Page 1

Page 2

TABLE OF CONTENTS

Technical Data……………………………………………. 2

Rules for Safe Operation…………………………………. 3

General Instructions for All Power Tools………………… 3

Extension Cords………………………………………….. 5

Specific Safety Rules for ROTARY TOOL KIT………… 6

List of Accessories (100 sets)……………………………. 7

Getting to know the ROTARY TOOL KIT……………… 7

Using the Attachments……………………………………. 8

Using the ROTARY TOOL KIT…………………………. 9

Maintenance………………………………………………. 9

Exploded View and Parts List……………………………. 10

Warranty………………………………………………….. 11

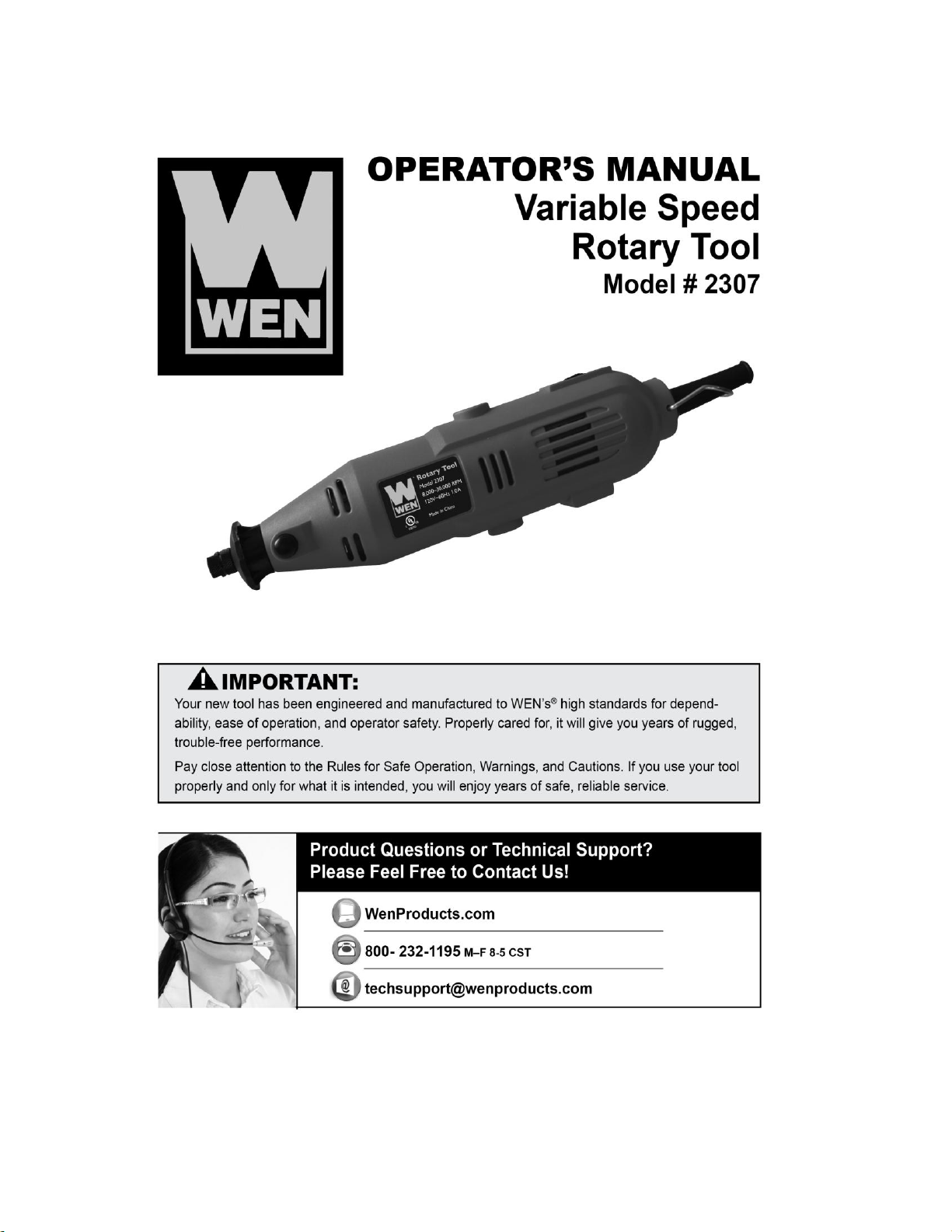

TECHNICAL DATA

ROTARY TOOL KIT

MODEL: 2307

RATING: 120V, 60Hz, AC only

INPUT: 1.0AMP

NO LOAD SPEED: 8,000-30,000 rpm

COLLET SIZE: Supplied with 3/32" & 1/8" collets

WEIGHT: 1.1 lbs.

2

Page 3

RULES FOR SAFE OPERATION

The purpose of safety symbols is to attract your attention to possible dangers. The safety symbols,

and the explanations with them, deserve your careful attention and understanding. The safety

warnings do not by themselves eliminate any danger. The instructions or warnings they give are not

substitutes for proper accident prevention measures.

Symbol Meaning

Safety Alert Symbol:

Indicates danger, warning, or caution, may be used in conjunction with other symbols

or pictographs. Always follow the safety precautions to reduce the risk of fire, electric

shock and personal injury.

Note: Advises you of information or instructions vital to the operation or maintenance of the

equipment

IMPORTANT

Servicing requires extreme care and knowledge and should be performed only by a qualified service

technician. For service we suggest you return the tool to WEN® PRODUCTS a division of Great

Lakes Technologies, LLC for repair. When servicing, use only identical WEN® replacement parts.

WARNING:

Do not attempt to operate this tool until you have read thoroughly and understand completely all

instructions, safety rules, etc…contained in this manual. Failure to comply can result in accidents

involving fire, electric shock, or serious personal injury. Save this operator‟s manual and review

frequently for continuing safe operation and instructing others who may use this tool.

Safe operation of this power tool requires that you read and understand this operator‟s manual and all

labels affixed to the tool. Safety is a combination of common sense, staying alert, and knowing how

