Page 1

WELLS MANUFACTURING

265 Hobson Street, Smithville, Tennessee 37166

telephone: 314-678-6314

fax: 314-781-2714

www.wells-mfg

.com

OWNER'S MANUAL

DROP-IN REFRIGERATED

COLD PANS, NSF7

RCP-7050, RCP-7067,

RCP-7100, RCP-7200,

RCP-7300, RCP-7400,

RCP-7500, RCP-7600.

DROP-IN REFRIGERATED

COLD PANS, NSF2

RCP-050, RCP-067,

RCP-100, RCP-200,

RCP-300, RCP-400,

RCP-500, RCP-600.

405

Model RCP-7200

This manual is considered to be part of the appliance and is to be given to the OWNER or

MANAGER of the restaurant, or to the person responsible for TRAINING the operators of

THIS MANUAL MUST BE READ AND UNDERSTOOD BY ALL PERSONS USING OR

DROP-IN REFRIGERATED

COLD PANS, SLOPE TOP NSF7

RCP-7100ST, RCP-7200ST,

RCP-7300ST, RCP-7400ST,

RCP-7500ST, RCP-7600ST.

DROP-IN REFRIGERATED

COLD PANS, SLOPE TOP NSF2

RCP-100ST, RCP-200ST,

RCP-300ST, RCP-400ST,

RCP-500ST, RCP-600ST.

INCLUDES INSTALLATION, USE,

CARE, SERVICE AND DIAGRAMS.

IMPORTANT: DO NOT DISCARD THIS MANUAL

this appliance. Additional manuals are available from your WELLS DEALER.

INSTALLING THIS APPLIANCE. Contact your WELLS DEALER if you have any

questions concerning installation, operation or maintenance of this equipment.

2M-305101 Rev.

H

04/18

Page 2

LIMITED EQUIPMENT WARRANTY

Wells Manufacturing warranties new products to be free from defects

in material and/or workmanship for a period of one [1] year from the

date of original installation, except as noted below. Defects that occur

as a result of normal use, within the time period and limitations defined

in this warranty, will at Wells’ discretion have the parts replaced or

repaired by Wells or a Wells-authorized service agency.

THIS WARRANTY IS SUBJECT TO ALL LISTED CONDITIONS.

Repairs performed under this warranty are to be performed by a Wellsauthorized service agency. Wells will not be responsible for charges

incurred or service performed by non-authorized repair agencies.

In all cases, the nearest Wells-authorized service agency must be used.

Wells will be responsible for normal labor charges incurred in the repair

or replacement of a warrantied product within 50 miles (80.5 km) of

an authorized service agency. Time and expense charges for anything

beyond that distance will be the responsibility of the owner. All labor

will need to be performed during regular service hours. Any overtime

premium will be charged to the owner. For all shipments outside the

U.S.A. and Canada, please see the International Warranty for specific

details.

It is the responsibility of the owner to inspect and report any shipping

damage claims, hidden or otherwise, promptly following delivery.

No mileage or travel charges will be honored on any equipment that is

deemed portable. In general, equipment with a cord and plug weighing

less than 50 lb. (22.7 kg) is considered portable and should be taken or

shipped to the closest authorized service agency, transportation prepaid .

CO NTAC T

Should you require any assistance regarding the operation or

maintenance of any Wells equipment; write, phone, fax or email

our service department. In all correspondence mention the

model number and the serial number of your unit, as well as

the voltage or type of gas you are using.

Business hours are 8:00 a.m. to 4:30 p.m. Central Standard Time

Telephone 314.678.6314

Fax 314.781.2714

Email customerservice@star-mfg.com

www.wells-mfg.com

WARRA

THE FOLLOWING WILL NOT BE COVERED UNDER WARRANTY.

• Any product which has not been installed, cleaned, maintained,

or used in accordance with the directions published in the appropriate

installation sheet and/or owner’s manual as well as national and local

codes, including incorrect gas or electrical connection. Wells is not liable

for any unit which has been mishandled, abused, misapplied, subjected

to chlorides, harsh chemicals, or caustic cleaners, damaged from

exposure to hard water, modified by unauthorized personnel, damaged

by flood, fire, or other acts of nature [or God], or which have an altered

or missing serial number.

• Installation, labor, and job checkouts, calibration of heat controls, air

and gas burner/bypass/pilot adjustments, gas or electrical system

checks, voltage and phase conversions, cleaning of equipment,

or seasoning of griddle surface.

• Replacement of fuses or resetting of circuit breakers, safety controls,

or reset buttons.

• Replacement of broken or damaged glass components, quartz heating

elements, and light bulbs.

• Labor charges for all removable parts in gas charbroilers and hotplates,

including but not limited to burners, grates, and radiants.

• Any labor charges incurred by delays, waiting time, or operating

restrictions that hinder a service technician’s ability to perform service.

• Parts that fail or are damaged due to normal wear or labor for

replacement of Items that can easily be replaced during a daily cleaning

routine. such as but not limited to silicone belts, PTFE non-stick sheets,

knobs, control labels, bulbs, fuses, quartz heating elements, baskets,

racks, and grease drawers.

• Components that should be replaced when damaged or worn, but have

been field-repaired instead [eg. field-welded fry pots].

• Any loss of business or profits.

ADDITIONAL WARRANTIES

Specialty/chain specific versions may also have additional and/or

extended warranties.

