Page 1

Printed In All Rights Reserved

BISCUIT CABINET

WELLS MODEL MDBC-1

Place this chapter in the Cabinets Section of the Equipment

Manual.

MANUFACTURED EXCLUSIVELY FOR

McDONALD'S®

BY

WELLS MANUFACTURING 2 ERIK CIRCLE VERDI,

NEVADA 89439 PHONE: 1 (702) 345-0444 1 (800) 777-0450

TELEX: 170074

TABLE OF CONTENTS

WARRANTY................................................................................................................. Page 2

INTRODUCTION........................................................................................................... Page 2

SAFETY....................................................................................................................... Page 2

PARTS /IDENTIFICATION/PHOTO/FUNCTION ............................................................. Page 3

HARDWARE IDENTIFICATION....................................................................................Page 12

EQUIPMENT SET UP AND CLOSE PROCEDURES .....................................................Page 12

TROUBLESHOOTING .................................................................................................Page 12

ORDERING/SERVICE INFORMATION.........................................................................Page 15

NON-SCHEDULED MAINTENANCE ............................................................................Page 15

WIRING DIAGRAM......................................................................................................Page 20

WIRING PICTORIAL ....................................................................................................Page 21

This manual is for the exclusive use of licensees and employees of McDonald's Systems, Inc.

© 1985 McDonald's Corporation

Printed in September The United States of America

Page 2

WARRANTY STATEMENT

This MDBC-1 Biscuit Cabinet Manufactured by

Wells is warranted to be free from defects in

materials and workmanship for a period of one

year from the date of original installation and is for

the benefit of the original purchaser only, BUT

NOT AGAINST DAMAGE CAUSED BY ABUSE,

FAULTY INSTALLATION, INCLUDING IMPROPER ELECTRICAL CURRENT (125 VOLTS,

AC). THIS WARRANTY IS THE COMPLETE AND

ONLY WARRANTY, THERE BEING NO OTHER

WARRANTIES, EXPRESSED OR IMPLIED IN

LAW OR IN FACT, INCLUDING BUT NOT

LIMITED TO, WARRANTIES OF MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE, AND/OR FOR DIRECT, INDIRECT, OR CONSEQUENTIAL DAMAGES IN

CONNECTION WITH WELLS PRODUCTS.

Wells' obligation under this warranty is limited to

the repair of defects or replacement without

charge by a WELLS factory authorized service

agency or one or its sub-service agencies. This

service will be provided on customer's request.

Please contact the Service Department: Wells

Manufacturing Company, P. O. Box 280, Verdi,

Nevada 89439; to arrange service or for additional

information and other details concerning the

product and/or this warranty.

INTRODUCTION

This Commercial Biscuit Cabinet Model MDBC-1

is designed to hold food at the desired serving

temperature and moistness.

SAFETY

Knowledge of proper installation, operation and

maintenance procedures is essential to ensure

safe operation of any equipment. The instructions

in this chapter are meant as guidelines; major

considerations to be kept always in mind are:

1. Always have dry hands prior to turning

power switch on or off.

2. Turn off power switch anytime cabinet is not

in use.

3. If an electric shock is felt when touching the

cabinet, disconnect immediately. Call Wells

Service Department for repair.

4. Have electrical supply outlet installed by a

licensed electrician. Make sure that equipment is properly grounded.

5. If you find that the electrical cord is frayed,

DO NOT PLUG INTO A RECEPTACLE.

If it is already plugged in, disconnect the plug after

shutting off the circuit breaker.

6. DISCONNECT POWER CORD BEFORE

ATTEMPTING ANY REPAIRS AND/OR

CLEANING THE UNIT WITH WATER.

7. Allow unit to cool before cleaning.

8. DON'T EVER SPLASH WATER WITH A

HOSE OR OTHERWISE ONTO THE UNIT.

WET ELECTRICAL COMPONENTS AND

WIRING WILL PRESENT A SHOCK

HAZARD.

9. Follow cleaning procedures described on

the Planned Maintenance System, Card

#64.

10. CAUTION: Do not operate unit until the legs

are installed. Four (4) legs are provided and

can be installed by screwing into bottom of

unit as shown on page 10.

11. For biscuit table installation: Bolt unit legs to

table using four (4) 1/4-20 UNC x 1 1/4" long

bolts and four (4) 1 1/4" O. D. flat washers.

Apply Loctite #242 to the leg bolt threads

upon installation of the unit on to the table.