your tool works.

GENERAL INSTRUCTIONS FOR ALL POWER TOOLS

READ ALL INSTRUCTIONS!!!

Know your power tool. Read the operator‟s manual carefully. Learn the application and limitations

as well as specific potential hazards related to this tool.

Keep guards in place and in working order. Never operate the tool with any guard or cover removed.

Make sure all guards are operating properly before each use.

Remove adjusting keys & wrenches. Form a habit of checking to see keys and adjusting wrenches

are removed from tool before turning it on.

Keep work area clean. Cluttered work areas and work benches invite accidents.

Do not use in dangerous environments. Do not use power tools near gasoline or other flammable

liquids, in damp or wet locations or expose them to rain. Keep work area well lighted.

3

Page 4

Keep children and visitors away. All visitors should wear ANSI-Z87.1 approved safety glasses and

be kept a safe distance from work area.

Make workshop childproof with padlocks, master switches, or by removing starter keys.

Don‟t force the tool. It will do the job better and safer at the rate for which it was designed.

Use the right tool. Do not force the tool or attachment to do a job for which it was not designed.

Wear proper apparel. Do not wear loose clothing, neckties, or jewelry that can get caught in the

tool‟s moving parts and cause personal injury. Non-slip footwear is recommended when working

outdoors. Wear protective hair covering to contain long hair.

Always wear ANSI-Z87.1 approved safety glasses with side shields. Everyday eyeglasses have only

impact-resistant lenses; they are NOT safety glasses.

Secure work. Use clamps or a vise to hold work when practical. It‟s safer than using your hand and

it frees both hands to operate the tool.

Do not overreach. Keep proper footing and balance at all times.

Maintain tools with care. Keep tools sharp and clean for best and safest performance. Follow

instructions for lubricating and changing accessories.

Disconnect all tools. When not in use, before servicing, or when changing attachments, blades, bits,

cutters, etc…, all tools should be disconnected from power source.

Reduce the risk of unintentional starting. Be sure switch is off when plugging in.

Use recommended accessories. Consult the operator‟s manual for recommended accessories. The

use of improper accessories may cause risk of injury.