NTY EXCLUSIONS

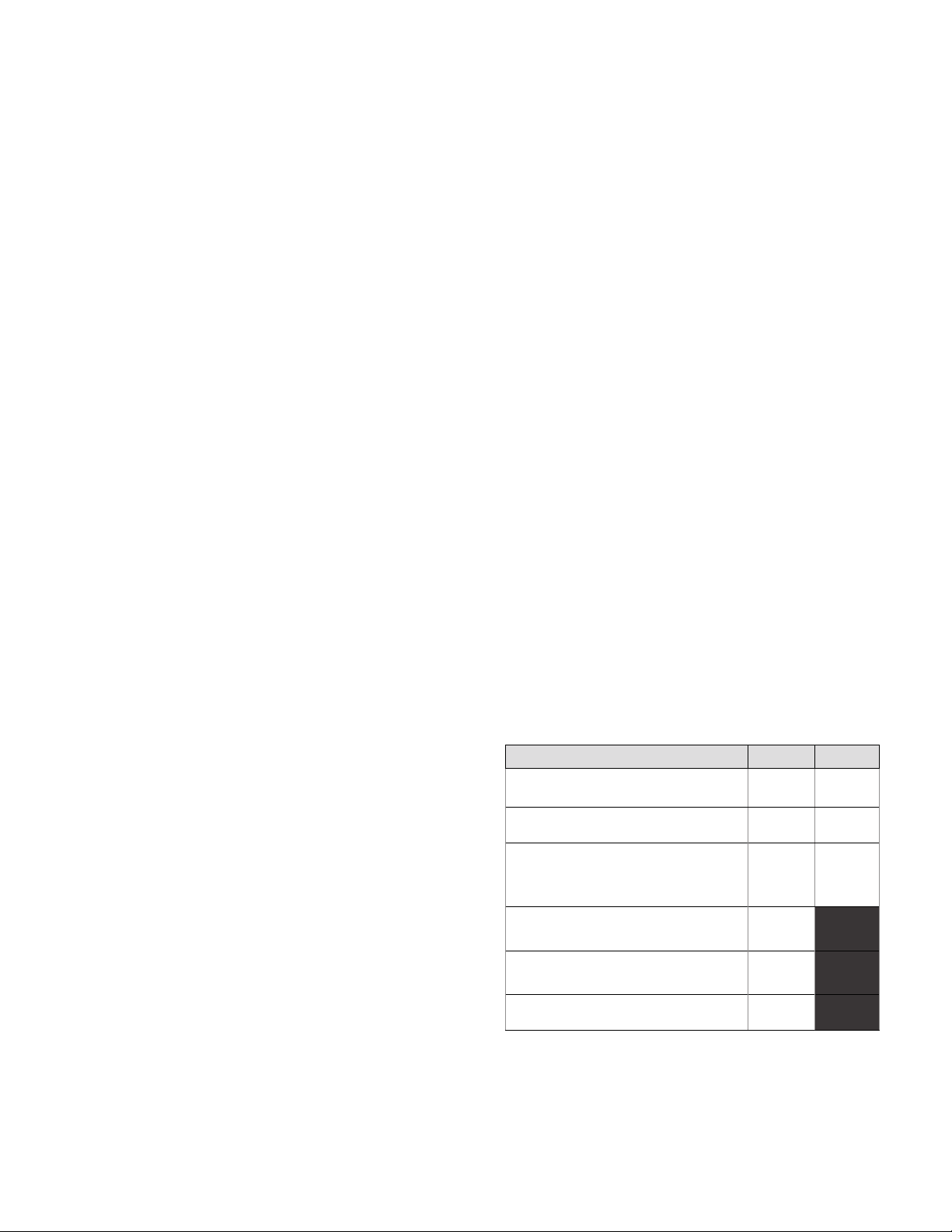

PRODUCTS PARTS LABOR

universal ventless hoods 2 years 1 year

canopy hoods 2 years 1 year

“Cook’n Hold” equipment [HW10,

HWSMP, LLSC7, LLSC7WA, LLSC11,

2 years 1 year

an d LLSC 1 1WA]

cast iron grates, burners, and burner

shields

original Wells parts sold to repair

Wells equipment

1 year

90 days

Service First 1 year

The fore going warrant y is in lieu of any and a ll other warranti es expresse d or implied and c onstitutes the e ntire warranty. 2M-Z22393 • Rev A • 02.2018

Page 3

TABLE OF CONTENTS

WARRANTY

INTRODUCTION & SPECIFICATIONS 1

FEATURES & OPERATING CONTROLS 2

PRECAUTIONS & GENERAL INFORMATION 3

AGENCY LISTING INFORMATION 4

INSTALLATION 5, 6, 7

OPERATION 8

CLEANING INSTRUCTIONS 9

MAINTENANCE INSTRUCTIONS 10, 11

OPERATING INSTRUCTIONS 12, 13

TROUBLESHOOTING SUGGESTIONS 14

WIRING AND REFR. DIAGRAMS 15

BLANK PAGE FOR NOTES 16

ACCESSORY PARTS & SERVICE DATA 17

INTRODUCTION

Thank you for purchasing this Wells Manufacturing appliance.

Proper installation, professional operation and consistent maintenance of this appliance will ensure that

it gives you the very best performance and a long, economical service life.

This manual contains the information needed to properly install this appliance, and to use and care for

the appliance in a manner which will ensure its optimum performance.