2

Page 3

PARTS IDENTIFICATION/PHOTO/FUNCTION

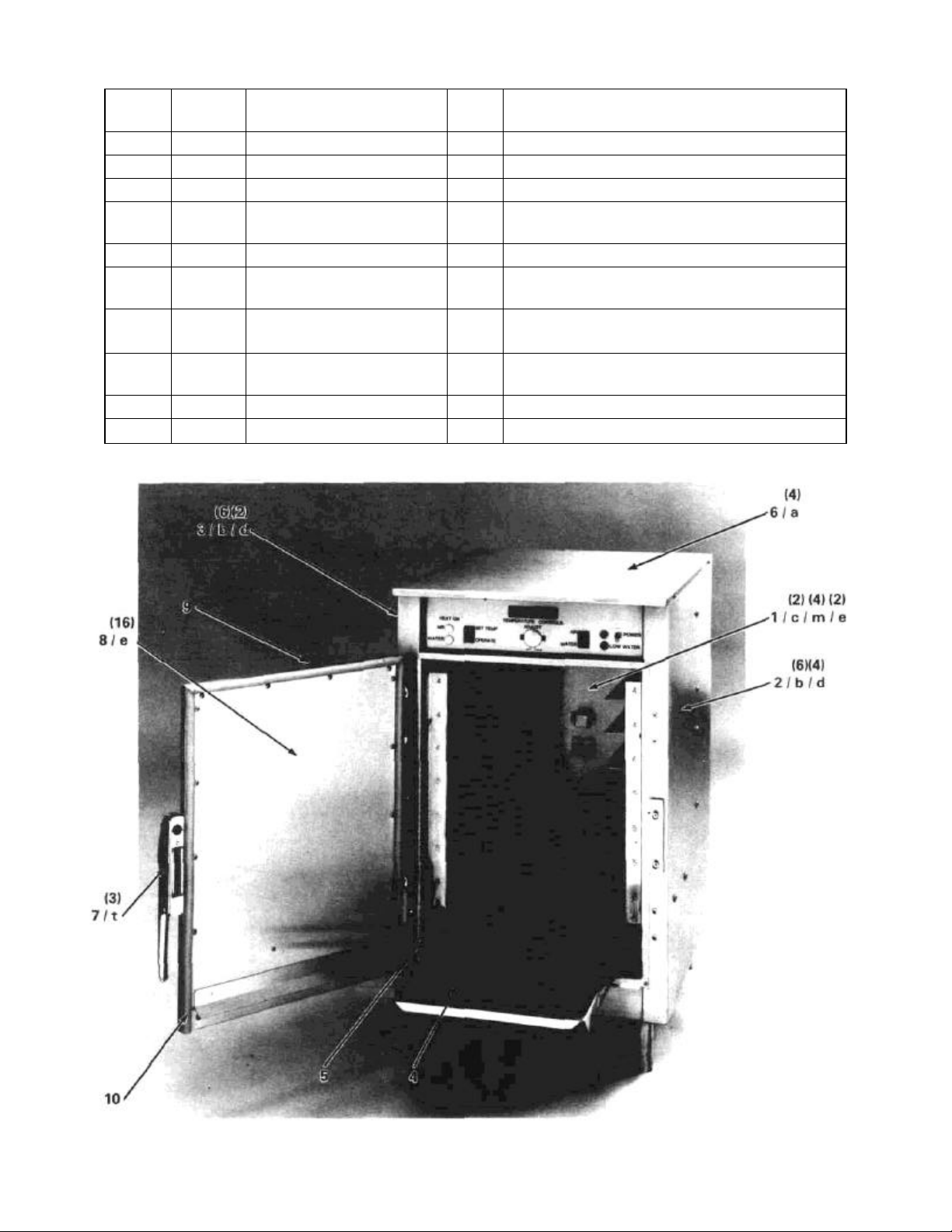

ITEM PART NO. DESCRIPTION QTY. FUNCTION

1 60755 Cavity 1 Provides the Interior Surface of this Unit

2 61044 Right Side Panel 1 Outer Side of Unit

3 61043 Left Side Panel 1 Outer Side of Unit

4 60794 Crumb Shield 1 Prevents Crumbs From Falling into the water pan

5 60756 Air Heating Element 2 Heats the Air Inside of the Unit

6 60783 Cabinet Top 1 Covers and Protects Controls and Components

7 60786 Door Handle and Plate Assy 1

8 60804 Door Interior Panel 1 Secures the Door Gasket and Protects Insulation

9 60820 Door Gasket 1 Seal to Retain the Interior Environment

10 60790 Door 1 Allows Access to the Interior Cavity

Provides Access to Unit and Secures the Door when

Closed

3

Page 4

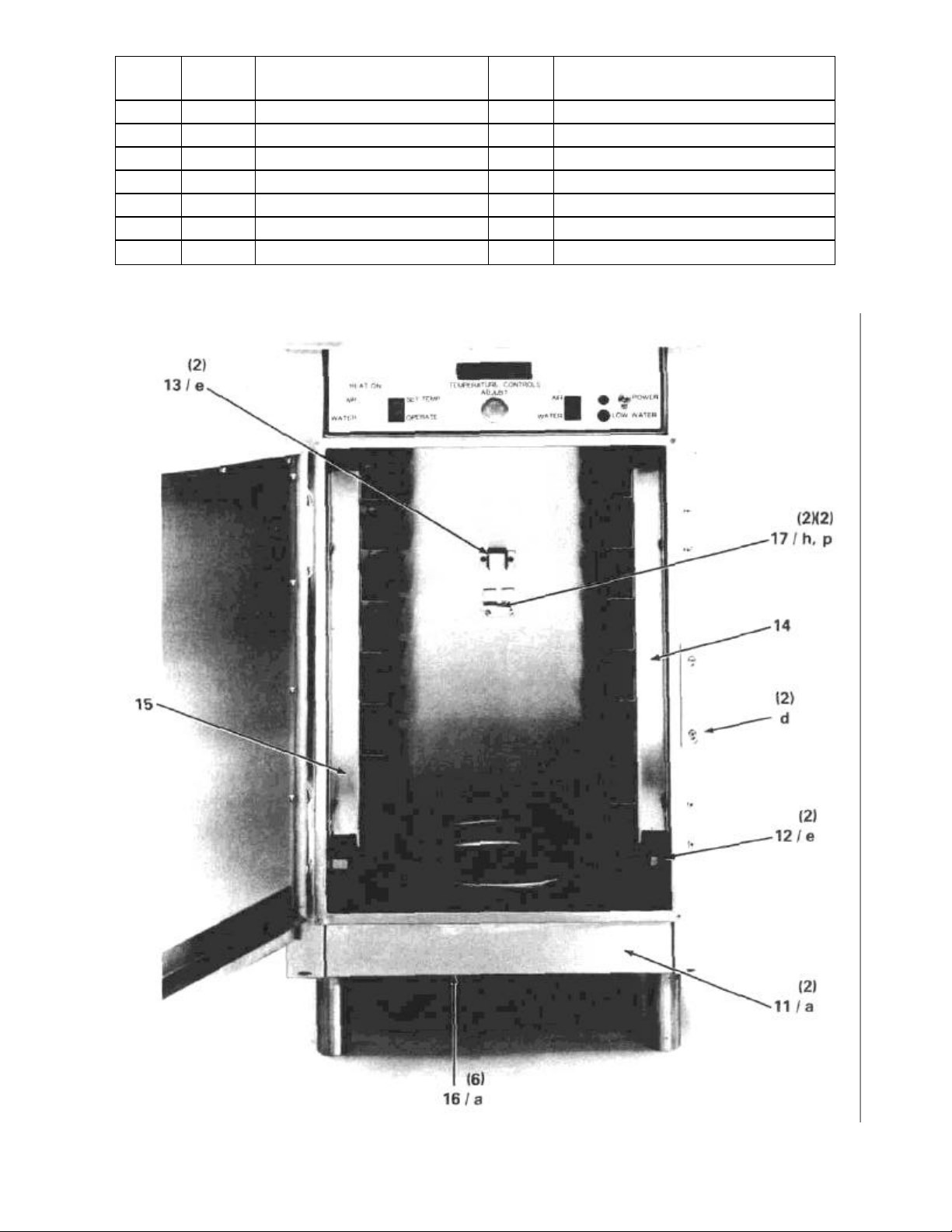

ITEM

11 60779 Front Bottom Panel 1 Protective Front Cover

12 60752 Element Clip 2 Holds Element in Place

13 60789 Thermo Bracket 1 Protective Guard for the Air Sensor

14 60760 Right Tray Rack 1 Holds Right Side of Biscuit Tray

15 60760 Left Tray Rack 1 Holds Left Side of Biscuit Tray

16 60784 Bottom Cover 1 Protective Bottom Cover

17 61105 Air Probe Bracket 1 To Hold the Biscuit Oven Probe

PART

NO.

