stand or

workbench.

1. Tighten all mounting hardware.

2. Stand or bench on uneven floor.

2. Reposition on flat level surface. Fasten

to floor if necessary.

3. Damaged saw blade.

3. Replace blade.

Does not make 45° and 90°

cross cuts.

Miter gauge out of adjustment.

Adjust miter gauge.

WARNING: To avoid injury from an accidental start, turn the power switch off, remove the

safety key and remove the plug from the power source before making any adjustment.

25

Page 26

Exploded View

26

Page 27

Parts List

Item #

Stock #

Description

Qty

Item #

Stock #

Description

Qty

1

3710-001

Nut 1 41

3710-041

Spring washer

4

2

3710-002

Outer flange

1

42

3710-042

Socket head cap screw

4 3 3710-003

Blade 1 43

3710-043

Casing pipe

1

4

3710-004

Inner flange

1

44

3710-044

Flat washer

1 5 3710-005

Spring block circle

1

45

3710-045

Spin pin

1 6 3710-006

Front cover

1

46

3710-046

Socket head cap screw

1 7 3710-007

Bearing

1

47

3710-047

Casing pipe

1

8

3710-008

Spring block circle

1

48

3710-048

Nut 3 9

3710-009

Output axis

1

49

3710-049

Nut

6

10

3710-010

Half circle key

1

50

3710-050

Support iron

1

11

3710-011

Gear 1 51

3710-051

Spindle washer

3

12

3710-012

Spring block circle

1

52

3710-052

Mat plate

1

13

3710-013

Bearing

1

53

3710-053

Ruler

1

14

3710-014

Gear cover

1

54

3710-054

Caution sign

1

15

3710-015

Bearing

1

55

3710-055

Socket head cap screw

1

16

3710-016

Rotor 1 56

3710-056

Spindle washer

1

17

3710-017

Bearing

1

57

3710-057

Spindle

1

18

3710-018

Block wind cover

1

58

3710-058

Spring washer

1

19

3710-019

Stator 1 59

3710-059

Spindle washer

3

20

3710-020

Motor cover

1

60

3710-060

Nut

6

21

3710-021

Flat washer

4

61

3710-061

Nut 1 22

3710-022

Spring washer

4

62

3710-062

Casing pipe

1

23

3710-023

Socket head cap screw

4

63

3710-063

Screw rod

1

24

3710-024

Binding post

2

64

3710-064

Socket head cap screw

1

25

3710-025

Back cover

1

65

3710-065

Hand wheel

1

26

3710-026

Cable flat

1

66

3710-066

Flat washer

1

27

3710-027

Screw 2 67

3710-067

Handle

1

28

3710-028

Screw 1 68

3710-068

Screw

1

29

3710-029

Lead wire

1

69

3710-069

Nut

1

30

3710-030

Wire clip

1

70

3710-070

Flat washer

1

31

3710-031

Pin 1 71

3710-071

Locking handle

1

32

3710-032

Spring

1

72

3710-072

Locking piece

2

33

3710-033

Screw 2 73

3710-073

Screw 1 34

3710-034

Brush hold

2

74

3710-074

Pointer

1

35

3710-035

Carbon brush

2

75

3710-075

Locking piece

1

36

3710-036

Brush cover

2

76

3710-076

Limit board

1

37

3710-037

Screw 1 77

3710-077

Nut

1

38

3710-038

Spring washer

1

78

3710-078

Screw

1

39

3710-039

Flat washer

1

79

3710-079

Cover plate

1

40

3710-040

Flat washer

4

80

3710-080

Nut

1

27

Page 28

Item #

Stock #

Description

Qty

Item #

Stock #

Description

Qty

81

3710-081

Socket head cap screw

3

121

3710-121

Disk spring

2

82

3710-082

Spring washer

3

122

3710-122

Locking axis

1

83

3710-083

Flat washer

3

123

3710-123

Locking handle

1

84

3710-084

Swinging bracket

1

124

3710-124

Round pin

1

85

3710-085

Flat washer

1

125

3710-125

Screw 3 86

3710-086

Bolt 1 126

3710-126

Washer

3

87