Never stand on tool. Serious injury could occur if the tool is tipped or if the blade is unintentionally

contacted.

Direction of feed. Feed work into a blade or cutter against the direction or rotation of the blade or

cutter only

Never leave tool running unattended. Turn power off. Don‟t leave tool until it comes to a complete

stop.

Check damaged parts. Before further use of the tool, a guard or other part that is damaged should be

carefully checked to determine that it will operate properly and perform its intended function.

Check for alignment of moving parts, binding or moving parts, breakage of parts, mounting and any

other conditions that may affect its operation. A guard or other part that is damaged must be

properly repaired or replaced by an authorized service center to avoid risk of personal injury.

Protect your hearing. Wear hearing protection during extended periods of operation.

Keep tools dry, clean, and free from oil and grease. Always use a clean cloth when cleaning. Never

use brake fluids, gasoline, petroleum-based products, or any solvents to clean tool.

PROTECT YOUR LUNGS. Wear a face or dust mask if the operation is dusty.

WARNING: Some dust created by power sanding, sawing, grinding, drilling, and other

construction activities contains chemicals known to cause cancer, birth defects or other

reproductive harm. Some examples of these chemicals are:

Lead from lead-based paints

Crystalline silica from bricks and cement and other masonry products

Arsenic and chromium from chemically treated lumber

Your risk from these exposures varies, depending on how often you do this type of work. To reduce

your exposure to these chemicals, work in a well ventilated area, and work with approved safety

equipment, such as those dust mask that are specially designed to filter out microscopic particles.

4

Page 5

Guard against electrical shock by preventing body contact with grounded surfaces. For example:

pipes, radiators, ranges, refrigerator enclosures.

Inspect tool cords and extension cords periodically and, if damaged, have repaired by a qualified

service technician. Stay constantly aware of cord location and keep it away from the rotating

wheel.

Never use in an explosive atmosphere. Normal sparking of the motor could ignite fumes.

Use only outdoor extension cords with approved ground connection that are intended for use outdoors

and so marked.

Avoid awkward operations and hand positions where a sudden slip could cause your hand to move

into the blade. ALWAYS make sure you have good balance.

Allow the motor to come up to full speed before working.

Do not use tool if switch does not turn it on and off. Have defective switches replaced by an

authorized service center.

Replacement parts. All repairs, whether electrical or mechanical, should be made by a qualified

service technician at an authorized service center.

WARNING: when servicing use only identical WEN® replacement parts. Use of any other

parts may create a hazard or cause product damage

DO NOT OPERATE THIS TOOL WHILE UNDER THE INFLUENCE OF DRUGS,

ALCOHOL OR ANY MEDICATION THAT MAY IMPAIR YOUR JUDGMENT OR

CONTROL!

Stay alert and exercise control. Watch what you are doing and use common sense. DO NOT operate

tool when you are tired. DO NOT RUSH!

Make sure work area has ample lighting to see the work and that no obstructions will interfere with

safe operation BEFORE performing any work using your saw.

Save these instructions. Refer to them frequently and use them to instruct other users. If you loan

someone this tool, loan them these instructions also.

Use the proper extension cord. Make sure your extension cord is in good condition. When using an

extension cord, be sure to use one heavy enough to carry the current your product will draw. An

undersized cord will cause a drop in line voltage resulting in loss of power and overheating. A wire

gauge size (A.W.G.) of at least 16 is recommended for an extension cord 25 feet or less in length.

If in doubt, use the next heavier gauge. The smaller the gauge number, the heavier the cord.

Don‟t abuse cord. Never carry tool by the cord or yank it to disconnect from receptacle. Keep cord

from heat, oil, and sharp edges.

EXTENSION CORDS

In the event of a malfunction or breakdown, grounding provides a path or least resistance for electric

current and reduces the risk of electrical shock. Tools equipped with an electrical cord having an

equipment-grounding conductor must be plugged into a matching outlet that is properly installed and

grounded in accordance with all local codes and ordinances.

Do not modify the plug provided in any way. If the plug does not fit the outlet, have the proper outlet

installed by a qualified electrician.