DESCRIPTION QTY. FUNCTION

4

Page 5

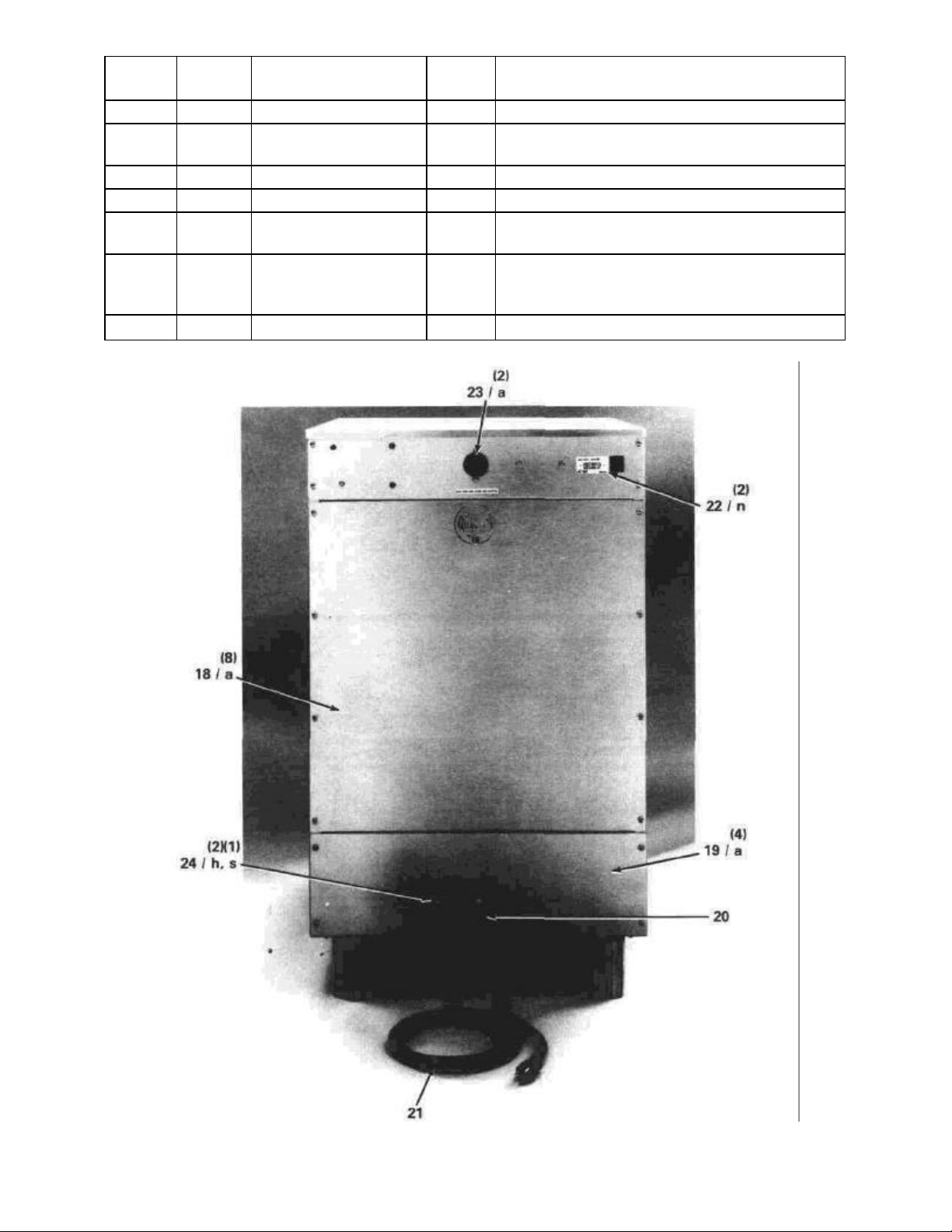

ITEM PART NO. DESCRIPTION QTY. FUNCTION

18 60771 Rear Panel 1 Protective Rear Cover

19 61735 Lower Back Panel 1

20 60589 Strain Relief 1 Attaches Cord to Unit

21 61050 Cord Set 1 Transfer Electric Power to Unit

22 60809 Specification Plate 1

23 60590 Convenience Outlet 1

24 53068 Terminal Block 1 Distribute Power to Components

Electrical Components Mounting and Protective Lower

Back Cover.

Indicates Model Number, Serial Number and Electrical

Rating of the Unit

120V, 4 Amp, 500 Watt max. Outlet for limited Usage

Device. Electrically "hot" when cabinet cord is plugged

in.