ELECTRICAL & REFRIGERATION SPECIFICATIONS

MODELS HP

RCP-050, RCP-067

RCP-7050, RCP-7067

RCP-100, RCP-200, RCP-300

RCP-7100, RCP-7200

RCP-100ST, RCP200ST, RCP300ST

RCP-7100ST, RCP7200ST

RCP-400, RCP-7300, RCP-400ST

RCP-7300ST

RCP-500, RCP-600, RCP-500ST,

RCP-600ST, RCP-7400, RCP-7400ST

M405 p/n 2M-305101 Owmers Manual Drop-In Refrigerated Cold Pans

RCP-7500, RCP-7500ST

RCP-7600, RCP-7600ST

1/4 5.5 8 15 38 R-134a 28 oz. 440 162 NEMA 5-15P

1/4 5.5 8 15 38 R-134a 28 oz. 440 162 NEMA 5-15P

1/3 7 11 15 29 R-404a 24 oz. 500 174 NEMA 5-15P

1/2 7.5 12 15 33 R-404a 32 oz. 500 174 NEMA 5-15P

3/4 15.3 21 30 59 R-404a 54 oz. 500 174 NEMA 5-20P

AMPS 120VAC 1ø REFRIGERANT

TOTAL MCA MFS LRA TYPE AMT. HIGH LOW CORD

PRESSURE POWER

(psig) SUPPLY

1

Page 4

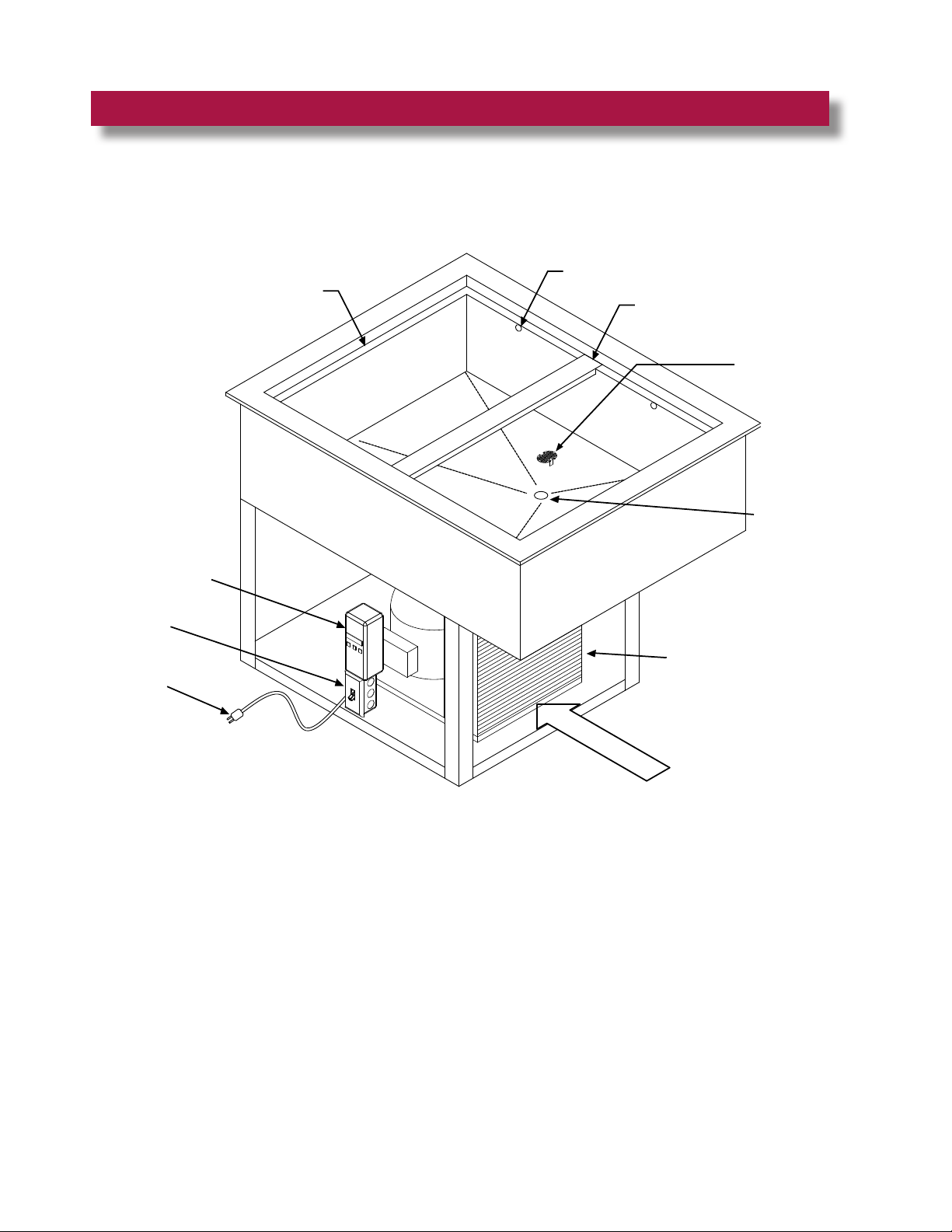

FEATURES & OPERATING CONTROLS

IL2961

PAN RAIL SUPPORT

PAN RAIL

TEMPERATURE

CONTROL UNIT

POWER

SWITCH

POWER

CORD

AIRFLOW

REFRIGERATION

CONDENSER

DRAIN

OPTIONAL

DRAIN

SCREEN

PAN ADAPTER BAR

NOTE:

This is a general arrangement drawing only. Actual component positions may vary between units.

2

Page 5

PRECAUTIONS AND GENERAL INFORMATION

This appliance is intended for use in commercial establishments

only, and is intended to hold pre-chilled prepared food for human

consumption. No other use is recommended or authorized by the

manufacturer or its agents.

Operators of this appliance must be familiar with the appliance use,

limitations and associated restrictions. Operating instructions must be

read and understood by all persons using or installing this appliance.

Food must be kept in appropriate inserts. Never place food directly

into the tank.

Cleanliness of this appliance is essential to good sanitation. Read and

follow all included cleaning instructions and schedules to ensure the

safety of the food product.

Disconnect this appliance from electrical power before performing any

maintenance or servicing.

This appliance is not jet stream approved. Do not direct water jet

or steam jet at this appliance, or at any control panel or wiring. Do

not splash or pour water on, in or over any controls, control panel or

wiring. Do not wash oor around this appliance with water or steam

jet.