3710-087

Push post

1

130

3710-130

Rubber plug

1

88

3710-088

Push board

1

131

3710-131

Screw 4 89

3710-089

Flat washer

1

132

3710-132

Spring washer

4

90

3710-090

Nut 1 133

3710-133

Flat washer

4

91

3710-091

Nut 1 134

3710-134

Screw 6 92

3710-092

Flat washer

1

135

3710-135

Bracing sheet

1

93

3710-093

Connecting rod

1

136

3710-136

Nut

6

94

3710-094

Binding post

1

137

3710-137

Screw 2 95

3710-095

Nut 1 138

3710-138

Cable flat

1

96

3710-096

Flat washer

1

139

3710-139

Jacket 1 97

3710-097

Nut 2 140

3710-140

Cable 1 98

3710-098

Nut 1 141

3710-141

Base

1

99

3710-099

Flat washer

1

142

3710-142

Grip slipper

1

100

3710-100

Pin 1 143

3710-143

Spring piece

1

101

3710-101

Nut 1 144

3710-144

Screw

1

102

3710-102

Flat washer

1

145

3710-145

Switch

1

103

3710-103

Holder

1

146

3710-146

Screw

4

104

3710-104

Nut 2 147

3710-147

Switch box cover

1

105

3710-105

Connecting rod

1

148

3710-148

Protector

1

106

3710-106

Binding post

2

149

3710-149

Switch box

1

107

3710-107

Connecting rod

1

150

3710-150

2 108

3710-108

Nut 1 151

3710-151

Plus screw

2

109

3710-109

Flat washer

2

152

3710-152

Spring washer

2

110

3710-110

Spring washer

2

153

3710-153

Flat washer

2

111

3710-111

Socket head cap screw

2

154

3710-154

Nut

2

112

3710-112

Nut 1 155

3710-155

socket head cap screw

2

113

3710-113

Flat washer

1

156

3710-156

Angle ruler button

1

114

3710-114

Socket head cap screw

3

157

3710-157

Bolt 1 115

3710-115

Spring washer

3

158

3710-158

Pointer

1

116

3710-116

Flat washer

3

159

3710-159

Screw

1

117

3710-117

Connecting piece

1

160

3710-160

Flat washer

1

118

3710-118

Splitter heel

1

161

3710-161

Spring washer

1

119

3710-119

Splitter

1

162

3710-162

Miter gauge

1

120

3710-120

Splitter flat

1

163

3710-163

Flat washer

1

28

Page 29

Item #

Stock #

Description

Qty

Item #

Stock #

Description

Qty

164

3710-164

lock knob

1

205

3710-205

Guiding rule

1

165

3710-165

lock knob cover

1

206

3710-206

Flat washer

1

166

3710-166

Ruler 1 207

3710-207

Splint

1

168

3710-168

Bolt 2 208

3710-208

Pull rod

1

169

3710-169

Back plate

1

209

3710-209

Spring

1

170

3710-170

Bolt 2 210

3710-210

Splint

1

171

3710-171

Screw

2

211

3710-211

Spring plate

1

172

3710-172

Spring

1

212

3710-212

Screw

1

173

3710-173

Cage 1 213

3710-213

Spring washer

1

174

3710-174

Back plate

1

214

3710-214

Flat washer

1

175

3710-175

Pin 1 215

3710-215

Pointer

1

176

3710-176

Slide post

1

216

3710-216

Adjusting knob

1

177

3710-177

Back plate

1

217

3710-217

Pin

1

178

3710-178

Slide post

1

218

3710-218

Holder

1

179

3710-179

Back plate

1

219

3710-219

Pin 1 180

3710-180

Screw

2

220

3710-220

Wobbler

1

181

3710-181

Screw

2

221

3710-221

Round pin

1

182

3710-182

Pin 1 222

3710-222

Nut

1

183

3710-183

Locking wheel

1

223

3710-223

Handle

1

184

3710-184

Pin 1 224

3710-224

Table

1

185

3710-185

Casing pipe

1

225

3710-225

Base plate

1

186

3710-186

Connecting rod

4

226

3710-226

Table insert

1

187

3710-187

Locking wheel

1

227

3710-227

Screw

2

188

3710-188

Pin 1 228

3710-228