5

Page 6

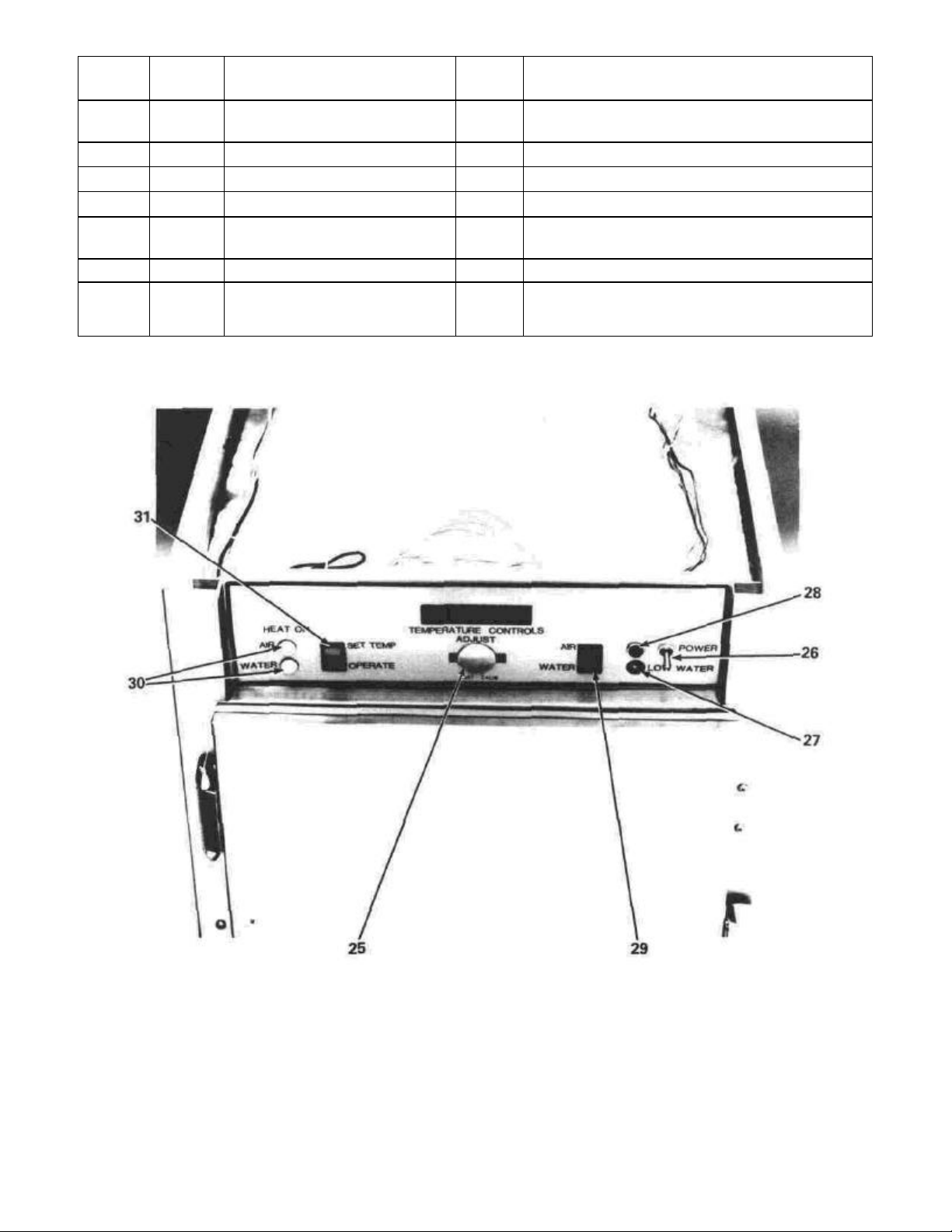

ITEM PART NO. DESCRIPTION QTY. FUNCTION

25 60830 Plug 1

26 50169 Power Switch 1 Turns Electric Power On or Off to the Unit

27 60825 Water Telite (Amber) 1 Low Water Warning Light

28 60758 Power Telite (Red) 1 When Lit, Indicates the Power is On to the Unit

29 60763 Air/Water (Rocker) Switch 1

30 60563 Thermostat Telite (White) 2 Indicates Heater is On

31 60763 Mode (Rocker) Switch 1

Provides Access to Controls for Adjusting and Setting

the Temperatures

To Select Which System the Temperature Readout

Indicates. (Air or Water)

Set Temperature Displays in a Flashing Manner, the

Temperature at Which the Control is Set to Operate:

OR Displays the Actual Temperature

6

Page 7

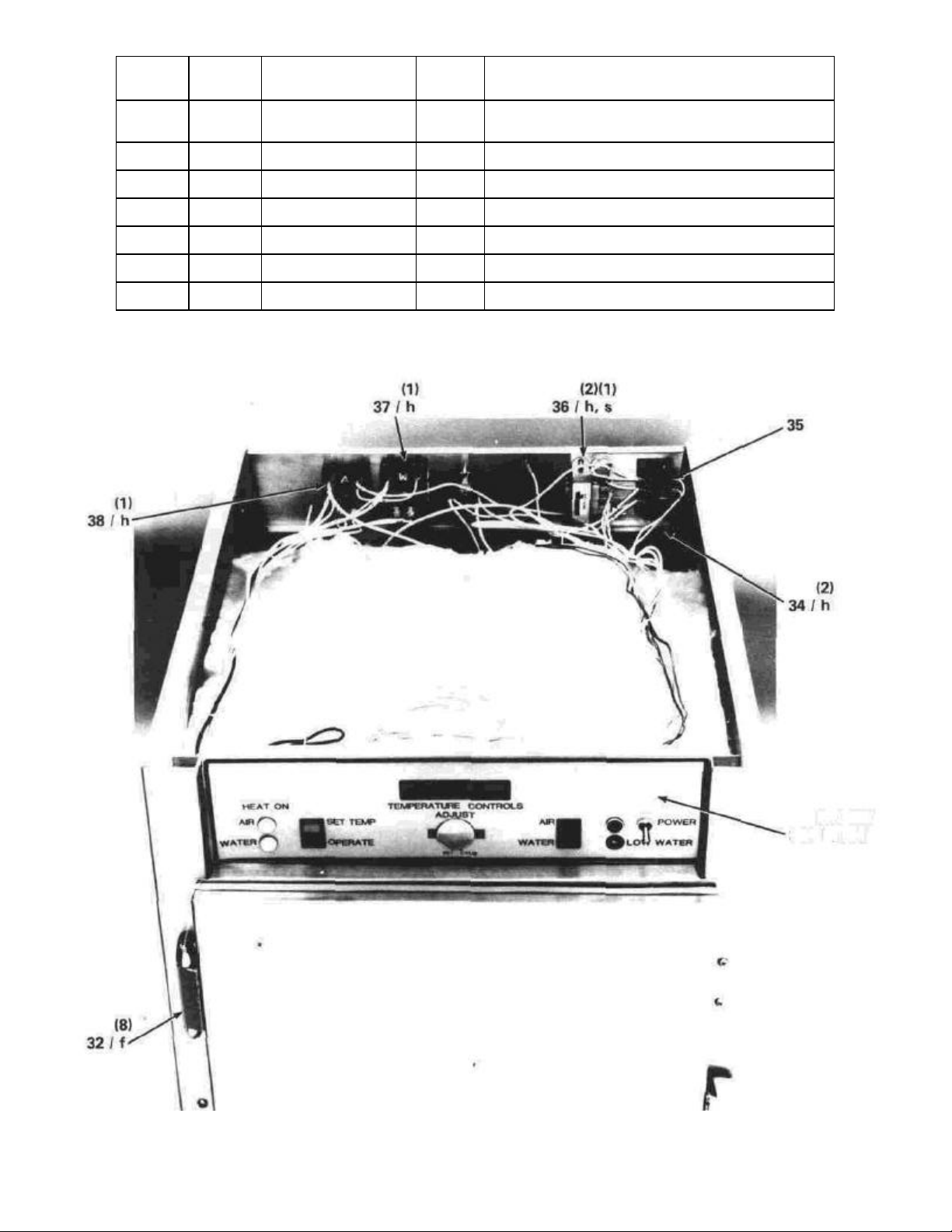

ITEM

PART

NO.

DESCRIPTION QTY. FUNCTION

32 60787 Door Hinge 2

33 60795 Control Panel 1 Used to Mount Electrical Control Components

34 50252 Terminal Block 1 To Distribute Power to the Components

35 54005 Jumper Strap 1 The Electrical Supply Neutral Terminal

36 60818 Transformer 1 Provides Low Voltage to the Printed Circuit Board

37 60964 Water Relay 1 Turns the Water Heater On and Off

38 60870 Air Relay 1 Turns the Air Heaters On and Off

Mounts Door to Cabinet and Allows the Door to Open

and Close

(2) (2X2)