The technical content of this manual, including any wiring diagrams,

schematics, parts breakdown illustrations and/or adjustment

procedures, is intended for use by qualied technical personnel.

Any procedure which requires the use of tools must be performed by a

qualied technician.

This manual is considered to be a permanent part of the appliance.

This manual and all supplied instructions, diagrams, schematics, parts

breakdown illustrations, notices and labels must remain with the

appliance if it is sold or moved to another location.

This appliance is made in the USA. Unless otherwise noted, this

appliance uses all American-sized hardware.

WARNING:

ELECTRIC SHOCK

HAZARD

All servicing requiring

access to non-insulated

electrical components must

be performed by a factory

authorized technician.

DO NOT open any access

panel which requires the use

of tools. Failure to

follow this warning can

result in severe electrical

shock.

CAUTION:

RISK OF

DAMAGE

DO NOT connect or

energize this appliance

until all installation

instructions are read and

followed. Damage to the

appliance will result if the

instructions are not

followed.

M405 p/n 2M-305101 Owmers Manual Drop-In Refrigerated Cold Pans

3

Page 6

AGENCY LISTING INFORMATION

STD 2

STD 7

UL471

This appliance performance tested to NSF Standard 7 for storage of

potentially hazardous foods. This appliance meets NSF Standard 7

only when pan rails are installed in the lowest position, otherwise it

meets NSF Standard 2.

RCP units are ETL listed for US and Canada

RCP units are evaluated to UL standard 471.

Components used in the manufacture of this unit are Underwriters

Laboratory recognized.

4

Page 7

INSTALLATION

UNPACKING & INSPECTION

Carefully remove the appliance from the carton. Remove all protective

plastic lm, packing materials and accessories from the Appliance

before connecting electrical power or otherwise performing any

installation procedure.

Carefully read all instructions in this manual and the Installation

Instruction Sheet packed with the appliance before starting any

installation.

Read and understand all labels and diagrams attached to the

appliance.

Carefully account for all components and accessories before discarding

packing materials. Store all accessories in a convenient place for later

use.

RCP units must remain upright at all times (shipping and installation)

to prevent damage to the condensing unit. If the unit is accidentally

tipped, allow unit to sit upright for at least 24 hours before connecting to

electric power.

COMPONENTS

1 ea. PAN RAIL

1 - 5 ea. PAN ADAPTER BAR ( quantity differs with unit)

PREPARATION

Cutout dimensions for tank units and control panels are listed on the

Installation Instructions provided with the unit.

Provide at least 1” clearance around the condensing unit chassis.

Countertop must be at and level before the unit is installed. After

cutout is made, add stiffeners or bottom braces to counter as required

to support unit weight.

IMPORTANT:

Refrigeration system is air cooled. Recommend louvered grills or

equivalent openings front and rear, each with a minimum size of

twice the surface area of the condenser, to provide adequate air

circulation.

NOTE: The condenser fan is provided with a fan guard.

DO NOT remove the condenser fan guard.

Provide louvered grills and service access below control panel. Provide

access to the POWER SWITCH and TEMPERATURE CONTROL UNIT

located at the front of the condenser.

Verify that provided sealants are applied to the underside of the top

ange prior to setting the unit into the cutout.

After installation, apply a thin bead of food-grade silicone sealant

around the ange to seal it to the counter.

M405 p/n 2M-305101 Owmers Manual Drop-In Refrigerated Cold Pans

Avoid storing ammable or combustible materials in, on or near the

appliance.

Clean the unit thoroughly after installation and before rst use.

NOTE: DO NOT discard

the carton or other packing

materials until you have

inspected the appliance for

hidden damage and tested it

for proper operation.

Refer to SHIPPING DAMAGE

CLAIM PROCEDURE on the

inside front cover of this

manual.

WARNING:

RISK OF PERSONAL

INJURY

Installation procedures must

be performed by a qualied

technician with full knowledge

of all applicable electrical and

plumbing codes. Failure can

result in personal injury and

property damage.

IMPORTANT:

Unit must remain in an upright

position during installation

to prevent damage to the

refrigeration system.

IMPORTANT:

Refrigeration system is air

cooled. Recommend louvered

grills or equivalent openings

front and rear, each with a

minimum size of twice the

surface area of the condenser,

to provide adequate air

circulation.

IMPORTANT:

Access is required for the

operation of the drain valve

and for maintenance of the

refrigeration unit. Provide

adequate access to the drain

valve and refrigeration unit.

IMPORTANT:

Unit ange must be sealed

to the counter top. Damage

caused by leaks due to

improper installation is NOT

covered by warranty.

5

Page 8

INSTALLATION

WARNING:

ELECTRIC SHOCK

HAZARD

All servicing requiring

access to non-insulated

electrical components must

be performed by a factory

authorized technician.

DO NOT open any access

panel which requires the use

of tools. Failure to

follow this warning can

result in severe electrical

shock.

CAUTION:

RISK OF

DAMAGE

DO NOT connect or energize

this appliance until all

installation instructions are read

and followed. Damage to the

appliance will result if these

instructions are not followed.

CAUTION:

ELECTRIC SHOCK

HAZARD

Cord -connected units are

equipped with a three-prong

plug for your protection

against electric shock. Never

cut the large round prong

from the plug, or twist a blade

to t an existing receptacle.

ELECTRICAL INSTALLATION

1 Refer to the nameplate. Verify the electrical service power.

Voltage and phase must match the nameplate specications.

Wiring the unit to the wrong voltage can severely damage the

unit, or cause a signicant decrease in performance.

2. Available electrical amperage must meet or exceed the

specications listed on the specications sheet provided with

the unit.