The use of any extension cord will cause some loss of power. To keep this to a minimum and to

prevent overheating and motor burn-out; use the table below to determine the minimum wire size

(A.W.G.) extension cord.

5

Page 6

Use only three (3) wire extension cords that have three (3) prong grounding plugs, and three (3) pole

receptacles that accept the tool‟s plug.

AMERICAN WIRE GAUGE RATING CHART

EXTENSION CORD 25 50 75 100 125 150 175 200

LENGTH (FEET)

AMPS AWG

0 to 10.0 18 18 16 16 14 14 12 12

10.1 to 13.0 16 16 14 14 14 12 12 12

13.1 to 15 14 12 12 12 12 12 12 NA

15 to 18 14 12 12 12 12 12 NA NA

Class II construction double insulated. This product must not be connected to earth.

SPECIFIC SAFETY RULES FOR ROTARY TOOL KIT

1. Check the work piece for any cracks, knots, nails or other obstructions before commencing

operation.

2. Never press the locking pin when the rotary tool is running.

3. Do not cut any size work piece that is beyond the tool‟s capacity.

4. Always grip the tool firmly.

5. Always secure the work piece wherever possible.

6. Always use safety spectacles, a face mask and hearing protection.

7. Ensure the tool is clear of the work piece before turning on.

8. Never touch the moving parts by hand.

9. Check the position of power cables when drilling into walls or floors.

10. Do not remove the attachment from the tool until it has completely stopped.

11. Do not touch the attachment after operation, it will be very hot. Allow it to cool down before

removing it.

12. Do not operate the tool in wet or damp conditions.

13. Do not use the tool if : The on/off switch is faulty.

: The plug or cable is damaged.

: There is excessive sparking through the brush or spark bridges in the

collector.

: Smoke or bad odours is produced, caused by burnt insulating

materials.

6

Page 7

LIST OF ACCESSORIES (100 pieces)

Bit changing spanner wrench

2 felt polishing wheels

2 high speed cutters

10 grinding stones

54 sanding discs

1 dressing stone

20 cut-off wheels

4 sander bands

1 drum sander

2 mandrels

2 drill bits

2 collets

GETTING TO KNOW THE ROTARY TOOL KIT

The rotary tool can be used for drilling, milling, grinding

and polishing. In addition, it can be used for engraving,

cutting and removing rust. It can be used on most metals,

glass, wood and ceramics.

Operating the ON/OFF Switch

1. The ON/OFF switch is located on the underside of

the handle. It has two setting “O” (OFF) and “I”

(On).

2. To switch on the tool, press the switch into “I “(ON)

position. There is no need to hold it down as it will

automatically lock in position.

3. To switch the tool off, simply press the switch back into the “O” (OFF) position.

4. Always ensure that the switch is in the OFF position before connecting the tool to the mains.

Always disconnect the tool from the mains when not in use.

Adjusting the Speed

1. The tool has a range of speed settings from 8,000 to 30,000 rpm. The speed can be adjusted using

the speed control wheel located on the top of the handle.

2. There are some signs, „1‟ „2‟ „3‟- „6‟and „MAX‟ marked on the wheel. To increase speed, turn

the wheel towards the „MAX‟ sign. To reduce speed, turn the wheel towards the „1‟ sign.

3. As a guide, use low speed for larger attachments and higher speed for small attachments.

4. Do not force the tool. Best performance is achieved by an even speed, not high pressure.

High Speed Uses:

Higher speeds are better for carving, cutting, routing shaping. Hardwoods, metals and glass require

high speed operation and drilling should also be done at high speeds.

Warning: Do not use grinding wheels over 1” in diameter. The tool‟s high speed can cause

larger wheels to fly apart and could cause injury.

7

Page 8

Attachment

Arbor Required?

Uses

Drill Bits-3/32" & 1/8"

None

Drilling

Assorted Grinding Bits

None

Grinding, Milling

Engraving Bit

None

Engraving

Burr Bau Bit

None

Engraving

Abrasive Cutting Discs

Sanding Disc Arbor

Cutting

Sanding Drums-1/2" diameter

Sanding Disc Arbor

Sanding

Sanding Discs-7/8" diameter

Sanding Disc Arbor

Sanding

Polishing Wheels-1/2" & 1"

Polishing Wheel Arbor

Polishing

Low Speed uses:

Certain materials (some plastics) require a relatively slow speed because at high speed the friction of

the tool generates heat and causes the plastic to melt. Slow speeds usually are best for polishing

operations employing the felt polishing accessories. They may also be for working on delicate

projects.