33 / h. p, j

7

Page 8

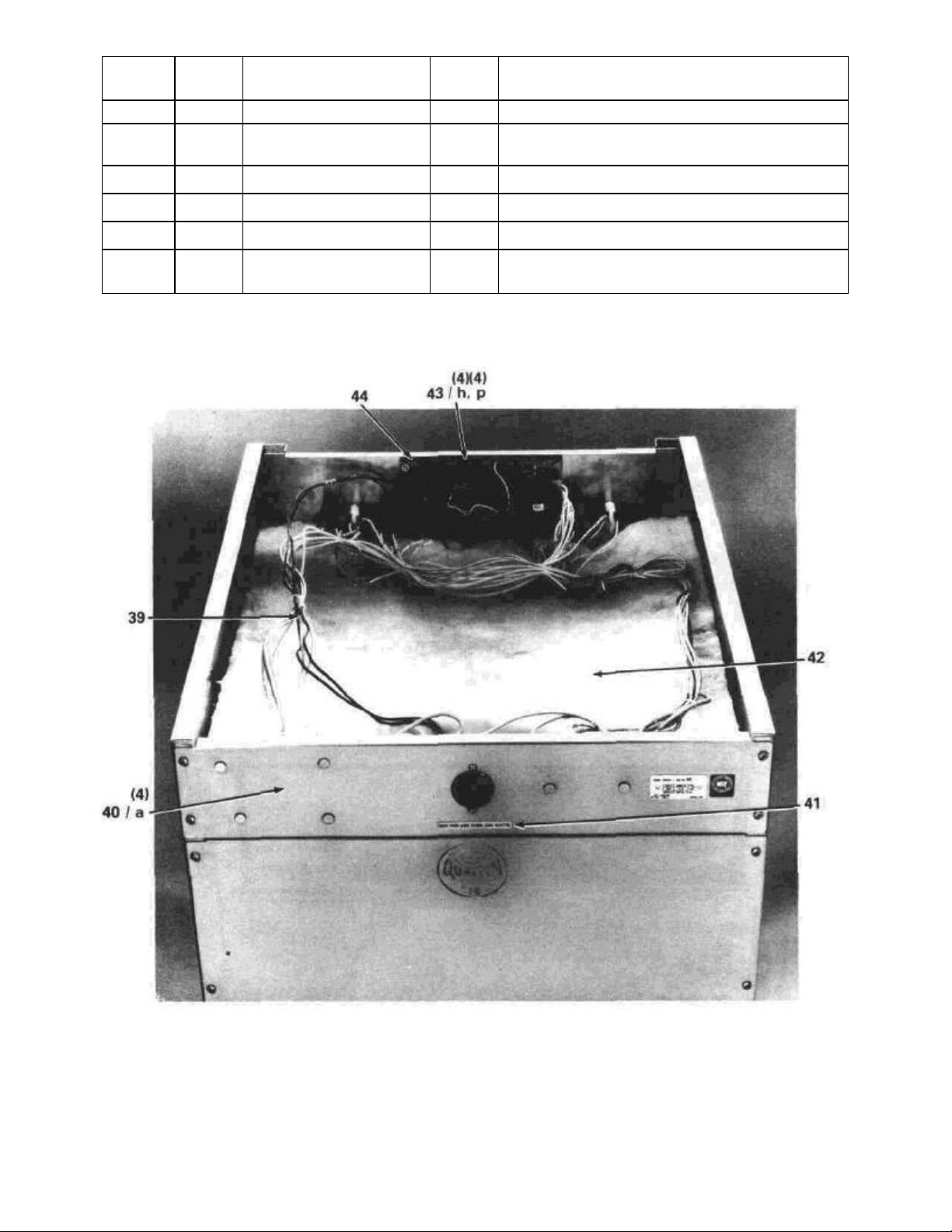

ITEM

39 60863 Wire Harness 1 Permits Connection of All Electrical Parts

40 60778 Rear Top Panel 1

41 60565 Label 1 Rating Size for Convenience Outlet (500 Watts max.)

42 60824 Top Insulation 1 Insulates Controls From the Heated Cavity

43 60816 Printed Circuit Board 1 Solid State Device. Controls All Functions

PART

NO.

DESCRIPTION QTY. FUNCTION

Electrical Components Mounting and Protective Upper

Rear Cover

44 60813 Spacer 4

Provides Required Spacing for Printed Circuit Board to

the Control Panel

8

Page 9

ITEM

45 60785 Right Side Insulation 2

46 60785 Left Side Insulation 2

47 60814 Air Temperature Sensor 1 Senses the Air Temperature Inside the Unit

48 61102 Thermo Strap 1 Holds the Air Sensor Thermostat in Place

49 61183 High Limit Thermostat - Air 1

50 60782 Lower Bottom Insulation 1

51 60777 Cavity Support Bracket 2 Rear Supports of the Cavity

PART

NO.

DESCRIPTION

QTY.

Provides Thermal Seal Between Cavity and Right Side

Panel

Provides Thermal Seal Between Cavity and Left Side

Panel

Safety Device Which Prevents Excessive Cabinet

Temperature if the Relay Fails

Provides Thermal Seal Between the Water Heater and

the Bottom Cover

FUNCTION

9

Page 10

ITEM

52 60751 Upper Bottom Insulation 1 Thermal Seal Around the Water Pan

53 60764 Leg 4 Allows for Cleaning Under Cabinet

54 60810 Heater Element Retainer 1 Holds Water Heating Element in Place

55 60527 High Limit Thermostat-Water 1

56 60768 Water Heating Element 1 Heats the Water in the Pan

57 60815 Thermal/Low Water Sensor Assy. 1

58 60807 Water Pan 1 Holds Water for Humidity

PART

NO.

DESCRIPTION QTY. FUNCTION

Safety Device Which Prevents Excessive Water

Pan Temperature if the Relay Fails

Senses Temperature and Low Water in the

Water Pan

10

Page 11

ITEM

59 61056 Water Pan Gasket 1 Seals Water Pan to the Bottom of the Cavity

60 61030 Shoulder Washer 1 Water Seal and Sensor Insulator (Upper)

61 61031 Washer 1 Water Seal and Sensor Insulator (Lower)

PART

NO.

DESCRIPTION QTY. FUNCTION

SIDE VIEW (BOTTOM OF

CABINET)

CROSS SECTION A-A

11

Page 12

HARDWARE IDENTIFICATION

ITEM PART NO. DESCRIPTION QTY.

a 54910 Screw, Pan Hd. Phil. #8-32 UNC X 3/8 Lg 30

b 60670 Screw, Truss Hd. #1/4-20 UNC X 3/8 Lg 12

c 54285 Screw, Fl. Hd. Phil. #8-32 UNC X 3/8 Lg 2

d 53971 Screw, Pan Hd. Phil. #10-32 UNF X 3/8 Lg 10

e 61620 Screw, Truss Hd. Phil. SS #8-32 UNC X 1/2 Lg 22

f 60822 Screw, Fl. Hd. Phil. SS #10-32 UNF X 1/2 Lg 8

9 61048 Bolt, Hex Hd. #1/4-20 UNC X 3/4 Lg 4

h 51053 Nut, Hex #8-32 UNC 22

j 54222 Washer, Flat #10 4

k 60874 Washer, Lock Zinc Plate 5/16 2

m 61020 Washer Assembly 4

n 54284 Rivet 2

P 52242 Washer, Flat #8 15

r 61036 Nut, Hex SS 5/16-18 UNC 3

s 55736 Nut, Hex Green #8-32 UNC 2

t 60821 Screw, Fl. Hd. SS #10-32 UNF X 1 1/2 Lg 3

u 60680 Nut, Hex #10-32 UNF 2

SET UP AND CLOSE PROCEDURES Set

Up - Complete the Following:

Using a clean damp cloth, wipe out the water pan

and interior of the cabinet.

Wipe down the exterior of the cabinet.

Ensure that the power cord is plugged into the

appropriate receptacle.

Ensure that water pan has melted ice and is approximately two-thirds (2/3rds) full.

Ensure that temperature setting for both air and

water (flashing digital display) is set correctly.

Allow the unit to warm up for 45 minutes before

placing product inside.

Close - Complete the Following:

Turn the power switch to the off position.