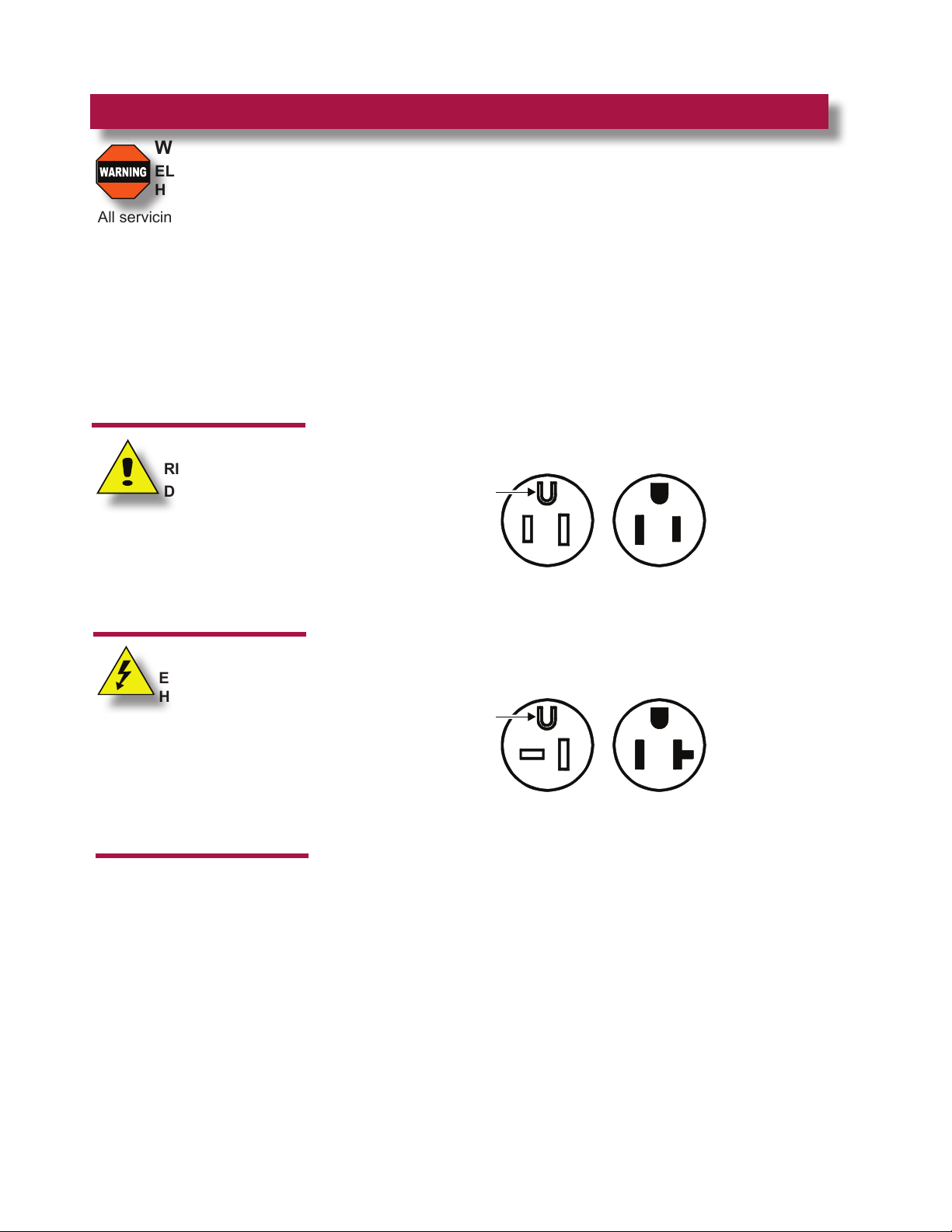

a. Units are equipped with a three-prong (grounding) plug for your

protection against electrical shocks. This must be plugged into

a properly grounded matching receptacle.

b. RCP-100 through RCP-600 and RCP-7100 through RCP-7400

are equipped with a NEMA 5-15P plug and require a matching

NEMA 5-15R receptacle.

GROUND

PIN

NEMA 5-15P

PLUG

c. RCP-7500 and RCP-7600 are equipped with a

NEMA 5-20P plug and require a matching NEMA 5-20R

receptacle.

GROUND

PIN

NEMA 5-20P

PLUG

NEMA 5-15R

RECEPTACLE

NEMA 5-20R

RECEPTACLE

IL2960

IMPORTANT:

Contact a licensed electrician

to install the correct circuit

and receptacle (cordconnected units) or to install

and connect electric power

(eld-wired units).

IMPORTANT:

Damage due to being

connected to the wrong

voltage or phase is NOT

covered by warranty.

6

Page 9

INSTALLATION

USE A

SPUD

WRENCH

0.25”

0.85” dia.

SINK

DRAIN

SPUD

WITH

CROSS

GUARD

OR ...

GRIP

HERE

WHEN

ATTACHING

DRAIN

FITTING

GASKET

NUT

IL2958

PLUMBING INSTALLATION

Install 1” drain valve (provided by others) on unit drain. Plumb to

an appropriate waste as required by local plumbing and sanitation

ordinances. Consult local codes for approved drain congurations.

IMPORTANT:

DO NOT allow the sink drain spud to turn during installation. Hold the

spud with an appropriate cross-guard-style spud wrench, or carefully

grip the center threaded portion with a strap wrench or slip-joint pliers to

immobilize the drain spud during drain tting installation.

DO NOT grip the drain spud nut or gasket.

IMPORTANT:

Plumbing connections must

be made in compliance with

all Federal, State and Local

Codes and Ordinances.

IMPORTANT:

All drain plumbing

installations must be

performed by a qualied

plumber.

M405 p/n 2M-305101 Owmers Manual Drop-In Refrigerated Cold Pans

7

Page 10

OPERATION

CAUTION:

ELECTRIC SHOCK

HAZARD

DO NOT splash or pour water

onto control panel or wiring.