Dust leg

1

189

3710-189

Socket head cap screw

2

229

3710-229

Flat washer

4

190

3710-190

Locking piece

1

230

3710-230

Spring washer

4

191

3710-191

Spring block circle

1

231

3710-231

Screw

4

192

3710-192

Kick paw

1

232

3710-232

Push stick

1

193

3710-193

Spacer sleeve

1

233

3710-233

Open spanner

1

194

3710-194

Kick plate

1

234

3710-234

Spanner

1

195

3710-195

Round pin

1

196

3710-196

Spacer sleeve

1

197

3710-197

Kick paw

1

198

3710-198

Spring block circle

1

199

3710-199

Tensional spring

1

200

3710-200

Lock pin

1

201

3710-201

Lock spring

1

202

3710-202

Pull knob

1

203

3710-203

Screw

2

204

3710-204

Lock washer

2

29

Page 30

Limited Two Years Warranty

WEN Products is committed to build tools that are dependable for years. Our warranties are consistent with this

commitment and our dedication to quality.

LIMITED WARRANTY OF WEN CONSUMER POWER TOOLS PRODUCTS FOR HOME USE

GREAT LAKES TECHNOLOGIES, LLC ("Seller") warrants to the original purchaser only, that all WEN consumer power

tools will be free from defects in material or workmanship for a period of two (2) years from date of purchase. Ninety days

for all WEN products, if the tool is used for professional use.

SELLER'S SOLE OBLIGATION AND YOUR EXCLUSIVE REMEDY under this Limited Warranty and, to the extent

permitted by law, any warranty or condition implied by law, shall be the repair or replacement of parts, without charge,

which are defective in material or workmanship and which have not been misused, carelessly handled, or misrepaired by

persons other than Seller or Authorized Service Center. To make a claim under this Limited Warranty, you must return the

complete power tool product; transportation prepaid, to Great Lakes Technologies, LL C – 501 Davis Road – Elgin, IL.

60123 with a copy of the original receipt which is legible and clearly defines Date of Purchase including month and year

and Place of Purchase.

THIS LIMITED WARRANTY DOES NOT APPLY TO ACCESSORY ITEMS SUCH AS CIRCULAR SAW BLADES,

DRILL BITS, ROUTER BITS, JIGSAW BLADES, SANDING BELTS, GRINDING WHEELS AND OTHER RELATED

ITEMS.

ANY IMPLIED WARRANTIES SHALL BE LIMITED IN DURATION TO TWO (2) YEARS FROM DATE OF

PURCHASE. SOME STATES IN THE U.S., SOME CANADIAN PROVINCES DO NOT ALLOW LIMITATIONS ON

HOW LONG AN IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

IN NO EVENT SHALL SELLER BELIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES

(INCLUDING BUT NOT LIMITED TO LIABILITY FOR LOSS OF PROFITS) ARISING FROM THE SALE OR USE

OF THIS PRODUCT. SOME STATES IN THE U.S. AND SOME CANADIAN PROVINCES DO NOT ALLOW THE

EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE

LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

THIS LIMITED WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, AND YOU MAY ALSO HAVE OTHER

RIGHTS WHICH VARY FROM STATE TO STATE IN THE U.S., PROVINCE TO PROVINCE IN CANADA AND

FROM COUNTRY TO COUNTRY.

THIS LIMITED WARRANTY APPLIES ONLY TO PORTABL EELECTRIC TOOLS, BENCH POWER TOOLS,

OUTDOOR POWER EQUIPMENT AND PNUMATIC TOOLS SOLD WITHIN THE UNITED STATES OF

AMERICA, CANADA AND THE COMMONWEALTH OF PUERTO RICO. FOR WARRANTY COVERAGE WITHIN

OTHER COUNTRIES, CONTACT THE WEN CUSTOMER SUPPORT.

30

Loading...

Loading...