Unplug power cord from receptacle, allow unit to

cool down..

CAUTION: Equipment and water contents are hot,

heaters will burn you! Allow the cabinet to "Cool

Down". Wait approximately 60 minutes (1 hour) with

door "Open".

Remove the crumb shield and side racks.

Sponge out the remaining water in the water heater

pan.

Replace the side racks.

Fill the water pan with ice or melted ice.

Replace the crumb shield.

TROUBLESHOOTING

In servicing equipment which has malfunctioned, it

is very important to:

1. DEFINE the problem and accurately determine

what is the malfunction.

2. Determine the BASIC CAUSE.

3. ELIMINATE the cause and repair the

malfunction (obviously, if the cause is not

properly identified and eliminated, the

malfunction may recur).

It is usually relatively easy to define the malfunction, but sometimes very difficult to spot the cause.

If the problem remains after following the suggestions listed, contact Wells Manufacturing

Company at (702) 345-0444.

12

Page 13

TROUBLESHOOTING GUIDE

PROBLEM PROBABLE CAUSE CORRECTIVE ACTION

Unit Fails to Operate (No Telite

Indications)

Power Off. Turn power "ON".

Faulty power switch. Replace power switch. (See page 15).

No power to unit. Check circuit breaker, check voltage supply to unit.

Air temperature set too high. Adjust air temperature setting (See PMS Card #64.) Holding Temperature too High

Food too Dry

Above Set Temperature and

the Telite Does Signal Power

to the Heaters

Actual operating temperature

higher than set temperature.

Air temperature set too low. Adjust air temperature setting (See PMS Card #64.) Holding Temperature too Low

Actual operating temperature

lower than set temperature.

Air temperature set too high. Adjust air temperature setting. (See PMS Card #64.)

Door gasket leak. Adjust door. (See Page 18.)

Water temperature too low. Adjust water temperature setting. (See PMS Card #64.)

Low water level.

Air temperature set too low. Adjust air temperature setting. (See PMS Card #64.) Food too Moist

Water temperature set too high. Adjust water temperature setting. (See PMS Card #64.)

Thermostat out of calibration. Recalibrate the unit. (See PMS Card #64.) Air or Water Temperature is

Defective printed circuit board or

defective relay.

Recalibrate the unit. (See PMS Card #64.)

Recalibrate the unit. (See PMS Card #64.)

1. Check low water indicator, should be on and sounding.

2. Refill with water.

Consult Wells Authorized Service Agency for repair.

Below Set Temperature and

the Telite Does Not Signal

Power to the Heaters

Below the Set Temperature

and the Telite is Constantly On

-

Thermostat out of calibration. Recalibrate the unit. (See PMS Card #64.) Air or Water Temperature is

Defective printed circuit board or

defective relay.

Defective heating element. Replace element. (See page 17 for Water or Air). Air or Water Temperature is

High limit thermostat-water,

defective (For water only).

Consult Wells Authorized Service Agency for repair.

Replace high limit thermostat-water (See page 19).

13

Page 14

PROBLEM PROBABLE CAUSE CORRECTIVE ACTION

Low Water Indicator On, But

the Water Tray is Full

Display Not Lit

Short circuit between

thermal/low water sensor assy.

and water pan.

Defective printed circuit board. Replace printed circuit board. (See page 16).

Soft or distilled water being

used.

Cavity temperature too high. Check calibration after unit cools and display is lit. Power On (Red) Telite Lit;

High limit thermostat-Air

defective.

PROCEDURE TO ATTACH OVEN PROBE TO

CABINET

1. Hold Biscuit Oven Probe with Sloped Angle

Toward Cavity Rear and with the Alligator Clip at

the Bottom on the Right Side.

2. Move the Biscuit Oven Probe Up Above the Air

Probe Bracket (Item 17) and Move it Back Near

the Rear Wall of the Cavity (Item 1).

3. Move the Biscuit Oven Probe Down on to the Air

Probe Bracket (Item 17) so that the Narrow Section of the Tapered Angle (Cobra Neck) of the

Biscuit Oven Probe fits into the Slot in the Air

Probe Bracket (Item 17).

4. Push the Biscuit Oven Probe Down on to the Air

Probe Bracket (Item 17) Until it Stops.

Replace shoulder washer (Item 60) and washer (Item 61)

(See page 18) (Procedure to replace the thermal/low water

sensor assy.)

Use a pinch of salt in the water pan.

Replace defective high limit thermostat-Air (See page 17).

14

Page 15

PARTS ORDERING/SERVICE INFORMATION

If service parts or technical information is required,

please contact the Factory Service Department. To

help speed up your inquiry the following information

is required:

1. Model Number: MDBC-1

2. Serial Number:

(Fill in for your records.)

3. Voltage: 125V. A. C.

4. Item Part Number:.

5. Quantity Required:

6. Nature of Service problem and symptoms.

7. Any other information that may be helpful in

solving your service problem.

NON-SCHEDULED MAINTENANCE

Under normal conditions, with proper use and

cleaning, very little non-scheduled maintenance will

be required for this unit. However, this section

provides procedures for checking and replacement

of the various parts used within the cabinet in the

event that it becomes necessary. Before

replacement of any parts, refer to the

Troubleshooting Section for assistance in determining the cause of any malfunction to insure that

maintenance is required.

WARNING: The procedures contained in this

section involve accessing bare electrical terminals

and exposes one to voltages capable of producing

fatal shock.

NOTE: Loctite #242 should be applied to all

threaded hardware parts before reassembly (except

electrical wire connection terminals).

Procedure To Replace A Telite (Red or

White)

Tools: #2. Phillips Head Screwdriver, Needle Nose

Pliers

Parts: Telite (Item 30) White or (Item 28) Red

1. Unplug the power cord.

2. Remove the top from the cabinet.

3. Pull the wires with spade terminals off the telite.

4. Squeeze the two (2) ears on the plastic body of

the telite and push the telite out to the front.

5. Follow the reverse procedure to install a new

telite.

Procedure To Replace The Power Switch

Tools: Phillips Head Screwdriver, Pliers,

5/16 Slotted Head Screwdriver

Parts: Power Switch (Item 26)

1. Unplug the power cord.

2. Remove the top from the cabinet.

3. Unscrew the nut over the switch located on the

outside of the control panel.

4. Pull the switch out from the inside.

5. Unscrew the wire. terminals and remove.

6. Reverse procedure to install new switch.

NOTE: Ensure that ON-OFF plate or marking is in

place on the control panel and around the switch

bushing.

15

Procedure To Replace The Convenience Outlet

Tools: #2 Phillips Head Screwdriver, 5/16

Slotted Head Screwdriver

Parts: Convenience Outlet (Item 23)

1. Unplug the power cord.

2. Remove the top from the cabinet.

3. Unscrew two (2) screws holding the convenience outlet on the rear panel.

4. Pull the convenience outlet out.

5. Unscrew the wire terminals on the outlet and

remove wires.