RCP units are designed

to hold REFRIGERATED

PRE-CHILLED product at

serving temperature.

RCP units should not be used

to chill product, nor to hold

product for long term storage.

OPERATION NOTES

1. Never place food directly in cold tank. Always use insets or

food pans.

2. Use only pre-chilled products. Stir product occasionally to

maintain an even temperature.

3. Use perforated bottom strainer plates when operating units

with ice. Perforated bottom strainer plates are optional and

must be ordered separately.

4. Models RCP-7100(ST) thru RCP-7600(st) are NSF-7 listed

for use with potentially hazardous foods.

5. Periodically clean condensing coils to remove accumulated

dust and debris. Failure to clean coils will decrease

performance and may void the warranty.

See CONDENSER CLEANING, page 8.

DAILY START-UP

1. Turn POWER SWITCH (located on condensing unit) ON.

Allow unit to run for approximately 30 minutes to reach

operating temperature.

2. Add necessary adapter bars or adapter plates. Adapter bars

provided with the unit are designed to hold 12” x 20” food

pans up to 6” deep.

3. Install appropriate food pans or insets. Place pre-chilled

product in food pans.

DAILY SHUT-DOWN

1. Turn POWER SWITCH OFF. Remove product, food pans

and adapters.

2. Allow unit to defrost before cleaning.

See CLEANING INSTRUCTIONS, page 7.

8

Page 11

CLEANING INSTRUCTIONS

PREPARATIONS: Turn POWER SWITCH OFF. Unplug unit or

disconnect from electric power.

Allow unit to defrost before proceeding.

Remove any insets, pans and/or adapter tops

(if used). Drain water from tank.

FREQUENCY: Daily

TOOLS: Warm Water and Mild Detergent

Solution: 10 Parts Warm Water to 4 Parts Vinegar

Plastic Scouring Pad

Clean Cloth or Sponge

Food-Grade Silicone Sealant

1. Remove pan adapter bars, pan rail and drain screen. Wipe

interior of tank using a clean cloth or sponge and mild

detergent.

2. Use a plastic scouring pad to remove any mineral deposits.

3. Rinse tank thoroughly with a vinegar and water solution to

neutralize all detergent / cleanser residue.

4. Clean pan adapter bars and pan rail with a cloth or sponge

dampened in clean water. Dry thoroughly, then reinstall.

CAUTION:

ELECTRIC SHOCK

HAZARD

DO NOT splash or pour water

onto control panel or wiring.

IMPORTANT: DO NOT use

steel wool for cleaning

5. Check drain screen, clean if necessary and reinstall.

6. Periodically inspect warmer ange-to-counter seal. Reseal

with food-grade silicone sealant if necessary.

7. Inspect condenser. Clean if required.

8. Inspect cooling louvers in counter. Remove any lint or debris.

9. Reconnect to electric power. Turn POWER SWITCH ON only

when unit is to be used.

Procedure is complete

M405 p/n 2M-305101 Owmers Manual Drop-In Refrigerated Cold Pans

9

Page 12

MAINTENANCE INSTRUCTIONS

CAUTION:

PERSONAL

INJURY HAZARD

Disconnect appliance from

electrical power before

cleaning condenser coil.

CAUTION:

PERSONAL

INJURY HAZARD

Condenser coil ns are sharp.

Use care to avoid cuts while

cleaning the condenser.

CONDENSER COIL CLEANING INSTRUCTIONS

The condenser coil must be kept clean to allow adequate air ow for

proper heat dissipation. Recommend this procedure be performed

monthly.

1. Turn POWER SWITCH OFF. Disconnect unit from electrical

power.

2. Remove louvers or access panel to allow coil to be reached.

3. Using a stiff bristle brush, brush lint and debris from the

condenser ns. Brush vertically, top to bottom. Collect and

discard all lint and debris gathered from this operation

IMPORTANT: The ns of the condenser coil are delicate and easily

damaged. Use care to brush only in a vertical motion to avoid

damaging the coil ns.

5. Wipe the fan blades to remove accumulated lint.

5. Reconnect to electrical power. Test for proper operation.

10

Page 13

MAINTENANCE INSTRUCTIONS

CARE OF STAINLESS STEEL

1. The surface can be damaged by mechanical abrasion, hard

water deposits and chlorine:

a. NEVER use steel wool, wire brushes or metal scrapers to clean

the appliance. These will damage the surface.

b. Hard water deposits left behind when water is evaporated will

attack the surface and allow the stainless steel to rust.

c. Chlorides from chlorinated cleansers, calcium / lime / rust

removers (e.g. muriatic acid), even heavily chlorinated city water

will attack the surface and allow the stainless steel to rust.

d. DO NOT use any highly caustic cleaners. Use of highly caustic

cleaners will damage the surface.

e. LIMIT USE of strong caustic cleaners on warmers. Rinse

thoroughly with a vinegar and water solution to neutralize any

residue. Failure to do so may cause damage to the surface and

allow the stainless steel to rust.

f. Cleaners containing ammonia will attack the surface and allow

the stainless steel to rust.

2. Use the proper tools in the proper way to clean your Wells cold

pan.

a. Soft cloth and plastic scouring pads are safe to use on stainless

steel surfaces.

b. Stainless steel pads may be used ONLY IF the scrubbing motion

is in the direction of the visible grain. DO NOT use a circular

motion.

c. In the absence of visible grain, use only soft cloth or plastic

pads. Scrub only in a linear motion along the longest axis of the

equipment.

CAUTION:

PERSONAL

INJURY HAZARD

Disconnect appliance from

electrical power before

cleaning.

Wells refrigerated cold pans

are constructed of high quality

stainless steel. As long as

the stainless steel surface is

intact, the equipment will not

rust or corrode.