Fitting the Attachments

1. Before fitting the attachments, ensure that the tool is unplugged from the mains.

2. Turn the clamping jaw nut slowly, whilst pressing the locking pin located in the jaw end of the

tool.

3. The locking pin will engage, and prevent the jaw from turning.

4. Keeping the locking pin depressed, turn the clamping jaw nut to open the clamping jaw.

5. Insert the required tool into the jaw.

6. Clamp all attachments as short as possible. Shafts that stick out too far may bend or cause the

tool to vibrate.

7. Tighten the clamping jaw nut again depressing the locking pin. Ensure that the attachment is

firmly secured in the jaws.

Changing the Collet

1. Before changing the collet, ensure that the tool is unplugged from the mains.

2. Turn the clamping jaw nut slowly, whilst pressing the locking pin located in the jaw end of the

tool.

3. The locking pin will engage, and prevent the jaw from turning.

4. Keeping the locking pin depressed, turn the clamping jaw nut continuously until the nut is

completely unscrewed and detaches from the jaw.

5. Remove the collet from the holder, and replace it with the new collet. Dispose of the old collet if

it is broken or damaged.

6. Replace the clamping jaw nut and retighten.

USING THE ATTACHMENTS

There are a variety of attachments supplied with this tool. Some of these come ready to use and can

be fitted to the tool without any further assembly. However, others require fitting to an arbor before

they can be used.

The attachments supplied may vary from those listed above.

8

Page 9

Sanding Disc Arbor

1. To fit a disc to the Sanding Disc Arbor, unscrew the fitting screw.

2. Remove the screw and washer.

3. Place the required disc over the end of the arbor.

4. Replace the washer and screw.

5. Tighten the screw until the disc is firmly secured.

6. Fit the arbor to the tool as described in “Fitting the Attachments”.

Sanding Drum Arbor

1. To fit a disc to the Sanding Drum Arbor, unscrew the fitting screw.

2. Remove the screw, washer and rubber drum holder.

3. Push the required Sanding Drum on to the rubber drum holder.

4. Ensure that the drum is completely pushed on to the holder so that edges of the drum and holder

are aligned.

5. Replace the drum holder on the arbor.

6. Replace the washer and screw.

7. Tighten the screw until the disc is firmly secured.

8. Fit the arbor to the tool as described in “Fitting the Attachments”.

Polishing Wheel Arbor

1. Push the threaded point of the Polishing Wheel Arbor into the required polishing wheel.

2. Twist the arbor anticlockwise to secure the polishing wheel firmly on to the arbor.

3. Fit the arbor to the tool as described in “Fitting the Attachments”.

4. Occasionally check the wheel during use to ensure it is still secure.

USING THE ROTARY TOOL KIT

1. Always wear face mask, safety spectacles and hearing protection when using the tool.

2. Always inspect the tool and attachments for damage before use. Never use broken grinding discs

or attachments with bent shafts – Discard immediately.

3. For milling or engraving, hold the tool like a pen to allow better control. Ensure the ventilation

slots are kept clear to prevent overheating.

4. For heavier work such as drilling, hold the tool like a hammer.

5. Use the correct attachment for the job.

6. The abrasive stone supplied can be used to sharpen the engraving bit, if required.

7. This tool is supplied with a 1/8" collet (fitted already on the tool) and a 3/32" spare collet.

Always select the correct size of collet.

MAINTENANCE

Warning: Remove the plug from the socket before carrying out any adjustments, servicing or

maintenance.

Never use water or other liquids to clean the electrical parts of the tool.

Always clean the tool after use.

Ensure that the ventilation slots do not become blocked to prevent overheating.

Remove the dispose of damaged attachments.

Check that the locking jaw is correctly aligned.