Page 16

6. Follow reverse procedure to install new convenience outlet.

Procedure To Replace The Printed Circuit Board

Tools: 3/16 Slotted Head Screwdriver, #2 Phillips

Head Screwdriver, 11/32 Nutdriver or Open

End Wrench

Parts: Printed Circuit Board (Item 43)

1. Unplug the power cord.

2. Remove the top from cabinet.

3. Remove the wires from spade terminals by

pulling the connectors with needle nose pliers.

Step 3

1. Unplug the power cord.

2. Remove the top from the cabinet.

3. Remove the wire connectors by pulling them

from the pin connectors on the printed circuit

board.

4. Remove the air and water temperature probe

wires by loosening the screws on the

temperature probe terminal block.

5. Remove the four (4) mounting nuts located in

the corners of printed circuit board. Remove the

board from the mounting studs.

6. Follow the reverse procedure and the wiring

diagram to install a new printed circuit board.

4. Push the rocker switch through the control

panel by depressing the securing clips on the

back side of the switch body.

5. Follow the reverse procedure and the wiring

diagram to install a new rocker switch.

Procedure To Replace An Air or Water Relay

Tools: 11/32 Nutdriver, or Open End Wrench, #2

Phillips Head Screwdriver

Parts: Air Relay (Item 38) or Water Relay (Item 37)

1. Unplug the power cord.

2. Remove the top from cabinet.

3. Remove the spade terminals from the relay by

pulling the terminals off with the needle nose

pliers.

4. Remove the 11/32 nut from the mounting stud.

NOTE: The new printed circuit board will require

calibration (See PMS Card #64).

Procedure To Replace Rocker Switches

Tools: Needle Nose Pliers, #2 Phillips Head

Screwdriver

Parts: Rocker Switch (Item 29 or 31)

5. Remove the relay from its location on the mounting

stud.

6. Follow the reverse procedure and the wiring

diagram to install the replacement relay.

16

Page 17

Procedure To Replace The Water Heating

Element

Tools: Phillips Head Screwdriver, 11/32 and 5/16

Nutdrivers

Parts: Water Heating Element (Item 56)

1. Unplug the power cord.

2. Remove the bottom cover from cabinet.

3. Remove three (3) 11 /32 nuts from element retaining plate.

4. Remove three (3) 5/16 nuts from the wire terminals and remove the wires from the element.

5. Remove the element from the bottom of the

water pan.

6. Slide the element out towards the front of the

unit.

7. Follow the reverse procedure to install a new

element.

Procedure To Replace High Limit

Thermostat-Air

Tools: #8 Nutdriver, #6 Nutdriver Parts: High Limit

Thermostat-Air (Part Item 49)

1. Unplug the power cord.

2. Remove the rear panel of the cabinet.

3. Disconnect the two wires from the High Limit

thermostat-air.

4. Remove the two (2) hex nuts and washers from

the strap that holds the High Limit thermostatair in place.

5. Remove the Thermo Strap from the High Limit

thermostat-air and remove the High Limit

6. Follow the reverse procedure and the wiring

diagram to install new water heating element.

Procedure To Replace Air Heating Element

Tools: #2 Phillips Head Screwdriver, 5/16 Flat

Head Screwdriver

Parts: Air Heating Element (Item 5)

1. Unplug the power cdrd.

2. Remove biscuit pans and rack assemblies from

interior of cabinet.

3. Remove rear panel from cabinet.

4. Remove the wire terminals from the element

using the 5/16 flat head screwdriver.

5. Remove the element clip from the interior of the

cabinet using the #2 phillips head screwdriver.

thermostat-air.

6. Follow the reverse procedure to install a new

High Limit thermostat-air.

17

Page 18

Procedure To Replace The Air Temperature

Sensor

Procedure To Replace The Thermal/Low Water

Sensor Assy.

Tools: #2 Phillips Head Screwdriver, 3/16 Flat

Head Screwdriver, 112 Wrench (2 Required)

Parts: Air Temperature Sensor (Item 47)

1. Unplug the power cord.

2. Remove the top and rear of cabinet.

3. Disconnect thermocouple leads from the

printed circuit board.

4. Remove the thermoguard from the interior of

cabinet.

5. Hold the air temperature sensor on the inside

of the cabinet with a 5/16 wrench and

remove the nut on the rear of the air

temperature sensor with a 5/16 wrench.

6. Pull the air temperature sensor and the thermocouple wire through to the interior of

cabinet and remove.

7. Follow the reverse procedure to install the

replacement air temperature sensor.

Tools: #2 Phillips Head Screwdriver, 3/16 Flat

Head Screwdriver, 1 /2 Wrench (2 Required)

Parts: Thermo/Low Water Sensor Assy.

(Item 57)

1. Unplug the power cord.

2. Remove the top, rear, and bottom from the

cabinet.

3. Disconnect thermocouple leads from the

printed circuit board.

4. Hold the thermo/low water sensor assy. on the

inside of the water pan with a 5/16 wrench

and remove the nut on the rear of the

thermo/low water sensor assy. with another

5/16 wrench.

5. Pull the thermo/low water sensor assy. and

the thermocouple wire through to the interior

of cabinet and remove.

Procedure To Reverse or Adjust The Door

Assembly

Tools: #2 Phillips Head Screwdriver, 5/16 Flat

Head Screwdriver

Parts: None

1. Unplug the power cord.

2. Pry the decorative covers off the hinge

assembly with the 5/16 Flat Head Screwdriver.

Page 19

3. Remove the four (4) Phillips head screws which

attach the two (2) hinges to the cabinet (Leave

the hinges attached to the door).

4. Remove the handle and striker plate from the

door and cabinet respectively.

5. Remove the inner door panel and gasket from

the door.

6. Remove all six (6) Phillips screws from the front

of the cabinet.

7. Install the door with its hinges to the opposite

side of the cabinet.

8. Re-install the inner door panel and the gasket to

the door. (Note: The deflector should always be

at the bottom of the door).

9. Mount the handle and the striker plate to the

opposite side of the door and cabinet.

CAUTION: When mounting the handle, do not re-use

the three (3) screws "t", (P/N 60821). Discard the

previously used three (3) screws and use the new

screws supplied with the unit.

10. Adjust the handle and hinges to provide an air

tight seal along the door gasket.

11. Re-install the decorative hinge covers.

12. Re-install the six (6) Phillips head screws to fill

the un-used holes in the cabinet.

Procedure To Replace The High Limit

Thermostat (Water)

Tools: #8 Nutdriver, 5/16 Flat Head Screwdriver, #2.

Phillips Head Screwdriver

Parts: High Limit Thermostat-Water (Item 55)

1. Unplug the power cord.

2. Remove the bottom cover from the cabinet.

3. Remove the bottom outside insulation.

4. Remove the wire from the High Limit ThermostatWater using the 5/16 Flat Head Screwdriver.

5. Remove the #6 nut and washer using a #8

Nutdriver and remove the High Limit ThermostatWater.

6. Follow the reverse procedure to install a new

High Limit Thermostat-Water.