Recommendation:

A water softening device or a

cartridge-type ltration device

may be used to minimize lime

and calcium build-up.

3. Use only non-chloride and non-ammonia cleansers:

a. DO NOT use any cleanser listed as “chlorinated”.

b. DO NOT use any cleanser listing “ammonia” or “ammonium” in its

contents.

c. Contact your cleaning materials supplier for suitable alkaline

cleansers.

4. Keep your Wells cold pan clean. Clean frequently to avoid

build-up of hard stubborn stains and hard-to-remove deposits.

a. Rinse thoroughly with a vinegar and water solution to neutralize

any residue.

b. For discoloration caused by using the warmer in dry operation,

use a cleaner made specically for stainless steel.

c. Wipe dry with a soft, clean, dry cloth.

d. Restore the surface by using a polishing product specically

made for stainless steel after each cleaning.

M405 p/n 2M-305101 Owmers Manual Drop-In Refrigerated Cold Pans

11

Page 14

OPERATING INSTRUCTIONS

LCD READOUT

“SET” KEY

“ ” KEY (INCREASE)

“ ” KEY (DECREASE)

IL2957

IMPORTANT:

DO NOT adjust the differential

settings of the refrigeration

system. Field adjustments

of the differential settings

must be made by qualied

refrigeration personnel only.

Unauthorized adjustment of

the differential settings will

void the warranty.

The temperature setting

of the NSF-7 Refrigerated

Cold Pan has been pre-set

at the factory to meet most

applications. An electronic

temperature control maintains

food temperature between

33ºF (.05°C) and 44ºF

(6.6°C).

TEMPERATURE ADJUSTMENT

RCP-100(ST) thru RCP-600(ST)

1. The temperature has been preset at the factory to meet most

applications.

2. If temperature adjustments are required, the pressure switch,

located on the condensing unit, is adjustable. Temperature

adjustment must be performed by a qualied refrigeration

personnel only.

3. Normal temperature setting would be 28ºF.

RCP-7100(ST) thru RCP-7600(ST)

The LCD Display provides a readout of the sensor temperature

during normal operation. Use the following to change the setpoint

temperature:

1. To start programming, press SET key once. This will access the

Fahrenheit/Celsius mode. The readout will show the current

status, either F (degrees Fahrenheit) or C (degrees Celsius).

Press either “up arrow” (é) or “down arrow” (ê) to toggle between

F and C designation.

2. Press SET again to access the setpoint. The LCD will display

the current setpoint, and the S1 annunciator will blink off and on

to indicate that control is in the setpoint mode.

Press either “up arrow” (é) to increase the setpoint, or “down

arrow” (ê) to decrease the setpoint to the desired temperature.

Factory setpoint is 21°F (-6°C).

12

Page 15

OPERATING INSTRUCTIONS

3. Press the SET key again to access the differential. The LCD will

display the current differential, and the DIF1 annunciator will blink

off and on to indicate that control is in the differential mode.

IMPORTANT: DO NOT adjust the differential settings of the

refrigeration system. Field adjustments of the differential settings

must be made by qualied refrigeration personnel only.

Unauthorized adjustment of the differential settings will void the

warranty.

Press either “up arrow” (é) to increase the differential, or “down

arrow” (ê) to decrease the differential to the desired setting.

Factory differential is 3ºF (.

4. Press the SET key again to access the Heating / Cooling mode.

The LCD will display the current mode. Either “C1” for cooling or

“H1” for heating. The control must be set to C1 for proper

operation of the cold pan.

5. Press the SET key again to complete programming. Programming

ends automatically if no keys are pressed for 30 seconds. Any

settings that have been input to the control will be accepted at that

time.

IMPORTANT:

DO NOT adjust the differential

settings of the refrigeration

system. Field adjustments

of the differential settings

must be made by qualied

refrigeration personnel only.

Unauthorized adjustment of

the differential settings will

void the warranty.

NOTE:

The controller has both

“heating” and “cooling”

modes. Heating mode is

not used on the RCP-series

units. The control must be set

to “cooling” (C1) for proper

operation of the cold pan.

6. Control settings are stored in non-volatile memory. Loss of power

to the unit will not require reprogramming.