9

Page 10

EXPLODED VIEW AND PARTS LIST

Part#

Stock #

Description

Qty

1

2307-001

COLLET NUT

1

2

2307-002

BRASS COLLET

1

3

2307-003

BEARING 626zz

1 4 2307-004

ROTOR

1 5 2307-005

BEARING 698zz

1 6 2307-006

STATOR

1 7 2307-007

PREVENT SPRING

1 8 2307-008

SPINDLE LOCK BUTTON

1 9 2307-009

LOCKING SLEEVE

1

10

2307-010

BRUSH

2

11

2307-011

BRUSH SPRING

2

12

2307-012

BRUSH BASE

2

13

2307-013

BRUSH CAP

2

14

2307-014

SCREW

6

15

2307-015

RIGHT HOUSING

1

16

2307-016

CIRCUIT BOARD

1

17

2307-017

SWITCH

1

18

2307-018

SCREW

2

19

2307-019

PLACE BOARD

1

20

2307-020

LEFT HOUSING

1

21

2307-021

CORD SLEEVE

1

22

2307-022

POWER CORD

1

10

Page 11

LIMITED ONE YEAR WARRANTY

WEN Products is committed to build tools that are dependable for years. Our warranties are

consistent with this commitment and our dedication to quality

LIMITED WARRANTY OF WEN CONSUMER POWER TOOLS PRODUCTS FOR HOME USE

GREAT LAKES TECHNOLOGIES, LLC ("Seller") warrants to the original purchaser only, that all

WEN consumer power tools will be free from defects in material or workmanship for a period of one

(1) year from date of purchase. Ninety days for all WEN products, if the tool is used for professional

use.

SELLER'S SOLE OBLIGATION AND YOUR EXCLUSIVE REMEDY under this Limited

Warranty and, to the extent permitted by law, any warranty or condition implied by law, shall be the

repair or replacement of parts, without charge, which are defective in material or workmanship and

which have not been misused, carelessly handled, or misrepaired by persons other than Seller or

Authorized Service Center. To make a claim under this Limited Warranty, please contact us at 1-800232-1195 or write to us at WEN Products, 501 Davis Road, Elgin, IL 60123. To acquire service, you

will have to provide proof of purchase and may be asked to ship the tool back to us freight prepaid.

THIS LIMITED WARRANTY DOES NOT APPLY TO ACCESSORY ITEMS SUCH AS

CIRCULAR SAW BLADES, DRILL BITS, ROUTER BITS, JIGSAW BLADES, SANDING

BELTS, GRINDING WHEELS AND OTHER RELATED ITEMS.

ANY IMPLIED WARRANTIES SHALL BE LIMITED IN DURATION TO ONE (1) YEAR FROM

DATE OF PURCHASE. SOME STATES IN THE U.S., SOME CANADIAN PROVINCES DO

NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY LASTS, SO THE

ABOVE LIMITATION MAY NOT APPLY TO YOU.

IN NO EVENT SHALL SELLER BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL

DAMAGES (INCLUDING BUT NOT LIMITED TO LIABILITY FOR LOSS OF PROFITS)

ARISING FROM THE SALE OR USE OF THIS PRODUCT. SOME STATES IN THE U.S. AND

SOME CANADIAN PROVINCES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF

INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR

EXCLUSION MAY NOT APPLY TO YOU.

THIS LIMITED WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, AND YOU MAY ALSO

HAVE OTHER RIGHTS WHICH VARY FROM STATE TO STATE IN THE U.S., PROVINCE

TO PROVINCE IN CANADA AND FROM COUNTRY TO COUNTRY.

THIS LIMITED WARRANTY APPLIES ONLY TO PORTABLE ELECTRIC TOOLS, BENCH

POWER TOOLS, OUTDOOR POWER EQUIPMENT AND PNUMATIC TOOLS SOLD WITHIN

THE UNITED STATES OF AMERICA, CANADA AND THE COMMONWEALTH OF PUERTO

RICO. FOR WARRANTY COVERAGE WITHIN OTHER COUNTRIES, CONTACT THE WEN

CUSTOMER SUPPORT.

11

Loading...

Loading...