Page 20

Page 21

Page 22

MDBC-1 PASTA CONVERSION INSTRUCTIONS

P/N 46537

NOTE: If the power switch has an "Aux" position, omit Steps 2-7

1. Disconnect power supply cord (plug) from power receptacle, remove

top cover by removing the 4 screws that secure the top to the cabinet and lift off top

cover.

2. Remove original On/Off toggle type double pole power switch from

the control panel. Remove all the wires from the 4 push-on terminals.

3. Insert the new 4 pole power switch through the 15/32" hole in the control panel where

the original power switch was removed. Place the "Aux/Std" trim plate over the

threaded shaft, thread the mounting nut on the shaft and tighten the nut.

4. Reconnect original cabinet wiring per the new wiring diagram (supplied with kit).

Install new wire leads 69 through 72 supplied in the kit to the new power switch per

the new wiring diagram.

NOTE: wire 70 has an insulated terminal on one end. Install this terminal at the

power switch.

5. When wires 13 and 22 are connected to the new power switch, be sure to install the

piggy-back terminal so that the terminal is placed close to the insulated terminal of

wire 70 towards the center of the switch so that the terminals do not contact or press

on the side of the pilot light next to the switch. Install wires 11 and 12 to the

piggy-back terminals on jumpers 74 and 73. Connect the switch.

NOTE: Make sure all push-on terminals are tight. If you can remove any of these terminals by

pulling on the wires, they are not tight enough and you will have to pre-load the female

terminal (with the connector unplugged) by lightly squeezing the rolled edges of the connector

terminal with long nose pliers to ensure a tight connection between the male and female

terminals.

6. Remove jumper wire 23 that connects terminal 4 of the water relay to terminal 4 of the

air relay. Discard wire 23.

7. Connect the 4 in-line splice connectors supplied with the kit to the other end of wires

69, 70, 71, 72 and one end of wire 73. Connect the other end of wire 73 to pin 4 of

the water relay.

22

EPCOS/13/91@002-CI46937

Page 23

MDBC-1 Pasta Conversion Instructions

8. NOTE: Applies to cabinets with "AUK" power switch position only.

Remove wire 73 from the power switch and install 1 in-line splice connector

supplied with the kit to wire 73.

PRINTED CIRCUIT BOARD REMOVAL AND REPLACEMENT WITH AUXILIARY OPERATION PRINTED CIRCUIT

BOARD

NOTE: Spacers between the rear of the printed circuit board and the front control panel must

be reused when installing the new auxiliary operation printed circuit board.

9. Remove the original temperature control printed circuit board

P/N 60816 (or 63305) from the front control panel by removing the 6 wires (4, 24,

27, 28, 29 and 39) from the mounting studs. Be sure the spacers listed in the

warning above are left in place on the studs.

NOTE: On printed circuit board P/N 63305, remove the red, violet, black and orange

wires from the in-line splices.

10. Remove the thermocouple leads from the 4 pin terminal block on the upper left of the

printed circuit board.

11. Remove the air and water relay control wires (20 and 21) from the controller board

pins marked air and water.

12. Remove the orange 8 pin terminal block from the right side of the printed circuit board

by inserting a small flat blade screwdriver under the terminal block and lifting it

straight up and off the pins on the boards. (It is not necessary to remove the wires

from the terminal block to remove the block from the board.)

NOTE: There are 2 anti-static single color band resistors attached to the 4 screw terminals

on the terminal block on the left side of the printed circuit board. These 2 resistors MUST

be removed from the new controller board and reinstalled on the old controller board to

protect it from static damage during shipment.

13. Install the new printed circuit board P/N 66521 on the front control panel, reconnect wires

4, 18, 19, 20, 21, 22 and 23 to the proper push-on terminals on the board, reconnect the

thermocouple leads removed in Step 9 above, make sure the red leads are on top and the

yellow lead are on the bottom (see wiring diagram for wiring connections). Reinstall the

orange terminal block removed in Step 11 above.

23

Page 24

MDBC-l Pasta Conversion Instructions

14. Connect the orange wire from the printed circuit board to the new

wire 69, the black wire to the new wire 73, the red wire to the new wire 71, the violet

wire to the new wire 72.

NOTE: Make sure all push-on terminals are tight. If you can remove any of

these terminals by pulling on the wires, they are not tight enough and you will have to pre-load

the female terminal (with the connector unplugged) by

lightly squeezing the rolled edges of the connector terminal with long nose pliers to ensure a

tight connection between the male and female terminals.

15. Inspect general layout of components altered during this conversion

for lead dress and mounting to avoid shorting of components or wiring.

16. Fill the water pan, connect the power cord plug to the proper 120VAC supply. Place the

"Operate/Set" rocker switch to the "Set" position. Place the "Air/water" rocker switch in

the "Air" position. Turn the new "Power Switch" to the "Aux" position.

17. The digital display will be flashing, with a small flat blade

screwdriver, adjust the "Air -Set" potentiometer on the REAR of the controller printed

circuit board (adjust only the one on the small auxiliary printed circuit board attached to

the rear of the controller printed circuit board) to show a flashing 165°F (74°C).

NOTE: If the display shows a "C" in the upper window just to the right of the temperature

display, the small toggle switch located in the upper left of the printed circuit board is

switched to the Celsius position.

18. Place the "Air/Water" rocker switch in the "water" position.

19. The digital display will be flashing, with a small flat blade

screwdriver, adjust the "water Set" potentiometer on the REAR of the controller printed

circuit board (adjust only the one on the small auxiliary printed circuit board attached to

the rear of the controller printed circuit board) to show a flashing 165°F (74°C) reading.

20. Place the new wiring diagram inside the unit on top of the insulation below the top cover.

Replace the top cover on the unit, install the 4 screws removed in Step 1.

21. Set the new power switch to the "Std" position. Pry off the snap-in cover plate on the

front control panel, when looking into the hole where the snap-in cover was just removed,

you will see the adjustment potentiometers for setting the air and water temperatures for

standard operation. The upper left potentiometer is the "Air" set. Set it for l45°F

(63°C). The display will be flashing.

24

Page 25

MDBC-l Pasta Conversion Instructions

22. Position the "Air/Mater" rocker switch to the "Mater" position.

The display will be flashing. Adjust the lower left potentiometer to give a flashing 135°F

<57°C) reading. (The 2 potentiometers on the right are for calibrating the air and water.

(See Card No. 64 to adjust.)

This completes the "Pasta" conversion of the unit. A calibration check is now required! Use the

Standard Maintenance Card No. 64 published for this unit to perform the normal calibration of the

air and water sensors.

WARNING: The water pan must have water in it for calibration.

NOTE: Instruct store management personnel on the operation of the unit in the "Aux" operation

mode. Be sure to advise them that a IS minute period of stabilization of the temperature inside

is required before changing products after changing from "Aux/Std" modes. Also advise them of

the location of the auxiliary temperature "Set" potentiometer and that the adjustment cannot be

accessed through the front control panel. This adjustment can only be accessed from inside the

component area with the top removed.

25

Loading...

Loading...