M405 p/n 2M-305101 Owmers Manual Drop-In Refrigerated Cold Pans

13

Page 16

TROUBLESHOOTING

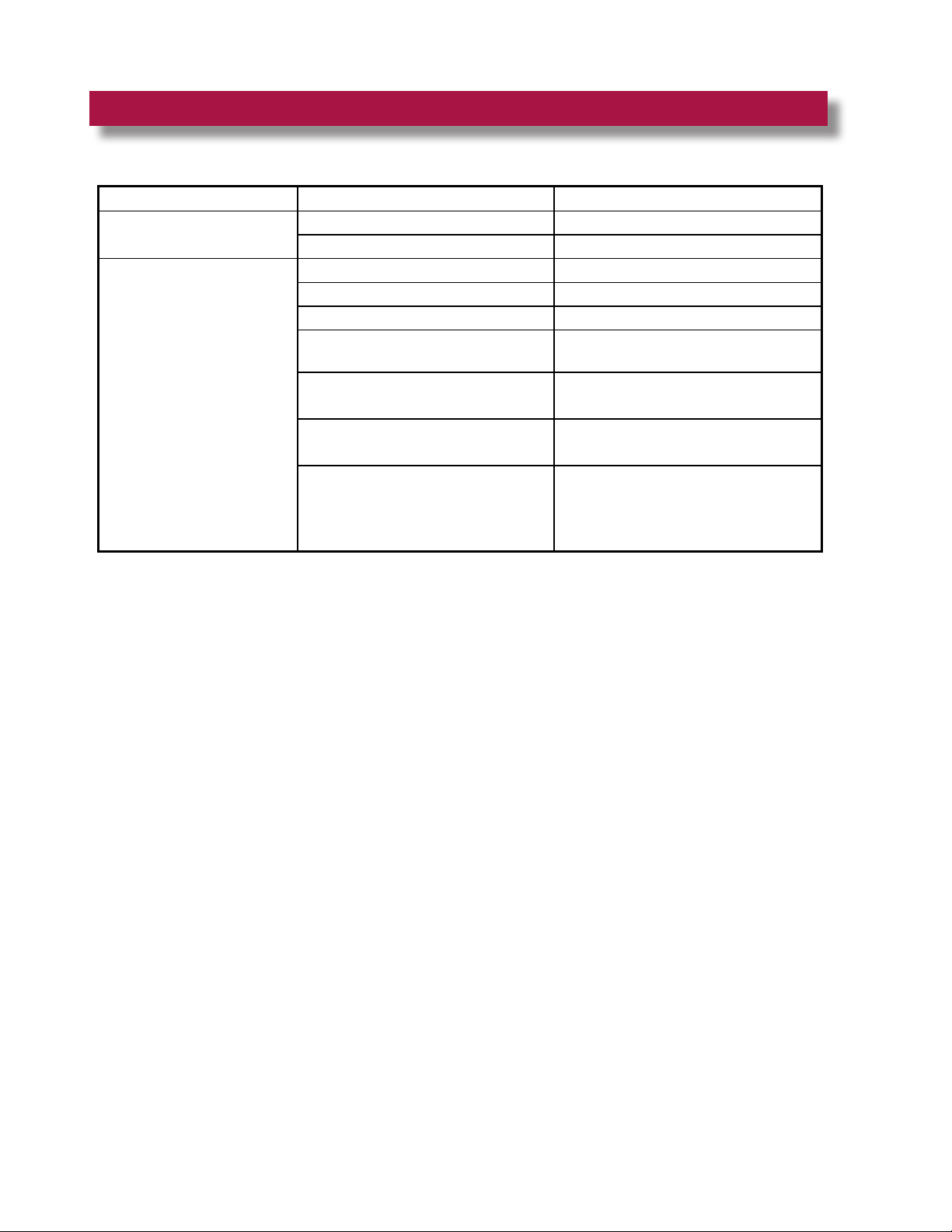

SYMPTOM POSSIBLE CAUSE REMEDY

No power to unit

Food not kept cold enough

Circuit breaker tripped Reset circuit breaker

Power switch OFF Turn power switch ON

Food not chilled to start Add only pre-chilled food

Food too thick Stir thick food frequently

Setpoint too high Set to desired temperature

Condenser cooling louvers or coil

plugged

Refrigerant level low

Clean condenser louvers and/or coil

Contact Authorized Wells Service

Agency for Repairs

Internal damage

NSF-7 operation using wrong rail

position

Contact Authorized Wells Service

Agency for Repairs

For holding critical foods, pan rails

must be assembled using the lower

pan rail supports. Also pans can be

no deeper than 4”.

14

Page 17

WIRING AND REFRIGERATION SCHEMATICS

M405 p/n 2M-305101 Owmers Manual Drop-In Refrigerated Cold Pans

15

Page 18

NOTES:

16

Page 19

ACCESSORY PARTS & SERVICE

DESCRIPTION PART NO.

DRAIN SCREEN 2V-Z17446

ADAPTER BAR FOR 12” X 20” PANS O3-303100

PERFORATED BOTTOM PLATE STRAINER

FOR RCP-100 (1 PC) M2-22107

PERFORATED BOTTOM PLATE STRAINER

FOR RCP-200 (1 PC) O3-303102

PERFORATED BOTTOM PLATE STRAINER

FOR RCP-300 (2 PC) O3-303103

PERFORATED BOTTOM PLATE STRAINER

FOR RCP-400 (2 PC) O3-303104

PERFORATED BOTTOM PLATE STRAINER

FOR RCP-500 (2 PC) O3-303105

PERFORATED BOTTOM PLATE STRAINER

FOR RCP-600 (3 PC) O3-303106

PAN RAIL FOR RCP-7100 WS-22696

PAN RAIL FOR RCP-7200 WS-22697

PAN RAIL FOR RCP-7300 WS-22698

PAN RAIL FOR RCP-7400 WS-22699

PAN RAIL FOR RCP-7500 WS-22700

PAN RAIL FOR RCP-7600 WS-22701

IMPORTANT: Use only factory

authorized service parts and

replacement filters.

For factory authorized service, or to

order factory authorized

replacement parts, contact your

Wells authorized service agency, or

call:

Wells Manufacturing

265 Hobson Street

Smithville, Tennessee 37166 U

Service Dept.

phone: (314) 678-6314

fax: (314) 781-2714

Service Parts Department

can supply you with the name

and telephone number of

the WELLS AUTHORIZED

SERVICE AGENCY

nearest you.

.S.A.

CUSTOMER SERVICE DATA

please have this information available if calling for service

RESTAURANT _____________________________ LOCATION _____________

INSTALLATION DATE ________________________ TECHNICIAN ___________

SERVICE COMPANY ________________________________________________

ADDRESS ___________________________ STATE ______ ZIP__________

TELEPHONE NUMBER (_____)_____-_________

EQUIPMENT MODEL NO. _______________

EQUIPMENT SERIAL NO. _______________

VOLTAGE: (check one) 120 _______

M405 p/n 2M-305101 Owmers Manual Drop-In Refrigerated Cold Pans

17

Page 20

WELLS MANUFACTURING

265 Hobson Street, Smithville, Tennessee 37166

telephone: 314-678-6314

fax: 314-781-2714

www.wells-mfg.com

Loading...

Loading...